Gluten-Free Rice Instant Pasta: Effect of Extrusion-Cooking Parameters on Selected Quality Attributes and Microstructure

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material

2.2. Pasta Processing

2.3. Cooking Quality

2.3.1. Minimal Preparation Time

2.3.2. Water Absorption Capacity

2.3.3. Cooking Loss

2.4. Texture Measurements

2.5. Specific Mechanical Energy

2.6. Microscopic Structure of Rice Pasta

2.7. Statistical Analysis

3. Results and Discussion

3.1. Effect of Extrusion-Cooking Parameters on Cooking Quality

3.2. Effect of Extrusion-Cooking Parameters on the Textural Properties of Rice Pasta

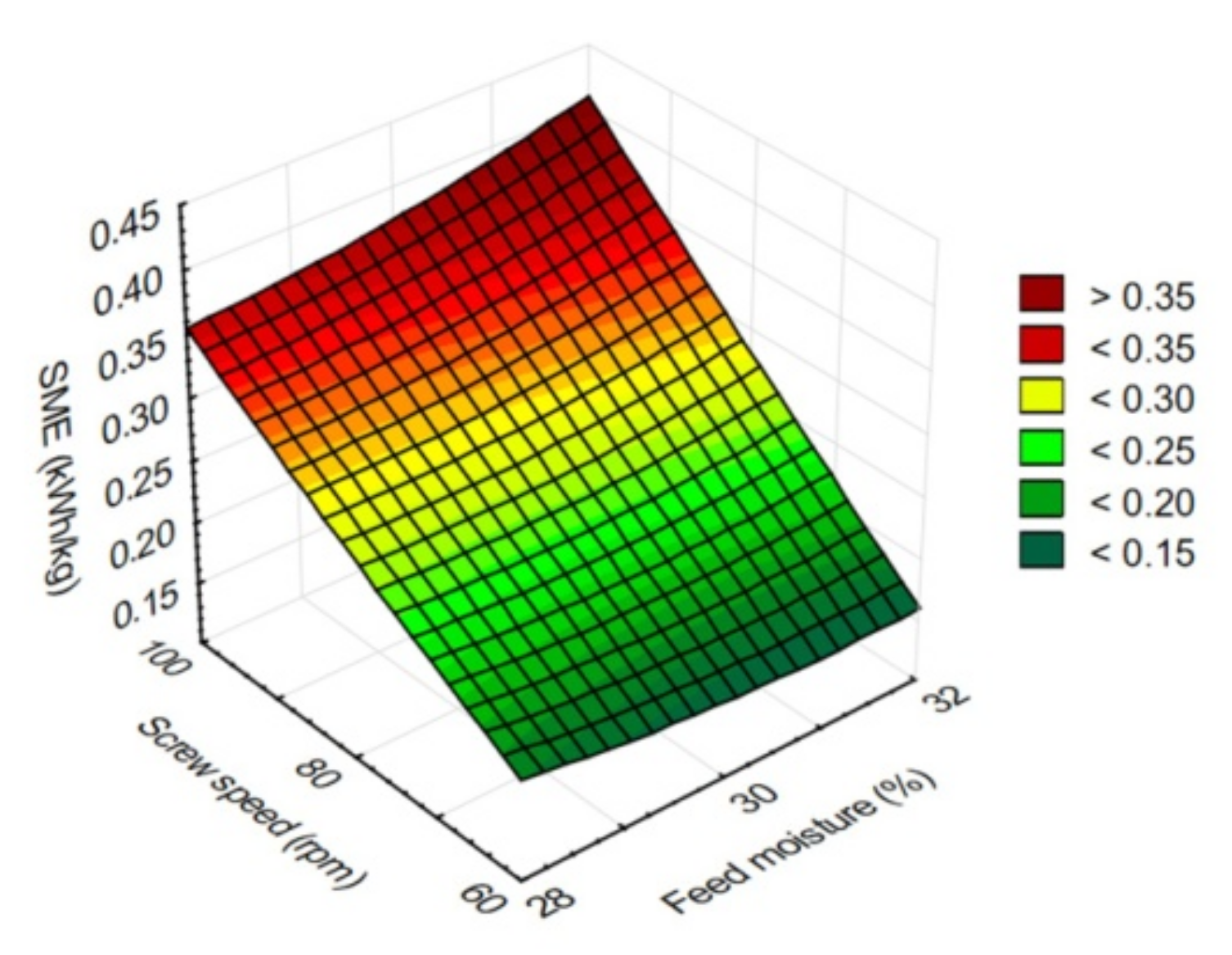

3.3. Effect of Extrusion-Cooking Parameters on Specific Mechanical Energy

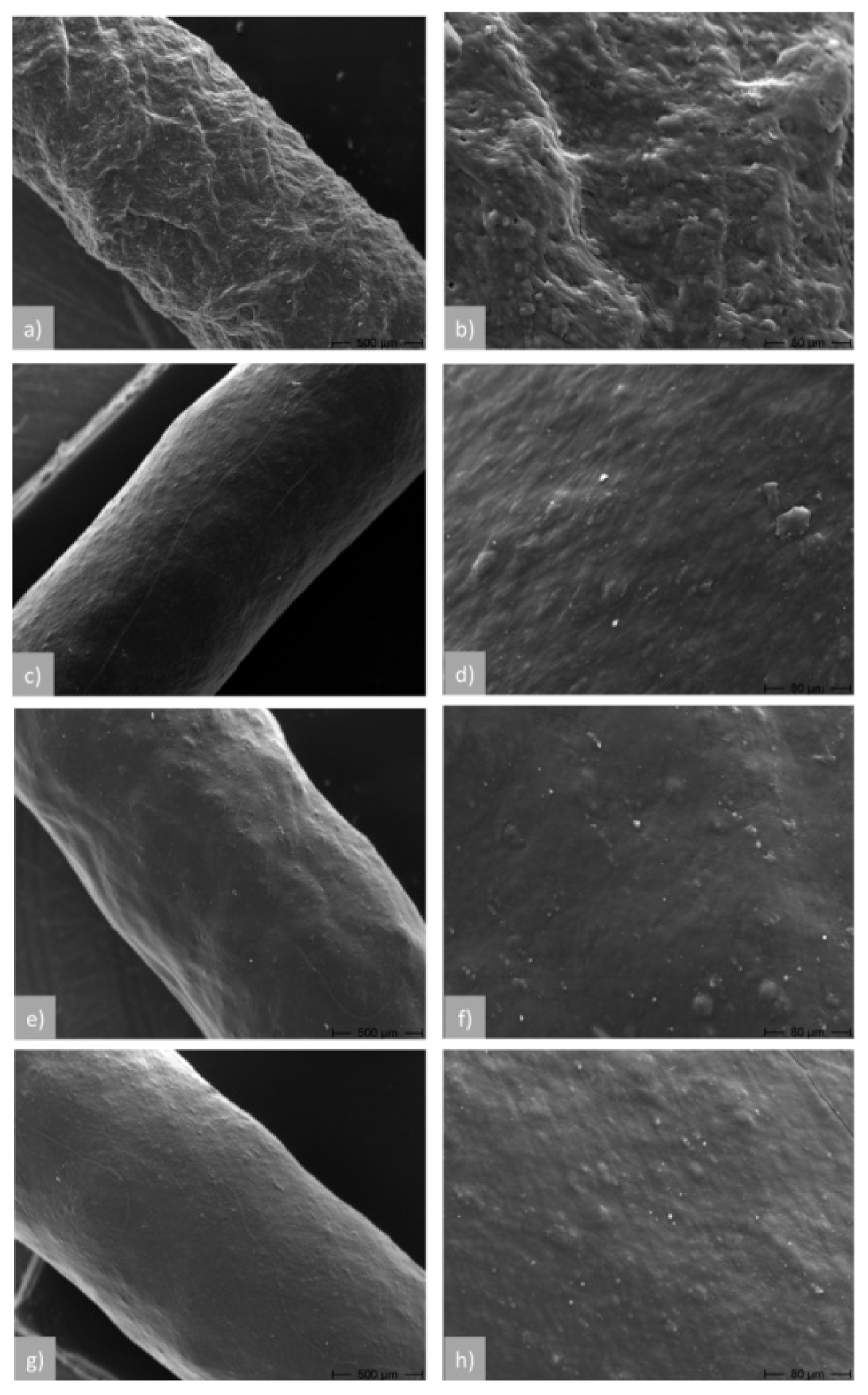

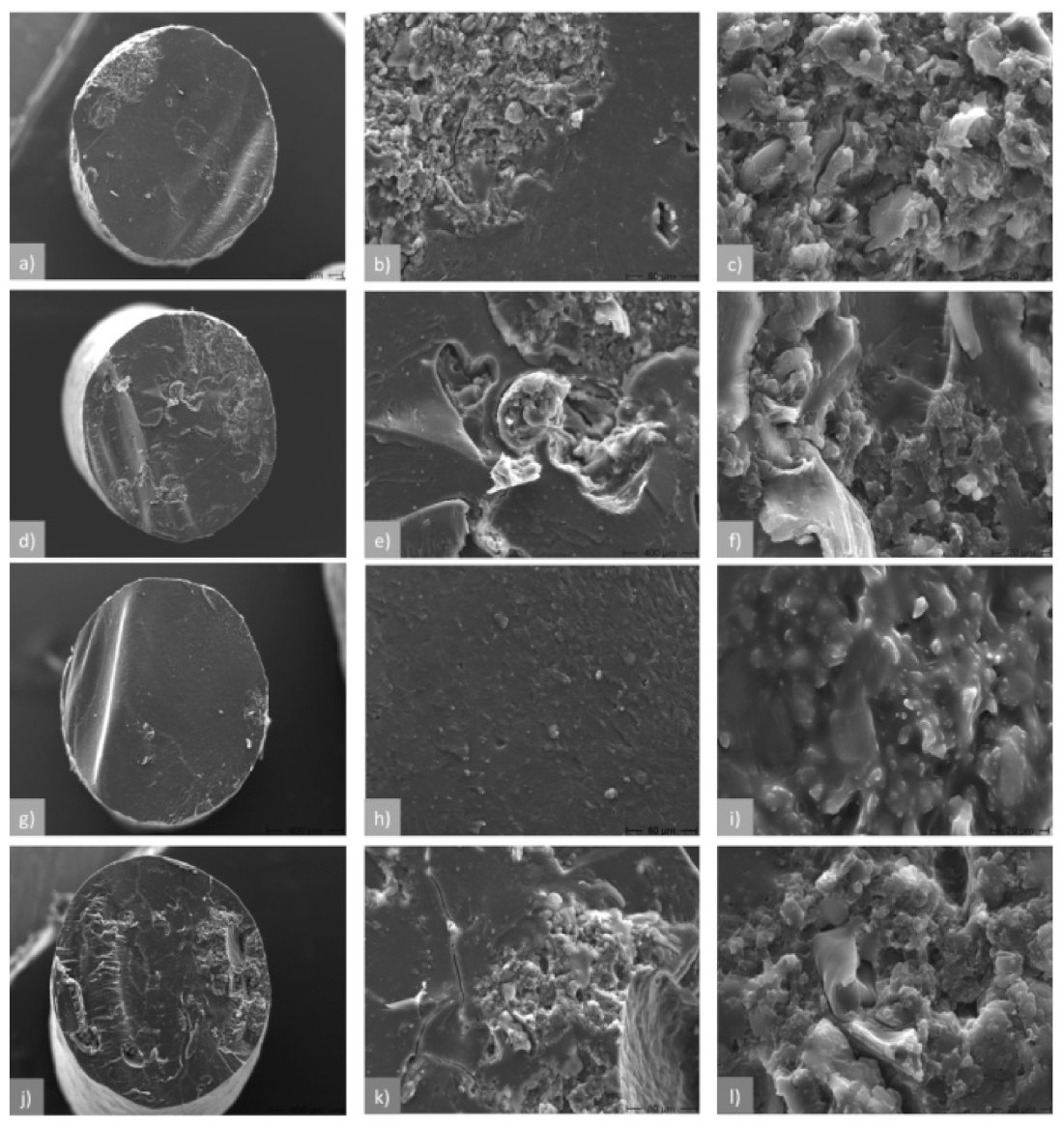

3.4. Effect of Extrusion-Cooking Parameters on the Microstructure of Rice Pasta

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mercier, S.; Moresoli, C.; Mondor, M.; Villeneuve, S.; Marcos, B. A meta-analysis of enriched pasta: What are the effects of enrichment and process specifications on the quality attributes of pasta? Compr. Rev. Food Sci. Food Saf. 2016, 15, 685–704. [Google Scholar] [CrossRef] [PubMed]

- Petitot, M.; Boyer, L.; Minier, C.; Micard, V. Fortification of pasta with split pea and faba bean flours: Pasta processing and quality evaluation. Food Res. Int. 2010, 43, 634–641. [Google Scholar] [CrossRef]

- Rafiq, A.; Sharma, S.; Singh, B. Regression analysis of gluten-free pasta from brown rice for characterization and in vitro digestibility. J. Food Proc. Preserv. 2017, 41, e12830. [Google Scholar] [CrossRef]

- Elli, L.; Branchi, F.; Tomba, C.; Villalta, D.; Norsa, L.; Ferretti, F.; Roncoroni, L.; Bardella, M.T. Diagnosis of gluten related disorders: Celiac disease, wheat allergy and non-celiac gluten sensitivity. World J. Gastroenterol. 2015, 21, 7110–7119. [Google Scholar] [CrossRef] [PubMed]

- Plugis, N.M.; Khosla, C. Therapeutic approaches for celiac disease. Best Prac. Res. Clin. Gastroenterol. 2015, 29, 503–521. [Google Scholar] [CrossRef] [PubMed]

- Tovoli, F.; Masi, C.; Guidetti, E.; Negrini, G.; Paterini, P.; Bolondi, L. Clinical and diagnostic aspects of gluten related disorders. World J. Clin. Cases 2015, 3, 275–284. [Google Scholar] [CrossRef] [PubMed]

- Shannahan, S.; Leffler, D.A. Diagnosis and updates in celiac disease. Gastrointest. Endosc. Clin. N. Am. 2017, 27, 79–92. [Google Scholar] [CrossRef]

- Bascuñán, K.A.; Vespa, M.C.; Araya, M. Celiac disease: Understanding the gluten free diet. Eur. J. Nutr. 2017, 56, 449–459. [Google Scholar] [CrossRef]

- Gobbetti, M.; Pontonio, E.; Filannino, P.; Rizzello, C.G.; De Angelis, M.; Di Cagno, R. How to improve the gluten-free diet: The state of the art from a food science perspective. Food Res. Int. 2018, 110, 22–32. [Google Scholar] [CrossRef]

- Marti, A.; Pagani, M.A. What can play the role of gluten in gluten free-pasta? Trends Food Sci. Technol. 2013, 31, 63–71. [Google Scholar] [CrossRef]

- Bouasla, A.; Wójtowicz, A.; Zidoune, M.N. Gluten-free precooked rice pasta enriched with legumes flours: Physical properties, texture, sensory attributes and microstructure. LWTFood Sci. Technol. 2017, 75, 569–577. [Google Scholar] [CrossRef]

- Alam, M.S.; Kaur, J.; Khaira, H.; Gupta, K. Extrusion and extruded products: Changes in quality attributes as affected by extrusion process parameters: A review. Crit. Rev. Food Sci. Nutr. 2016, 56, 445–473. [Google Scholar] [CrossRef]

- Rosell, C.M.; Marco, C. Rice. In Gluten-Free Cereal Products and Beverages; Arendt, E.K., Dal Bello, F., Eds.; Academic Press: Cambridge, MA, USA, 2008; pp. 81–100. [Google Scholar]

- Dalbhagat, C.G.; Mahato, D.K.; Mishra, H.N. Effect of extrusion processing on physicochemical, functional and nutritional characteristics of rice and rice-based products: A review. Trends Food Sci. Technol. 2019, 85, 226–240. [Google Scholar] [CrossRef]

- Wójtowicz, A.; Mościcki, L. Influence of legume type and addition level on quality characteristics, texture and microstructure of enriched precooked pasta. LWTFood Sci. Technol. 2014, 59, 1175–1185. [Google Scholar] [CrossRef]

- Bouasla, A.; Wójtowicz, A.; Zidoune, M.N.; Olech, M.; Nowak, R.; Mitrus, M.; Oniszczuk, A. Gluten-free precooked rice-yellow pea pasta: Effect of extrusion-cooking conditions on phenolic acids composition, selected properties and microstructure. J. Food Sci. 2016, 81, 1070–1079. [Google Scholar] [CrossRef]

- Charutigon, C.; Jitpupakdree, J.; Namsree, P.; Rungsardthong, V. Effects of processing conditions and the use of modified starch and monoglyceride on some properties of extruded rice vermicelli. LWT Food Sci. Technol. 2008, 41, 642–651. [Google Scholar] [CrossRef]

- Ross, A. Instrumental measurement of physical properties of cooked Asian wheat flour noodles. Cereal Chem. 2006, 83, 42–51. [Google Scholar] [CrossRef]

- Bouasla, A.; Wójtowicz, A.; Juśko, S.; Zidoune, M.N. Energy consumption and process efficiency as affected by extrusion-cooking conditions and recipe formulation during the production of gluten-free rice-legumes products. Agric. Eng. 2017, 21, 39–46. [Google Scholar] [CrossRef][Green Version]

- Wang, N.; Bhirud, P.R.; Sosulski, F.W.; Tyler, R.T. Pasta-like product from pea flour by twin-screw extrusion. J. Food Sci. 1999, 64, 671–678. [Google Scholar] [CrossRef]

- Wang, N.; Maximiuk, L.; Toews, R. Pea starch noodles: Effect of processing variables on characteristics and optimisation of twin-screw extrusion process. Food Chem. 2012, 133, 742–753. [Google Scholar] [CrossRef]

- Giménez, M.A.; González, R.J.; Wagner, J.; Torres, R.; Lobo, M.O.; Samman, N.C. Effect of extrusion conditions on physicochemical and sensorial properties of corn-broad beans (Viciafaba) spaghetti type pasta. Food Chem. 2013, 136, 538–545. [Google Scholar] [CrossRef] [PubMed]

- Anderson, R.A.; Conway, H.F.; Pfeifer, V.F.; Griffin, E.L.J. Gelatinization of corn grits by roll cooking, extrusion cooking and steaming. Starch 1969, 22, 130–135. [Google Scholar] [CrossRef]

- Marti, A.; Seetharaman, K.; Pagani, M.A. Rice-based pasta: A comparison between conventional pasta-making and extrusion-cooking. J. Cereal Sci. 2010, 52, 404–409. [Google Scholar] [CrossRef]

- Camire, M.E.; Camire, A.; Krumhar, K. Chemical and nutritional changes in foods during extrusion. Crit. Rev. Food Sci. Nutr. 1990, 29, 35–57. [Google Scholar] [CrossRef] [PubMed]

- Cunningham, S.; McMinn, W.; Magee, T.; Richardson, P. Modeling water absorption of pasta during soaking. J. Food Eng. 2007, 82, 600–607. [Google Scholar] [CrossRef]

- Wójtowicz, A.; Mościcki, L. Influence of extrusion-cooking parameters on some quality aspects of precooked pasta-like products. J. Food Sci. 2009, 74, 226–233. [Google Scholar] [CrossRef]

- Diosady, L.L.; Paton, D.; Rosen, N.; Rubin, L.J.; Athanssoulias, C. Degradation of wheat starch in a single-screw extruder: Mechano-kinetic breakdown of cooked starch. J. Food Sci. 1985, 50, 1697–1706. [Google Scholar] [CrossRef]

- Amerayo, Y.; Gonzalez, R.; Drago, S.; Torres, R.; De Greef, D. Extrusion condition and zea mays endosperm affecting gluten-free spaghetti quality. J. Food Sci. Technol. 2011, 46, 2321–2328. [Google Scholar] [CrossRef]

- Marti, A.; Pagani, M.; Seetharaman, K. Understanding starch organisation in gluten-free pasta from rice flour. Carbohydr. Polym. 2011, 84, 1069–1074. [Google Scholar] [CrossRef]

- Galvez, F.C.F.; Resurreccion, A.V.A.; Ware, G.O. Process variables, gelatinized starch and moisture effects on physical properties of mungbean noodles. J. Food Sci. 1994, 59, 378–381. [Google Scholar] [CrossRef]

- Sissons, M.; Abecassis, J.; Marchylo, B.; Cubadda, R. Methods used to assess and predict quality of durum wheat, semolina, and pasta. In Durum Wheat: Chemistry and Technology, 2nd ed.; Sissons, M., Abecassis, J., Marchylo, B., Carcea, R., Eds.; American Association of Cereal Chemists International: St. Paul, MN, USA, 2012; pp. 213–234. [Google Scholar]

- Lucisano, M.; Cappa, C.; Fongaro, L.; Mariotti, M. Characterisation of gluten-free pasta through conventional and innovative methods: Evaluation of the cooking behavior. J. Cereal Sci. 2012, 56, 667–675. [Google Scholar] [CrossRef]

- Resmini, P.; Pagani, M.A. Ultrastructure studies of pasta: A review. Food Microstruct. 1983, 2, 1–12. [Google Scholar]

- Guha, M.; Ali, S.Z.; Bhattacharya, S. Twin-screw extrusion of rice flour without a die: Effect of barrel temperature and screw speed on extrusion and extrudate characteristics. J. Food Eng. 1997, 32, 251–267. [Google Scholar] [CrossRef]

- Singha, P.; Singh, S.K.; Muthukumarappan, K.; Krishnan, P. Physicochemical and nutritional properties of extrudates from food grade distiller’s dried grains, garbanzo flour, and corn grits. Food Sci. Nutr. 2018, 6, 1914–1926. [Google Scholar] [CrossRef]

- Colonna, P.; Mercier, C. Macromolecular modifications of manioc starch components by extrusion-cooking with and without lipids. Carbohydr. Polym. 1983, 3, 87–108. [Google Scholar] [CrossRef]

- Bouasla, A.; Wójtowicz, A. Rice-buckwheat gluten-free pasta: Effect of processing parameters on quality characteristics and optimization of extrusion-cooking process. Foods 2019, 8, 496. [Google Scholar] [CrossRef]

- Wójtowicz, A. Influence of process conditions on selected texture properties of precooked buckwheat pasta. Teka Com. Motor. Energ. Agric. 2012, 12, 315–322. [Google Scholar]

- Jalgaonkar, K.; Jha, S.K.; Mahawar, M.K.; Yadav, D.N. Pearl millet based pasta: Optimization of extrusion process through response surface methodology. J. Food Sci. Technol. 2019, 56, 1134–1144. [Google Scholar] [CrossRef]

- Dexter, J.E.; Matsuo, R.R.; Macgregor, A.W. Relationships of instrumental assessment of spaghetti cooking quality to the type and the amount of material rinsed from cooked spaghetti. J. Cereal Sci. 1985, 3, 39–53. [Google Scholar] [CrossRef]

- Wood, J.A. Texture, processing and organoleptic properties of chickpea-fortified spaghettiwith insights to the underlying mechanisms of traditional durum pasta quality. J. Cereal Sci. 2009, 49, 128–133. [Google Scholar] [CrossRef]

- Bhattacharya, M.; Zee, S.Y.; Corke, H. Physicochemical properties related to quality of rice noodles. Cereal Chem. 1999, 76, 861–867. [Google Scholar] [CrossRef]

- Kantrong, H.; Charunuch, C.; Limsangouan, N.; Pengpinit, W. Influence of process parameters on physical properties and specific mechanical energy of healthy mushroom-rice snacks and optimization of extrusion process parameters using response surface methodology. J. Food Sci. Technol. 2018, 55, 3462–3472. [Google Scholar] [CrossRef]

- Wójtowicz, A.; Mościcki, L. Energy consumption during extrusion-cooking of precooked pasta. Teka. Com. Motor. Energ. Agric. 2008, 8, 311–318. [Google Scholar]

- Wójtowicz, A. Precooked pasta. In Extrusion-Cooking Techniques. Applications, Theory and Sustainability; Mościcki, L., Ed.; Wiley: Weinheim, Germany, 2011; pp. 99–117. [Google Scholar]

| Source | SS | df | MS | F | p | |

|---|---|---|---|---|---|---|

| MPT (min) | Feed moisture (M) | 12.667 | 2 | 6.333 | 6.333 | 0.008 * |

| Screw speed (S) | 2.667 | 2 | 1.333 | 1.333 | 0.288 | |

| M × S | 5.333 | 4 | 1.333 | 1.333 | 0.296 | |

| WAC (%) | Feed moisture (M) | 4334 | 2 | 2167 | 12.554 | 0.000 * |

| Screw speed (S) | 2577 | 2 | 1288 | 7.464 | 0.004 * | |

| M × S | 865 | 4 | 216 | 1.253 | 0.324 | |

| CL (%) | Feed moisture (M) | 18.802 | 2 | 9.401 | 50.463 | 0.000 * |

| Screw speed (S) | 5.180 | 2 | 2.590 | 13.903 | 0.000 * | |

| M × S | 8.391 | 4 | 2.098 | 11.260 | 0.000 * | |

| Hardness (N) | Feed moisture (M) | 268.445 | 2 | 134.222 | 64.030 | 0.000 * |

| Screw speed (S) | 318.835 | 2 | 159.418 | 76.049 | 0.000 * | |

| M × S | 141.310 | 4 | 35.328 | 16.853 | 0.000 * | |

| Firmness (N) | Feed moisture (M) | 21,794 | 2 | 10897 | 71.928 | 0.000 * |

| Screw speed (S) | 3051 | 2 | 1525 | 10.069 | 0.005 * | |

| M × S | 68,937 | 4 | 17,234 | 113.758 | 0.000 * | |

| Stickiness (mJ) | Feed moisture (M) | 705.640 | 2 | 352.820 | 115.329 | 0.000 * |

| Screw speed (S) | 8.126 | 2 | 4.063 | 1.328 | 0.312 | |

| M × S | 59.234 | 4 | 14.808 | 4.840 | 0.023 * | |

| SME (kWh/kg) | Feed moisture (M) | 0.002 | 2 | 0.001 | 8.13 | 0.003 * |

| Screw speed (S) | 0.203 | 2 | 0.101 | 980.71 | 0.000 * | |

| M × S | 0.005 | 4 | 0.001 | 11.05 | 0.000 * |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bouasla, A.; Wójtowicz, A. Gluten-Free Rice Instant Pasta: Effect of Extrusion-Cooking Parameters on Selected Quality Attributes and Microstructure. Processes 2021, 9, 693. https://doi.org/10.3390/pr9040693

Bouasla A, Wójtowicz A. Gluten-Free Rice Instant Pasta: Effect of Extrusion-Cooking Parameters on Selected Quality Attributes and Microstructure. Processes. 2021; 9(4):693. https://doi.org/10.3390/pr9040693

Chicago/Turabian StyleBouasla, Abdallah, and Agnieszka Wójtowicz. 2021. "Gluten-Free Rice Instant Pasta: Effect of Extrusion-Cooking Parameters on Selected Quality Attributes and Microstructure" Processes 9, no. 4: 693. https://doi.org/10.3390/pr9040693

APA StyleBouasla, A., & Wójtowicz, A. (2021). Gluten-Free Rice Instant Pasta: Effect of Extrusion-Cooking Parameters on Selected Quality Attributes and Microstructure. Processes, 9(4), 693. https://doi.org/10.3390/pr9040693