Development of a Multihole Atmospheric Plasma Jet for Growth Rate Enhancement of Broccoli Seeds

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Plasma Temperature and Current-Voltage Measurements

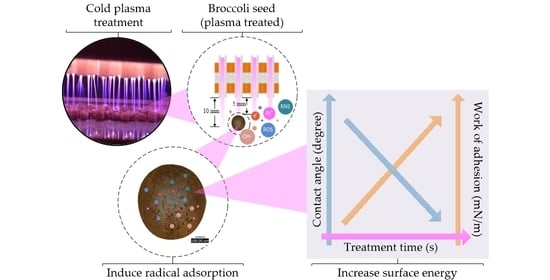

3.2. Contact Angle Measurement

3.3. SEM and XTM Images

3.4. Effect of Plasma Treatment on Broccoli Seed Germination

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hertwig, C.; Meneses, N.; Mathys, A. Cold atmospheric pressure plasma and low energy electron beam as alternative nonthermal decontamination technologies for dry food surfaces: A review. Trends Food Sci. Technol. 2018, 77, 131–142. [Google Scholar] [CrossRef]

- Kogoma, M.; Tanaka, K. Low-temperature atmospheric discharge plasma and its applications for the surface treatment. Rev. Mod. Plasma Phys. 2021, 5, 3. [Google Scholar] [CrossRef]

- Domonkos, M.; Tichá, P.; Trejbal, J.; Demo, P. Applications of Cold Atmospheric Pressure Plasma Technology in Medicine, Agriculture and Food Industry. Appl. Sci. 2021, 11, 4809. [Google Scholar] [CrossRef]

- Adamovich, I.; Baalrud, S.D.; Bogaerts, A.; Bruggeman, P.J.; Cappelli, M.; Colombo, V.; Czarnetzki, U.; Ebert, U.; Eden, J.G.; Favia, P.; et al. The 2017 Plasma Roadmap: Low temperature plasma science and technology. J. Phys. D Appl. Phys. 2017, 50, 323001. [Google Scholar] [CrossRef]

- Taccogna, F.; Dilecce, G. Non-equilibrium in low-temperature plasmas. Eur. Phys. J. D 2016, 70, 251. [Google Scholar] [CrossRef]

- Sugai, H.; Ghanashev, I.; Hosokawa, M.; Mizuno, K.; Nakamura, K.; Toyoda, H.; Yamauchi, K. Electron energy distribution functions and the influence on fluorocarbon plasma chemistry. Plasma Sources Sci. Technol. 2001, 10, 378–385. [Google Scholar] [CrossRef]

- Uhm, H.S. Generation of various radicals in nitrogen plasma and their behavior in media. Phys. Plasma 2015, 22, 123506. [Google Scholar] [CrossRef]

- Luque-Agudo, V.; Hierro-Oliva, M.; Gallardo-Moreno, A.M.; González-Martín, M.L. Effect of plasma treatment on the surface properties of polylactic acid films. Polym. Test. 2021, 96, 107097. [Google Scholar] [CrossRef]

- Peran, J.; Razic, S.E. Application of atmospheric pressure plasma technology for textile surface modification. Text. Res. J. 2020, 90, 1174–1197. [Google Scholar] [CrossRef]

- Zhou, Z.; Huang, Y.; Yang, S.; Chen, W. Introduction of a new atmospheric pressure plasma device and application on tomato seeds. Agric. Sci. 2011, 2, 23–27. [Google Scholar] [CrossRef] [Green Version]

- Penkov, O.V.; Khadem, M.; Lim, W.S.; Kim, D.E. A review of recent applications of atmospheric pressure plasma jets for materials processing. J. Coat. Technol. Res. 2015, 12, 225–235. [Google Scholar] [CrossRef]

- Luan, P.; Oehrlein, G.S. Interaction of long-lived reactive species from cold atmospheric pressure plasma with polymers: Chemical modification by ozone and reactive oxygen-nitrogen species. J. Vac. Sci. Technol. A 2019, 37, 051303. [Google Scholar] [CrossRef]

- Graves, D.B. The emerging role of reactive oxygen and nitrogen species in redox biology and some implications for plasma applications to medicine and biology. J. Phys. D Appl. Phys. 2012, 45, 263001. [Google Scholar] [CrossRef]

- Tendero, C.; Tixier, C.; Tristant, P.; Desmaison, J.; Leprince, P. Atmospheric pressure plasmas: A review. Spectrochim. Acta Part B At. Spectrosc. 2006, 61, 2–30. [Google Scholar] [CrossRef]

- Winter, J.; Brandenburg, R.; Weltmann, K.D. Atmospheric pressure plasma jets: An overview of devices and new directions. Plasma Sources Sci. Technol. 2015, 24, 064001. [Google Scholar] [CrossRef]

- Hsu, A.R.; Chien, H.-H.; Liao, C.-Y.; Lee, C.-C.; Tsai, J.-H.; Hsu, C.-C.; Cheng, I.-C.; Chen, J.-Z. Scan-mode atmospheric-pressure plasma jet processed reduced graphene oxides for quasi-solid-state gel-electrolyte supercapacitors. Coatings 2018, 8, 52. [Google Scholar] [CrossRef] [Green Version]

- Jiayun, T.; Rui, H.; Xiaoli, Z.; Ruoting, Z.; Weiwen, C.; Size, Y. Effects of atmospheric pressure air plasma pretreatment on the seed germination and early growth of andrographis paniculata. Plasma Sci. Technol. 2014, 16, 260–266. [Google Scholar] [CrossRef] [Green Version]

- Dhayal, M.; Lee, S.Y.; Park, S.U. Using low-pressure plasma for Carthamus tinctorium L. seed surface modification. Vacuum 2006, 80, 499–506. [Google Scholar] [CrossRef]

- Ashrafi, E.; Razmjoo, J. Seed Treatment to Overcome Salt and Drought Stresses During Germination in Safflower (Carthamus tinctorius L.). J. Plant. Nutr. 2015, 38, 2151–2158. [Google Scholar] [CrossRef]

- Miano, A.C.; Forti, V.A.; Abud, H.F.; Gomes-Junior, F.G.; Cicero, S.M.; Augusto, P.E.D. Effect of ultrasound technology on barley seed germination and vigour. Seed Sci. Technol. 2015, 43, 297–302. [Google Scholar] [CrossRef]

- Ling, L.; Jiafeng, J.; Jiangang, L.; Minchong, S.; Xin, H.; Hanliang, S.; Yuanhua, D. Effects of cold plasma treatment on seed germination and seedling growth of soybean. Sci. Rep. 2014, 4, 5859. [Google Scholar] [CrossRef] [Green Version]

- Meng, Y.; Qu, G.; Wang, T.; Sun, Q.; Liang, D.; Hu, S. Enhancement of Germination and Seedling Growth of Wheat Seed Using Dielectric Barrier Discharge Plasma with Various Gas Sources. Plasma Chem. Plasma Process. 2017, 37, 1105–1119. [Google Scholar] [CrossRef]

- De Groot, G.J.J.B.; Hundt, A.; Murphy, A.B.; Bange, M.P.; Mai-Prochnow, A. Cold plasma treatment for cotton seed germination improvement. Sci. Rep. 2018, 8, 14372. [Google Scholar] [CrossRef] [Green Version]

- Molina, R.; López-Santos, C.; Gómez-Ramírez, A.; Vílchez, A.; Espinós, J.P.; González-Elipe, A.R. Influence of irrigation conditions in the germination of plasma treated Nasturtium seeds. Sci. Rep. 2018, 8, 16442. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ahn, C.; Gill, J.; Ruzic, D.N. Growth of Plasma-Treated Corn Seeds under Realistic Conditions. Sci. Rep. 2019, 9, 4355. [Google Scholar] [CrossRef] [Green Version]

- Srakaew, K.; Chingsungnoen, A.; Janpeng, P.; Sutthisa, W. Development of multi-hole atmospheric pressure plasma jet for seed treatment. KKU Sci. J. 2020, 48, 117–129. [Google Scholar]

- Tribouillois, H.; Dürr, C.; Demilly, D.; Wagner, M.H.; Justes, E. Determination of germination response to temperature and water potential for a wide range of cover crop species and related functional groups. PLoS ONE 2016, 11, e0161185. [Google Scholar] [CrossRef]

- Elson, M.K.; Morse, R.D.; Wolf, D.D.; Vaughan, D.H. High-temperature Inhibition of Seed Germination and Seedling Emergence of Broccoli. Horttechnology 1992, 2, 417–419. [Google Scholar] [CrossRef] [Green Version]

- Kebreab, E.; Murdoch, A.J. The effect of water stress on the temperature range for germination of Orobanches aegyptiaca seeds. Seed Sci Res. 2000, 10, 127–133. [Google Scholar] [CrossRef]

- Heidari, Z.; Kamkar, B.; Sinaky, J.M. Influence of Temperature on Seed Germination Response of Fennel. Adv. Plants Agric. Res. 2014, 1, 00032. [Google Scholar] [CrossRef] [Green Version]

- Hatfield, J.L.; Prueger, J.H. Temperature extremes: Effect on plant growth and development. Weather Clim. Extrem. 2015, 10, 4–10. [Google Scholar] [CrossRef] [Green Version]

- Waskow, A.; Howling, A.; Furno, I. Mechanisms of Plasma-Seed Treatments as a Potential Seed Processing Technology. Front. Phys. 2021, 9, 617345. [Google Scholar] [CrossRef]

- Puač, N.; Maletić, D.; Lazović, S.; Malović, G.; Đorđević, A.; Petrović, Z. Current—Voltage Characteristics of Atmospheric Pressure Plasma Jet. Publ. Astron. Obs. Belgrade 2010, 89, 307–310. [Google Scholar]

- Sarinont, T.; Amano, T.; Attri, P.; Koga, K.; Hayashi, N.; Shiratani, M. Effects of plasma irradiation using various feeding gases on growth of Raphanus sativus L. Arch. Biochem. Biophys. 2016, 605, 129–140. [Google Scholar] [CrossRef] [PubMed]

- Bormashenko, E.; Grynyov, R.; Bormashenko, Y.; Drori, E. Cold radiofrequency plasma treatment modifies wettability and germination speed of plant seeds. Sci. Rep. 2012, 2, 741. [Google Scholar] [CrossRef]

- Ström, G.; Fredriksson, M.; Stenius, P. Contact angles, work of adhesion, and interfacial tensions at a dissolving Hydrocarbon surface. J. Colloid Interface Sci. 1987, 119, 352–361. [Google Scholar] [CrossRef]

- Xiu, Y.; Zhu, L.; Hess, D.W.; Wong, C.P. Relationship between work of adhesion and contact angle hysteresis on superhydrophobic surfaces. J. Phys. Chem. C 2008, 112, 11403–11407. [Google Scholar] [CrossRef]

- Volkov, A.G.; Hairston, J.S.; Patel, D.; Gott, R.P.; Xu, K.G. Cold plasma poration and corrugation of pumpkin seed coats. Bioelectrochemistry 2019, 128, 175–185. [Google Scholar] [CrossRef] [PubMed]

- Breden, D.; Raja, L.L. Computational study of the interaction of cold atmospheric helium plasma jets with surfaces. Plasma Sources Sci. Technol. 2014, 23, 065020. [Google Scholar] [CrossRef] [Green Version]

- Butscher, D.; Loon, H.V.; Waskow, A.; Rudolf von Rohr, P.; Schuppler, M. Plasma inactivation of microorganisms on sprout seeds in a dielectric barrier discharge. Int. J. Food Microbiol. 2016, 238, 222–232. [Google Scholar] [CrossRef]

- Bafoil, M.; Jemmat, A.; Martinez, Y.; Merbahi, N.; Eichwald, O.; Dunand, C.; Yousfi, M. Effects of low temperature plasmas and plasma activated waters on Arabidopsis thaliana germination and growth. PLoS ONE 2018, 13, e0195512. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Srakaew, K.; Chingsungnoen, A.; Sutthisa, W.; Lakhonchai, A.; Poolcharuansin, P.; Chunpeng, P.; Rojviriya, C.; Thumanu, K.; Tunmee, S. Development of a Multihole Atmospheric Plasma Jet for Growth Rate Enhancement of Broccoli Seeds. Processes 2021, 9, 1134. https://doi.org/10.3390/pr9071134

Srakaew K, Chingsungnoen A, Sutthisa W, Lakhonchai A, Poolcharuansin P, Chunpeng P, Rojviriya C, Thumanu K, Tunmee S. Development of a Multihole Atmospheric Plasma Jet for Growth Rate Enhancement of Broccoli Seeds. Processes. 2021; 9(7):1134. https://doi.org/10.3390/pr9071134

Chicago/Turabian StyleSrakaew, Khattiya, Artit Chingsungnoen, Waraporn Sutthisa, Anthika Lakhonchai, Phitsanu Poolcharuansin, Poramate Chunpeng, Catleya Rojviriya, Kanjana Thumanu, and Sarayut Tunmee. 2021. "Development of a Multihole Atmospheric Plasma Jet for Growth Rate Enhancement of Broccoli Seeds" Processes 9, no. 7: 1134. https://doi.org/10.3390/pr9071134

APA StyleSrakaew, K., Chingsungnoen, A., Sutthisa, W., Lakhonchai, A., Poolcharuansin, P., Chunpeng, P., Rojviriya, C., Thumanu, K., & Tunmee, S. (2021). Development of a Multihole Atmospheric Plasma Jet for Growth Rate Enhancement of Broccoli Seeds. Processes, 9(7), 1134. https://doi.org/10.3390/pr9071134