Basalt-Fiber-Reinforced Phosphorus Building Gypsum Composite Materials (BRPGCs): An Analysis on Their Working Performance and Mechanical Properties

Abstract

:1. Introduction

2. Results and Discussion

2.1. Working Performance

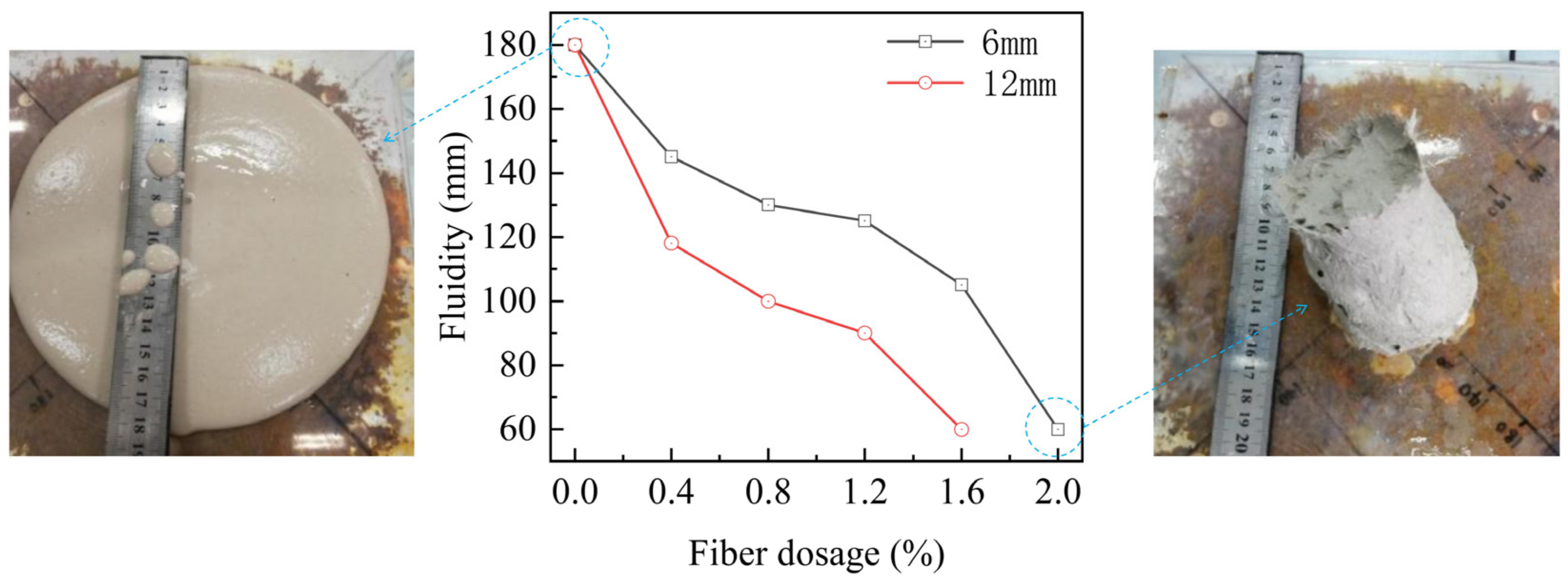

2.1.1. Fluidity

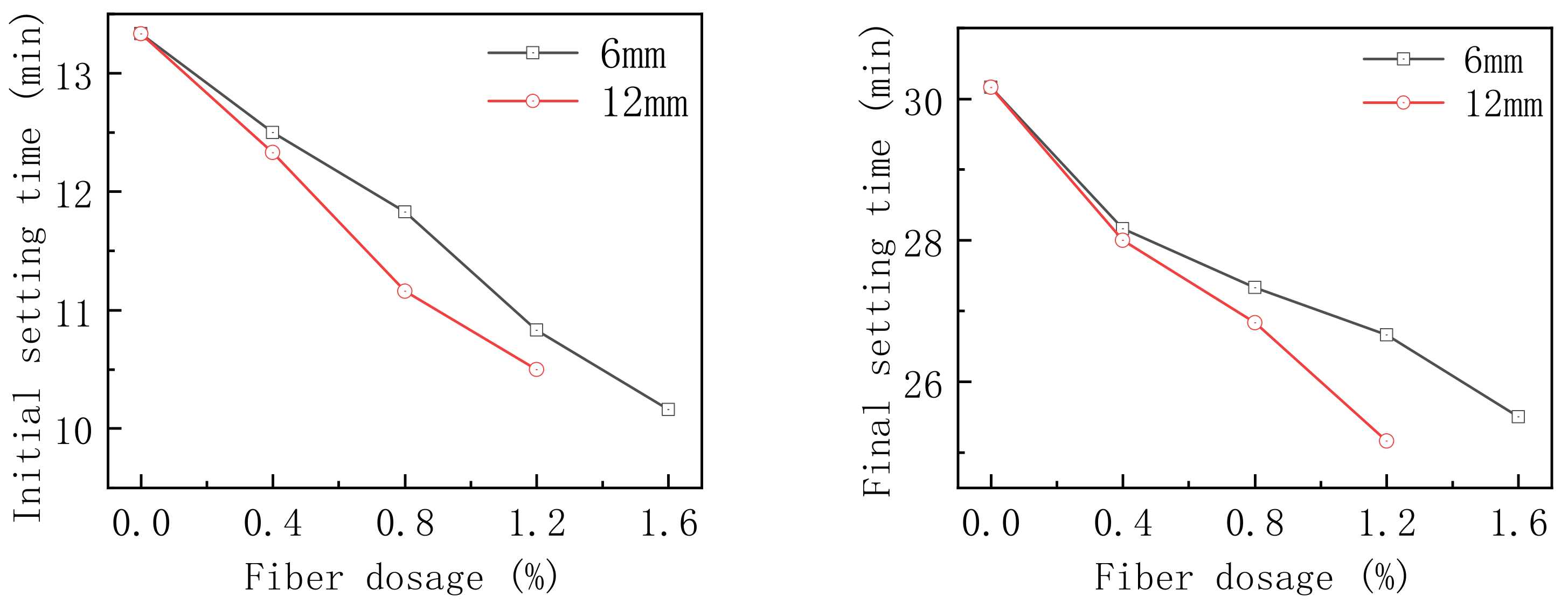

2.1.2. Setting Time

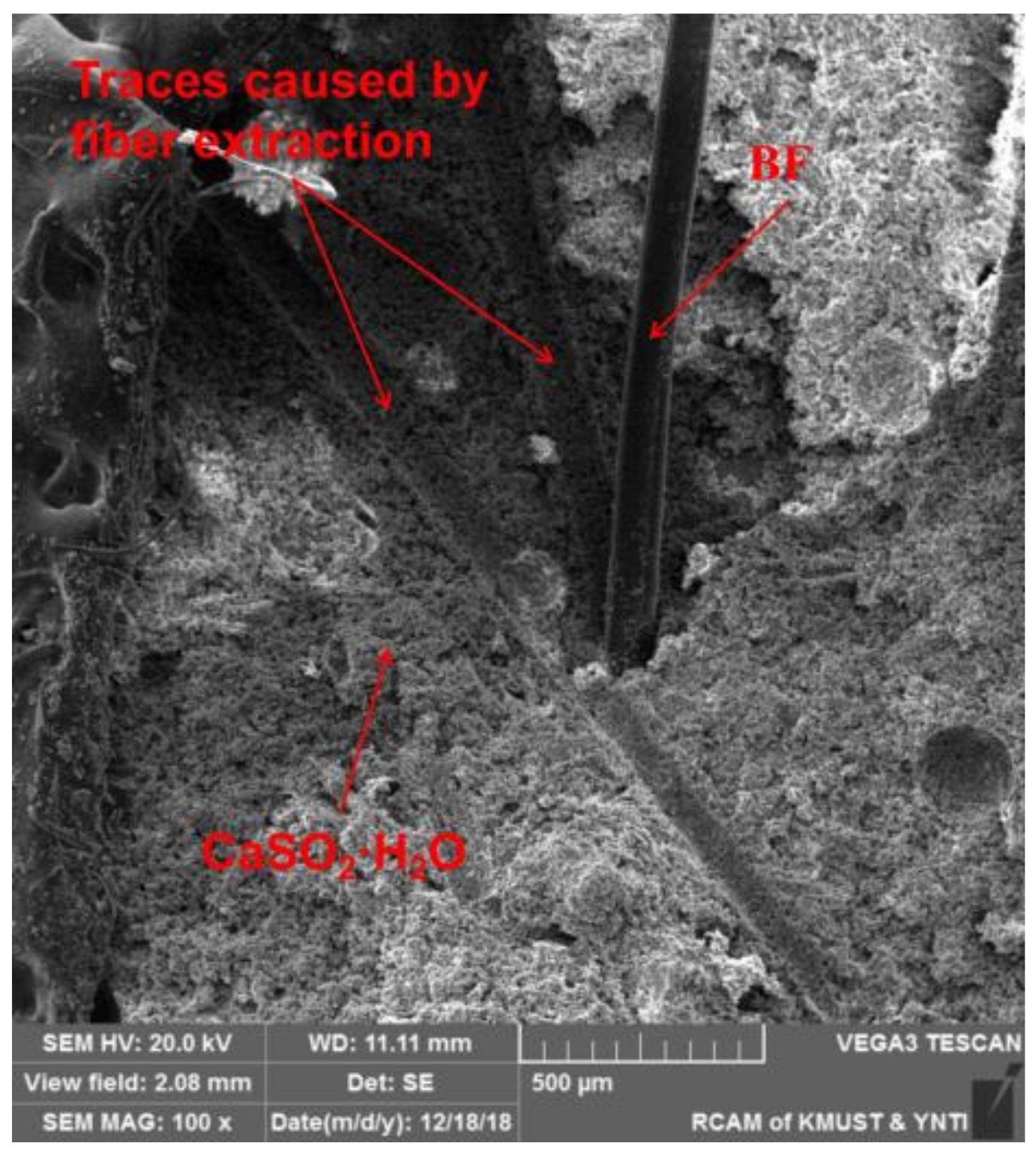

2.2. Mechanical Properties

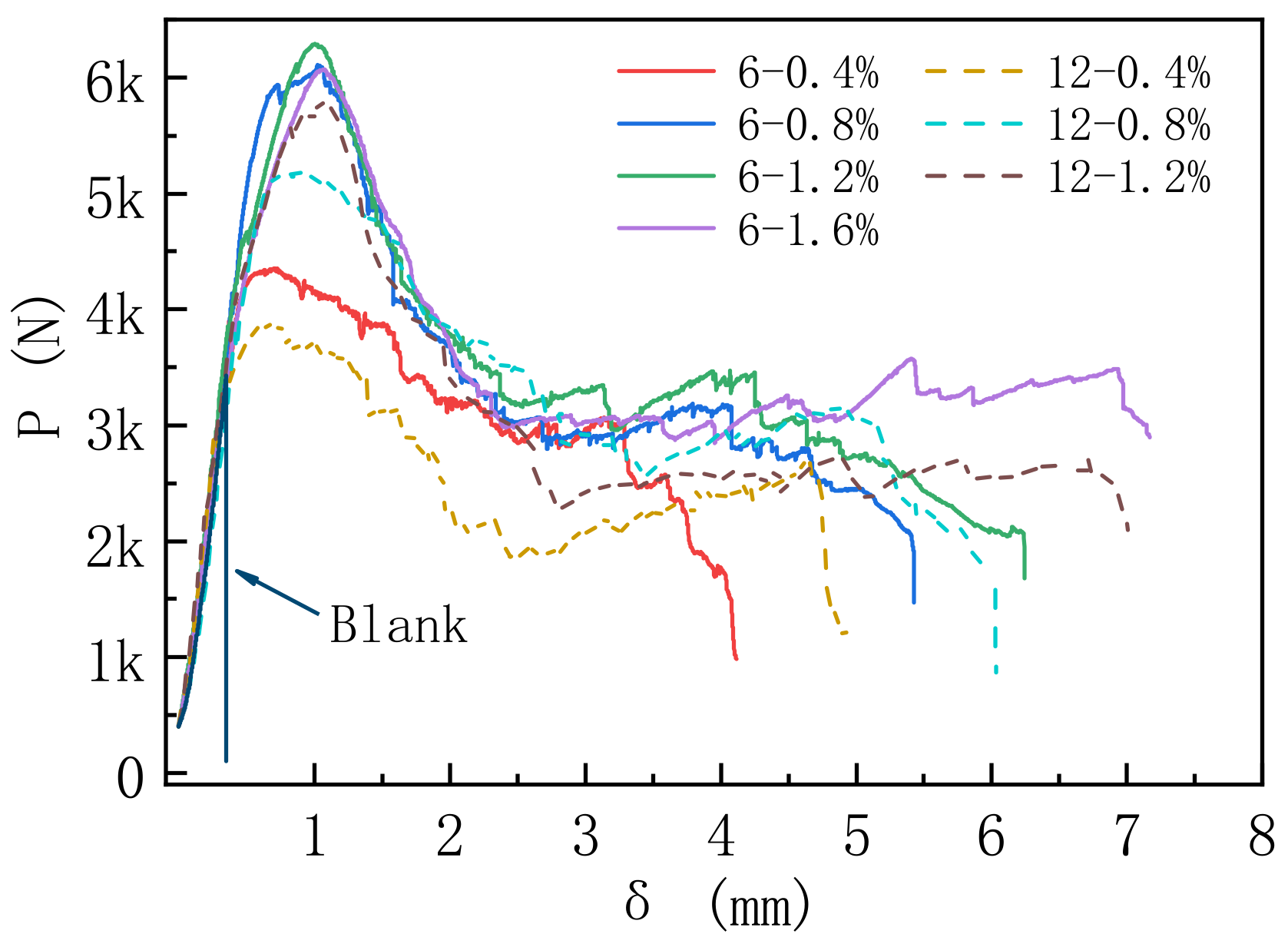

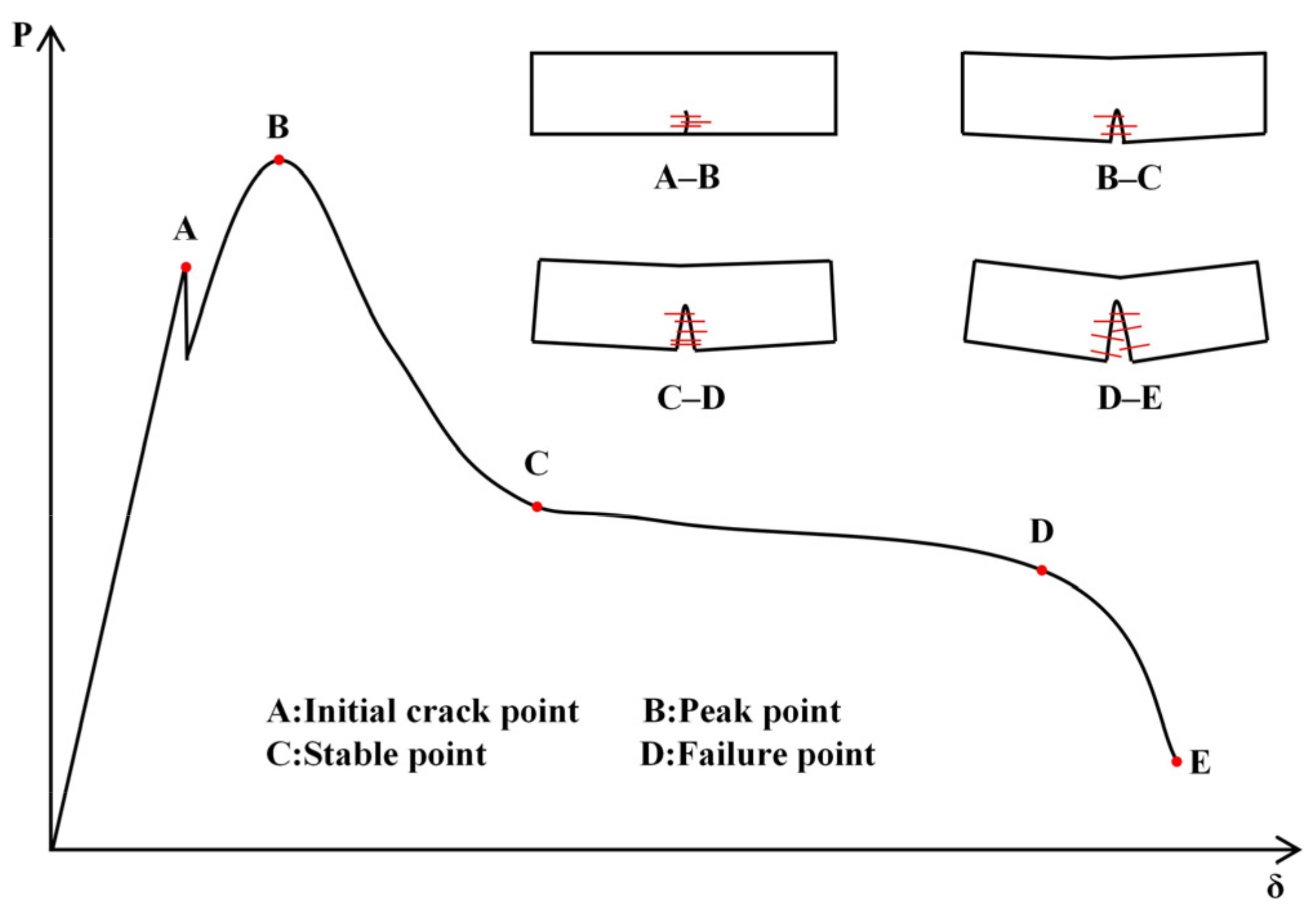

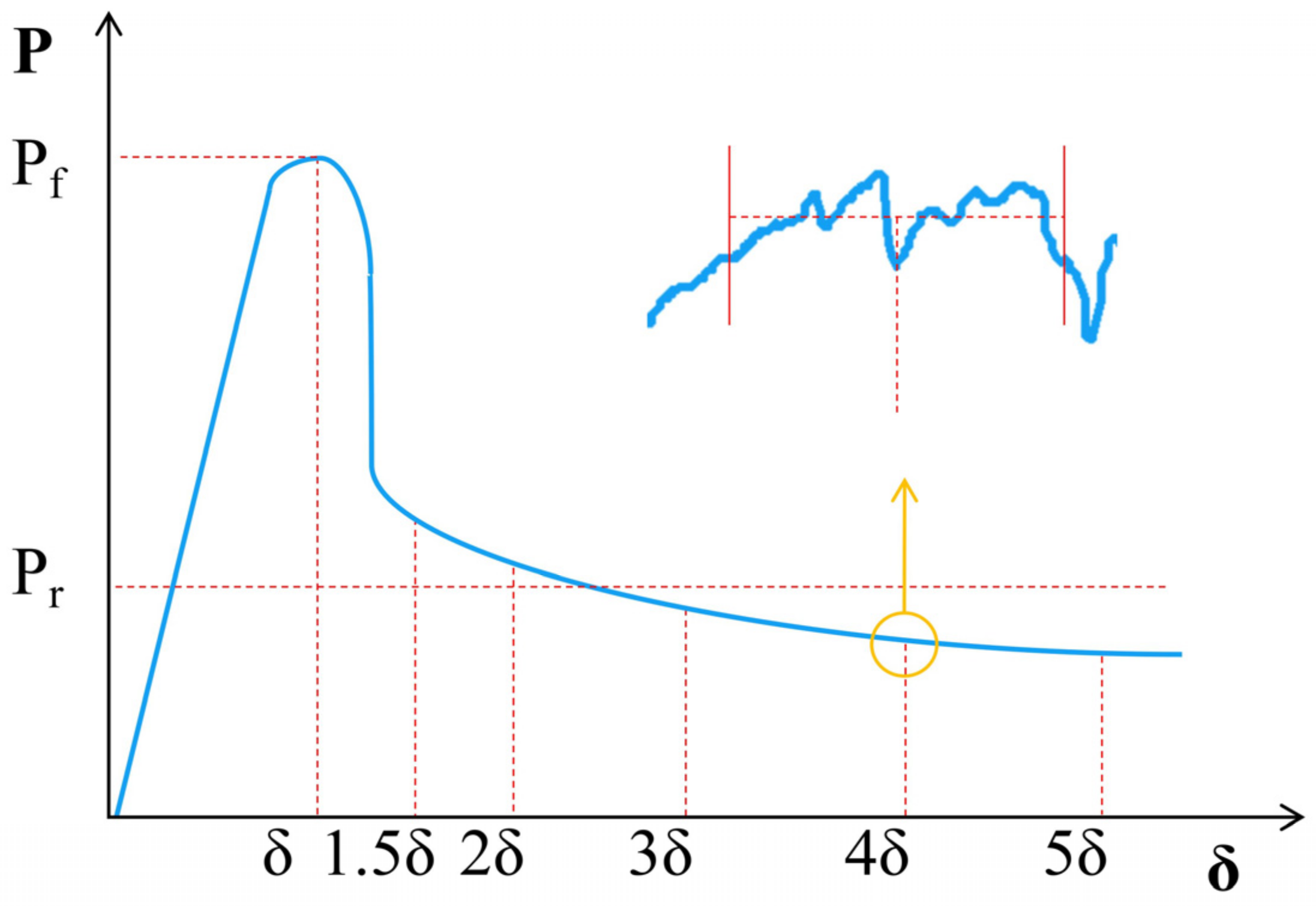

2.2.1. Analysis of P-δ Curve

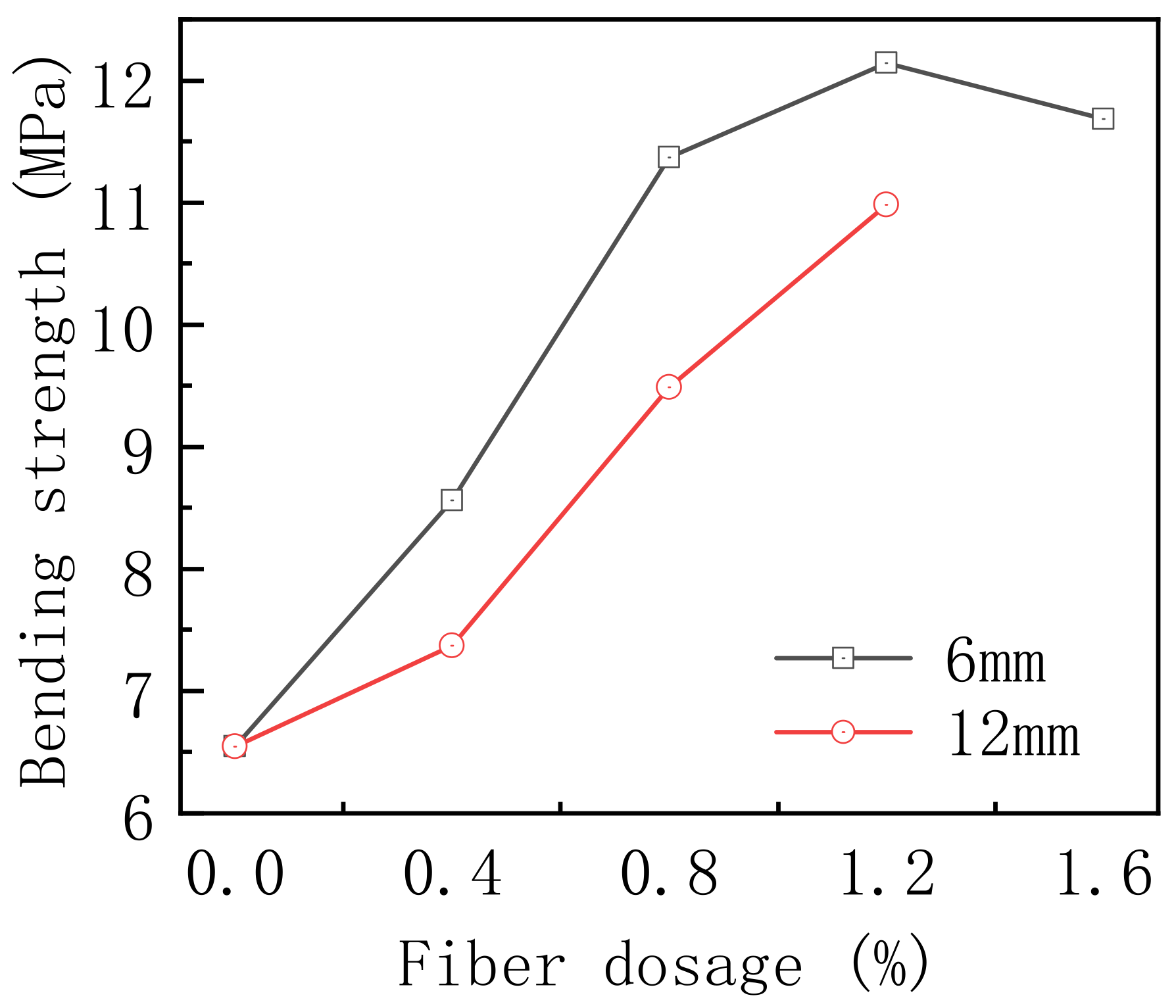

2.2.2. Bending Strength

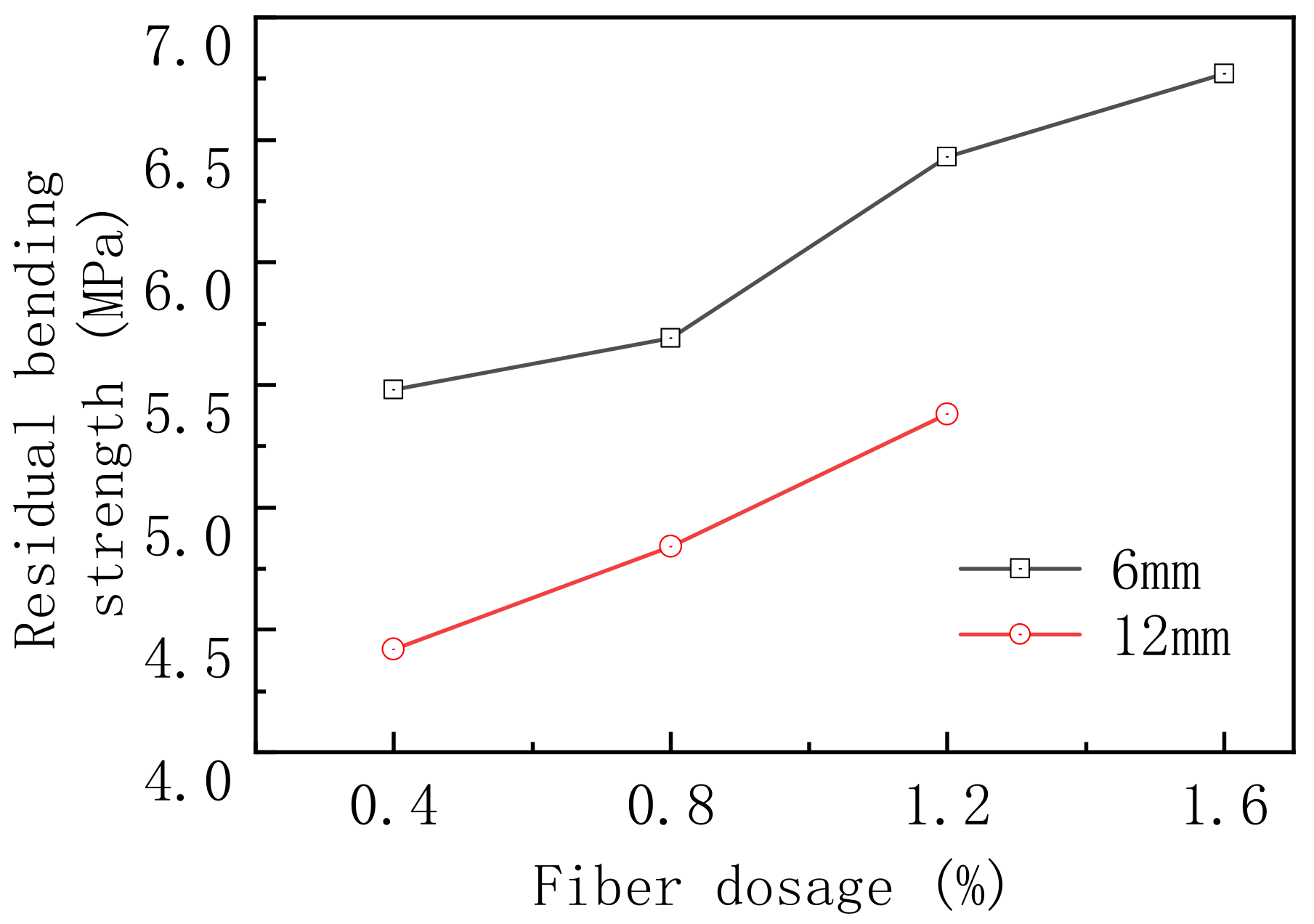

2.2.3. Bending Toughness

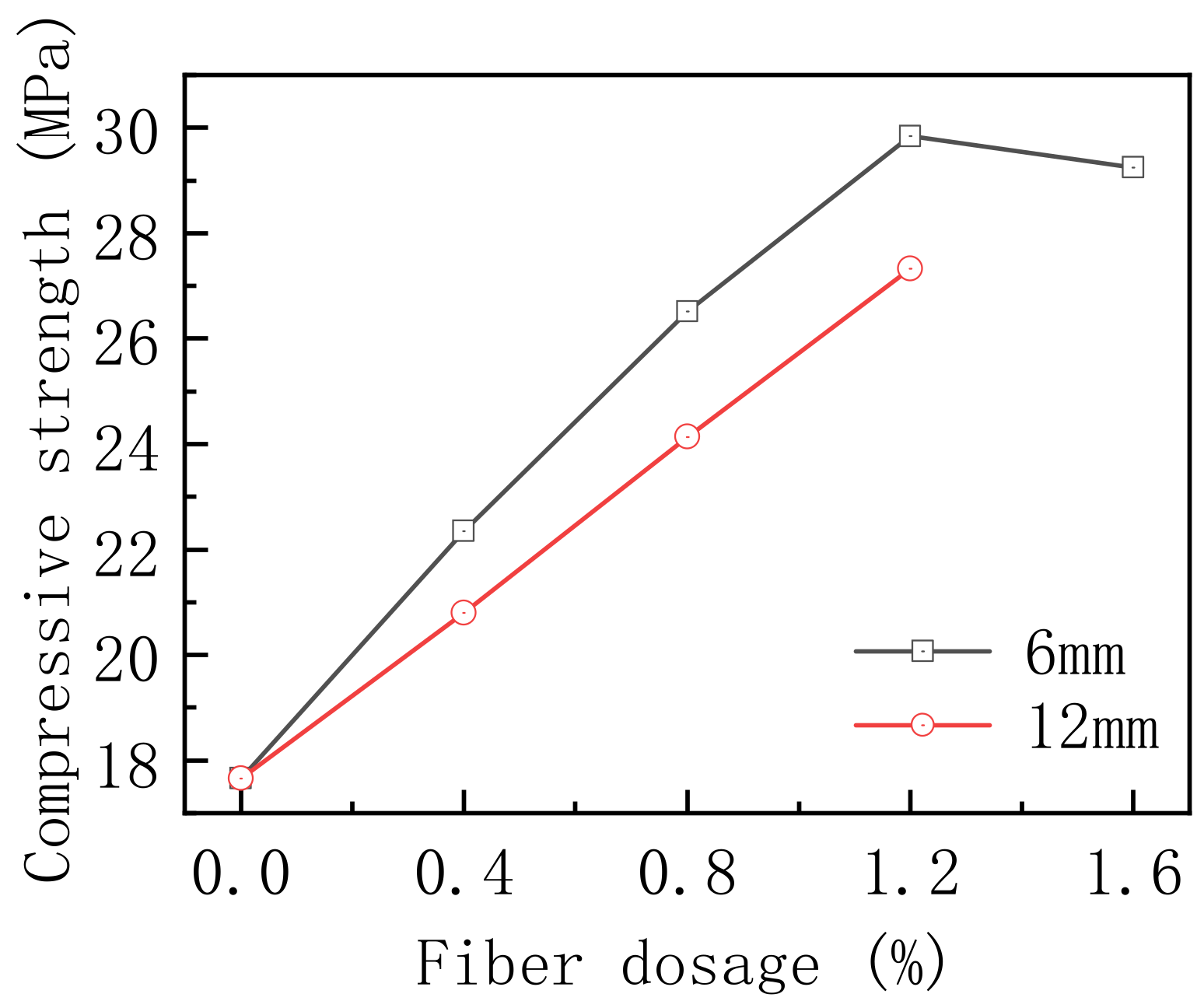

2.2.4. Compressive Strength

3. Materials and Methods

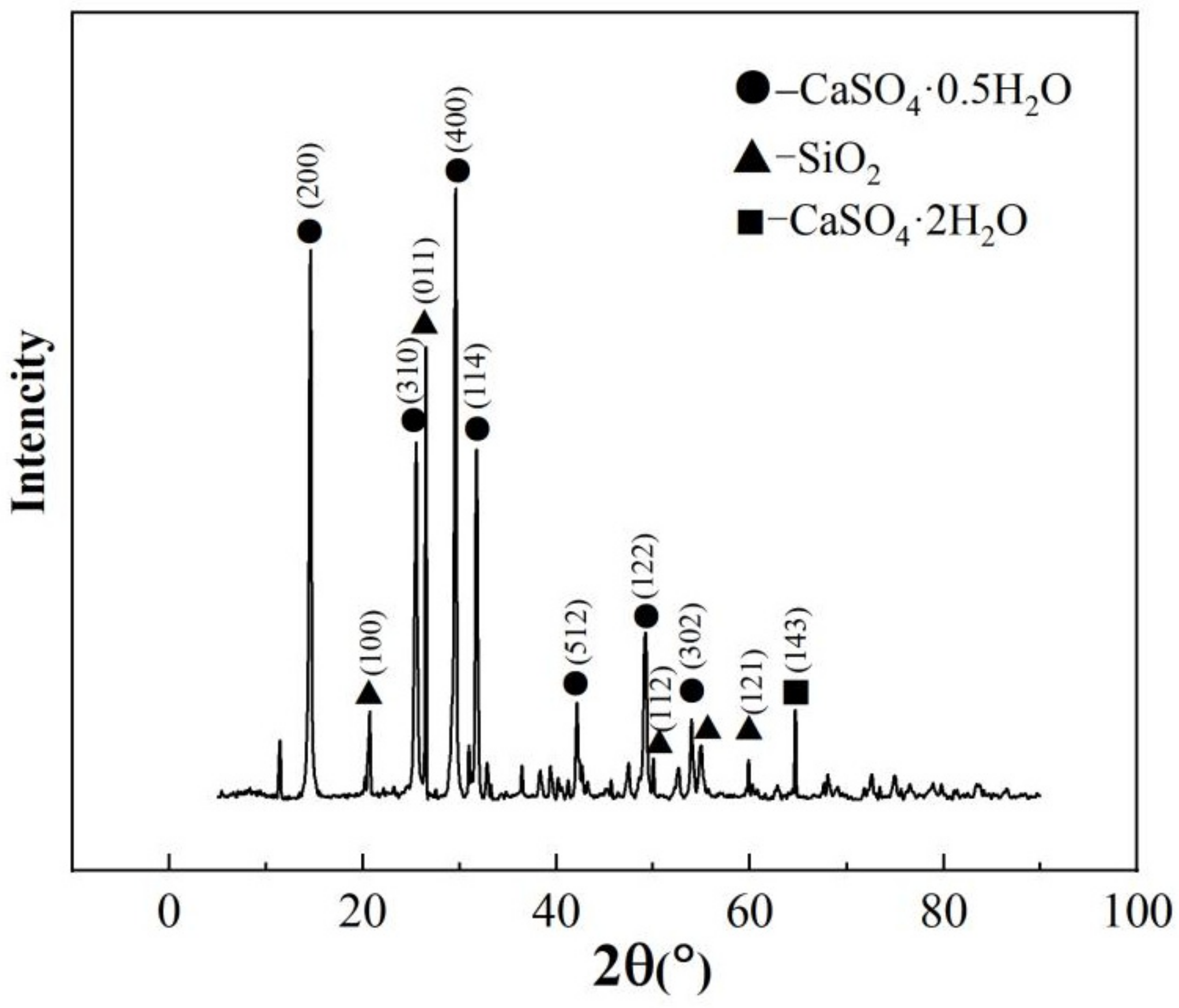

3.1. Raw Materials

3.2. Experiment Design

3.3. Experiment Methods

3.3.1. Working Performance

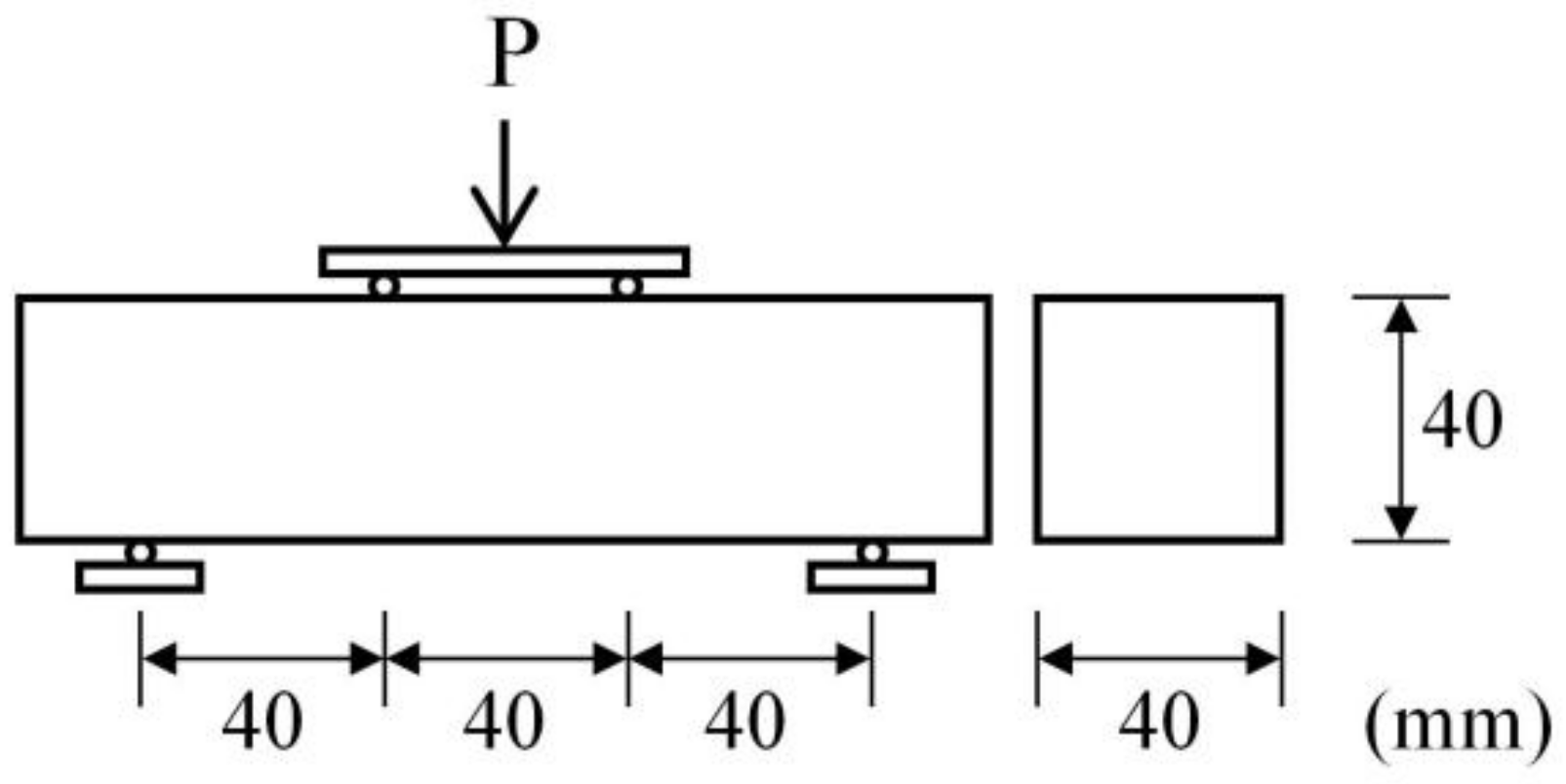

3.3.2. Mechanical Properties

4. Conclusions

- (1)

- The addition of BF had a negative impact on the working performance of the slurry from BRPGCs. As the fiber content and length increased, the fluidity of the slurry from BRPGCs decreased and the setting time shortened.

- (2)

- Adding BF significantly improved the mechanical properties of BRPGCs. With the increase in fiber content, the bending strength and compressive strength of BRPGCs were markedly promoted. However, the increase in fiber length had adverse effects on the mechanical properties of BRPGCs. When adding 1.2% of 6 mm BF, the bending strength and compressive strength of BRPGCs reached the maximum values of 10.98 MPa and 29.83 MPa, 67.7% and 69.0% higher than the blank group, respectively.

- (3)

- The P-δ curve of BRPGCs exhibited a typical characteristic of five stages. BRPGCs could reserve a good residual strength after cracking. As the fiber content increased, the toughness of the composite material increased. When 1.6% of 6 mm BF was added, the residual strength of FRPGCs reached the maximum value of 6.77 MPa.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Francisco, M.; Rafael, P.; Carlos, R.C.; Sergio, C.; Pablo, C. Environmental Assessment and Management of Phosphogypsum According to European and United States of America Regulations. Procedia Earth Planet. Sci. 2017, 17, 666–669. [Google Scholar]

- Qiang, W.; Shiyu, Z.; Ruiquan, J. An Investigation On the Anti-Water Properties of Phosphorus Building Gypsum (Pbg)-Based Mortar. J. Therm. Anal. Calorim. 2019, 136, 1575–1585. [Google Scholar]

- Zhou, Y.; Zheng, G.; Liu, Z.; Liu, R.; Tao, C. Multi-Stage Precipitation for the Eco-Friendly Treatment of Phosphogypsum Leachates Using Hybrid Alkaline Reagents. J. Water Process. Eng. 2023, 53, 103626. [Google Scholar] [CrossRef]

- Ignacio, V.F.; Viktoras, D.; Danutė, V.; Dalia, N. The Investigation of Phosphogypsum Specimens Processed by Press-Forming Method. Waste Biomass Valorization 2020, 12, 1539–1551. [Google Scholar]

- Shuhua, L.; Peipei, F.; Jun, R.; Shefeng, L. Application of Lime Neutralised Phosphogypsum in Supersulfated Cement. J. Clean Prod. 2020, 272, 122660. [Google Scholar]

- Wu, H.; Han, C.N.; Tan, Y. Research progress on reutilization of phosphogypsum on China. Mod. Chem. Ind. 2023, 43, 18–21. [Google Scholar]

- Qiang, W.; Ruiquan, J. A Novel Gypsum-Based Self-Leveling Mortar Produced by Phosphorus Building Gypsum. Constr. Build. Mater. 2019, 226, 11–20. [Google Scholar]

- Huang, W.; Tan, Y.; Ming, H.; Li, H.; Wu, J.; Wu, C.; Hu, B. A Novel Method for Preparing Phosphorus Building Gypsum (Pbg)-Based Building Materials with Low Water/Gypsum Ratios. J. Mater. Cycles Waste Manag. 2023, 25, 1035–1049. [Google Scholar] [CrossRef]

- Qin, X.; Cao, Y.; Guan, H.; Hu, Q.; Liu, Z.; Xu, J.; Hu, B.; Zhang, Z.; Luo, R. Resource Utilization and Development of Phosphogypsum-Based Materials in Civil Engineering. J. Clean Prod. 2023, 387, 135858. [Google Scholar] [CrossRef]

- Philip, C.; Sivakumar, P.; Devdas, M.; Meher, P.A. Comparative Study of Embodied Energy of Affordable Houses Made Using Gfrg and Conventional Building Technologies in India. Energy Build. 2020, 223, 110138. [Google Scholar]

- Jun, Z.; Xiaoqian, L.; Yu, Z.; Zhu, S.; Yanxin, W.; Yi, Z.; Xiang, S. Preparation of Paper-Free and Fiber-Free Plasterboard with High Strength Using Phosphogypsum. Constr. Build. Mater. 2020, 243, 118091. [Google Scholar]

- Jia, R.; Wang, Q.; Feng, P. A Comprehensive Overview of Fibre-Reinforced Gypsum-Based Composites (Frgcs) in the Construction Field. Compos. Part B 2021, 205, 108540. [Google Scholar] [CrossRef]

- Gonçalves, R.M.; Martinho, A.; Oliveira, J.P. Evaluating the Potential Use of Recycled Glass Fibers for the Development of Gypsum-Based Composites. Constr. Build. Mater. 2022, 321, 126320. [Google Scholar] [CrossRef]

- Suárez, F.; Felipe-Sesé, L.; Díaz, F.A.; Gálvez, J.C.; Alberti, M.G. On the Fracture Behaviour of Fibre-Reinforced Gypsum Using Micro and Macro Polymer Fibres. Constr. Build. Mater. 2020, 244, 118347. [Google Scholar] [CrossRef]

- Cong, Z.; Jianxin, Z.; Jiahui, P.; Wenxiang, C.; Jiangsen, L. Physical and Mechanical Properties of Gypsum-Based Composites Reinforced with Pva and Pp Fibers. Constr. Build. Mater. 2018, 163, 695–705. [Google Scholar] [CrossRef]

- Adeyemi, A. Performance of cementitious composites reinforced with chopped basalt fibres—An overview. Constr. Build. Mater. 2021, 266 Pt A, 120970. [Google Scholar] [CrossRef]

- Li, X.; Yu, T.; Park, S.; Kim, Y. Reinforcing Effects of Gypsum Composite with Basalt Fiber and Diatomite for Improvement of High-Temperature Endurance. Constr. Build. Mater. 2022, 325, 126762. [Google Scholar] [CrossRef]

- Li, Z.; Wang, X.; Yan, W.; Ding, L.; Liu, J.; Wu, Z.; Huang, H. Physical and Mechanical Properties of Gypsum-Based Composites Reinforced with Basalt, Glass, and Pva Fibers. J. Build. Eng. 2023, 64, 695–705. [Google Scholar] [CrossRef]

- Li, Z.; Wang, X.; Zhu, Z.; Wu, Z. Effect of Mixing Methods On the Dispersion of Fibers in the Gypsum Matrix and Performance Improvement Mechanism. Constr. Build. Mater. 2022, 320, 126193. [Google Scholar] [CrossRef]

- Xie, L.; Zhou, Y.S.; Luo, S.; Fu, R.B.; Kong, D.W.; Wang, L.L. Study on Basalt Fiber Modified Desulfurized Building Gypsum. Non-Met. Mines 2020, 43, 49–51. [Google Scholar]

- Wu, L.; Zhao, Z.M.; Zhu, w.m.; Luan, Y.; Wu, B. Effect of Chopped Basalt Fiber on the Bending Strength of Phosphogypsum. Non-Met. Mines 2017, 40, 9–11. [Google Scholar]

- GB/T 17669.4-1999.1999-02-08; Gypsum Plasters—Determination of Physical Properties of Pure Paste. State Bureau of Building Materials Industry: Beijing, China, 1999.

- Wu, L.; Zhao, Z.M.; Tian, R.; Quan, S.C.; Liu, Y.; He, J.Y.; Wu, B.; Dai, H.J. Orthogonal Test of Modified Phosphogypsum by Polypropylene Fibers and Polyvinyl Alcohol. Bull. Chin. Ceram. Soc. 2018, 37, 4022–4026. [Google Scholar] [CrossRef]

| Fiber | Bending Strength/Flexural Strength | Compressive Strength | |

|---|---|---|---|

| This paper | 6 mm, 17.4 μm, and 1.2% BF | Increased by 85.4% | Increased by 69% |

| Gonçalves [13] | 10 mm; 6 wt% E-glass fiber | Increased by 66% | - |

| Suarez [14] | 12 mm, 31 μm, and 10 Kg/m3 | - | Decreased by 6.7% |

| Cong [15] | 12 mm, 12 μm, and 1.2% PVA | Increased by 48% | Decreased by 6.6% |

| Li [18] | 10 mm; 10% PVA | Increased by 78.3% | - |

| Li [19] | 10 mm, 13 μm, and 0.5% BF | Increased by 40.6% | Decreased by 11.1% |

| Xie [20] | 6 mm, 17 μm, and 0.7 wt% BF | Increased by 36.53% | Increased by 10.31% |

| Component | SiO2 | Al2O3 | Fe2O3 | MnO | MgO | CaO | K2O | P2O5 | SO3 | Organism |

|---|---|---|---|---|---|---|---|---|---|---|

| Content (%) | 14.52 | 1.66 | 0.15 | 0.005 | 0.17 | 31.94 | 0.22 | 0.94 | 45.38 | 0.25 |

| Density | Tensile Strength | Elongation Rate | Maximum Working Temperature | Diameter | Tensile Modulus of Elasticity |

|---|---|---|---|---|---|

| 2.65 g/cm | ≥2000 MPa | ≥2.5% | 650 °C | 17.4 μm | 100 GPa |

| No. | PBG/g | Water Reducer/g | Water/g | Length of BF/mm | Volume Fractions for BF/% |

|---|---|---|---|---|---|

| 1 | 1200 | 6 | 370 | - | - |

| 2 | 1200 | 6 | 370 | 6 | 0.4 |

| 3 | 1200 | 6 | 370 | 6 | 0.8 |

| 4 | 1200 | 6 | 370 | 6 | 1.2 |

| 5 | 1200 | 6 | 370 | 6 | 1.6 |

| 6 | 1200 | 6 | 370 | 6 | 2.0 |

| 7 | 1200 | 6 | 370 | 12 | 0.4 |

| 8 | 1200 | 6 | 370 | 12 | 0.8 |

| 9 | 1200 | 6 | 370 | 12 | 1.2 |

| 10 | 1200 | 6 | 370 | 12 | 1.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, L.; Tao, Z.; Huang, R.; Zhang, Z.; Shen, J.; Xu, W. Basalt-Fiber-Reinforced Phosphorus Building Gypsum Composite Materials (BRPGCs): An Analysis on Their Working Performance and Mechanical Properties. Inorganics 2023, 11, 254. https://doi.org/10.3390/inorganics11060254

Wu L, Tao Z, Huang R, Zhang Z, Shen J, Xu W. Basalt-Fiber-Reinforced Phosphorus Building Gypsum Composite Materials (BRPGCs): An Analysis on Their Working Performance and Mechanical Properties. Inorganics. 2023; 11(6):254. https://doi.org/10.3390/inorganics11060254

Chicago/Turabian StyleWu, Lei, Zhong Tao, Ronggui Huang, Zhiqi Zhang, Jinjin Shen, and Weijie Xu. 2023. "Basalt-Fiber-Reinforced Phosphorus Building Gypsum Composite Materials (BRPGCs): An Analysis on Their Working Performance and Mechanical Properties" Inorganics 11, no. 6: 254. https://doi.org/10.3390/inorganics11060254

APA StyleWu, L., Tao, Z., Huang, R., Zhang, Z., Shen, J., & Xu, W. (2023). Basalt-Fiber-Reinforced Phosphorus Building Gypsum Composite Materials (BRPGCs): An Analysis on Their Working Performance and Mechanical Properties. Inorganics, 11(6), 254. https://doi.org/10.3390/inorganics11060254