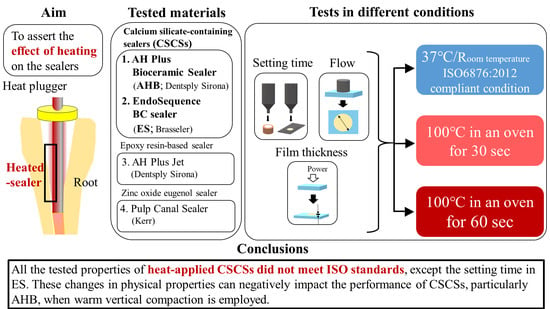

Heat-Induced Changes in the Physical Properties of a New Premixed Calcium Silicate-Containing Root Canal Sealer: An In Vitro Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Setting Time

2.2. Flow

2.3. Film Thickness

2.4. Scanning Electron Microscopy and Energy-Dispersive X-ray Spectroscopy

2.5. Statistics

3. Results

3.1. Setting Time

3.2. Flow

3.3. Film Thickness

3.4. Surface Ultrastructure and Elemental Composition

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ørstavik, D. Materials used for root canal obturation: Technical, biological and clinical testing. Endod. Top. 2005, 12, 25–38. [Google Scholar] [CrossRef]

- Wu, M.K.; Van Der Sluis, L.W.; Wesselink, P.R. Fluid transport along gutta-percha backfills with and without sealer. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 2004, 97, 257–262. [Google Scholar] [CrossRef]

- Schäfer, E.; Zandbiglari, T. Solubility of root-canal sealers in water and artificial saliva. Int. Endod. J. 2003, 36, 660–669. [Google Scholar] [CrossRef]

- Pane, E.; Palamara, J.; Messer, H. Behavior of resin-based endodontic sealer cements in thin and thick films. Dent. Mater. 2012, 28, 150–159. [Google Scholar] [CrossRef] [PubMed]

- Iglecias, E.F.; Freire, L.G.; de Miranda Candeiro, G.T.; Dos Santos, M.; Antoniazzi, J.H.; Gavini, G. Presence of voids after continuous wave of condensation and single-cone obturation in mandibular molars: A Micro-computed Tomography Analysis. J. Endod. 2017, 43, 638–642. [Google Scholar] [CrossRef] [PubMed]

- Karatekin, A.; Keles, A.; Gencoglu, N. Comparison of continuous wave and cold lateral condensation filling techniques in 3D printed simulated C-shape canals instrumented with Reciproc Blue or Hyflex EDM. PLoS ONE 2019, 14, e0224793. [Google Scholar] [CrossRef]

- Atmeh, A.R.; AlShwaimi, E. The effect of heating time and temperature on epoxy resin and calcium silicate-based endodontic sealers. J. Endod. 2017, 43, 2112–2118. [Google Scholar] [CrossRef]

- Camilleri, J. Sealers and warm gutta-percha obturation techniques. J. Endod. 2015, 41, 72–78. [Google Scholar] [CrossRef] [PubMed]

- Marciano, M.A.; Duarte, M.A.; Camilleri, J. Calcium silicate-based sealers: Assess-ment of physicochemical properties, porosity and hydration. Dent. Mater. 2016, 32, e30–e40. [Google Scholar] [CrossRef]

- Zoufan, K.; Jiang, J.; Komabayashi, T.; Wang, Y.; Safavi, K.E.; Zhu, Q. Cytotoxicity evaluation of Gutta Flow and Endo Sequence BC sealers. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 2011, 112, 657–661. [Google Scholar] [CrossRef]

- Zhou, H.M.; Shen, Y.; Zheng, W.; Li, L.; Zheng, Y.F.; Haapasalo, M. Physical properties of 5 root canal sealers. J. Endod. 2013, 39, 1281–1286. [Google Scholar] [CrossRef] [PubMed]

- Han, L.; Okiji, T. Bioactivity evaluation of three calcium silicate-based endodontic materials. Int. Endod. J. 2013, 46, 808–814. [Google Scholar] [CrossRef] [PubMed]

- Tay, F.R.; Pashley, D.H.; Rueggeberg, F.A.; Loushine, R.J.; Weller, R.N. Calcium phosphate phase transformation produced by the interaction of the Portland cement component of white mineral trioxide aggregate with a phosphatecontaining fluid. J. Endod. 2007, 33, 1347–1351. [Google Scholar] [CrossRef] [PubMed]

- Komabayashi, T.; Colmenar, D.; Cvach, N.; Bhat, A.; Primus, C.; Imai, Y. Comprehensive review of current endodontic sealers. Dent. Mater. J. 2020, 39, 703–720. [Google Scholar] [CrossRef] [PubMed]

- Zamparini, F.; Siboni, F.; Prati, C.; Taddei, P.; Gandolfi, M.G. Properties of calcium sili-cate-monobasic calcium phosphate materials for endodontics containing tantalum pentoxide and zirconium oxide. Clin. Oral Investig. 2019, 23, 445–457. [Google Scholar] [CrossRef] [PubMed]

- Giacomino, C.M.; Wealleans, J.A.; Kuhn, N.; Diogenes, A. Comparative biocompatibility and osteogenic potential of two bioceramic sealers. J. Endod. 2019, 45, 51–56. [Google Scholar] [CrossRef] [PubMed]

- Alchawoosh, A.; Hashimoto, K.; Kawashima, N.; Noda, S.; Nozaki, K.; Okiji, T. Hydraulic calcium silicate-based root canal sealers mitigate proinflammatory cytokine synthesis and promote osteogenesis in vitro. J. Dent. Sci. 2023, 18, 1731–1739. [Google Scholar] [CrossRef] [PubMed]

- Aksel, H.; Makowka, S.; Bosaid, F.; Guardian, M.G.; Sarkar, D.; Azim, A.A. Effect of heat application on the physical properties and chemical structure of calcium silicate-based sealers. Clin. Oral Investig. 2021, 25, 2717–2725. [Google Scholar] [CrossRef]

- Kharouf, N.; Sauro, S.; Eid, A.; Zghal, J.; Jmal, H.; Seck, A.; Macaluso, V.; Addiego, F.; Inchingolo, F.; Affolter-Zbaraszczuk, C.; et al. Physicochemical and mechanical properties of premixed calcium silicate and resin sealers. J. Funct. Biomater. 2023, 14, 9. [Google Scholar] [CrossRef]

- Trope, M.; Bunes, A.; Debelian, G. Root filling materials and techniques: Bioceramics a new hope? Endod. Top. 2015, 32, 86–96. [Google Scholar] [CrossRef]

- Yamauchi, S.; Watanabe, S.; Okiji, T. Effects of heating on the physical properties of premixed calcium silicate-based root canal sealers. J. Oral Sci. 2020, 63, 65–69. [Google Scholar] [CrossRef] [PubMed]

- Mann, A.; Zeng, Y.; Kirkpatrick, T.; van der Hoeven, R.; Silva, R.; Letra, A.; Chaves de Souza, L. Evaluation of the physicochemical and biological properties of EndoSequence BC Sealer HiFlow. J. Endod. 2022, 48, 123–131. [Google Scholar] [CrossRef] [PubMed]

- Antunes, T.B.M.; Janini, A.C.P.; Pelepenko, L.E.; Abuna, G.F.; Paiva, E.M.; Sinhoreti, M.A.C.; Raimundo, I.M., Jr.; Gomes, B.P.F.A.; de-Jesus-Soares, A.; Marciano, M.A. Heating stability, physical and chemical analysis of calcium silicate-based endodontic sealers. Int. Endod. J. 2021, 54, 1175–1188. [Google Scholar] [CrossRef]

- Donnermeyer, D.; Ibing, M.; Bürklein, S.; Weber, I.; Reitze, M.P.; Schäfer, E. Physico-chemical investigation of endodontic sealers exposed to simulated intracanal heat application: Hydraulic calcium silicate-based sealers. Materials 2021, 14, 728. [Google Scholar] [CrossRef] [PubMed]

- Donnermeyer, D.; Schemkämper, P.; Bürklein, S.; Schäfer, E. Short and long-term solubility, alkalizing effect, and thermal persistence of premixed calcium silicate-based sealers: AH Plus Bioceramic Sealer vs. Total Fill BC Sealer. Materials 2022, 15, 7320. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.; Zhu, Y.; Deng, S.; Wang, Z.; He, F. Outcome of root canal treatment using warm vertical compaction with bioceramic and resin-based sealers: A randomised clinical trial. Aust. Endod. J. 2023, 49 (Suppl. S1), 170–178. [Google Scholar] [CrossRef] [PubMed]

- Pontoriero, D.; Cagidiaco, E.; Maccagnola, V.; Manfredini, D.; Ferrari, M. Outcomes of endodontic-treated teeth obturated with bioceramic sealers in combination with warm gutta-percha obturation techniques: A prospective clinical study. J. Clin. Med. 2023, 12, 2867. [Google Scholar] [CrossRef] [PubMed]

- Spinelli, A.; Zamparini, F.; Lenzi, J.; Gandolfi, M.G.; Prati, C. Clinical evaluation of a novel premixed tricalcium silicate containing bioceramic sealer used with warm carri-er-based technique: A 12-month prospective pilot study. Appl. Sci. 2023, 13, 11835. [Google Scholar] [CrossRef]

- Zamparini, F.; Spinelli, A.; Cardinali, F.; Ausiello, P.; Gandolfi, M.G.; Prati, C. The use of premixed calcium silicate bioceramic sealer with warm carrier-based technique: A 2-year study for patients treated in a master program. J. Funct. Biomater. 2023, 14, 164. [Google Scholar] [CrossRef]

- Dental Root Canal Sealing Materials. ISO 6876; International Organization for Standardization: Geneva, Switzerland, 2012.

- Viapiana, R.; Flumignan, D.L.; Guerreiro-Tanomaru, J.M.; Camilleri, J.; Tanomaru-Filho, M. Physicochemical and mechanical properties of zirconium oxide and niobium oxide modified Portland cement-based experimental endodontic sealers. Int. Endod. J. 2014, 47, 437–448. [Google Scholar] [CrossRef]

- Viapiana, R.; Baluci, C.A.; Tanomaru-Filho, M.; Camilleri, J. Investigation of chemical changes in sealers during application of the warm vertical compaction technique. Int. Endod. J. 2015, 48, 16–27. [Google Scholar] [CrossRef] [PubMed]

- Diegritz, C.; Gerlitzki, O.; Fotiadou, C.; Folwaczny, M. Temperature changes on the root surface during application of warm vertical compaction using three different obturation units. Odontology 2020, 108, 358–365. [Google Scholar] [CrossRef] [PubMed]

- Barrieshi, K.; Walton, R.; Johnson, W.; Drake, D. Coronal leakage of mixed anaerobic bacteria after obturation and post space preparation. Oral Surg. Oral Med. Oral Pathol. 1997, 84, 310–314. [Google Scholar] [CrossRef] [PubMed]

- Escalante-García, J.J.; Sharp, J.H. Effect of temperature on the hydration of the main clinker phases in portland cements: Part I, neat cements. Cem. Concr. Res. 1998, 28, 1245–1257. [Google Scholar] [CrossRef]

- Maruyama, I.; Matsushita, T.; Noguchi, T. Numerical modelling of Portland cement hydration. In Proceedings of the International RILEM Symposium on Concrete Modelling—ConMod’08, Delft, The Netherlands, 26–28 May 2008; Schlangen, E., Shutter, G.D., Eds.; RILEM Publications SARL: Bagneux, France, 2008; Volume 58, pp. 155–164. [Google Scholar]

- Han, W.; Sun, T.; Li, X.; Shui, Z.; Chen, Y.; Sun, M. Influence of lithium carbonate on C3A hydration. Adv. Mater. Sci. Eng. 2018, 2018, 6120269. [Google Scholar] [CrossRef]

- Donnermeyer, D.; Urban, K.; Bürklein, S.; Schäfer, E. Physico-chemical investigation of endodontic sealers exposed to simulated intracanal heat application: Epoxy resins and zinc oxide-eugenols. Int. Endod. J. 2020, 53, 690–697. [Google Scholar] [CrossRef] [PubMed]

- Souza, L.C.; Neves, G.S.T.; Kirkpatrick, T.; Letra, A.; Silva, R. Physicochemical and biological properties of AH Plus Bioceramic. J. Endod. 2023, 49, 69–76. [Google Scholar] [CrossRef] [PubMed]

- Kebudi Benezra, M.; Schembri Wismayer, P.; Camilleri, J. Influence of environment on testing of hydraulic sealers. Sci. Rep. 2017, 7, 17927. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.K.; Kwak, S.W.; Ha, J.H.; Lee, W.; Kim, H.C. Physicochemical properties of epoxy resin-based and bioceramic-based root canal sealers. Bioinorg. Chem. 2017, 2017, 2582849. [Google Scholar] [CrossRef]

- Kim, Y.K.; Grandini, S.; Ames, J.M.; Gu, L.S.; Kim, S.K.; Pashley, D.H.; Gutmann, J.L.; Tay, F.R. Critical review on methacrylate resin-based root canal sealers. J. Endod. 2010, 36, 383–399. [Google Scholar] [CrossRef]

- Prati, C.; Gandolfi, M.G. Calcium silicate bioactive cements: Biological perspectives and clinical applications. Dent. Mater. 2015, 31, 351–370. [Google Scholar] [CrossRef] [PubMed]

- Gandolfi, M.G.; Parrilli, A.P.; Fini, M.; Prati, C.; Dummer, P.M.H. 3D micro-CT analysis of the interface voids associated with Thermafil root fillings used with AH Plus or a flowable MTA sealer. Int. Endod. J. 2013, 46, 253–263. [Google Scholar] [CrossRef] [PubMed]

- Georgopoulou, M.K.; Wu, M.K.; Nikolaou, A.; Wesselink, P.R. Effect of thickness on the sealing ability of some root canal sealers. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 1995, 80, 338–344. [Google Scholar] [CrossRef] [PubMed]

- De-Deus, G.; Santos, G.O.; Monteiro, I.Z.; Cavalcante, D.M.; Simões-Carvalho, M.; Belladonna, F.G.; Silva, E.J.N.L.; Souza, E.M.; Licha, R.; Zogheib, C.; et al. Micro-CT assessment of gap-containing areas along the gutta-percha-sealer interface in oval-shaped canals. Int. Endod. J. 2022, 55, 795–807. [Google Scholar] [CrossRef] [PubMed]

| Root Canal Sealer | Composition | Lot No. |

|---|---|---|

| AH Plus Bioceramic Sealer | Zirconium oxide, dimethyl sulfoxide, tricalcium silicate, lithium carbonate, thickening agents | KI210810 |

| EndoSequence BC Sealer | Zirconium oxide, calcium silicates, calcium phosphate monobasic, calcium hydroxide, filler, thickening agents | 19003SP |

| AH Plus Jet | Paste A: diepoxide, calcium tungstate, zirconium oxide, aerosol, pigment Paste B: 1-adamantane amine; N,N′-dibenzyl-5-oxa-nonandiamine-1,9; TCD diamine; calcium tungstate; zirconium oxide; aerosol silica; silicone oil | 2202000427 |

| Pulp Canal Sealer | Powder: zinc oxide, silver, resins, thymol iodide Liquid: eugenol, Canada balsams | 9040827 |

| Root Canal Sealer | Temperature Condition | Setting Time (min) | Flow (mm) | Film Thickness (µm) |

|---|---|---|---|---|

| AH Plus Bioceramic Sealer | 37 °C/23 ± 2 °C § | 884.4 ± 40.5 Aa | 26.9 ± 2.5 Aa | 12.5 ± 2.4 Aa |

| 100 °C 30 s # | 13.0 ± 5.0 Ba | 6.4 ± 0.6 Ba | 206.5 ± 59.4 Ba | |

| 100 °C 60 s ## | 2.4 ± 0.5 Ca | 6.7 ± 0.6 Ba | 426.4 ± 109.6 Ca | |

| EndoSequence BC Sealer | 37 °C/23 ± 2 °C | 559.9 ± 12.2 Ab | 22.1 ± 1.0 Abc | 13.6 ± 1.8 Aa |

| 100 °C 30 s | 412.5 ± 13.1 Bb | 11.1 ± 2.5 Bb | 31.7 ± 6.0 Bbc | |

| 100 °C 60 s | 233.3 ±1 6.3 Bb | 8.6 ± 1.0 Bab | 69.2 ± 9.5 Cb | |

| AH Plus Jet | 37 °C/23 ± 2 °C | 725.4 ± 34.6 Ac | 24.1 ± 0.9 Ab | 19.5 ± 2.5 Aa |

| 100 °C 30 s | 586.3 ± 12.5 Bc | 19.0 ± 2.2 Bc | 18.4 ± 4.1 Abc | |

| 100 °C 60 s | 402.8 ± 45.0 Cc | 10.9 ± 1.0 Cbc | 21.1 ± 2.4 Ab | |

| Pulp Canal Sealer | 37 °C/23 ± 2 °C | 4063.1 ± 93.5 Ad | 21.6 ± 1.10 Ac | 16.0 ± 2.0 Aa |

| 100 °C 30 s | 2962.5 ± 16.3 Bd | 14.9 ± 0.8 Bd | 24.2 ± 2.5 Ab | |

| 100 °C 60 s | 2558.8 ± 59.1 Cd | 11.7 ± 1.29 Cc | 24.9 ± 5.8 Ab |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ito, R.; Watanabe, S.; Kouno, A.; Yamauchi, S.; Okiji, T. Heat-Induced Changes in the Physical Properties of a New Premixed Calcium Silicate-Containing Root Canal Sealer: An In Vitro Study. Dent. J. 2024, 12, 106. https://doi.org/10.3390/dj12040106

Ito R, Watanabe S, Kouno A, Yamauchi S, Okiji T. Heat-Induced Changes in the Physical Properties of a New Premixed Calcium Silicate-Containing Root Canal Sealer: An In Vitro Study. Dentistry Journal. 2024; 12(4):106. https://doi.org/10.3390/dj12040106

Chicago/Turabian StyleIto, Ryota, Satoshi Watanabe, Akira Kouno, Shinya Yamauchi, and Takashi Okiji. 2024. "Heat-Induced Changes in the Physical Properties of a New Premixed Calcium Silicate-Containing Root Canal Sealer: An In Vitro Study" Dentistry Journal 12, no. 4: 106. https://doi.org/10.3390/dj12040106

APA StyleIto, R., Watanabe, S., Kouno, A., Yamauchi, S., & Okiji, T. (2024). Heat-Induced Changes in the Physical Properties of a New Premixed Calcium Silicate-Containing Root Canal Sealer: An In Vitro Study. Dentistry Journal, 12(4), 106. https://doi.org/10.3390/dj12040106