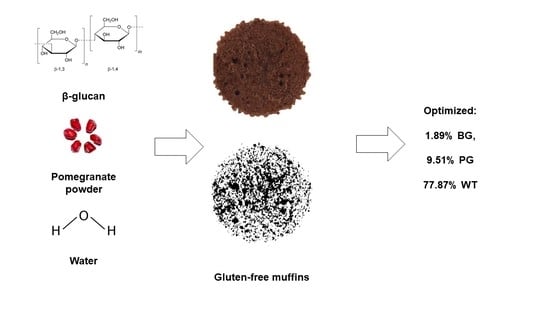

Development of Gluten-Free Muffins with β-Glucan and Pomegranate Powder Using Response Surface Methodology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Preparation of Muffins

2.3. Physical Properties

2.3.1. Specific Volume and Moisture Content

2.3.2. Texture, Color, and Porosity

2.4. Chemical Properties

2.5. Consumer Acceptance

2.6. Statistical Analysis

3. Results and Discussion

3.1. Effect of Pomegranate and β-Glucan on Technological Properties of Muffins

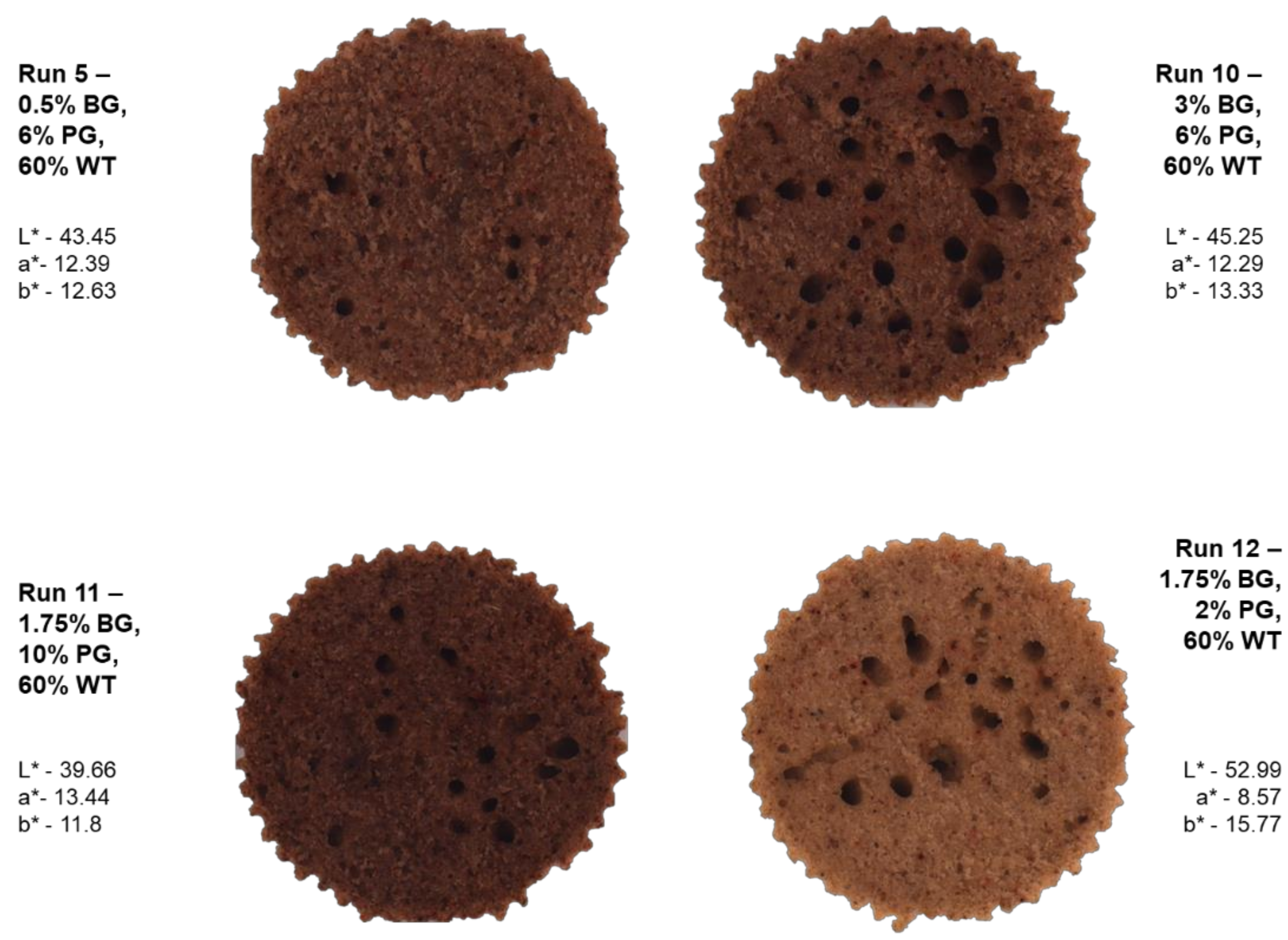

3.2. Effect of Pomegranate and β-Glucan on Physical Properties of Muffins

3.3. Effect of Pomegranate and β-Glucan on Chemical Properties of Muffins

3.4. Effect of Pomegranate and β-Glucan on Taste, Texture, and Overall Acceptability Properties of Muffins

3.5. Optimization of Muffin Composition

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Levent, H.; Sayaslan, A.; Yeşil, S. Physicochemical and Sensory Quality of Gluten-Free Cakes Supplemented with Grape Seed, Pomegranate Seed, Poppy Seed, Flaxseed, and Turmeric. J. Food Process. Preserv. 2021, 45, 1–10. [Google Scholar] [CrossRef]

- Lebwohl, B.; Rubio-Tapia, A. Epidemiology, Presentation, and Diagnosis of Celiac Disease. Gastroenterology 2021, 160, 63–75. [Google Scholar] [CrossRef] [PubMed]

- Sharma, N.; Bhatia, S.; Chunduri, V.; Kaur, S.; Sharma, S.; Kapoor, P.; Kumari, A.; Garg, M. Pathogenesis of Celiac Disease and Other Gluten Related Disorders in Wheat and Strategies for Mitigating Them. Front. Nutr. 2020, 7, 1–26. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Larretxi, I.; Churruca, I.; Navarro, V.; Miranda, J.; Lasa, A.; Bustamante, M.Á.; Simon, E. Effect of Analytically Measured Fiber and Resistant Starch from Gluten-Free Products on the Diets of Individuals with Celiac Disease. Nutrition 2020, 70, 110586. [Google Scholar] [CrossRef]

- Melini, V.; Melini, F. Gluten-Free Diet: Gaps and Needs for a Healthier Diet. Nutrients 2019, 11, 170. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sharma, S.; Saxena, D.C.; Riar, C.S. Effect of Addition of Different Levels of β-Glucan from Minor Millet on the Functional, Textural and Sensory Characteristics of Cake Premix and Cake. J. Food Meas. Charact. 2018, 12, 1186–1194. [Google Scholar] [CrossRef]

- Karp, S.; Wyrwisz, J.; Kurek, M.A. The Impact of Different Levels of Oat β-Glucan and Water on Gluten-Free Cake Rheology and Physicochemical Characterisation. J. Food Sci. Technol. 2020, 57, 3628–3638. [Google Scholar] [CrossRef] [Green Version]

- Viuda-Martos, M.; Fernández-Lóaez, J.; Pérez-álvarez, J.A. Pomegranate and Its Many Functional Components as Related to Human Health: A Review. Compr. Rev. Food Sci. Food Saf. 2010, 9, 635–654. [Google Scholar] [CrossRef] [PubMed]

- Surek, E.; Nilufer-Erdil, D. Phenolic Contents, Antioxidant Activities and Potential Bioaccessibilities of Industrial Pomegranate Nectar Processing Wastes. Int. J. Food Sci. Technol. 2016, 51, 231–239. [Google Scholar] [CrossRef] [Green Version]

- Topkaya, C.; Isik, F. Effects of Pomegranate Peel Supplementation on Chemical, Physical, and Nutritional Properties of Muffin Cakes. J. Food Process. Preserv. 2019, 43, e13868. [Google Scholar] [CrossRef]

- Kurek, M.A.; Karp, S.; Stelmasiak, A.; Pieczykolan, E.; Juszczyk, K.; Rieder, A. Effect of natural flocculants on purity and properties of β-glucan extracted from barley and oat. Carbohydr. Polym. 2018, 188, 60–67. [Google Scholar] [CrossRef] [PubMed]

- Karp, S.; Wyrwisz, J.; Kurek, M.; Wierzbicka, A. Physical Properties of Muffins Sweetened with Steviol Glycosides as the Sucrose Replacement. Food Sci. Biotechnol. 2016, 25, 1591–1596. [Google Scholar] [CrossRef]

- Kurek, M.A.; Wyrwisz, J.; Wierzbicka, A. Optimization of Beta-Glucan and Water Content in Fortified Wheat Bread Using Response Surface Methodology According to Staling Kinetics. LWT-Food Sci. Technol. 2017, 75, 352–357. [Google Scholar] [CrossRef]

- Turan, F.T.; Cengiz, A.; Kahyaoglu, T. Evaluation of Ultrasonic Nozzle with Spray-Drying as a Novel Method for the Microencapsulation of Blueberry’s Bioactive Compounds. Innov. Food Sci. Emerg. Technol. 2015, 32, 136–145. [Google Scholar] [CrossRef]

- Jan, K.N.; Panesar, P.S.; Singh, S. Optimization of Antioxidant Activity, Textural and Sensory Characteristics of Gluten-Free Cookies Made from Whole Indian Quinoa Flour. LWT-Food Sci. Technol. 2018, 93, 573–582. [Google Scholar] [CrossRef]

- Saeidi, Z.; Nasehi, B.; Jooyandeh, H. Optimization of Gluten-Free Cake Formulation Enriched with Pomegranate Seed Powder and Transglutaminase Enzyme. J. Food Sci. Technol. 2018, 55, 3110–3118. [Google Scholar] [CrossRef]

- Gularte, M.A.; de la Hera, E.; Gómez, M.; Rosell, C.M. Effect of Different Fibers on Batter and Gluten-Free Layer Cake Properties. LWT-Food Sci. Technol. 2012, 48, 209–214. [Google Scholar] [CrossRef] [Green Version]

- Singh, J.P.; Kaur, A.; Singh, N. Development of Eggless Gluten-Free Rice Muffins Utilizing Black Carrot Dietary Fibre Concentrate and Xanthan Gum. J. Food Sci. Technol. 2016, 53, 1269–1278. [Google Scholar] [CrossRef] [Green Version]

- Mohebbi, Z.; Homayouni, A.; Azizi, M.H.; Hosseini, S.J. Effects of Beta-Glucan and Resistant Starch on Wheat Dough and Prebiotic Bread Properties. J. Food Sci. Technol. 2018, 55, 101–110. [Google Scholar] [CrossRef]

- Ronda, F.; Perez-Quirce, S.; Lazaridou, A.; Biliaderis, C.G. Effect of Barley and Oat β-Glucan Concentrates on Gluten-Free Rice-Based Doughs and Bread Characteristics. Food Hydrocoll. 2015, 48, 197–207. [Google Scholar] [CrossRef]

- Bourekoua, H.; Różyło, R.; Gawlik-Dziki, U.; Benatallah, L.; Zidoune, M.N.; Dziki, D. Pomegranate Seed Powder as a Functional Component of Gluten-Free Bread (Physical, Sensorial and Antioxidant Evaluation). Int. J. Food Sci. Technol. 2018, 53, 1906–1913. [Google Scholar] [CrossRef]

- Wilderjans, E.; Luyts, A.; Brijs, K.; Delcour, J.A. Ingredient Functionality in Batter Type Cake Making. Trends food Sci. Technol. 2013, 30, 6–15. [Google Scholar] [CrossRef]

- Ahmed, J.; Thomas, L.; Al-Hazza, A. Effects of Frozen Storage on Texture, Microstructure, Water Mobility and Baking Quality of Brown Wheat Flour/β-Glucan Concentrate Arabic Bread Dough. J. Food Meas. Charact. 2021, 15, 1258–1269. [Google Scholar] [CrossRef]

- Ortiz de Erive, M.; He, F.; Wang, T.; Chen, G. Development of β-Glucan Enriched Wheat Bread Using Soluble Oat Fiber. J. Cereal Sci. 2020, 95, 103051. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, M.; Wang, C.; Zhang, Y.; Bai, X.; Zhang, Y.; Zhang, J. Effects of High Hydrostatic Pressure on Microstructure, Physicochemical Properties and in Vitro Digestibility of Oat Starch/β-Glucan Mixtures. Int. J. Food Sci. Technol. 2021. [Google Scholar] [CrossRef]

- Hussain, S.Z.; Beigh, M.A.; Qadri, T.; Naseer, B.; Zargar, I. Development of Low Glycemic Index Muffins Using Water Chestnut and Barley Flour. J. Food Process. Preserv. 2019, 43, 1–9. [Google Scholar] [CrossRef]

- Mäkelä, N.; Rosa-Sibakov, N.; Wang, Y.-J.; Mattila, O.; Nordlund, E.; Sontag-Strohm, T. Role of β-Glucan Content, Molecular Weight and Phytate in the Bile Acid Binding of Oat β-Glucan. Food Chem. 2021, 358, 129917. [Google Scholar] [CrossRef]

- Summo, C.; De Angelis, D.; Difonzo, G.; Caponio, F.; Pasqualone, A. Effectiveness of Oat-Hull-Based Ingredient as Fat Replacer to Produce Low Fat Burger with High Beta-Glucans Content. Foods 2020, 9, 1057. [Google Scholar] [CrossRef] [PubMed]

- Sun, T.; Li, J.; Qin, Y.; Xie, J.; Xue, B.; Li, X.; Gan, J.; Bian, X.; Shao, Z. Rheological and Functional Properties of Oat β-Glucan with Different Molecular Weight. J. Mol. Struct. 2020, 1209, 127944. [Google Scholar] [CrossRef]

- Khatib, M.; Giuliani, C.; Rossi, F.; Adessi, A.; Al-Tamimi, A.; Mazzola, G.; Di Gioia, D.; Innocenti, M.; Mulinacci, N. Polysaccharides from By-Products of the Wonderful and Laffan Pomegranate Varieties: New Insight into Extraction and Characterization. Food Chem. 2017, 235, 58–66. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Song, K.Y.; Kim, Y. Physicochemical and Retrogradation Properties of Low-Fat Muffins with Inulin and Hydroxypropyl Methylcellulose as Fat Replacers. J. Food Process. Preserv. 2020, 44, 1–8. [Google Scholar] [CrossRef]

- Kour, J.; Singh, S.; Saxena, D.C. Effect of Nutraceuticals (Beta-Glucan Concentrate, Flaxseed Lignan Concentrate and Gamma Oryzanol Concentrate) on Nutritional, Textural, Pasting, Thermal, Structural and Morphological Properties of Corn and Rice Flour Blend Based RTE Extrudates. J. Food Meas. Charact. 2019, 13, 988–1003. [Google Scholar] [CrossRef]

- Cakmak, I.; Kutman, U.B. Agronomic Biofortification of Cereals with Zinc: A Review. Eur. J. Soil Sci. 2018, 69, 172–180. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.-Y.; Zhou, H.-M.; Bai, Y.-P. Use of Glycosylated Wheat Protein in Emulsions and Its Application as a Fat Replacer in Microwave Cakes. J. Cereal Sci. 2021, 100, 103256. [Google Scholar] [CrossRef]

- Karp, S.; Wyrwisz, J.; Kurek, M.A.; Wierzbicka, A. The Use of High-in-β-Glucan Oat Fibre Powder as a Structuring Agent in Gluten-Free Yeast-Leavened Cake. Food Sci. Technol. Int. 2019, 25, 618–629. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Mu, T.; Sun, H.; Zhang, M.; Chen, J.; Fauconnier, M.L. Influence of Different Hydrocolloids on Dough Thermo-Mechanical Properties and in Vitro Starch Digestibility of Gluten-Free Steamed Bread Based on Potato Flour. Food Chem. 2018, 239, 1064–1074. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bhol, S.; Lanka, D.; Bosco, S.J.D. Quality Characteristics and Antioxidant Properties of Breads Incorporated with Pomegranate Whole Fruit Bagasse. J. Food Sci. Technol. 2016, 53, 1717–1721. [Google Scholar] [CrossRef] [Green Version]

- Réblová, Z. Effect of Temperature on the Antioxidant Activity of Phenolic Acids. Czech J. Food Sci. 2012, 30, 171–177. [Google Scholar] [CrossRef] [Green Version]

- Shah, A.; Gani, A.; Ahmad, M.; Ashwar, B.A.; Masoodi, F.A. β-Glucan as an Encapsulating Agent: Effect on Probiotic Survival in Simulated Gastrointestinal Tract. Int. J. Biol. Macromol. 2016, 82, 217–222. [Google Scholar] [CrossRef]

| Independent Variables | Units | Symbols | Levels | ||||

|---|---|---|---|---|---|---|---|

| −α | −1 | 0 | 1 | +α | |||

| β-glucan | g 100 g−1 | A | 0.5 | 0.86 | 1.75 | 2.63 | 3.00 |

| Pomegranate | g 100 g−1 | B | 2 | 3.17 | 6 | 8.82 | 10 |

| Water content | % | C | 30 | 38.78 | 60 | 81.21 | 90 |

| Runs | Variables | Responses | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| β-Glucan (g 100 g−1) | Pomegranate (g 100 g−1) | Water (%) | Specific Volume (cm3 g−1) | Moisture (%) | Hardness 24 h (N) | Hardness 48 h (N) | Springiness 24 h (-) | Springiness 48 h (-) | L* | a* | b* | Porosity (%) | TPC (mg GAE g−1 d.w.) | Radical Scavenging Activity (%) | Taste | Texture | Overall Acceptability | ||

| 1 | 1.75 | 6 | 60 | 4.51 | 37.42 | 14.90 | 16.54 | 0.872 | 0.741 | 44.78 | 12.24 | 12.35 | 29.21 | 1.547 | 21.91 | 7.63 | 6.08 | 7.73 | |

| 2 | 1.75 | 6 | 60 | 4.52 | 37.24 | 14.82 | 16.34 | 0.861 | 0.735 | 44.56 | 12.18 | 12.29 | 31.45 | 1.536 | 21.8 | 7.86 | 6.48 | 7.84 | |

| 3 | 1.75 | 6 | 60 | 4.50 | 37.16 | 14.79 | 16.44 | 0.875 | 0.738 | 44.47 | 12.16 | 12.27 | 31.76 | 1.547 | 21.76 | 8.28 | 6.48 | 8.15 | |

| 4 | 0.87 | 3.17 | 38.78 | 3.87 | 24.27 | 28.83 | 37.14 | 0.624 | 0.521 | 43.56 | 12.16 | 12.34 | 32.09 | 0.724 | 20.42 | 7.56 | 5.36 | 5.97 | |

| 5 | 0.5 | 6 | 60 | 3.92 | 31.07 | 21.18 | 24.22 | 0.641 | 0.541 | 43.45 | 12.39 | 12.63 | 26.88 | 1.524 | 19.46 | 4.64 | 4.54 | 4.05 | |

| 6 | 1.75 | 6 | 60 | 4.48 | 37.05 | 14.75 | 16.64 | 0.851 | 0.745 | 44.34 | 12.12 | 12.23 | 28.02 | 1.554 | 21.7 | 5.08 | 7.96 | 5.10 | |

| 7 | 1.75 | 6 | 30 | 4.24 | 28.82 | 29.50 | 35.42 | 0.682 | 0.574 | 45.85 | 12.15 | 14.06 | 35.30 | 1.549 | 20.27 | 4.19 | 3.45 | 4.49 | |

| 8 | 2.63 | 8.82 | 38.78 | 4.21 | 32.66 | 28.32 | 34.97 | 0.697 | 0.598 | 44.01 | 11.66 | 13.5 | 35.27 | 2.475 | 19.46 | 4.32 | 3.94 | 4.70 | |

| 9 | 2.63 | 3.17 | 81.21 | 4.79 | 37.72 | 18.04 | 19.74 | 0.644 | 0.602 | 44.09 | 12.31 | 12.48 | 32.90 | 0.798 | 20.67 | 7.15 | 5.29 | 7.29 | |

| 10 | 3 | 6 | 60 | 4.62 | 37.90 | 21.79 | 22.87 | 0.712 | 0.694 | 45.25 | 12.29 | 13.33 | 39.32 | 0.812 | 22.23 | 7.22 | 5.00 | 7.39 | |

| 11 | 1.75 | 10 | 60 | 4.42 | 36.37 | 25.39 | 26.27 | 0.687 | 0.644 | 39.66 | 13.44 | 11.89 | 33.28 | 3.245 | 32.5 | 4.56 | 4.38 | 4.62 | |

| 12 | 1.75 | 2 | 60 | 4.54 | 37.46 | 15.75 | 17.24 | 0.623 | 0.647 | 52.99 | 8.57 | 15.77 | 20.76 | 0.524 | 21.7 | 5.39 | 6.74 | 6.49 | |

| 13 | 1.75 | 6 | 90 | 4.87 | 43.56 | 15.54 | 17.02 | 0.674 | 0.654 | 42.44 | 12.3 | 11.47 | 25.34 | 1.498 | 20.89 | 8.51 | 6.25 | 8.15 | |

| 14 | 0.86 | 8.82 | 81.21 | 4.24 | 35.04 | 16.76 | 18.24 | 0.761 | 0.705 | 40.95 | 11.43 | 11.6 | 25.80 | 2.987 | 19.2 | 8.73 | 5.87 | 8.23 | |

| 15 | 1.75 | 6 | 60 | 4.48 | 37.22 | 14.82 | 16.17 | 0.863 | 0.735 | 44.54 | 12.17 | 12.28 | 26.69 | 1.524 | 21.79 | 7.11 | 7.77 | 8.24 | |

| Parameters | Specific Volume | Moisture | Hardness 24 h | Hardness 48 h | Springiness 24 h | Springiness 48 h | L* | a* | b* | Porosity | TPC | Radical Scavenging Activity (%) | Taste | Texture | Overall Acceptability |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Constant | 4.5167 | 37.627 | 15.096 | 16.8 | 0.8483 | 0.73 | 44.833 | 12.45 | 12.457 | 29.276 | 15.08 | 22.30 | 6.908 | 6.807 | 7.197 |

| β-glucan | 0.3500 *** | 3.42 * | 0.305 | −0.675 | 0.0355 | 0.077 ** | 0.9 | −0.05 | 0.35 | 6.22 ** | −0.35 ** | 1.385 * | 1.29 | 0.233 * | 1.666 * |

| Pomegranate | −0.0600 | −0.55 | 4.820 ** | 4.515 ** | 0.0320 | −0.0015 | −6.665 *** | 2.44 *** | −1.940 ** | 6.26 ** | 13.60 *** | 5.4 *** | −0.42 | −1.176 | −0.932 |

| Water | 0.3150 *** | 7.37 *** | −6.980 *** | −9.200 *** | −0.0040 | 0.04 * | −1.705 | 0.075 | −1.295 * | −4.98 * | −0.025 | 0.31 | 2.16 ** | 1.4 ** | 1.829 ** |

| β-glucan2 | −0.2933 ** | −4.17 ** | 5.688 *** | 5.810 ** | −0.1314 ** | −0.101 ** | −1.219 | 0.265 * | 0.092 | 4.19 * | −0.255 * | −2.71 | −0.27 | −1.666 | −0.94 |

| Pomegranate2 | −0.0833 ** | −1.74 | 4.773 ** | 4.020 ** | −0.1529 ** | −0.074 ** | 0.756 | −1.069 *** | 0.942 | −1.88 | 0.461 ** | 3.53 | −1.23 | −0.876 | −1.1 |

| Water2 | −0.0083 | −2.46 * | 6.723 ** | 8.485 *** | −0.1299 * | −0.105 ** | −1.424 | 0.1502 | −0.123 | 1.42 | 0.105 | −2.694 | 0.15 | −1.585 * | −0.34 |

| β-glucan (%) · Pomegranate (%) | −0.0295 | 2.51 | 1.30 | −0.95 | −0.0477 | −0.0374 | −1.14 | 0.148 | −0.953 | −2.71 | −0.33 | 0.443 | 1.05 | 1.05 | 0.16 |

| β-glucan (%) · Water (%) | 0.0201 | −3.62 | 7.71 | 13.22 ** | −0.0497 | −0.0921 * | −8.08 ** | 4.132 *** | −2.882 * | 10.81 * | −0.05 | 8.85 ** | 0.24 | −1.24 | −1.15 |

| Pomegranate (%) · Water (%) | 0.0500 | −0.71 | 0.05 ** | 4.38 * | 0.0722 | 0.1212 ** | −0.52 | −0.259 | −0.527 | 3.66 | −0.28 | 1.704 | 4.24 ** | 1.33 | 3.46 ** |

| R2 | 0.9772 | 0.9612 | 0.9884 | 0.9856 | 0.987 | 0,9741 | 0.995 | 0.992 | 0.992 | 0.999 | 0.9909 | 0.998 | 0.995 | 0.996 | 0.994 |

| Lack of fit | 0.023 | 0.754 | 0.125 | 0.245 | 0.433 | 0.022 | 0.206 | 0.119 | 0.14 | 0.22 | 0.168 | 0.147 | 0.118 | 0.14 | 0.265 |

| Optimum Value | |||

|---|---|---|---|

| β-glucan (g·100 g−1) | 1.86 | ||

| Pomegranate (g·100 g−1) | 9.51 | ||

| Water (%) | 77.87 | ||

| Desirability | 0.941 | ||

| Variables | Target | Optimized | Experimental |

| Specific volume (cm3·g−1) | Maximum | 4.87 | 4.57 |

| Hardness 48 h (N) | Minimum | 16.17 | 17.12 |

| TPC (mg·g−1 dry weight) | Maximum | 2.89 | 2.78 |

| Radical scavenging activity (%) | Maximum | 32.52 | 31.25 |

| Overall acceptability | Maximum | 8.23 | 8.78 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurek, M.A.; Moczkowska-Wyrwisz, M.; Wyrwisz, J.; Karp, S. Development of Gluten-Free Muffins with β-Glucan and Pomegranate Powder Using Response Surface Methodology. Foods 2021, 10, 2551. https://doi.org/10.3390/foods10112551

Kurek MA, Moczkowska-Wyrwisz M, Wyrwisz J, Karp S. Development of Gluten-Free Muffins with β-Glucan and Pomegranate Powder Using Response Surface Methodology. Foods. 2021; 10(11):2551. https://doi.org/10.3390/foods10112551

Chicago/Turabian StyleKurek, Marcin Andrzej, Małgorzata Moczkowska-Wyrwisz, Jarosław Wyrwisz, and Sabina Karp. 2021. "Development of Gluten-Free Muffins with β-Glucan and Pomegranate Powder Using Response Surface Methodology" Foods 10, no. 11: 2551. https://doi.org/10.3390/foods10112551