Investigating Methods to Mitigate Whey Protein Derived Mouthdrying

Abstract

:1. Introduction

2. Materials and Methods

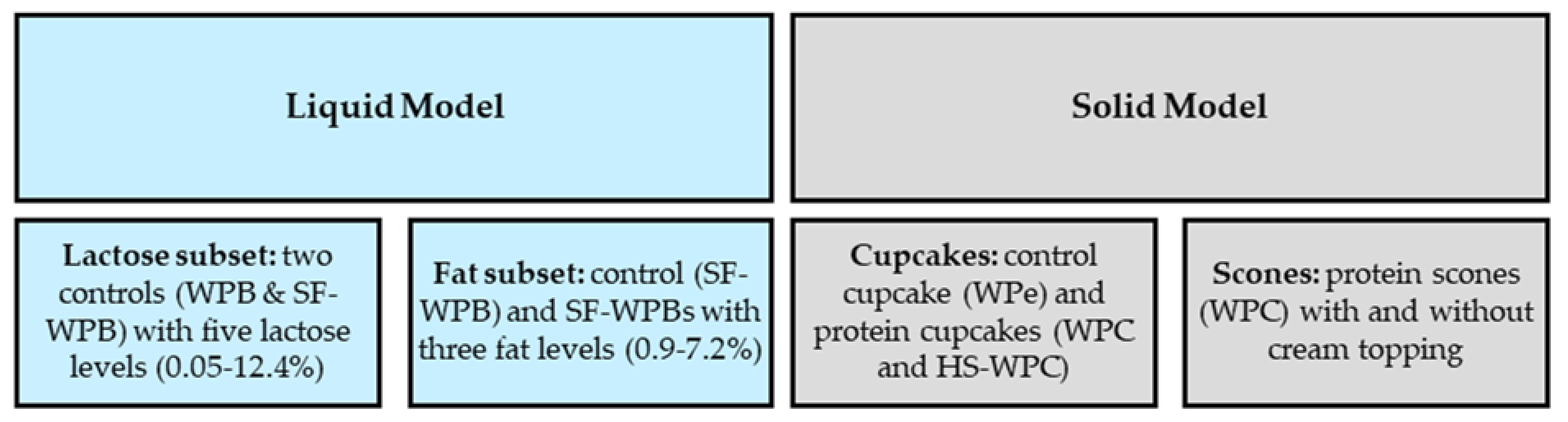

2.1. Overview of Experiments

2.2. Materials

2.3. Whey Protein Liquid Models

2.3.1. Lactose Subset

2.3.2. Fat Subset

2.4. Whey Protein Solid Models

2.4.1. Cupcakes

2.4.2. Scones

Scones Sensory Profiling

Scones with and without Topping

2.4.3. Physical Properties of Cupcakes and Scones

2.5. Sensory Profile

2.6. Statistical Analysis

3. Results

3.1. Whey Protein Beverages with Lactose

3.2. Whey Protein Beverages with Fat

3.3. Cupcakes

3.4. Scones

4. Discussion

4.1. Whey Protein Beverages with Lactose

4.2. Whey Protein Beverages with Fat

4.3. Cupcakes

4.4. Scones

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Madureira, A.R.; Pereira, C.I.; Gomes, A.M.P.; Pintado, M.E.; Malcata, F.X. Bovine whey proteins—Overview on their main biological properties. Food Res. Int. 2007, 40, 1197–1211. [Google Scholar] [CrossRef]

- Solak, B.B.; Akin, N. Health benefits of whey protein: A review. J. Food Sci. Eng. 2012, 2, 129–137. [Google Scholar]

- Phillips, S.M.; Chevalier, S.; Leidy, H.J. Protein ‘requirements’ beyond the RDA: Implications for optimisizing health. Appl. Physiol. Nutr. Metab. 2016, 41, 565–572. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Norton, V.; Lignou, S.; Methven, L. Influence of age and individual differences on mouthfeel perception of whey protein fortified products: A review. Foods 2021, 10, 433. [Google Scholar] [CrossRef] [PubMed]

- Norton, V.; Lignou, S.; Bull, S.P.; Gosney, M.A.; Methven, L. An investigation of the influence of age and saliva flow on the oral retention of whey protein and its potential effect on the perception and acceptance of whey protein beverages. Nutrients 2020, 12, 2506. [Google Scholar] [CrossRef]

- Norton, V.; Lignou, S.; Bull, S.P.; Gosney, M.A.; Methven, L. Consistent effects of whey protein fortification on consumer perception and liking of solid food matrices (cakes and biscuits) regardless of age and saliva flow. Foods 2020, 9, 1328. [Google Scholar] [CrossRef] [PubMed]

- Norton, V.; Lignou, S.; Methven, L. Whey protein derived mouthdrying found to relate directly to retention post consumption but not to induced differences in salivary flow rate. Foods 2021, 10, 587. [Google Scholar] [CrossRef]

- Bull, S.P.; Hong, Y.; Khutoryanskiy, V.V.; Parker, J.K.; Faka, M.; Methven, L. Whey protein mouth drying influenced by thermal denaturation. Food Qual. Prefer. 2017, 56, 233–240. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wendin, K.; Hoglund, E.; Andersson, M.; Rothenberg, E. Protein enriched foods and healthy ageing: Effects of protein fortification on muffin characteristics. Agro-Food Ind. Hi-Tech 2017, 28, 16–18. [Google Scholar]

- Song, X.; Perez-Cueto, F.J.A.; Bredie, W.L. Sensory-driven development of protein-enriched rye bread and cream cheese for the nutritional demands of older adults. Nutrients 2018, 10, 1006. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Withers, C.; Gosney, M.A.; Methven, L. Perception of thickness, mouth coating and mouth drying of dairy beverages by younger and older volunteers. J. Sens. Stud. 2013, 28, 230–237. [Google Scholar] [CrossRef]

- Withers, C.A.; Lewis, M.J.; Gosney, M.A.; Methven, L. Potential sources of mouth drying in beverages fortified with dairy proteins: A comparison of casein- and whey-rich ingredients. J. Dairy Sci. 2014, 97, 1233–1247. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Methven, L.; Rahelu, K.; Economou, N.; Kinneavy, L.; Ladbrooke-Davis, L.; Kennedy, O.B.; Mottram, D.S.; Gosney, M.A. The effect of consumption volume of profile and liking of oral nutritional supplements of varied sweetness: Sequential profiling and boredom tests. Food Qual. Prefer. 2010, 21, 948–955. [Google Scholar] [CrossRef] [Green Version]

- Courregelongue, S.; Schlich, P.; Noble, A.C. Using repeated ingestion to determine the effect of sweetness, viscosity and oiliness on temporal perception of soymilk astringency. Food Qual. Prefer. 1999, 10, 273–279. [Google Scholar] [CrossRef]

- Li, Y.; Joyner, B.G.; Drake, M.A. Effects of fat content, pasteurization method, homogenization pressure and storage time on the mechanical and sensory properties of bovine milk. J. Dairy Sci. 2018, 101, 2941–2955. [Google Scholar] [CrossRef]

- Engelen, L.; Fontijn-Tekamp, A.; van der Bilt, A. The influence of product and oral characteristics on swallowing. Arch. Oral Biol. 2005, 50, 739–746. [Google Scholar] [CrossRef] [PubMed]

- Van Eck, A.; Hardenman, N.; Karatza, N.; Fogliano, V.; Scholten, E.; Stieger, M. Oral processing behavior and dynamic sensory perception of composite foods: Toppings assist saliva in bolus formulation. Food Qual. Prefer. 2019, 71, 497–509. [Google Scholar] [CrossRef] [Green Version]

- Kew, B.; Holmes, M.; Stieger, M.; Sarkar, A. Review on fat replacement using protein-based microparticulated powders or microgels: A textural perspective. Trends Food Sci. Technol. 2020, 106, 457–468. [Google Scholar] [CrossRef]

- Ipsen, R. Microparticulated whey proteins for improving dairy product texture. Int. Dairy J. 2017, 67, 73–79. [Google Scholar] [CrossRef]

- Cakir-Fuller, E. Enhanced heat stability of high protein emulsion systems provided by microparticulated whey protein. Food Hydrocoll. 2015, 47, 41–50. [Google Scholar] [CrossRef]

- Aggarwal, D.; Sabikhi, L.; Kumar, M.H.S. Formulation of reduced-calorie biscuits using artificial sweeteners and fat replacer with dairy-multigrain approach. NFS J. 2016, 2, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Belitz, H.D.; Grosch, W.; Schieberle, P. Food Chemistry, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2004; pp. 245–339. [Google Scholar]

- Wang, S.; Li, C.; Copeland, L.; Niu, Q.; Wang, S. Starch retrogradation: A comprehensive review. Compr. Rev. Food Sci. Food Saf. 2015, 14, 568–585. [Google Scholar] [CrossRef]

- McLellan, M.R.; Lind, L.R.; Kime, R.W. Hue angle determinations and statistical analysis for multiquadrant hunter L, a, b data. J. Food Qual. 1995, 18, 235–240. [Google Scholar] [CrossRef]

- Stone, H.; Sidel, J.; Oliver, R.S.; Woolsey, A.; Singleton, R.C. Sensory evaluation by quantitative descriptive analysis. Food Technol. 1974, 28, 24–34. [Google Scholar]

- International Organization for Standardization. Sensory Analysis—General Guidelines for the Selection, Training and Monitoring of Selected Assessors and Expert Sensory Assessors; ISO Standard No. 8586; ISO: Geneva, Switzerland, 2012. [Google Scholar]

- International Organization for Standardization. Sensory Analysis—Methodology—Guidelines for Monitoring the Performance of a Quantitative Sensory Panel; ISO Standard No. 1132; ISO: Geneva, Switzerland, 2012. [Google Scholar]

- Heymann, H.; Machado, B.; Torri, L.; Robinson, A.L. How many judges should one use for sensory descriptive analysis? J. Sens. Stud. 2012, 27, 111–122. [Google Scholar] [CrossRef]

- Hasted, A. Statistical analysis of descriptive data. In Descriptive Analysis in Sensory Evaluation; Kemp, S.E., Hort, J., Hollowood, T., Eds.; Wiley-Blackwell: West Sussex, UK, 2018; pp. 165–213. [Google Scholar]

- de Wijk, R.A.; Prinz, J.F. The role of friction in perceived oral texture. Food Qual. Prefer. 2005, 16, 121–129. [Google Scholar] [CrossRef]

- Wilderjans, E.; Luyts, A.; Goesaert, H.; Brijs, K.; Delcour, J.A. A model approach to starch and protein functionality in a pound cake system. Food Chem. 2010, 120, 44–51. [Google Scholar] [CrossRef]

- van der Sman, R.G.M.; Renzetti, S. Understanding functionality of sucrose in cake for reformulation purposes. Crit. Rev. Food Sci. Nutr. 2021, 61, 2756–2772. [Google Scholar] [CrossRef] [PubMed]

- Lambrecht, M.A.; Deleu, L.J.; Rombouts, I.; Delcour, J.A. Heat-induced network formation between proteins of different sources in model systems, wheat-based noodles and pound cakes. Food Hydrocoll. 2018, 79, 352–370. [Google Scholar] [CrossRef]

- Liu, K.; Tian, Y.; Stieger, M.; van der Linden, E.; van de Velde, F. Evidence for ball-bearing mechanism of microparticulated whey protein as fat replacer in liquid and semi-solid multi-component model foods. Food Hydrocoll. 2016, 52, 403–414. [Google Scholar] [CrossRef]

- Liu, K.; Stieger, M.; van der Linden, E.; van de Velde, F. Effect of microparticulated whey protein on sensory properties of liquid and semi-solid model foods. Food Hydrocoll. 2016, 60, 186–198. [Google Scholar] [CrossRef]

| Lactose Subset | Fat Subset | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Controls | SF-WPBs Varying in Added Lactose | Control | SF-WPBs Varying in Added Fat | |||||||||

| WPB (0.4%) | SF-WPB (0.05%) | SF-WPB (0.4%) | SF-WPB (3.4%) | SF-WPB (6.4%) | SF-WPB (9.4%) | SF-WPB (12.4%) | SF-WPB (0.9%) | SF-WPB (1.8%) | SF-WPB (3.6%) | SF-WPB (7.2%) | ||

| Formulations | ||||||||||||

| Deionised water (mL) | 90 | 90 | 90 | 87 | 84 | 81 | 78 | 90 | 88 | 84 | 77 | |

| WPC (g) | 10 | - | - | - | - | - | - | - | - | - | - | |

| SF-WPC (g) | - | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | |

| Lactose (g) | - | - | 0.4 | 3.4 | 6.4 | 9.4 | 12.4 | - | - | - | - | |

| Double cream (g) | - | - | - | - | - | - | - | - | 1.8 | 5.6 | 13.2 | |

| Lecithin (g) | - | - | - | - | - | - | - | - | 0.1 | 0.1 | 0.1 | |

| Hydrocolloid (g) | - | - | - | - | - | - | - | 0.1 | 0.05 | 0.03 | - | |

| Composition | ||||||||||||

| Energy (kcal) | 40.1 | 41.6 | 41.8 | 43.0 | 44.1 | 45.3 | 46.5 | 41.6 | 49.5 | 66.1 | 99.3 | |

| Fat (g) | 0.8 | 0.95 | 0.95 | 0.95 | 0.95 | 0.95 | 0.95 | 0.95 | 1.8 | 3.6 | 7.2 | |

| of which saturates (g) | 0.3 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.35 | 0.9 | 2.0 | 4.3 | |

| Carbohydrate (g) | 0.4 | 0.05 | 0.4 | 3.4 | 6.4 | 9.4 | 12.4 | 0.05 | 0.08 | 0.1 | 0.2 | |

| of which sugars (g) | 0.4 | 0.05 | 0.4 | 3.4 | 6.4 | 9.4 | 12.4 | 0.05 | 0.08 | 0.1 | 0.2 | |

| Protein (g) | 8.2 | 8.6 | 8.6 | 8.6 | 8.6 | 8.6 | 8.6 | 8.6 | 8.6 | 8.7 | 8.8 | |

| Cupcakes | Scones | ||||||

|---|---|---|---|---|---|---|---|

| Control | WPC | HS-WPC | Control | Protein | Protein + Cream Topping | ||

| Formulations | |||||||

| Unsalted butter (g) | 23.0 | 23.0 | 22.7 | 10.2 | 10.2 | 10.2 | |

| Self-raising flour (g) | 23.0 | 23.0 | 22.7 | 46.0 | 46.0 | 46.0 | |

| Caster sugar (g) | 23.0 | 23.0 | 22.7 | 5.1 | 5.1 | 5.1 | |

| Milk (whole) (g) | 5.0 | 5.0 | 4.9 | 20.4 | 20.4 | 20.4 | |

| Eggs (free-range) (g) | 18.6 | 18.6 | 18.4 | 10.2 | 10.2 | 10.2 | |

| Lemon zest (g) | 0.76 | 0.76 | 0.75 | - | - | - | |

| Whey permeate (g) | 6.64 | - | - | 8.0 | - | - | |

| WPC (g) | - | 6.64 | - | - | 8.0 | 8.0 | |

| HS-WPC (g) | - | - | 7.7 | - | - | - | |

| Clotted cream (g) | - | - | - | - | - | 26.7 | |

| Composition | |||||||

| Energy (kcal) | 442 | 445 | 448 | 350 | 353 | 509 | |

| Fat (g) | 23.0 | 24.0 | 25.0 | 12.0 | 13.0 | 30.0 | |

| of which saturates (g) | 14.0 | 14.0 | 14.0 | 6.9 | 7.2 | 17.8 | |

| Carbohydrate (g) | 51.0 | 45.0 | 44.0 | 52.0 | 44.0 | 44.6 | |

| of which sugars (g) | 26.0 | 26.0 | 26.0 | 15.0 | 7.5 | 8.1 | |

| Fibre (g) | 1.1 | 1.1 | 1.1 | 2.0 | 2.0 | 2.0 | |

| Protein (g) | 6.0 | 12.0 | 12.0 | 7.6 | 15.0 | 15.4 | |

| Salt (g) | 0.2 | 0.2 | 0.2 | 0.5 | 0.5 | 0.5 | |

| Modality | Attribute | Reference and/or Description |

|---|---|---|

| Appearance | Moist appearance 3,4 | Slightly or moderately wet to touch |

| Dense appearance of sponge/dough 3,4 | Compact in structure | |

| Appearance of large holes in sponge 3,4 | Holes within crumb/dough structure (none to lots) | |

| Yellow colour of crumb/dough (inside) 3,4 | Intensity of yellow colour within crumb/dough (pale to dark) | |

| Aroma | Cooked milk 1 | Heated pasteurised semi-skimmed milk |

| Powdered milk (wet) 1 | Skimmed milk powder (10% w/v, skimmed milk powder in deionised water) | |

| Whey isolate 1 | Volactive Ultra-Whey 90 Instant (5% w/v, WPI powder in deionised water) | |

| Overall aroma intensity 3,4 | Intensity of aroma within cupcake/scone | |

| Sweet 3,4 | Sucrose (5.76 g/L) | |

| Lemon 3 | Lemon zest (grated) | |

| Buttery 3,4 | Cooked butter (melted unsalted butter) | |

| Eggy 3 | Intensity of eggy notes | |

| Floury 4 | Intensity of floury notes (self-raising flour) | |

| Savoury/Cheesey 4 | Toasted cheddar cheese | |

| Off-Flavours 3,4 | Curded buttermilk (cooked buttermilk) | |

| Flavour | Sour 1,2 | Citric acid (0.76 g/L) |

| Metallic 1,2,3,4 | Iron (II) sulphate heptahydrate (0.0036 g/L) | |

| Salty 1,2 | Sodium chloride (1.19 g/L) | |

| Sweet 1,2,3,4 | Sucrose (5.76 g/L) | |

| Cooked butter 1,2 | Melted unsalted butter | |

| Cooked milk 1,2 | Heated pasteurised semi-skimmed milk | |

| Powdered milk (wet) 1,2 | Skimmed milk powder (10% w/v, skimmed milk powder in deionised water) | |

| Whey isolate 1,2 | Volactive Ultra-Whey 90 Instant (5% w/v, WPI powder in deionised water) | |

| Overall flavour intensity 3,4 | Intensity of flavour within cake | |

| Lemony 3 | Lemon zest (grated) | |

| Buttery 3,4 | Cooked butter (melted unsalted butter) | |

| Floury 4 | Intensity of floury notes (self-raising flour) | |

| Savoury/Cheesey 4 | Toasted cheddar cheese | |

| Eggy 3 | Intensity of eggy note | |

| Liquorice 3 | Liquorice (liquorice twists) | |

| Off-flavours 3,4 | Curded buttermilk (cooked buttermilk) | |

| Mouthfeel | Body 1,2 | Fullness of sample (low to high) |

| Powdery 1,2 | Dry fine insoluble powder | |

| Mouthdrying 1.2,3,4,5 | Drying sensation in the mouth | |

| Firmness of bite 3,4,5 | Degree of force with first bite (soft to firm) | |

| Moist sponge/dough 3,4,5 | Slightly damp sponge/dough (dry to moist) | |

| Chewy 3,4,5 | Ease of ability to chew | |

| Greasy lips 3,4 | Degree of oiliness/greasiness on lips | |

| Crumbliness of sponge/dough 3,4,5 | Ease to break into small pieces | |

| Crumb size 3 | Size of crumb inside of cake | |

| Pasty (cohesive) 3,4,5 | Sticking to surfaces | |

| Rate of breakdown & clearance 3,4,5 | Clearing sample from mouth (slow to fast) | |

| Cooling sensation 3 | A stimulation resulting in feeling of coolness | |

| Aftertaste | Aftertaste strength 1,2 | The strength of the overall aftertaste |

| Mouthdrying 1,2,3,4 | Drying sensation in the mouth | |

| Metallic 1,2,3,4 | Iron (II) sulphate heptahydrate (0.0036 g/L) | |

| Sweet 1,3,4 | Sucrose (5.76 g/L) | |

| Lemon 3 | Lemon zest (grated) | |

| Buttery 3,4 | Cooked butter (melted unsalted butter) | |

| Savoury/Cheesey 4 | Toasted cheddar cheese | |

| Off-flavours 3,4 | Curded buttermilk (cooked buttermilk) | |

| Salty 3,4 | Sodium chloride (1.19 g/L) | |

| Salivating 3,4 | Increased saliva within mouth | |

| Liquorice 3 | Liquorice (liquorice twists) |

| Experiment | Panellists a | Attributes b | Consumption Instructions | Additional Comments |

|---|---|---|---|---|

| WPBs with lactose 1 | 10 | 18 |

|

|

| WPBs with fat 2 | 11 | 14 |

|

|

| Cupcakes 3 | 10 | 37 |

|

|

| Scones 4 | 10 | 32 |

|

|

| Scones with and without cream topping 5 | 8 | 7 |

|

|

| Modality | Attribute | Controls | SF-WPBs Varying in Added Lactose | Significance of Sample (p Value) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| WPB (0.4%) | SF-WPB (0.05%) | SF-WPB (0.4%) | SF-WPB (3.4%) | SF-WPB (6.4%) | SF-WPB (9.4%) | SF-WPB (12.4%) | ||||

| Aroma | Cooked milk | 12.3 ± 2.8 | 16.5 ± 3.9 | 12.9 ± 3.5 | 10.4 ± 2.6 | 16.2 ± 3.4 | 16.8 ± 3.6 | 18.4 ± 3.5 | 0.48 | |

| Powdered milk (wet) | 21.0 ± 3.8 | 18.8 ± 4.1 | 21.6 ± 4.1 | 24.9 ± 4.1 | 18.7 ± 4.3 | 22.0 ± 4.1 | 18.6 ± 4.0 | 0.72 | ||

| Whey isolate | 18.6 ± 3.7 | 12.9 ± 3.6 | 13.2 ± 3.6 | 15.4 ± 3.1 | 17.6 ± 3.4 | 14.0 ± 2.3 | 13.6 ± 3.1 | 0.57 | ||

| Flavour | Sour | 22.1 ± 3.5 a | 24.4 ± 4.0 a | 21.8 ± 4.1 ab | 22.0 ± 3.8 a | 18.5 ± 3.3 abc | 13.7 ± 3.2 c | 13.8 ± 3.3 bc | 0.0002 | |

| Metallic | 12.4 ± 3.1 | 11.8 ± 2.8 | 11.6 ± 3.2 | 12.1 ± 2.7 | 8.8 ± 2.4 | 9.5 ± 2.1 | 9.1 ± 2.4 | 0.27 | ||

| Salty | 9.5 ± 1.4 | 7.2 ± 2.0 | 7.7 ± 1.9 | 9.1 ± 1.8 | 10.2 ± 1.2 | 10.3 ± 1.3 | 7.7 ± 1.2 | 0.50 | ||

| Sweet | 8.1 ± 2.1 c | 5.3 ± 1.3 c | 5.7 ± 2.2 c | 15.0 ± 2.5 c | 29.7 ± 3.3 b | 42.0 ± 1.9 a | 47.2 ± 2.0 a | <0.0001 | ||

| Cooked butter | 6.2 ± 1.7 | 2.7 ±1.4 | 6.3 ± 2.1 | 2.6 ± 1.2 | 4.3 ± 1.4 | 5.5 ± 1.6 | 6.4 ± 1.5 | 0.47 | ||

| Cooked milk | 7.5 ± 2.2 b | 9.6 ± 2.8 b | 9.0 ± 2.8 b | 10.4 ± 2.6 b | 19.7 ± 3.3 ab | 24.5 ± 3.0 a | 23.8 ± 3.6 a | <0.0001 | ||

| Powdered milk (wet) | 22.3 ± 4.1 | 17.9 ± 4.3 | 23.3 ± 3.8 | 22.0 ± 3.9 | 16.6 ± 4.6 | 21.1 ± 4.2 | 19.0 ± 4.3 | 0.67 | ||

| Whey isolate | 27.9 ± 3.1 a | 28.5 ± 3.9 a | 22.2 ± 4.0 ab | 25.0 ± 3.1 ab | 21.8 ± 3.0 ab | 17.7 ± 2.5 ab | 15.3 ± 2.6 b | 0.003 | ||

| Mouthfeel | Body | 30.4 ± 2.1 | 29.4 ± 1.9 | 31.6 ± 2.3 | 29.7 ± 2.1 | 26.8 ± 1.9 | 30.9 ± 1.9 | 28.4 ± 1.8 | 0.36 | |

| Powdery | 14.3 ± 4.2 ab | 11.5 ± 4.0 ab | 16.2 ± 4.8 a | 12.5 ± 3.9 ab | 7.5 ± 2.5 b | 8.6 ± 3.4 ab | 8.1 ± 3.1 ab | 0.02 | ||

| Mouthdrying | 47.2 ± 3.6 ab | 49.1 ± 3.7 a | 45.8 ± 4.0 ab | 47.0 ± 3.9 ab | 41.7 ± 3.4 ab | 39.9 ± 3.1 b | 41.2 ± 3.1 ab | 0.02 | ||

| Aftertaste | Aftertaste strength | 26.9 ± 2.3 ab | 22.2 ± 1.8 b | 23.0 ± 1.9 b | 24.0 ± 1.9 b | 27.8 ± 1.5 ab | 30.2 ± 1.5 a | 27.9 ± 1.7 ab | 0.0004 | |

| Mouthdrying | 43.0 ± 3.2 | 45.9 ± 4.0 | 46.5 ± 3.6 | 44.2 ± 2.6 | 38.6 ± 3.4 | 41.5 ± 2.8 | 41.7 ± 2.7 | 0.32 | ||

| Metallic | 7.9 ± 2.7 a | 6.4 ± 2.1 a | 8.0 ± 2.9 a | 5.0 ± 1.8 a | 3.7 ± 1.5 a | 3.0 ± 1.3 a | 4.1 ± 1.8 a | 0.01 | ||

| Sweet | 4.7 ± 1.3 c | 3.3 ± 1.5 c | 5.3 ± 2.1 c | 7.0 ± 1.9 c | 18.6 ± 2.3 b | 27.1 ± 2.0 a | 30.3 ± 2.4 a | <0.0001 | ||

| Modality | Attribute | Cupcakes | Significance of Sample (p Value) | ||

|---|---|---|---|---|---|

| Control | WPC | HS-WPC | |||

| Appearance | Moist appearance | 52.3 ± 3.1 a | 26.7 ± 2.6 b | 19.1 ± 2.3 b | <0.0001 |

| Dense appearance of sponge | 39.9 ± 2.7 b | 56.7 ± 3.2 a | 64.0 ± 3.3 a | 0.0001 | |

| Appearance of large holes in sponge | 19.8 ± 2.1 b | 39.8 ± 4.0 a | 48.1 ± 4.0 a | <0.0001 | |

| Yellow colour of crumb (inside) | 52.6 ± 1.9 a | 35.9 ± 2.2 c | 46.8 ± 2.8 b | <0.0001 | |

| Aroma | Overall aroma intensity | 53.6 ± 2.1 | 51.3 ± 2.4 | 52.2 ± 1.7 | 0.73 |

| Sweet | 38.2 ± 2.9 | 38.4 ± 1.8 | 38.3 ± 1.7 | 1.00 | |

| Lemon | 36.7 ± 3.1 | 37.7 ± 3.3 | 37.4 ± 3.2 | 0.97 | |

| Buttery | 22.2 ± 3.2 a | 12.6 ± 2.6 b | 14.3 ± 2.9 b | 0.003 | |

| Eggy | 14.7 ± 2.8 | 13.9 ± 2.9 | 14.2 ± 3.1 | 0.98 | |

| Off-flavours | 0.0 ± 0.03 | 3.2 ± 1.5 | 4.1 ± 2.1 | 0.22 | |

| Flavour | Overall flavour intensity | 51.6 ± 2.2 | 44.3 ± 2.3 | 48.5 ± 2.2 | 0.07 |

| Sweet | 44.2 ± 3.2 | 38.2 ± 2.1 | 43.0 ± 1.9 | 0.22 | |

| Metallic | 0.6 ± 0.5 b | 4.1 ± 1.8 ab | 6.7 ± 2.2 a | 0.04 | |

| Lemony | 37.9 ± 2.5 | 32.1 ± 2.7 | 32.1 ± 2.3 | 0.28 | |

| Buttery | 23.0 ± 2.8 a | 8.7 ± 2.1 b | 11.1 ± 2.7 b | 0.0005 | |

| Eggy | 12.3 ± 2.5 | 9.2 ± 2.6 | 12.3 ± 2.8 | 0.55 | |

| Liquorice | 1.4 ± 1.1 | 5.3 ± 1.9 | 5.6 ± 2.7 | 0.23 | |

| Off-flavours | 0.0 ± 0.03 | 2.3 ± 1.3 | 3.1 ± 1.5 | 0.19 | |

| Mouthfeel | Firmness of bite | 31.3 ± 1.7 b | 60.1 ± 2.5 a | 63.2 ± 2.8 a | <0.0001 |

| Moist sponge | 60.8 ± 2.2 a | 18.9 ± 1.6 b | 19.0 ± 2.6 b | <0.0001 | |

| Chewy | 27.5 ± 2.3 b | 48.8 ± 4.4 a | 56.4 ± 3.0 a | <0.0001 | |

| Mouthdrying | 24.5 ± 2.6 b | 42.3 ± 3.6 a | 46.3 ± 3.3 a | <0.0001 | |

| Greasy lips | 13.7 ± 2.5 a | 2.3 ± 1.1 b | 3.2 ± 1.5 b | 0.0003 | |

| Crumbliness of sponge | 36.5 ± 3.4 | 33.3 ± 3.8 | 32.0 ± 4.1 | 0.76 | |

| Crumb size | 35.0 ± 2.2 | 45.4 ± 3.6 | 43.7 ± 3.9 | 0.06 | |

| Pasty (cohesive) | 40.0 ± 4.1 | 36.5 ± 3.7 | 36.4 ± 4.6 | 0.84 | |

| Rate of breakdown & clearance | 52.6 ± 3.5 a | 32.8 ± 1.7 b | 35.1 ± 2.9 b | 0.0001 | |

| Cooling sensation | 4.9 ± 2.2 | 3.7 ± ± 1.9 | 7.1 ± 2.3 | 0.33 | |

| Aftertaste | Mouthdrying | 27.4 ± 2.7 b | 38.8 ± 3.5 a | 40.6 ± 3.8 a | 0.0001 |

| Sweet | 39.3 ± 3.1 | 35.9 ± 2.8 | 36.8 ± 2.7 | 0.45 | |

| Lemon | 27.3 ± 2.8 | 24.5 ± 2.7 | 25.1 ± 2.3 | 0.54 | |

| Buttery | 11.3 ± 2.2 a | 4.9 ± 1.9 b | 8.6 ± 2.1 ab | 0.01 | |

| Off-flavours | 0.0 ± 0.02 | 1.8 ± 1.2 | 1.7 ± 1.0 | 0.36 | |

| Salty | 2.1 ± 0.9 | 5.8 ± 1.7 | 3.8 ± 1.6 | 0.18 | |

| Salivating | 29.4 ± 2.5 | 32.3 ± 3.5 | 34.4 ± 3.1 | 0.26 | |

| Metallic | 2.5 ± 1.4 | 6.5 ± 2.4 | 8.4 ± 2.2 | 0.06 | |

| Liquorice | 1.7 ± 1.2 | 2.6 ± 1.4 | 5.8 ± 2.6 | 0.11 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Norton, V.; Lignou, S.; Faka, M.; Rodriguez-Garcia, J.; Methven, L. Investigating Methods to Mitigate Whey Protein Derived Mouthdrying. Foods 2021, 10, 2066. https://doi.org/10.3390/foods10092066

Norton V, Lignou S, Faka M, Rodriguez-Garcia J, Methven L. Investigating Methods to Mitigate Whey Protein Derived Mouthdrying. Foods. 2021; 10(9):2066. https://doi.org/10.3390/foods10092066

Chicago/Turabian StyleNorton, Victoria, Stella Lignou, Marianthi Faka, Julia Rodriguez-Garcia, and Lisa Methven. 2021. "Investigating Methods to Mitigate Whey Protein Derived Mouthdrying" Foods 10, no. 9: 2066. https://doi.org/10.3390/foods10092066