Brown Algae Fucus vesiculosus in Pasta: Effects on Textural Quality, Cooking Properties, and Sensorial Traits

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Pasta Production

2.3. Physicochemical Analysis

2.4. Pasta Cooking Quality

2.5. Texture Analysis

2.6. Pasta Color

2.7. Microscopic Structure of Cooked Pasta

2.8. Sensory Evaluation of Pasta Products

2.9. Statistical Analysis

3. Results and Discussion

3.1. Proximate Composition

3.2. Pasta Quality and Texture

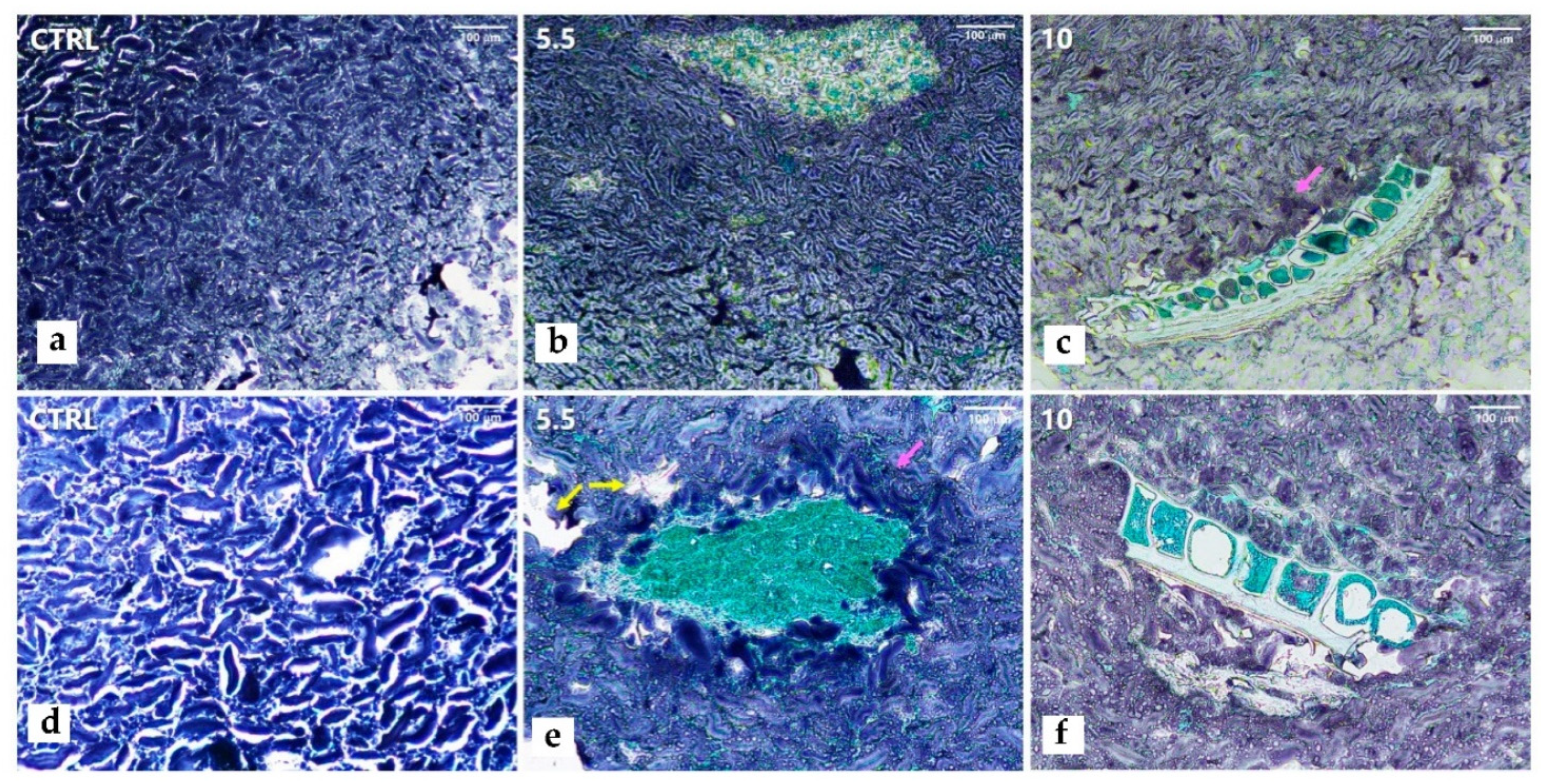

3.3. Microscopic Structure

3.4. Color

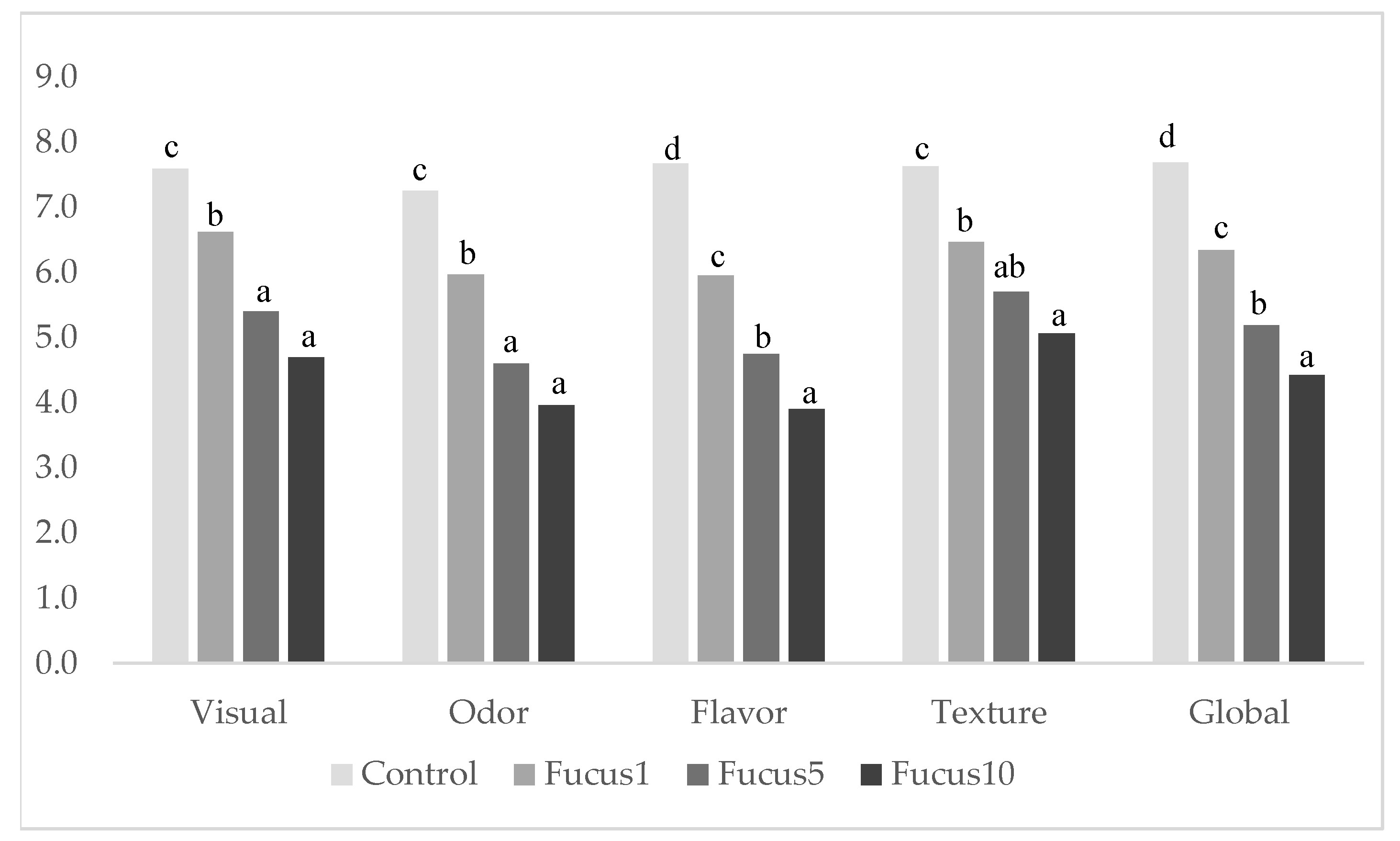

3.5. Sensory Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gupta, S.; Abu-Ghannam, N. Bioactive potential and possible health effects of edible brown seaweeds. Trends Food Sci. Technol. 2011, 22, 315–326. [Google Scholar] [CrossRef] [Green Version]

- Shannon, E.; Abu-Ghannam, N. Seaweeds as nutraceuticals for health and nutrition. Phycologia 2019, 58, 563–577. [Google Scholar] [CrossRef] [Green Version]

- Fitzgerald, C.; Mora-Soler, L.; Gallagher, E.; O’Connor, P.; Prieto, J.; Soler-Vila, A.; Hayes, M. Isolation and characterization of bioactive pro-peptides with in vitro renin inhibitory activities from the macroalga Palmaria palmata. J. Agric. Food Chem. 2012, 60, 7421–7427. [Google Scholar] [CrossRef] [PubMed]

- Roohinejad, S.; Koubaa, M.; Barba, F.J.; Saljoughian, S.; Amid, M.; Greiner, R. Application of seaweeds to develop new food products with enhanced shelf-life, quality and health-related beneficial properties. Food Res. Int. 2017, 99, 1066–1083. [Google Scholar] [CrossRef]

- Francezon, N.; Tremblay, A.; Mouget, J.-L.; Pasetto, P.; Beaulieu, L. Algae as a Source of Natural Flavors in Innovative Foods. J. Agric. Food Chem. 2021, 69, 11753–11772. [Google Scholar] [CrossRef]

- American Dietetic Association. Position of the American Dietetic Association: Fortification and Nutritional Supplements. J. Am. Diet. Assoc. 2005, 105, 1300–1311. [Google Scholar] [CrossRef]

- Hall, A.C.; Fairclough, A.C.; Mahadevan, K.; Paxman, J.R. Seaweed (Ascophyllum nodosum) enriched bread is acceptable to consumers. Proc. Nutr. Soc. 2010, 69, E352. [Google Scholar] [CrossRef] [Green Version]

- Nuñez, M.; Picon, A. Seaweeds in yogurt and quark supplementation: Influence of five dehydrated edible seaweeds on sensory characteristics. Int. J. Food Sci. Technol. 2017, 52, 431–438. [Google Scholar] [CrossRef]

- Prabhasankar, P.; Ganesan, P.; Bhaskar, N.; Hirose, A.; Stephen, N.; Gowda, L.R.; Hosokawa, M.; Miyashita, K. Edible Japanese seaweed, wakame (Undaria pinnatifida) as an ingredient in pasta: Chemical, functional and structural evaluation. Food Chem. 2009, 115, 501–508. [Google Scholar] [CrossRef]

- Fuad, T.; Prabhasankar, P. Role of ingredients in pasta product quality: A review on recent developments. Crit. Rev. Food Sci. Nutr. 2010, 50, 787–798. [Google Scholar] [CrossRef]

- Desai, A.; Brennan, M.A.; Brennan, C.S. The effect of semolina replacement with protein powder from fish (Pseudophycis bachus) on the physicochemical characteristics of pasta. LWT 2018, 89, 52–57. [Google Scholar] [CrossRef] [Green Version]

- Cubadda, R.E.; Carcea, M.; Marconi, E.; Trivisonno, M.C. Influence of Gluten Proteins and Drying Temperature on the Cooking Quality of Durum Wheat Pasta. Cereal Chem. 2007, 84, 48–55. [Google Scholar] [CrossRef]

- Tudorica, C.M.; Kuri, V.; Brennan, C.S. Nutritional and physicochemical characteristics of dietary fiber enriched pasta. J. Agric. Food Chem. 2002, 50, 347–356. [Google Scholar] [CrossRef] [PubMed]

- Fradique, M.; Batista, A.P.; Nunes, M.C.; Gouveia, L.; Bandarra, N.M.; Raymundo, A. Incorporation of Chlorella vulgaris and Spirulina maxima biomass in pasta products. Part 1: Preparation and evaluation. J. Sci. Food Agric. 2010, 90, 1656–1664. [Google Scholar] [CrossRef] [PubMed]

- GBIF Secretariat. GBIF Backbone Taxonomy. Available online: https://doi.org/10.15468/39omei (accessed on 6 November 2020).

- Zimmermann, M.B. The role of iodine in human growth and development. Semin. Cell Dev. Biol. 2011, 22, 645–652. [Google Scholar] [CrossRef]

- Maeda, H.; Tsukui, T.; Sashima, T.; Hosokawa, M.; Miyashita, K. Seaweed carotenoid, fucoxanthin, as a multi-functional nutrient. Asia Pac. J. Clin. Nutr. 2008, 17, 196–199. [Google Scholar] [PubMed]

- Li, Y.-X.; Wijesekara, I.; Li, Y.; Kim, S.-K. Phlorotannins as bioactive agents from brown algae. Process Biochem. 2011, 46, 2219–2224. [Google Scholar] [CrossRef]

- Catarino, M.D.; Silva, A.M.S.; Mateus, N.; Cardoso, S.M. Optimization of phlorotannins extraction from fucus vesiculosus and evaluation of their potential to prevent metabolic disorders. Mar. Drugs 2019, 17, 162. [Google Scholar] [CrossRef] [Green Version]

- Catarino, M.D.; Silva, A.; Cruz, M.T.; Mateus, N.; Silva, A.M.S.; Cardoso, S.M. Phlorotannins from Fucus vesiculosus: Modulation of Inflammatory Response by Blocking NF-κB Signaling Pathway. Int. J. Mol. Sci. 2020, 21, 6897. [Google Scholar] [CrossRef]

- Radwan, A.; Davies, G.; Fataftah, A.; Ghabbour, E.A.; Jansen, S.A.; Willey, R.J. Isolation of humic acid from the brown algaeAscophyllum nodosum, Fucus vesiculosus, Laminaria saccharina and the marine angiospermZostera marina. J. Appl. Phycol. 1996, 8, 553–562. [Google Scholar] [CrossRef]

- Steevensz, A.J.; Mackinnon, S.L.; Hankinson, R.; Craft, C.; Connan, S.; Stengel, D.B.; Melanson, J.E. Profiling phlorotannins in brown macroalgae by liquid chromatography-high resolution mass spectrometry. Phytochem. Anal. 2012, 23, 547–553. [Google Scholar] [CrossRef] [PubMed]

- Afonso, N.C.; Catarino, M.D.; Silva, A.M.S.; Cardoso, S.M. Brown Macroalgae as Valuable Food Ingredients. Antioxidants 2019, 8, 365. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Grahl, S.; Strack, M.; Mensching, A.; Mörlein, D. Alternative protein sources in Western diets: Food product development and consumer acceptance of spirulina-filled pasta. Food Qual. Prefer. 2020, 84, 103933. [Google Scholar] [CrossRef]

- Arufe, S.; Della Valle, G.; Chiron, H.; Chenlo, F.; Sineiro, J.; Moreira, R. Effect of brown seaweed powder on physical and textural properties of wheat bread. Eur. Food Res. Technol. 2018, 244, 1–10. [Google Scholar] [CrossRef]

- AACC. AACC Approved Methods of Analysis, 11th ed.; Cereals & Grains Association: St. Paul, MN, USA, 2010. [Google Scholar]

- Mariotti, F.; Tomé, D.; Mirand, P.P. Converting Nitrogen into Protein—Beyond 6.25 and Jones’ Factors. Crit. Rev. Food Sci. Nutr. 2008, 48, 177–184. [Google Scholar] [CrossRef]

- AOAC—Association of Official Analytical Chemists. Changes in methods. J. Assoc. Off. Anal. Chem. 1987, 70, 393. [Google Scholar]

- Grant, L.A.; Dick, J.W.; Shelton, D.R. Effects of drying temperature, starch damage, sprouting, and additives on spaghetti quality characteristics. Cereal Chem. 1993, 70, 676–684. [Google Scholar]

- Mahy, M.; Van Eycken, L.; Oosterlinck, A. Evaluation of Uniform Color Spaces Developed after the Adoption of CIELAB and CIELUV. Color Res. Appl. 1994, 19, 105–121. [Google Scholar] [CrossRef]

- Laleg, K.; Barron, C.; Cordelle, S.; Schlich, P.; Walrand, S.; Micard, V. How the structure, nutritional and sensory attributes of pasta made from legume flour is affected by the proportion of legume protein. LWT—Food Sci. Technol. 2017, 79, 471–478. [Google Scholar] [CrossRef] [Green Version]

- Petitot, M.; Barron, C.; Morel, M.-H.; Micard, V. Impact of Legume Flour Addition on Pasta Structure: Consequences on Its in Vitro Starch Digestibility. Food Biophys. 2010, 5, 284–299. [Google Scholar] [CrossRef]

- Australian Standard 2542.2.30; Sensory analysis—Guidelines for the Use of Quantitative Response Scales (Rating). Standards Association of Australia: North Ryde, Australia, 2014.

- Arufe, S.; Sineiro, J.; Moreira, R. Determination of thermal transitions of gluten-free chestnut flour doughs enriched with brown seaweed powders and antioxidant properties of baked cookies. Heliyon 2019, 5, e01805. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mamat, H.; Matanjun, P.; Ibrahim, S.; Amin, S.F.; Abdul Hamid, M.; Rameli, A.S. The effect of seaweed composite flour on the textural properties of dough and bread. J. Appl. Phycol. 2014, 26, 1057–1062. [Google Scholar] [CrossRef]

- Walsh, D.E.; Gilles, K.A. Pasta Technology Elements of Food Technology; Desroiser, N.W., Ed.; AVI Publ.: Cambridge, MA, USA, 1977. [Google Scholar]

- Lorenzo, J.M.; Agregán, R.; Munekata, P.E.S.; Franco, D.; Carballo, J.; Şahin, S.; Lacomba, R.; Barba, F.J. Proximate Composition and Nutritional Value of Three Macroalgae: Ascophyllum nodosum, Fucus vesiculosus and Bifurcaria bifurcata. Mar. Drugs 2017, 15, 360. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Biancarosa, I.; Espe, M.; Bruckner, C.G.; Heesch, S.; Liland, N.; Waagbø, R.; Torstensen, B.; Lock, E.J. Amino acid composition, protein content, and nitrogen-to-protein conversion factors of 21 seaweed species from Norwegian waters. J. Appl. Phycol. 2017, 29, 1001–1009. [Google Scholar] [CrossRef]

- Angell, A.R.; Mata, L.; de Nys, R.; Paul, N.A. The protein content of seaweeds: A universal nitrogen-to-protein conversion factor of five. J. Appl. Phycol. 2016, 28, 511–524. [Google Scholar] [CrossRef]

- Matsuo, R.R.; Irvine, G.N. Effect of gluten on the cooking quality of spaghetti. Cereal Chem. 1970, 47, 173–180. [Google Scholar]

- Matsuo, R.R.; Irvine, G.N.; Bradley, J.W. Effect of protein content on the cooking quality of spaghetti. Cereal Chem. 1972, 49, 707–711. [Google Scholar]

- Prabhasankar, P.; Ganesan, P.; Bhaskar, N. Influence of Indian brown seaweed (Sargassum marginatum) as an ingredient on quality, biofunctional, and microstructure characteristics of pasta. Food Sci. Technol. Int. 2009, 15, 471–479. [Google Scholar] [CrossRef]

- Aravind, N.; Sissons, M.; Egan, N.; Fellows, C.M.; Blazek, J.; Gilbert, E.P. Effect of β-Glucan on Technological, Sensory, and Structural Properties of Durum Wheat Pasta. Cereal Chem. 2012, 89, 84–93. [Google Scholar] [CrossRef]

- Mercier, S.; Moresoli, C.; Mondor, M.; Villeneuve, S.; Marcos, B. A Meta-Analysis of Enriched Pasta: What Are the Effects of Enrichment and Process Specifications on the Quality Attributes of Pasta? Compr. Rev. Food Sci. Food Saf. 2016, 15, 685–704. [Google Scholar] [CrossRef] [Green Version]

- D’Egidio, M.G.; Mariani, B.M.; Nardi, S.; Novaro, P.; Cubadda, R. Chemical and technological variables and their relationships: A predictive equation for pasta cooking quality. Cereal Chem. 1990, 67, 275–281. [Google Scholar]

- D’Egidio, M.G.; Nardi, S. Textural measurement of cooked spaghetti. In Pasta Noodle Technology; Kruger, E.J., Matsuo, R.B., Dick, J.W., Eds.; AACC: St. Paul, MN, USA, 1996; pp. 133–169. [Google Scholar]

- Riva, M.; Pagani, M.A. Cooking quality of pasta by image analysis. In Durum Wheat and Pasta Quality: Recent Achievements and New Trends; D’Egidio, M.G., Ed.; Istituto Sperimentale per la Cerealicoltura: Rome, Italy, 2003; pp. 343–347. [Google Scholar]

- Bock, J.E.; Connelly, R.K.; Damodaran, S. Impact of Bran Addition on Water Properties and Gluten Secondary Structure in Wheat Flour Doughs Studied by Attenuated Total Reflectance Fourier Transform Infrared Spectroscopy. Cereal Chem. 2013, 90, 377–386. [Google Scholar] [CrossRef]

- Gallo, V.; Romano, A.; Masi, P. Does the presence of fibres affect the microstructure and in vitro starch digestibility of commercial Italian pasta? Food Struct. 2020, 24, 100139. [Google Scholar] [CrossRef]

- Padalino, L.; Caliandro, R.; Chita, G.; Conte, A.; Del Nobile, M.A. Study of drying process on starch structural properties and their effect on semolina pasta sensory quality. Carbohydr. Polym. 2016, 153, 229–235. [Google Scholar] [CrossRef] [PubMed]

- Dick, J.W.; Youngs, V.L. Evaluation of Durum Wheat Semolina and Pasta in the United States. In Durum Wheat Chemistry and Technology; AACC: St. Paul, MN, USA, 1988. [Google Scholar]

- Sęczyk, Ł.; Świeca, M.; Gawlik-Dziki, U. Effect of carob (Ceratonia siliqua L.) flour on the antioxidant potential, nutritional quality, and sensory characteristics of fortified durum wheat pasta. Food Chem. 2016, 194, 637–642. [Google Scholar] [CrossRef]

- Cunin, C.; Handschin, S.; Walther, P.; Escher, F. Structural changes of starch during cooking of durum wheat pasta. LWT—Food Sci. Technol. 1995, 28, 323–328. [Google Scholar] [CrossRef]

- Manthey, F.A.; Schorno, A.L. Physical and Cooking Quality of Spaghetti Made from Whole Wheat Durum. Cereal Chem. 2002, 79, 504–510. [Google Scholar] [CrossRef]

- Steglich, T.; Bernin, D.; Röding, M.; Nydén, M.; Moldin, A.; Topgaard, D.; Langton, M. Microstructure and water distribution of commercial pasta studied by microscopy and 3D magnetic resonance imaging. Food Res. Int. 2014, 62, 644–652. [Google Scholar] [CrossRef]

- Hutchings, J.B. Food Colour and Appearance in Perspective. In Food Colour and Appearance; Springer: Boston, MA, USA, 1999; pp. 1–29. ISBN 978-1-4615-2373-4. [Google Scholar]

- Spence, C.; Levitan, C.A.; Shankar, M.U.; Zampini, M. Does food color influence taste and flavor perception in humans? Chemosens. Percept. 2010, 3, 68–84. [Google Scholar] [CrossRef]

- Zouari, N.; Abid, M.; Fakhfakh, N.; Ayadi, M.A.; Zorgui, L.; Ayadi, M.; Attia, H. Blue-green algae (Arthrospira platensis) as an ingredient in pasta: Free radical scavenging activity, sensory and cooking characteristics evaluation. Int. J. Food Sci. Nutr. 2011, 62, 811–813. [Google Scholar] [CrossRef]

- Peinado, I.; Girón, J.; Koutsidis, G.; Ames, J.M. Chemical composition, antioxidant activity and sensory evaluation of five different species of brown edible seaweeds. Food Res. Int. 2014, 66, 36–44. [Google Scholar] [CrossRef] [Green Version]

- O’Sullivan, A.M.; O’Callaghan, Y.C.; O’Grady, M.N.; Waldron, D.S.; Smyth, T.J.; O’Brien, N.M.; Kerry, J.P. An examination of the potential of seaweed extracts as functional ingredients in milk. Int. J. Dairy Technol. 2014, 67, 182–193. [Google Scholar] [CrossRef]

- O’Sullivan, A.M.; O’Grady, M.N.; O’Callaghan, Y.C.; Smyth, T.J.; O’Brien, N.M.; Kerry, J.P. Seaweed extracts as potential functional ingredients in yogurt. Innov. Food Sci. Emerg. Technol. 2016, 37, 293–299. [Google Scholar] [CrossRef]

- Diaz-Rubio, M.E.; Serrano, J.; Borderias, J.; Saura-Calixto, F. Technological effect and nutritional value of dietary antioxidant fucus fiber added to fish mince. J. Aquat. Food Prod. Technol. 2011, 20, 295–307. [Google Scholar] [CrossRef]

- Grunert, K.G. European consumers’ acceptance of functional foods. Ann. N. Y. Acad. Sci. 2010, 1190, 166–173. [Google Scholar] [CrossRef]

- Verbeke, W. Functional foods: Consumer willingness to compromise on taste for health? Food Qual. Prefer. 2006, 17, 126–131. [Google Scholar] [CrossRef]

- Catarino, M.D.; Silva, A.M.S.; Cardoso, S.M. Phycochemical Constituents and Biological Activities of Fucus spp. Mar. Drugs 2018, 16, 249. [Google Scholar] [CrossRef] [Green Version]

- EFSA Panel on Dietetic Products, Nutrition and Allergies (NDA). Scientific Opinion on the substantiation of a health claim related to iodine and contribution to normal thyroid function pursuant to Article 14 of Regulation (EC) No 1924/2006. EFSA J. 2014, 12, 3516. [Google Scholar] [CrossRef] [Green Version]

| Pasta | Moisture | Protein | Total Fiber | Ash |

|---|---|---|---|---|

| CTRL | 11.59 ± 0.01 a | 11.75 ± 0.01 a | 4.12 ± 0.48 a | 0.75 ± 0.03 a |

| F1 | 12.17 ± 0.10 a | 11.78 ± 0.12 a | 3.86 ± 0.06 a | 1.04 ± 0.10 b |

| F5 | 12.31 ± 0.36 a | 12.21 ± 0.14 a | 4.52 ± 0.34 a | 1.84 ± 0.04 c |

| F10 | 11.83 ± 0.09 a | 11.82 ± 0.59 a | 7.00 ± 0.06 b | 2.89 ± 0.07 d |

| Pasta | Firmness Raw (g) | Firmness Cooked (g) | Hardness (g) | Weight Gain (g/g) | Cooking Loss (g/g) |

|---|---|---|---|---|---|

| CTR | 198 ± 31 c | 428 ± 66 b | 5179 ± 479 b | 1.45 ± 0.11 a | 3.78 ± 0.42 a |

| F1 | 123 ± 33 b | 396 ± 26 ab | 5479 ± 517 b | 1.75 ± 0.06 b | 4.55 ± 0.20 a |

| F5 | 117 ± 15 b | 422 ± 53 b | 5293 ± 484 b | 1.88 ± 0.10 b | 6.09 ± 0.23 b |

| F10 | 77 ± 18 a | 360 ± 30 a | 4537 ± 311 a | 1.88 ± 0.06 b | 7.54 ± 0.35 c |

| Sample | CTRL | F1 | F5.5 | F10 |

|---|---|---|---|---|

| L* lightness | 78.7 ± 2.1 c | 66.4 ± 1.8 b | 40.8 ± 2.7 a | 38.2 ± 3.4 a |

| a* | −3.1 ± 0.4 a | −2.7 ± 0.7 a | −112.8 ± 5.8 b | −131.2 ± 30.7 b |

| b* | 27.8 ± 3.7 a | 27.3 ± 1.1 a | 53.7 ± 11.4 b | 51.8 ± 13.3 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ribeiro, A.R.; Madeira, T.; Botelho, G.; Martins, D.; Ferreira, R.M.; Silva, A.M.S.; Cardoso, S.M.; Costa, R. Brown Algae Fucus vesiculosus in Pasta: Effects on Textural Quality, Cooking Properties, and Sensorial Traits. Foods 2022, 11, 1561. https://doi.org/10.3390/foods11111561

Ribeiro AR, Madeira T, Botelho G, Martins D, Ferreira RM, Silva AMS, Cardoso SM, Costa R. Brown Algae Fucus vesiculosus in Pasta: Effects on Textural Quality, Cooking Properties, and Sensorial Traits. Foods. 2022; 11(11):1561. https://doi.org/10.3390/foods11111561

Chicago/Turabian StyleRibeiro, Ana Ramalho, Tiago Madeira, Goreti Botelho, Diana Martins, Ricardo M. Ferreira, Artur M. S. Silva, Susana M. Cardoso, and Rui Costa. 2022. "Brown Algae Fucus vesiculosus in Pasta: Effects on Textural Quality, Cooking Properties, and Sensorial Traits" Foods 11, no. 11: 1561. https://doi.org/10.3390/foods11111561

APA StyleRibeiro, A. R., Madeira, T., Botelho, G., Martins, D., Ferreira, R. M., Silva, A. M. S., Cardoso, S. M., & Costa, R. (2022). Brown Algae Fucus vesiculosus in Pasta: Effects on Textural Quality, Cooking Properties, and Sensorial Traits. Foods, 11(11), 1561. https://doi.org/10.3390/foods11111561