Characteristics and Antioxidant Activity of Walnut Oil Using Various Pretreatment and Processing Technologies

Abstract

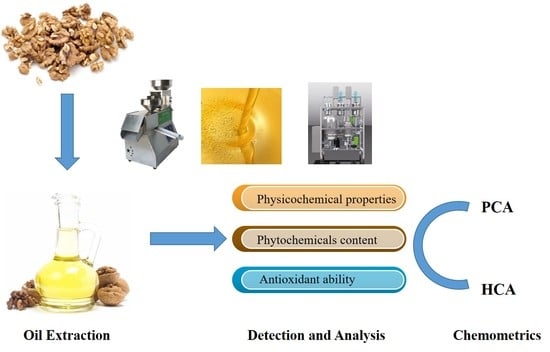

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Chemicals and Standards

2.3. Oil Extraction

2.3.1. Roasting Pretreatment

2.3.2. Processing

2.4. Physicochemical Properties

2.5. Fatty Acid Composition

2.6. Phytochemicals Content

2.7. Free Radical Scavenging Capacity

2.8. Statistical Analysis

3. Results and Discussion

3.1. Lipid Yield

3.2. Physicochemical Properties

3.3. Fatty Acid Composition

3.4. Phytochemicals Content

3.5. Antioxidant Activity

3.6. HCA Analysis

3.7. MLR Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Garcia-Mendoza, M.D.P.; Espinosa-Pardo, F.A.; Savoire, R.; Etchegoyen, C.; Harscoat-Schiavo, C.; Subra-Paternault, P. Recovery and antioxidant activity of phenolic compounds extracted from walnut press-cake using various methods and conditions. Ind. Crop. Prod. 2021, 167, 113546. [Google Scholar] [CrossRef]

- Zhao, F.; Liu, C.; Fang, L.; Lu, H.; Wang, J.; Gao, Y.; Gabbianelli, R.; Min, W. Walnut-Derived Peptide Activates PINK1 via the NRF2/KEAP1/HO-1 Pathway, Promotes Mitophagy, and Alleviates Learning and Memory Impairments in a Mice Model. J. Agric. Food Chem. 2021, 69, 2758–2772. [Google Scholar] [CrossRef] [PubMed]

- Liao, J.; Nai, Y.; Feng, L.; Chen, Y.; Li, M.; Xu, H. Walnut Oil Prevents Scopolamine-Induced Memory Dysfunction in a Mouse Model. Molecules 2020, 25, 1630. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bartoszek, A.; Makaro, A.; Bartoszek, A.; Kordek, R.; Fichna, J.; Salaga, M. Walnut Oil Alleviates Intestinal Inflammation and Restores Intestinal Barrier Function in Mice. Nutrients 2020, 12, 1302. [Google Scholar] [CrossRef] [PubMed]

- Miao, F.; Shan, C.; Shah, S.A.H.; Akhtar, R.W.; Wang, X.; Ning, D. Effect of walnut (Juglans sigillata) oil on intestinal antioxidant, anti-inflammatory, immunity, and gut microbiota modulation in mice. J. Food Biochem. 2020, 45, e13567. [Google Scholar] [CrossRef] [PubMed]

- Miao, F.; Shan, C.; Ning, D. Walnut oil alleviates LPS-induced intestinal epithelial cells injury by inhibiting TLR4/MyD88/NF-κB pathway activation. J. Food Biochem. 2021, 45, e13955. [Google Scholar] [CrossRef]

- Miao, F.; Shan, C.; Ma, T.; Geng, S.; Ning, D. Walnut oil alleviates DSS–induced colitis in mice by inhibiting NLRP3 inflammasome activation and regulating gut microbiota. Microb. Pathog. 2021, 154, 104866. [Google Scholar] [CrossRef]

- Tian, W.; Wu, B.; Sun, L.; Zhuang, Y. Protective effect against d-gal-induced aging mice and components of polypeptides and polyphenols in defatted walnut kernel during simulated gastrointestinal digestion. J. Food Sci. 2021, 86, 2736–2752. [Google Scholar] [CrossRef]

- Gencoglu, H.; Orhan, C.; Tuzcu, M.; Sahin, N.; Juturu, V.; Sahin, K. Effects of walnut oil on metabolic profile and transcription factors in rats fed high-carbohydrate/fat diets. J. Food Biochem. 2020, 44, e13235. [Google Scholar] [CrossRef]

- Gao, P.; Liu, R.; Jin, Q.; Wang, X. Effects of processing methods on the chemical composition and antioxidant capacity of walnut (Juglans regia L.) oil. LWT 2021, 135, 109958. [Google Scholar] [CrossRef]

- Juhaimi, F.; Özcan, M.M.; Ghafoor, K.; Babiker, E.E.; Hussain, S. Comparison of cold-pressing and soxhlet extraction systems for bioactive compounds, antioxidant properties, polyphenols, fatty acids and tocopherols in eight nut oils. J. Food Sci. Technol. 2018, 55, 3163–3173. [Google Scholar] [CrossRef] [PubMed]

- Gharibzahedi, S.M.T.; Mousavi, M.; Hamedi, M.; Rezaei, K.; Khodaiyan, F. Evaluation of physicochemical properties and antioxidant activities of Persian walnut oil obtained by several extraction methods. Ind. Crop. Prod. 2013, 45, 133–140. [Google Scholar] [CrossRef]

- Aquino, D.S.; Fanhani, A.; Stevanato, N.; Da Silva, C. Sunflower oil from enzymatic aqueous extraction process: Maximization of free oil yield and oil characterization. J. Food Process Eng. 2019, 42, e13169. [Google Scholar] [CrossRef]

- Liu, Z.; Gui, M.; Xu, T.; Zhang, L.; Kong, L.; Qin, L.; Zou, Z. Efficient aqueous enzymatic-ultrasonication extraction of oil from Sapindus mukorossi seed kernels. Ind. Crop. Prod. 2019, 134, 124–133. [Google Scholar] [CrossRef]

- Rabadán, A.; Pardo, J.E.; Gómez, R.; Álvarez-Ortí, M. Influence of temperature in the extraction of nut oils by means of screw pressing. LWT 2018, 93, 354–361. [Google Scholar] [CrossRef]

- Díaz-Suárez, P.; Rosales-Quintero, A.; Fernandez-Lafuente, R.; Pola-Sánchez, E.; Hernández-Cruz, M.C.; Ovando-Chacón, S.L.; Rodrigues, R.C.; Tacias-Pascacio, V.G. Aqueous enzymatic extraction of Ricinus communis seeds oil using Viscozyme L. Ind. Crop. Prod. 2021, 170, 113811. [Google Scholar] [CrossRef]

- Liu, J.J.; Gasmalla, M.A.A.; Li, P.; Yang, R. Enzyme-assisted extraction processing from oilseeds: Principle, processing and application. Innov. Food Sci. Emerg. Technol. 2016, 35, 184–193. [Google Scholar] [CrossRef]

- Uoonlue, N.; Muangrat, R. Effect of different solvents on subcritical solvent extraction of oil from Assam tea seeds (Camellia sinensis var. assamica): Optimization of oil extraction and physicochemical analysis. J. Food Process Eng. 2019, 42, e12960. [Google Scholar] [CrossRef]

- Song, Y.; Zhang, W.; Wu, J.; Admassu, H.; Liu, J.; Zhao, W.; Yang, R. Ethanol-Assisted Aqueous Enzymatic Extraction of Peony Seed Oil. J. Am. Oil Chem. Soc. 2019, 96, 595–606. [Google Scholar] [CrossRef]

- Gao, P.; Liu, R.; Jin, Q.; Wang, X. Comparison of Different Processing Methods of Iron Walnut Oils (Juglans sigillata): Lipid Yield, Lipid Compositions, Minor Components, and Antioxidant Capacity. Eur. J. Lipid Sci. Technol. 2018, 120, 1800151. [Google Scholar] [CrossRef]

- Niu, B.; Olajide, T.; Liu, H.; Pasdar, H.; Weng, X. Effects of different baking techniques on the quality of walnut and its oil. Grasas y Aceites 2021, 72, e406. [Google Scholar] [CrossRef]

- Ghafoor, K.; Al Juhaimi, F.; Geçgel, Ü.; EBabiker, E.; Özcan, M.M. Influence of Roasting on Oil Content, Bioactive Components of Different Walnut Kernel. J. Oleo Sci. 2020, 69, 423–428. [Google Scholar] [CrossRef] [PubMed]

- Chang, S.K.; Alasalvar, C.; Bolling, B.; Shahidi, F. Nuts and their co-products: The impact of processing (roasting) on phenolics, bioavailability, and health benefits—A comprehensive review. J. Funct. Foods 2016, 26, 88–122. [Google Scholar] [CrossRef]

- Anjum, S.; Gani, A.; Ahmad, M.; Shah, A.; Masoodi, F.A.; Shah, Y.; Gani, A. Antioxidant and Antiproliferative Activity of Walnut Extract (Juglans regia L.) Processed by Different Methods and Identification of Compounds Using GC/MS and LC/MS Technique. J. Food Process. Preserv. 2017, 41, e12756. [Google Scholar] [CrossRef]

- Li, J.; Zu, Y.G.; Luo, M.; Gu, C.B.; Zhao, C.; Efferth, T.; Fu, Y.J. Aqueous enzymatic process assisted by microwave extraction of oil from yellow horn (Xanthoceras sorbifolia Bunge.) seed kernels and its quality evaluation. Food Chem. 2013, 138, 2152–2158. [Google Scholar] [CrossRef]

- Zhang, W.G. Aqueous Extraction and Nutraceuticals Content of Oil Using Industrial Enzymes from Microwave Puffing-pretreated Camellia oleifera Seed Powder. Food Sci. Technol. Res. 2016, 22, 31–38. [Google Scholar] [CrossRef] [Green Version]

- Suri, K.; Singh, B.; Kaur, A.; Yadav, M.P.; Singh, N. Influence of microwave roasting on chemical composition, oxidative stability and fatty acid composition of flaxseed (Linum usitatissimum L.) oil. Food Chem. 2020, 326, 126974. [Google Scholar] [CrossRef]

- Güneşer, B.A.; Yilmaz, E. Comparing the effects of conventional and microwave roasting methods for bioactive composition and the sensory quality of cold-pressed orange seed oil. J. Food Sci. Technol. 2018, 56, 634–642. [Google Scholar] [CrossRef]

- Yu, G.; Guo, T.; Huang, Q.; Shi, X.; Zhou, X. Preparation of high-quality concentrated fragrance flaxseed oil by steam explosion pretreatment technology. Food Sci. Nutr. 2020, 8, 2112–2123. [Google Scholar] [CrossRef]

- He, J.; Wu, X.; Zhou, Y.; Chen, J. Effects of different preheat treatments on volatile compounds of camellia (Camellia oleifera Abel.) seed oil and formation mechanism of key aroma compounds. J. Food Biochem. 2021, 45, e13649. [Google Scholar] [CrossRef]

- Idrus, N.F.M.; Zzaman, W.; Yang, T.A.; Easa, A.M.; Sharifudin, M.S.; Noorakmar, B.W.; Jahurul, M.H.A. Effect of superheated-steam roasting on physicochemical properties of peanut (Arachis hypogea) oil. Food Sci. Biotechnol. 2017, 26, 911–920. [Google Scholar] [CrossRef] [PubMed]

- Cheng, M.H.; Rosentrater, K.A.; Sekhon, J.; Wang, T.; Jung, S.; Johnson, L.A. Economic Feasibility of Soybean Oil Production by Enzyme-Assisted Aqueous Extraction Processing. Food Bioprocess Technol. 2019, 12, 539–550. [Google Scholar] [CrossRef]

- Liu, S.; Hu, H.; Yu, Y.; Zhao, J.; Liu, L.; Zhao, S.; Xie, J.; Li, C.; Shen, M. Simultaneous Determination of Tocopherols, Phytosterols, and Squalene in Vegetable Oils by High Performance Liquid Chromatography-Tandem Mass Spectrometry. Food Anal. Methods 2021, 14, 1567–1576. [Google Scholar] [CrossRef]

- González-Gómez, D.; Ayuso-Yuste, M.C.; Blanco-Roque, C.; Bernalte-García, M.J. Optimization of enzyme-assisted aqueous method for the extraction of oil from walnuts using response surface methodology. J. Food Process. Preserv. 2019, 43, e14218. [Google Scholar] [CrossRef]

- Soo, P.; Ali, Y.; Lai, O.; Kuan, C.; Tang, T.; Lee, Y.; Phuah, E. Enzymatic and Mechanical Extraction of Virgin Coconut Oil. Eur. J. Lipid Sci. Technol. 2020, 122, 1900220. [Google Scholar] [CrossRef]

- Broznić, D.; Jurešić, G.; Milin, Č. Involvement of α-, γ- and δ-tocopherol isomers from pumpkin (Cucurbita pepo L.) seed oil or oil mixtures in the biphasic DPPH disappearance kinetics. Food Technol. Biotechnol. 2016, 54, 200–210. [Google Scholar] [CrossRef]

- Nguyen, H.C.; Vuong, D.P.; Nguyen, N.T.T.; Nguyen, N.P.; Su, C.H.; Wang, F.-M.; Juan, H.Y. Aqueous enzymatic extraction of polyunsaturated fatty acid–rich sacha inchi (Plukenetia volubilis L.) seed oil: An eco-friendly approach. LWT 2020, 133, 109992. [Google Scholar] [CrossRef]

- Teixeira, G.L.; Ghazani, S.M.; Corazza, M.L.; Marangoni, A.G.; Ribani, R.H. Assessment of subcritical propane, supercritical CO2 and Soxhlet extraction of oil from sapucaia (Lecythis pisonis) nuts. J. Supercrit. Fluids 2018, 133, 122–132. [Google Scholar] [CrossRef]

- Mazaheri, Y.; Torbati, M.; Azadmard-Damirchi, S.; Savage, G.P. Effect of roasting and microwave pre-treatments of Nigella sativa L. seeds on lipase activity and the quality of the oil. Food Chem. 2019, 274, 480–486. [Google Scholar] [CrossRef]

| SP | MR-SP | OR-SP | SR-SP | MR-AEE | OR-AEE | SR-AEE | MR-SBE | OR-SBE | SR-SBE | |

|---|---|---|---|---|---|---|---|---|---|---|

| Lipid yield (%) | 46.31±0.55 f * | 40.73 ± 0.41 h | 40.79 ± 0.17 h | 43.29 ± 0.71 g | 53.65 ± 0.33 c | 52.73 ± 0.31 d | 50.64 ± 0.39 e | 60.75 ± 0.30 a | 61.19 ± 0.25 a | 59.53 ± 0.44 b |

| Acid value (mg/g) | 0.45 ± 0.10 cd | 0.57 ± 0.00 c | 0.14 ± 0.02 f | 0.33 ± 0.01 de | 1.12 ± 0.03 b | 1.14 ± 0.01 b | 2.49 ± 0.16 a | 0.26 ± 0.01 ef | 0.23 ± 0.00 ef | 0.23 ± 0.00 ef |

| Peroxide value (mmol/kg) | 5.56 ± 0.07 a | 3.38 ± 0.34 c | 2.63 ± 0.24 de | 2.45 ± 0.02 e | 3.37 ± 0.08 c | 2.52 ± 0.18 de | 4.16 ± 0.11 b | 2.33 ± 0.02 e | 2.61 ± 0.05 de | 2.81 ± 0.04 d |

| Fatty acid (%) | ||||||||||

| C16:0 | 6.41 ± 0.02 a | 6.14 ± 0.00 f | 6.18 ± 0.02 e | 6.19 ± 0.00 de | 6.21 ± 0.00 d | 6.21 ± 0.01 d | 6.25 ± 0.00 c | 6.23 ± 0.02 c | 6.21 ± 0.01 d | 6.30 ± 0.01 b |

| C18:0 | 2.75 ± 0.00 abc | 2.62 ± 0.01 e | 2.70 ± 0.01 d | 2.70 ± 0.02 d | 2.77 ± 0.02 a | 2.76 ± 0.01 ab | 2.74 ± 0.00 bc | 2.76 ± 0.01 abc | 2.74 ± 0.01 c | 2.75 ± 0.01 abc |

| C18:1n-9 | 18.51 ± 0.03 b | 17.36 ± 0.04 i | 17.70 ± 0.02 g | 18.03 ± 0.02 f | 18.84 ± 0.02 a | 18.53 ± 0.02 b | 18.35 ± 0.02 c | 18.10 ± 0.02 e | 18.15 ± 0.01 d | 17.51 ± 0.02 h |

| C18:2n-6 | 62.10 ± 0.01 h | 64.95 ± 0.06 a | 63.21 ± 0.02 c | 62.94 ± 0.01 d | 61.73 ± 0.02 j | 61.98 ± 0.03 i | 62.31 ± 0.02 g | 62.55 ± 0.02 f | 62.64 ± 0.01 e | 63.89 ± 0.02 b |

| C18:3n-3 | 10.04 ± 0.02 de | 8.75 ± 0.01 h | 10.01 ± 0.01 e | 9.95 ± 0.01 f | 10.26 ± 0.02 b | 10.33 ± 0.05 a | 10.17 ± 0.03 c | 10.17 ± 0.01 c | 10.08 ± 0.02 d | 9.36 ± 0.02 g |

| C20:1 | 0.18 ± 0.00 a | 0.19 ± 0.00 a | 0.19 ± 0.01 a | 0.19 ± 0.00 a | 0.19 ± 0.01 a | 0.19 ± 0.01 a | 0.19 ± 0.00 a | 0.19 ± 0.01 a | 0.18 ± 0.01 a | 0.19 ± 0.00 a |

| SFA # | 9.16 ± 0.02 a | 8.76 ± 0.01 f | 8.89 ± 0.01e | 8.89 ± 0.02 e | 8.98 ± 0.02 c | 8.97 ± 0.02 cd | 8.99 ± 0.00 c | 8.99 ± 0.02 c | 8.94 ± 0.01 d | 9.05 ± 0.01 b |

| MUFA | 18.69 ± 0.03 b | 17.55 ± 0.04 i | 17.89 ± 0.01 g | 18.22 ± 0.02 f | 19.03 ± 0.02 a | 18.71 ± 0.02 b | 18.54 ± 0.02 c | 18.29 ± 0.03 e | 18.34 ± 0.02 de | 17.70 ± 0.02 h |

| PUFA | 72.15 ± 0.01 g | 73.69 ± 0.05 a | 73.22 ± 0.02 b | 72.89 ± 0.00 c | 71.99 ± 0.03 h | 72.32 ± 0.03 f | 72.47 ± 0.02 e | 72.72 ± 0.03 d | 72.72 ± 0.02 d | 73.25 ± 0.01 b |

| α-Tocopherol | γ-Tocopherol | δ-Tocopherol | Total Tocopherol | Phytosterols | Squalene | TPC | |

|---|---|---|---|---|---|---|---|

| SP | 5.64 ± 0.22 g * | 244.67 ± 14.49 f | 35.64 ± 0.21 g | 285.95 ± 14.40 e | 1474.18 ± 6.31 d | 8.39 ± 0.01 g | 6.48 ± 0.02 e |

| MR-SP | 17.76 ± 0.11 b | 359.90 ± 15.02 a | 42.19 ± 0.09 e | 419.85 ± 15.01 a | 1462.65 ± 3.34 e | 9.60 ± 0.01 c | 13.12 ± 0.05 a |

| OR-SP | 16.94 ± 0.35 f | 263.48 ± 7.12 e | 38.36 ± 0.43 h | 304.78 ± 7.14 d | 1361.36 ± 4.62 g | 9.91 ± 0.01 a | 12.27 ± 0.12 ab |

| SR-SP | 13.73 ± 0.17 e | 313.36 ± 3.00 cd | 39.64 ± 0.27 f | 366.73 ± 3.10 bc | 1367.10 ± 1.31 g | 8.86 ± 0.01 f | 10.59 ± 0.14 c |

| MR-AEE | 17.76 ± 0.02 b | 316.42 ± 3.50 c | 44.61 ± 0.43 c | 378.79 ± 3.42 b | 1394.32 ± 3.30 g | 8.12 ± 0.02 i | 9.64 ± 0.10 d |

| OR-AEE | 17.41 ± 0.09 c | 296.60 ± 3.31 d | 44.70 ± 0.09 c | 358.71 ± 3.29 c | 1416.75 ± 1.91 f | 8.24 ± 0.03 h | 8.13 ± 0.07 c |

| SR-AEE | 15.60 ± 0.13 d | 318.93 ± 6.40 cd | 42.97 ± 0.60 d | 377.50 ± 6.31 b | 1557.00 ± 9.21 b | 7.65 ± 0.02 j | 10.45 ± 0.16 ab |

| MR-SBE | 18.84 ± 0.04 a | 305.25 ± 3.19 cd | 45.88 ± 0.30 b | 369.97 ± 2.99 bc | 1560.01 ± 8.19 b | 9.77 ± 0.03 b | 10.30 ± 0.11 ab |

| OR-SBE | 18.62 ± 0.10 a | 305.68 ± 3.86 c | 46.71 ± 0.59 a | 371.00 ± 4.24 bc | 1489.75 ± 4.32 c | 9.10 ± 0.02 e | 12.16 ± 0.10 ab |

| SR-SBE | 17.56 ± 0.17 bc | 340.23 ± 3.81 b | 46.17 ± 0.44 b | 403.96 ± 4.09 a | 1610.05 ± 7.69 a | 9.50 ± 0.02 d | 11.22 ± 0.05 b |

| OSI | DPPH-Oil | DPPH-Nonpolar | DPPH-Polar | ABTS | FRAP | |

|---|---|---|---|---|---|---|

| SP | 1.80 ± 0.05 e * | 132.93 ± 4.63 de | 91.64 ± 3.97 cd | 105.40 ± 10.56 e | 233.54 ± 3.72 def | 85.50 ± 5.01 bc |

| MR-SP | 2.63 ± 0.08 a | 171.70 ± 12.20 abc | 73.26 ± 1.30 f | 30.69 ± 2.48 f | 206.70 ± 3.06 g | 105.61 ± 5.13 a |

| OR-SP | 2.53 ± 0.06 ab | 193.19 ± 4.05 a | 76.83 ± 3.02 ef | 43.40 ± 4.92 f | 227.08 ± 1.22f | 67.22 ± 5.95 e |

| SR-SP | 2.34 ± 0.05 c | 157.76 ± 17.96 bc | 72.59 ± 7.79 f | 44.70 ± 6.31 f | 231.06 ± 5.76 ef | 84.79 ± 3.54 bc |

| MR-AEE | 2.14 ± 0.06 d | 153.92 ± 7.77 cd | 108.36 ± 3.59 a | 248.76 ± 9.54 c | 241.50 ± 3.06 d | 50.49 ± 5.60 f |

| OR-AEE | 2.32 ± 0.02 c | 128.07 ± 9.33 e | 101.96 ± 5.86 abc | 245.03 ± 24.71 c | 260.39 ± 0.70 c | 50.25 ± 4.88 f |

| SR-AEE | 2.51 ± 0.03 ab | 147.11 ± 13.64 de | 94.88 ± 9.22 bcd | 163.04 ± 18.90 d | 239.51 ± 9.30 de | 69.49 ± 7.05 de |

| MR-SBE | 2.52 ± 0.04 ab | 158.22 ± 11.38 bc | 107.01 ± 4.23 ab | 373.14 ± 20.78 a | 269.34 ± 4.28 b | 80.97 ± 3.94 bcd |

| OR-SBE | 2.51 ± 0.08 ab | 180.54 ± 7.76 ab | 87.15 ± 10.40 de | 341.24 ± 21.02 a | 275.80 ± 2.54 ab | 91.81 ± 7.28 b |

| SR-SBE | 2.48 ± 0.03 b | 181.67 ± 7.78 ab | 109.46 ± 2.85 a | 287.59 ± 20.48 b | 280.28 ± 1.86 a | 77.85 ± 1.54 cde |

| Dependent Variable | Adjusted R2 | Variable | Standardized Coefficient | Significance (Two Tails p) | Equation |

|---|---|---|---|---|---|

| OSI | 0.727 | TPC | 0.870 | 0.001 | Y = 0.870 (TPC) |

| DPPH-oil | 0.711 | TPC | 0.862 | 0.001 | Y = 0.862 (TPC) |

| DPPH-nonpolar | 0.772 | C18:0 | 1.344 | 0.001 | Y = 1.344 (C18:0) − 0.689 (C18:3) |

| C18:3 | −0.689 | 0.032 | |||

| DPPH-polar | 0.910 | δ-tocopherol | 1.260 | 0.000 | Y = 1.260 (δ-tocopherol) − 0.699 (γ-tocopherol) |

| γ-tocopherol | −0.699 | 0.001 | |||

| ABTS | 0.954 | C18:0 | 0.647 | 0.007 | Y = 0.647 (C18:0) − 0.657 (C18:1) + 0.942 (δ-tocopherol) − 0.601 (γ-tocopherol) |

| C18:1 | −0.657 | 0.002 | |||

| δ-tocopherol | 0.942 | 0.002 | |||

| γ-tocopherol | −0.601 | 0.016 | |||

| FRAP | 0.395 | C18:3 | −0.680 | 0.030 | Y = −0.680 (C18:3) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, P.; Ding, Y.; Chen, Z.; Zhou, Z.; Zhong, W.; Hu, C.; He, D.; Wang, X. Characteristics and Antioxidant Activity of Walnut Oil Using Various Pretreatment and Processing Technologies. Foods 2022, 11, 1698. https://doi.org/10.3390/foods11121698

Gao P, Ding Y, Chen Z, Zhou Z, Zhong W, Hu C, He D, Wang X. Characteristics and Antioxidant Activity of Walnut Oil Using Various Pretreatment and Processing Technologies. Foods. 2022; 11(12):1698. https://doi.org/10.3390/foods11121698

Chicago/Turabian StyleGao, Pan, Yunpeng Ding, Zhe Chen, Zhangtao Zhou, Wu Zhong, Chuanrong Hu, Dongping He, and Xingguo Wang. 2022. "Characteristics and Antioxidant Activity of Walnut Oil Using Various Pretreatment and Processing Technologies" Foods 11, no. 12: 1698. https://doi.org/10.3390/foods11121698

APA StyleGao, P., Ding, Y., Chen, Z., Zhou, Z., Zhong, W., Hu, C., He, D., & Wang, X. (2022). Characteristics and Antioxidant Activity of Walnut Oil Using Various Pretreatment and Processing Technologies. Foods, 11(12), 1698. https://doi.org/10.3390/foods11121698