Cereal and Confectionary Packaging: Background, Application and Shelf-Life Extension

Abstract

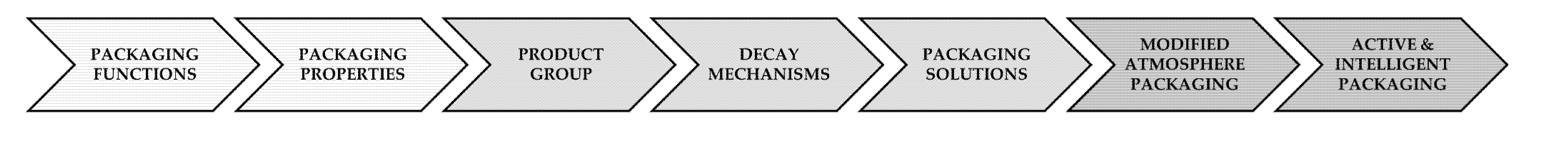

:1. Introduction

- Presenting relevant information on packaging functions and properties of packaging materials,

- detailing product group specific decay mechanisms and frequently used packaging solutions,

- and highlighting packaging-related shelf-life extension technologies.

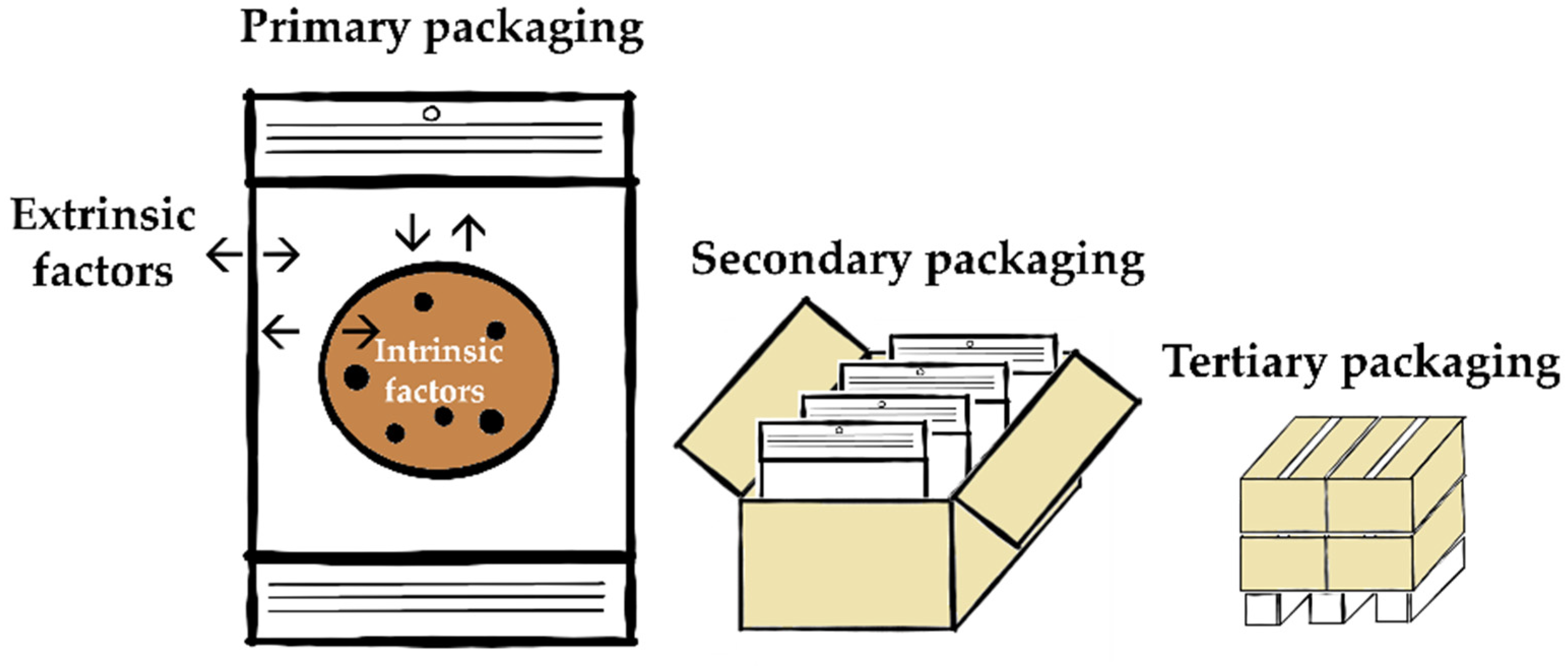

2. Packaging

2.1. Packaging Functions

2.2. Packaging Properties

3. Cereal and Confectionary Products

3.1. Categorization of Cereal and Confectionary Products

3.2. Decay Mechanisms and Shelf-Life

3.3. Product Group Specific Packaging

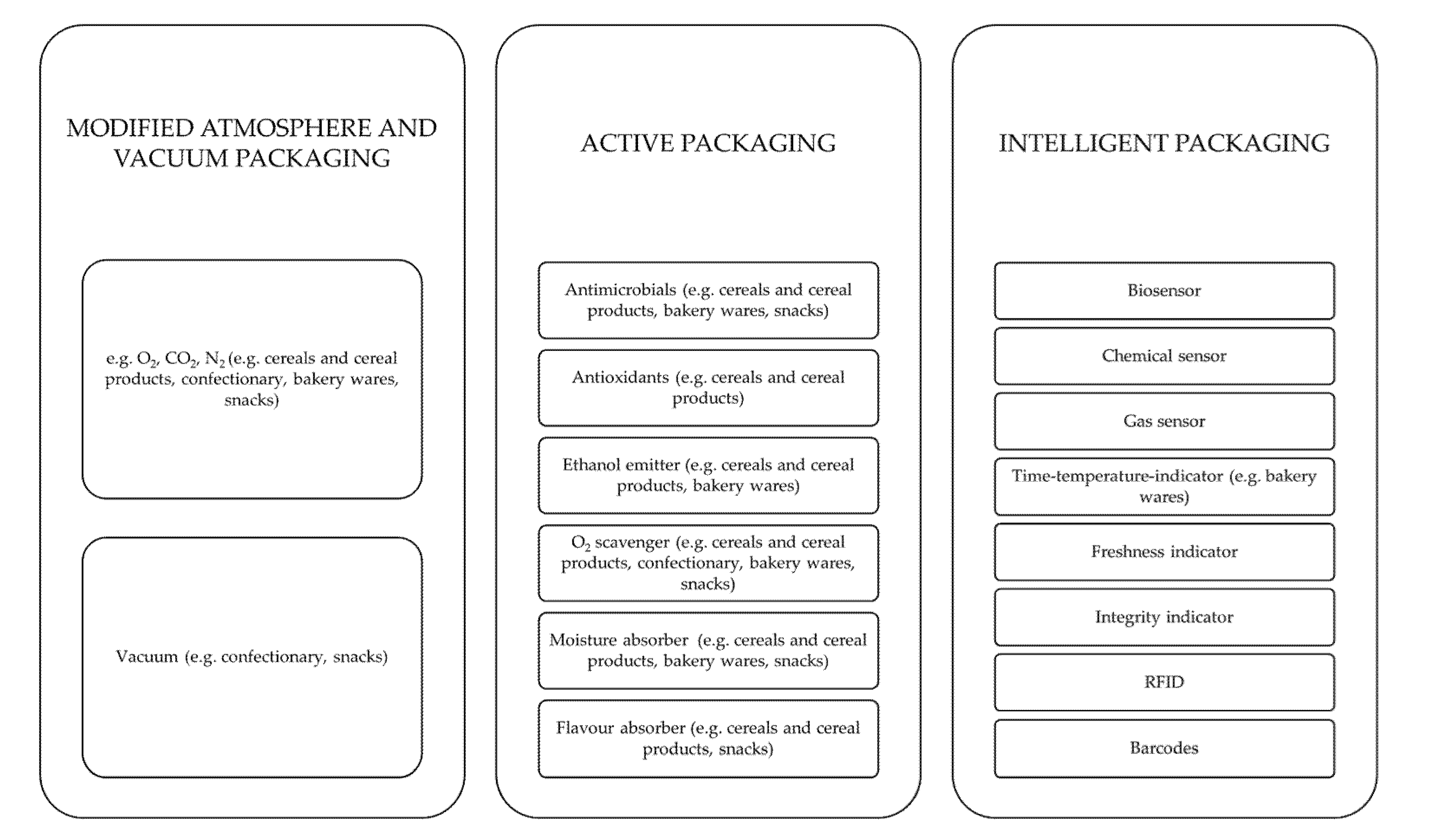

4. Shelf-Life Extension

4.1. Modified Atmosphere Packaging (MAP)

4.2. Active and Intelligtent Packaging (AIP)

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- United Nations Framework Convention on Climate Change. The Paris Agreement. 2016. Available online: https://unfccc.int/sites/default/files/resource/parisagreement_publication.pdf (accessed on 2 February 2022).

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development. Resolution Adopted by the General Assembly on 25 September 2015. Available online: http://www.un.org/ga/search/view_doc.asp?symbol=A/RES/70/1&Lang=E (accessed on 2 February 2022).

- Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions, Brussels, Belgium. 2019. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:b828d165-1c22-11ea-8c1f-01aa75ed71a1.0002.02/DOC_1&format=PDF (accessed on 2 February 2022).

- European Commission. Annex to the Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions: The European Green Deal, Brussels. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:b828d165-1c22-11ea-8c1f-01aa75ed71a1.0002.02/DOC2&format=PDF (accessed on 2 February 2022).

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A New Circular Economy Action Plan. For a Cleaner and More Competitive Europe. COM/2020/98 Final, European Commission Brussels, Belgium, 2020, 20. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1583933814386&uri=COM:2020:98:FIN (accessed on 2 February 2022).

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions a Farm to Fork Strategy for a Fair, Healthy and Environmentally Friendly Food System. COM (2020) 381 Final. 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52020DC0381 (accessed on 2 February 2022).

- Food and Agriculture Organization of the United Nations. Global Food Losses and Food Waste: Extent, Causes and Prevention. Study Conducted for the International Congress SAVE FOOD! at Interpack2011 Düsseldorf, Germany, Rome. 2011. Available online: http://www.fao.org/3/mb060e/mb060e.pdf (accessed on 2 February 2022).

- FAO—Food and Agriculture Organization of the United Nations. The State of Food and Agriculture 2019. Moving forward on Food Loss and Waste Reduction; Licence: CC BY-NC-SA 3.0 IGO; FAO: Rome, Italy, 2019; Available online: https://www.fao.org/3/ca6030en/ca6030en.pdf (accessed on 2 February 2022).

- Crippa, M.; Solazzo, E.; Guizzardi, D.; Monforti-Ferrario, F.; Tubiello, F.N.; Leip, A. Food systems are responsible for a third of global anthropogenic GHG emissions. Nat. Food 2021, 2, 198–209. [Google Scholar] [CrossRef]

- Hawkes, C.; Ruel, M. Value Chains for Nutrition: 2020 Conference Brief 4, Washington, DC, USA. 2011. Available online: https://a4nh.cgiar.org/files/2013/06/ValueChainsForNutrition.pdf (accessed on 2 February 2022).

- HLPE. Nutrition and Food Systems: A Report by the High-Level Panel of Experts on Food Security and Nutrition of the Committee on World Food Security, Rome. 2017. Available online: http://www.fao.org/3/i7846e/i7846e.pdf (accessed on 2 February 2022).

- Singh, P.; Wani, A.A.; Langowski, H.-C. (Eds.) Food Packaging Materials: Testing & Quality Assurance; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2017; ISBN 9781466559943. [Google Scholar]

- Robertson, G.L. Food Packaging: Principles and Practice, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2013; ISBN 9781439862414. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: A European Strategy for Plastics in a Circular Economy, Brussels. 2018. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:2df5d1d2-fac7-11e7-b8f5-01aa75ed71a1.0001.02/DOC_1&format=PDF (accessed on 2 February 2022).

- European Commission. ANNEXES to the Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: A European Strategy for Plastics in a Circular Economy, Brussels. 2018. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:2df5d1d2-fac7-11e7-b8f5-01aa75ed71a1.0001.02/DOC_2&format=PDF (accessed on 2 February 2022).

- HLPE. Food Losses and Waste in the Context of Sustainable Food Systems: A Report by the High-Level Panel of Experts on Food Security and Nutrition of the Committee on World Food Security, Rome. 2014. Available online: http://www.fao.org/3/i3901e/i3901e.pdf (accessed on 2 February 2022).

- Verghese, K.; Lewis, H.; Fitzpatrick, L. (Eds.) Packaging for Sustainability; Springer: London, UK, 2012; ISBN 9780857299871. [Google Scholar]

- Clune, S.; Crossin, E.; Verghese, K. Systematic review of greenhouse gas emissions for different fresh food categories. J. Clean. Prod. 2017, 140, 766–783. [Google Scholar] [CrossRef] [Green Version]

- Garnett, T. Where are the best opportunities for reducing greenhouse gas emissions in the food system (including the food chain). Food Policy 2011, 36, S23–S32. [Google Scholar] [CrossRef]

- Poore, J.; Nemecek, T. Reducing food’s environmental impacts through producers and consumers. Science 2018, 360, 987–992. [Google Scholar] [CrossRef] [Green Version]

- Miah, J.; Griffiths, A.; McNeill, R.; Halvorson, S.; Schenker, U.; Espinoza-Orias, N.; Morse, S.; Yang, A.; Sadhukhan, J. Environmental management of confectionery products: Life cycle impacts and improvement strategies. J. Clean. Prod. 2018, 177, 732–751. [Google Scholar] [CrossRef]

- Jeswani, H.K.; Burkinshaw, R.; Azapagic, A. Environmental sustainability issues in the food–energy–water nexus: Breakfast cereals and snacks. Sustain. Prod. Consum. 2015, 2, 17–28. [Google Scholar] [CrossRef]

- Konstantas, A.; Jeswani, H.K.; Stamford, L.; Azapagic, A. Environmental impacts of chocolate production and consumption in the UK. Food Res. Int. 2018, 106, 1012–1025. [Google Scholar] [CrossRef] [Green Version]

- Konstantas, A.; Stamford, L.; Azapagic, A. Evaluating the environmental sustainability of cakes. Sustain. Prod. Consum. 2019, 19, 169–180. [Google Scholar] [CrossRef]

- Konstantas, A.; Stamford, L.; Azapagic, A. Evaluation of environmental sustainability of biscuits at the product and sectoral levels. J. Clean. Prod. 2019, 230, 1217–1228. [Google Scholar] [CrossRef]

- Noya, L.I.; Vasilaki, V.; Stojceska, V.; González-García, S.; Kleynhans, C.; Tassou, S.; Moreira, M.T.; Katsou, E. An environmental evaluation of food supply chain using life cycle assessment: A case study on gluten free biscuit products. J. Clean. Prod. 2018, 170, 451–461. [Google Scholar] [CrossRef]

- Recanati, F.; Marveggio, D.; Dotelli, G. From beans to bar: A life cycle assessment towards sustainable chocolate supply chain. Sci. Total Environ. 2018, 613–614, 1013–1023. [Google Scholar] [CrossRef] [PubMed]

- Belitz, H.-D.; Grosch, W.; Schieberle, P. Cereals and Cereal Products. In Food Chemistry, 3rd ed.; Belitz, H.-D., Grosch, W., Schieberle, P., Eds.; Springer: Berlin/Heidelberg, Germany, 2004; pp. 673–746. ISBN 978-3-540-40818-5. [Google Scholar]

- Statista. Retail Sales of Bread Sold in Europe from 2012 to 2021: (in Million U.S. Dollars). Available online: https://www.statista.com/statistics/782120/bread-retail-sales-europe/ (accessed on 2 February 2022).

- Caobisco. Facts and Figures: Key Data of the European Sector (EU27 + Switzerland and Norway). Available online: https://caobisco.eu/facts/ (accessed on 17 January 2022).

- Soroka, W. Fundamentals of Packaging Technology, 5th ed.; Institute of Packaging Professional: Herndon, WV, USA, 2014; ISBN 0615709346. [Google Scholar]

- Kaßmann, M. Grundlagen der Verpackung: Leitfaden für die Fächerübergreifende Verpackungsausbildung; DIN Deutsches Institut für Normung: Berlin, Germany, 2014; ISBN 3410241922. [Google Scholar]

- Wani, A.A.; Singh, P.; Langowski, H.-C. Food Technologies: Packaging. In Encyclopedia of Food Safety; Motarjemi, Y., Ed.; Elsevier Science: Burlington, UK, 2014; ISBN 978-0-12-378613-5. [Google Scholar]

- Bauer, A.-S.; Tacker, M.; Uysal-Unalan, I.; Cruz, R.M.S.; Varzakas, T.; Krauter, V. Recyclability and Redesign Challenges in Multilayer Flexible Food Packaging—A Review. Foods 2021, 10, 2702. [Google Scholar] [CrossRef] [PubMed]

- Dahlbo, H.; Poliakova, V.; Mylläri, V.; Sahimaa, O.; Anderson, R. Recycling potential of post-consumer plastic packaging waste in Finland. Waste Manag. 2018, 71, 52–61. [Google Scholar] [CrossRef] [PubMed]

- Ceflex. Designing for a Circular Economy: Recyclability of Polylefin-Based Flexible Packaging. 2020. Available online: https://guidelines.ceflex.eu (accessed on 16 February 2021).

- FH Campus Wien; Circular Analytics TK GmbH. Circular Packaging Design Guideline: Empfehlungen für Die Gestaltung Recyclinggerechter Verpackungen, Vienna. 2021. Available online: https://www.fh-campuswien.ac.at/fileadmin/redakteure/Forschung/FH-Campus-Wien_Circular-Packaging-Design-Guideline_V04_DE.pdf (accessed on 9 February 2022).

- Bergmair, J.; Washüttl, M.; Wepner, B. Prüfpraxis für Kunststoffverpackungen: Lebensmittel-, Pharma- und Kosmetikverpackungen; Behr: Hamburg, Germany, 2012; ISBN 9783899479072. [Google Scholar]

- Regulation (EC) No 1935/2004 of the European Parliament and of the Council of 27 October 2004 on Materials and Articles Intended to Come into Contact with Food and Repealing Directives 80/590/EEC and 89/109/EEC; European Parliament, Council of the European Union: Brussels, Belgium, 2004.

- Han, J.H. (Ed.) Innovations in Food Packaging; Elsevier Ltd.: Amsterdam, The Netherlands, 2005; ISBN 978-0-12-311632-1. [Google Scholar]

- Campbell-Platt, G. (Ed.) Food Science and Technology, 2nd ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2017; ISBN 9780470673423. [Google Scholar]

- Marsh, K.; Bugusu, B. Food Packaging? Roles, Materials, and Environmental Issues. J. Food Sci. 2007, 72, R39–R55. [Google Scholar] [CrossRef]

- ISO 5801:2007 Industrial Fans Performance (Testing Using Standardized Airways). Available online: https://www.iso.org/obp/ui/#iso:std:iso:5801:ed-2:v1:en (accessed on 2 February 2022).

- Detzel, A.; Bodrogi, F.; Kauertz, B.; Bick, C.; Welle, F.; Schmid, M.; Schmitz, K.; Müller, K.; Käb, H. Biobasierte Kunststoffe als Verpackung von Lebensmitteln; Bundesministerium für Ernährung und Landwirtschaft: Heidelberg, Germany, 2018; Available online: https://www.ifeu.de/fileadmin/uploads/Endbericht-Bio-LVp_20180612.pdf (accessed on 27 September 2021).

- Carlsson, D.J.; Wiles, D.M. Composites, Fabrication to Die Design. In Encyclopedia of Polymer Science and Engineering, 2nd ed.; Mark, H., Bikales, N.M., Overberger, C.G., Menges, G., Eds.; John Wiley & Sons: New York, NY, USA, 1986; p. 665. [Google Scholar]

- Fellows, P. Food Processing Technology: Principles and Practice, 3rd ed.; Woodhead Publishing Limited, CRC Press: Cambridge, UK, 2009; ISBN 1615830413. [Google Scholar]

- Yam, K.L. (Ed.) The Wiley Encyclopedia of Packaging Technology, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2009; ISBN 0470087048. [Google Scholar]

- Commission Regulation (EU) No 10/2011 of 14 January 2011 on Plastic Materials and Articles Intended to Come into Contact with Food Text with EEA Relevance; European Commission: Brussels, Belgium, 2011.

- Commission Regulation (EC) No 2023/2006 of 22 December 2006 on Good Manufacturing Practice for Materials and Articles Intended to Come into Contact with Food (Text with EEA Relevance); European Commission: Brussels, Belgium, 2006.

- BFR. Database BfR Recommendations on Food Contact Materials: Recommendations. Available online: https://bfr.ble.de/kse/faces/DBEmpfehlung_en.jsp (accessed on 3 February 2022).

- EDQM Council of Europe. Food Contact Materials and Articles. Available online: https://www.edqm.eu/en/food-contact-materials-and-articles (accessed on 11 October 2021).

- SR 817. 023.21—Verordnung des EDI vom 16. Dezember 2016 über Materialien und Gegenstände, die Dazu Bestimmt Sind, mit Lebensmitteln in Berührung zu Kommen (Bedarfsgegenständeverordnung): Bedarfsgegenständeverordnung; Eidgenössische Departement des Innern: Switzerland, 2016. [Google Scholar]

- European Printing Ink Association EuPIA. EuPIA Guideline on Printing Inks Applied to Food Contact Materials. 2020. Available online: https://www.eupia.org/fileadmin/Documents/Food_contact_material/2020-12-22_EuPIA_Guideline_on_Printing_Inks_applied_to_Food_Contact_Materials.pdf (accessed on 3 February 2022).

- Barone, C.; Bolzoni, L.; Caruso, G.; Salvatore, P. (Eds.) Food Packaging Hygiene; Springer: Berlin/Heidelberg, Germany, 2015; ISBN 9783319148267. [Google Scholar]

- Smith, J.P.; Daifas, D.P.; El-Khoury, W.; Koukoutsis, J.; El-Khoury, A. Shelf Life and Safety Concerns of Bakery Products—A Review. Crit. Rev. Food Sci. Nutr. 2004, 44, 19–55. [Google Scholar] [CrossRef]

- Wolf, B. Confectionery and Sugar-Based Foods. Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2016; ISBN 978-0-08-100596-5. [Google Scholar]

- Subramaniam, P. The Stability and Shelf Life of Confectionery Products. In Stability and Shelf Life of Food, 2nd ed.; Subramaniam, P., Wareing, P., Eds.; Elsevier Science & Technology: Cambridge, UK, 2016; ISBN 9780081004364. [Google Scholar]

- Lusas, E.W.; Rooney, L.W. (Eds.) Snack Foods Processing; CRC Press LLC: Boca Raton, FL, USA, 2001; ISBN 1566769329. [Google Scholar]

- European Commission. Guidance Document Describing the Food Categories in Part E of Annex II to Regulation (EC) No 1333/2008 on Food Additives. 2017. Available online: https://ec.europa.eu/food/system/files/2017-09/fs_food-improvement-agents_guidance_1333-2008_annex-2.pdf (accessed on 4 February 2022).

- FAO. Cereal Supply and Demand Brief. Available online: http://www.fao.org/worldfoodsituation/csdb/en/ (accessed on 4 October 2021).

- EUROSTAT. Prodcom Annual Data. 2020. Available online: https://ec.europa.eu/eurostat/web/prodcom/data/excel-files-nace-rev.2 (accessed on 4 October 2021).

- Regulation (EC) No 178/2002 of the European Parliament and of the Council of 28 January 2002 Laying Down the General Principles and Requirements of Food Law, Establishing the European Food Safety Authority and Laying Down Procedures in Matters of Food Safety; EC: Brussels, Belgium, 2002.

- Regulation (EC) No 1331/2008 of the European Parliament and of the Council of 16 December 2008 Establishing a Common Authorisation Procedure for Food Additives, Food Enzymes and Food Flavourings (Text with EEA Relevance); EC: Brussels, Belgium, 2008.

- Regulation (EU) No 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the Provision of Food Information to Consumers, Amending Regulations (EC) No 1924/2006 and (EC) No 1925/2006 of the European Parliament and of the Council, and Repealing Commission Directive 87/250/EEC, Council Directive 90/496/EEC, Commission Directive 1999/10/EC, Directive 2000/13/EC of the European Parliament and of the Council, Commission Directives 2002/67/EC and 2008/5/EC and Commission Regulation (EC) No 608/2004 Text with EEA relevance; EC: Brussels, Belgium, 2011.

- Commission Regulation (EC) No 2073/2005 of 15 November 2005 on Microbiological Criteria for Foodstuffs (Text with EEA Relevance); EC: Brussels, Belgium, 2005.

- Regulation (EC) No 852/2004 of the European Parliament and of the Council of 29 April 2004 on the Hygiene of Foodstuffs; EC: Brussels, Belgium, 2004.

- Robertson, G.L. (Ed.) Food Packaging and Shelf Life: A Practical Guide; CRC Press: Boca Raton, FL, USA, 2009; ISBN 9781420078459. [Google Scholar]

- Subramaniam, P.; Wareing, P. (Eds.) Stability and Shelf Life of Food, 2nd ed.; Elsevier Science & Technology: Cambridge, UK, 2016; ISBN 9780081004364. [Google Scholar]

- Kong, F.; Singh, R.P. Chemical Deterioration and Physical Instability of Foods and Beverages. In Stability and Shelf Life of Food, 2nd ed.; Subramaniam, P., Wareing, P., Eds.; Elsevier Science & Technology: Cambridge, UK, 2016; pp. 43–76. ISBN 9780081004364. [Google Scholar]

- Fabra, M.J.; Talens, P.; Moraga, G.; Martínez-Navarrete, N. Sorption isotherm and state diagram of grapefruit as a tool to improve product processing and stability. J. Food Eng. 2009, 93, 52–58. [Google Scholar] [CrossRef]

- Lianou, A.; Panagou, E.Z.; Nychas, G.-J.E. Microbiological spoilage of foods and beverages. In The Stability and Shelf Life of Food, 2nd ed.; Subramaniam, P., Ed.; Woodhead Publishing: Cambridge, UK, 2016; pp. 3–42. [Google Scholar] [CrossRef]

- Schmidt, S.J.; Fontana, A.J. Appendix E: Water Activity Values of Select Food Ingredients and Products. In Water Activity in Foods: Fundamentals and Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007; pp. 407–420. [Google Scholar]

- Ergun, R.; Lietha, R.; Hartel, R.W. Moisture and Shelf Life in Sugar Confections. Crit. Rev. Food Sci. Nutr. 2010, 50, 162–192. [Google Scholar] [CrossRef]

- Bussiere, G.; Serpelloni, M. Confectionery and Water Activity Determination of AW by Calculation. In Properties of Water in Foods: In Relation to Quality and Stability; Simatos, D., Multon, J.L., Eds.; Springer: Dordrecht, The Netherlands, 1985; pp. 627–645. ISBN 978-94-010-8756-8. [Google Scholar]

- Subramaniam, P.J. Shelf-Life Prediction and Testing. In Science and Technology of Enrobed and Filled Chocolate, Confectionery and Bakery Products; Talbot, G., Ed.; CRC Press: Boca Raton, FL, USA, 2009; pp. 233–254. ISBN 9781845693909. [Google Scholar]

- Cauvain, S.P.; Young, L.S. Bakery Food Manufacture and Quality: Water Control and Effects, 2nd ed.; Wiley-Blackwell: Chichester, UK, 2008; ISBN 9781444301083. [Google Scholar]

- Dury-Brun, C.; Jury, V.; Guillard, V.; Desobry, S.; Voilley, A.; Chalier, P. Water barrier properties of treated-papers and application to sponge cake storage. Food Res. Int. 2006, 39, 1002–1011. [Google Scholar] [CrossRef]

- Davidson, I. Biscuit, Cookie and Cracker Production: Process, Production and Packaging Equipment, 2nd ed.; Academic Press, Elsevier: Amsterdam, The Netherlands, 2018; ISBN 0128155795. [Google Scholar]

- Pekmez, H. Properties of Flour used in Flat Bread (Gaziantep pita) Production. Turk. J. Agric. Food Sci. Technol. 2019, 7, 209–213. [Google Scholar] [CrossRef] [Green Version]

- Taoukis, P.; Labuza, T.; Sam Saguy, I. Kinetics of Food Deterioration and Shelf-Life Prediction. Handbook of Food Engineering Practice; CRC Press: New York, NY, USA, 1997. [Google Scholar]

- Costa, A.L.C. Combination of Process Technology and Packaging Conditions to Improve the Shelf Life of Fresh Pasta. J. Food Process. Technol. 2014, 5. [Google Scholar] [CrossRef] [Green Version]

- Machálková, L.; Hřivna, L.; Nedomová, Š.; Jůzl, M. The effect of storage temperature on the quality and formation of blooming defects in chocolate confectionery. Potravinarstvo Slovak J. Food Sci. 2015, 9. [Google Scholar] [CrossRef]

- Jaroni, D.; Ravishankar, S.; Juneja, V. Microbiology of Ready-to-Eat Foods. In Ready-to-Eat Foods, 1st ed.; Hwang, A., Huang, L., Eds.; CRC Press: Boca Raton, FL, USA, 2010; pp. 1–60. [Google Scholar] [CrossRef]

- Valerio, F.; de Bellis, P.; Di Biase, M.; Lonigro, S.L.; Giussani, B.; Visconti, A.; Lavermicocca, P.; Sisto, A. Diversity of spore-forming bacteria and identification of Bacillus amyloliquefaciens as a species frequently associated with the ropy spoilage of bread. Int. J. Food Microbiol. 2012, 156, 278–285. [Google Scholar] [CrossRef] [PubMed]

- Pepe, O.; Blaiotta, G.; Moschetti, G.; Greco, T.; Villani, F. Rope-producing strains of Bacillus spp. from wheat bread and strategy for their control by lactic acid bacteria. Appl. Environ. Microbiol. 2003, 69, 2321–2329. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Galić, K.; Gabrić, D.; Ćurić, D. Packaging and the Shelf Life of Bread; Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Omedi, J.O.; Huang, W.; Zhang, B.; Li, Z.; Zheng, J. Advances in present-day frozen dough technology and its improver and novel biotech ingredients development trends—A review. Cereal. Chem. 2018, 96, 34–56. [Google Scholar] [CrossRef] [Green Version]

- Neira, D.P. Energy sustainability of Ecuadorian cacao export and its contribution to climate change. A case study through product life cycle assessment. J. Clean. Prod. 2016, 112, 2560–2568. [Google Scholar] [CrossRef]

- Büsser, S.; Jungbluth, N. LCA of Chocolate Packed in Aluminium Foil Based Packaging, Switzerland. 2009. Available online: http://www.alufoil.org/files/alufoil/sustainability/ESU_-_Chocolate_2009_-_Exec_Sum.pdf (accessed on 4 February 2022).

- Boakye-Yiadom, K.; Duca, D.; Pedretti, E.F.; Ilari, A. Environmental Performance of Chocolate Produced in Ghana Using Life Cycle Assessment. Sustainability 2021, 13, 6155. [Google Scholar] [CrossRef]

- Pérez-Neira, D.; Copena, D.; Armengot, L.; Simón, X. Transportation can cancel out the ecological advantages of producing organic cacao: The carbon footprint of the globalized agrifood system of ecuadorian chocolate. J. Environ. Manag. 2020, 276, 111306. [Google Scholar] [CrossRef] [PubMed]

- Bianchi, F.R.; Moreschi, L.; Gallo, M.; Vesce, E.; Del Borghi, A. Environmental analysis along the supply chain of dark, milk and white chocolate: A life cycle comparison. Int. J. Life Cycle Assess. 2020, 26, 807–821. [Google Scholar] [CrossRef]

- PlascticsEurope. Plasctics—The Facts. 2020. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-facts-2020/ (accessed on 19 January 2022).

- Nilsson, K.; Sund, V.; Florén, B. Environmental Impact of the Consumption of Sweets, Crisps and Soft Drinks, Copenhagen. 2011. Available online: http://www.diva-portal.org/smash/get/diva2:702819/FULLTEXT01.pdf (accessed on 17 February 2022).

- Morris, B. Examples of Flexible Packaging Film Structures. The Science and Technology of Flexible Packaging; Elsevier: Amsterdam, The Netherlands, 2017; pp. 697–709. ISBN 9780323242738. [Google Scholar]

- Kägi, T.; Wettstein, D.; Dinkel, F. Comparing rice products: Confidence intervals as a solution to avoid wrong conclusions in communicating carbon footprints. In Proceedings of the 7th International Conference on Life Cycle Assessment in the Agrifood Sector, Bari, Italy, 24 September 2010; pp. 229–233. [Google Scholar]

- Nunes, F.A.; Seferin, M.; Maciel, V.G.; Flôres, S.H.; Ayub, M.A.Z. Life cycle greenhouse gas emissions from rice production systems in Brazil: A comparison between minimal tillage and organic farming. J. Clean. Prod. 2016, 139, 799–809. [Google Scholar] [CrossRef]

- Urbelis, J.H.; Cooper, J.R. Migration of food contact substances into dry foods: A review. Food Addit. Contam. Part A 2021, 38, 1044–1073. [Google Scholar] [CrossRef]

- Forsido, S.F.; Welelaw, E.; Belachew, T.; Hensel, O. Effects of storage temperature and packaging material on physico-chemical, microbial and sensory properties and shelf life of extruded composite baby food flour. Heliyon 2021, 7, e06821. [Google Scholar] [CrossRef] [PubMed]

- Monahan, E.J. Packaging of ready-to-eat breakfast cereals. Cereal Foods World 1988, 33, 215–221. [Google Scholar]

- Sakamaki, C.; Gray, J.I.; Harte, B.R. The influence of selected barriers and oxygen absorbers on the stability of oat cereal during storage. J. Packag. Technol. 1988, 2, 98–103. [Google Scholar]

- Sieti, N.; Rivera, X.C.S.; Stamford, L.; Azapagic, A. Environmental impacts of baby food: Ready-made porridge products. J. Clean. Prod. 2018, 212, 1554–1567. [Google Scholar] [CrossRef] [Green Version]

- Cimini, A.; Cibelli, M.; Moresi, M. Cradle-to-grave carbon footprint of dried organic pasta: Assessment and potential mitigation measures. J. Sci. Food Agric. 2019, 99, 5303–5318. [Google Scholar] [CrossRef]

- Röös, E.; Sundberg, C.; Hansson, P.-A. Uncertainties in the carbon footprint of refined wheat products: A case study on Swedish pasta. Int. J. Life Cycle Assess. 2011, 16, 338–350. [Google Scholar] [CrossRef]

- Saget, S.; Costa, M.P.; Barilli, E.; de Vasconcelos, M.W.; Santos, C.S.; Styles, D.; Williams, M. Substituting wheat with chickpea flour in pasta production delivers more nutrition at a lower environmental cost. Sustain. Prod. Consum. 2020, 24, 26–38. [Google Scholar] [CrossRef]

- Nette, A.; Wolf, P.; Schlüter, O.; Meyer-Aurich, A. A Comparison of Carbon Footprint and Production Cost of Different Pasta Products Based on Whole Egg and Pea Flour. Foods 2016, 5, 17. [Google Scholar] [CrossRef] [Green Version]

- Park, C.; Szabo, R.; Jean, A. A Survey of Wet Pasta Packaged Under a C02:N2 (20:80) Mixture for Staphylococci and their Enterotoxins. Can. Inst. Food Sci. Technol. J. 1988, 21, 109–111. [Google Scholar] [CrossRef]

- Sanguinetti, A.; Del Caro, A.; Mangia, N.; Secchi, N.; Catzeddu, P.; Piga, A. Quality Changes of Fresh Filled Pasta During Storage: Influence of Modified Atmosphere Packaging on Microbial Growth and Sensory Properties. Food Sci. Technol. Int. 2011, 17, 23–29. [Google Scholar] [CrossRef]

- Rachtanapun, P.; Tangnonthaphat, T. Effects of packaging types and storage temperatures on the shelf life of fresh rice noodles under vacuum conditions. Chiang Mai J. Sci. 2011, 38, 579–589. [Google Scholar]

- Espinoza-Orias, N.; Stichnothe, H.; Azapagic, A. The carbon footprint of bread. Int. J. Life Cycle Assess. 2011, 16, 351–365. [Google Scholar] [CrossRef]

- Jensen, J.K.; Arlbjørn, J.S. Product carbon footprint of rye bread. J. Clean. Prod. 2014, 82, 45–57. [Google Scholar] [CrossRef]

- Svanes, E.; Oestergaard, S.; Hanssen, O.J. Effects of Packaging and Food Waste Prevention by Consumers on the Environmental Impact of Production and Consumption of Bread in Norway. Sustainability 2018, 11, 43. [Google Scholar] [CrossRef] [Green Version]

- Williams, H.; Wikström, F. Environmental impact of packaging and food losses in a life cycle perspective: A comparative analysis of five food items. J. Clean. Prod. 2011, 19, 43–48. [Google Scholar] [CrossRef]

- Korsaeth, A.; Jacobsen, A.Z.; Roer, A.-G.; Henriksen, T.M.; Sonesson, U.; Bonesmo, H.; Skjelvåg, A.O.; Strømman, A.H. Environmental life cycle assessment of cereal and bread production in Norway. Acta Agric. Scand. Sect. A Anim. Sci. 2012, 62, 242–253. [Google Scholar] [CrossRef] [Green Version]

- Cauvain, S.P.; Young, L.S. Chemical and physical deterioration of bakery products. In Chemical Deterioration and Physical Instability of Food and Beverages; Skibsted, L., Risbo, J., Andersen, M., Eds.; Woodhead Publishing: Washington, DC, USA, 2010; pp. 381–412. ISBN 9781845699260. [Google Scholar]

- Chinnadurai, K.; Sequeira, V. Packaging of Cereals, Snacks, and Confectionery. Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2016; ISBN 978-0-08-100596-5. [Google Scholar]

- Qian, M.; Liu, D.; Zhang, X.; Yin, Z.; Ismail, B.B.; Ye, X.; Guo, M. A review of active packaging in bakery products: Applications and future trends. Trends Food Sci. Technol. 2021, 114, 459–471. [Google Scholar] [CrossRef]

- Kuswandi, B. Active and intelligent packaging, safety, and quality controls. In Fresh-Cut Fruits and Vegetables: Technologies and Mechanisms for Safety Control; Siddiqui, M.W., Ed.; Elsevier Science & Technology: San Diego, CA, USA, 2020; pp. 243–294. ISBN 9780128161845. [Google Scholar]

- Mexis, S.; Badeka, A.; Riganakos, K.; Kontominas, M. Effect of active and modified atmosphere packaging on quality retention of dark chocolate with hazelnuts. Innov. Food Sci. Emerg. Technol. 2010, 11, 177–186. [Google Scholar] [CrossRef]

- Lee, D.S.; Paik, H.D.; Im, G.H.; Yeo, I.H. Shelf life extension of Korean fresh pasta by modified atmosphere packaging. J. Food Sci. Nutr. 2001, 6, 240–243. [Google Scholar]

- Sanguinetti, A.M.; Del Caro, A.; Scanu, A.; Fadda, C.; Milella, G.; Catzeddu, P.; Piga, A. Extending the shelf life of gluten-free fresh filled pasta by modified atmosphere packaging. LWT 2016, 71, 96–101. [Google Scholar] [CrossRef]

- Hempel, A.W.; O’Sullivan, M.G.; Papkovsky, D.B.; Kerry, J.P. Use of smart packaging technologies for monitoring and extending the shelf-life quality of modified atmosphere packaged (MAP) bread: Application of intelligent oxygen sensors and active ethanol emitters. Eur. Food Res. Technol. 2013, 237, 117–124. [Google Scholar] [CrossRef]

- Jensen, S.; Oestdal, H.; Clausen, M.R.; Andersen, M.L.; Skibsted, L.H. Oxidative stability of whole wheat bread during storage. LWT 2011, 44, 637–642. [Google Scholar] [CrossRef]

- Khoshakhlagh, K.; Hamdami, N.; Shahedi, M.; Le-Bail, A. Quality and microbial characteristics of part-baked Sangak bread packaged in modified atmosphere during storage. J. Cereal Sci. 2014, 60, 42–47. [Google Scholar] [CrossRef]

- Degirmencioglu, N.; Göcmen, D.; Inkaya, A.N.; Aydin, E.; Guldas, M.; Gonenc, S. Influence of modified atmosphere packaging and potassium sorbate on microbiological characteristics of sliced bread. J. Food Sci. Technol. 2010, 48, 236–241. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rodríguez, M.; Medina, L.M.; Jordano, R. Effect of modified atmosphere packaging on the shelf life of sliced wheat flour bread. Food Nahr. 2000, 44, 247–252. [Google Scholar] [CrossRef]

- Del Nobile, M.A.; Martoriello, T.; Cavella, S.; Giudici, P.; Masi, P. Shelf life extension of durum wheat bread. Ital. J. Food Sci. 2003, 15, 383–394. [Google Scholar]

- Silva, A.S.; Hernández, J.L.; Losada, P.P. Modified atmosphere packaging and temperature effect on potato crisps oxidation during storage. Anal. Chim. Acta 2004, 524, 185–189. [Google Scholar] [CrossRef]

- Del Nobile, M. Packaging design for potato chips. J. Food Eng. 2001, 47, 211–215. [Google Scholar] [CrossRef]

- Latou, E.; Mexis, S.; Badeka, A.; Kontominas, M. Shelf life extension of sliced wheat bread using either an ethanol emitter or an ethanol emitter combined with an oxygen absorber as alternatives to chemical preservatives. J. Cereal Sci. 2010, 52, 457–465. [Google Scholar] [CrossRef]

- Luz, C.; Calpe, J.; Saladino, F.; Luciano, F.B.; Fernandez-Franzón, M.; Mañes, J.; Meca, G. Antimicrobial packaging based on ɛ-polylysine bioactive film for the control of mycotoxigenic fungi in vitro and in bread. J. Food Process. Preserv. 2017, 42, e13370. [Google Scholar] [CrossRef]

- Lee, J.; Park, M.A.; Yoon, C.S.; Na, J.H.; Han, J. Characterization and Preservation Performance of Multilayer Film with Insect Repellent and Antimicrobial Activities for Sliced Wheat Bread Packaging. J. Food Sci. 2019, 84, 3194–3203. [Google Scholar] [CrossRef] [PubMed]

- Jha, P. Effect of grapefruit seed extract ratios on functional properties of corn starch-chitosan bionanocomposite films for active packaging. Int. J. Biol. Macromol. 2020, 163, 1546–1556. [Google Scholar] [CrossRef] [PubMed]

- Srisa, A.; Harnkarnsujarit, N. Antifungal films from trans-cinnamaldehyde incorporated poly(lactic acid) and poly(butylene adipate-co-terephthalate) for bread packaging. Food Chem. 2020, 333, 127537. [Google Scholar] [CrossRef]

- Suwanamornlert, P.; Kerddonfag, N.; Sane, A.; Chinsirikul, W.; Zhou, W.; Chonhenchob, V. Poly(lactic acid)/poly(butylene-succinate-co-adipate) (PLA/PBSA) blend films containing thymol as alternative to synthetic preservatives for active packaging of bread. Food Packag. Shelf Life 2020, 25, 100515. [Google Scholar] [CrossRef]

- Passarinho, A.T.P.; Dias, N.F.; Camilloto, G.P.; Cruz, R.S.; Otoni, C.; Moraes, A.R.F.; Soares, N.D.F.F. Sliced Bread Preservation through Oregano Essential Oil-Containing Sachet. J. Food Process Eng. 2014, 37, 53–62. [Google Scholar] [CrossRef]

- Otoni, C.; Pontes, S.F.O.; Medeiros, E.A.A.; Soares, N.D.F.F. Edible Films from Methylcellulose and Nanoemulsions of Clove Bud (Syzygium aromaticum) and Oregano (Origanum vulgare) Essential Oils as Shelf Life Extenders for Sliced Bread. J. Agric. Food Chem. 2014, 62, 5214–5219. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.; Schaich, K.; Chen, X.; Yam, K. Antioxidant Effects of Sesamol Released from Polymeric Films on Lipid Oxidation in Linoleic Acid and Oat Cereal. Packag. Technol. Sci. 2012, 26, 31–38. [Google Scholar] [CrossRef]

- Janjarasskul, T.; Tananuwong, K.; Kongpensook, V.; Tantratian, S.; Kokpol, S. Shelf life extension of sponge cake by active packaging as an alternative to direct addition of chemical preservatives. LWT 2016, 72, 166–174. [Google Scholar] [CrossRef]

- Wells, J.H.; Singh, R.P. Application of Time-Temperature Indicators in Monitoring Changes in Quality Attributes of Perishable and Semiperishable Foods. J. Food Sci. 1988, 53, 148–152. [Google Scholar] [CrossRef]

- Vargas, M.C.A.; Simsek, S. Clean Label in Bread. Foods 2021, 10, 2054. [Google Scholar] [CrossRef]

- Leistner, L.; Gorris, L.G. Food preservation by hurdle technology. Trends Food Sci. Technol. 1995, 6, 41–46. [Google Scholar] [CrossRef]

- Senhofa, S.; Straumite, E.; Sabovics, M.; Klava, D.; Galoburda, R.; Rakcejeva, T. The effect of packaging type on quality of cereal muesli during storage. Agron. Res. 2015, 13, 1064–1073. [Google Scholar]

- Cozmuta, A.M.; Peter, A.; Cozmuta, L.M.; Nicula, C.; Crisan, L.; Baia, L.; Turila, A. Active Packaging System Based on Ag/TiO2Nanocomposite Used for Extending the Shelf Life of Bread. Chemical and Microbiological Investigations. Packag. Technol. Sci. 2014, 28, 271–284. [Google Scholar] [CrossRef]

- Fik, M.; Surówka, K.; Maciejaszek, I.; Macura, M.; Michalczyk, M. Quality and shelf life of calcium-enriched wholemeal bread stored in a modified atmosphere. J. Cereal Sci. 2012, 56, 418–424. [Google Scholar] [CrossRef]

- Smith, J.; Ooraikul, B.; Koersen, W.; Jackson, E.; Lawrence, R. Novel approach to oxygen control in modified atmosphere packaging of bakery products. Food Microbiol. 1986, 3, 315–320. [Google Scholar] [CrossRef]

- Lee, D.S. Modified Atmosphere Packaging of Foods: Principles and Applications; John Wiley & Sons Inc, Institute of Food Technologists: Hoboken, NJ, USA, 2021; ISBN 9781119530770. [Google Scholar]

- Lucas, J. Integrating MAP with new germicidal techniques. In Novel Food Packaging Techniques; Ahvenainen, R., Ed.; CRC Press: Boca Raton, FL, USA, 2003; ISBN 128037294X. [Google Scholar]

- Fernandez, U.; Vodovotz, Y.; Courtney, P.; Pascall, M.A. Extended Shelf Life of Soy Bread Using Modified Atmosphere Packaging. J. Food Prot. 2006, 69, 693–698. [Google Scholar] [CrossRef] [PubMed]

- Heinrich, V.; Zunabovic, M.; Nehm, L.; Bergmair, J.; Kneifel, W. Influence of argon modified atmosphere packaging on the growth potential of strains of Listeria monocytogenes and Escherichia coli. Food Control 2016, 59, 513–523. [Google Scholar] [CrossRef]

- European Parliament and Council Directive No 95/2/EC of 20 February 1995 on Food Additives Other than Colours and Sweeteners; EU Parliament: Brussels, Belgium, 1995.

- Kita, A.; Lachowicz, S.; Filutowska, P. Effects of package type on the quality of fruits and nuts panned in chocolate during long-time storage. LWT 2020, 125, 109212. [Google Scholar] [CrossRef]

- Tiekstra, S.; Dopico-Parada, A.; Koivula, H.; Lahti, J.; Buntinx, M. Holistic Approach to a Successful Market Implementation of Active and Intelligent Food Packaging. Foods 2021, 10, 465. [Google Scholar] [CrossRef]

- Actinpak. Cost Action FP1405. Available online: http://www.actinpak.eu/ (accessed on 4 February 2022).

- AIPIA. Active & Intelligent Packaging Industry Association. Available online: https://www.aipia.info/ (accessed on 4 February 2022).

- Commission Regulation (EC) No 450/2009 of 29 May 2009 on Active and Intelligent Materials and Articles Intended to Come into Contact with Food (Text with EEA Relevance); EC: Brussels, Belgium, 2009.

- Topuza, F.; Uyarb, T. Antioxidant, antibacterial and antifungal electrospun nanofibers for food packaging applications. Food Res. Int. 2019, 130, 108927. [Google Scholar] [CrossRef]

- Callaghan, K.A.O.; Kerry, J.P. Consumer attitudes towards the application of smart packaging technologies to cheese products. Food Packag. Shelf Life 2016, 9, 1–9. [Google Scholar] [CrossRef]

- Agriopoulou, S. Active packaging for food applications. EC Nutr. 2016, 6, 86–87. [Google Scholar]

- Conte, A.; Angiolillo, L.; Mastromatteo, M.; Del Nobile, M.A. Technological Options of Packaging to Control Food Quality. In Food Industry; Muzzalupo, I., Ed.; InTech: Houston, TX, USA, 2013. [Google Scholar] [CrossRef] [Green Version]

- Kerry, J. Smart Packaging Technologies for fast Moving Consumer Goods; John Wiley: Hoboken, NJ, USA, 2008; ISBN 9780470753699. [Google Scholar]

- Wilson, C.L. (Ed.) Intelligent and Active Packaging for Fruits and Vegetables; CRC Press: Boca Raton, FL, USA, 2007; ISBN 0849391660. [Google Scholar]

- Smithers. Future of Active and Intelligent Packaging|Market Reports and Trends|Smithers. Available online: https://www.smithers.com/services/market-reports/packaging/the-future-of-active-and-intelligent-packaging (accessed on 19 January 2022).

- Vilela, C.; Kurek, M.; Hayouka, Z.; Röcker, B.; Yildirim, S.; Antunes, M.D.C.; Nilsen-Nygaard, J.; Pettersen, M.K.; Freire, C.S.R. A concise guide to active agents for active food packaging. Trends Food Sci. Technol. 2018, 80, 212–222. [Google Scholar] [CrossRef]

- Yildirim, S.; Röcker, B. Chapter 7—Active Packaging. In Nanomaterials for Food Packaging: Properties, Processing and Regulation; Cerqueira, M.A.P.R., Lagaron, J.M., Pastrana Castro, L.M., de Oliveira Soares Vicente, A.A.M., Eds.; Elsevier: Saint Louis, MO, USA, 2018; pp. 173–202. ISBN 978-0-323-51271-8. [Google Scholar]

- Berryman, P. Advances in Food and Beverage Labelling: Information and Regulations; Woodhead Publishing: London, UK, 2014; ISBN 9781782420934. [Google Scholar]

- Wikström, F.; Verghese, K.; Auras, R.; Olsson, A.; Williams, H.; Wever, R.; Grönman, K.; Pettersen, M.K.; Møller, H.; Soukka, R. Packaging Strategies That Save Food: A Research Agenda for 2030. J. Ind. Ecol. 2018, 23, 532–540. [Google Scholar] [CrossRef]

- Directive 2012/19/EU of the European Parliament and of the Council of 4 July 2012 on Waste Electrical and Electronic Equipment (WEEE) Text with EEA Relevance; EU: Brussels, Belgium, 2012.

- Licciardello, F. Packaging, blessing in disguise. Review on its diverse contribution to food sustainability. Trends Food Sci. Technol. 2017, 65, 32–39. [Google Scholar] [CrossRef]

- Salminen, A.; Latva-Kala, K.; Randell, K.; Hurme, E.; Linko, P.; Ahvenainen, R. The effect of ethanol and oxygen absorption on the shelf-life of packed sliced rye bread. Packag. Technol. Sci. 1996, 9, 29–42. [Google Scholar] [CrossRef]

- Upasen, S.; Wattanachai, P. Packaging to prolong shelf life of preservative-free white bread. Heliyon 2018, 4, e00802. [Google Scholar] [CrossRef] [Green Version]

- Antunez, P.D.; Omary, M.B.; Rosentrater, K.; Pascall, M.; Winstone, L. Effect of an Oxygen Scavenger on the Stability of Preservative-Free Flour Tortillas. J. Food Sci. 2011, 77, S1–S9. [Google Scholar] [CrossRef]

- Balaguer, M.P.; Lopez-Carballo, G.; Catala, R.; Gavara, R.; Hernandez-Munoz, P. Antifungal properties of gliadin films incorporating cinnamaldehyde and application in active food packaging of bread and cheese spread foodstuffs. Int. J. Food Microbiol. 2013, 166, 369–377. [Google Scholar] [CrossRef]

- Chang, Y.; Lee, S.-H.; Na, J.H.; Chang, P.-S.; Han, J. Protection of Grain Products from Sitophilus oryzae (L.) Contamination by Anti-Insect Pest Repellent Sachet Containing Allyl Mercaptan Microcapsule. J. Food Sci. 2017, 11, 2634–2642. [Google Scholar] [CrossRef]

- Carpena, M.; Nuñez-Estevez, B.; Soria-Lopez, A.; Garcia-Oliveira, P.; Prieto, M.A. Essential Oils and Their Application on Active Packaging Systems: A Review. Resources 2021, 10, 7. [Google Scholar] [CrossRef]

- López-Gómez, A.; Navarro-Martínez, A.; Martínez-Hernández, G.B. Active Paper Sheets Including Nanoencapsulated Essential Oils: A Green Packaging Technique to Control Ethylene Production and Maintain Quality in Fresh Horticultural Products—A Case Study on Flat Peaches. Foods 2020, 9, 1904. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Mei, L.; Chen, X.; Wang, Q. Recent Developments in Food Packaging Based on Nanomaterials. Nanomaterials 2018, 8, 830. [Google Scholar] [CrossRef] [Green Version]

- Agriopoulou, S.; Stamatelopoulou, E.; Skiada, V.; Varzakas, T. Nanobiotechnology in Food Preservation and Molecular Per-spective. In Nanotechnology-Enhanced Food Packaging; Parameswaranpillai, J., Krishnankutty, R.E., Jayakumar, A., Rangappa, S.M., Siengchin, S., Eds.; Wiley-VCH: Weinheim, Germany, 2022; pp. 327–359. ISBN 978-3-527-82770-1. [Google Scholar]

- Ariyarathna, I.R.; Rajakaruna, R.; Karunaratne, D.N. The rise of inorganic nanomaterial implementation in food applications. Food Control 2017, 77, 251–259. [Google Scholar] [CrossRef]

- Tarazona, A.; Gómez, J.V.; Gavara, R.; Mateo-Castro, R.; Gimeno-Adelantado, J.V.; Jiménez, M.; Mateo, E.M. Risk management of ochratoxigenic fungi and ochratoxin A in maize grains by bioactive EVOH films containing individual components of some essential oils. Int. J. Food Microbiol. 2018, 269, 107–119. [Google Scholar] [CrossRef] [PubMed]

- Mateo, E.M.; Gómez, J.V.; Domínguez, I.; Gimeno-Adelantado, J.V.; Mateo-Castro, R.; Gavara, R.; Jiménez, M. Impact of bioactive packaging systems based on EVOH films and essential oils in the control of aflatoxigenic fungi and aflatoxin production in maize. Int. J. Food Microbiol. 2017, 254, 36–46. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alhendi, A.; Choudhary, R. Current practices in bread packaging and possibility of improving bread shelf life by nano-technology. Int. J. Food Sci. Nutr. Eng. 2013, 3, 55–60. [Google Scholar]

- Sharma, C.; Dhiman, R.; Rokana, N.; Panwar, H. Nanotechnology: An Untapped Resource for Food Packaging. Front. Microbiol. 2017, 8, 1735. [Google Scholar] [CrossRef] [Green Version]

- Metak, A.M.; Ajaal, T.T. Investigation on Polymer Based Nano-Silver as Food Packaging Materials. Int. J. Chem. Mol. Eng. 2013, 7, 1103–1109. [Google Scholar] [CrossRef]

- Metak, A.M. Effects of nanocomposite based nano-silver and nano-titanium dioxide on food packaging materials. Int. J. Appl. Sci. Technol. 2015, 5, 26–40. [Google Scholar]

- European Commission. Commission Directive 2007/19/EC of 30 March 2007 amending Directive 2002/72/EC Relating to Plastic Materials and Articles Intended to Come into Contact with Food and Council Directive 85/572/EEC Laying Down the List of Simulants to be Used for Testing Migration of Constituents of Plastic Materials and Articles Intended to Come into Contact with Foodstuffs; EC: Brussels, Belgium, 2007. [Google Scholar]

- Avella, M.; De Vlieger, J.J.; Errico, M.; Fischer, S.; Vacca, P.; Volpe, M.G. Biodegradable starch/clay nanocomposite films for food packaging applications. Food Chem. 2005, 93, 467–474. [Google Scholar] [CrossRef]

- Echegoyen, Y.; Nerin, C. Nanoparticle release from nano-silver antimicrobial food containers. Food Chem. Toxicol. 2013, 62, 16–22. [Google Scholar] [CrossRef] [PubMed]

- Rešček, A.; Ščetar, M.; Hrnjak-Murgić, Z.; Dimitrov, N.; Galić, K. Polyethylene/Polycaprolactone Nanocomposite Films for Food Packaging Modified with Magnetite and Casein: Oxygen Barrier, Mechanical, and Thermal Properties. Polym. Technol. Eng. 2016, 55, 1450–1459. [Google Scholar] [CrossRef]

- Peter, A.; Mihaly-Cozmuta, L.; Mihaly-Cozmuta, A.; Nicula, C.; Ziemkowska, W.; Basiak, D.; Danciu, V.; Vulpoi, A.; Baia, L.; Falup, A.; et al. Changes in the microbiological and chemical characteristics of white bread during storage in paper packages modified with Ag/TiO2–SiO2, Ag/N–TiO2 or Au/TiO2. Food Chem. 2016, 197, 790–798. [Google Scholar] [CrossRef]

- Agarwal, A.; Raheja, A.; Natarajan, T.; Chandra, T. Effect of electrospun montmorillonite-nylon 6 nanofibrous membrane coated packaging on potato chips and bread. Innov. Food Sci. Emerg. Technol. 2014, 26, 424–430. [Google Scholar] [CrossRef]

- Melini, V.; Melini, F. Strategies to Extend Bread and GF Bread Shelf-Life: From Sourdough to Antimicrobial Active Packaging and Nanotechnology. Fermentation 2018, 4, 9. [Google Scholar] [CrossRef] [Green Version]

- Gutiérrez, L.; Batlle, R.; Andújar, S.; Sánchez, C.; Nerín, C. Evaluation of Antimicrobial Active Packaging to Increase Shelf Life of Gluten-Free Sliced Bread. Packag. Technol. Sci. 2011, 24, 485–494. [Google Scholar] [CrossRef]

- Muizniece-Brasava, S.; Dukalska, L.; Murniece, I.; Dabina-Bicka, I.; Kozlinskis, E.; Sarvi, S.; Santars, R.; Silvjane, A. Active Packaging Influence on Shelf Life Extension of Sliced Wheat Bread. Int. J. Nutr. Food Eng. 2012, 6, 480–486. [Google Scholar] [CrossRef]

- Opara, U.L. A review on the role of packaging in securing food system: Adding value to food products and reducing losses and waste. AJAR 2013, 8, 2621–2630. [Google Scholar] [CrossRef]

- Wells, J.H.; Singh, R.P. Response characteristics of full-history time-temperature indicators suitable for perishable food handling. J. Food Process. Preserv. 1988, 12, 207–218. [Google Scholar] [CrossRef]

- Floros, J.D.; Newsome, R.; Fisher, W.; Barbosa-Cánovas, G.V.; Chen, H.; Dunne, C.P.; German, J.B.; Hall, R.L.; Heldman, D.R.; Karwe, M.V.; et al. Feeding the World Today and Tomorrow: The Importance of Food Science and Technology. Compr. Rev. Food Sci. Food Saf. 2010, 9, 572–599. [Google Scholar] [CrossRef] [PubMed]

- Lillford, P.; Hermansson, A.-M. Global missions and the critical needs of food science and technology. Trends Food Sci. Technol. 2020, 111, 800–811. [Google Scholar] [CrossRef]

| Packaging Material | Barrier | Heat Seal-Ability | Mechanical, Physical and Chemical Properties | Application | Reference | |||

|---|---|---|---|---|---|---|---|---|

| Oxygen | Moisture | Light | ||||||

| Plastic | Low-density polyethylene (LDPE) | Very low | High | Low | Yes | Toughness, flexibility, resistance to grease and chemicals, temperature range −50 – +80 °C | Bags, flexible lids and bottles | [12] |

| Linear low-density polyethylene (LLDPE) | High | Toughness, extensibility, resistant to grease, temperature range −30 – +100 °C | (Strech) wrap | |||||

| High-density polyethylene (HDPE) | Extremely high | Toughness, stiffness, resistance to grease and chemicals, easy processing and forming, temperature range −40 – +120 °C | Bottles, cardboard liners, tubs, bags | |||||

| Polypropylene (PP) | Low | High | Low | Yes | Moderate stiffness, strong, resistant to grease and chemicals, temperature range −40 – +120 °C | Bottles, cardboard liners, tubs, microwavable packaging, bags | ||

| Polyethylene terephthalate (PET) | Good | Good | Low | Yes | Stiffness, strong, resistance to grease and oil, temperature range −60 – +200 °C | Bottles, jars, tubs, trays, blisters, films (bags and wrappers) | [12,40] | |

| Glass | Transparent | Absolute | Low | No | High temperature and pressure stability, brittle, chemical resistance, microwave-able | Bottles, jars | [12,40,41,42] | |

| Green | Good | |||||||

| Brown | High | |||||||

| Metal (aluminium, tinplate, tin-free steel) | Absolute | No | High temperature stability | Bottles, cans, tubs, caps | [12,40] | |||

| Paper and board | Extremely low | High – extremely high | No | Mechanical stability | Boxes, liners | [12,40,41] | ||

| Product category | Subcategory | Product | Water Activity [aw] | Moisture Content [%] | Reference |

|---|---|---|---|---|---|

| Confectionery | Cocoa and chocolate products | Chocolate | 0.42–0.60 | 1.2 | [72] |

| Other confectionery including breath freshening micro-sweets | Hard candy | 0.25–0.40 | 2.0–5.0 | [73,74] | |

| Fudge, toffee | 0.45–0.60 | 6.0–18.0 | |||

| Nougat (white, dark) | 0.55 | 8.00–10.0 | [13,75] | ||

| Jelly, liquorice | 0.50–0.75 | 8.0–22.0 | [73,74] | ||

| Marshmallow | 0.60–0.75 | 12.0–22.0 | |||

| Marzipan | 0.75–0.80 | – | [13] | ||

| Chewing gum | Chewing gum | 0.40–0.65 | 3.0–6.0 | [73,74] | |

| Cereals and cereal products | Whole, broken, or flaked grain | Oats, grains, cereals | 0.34–0.70 | 8.8–9.2 | [13,72] |

| Breakfast cereals | Cornflakes | 0.25–0.38 | 1.7–3.5 | ||

| Puffs | 0.17–0.20 | 0.48–1.70 | |||

| Fresh pasta | Fresh pasta | 0.91–0.98 | ≥24 | ||

| Dry pasta | Dry pasta | 0.33–0.57 | 5.4–8.3 | ||

| Bakery wares | Fine bakery wares | Sponge cake, muffins | 0.84–0.95 | 21.0–40.0 | [76,77] |

| Croissant crust | 0.59–0.61 | 8.0–10–0 | |||

| Croissant crumb | 0.92–0.94 | 30.0–33.0 | |||

| Biscuits | 0.60–0.63 | 1.5–3.0 | [72,78] | ||

| Wafers | 0.13–0.15 | 2.1 | [72] | ||

| Cookies | 0.18–0.64 | 1.4–11.7 | |||

| Bread and rolls | Flat bread (no yeast) | - | 33.0–35.0 | [79] | |

| Sourdough bread, yeast bread crumb | 0.91–0.95 | 29.0–40.0 | [72] | ||

| Sourdough bread, yeast bread crust | 0.88–0.94 | 26.0–32.0 | |||

| Bagel crust | 0.96 | 38.5 | |||

| Bagel crumb | 0.92 | 31.0 | |||

| Ready-to-eat savouries and snacks | Potato-, cereal-, flour- or starch-based snacks | Popcorn | 0.07 | 0.28 | |

| Chips | 0.09–0.27 | 0.3–1.3 | |||

| Crackers, grissini, sticks, pretzels | 0.05–0.54 | 1.1–5.4 | |||

| Processed nuts | Nuts, seeds, nibs | 0.15–0.75 | 0.5–3.1 |

| Category | Product | Packaging Material | AIP/MAP Applied | Storage | Shelf-Life | Reference |

|---|---|---|---|---|---|---|

| Confectionary | Dark chocolate with hazelnuts | Alu (commercial) | Air | 20 °C in dark | 8 m | [119] |

| PET/LDPE | Vacuum or N2 | 8–9 m | ||||

| PET-SiOx/LDPE | 11 m | |||||

| PET/LDPE or PET-SiOx/LDPE | Oxygen absorber | ≥ 12 m | ||||

| Cereals and cereal products | Muesli with chocolate and apricots | Paper bag: PAP + PP window | Air | 20 °C, RH 55 % | 2 m | [143] |

| Pouch: PAP/Alu/PE | 9 m | |||||

| Can:PAP/Alu + LDPE lid | ||||||

| Fresh pasta | PS tray + PVC film | Air | 8 °C | 20 d | [120] | |

| PA/EVOH/LLDPE | CO2:N2 22:78% MAP | 40 d | ||||

| Fresh pasta filled with cheese | Tray: EVOH/PS/PE wrapped in film: EVOH/OPET/PE | Air | 4 °C | 7–14 d | [108] | |

| CO2:N2 50:50% MAP | 42 d | |||||

| Gluten-free fresh filled pasta | Tray: PETFilm: antifog PET film | Air | 4 °C | 14 d | [121] | |

| Tray: EVOH/PS/PEFilm: EVOH/OPET/PE | CO2:N2 30:70% MAP | 42 d | ||||

| Bakery wares | Sponge cake | PA/LLDPE | Combinations of oxygen scavengers with / without ethanol emitter | 30 °C, RH 60% | ≤42 d | [139] |

| PVDC/PA/cPP | ||||||

| Sliced wheat bread | PET-SiOx/LDPE | Bread | 20 °C | 4 d | [130] | |

| Bread + preservatives | 6 d | |||||

| Ethanol emitter | 24 d | |||||

| Ethanol emitter + oxygen absorber | 30 d | |||||

| Ciabatta bread | OPA/PE | Air (control) | 21 °C | 5 d | [122] | |

| Air + ethanol spray | 11 d | |||||

| CO2:N2 10:90% MAP | 12 d | |||||

| MAP + ethanol spray | 13 d | |||||

| Air + ethanol emitter | 25 d | |||||

| MAP + ethanol emitter | 30 d | |||||

| Wheat bread | HDPE/PE | - | 25.8 °C, 275.5 lx, RH 31.2% | 2 d | [144] | |

| Unpackaged bread | - | 3 d | ||||

| HDPE/Nanoparticles/PE | Ag-TiO2 | >6 d | ||||

| Calcium-enriched wholemeal bread | PA/PE bag + cardboard box | CO2:N2 60:40% MAP | 20 °C | 24 d | [145] | |

| Whole wheat bread | PA/PE | N2 | RT | 2–3 w | [123] | |

| Part-baked flat bread (Sangak) | PA/PE | Air | 25 °C | 9 d | [124] | |

| CO2:N2 20:80% MAP | 18 d | |||||

| CO2 100% MAP | 21 d | |||||

| Sliced wheat bread | Tray: APET/EVOH/PEAntifog-film: PA/PE | Air without potassium sorbate & with 0.15% potassium sorbate | 20 °C, RH 60% | 14 d | [125] | |

| N2 100% MAP, CO2:N2 30:70% MAP, CO2:N2 50:50% MAP, CO2:N2 70:30% MAP, CO2 100 %MAP;with & without potassium sorbate | 21 d | |||||

| Air with 0.30% potassium sorbate | >21 d | |||||

| Bread | Plastic bag | E-Poly-L-Lysine Biofilms1.6/3.2/6.5 mg of E-Poly-L-Lysine /cm2 | RT for 7 days inoculated with A. parasitus | +1 d | [131] | |

| E-Poly-L-Lysine Biofilms6.5 mg of E-Poly-L-Lysine /cm2 | RT for 7 days inoculated with P. expansum | +3 d | ||||

| Sliced wheat bread | PP/PET/LDPE | Star anise oil, thymol | 25 °C inoculated with P. roqueforti | 14 d | [132] | |

| Bread | Starch-based bionanocomposite film | Chitosan, grapefruit seed extract | 25 °C, RH 59% | 20 d | [133] | |

| Sliced white pan bread | PP bag | -- | 30°C | 3 d | [134] | |

| PBAT-PLA bag | ||||||

| Trans-cinnamaldehyde | ≥21 d | |||||

| Bread | BOPP | -- | 25 °C, RH 75% | 3 d | [135] | |

| PLA | 6 d | |||||

| PLA-PBSA bag | Thymol | 7–9 d |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bauer, A.-S.; Leppik, K.; Galić, K.; Anestopoulos, I.; Panayiotidis, M.I.; Agriopoulou, S.; Milousi, M.; Uysal-Unalan, I.; Varzakas, T.; Krauter, V. Cereal and Confectionary Packaging: Background, Application and Shelf-Life Extension. Foods 2022, 11, 697. https://doi.org/10.3390/foods11050697

Bauer A-S, Leppik K, Galić K, Anestopoulos I, Panayiotidis MI, Agriopoulou S, Milousi M, Uysal-Unalan I, Varzakas T, Krauter V. Cereal and Confectionary Packaging: Background, Application and Shelf-Life Extension. Foods. 2022; 11(5):697. https://doi.org/10.3390/foods11050697

Chicago/Turabian StyleBauer, Anna-Sophia, Kärt Leppik, Kata Galić, Ioannis Anestopoulos, Mihalis I. Panayiotidis, Sofia Agriopoulou, Maria Milousi, Ilke Uysal-Unalan, Theodoros Varzakas, and Victoria Krauter. 2022. "Cereal and Confectionary Packaging: Background, Application and Shelf-Life Extension" Foods 11, no. 5: 697. https://doi.org/10.3390/foods11050697

APA StyleBauer, A.-S., Leppik, K., Galić, K., Anestopoulos, I., Panayiotidis, M. I., Agriopoulou, S., Milousi, M., Uysal-Unalan, I., Varzakas, T., & Krauter, V. (2022). Cereal and Confectionary Packaging: Background, Application and Shelf-Life Extension. Foods, 11(5), 697. https://doi.org/10.3390/foods11050697