Trends in the Use of Lipases: A Systematic Review and Bibliometric Analysis

Abstract

1. Introduction

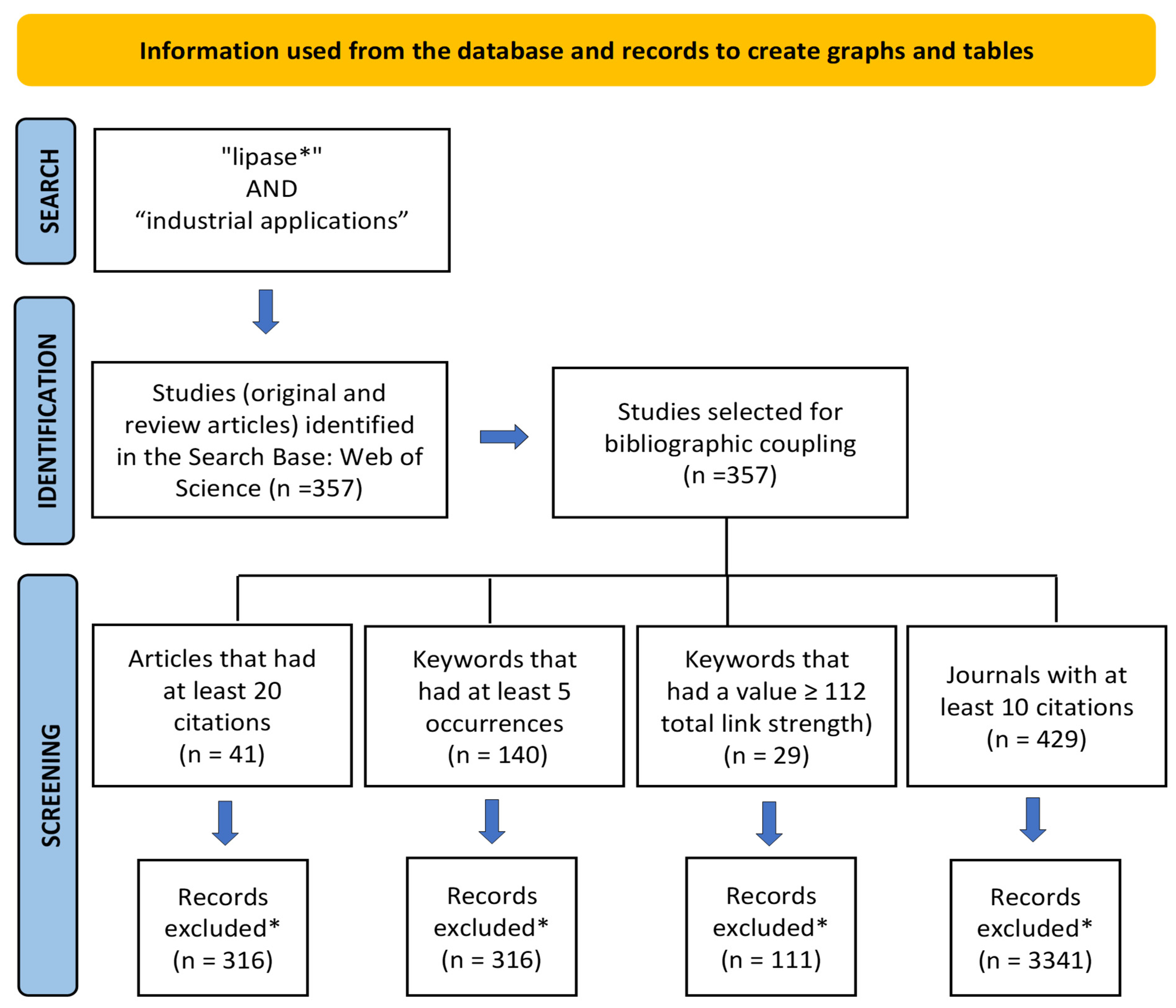

2. Research Process and Scientific Mapping

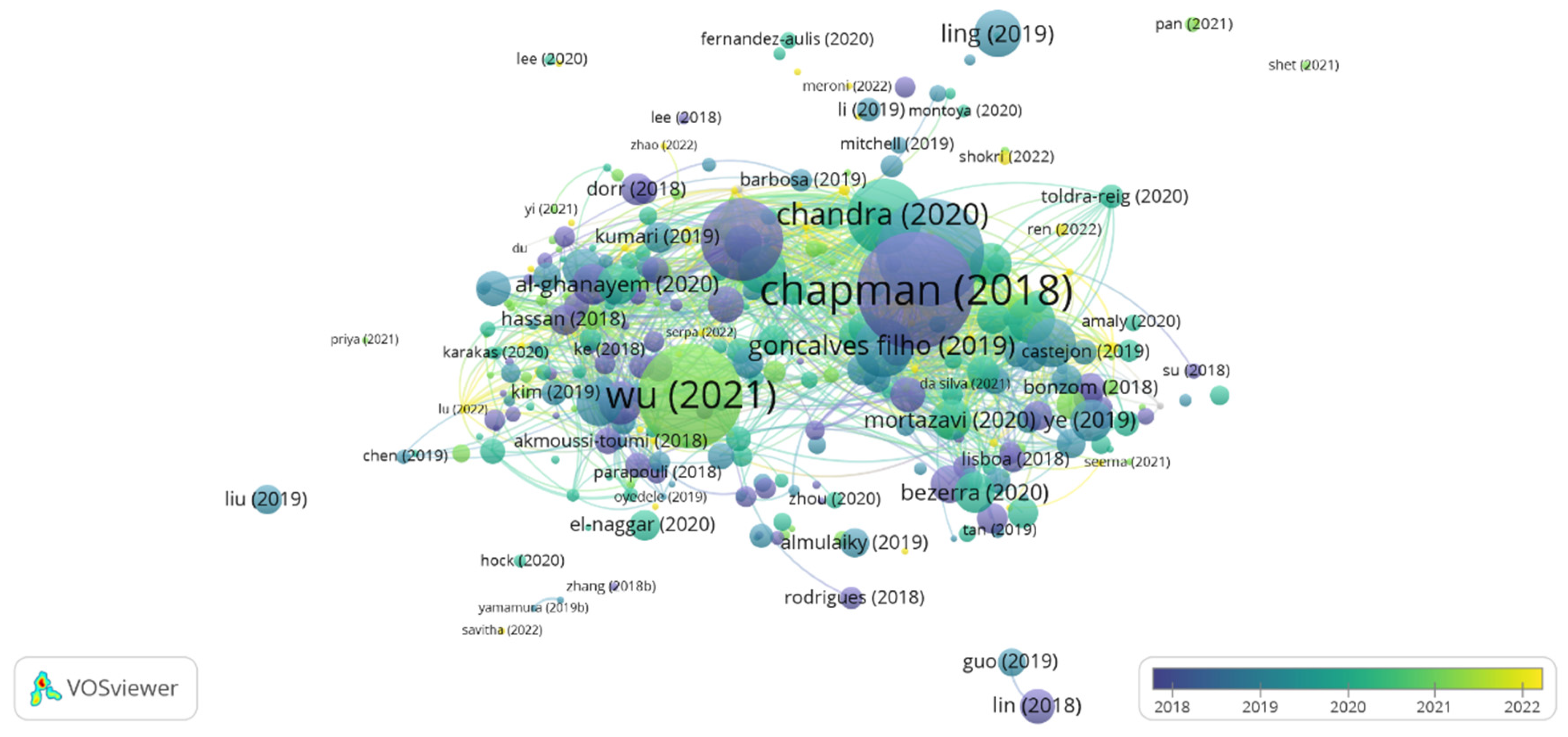

3. Bibliographic Coupling between Articles

| Article Title | Journal ISO Abbreviation | Citations | Total Link Strength | Authors |

|---|---|---|---|---|

| Industrial Applications of Enzymes: Recent Advances, Techniques, and Outlooks | Catalysts | 300 | 359 | [30] |

| Industrial applications of immobilized enzymes-A review | Mol. Catal. | 256 | 137 | [42] |

| Biocatalysis: Enzymatic Synthesis for Industrial Applications | Angew. Chem. Int. Edit. | 240 | 265 | [36] |

| Recent advances on sources and industrial applications of lipases | Biotechnol. Prog. | 149 | 733 | [32] |

| Microbial lipases and their industrial applications: a comprehensive review | Microb. Cell. Fact. | 125 | 229 | [5] |

| Lipases: sources, immobilization methods, and industrial applications | Appl. Microbiol. Biotechnol. | 76 | 434 | [1] |

| Driving Immobilized Lipases as Biocatalysts: 10 Years State of the Art and Future Prospects | Ind. Eng. Chem. Res. | 54 | 718 | [38] |

| Lipase immobilization with support materials, preparation techniques, and applications: Present and future aspects | Int. J. Biol. Macromol. | 51 | 434 | [46] |

| Recent advances in the improvement of enzyme thermostability by structure modification | Crit. Rev. Biotechnol. | 50 | 99 | [47] |

| Radio-frequency treatment for stabilization of wheat germ: Storage stability and physicochemical properties | Innov. Food Sci. Emerg. Technol. | 50 | 3 | [37] |

| Microbial lipases: An overview of screening, production and purification | Biocatal. Agric. Biotechnol. | 46 | 409 | [48] |

| Engineering Yarrowia lipolytica to Simultaneously Produce Lipase and Single Cell Protein from Agro-industrial Wastes for Feed | Sci. Rep. | 43 | 109 | [49] |

| Lipases in liquid formulation for biodiesel production: Current status and challenges | Biotechnol. Appl. Biochem. | 40 | 220 | [40] |

| A Versatile Approach for Enzyme Immobilization Using Chemically Modified 3D-Printed Scaffolds | ACS Sustain. Chem. Eng. | 39 | 99 | [50] |

| Current prospective in using cold-active enzymes as eco-friendly detergent additive | Appl. Microbiol. Biotechnol. | 38 | 107 | [51] |

| Make proper surfaces for immobilization of enzymes: Immobilization of lipase and alpha-amylase on modified Na-sepiolite | Int. J. Biol. Macromol. | 37 | 774 | [13] |

| A new heterofunctional support for enzyme immobilization: PEI functionalized Fe3O4 MNPs activated with divinyl sulfone. Application in the immobilization of lipase from Thermomyces lanuginosus | Enzyme Microb. Technol. | 36 | 358 | [52] |

| Novel lipases discovery specifically from marine organisms for industrial production and practical applications | Process Biochem. | 36 | 280 | [39] |

| Enzymes from Marine Polar Regions and Their Biotechnological Applications | Mar. Drugs | 36 | 214 | [53] |

| Solvent stable microbial lipases: current understanding and biotechnological applications | Biotechnol. Lett. | 32 | 381 | [14] |

| Remarkably enhanced activity and substrate affinity of lipase covalently bonded on zwitterionic polymer-grafted silica nanoparticles | J. Colloid Interface Sci. | 32 | 204 | [54] |

| Enhancing the Thermostability of Rhizomucor miehei Lipase with a Limited Screening Library by Rational-Design Point Mutations and Disulfide Bonds | Appl. Environ. Microbiol. | 29 | 128 | [55] |

| Biosensors and Bioassays Based on Lipases, Principles and Applications, a Review | Molecules | 28 | 220 | [56] |

| Evaluation of Strategies to Produce Highly Porous Cross-Linked Aggregates of Porcine Pancreas Lipase with Magnetic Properties | Molecules | 27 | 640 | [31] |

| Correlations of Molecular Weights of β-Glucans from Qingke (Tibetan Hulless Barley) to Their Multiple Bioactivities | Molecules | 27 | 10 | [57] |

| Substrate -Specificity of Candida rugosa Lipase and Its Industrial Application | ACS Sustain. Chem. Eng. | 24 | 470 | [33] |

| The Immobilization of Lipases on Porous Support by Adsorption and Hydrophobic Interaction Method | Catalysts | 24 | 398 | [35] |

| State-of-the-art strategies and applied perspectives of enzyme biocatalysis in food sector—current status and future trends | Crit. Rev. Food Sci. Nutr. | 24 | 280 | [58] |

| Enzymatic amidation for industrial applications | Curr. Opin. Chem. Biol. | 24 | 56 | [59] |

| Improved immobilization of lipase from Thermomyces lanuginosus on a new chitosan-based heterofunctional support: Mixed ion exchange plus hydrophobic interactions | Int. J. Biol. Macromol. | 23 | 658 | [60] |

| Biochemical aspects of lipase immobilization at polysaccharides for biotechnology | Adv. Colloid Interface Sci. | 22 | 566 | [6] |

| Production of Cold-Active Lipase by Free and Immobilized Marine Bacillus cereus HSS: Application in Wastewater Treatment | Front. Microbiol. | 22 | 245 | [34] |

| Recent Developments in Carriers and Non-Aqueous Solvents for Enzyme Immobilization | Catalysts | 22 | 217 | [17] |

| Immobilization of lipase B from Candida antarctica on epoxy-functionalized silica: characterization and improving biocatalytic parameters | J. Chem. Technol. Biotechnol. | 22 | 155 | [16] |

| Lipase immobilization on synthesized hyaluronic acid-coated magnetic nanoparticle-functionalized graphene oxide composites as new biocatalysts: Improved reusability, stability, and activity | Int. J. Biol. Macromol. | 22 | 138 | [15] |

| Validation of leaf enzymes in the detergent and textile industries: launching of a new platform technology | Plant Biotechnol. J. | 22 | 39 | [61] |

| Analysis of Aspergillus sp lipase immobilization for the application in organic synthesis | Int. J. Biol. Macromol. | 21 | 696 | [18] |

| Bioprocess development for L-asparaginase production by Streptomyces rochei, purification and in-vitro efficacy against various human carcinoma cell lines | Sci. Rep. | 21 | 71 | [62] |

| Synthesis and characterization of cross-linked enzyme aggregates (CLEAs) of thermostable xylanase from Geobacillus thermodenitrificans X1 | Process Biochem. | 20 | 226 | [63] |

| Enzyme-inorganic hybrid nanoflowers: Classification, synthesis, functionalization and potential applications | Chem. Eng. J. | 20 | 187 | [64] |

| Feruloyl esterase immobilization in mesoporous silica particles and characterization in hydrolysis and transesterification | BMC Boichem. | 20 | 204 | [65] |

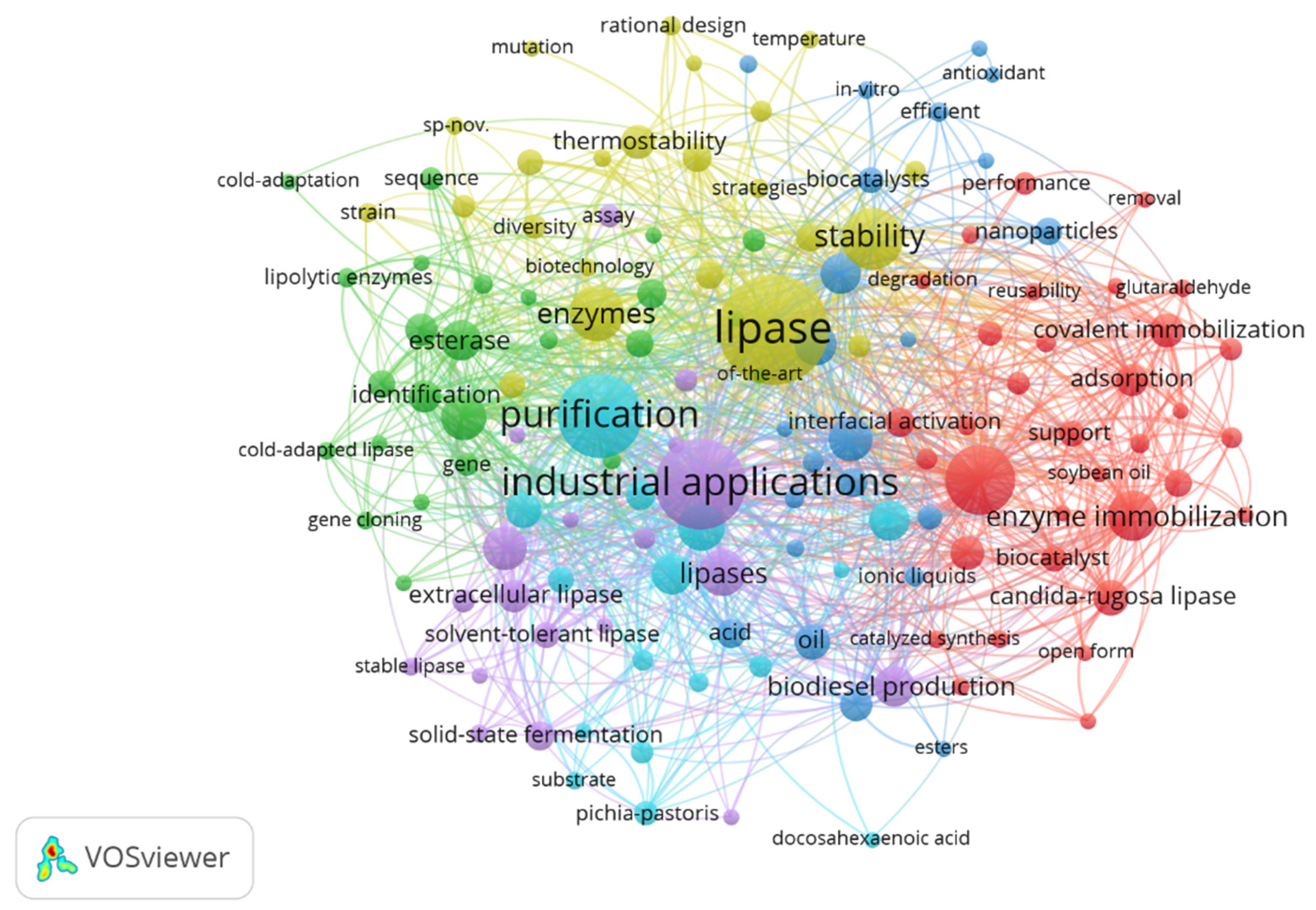

4. Network Visualization of Keyword Co-Occurrence

5. Journal Co-Citation Map

6. Main Challenges Reported on Lipase Application

7. The Impact of Enzyme Immobilization on Industrial Processes

8. Scaling Up the Lipase-Catalyzed Process

9. Conclusions

- The works with significant numbers of citations found in the search focus on lipase immobilization processes for application in industrial processes.

- Within this niche, the application is focused on the biotechnology and bioprocess sectors, which include food, cosmetics, biofuels, and environmental areas, which show the versatility of this enzyme.

- When observing the topics that comprise the optimization of lipases, studies are found evaluating both the supports for immobilization, fermentative processes of enzyme production, enzymatic purification, biochemical characterization, and the application in reactions in both an organic and inorganic media, reinforcing the breadth of use of this biocatalyst.

- It is verified that in the case of lipase immobilization techniques, the tests comprise the configuration of support materials, operational stability, and reuse.

- Kinetic studies are fundamental in this process of transition from laboratory scale to industrial scale. Allied with the computational modeling of these reactions, it allows us to determine and optimize operational parameters, in addition to enabling monitoring of the bioprocess and planning the structure necessary for implementation.

- Other factors that contribute to the previous topic are the genetic studies at the structural level of lipases, which allows the improvement of their characteristics regarding activity, productivity, thermal stability, reuse, and enantioselectivity.

- Compatibility studies considering the synergy of free or immobilized enzyme, reactor type, reaction medium, and product are fundamental to performing a combination that allows an efficient process, with high yields, and continuous operation processes.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Filho, D.G.; Silva, A.G.; Guidini, C.Z. Lipases: Sources, immobilization methods, and industrial applications. Appl. Microbiol. Biotechnol. 2019, 103, 7399–7423. [Google Scholar] [CrossRef]

- Utama, Q.D.; Sitanggang, A.B.; Adawiyah, D.R.; Hariyadi, P. Lipase-Catalyzed Interesterification for the Synthesis of Medium-Long-Medium (MLM) Structured Lipids—A Review. Food Technol. Biotechnol. 2019, 57, 305–318. [Google Scholar] [CrossRef] [PubMed]

- Ortiz, C.; Ferreira, M.L.; Barbosa, O.; Santos, J.C.S.; Rodrigues, R.C.; Berenguer-Murcia, Á.; Brian, L.E.; Fernandez-Lafuente, R. Novozym 435: The “perfect” lipase immobilized biocatalyst? Catal. Sci. Technol. 2019, 9, 2380. [Google Scholar] [CrossRef]

- Ali, S.; Khan, S.A.; Hamayun, M.; Lee, I.-J. Recent advances in the use of microbial lipases: A review. Microorganisms 2023, 11, 510. [Google Scholar] [CrossRef] [PubMed]

- Chandra, P.; Enespa, S.R.; Arora, P.K. Microbial lipases and their industrial applications: A comprehensive review. Microb. Cell Factories 2020, 19, 169. [Google Scholar] [CrossRef] [PubMed]

- Zaitsev, S.Y.; Savina, A.A.; Zaitsev, I.S. Biochemical aspects of lipase immobilization at polysaccharides for biotechnology. Adv. Colloid Interface Sci. 2019, 272, 102016. [Google Scholar] [CrossRef]

- de Araújo-Silva, R.; Vieira, A.C.; de Campos Giordano, R.; Fernández-Lafuente, R.; Tardioli, P.W. Enzymatic Synthesis of Fatty Acid Isoamyl Monoesters from Soybean Oil Deodorizer Distillate: A Renewable and Ecofriendly Base Stock for Lubricant Industries. Molecules 2022, 27, 2692. [Google Scholar] [CrossRef]

- Ahmad, M.; Rehab, R.; Fumiya, N.; Abrar, I.; Hafez, H. Highly selective synthesis of glyceryl monostearate via lipase catalyzed esterification of triple pressed stearic acid and glycerin. Sustain. Energy Technol. Assess. 2023, 57, 103200. [Google Scholar] [CrossRef]

- Moulin Cansian, A.B.; Waldir Tardioli, P.; Furlan, F.F.; de Sousa Júnior, R. Modeling and simulation of the biosurfactant production by enzymatic route using xylose and oleic acid as reagents. Chem. Ind. Chem. Eng. Q. 2022, 28, 265–276. [Google Scholar] [CrossRef]

- Balaji, L.; Chittoor, J.T.; Jayaraman, G. Optimization of extracellular lipase production by halotolerant Bacillus sp. VITL8 using factorial design and applicability of enzyme in pretreatment of food industry effluents. Preparative Biochemistry and Biotechnology. Prep. Biochem. Biotechnol. 2020, 50, 708–716. [Google Scholar] [CrossRef]

- Cipolatti, E.P.; Valério, A.; Henriques, R.O.; Cerqueira Pinto, M.C.; Lorente, G.F.; Manoel, E.A.; Guisán, J.M.; Ninow, J.L.; de Oliveira, D.; Pessela, B.C. Production of new nanobiocatalysts via immobilization of lipase B from C. antarctica on polyurethane nanosupports for application on food and pharmaceutical industries. Int. J. Biol. Macromol. 2020, 165, 2957–2963. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Pei, Y.; Cheng, K.; Deng, Y.; Dong, X.; Fang, R.; Chu, B.; Wei, P.; Chen, Q.; Xiao, G. Production and evaluation of enzyme-modified cheese adding protease or lipase to improve quality properties. J. Biosci. Bioeng. 2023, 135, 389–394. [Google Scholar] [CrossRef]

- Mortazavi, S.; Aghaei, H. Proper surfaces for immobilization of enzymes: Immobilization of lipase and α-amylase on modified Na-sepiolite. Int. J. Biol. Macromol. 2020, 164, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Priyanka, P.; Tan, Y.Q.; Kinsella, G.K.; Henehan, G.T.; Ryan, B.J. Solvent stable microbial lipases: Current understanding and biotechnological applications. Biotechnol. Lett. 2019, 41, 203–220. [Google Scholar] [CrossRef]

- Atiroglu, V. Lipase immobilization on synthesized hyaluronic acid-coated magnetic nanoparticle-functionalized graphene oxide composites as new biocatalysts: Improved reusability, stability, and activity. Int. J. Biol. Macromol. 2020, 145, 456–465. [Google Scholar] [CrossRef] [PubMed]

- Souza, S.P.; de Almeida, R.A.D.; Garcia, G.G.; Leao, R.A.C.; Bassut, J.; de Souza, R.; Itabaiana, I. Immobilization of lipase B from Candida antarctica on epoxy-functionalized silica: Characterization and improving biocatalytic parameters. J. Chem. Technol. Biotechnol. 2018, 93, 105–111. [Google Scholar] [CrossRef]

- Zhao, Z.P.; Zhou, M.C.; Liu, R.L. Recent Developments in Carriers and Non-Aqueous Solvents for Enzyme Immobilization. Catalysts 2019, 9, 647. [Google Scholar] [CrossRef]

- Gricajeva, A.; Kazlauskas, S.; Kalediene, L.; Bendikiene, V. Analysis of Aspergillus sp. lipase immobilization for the application in organic synthesis. Int. J. Biol. Macromol. 2018, 108, 1165–1175. [Google Scholar] [CrossRef]

- Soni, S. Trends in lipase engineering for enhanced biocatalysis. Biotechnol. Appl. Biochem. 2022, 69, 265–272. [Google Scholar] [CrossRef] [PubMed]

- Godoy, C.A.; Pardo-Tamayo, J.S.; Oveimar, B. Microbial Lipases and Their Potential in the Production of Pharmaceutical Building Blocks. Int. J. Mol. Sci. 2022, 23, 9933. [Google Scholar] [CrossRef]

- Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [PubMed]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; MarcLim, W. How to conduct a bibliometric analysis: An overview and guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- Li, J.; Wang, M.H.; Ho, Y.S. Trends in research on global climate change: A science citation index expanded-based analysis. Glob. Planet. Change 2011, 77, 13–20. [Google Scholar] [CrossRef]

- Gonçalves, M.C.P.; Kieckbusch, T.G.; Perna, R.F.; Fujimoto, J.T.; Morales, S.A.V.; Romanelli, J.P. Trends on enzyme immobilization researches based on bibliometric analysis. Process Biochem. 2019, 76, 95–110. [Google Scholar] [CrossRef]

- Gonçalves, M.C.P.; Romanelli, J.P.; Guimarães, J.R.; Vieira, A.C.; de Azevedo, B.P.; Tardioli, P.W. Reviewing research on the synthesis of CALB-catalyzed sugar esters incorporating systematic mapping principles. Crit. Rev. Biotechnol. 2021, 41, 865–878. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, M.C.P.; Romanelli, J.P.; Cansian, A.B.M.; Pucci, E.F.Q.; Guimarães, J.R.; Tardioli, P.W.; Saville, B.A. A review on the production and recovery of sugars from lignocellulosics for use in the synthesis of bioproducts. Ind. Crops Products. 2022, 186, 115213. [Google Scholar] [CrossRef]

- Uman, L.S. Systematic Reviews and Meta-Analyses. J. Can. Acad. Child Adolesc. Psychiatry 2011, 20, 57–59. [Google Scholar]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, 71. [Google Scholar] [CrossRef]

- Grácio, M.C.C. Bibliographic coupling and cocitation analysis: A theoretical-conceptual review. Bibliogr. Encount. Electron. J. Libr. Inf. Sci. 2016, 21, 82–99. [Google Scholar] [CrossRef]

- Chapman, J.; Ismail, A.E.; Dinu, C.Z. Industrial Applications of Enzymes: Recent Advances, Techniques, and Outlooks. Catalysts 2018, 8, 238. [Google Scholar] [CrossRef]

- Guimarães, J.R.; Giordano, R.d.L.C.; Fernandez-Lafuente, R.; Tardioli, P.W. Evaluation of Strategies to Produce Highly Porous Cross-Linked Aggregates of Porcine Pancreas Lipase with Magnetic Properties. Molecules 2018, 23, 2993. [Google Scholar] [CrossRef] [PubMed]

- Sarmah, N.; Revathi, D.; Sheelu, G.; Yamuna Rani, K.; Sridhar, S.; Mehtab, V.; Sumana, C. Recent advances on sources and industrial applications of lipases. Biotechnol. Prog. 2018, 34, 5–28. [Google Scholar] [CrossRef] [PubMed]

- Vanleeuw, E.; Winderickx, S.; Thevissen, K.; Lagrain, B.; Dusselier, M.; Cammue, B.P.A.; Sels, B.F. Substrate-Specificity of Candida Rugosa Lipase and Its Industrial Application. ACS Sustainable Chem. Eng. 2019, 7, 15828–15844. [Google Scholar] [CrossRef]

- Hassan, S.W.M.; Abd El Latif, H.H.; Ali, S.M. Production of Cold-Active Lipase by Free and Immobilized Marine Bacillus Cereus HSS: Application in Wastewater Treatment. Front. Microbiol. 2018, 9, 2377. [Google Scholar] [CrossRef]

- Mokhtar, N.F.; Abd. Rahman, R.N.Z.R.; Muhd Noor, N.D.; Mohd Shariff, F.; Mohamad Ali, M.S. The Immobilization of Lipases on Porous Support by Adsorption and Hydrophobic Interaction Method. Catalysts 2020, 10, 744. [Google Scholar] [CrossRef]

- Wu, S.; Snajdrova, R.; Moore, J.C.; Baldenius, K.; Bornscheuer, U.T. Biocatalysis: Enzymatic Synthesis for Industrial Applications. Angew. Chem. Int. Ed. Engl. 2021, 60, 88–119. [Google Scholar] [CrossRef]

- Ling, B.; Ouyang, S.; Wang, S. Radio-Frequency Treatment for Stabilization of Wheat Germ: Storage Stability and Physicochemical Properties. Innov. Food Sci. Emerg. Technol. 2019, 52, 158–165. [Google Scholar] [CrossRef]

- Facin, B.R.; Melchiors, M.S.; Valerio, A.; Oliveira, J.V.; Oliveira, D. Driving Immobilized Lipases as Biocatalysts: 10 Years State of the Art and Future Prospects. Ind. Eng. Chem. Res. 2019, 58, 5358–5378. [Google Scholar] [CrossRef]

- Navvabi, A.; Razzaghi, M.; Fernandes, P.; Karami, L.; Homaei, A. Novel Lipases Discovery Specifically from Marine Organisms for Industrial Production and Practical Applications. Process Biochem. 2018, 70, 61–70. [Google Scholar] [CrossRef]

- Wancura, J.H.C.; Tres, M.V.; Jahn, S.L.; de Oliveira, J.V. Lipases in liquid formulation for biodiesel production: Current status and challenges. Biotechnol. Appl. Biochem. 2020, 67, 648–667. [Google Scholar] [CrossRef]

- Yeo, W.S.; Yuniarto, A. The External Mass Transfer Model for the Hydrolysis of Palm Olein Using Immobilized Lipase in a Scaled-up Recirculated Packed-Bed Reactor. J. Environ. Chem. Eng. 2019, 7, 103185. [Google Scholar] [CrossRef]

- Basso, A.; Serban, S. Industrial applications of immobilized enzymes—A review. Mol. Catal. 2019, 479, 110607. [Google Scholar] [CrossRef]

- Eck, N.J.; Waltman, L. VOSviewer Manual; Centre for Science and Technology Studies (CWTS); Leiden University’s: Leiden, The Netherlands, 2021. [Google Scholar]

- Mahfoudhi, A.; Benmabrouk, S.; Fendri, A.; Sayari, A. Fungal lipases as biocatalysts: A promising platform in several industrial biotechnology applications. Biotechnol. Bioeng. 2022, 119, 3370–3392. [Google Scholar] [CrossRef] [PubMed]

- Rener, D.J.; Ruwaya, A. A minireview on the bioremediative potential of microbial enzymes as solution to emerging microplastic pollution. Front. Microbiol. Sec. Microbiotechnol. 2022, 13, 1066133. [Google Scholar] [CrossRef]

- Ismail, A.R.; Baek, K.H. Lipase immobilization with support materials, preparation techniques, and applications: Present and future aspects. Int. J. Biol. Macromol. 2020, 163, 1624–1639. [Google Scholar] [CrossRef]

- Xu, Z.; Cen, Y.K.; Zou, S.P.; Xue, Y.P.; Zheng, Y.G. Recent advances in the improvement of enzyme thermostability by structure modification. Crit. Rev. Biotechnol. 2020, 40, 83–98. [Google Scholar] [CrossRef]

- Bharathi, D.; Rajalakshmi, G. Microbial lipases: An overview of screening, production and purification. Biocatal. Agric. Biotechnol. 2019, 22, 101368. [Google Scholar] [CrossRef]

- Yan, J.Y.; Han, B.N.; Gui, X.H.; Wang, G.L.; Xu, L.; Yan, Y.; Madzak, C.; Pan, D.J.; Wang, Y.F.; Zha, G.H.; et al. Engineering Yarrowia lipolytica to Simultaneously Produce Lipase and Single Cell Protein from Agro-industrial Wastes for Feed. Sci. Rep. 2018, 8, 758. [Google Scholar] [CrossRef] [PubMed]

- Ye, J.J.; Chu, T.S.; Chu, J.L.; Gao, B.B.; He, B.F. A Versatile Approach for Enzyme Immobilization Using Chemically Modified 3D-Printed Scaffolds. ACS Sustain. Chem. Eng. 2019, 7, 18048–18054. [Google Scholar] [CrossRef]

- Al-Ghanayem, A.A.; Joseph, B. Current prospective in using cold-active enzymes as eco-friendly detergent additive. Appl. Microbiol. Biotechnol. 2020, 104, 2871–2882. [Google Scholar] [CrossRef]

- Bezerra, R.M.; Monteiro, R.R.C.; Neto, D.M.A.; da Silva, F.F.M.; de Paula, R.C.M.; de Lemos, T.L.G.; Fechine, P.B.A.; Correa, M.A.; Bohn, F.; Goncalves, L.R.B.; et al. A new heterofunctional support for enzyme immobilization: PEI functionalized Fe3O4 MNPs activated with divinyl sulfone. Application in the immobilization of lipase from Thermomyces Lanuginosus. Enzym. Microb. Technol. 2020, 138, 109560. [Google Scholar] [CrossRef]

- Bruno, S.; Coppola, D.; Prisco, G.; Giordano, D.; Verde, C. Enzymes from Marine Polar Regions and Their Biotechnological Applications. Mar. Drugs 2019, 17, 544. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Dong, X.Y.; Guo, Z.; Sun, Y. Remarkably enhanced activity and substrate affinity of lipase covalently bonded on zwitterionic polymer-grafted silica nanoparticles. J. Colloid Interface Sci. 2018, 519, 145–153. [Google Scholar] [CrossRef] [PubMed]

- Li, G.L.; Fang, X.R.; Su, F.; Chen, Y.; Xu, L.; Yan, Y.J. Enhancing the Thermostability of Rhizomucor miehei Lipase with a Limited Screening Library by Rational-Design Point Mutations and Disulfide Bonds. Appl. Environ. Microbiol. 2018, 84, 2. [Google Scholar] [CrossRef] [PubMed]

- Pohanka, M. Biosensors and Bioassays Based on Lipases, Principles and Applications, a Review. Molecules 2019, 24, 616. [Google Scholar] [CrossRef]

- Lin, S.; Guo, H.; Lu, M.; Lu, M.Y.; Gong, J.D.B.; Wang, L.; Zhang, Q.; Qin, W.; Wu, D.T. Correlations of Molecular Weights of β-Glucans from Qingke (Tibetan Hulless Barley) to Their Multiple Bioactivities. Molecules 2018, 23, 1710. [Google Scholar] [CrossRef]

- Bilal, M.; IqbaL, H.M.N. State-of-the-art strategies and applied perspectives of enzyme biocatalysis in food sector—Current status and future trends. Crit. Rev. Food Sci. Nutr. 2019, 60, 2052–2066. [Google Scholar] [CrossRef] [PubMed]

- Dorr, B.M.; Fuerst, D.E. Enzymatic amidation for industrial applications. Curr. Opin. Chem. Biol. 2018, 43, 127–133. [Google Scholar] [CrossRef]

- Okura, N.S.; Sabi, G.J.; Crivellenti, M.C.; Gomes, R.A.B.; Fernandez-Lafuente, R.; Mendes, A.A. Improved immobilization of lipase from Thermomyces lanuginosus on a new chitosan-based heterofunctional support: Mixed ion exchange plus hydrophobic interactions. Int. J. Biol. Macromol. 2020, 163, 550–561. [Google Scholar] [CrossRef]

- Kumari, U.; Singh, R.; Ray, T.; Rana, S.; Saha, P.; Malhotra, K.; Daniell, H. Validation of leaf enzymes in the detergent and textile industries: Launching of a new platform technology. Plant Biotechnol. J. 2019, 17, 1167–1182. [Google Scholar] [CrossRef]

- El-Naggar, N.E.A.; El-Shweihy, N.M. Bioprocess development for L-asparaginase production by Streptomyces rochei, purification and in-vitro efficacy against various human carcinoma cell lines. Sci. Rep. 2020, 14, 7942. [Google Scholar] [CrossRef] [PubMed]

- Verma, R.; Kumar, A.; Kumar, S. Synthesis and characterization of cross-linked enzyme aggregates (CLEAs) of thermostable xylanase from Geobacillus thermodenitrificans X1. Process Biochem. 2019, 80, 72–79. [Google Scholar] [CrossRef]

- Zhang, M.R.; Zhang, Y.; Yang, C.K.; Ma, C.Y.; Tang, J.G. Enzyme-inorganic hybrid nanoflowers: Classification, synthesis, functionalization and potential applications. Chem. Eng. J. 2021, 415, 129075. [Google Scholar] [CrossRef]

- Bonzom, C.; Schild, L.; Gustafsson, H.; Olsson, L. Feruloyl esterase immobilization in mesoporous silica particles and characterization in hydrolysis and transesterification. BMC Biochem. 2018, 19, 1. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Yue, C.; Wang, G. Beef quality monitoring using immobilization lipase on modified polypropylene non-woven fabric based on time-temperature indicator. J. Food Eng. 2023, 357, 111586. [Google Scholar] [CrossRef]

- Binhayeeding, N.; Klomklao, S.; Prasertsan, P.; Sangkharak, K. Improvement of biodiesel production using waste cooking oil and applying single and mixed immobilised lipases on polyhydroxyalkanoate. Renew. Energy 2020, 162, 1819–1827. [Google Scholar] [CrossRef]

- Toldrá-Reig, F.; Mora, L.; Toldrá, F. Developments in the use of lipase transesterification for biodiesel production from animal fat waste. Appl. Sci. 2020, 10, 5085. [Google Scholar] [CrossRef]

- Alexandre, J.Y.N.H.; Cavalcante, F.T.T.; Freitas, L.M.; Castro, A.P.; Borges, P.T.; de Sousa, P.G., Jr.; Filho, M.N.R.; Lopes, A.A.S.; da Fonseca, A.M.; Lomonaco, D.; et al. A Theoretical and Experimental Study for Enzymatic Biodiesel Production from Babassu Oil (Orbignya sp.) Using Eversa Lipase. Catalysts 2022, 12, 1322. [Google Scholar] [CrossRef]

- Giraldo, L.; Gómez-Granados, F.; Moreno-Piraján, J.C. Biodiesel Production Using Palm Oil with a MOF-Lipase B Biocatalyst from Candida Antarctica: A Kinetic and Thermodynamic Study. Int. J. Mol. Sci. 2023, 24, 10741. [Google Scholar] [CrossRef]

- Bonazza, H.L.; Manzo, R.M.; dos Santos, J.C.S.; Mammarella, E.J. Operational and Thermal Stability Analysis of Thermomyces lanuginosus Lipase Covalently Immobilized onto Modified Chitosan Supports. Appl. Biochem. Biotechnol. 2018, 184, 182–196. [Google Scholar] [CrossRef]

- Kuang, G.; Wang, Z.; Luo, X.; Geng, Z.; Cui, J.; Bilal, M.; Wang, Z.; Jia, S. Immobilization of lipase on hydrophobic MOF synthesized simultaneously with oleic acid and application in hydrolysis of natural oils for improving unsaturated fatty acid production. Int. J. Biol. Macromol. 2023, 242, 124807. [Google Scholar] [CrossRef]

- Richter, J.L.; Zawadzki, S.F.; Alves dos Santos, L.; Alnoch, R.C.; Moure, V.R.; Mitchell, D.A.; Krieger, N. Immobilization of the metagenomic lipase, LipG9, on porous pellets of poly-hydroxybutyrate produced by the double emulsion solvent evaporation technique. Biotechnol. Appl. Biochem. 2023, 70, 1279–1290. [Google Scholar] [CrossRef] [PubMed]

- Cornish-Bowden, A. Fundamentals of Enzyme Kinetics, 4th ed.; Wiley-Blackwell: Hoboken, NJ, USA, 2012; p. 498. ISBN 978-3-527-33074-4. [Google Scholar]

- Sokač Cvetnić, T.; Šalić, A.; Benković, M.; Jurina, T.; Valinger, D.; Gajdoš Kljusurić, J.; Zelić, B.; Jurinjak Tušek, A. A Systematic Review of Enzymatic Kinetics in Microreactors. Catalysts 2023, 13, 708. [Google Scholar] [CrossRef]

- Manoel, E.A.; dos Santos, J.C.S.; Freire, D.M.G.; Rueda, N.; Fernandez-Lafuente, R. Immobilization of lipases on hydrophobic supports involves the open form of the enzyme. Enzym. Microb. Technol. 2015, 71, 2015. [Google Scholar] [CrossRef]

- Rodrigues, C.R.; Virgen-Ortíz, J.J.; dos Santos, J.C.S.; Berenguer-Murcia, Á.; Alcantara, A.R.; Barbosa, O.; Ortiz, C.; Fernandez-Lafuente, R. Immobilization of lipases on hydrophobic supports: Immobilization mechanism, advantages, problems, and solutions. Biotechnol. Adv. 2019, 37, 746–770. [Google Scholar] [CrossRef] [PubMed]

- Nielsen, P.M.; Rancke-Madsen, A.; Holm, H.C.; Burton, R. Production of Biodiesel Using Liquid Lipase Formulations. J. Am. Oil Chem. Soc. 2016, 93, 905–910. [Google Scholar] [CrossRef]

- Lv, L.; Dai, L.; Du, W.; Liu, D. Effect of water on lipase NS81006-catalyzed alcoholysis for biodiesel production. Process Biochem. 2017, 58, 239–244. [Google Scholar] [CrossRef]

- Mibielli, G.M.; Fagundes, A.P.; Bender, J.P.; Oliveira, J.V. Lab and pilot plant FAME production through enzyme-catalyzed reaction of low-cost feedstocks. Bioresour. Technol. Rep. 2019, 5, 150–156. [Google Scholar] [CrossRef]

- Miranda, L.P.; Guimarães, J.R.; Giordano, R.C.; Fernandez-Lafuente, R.; Tardioli, P.W. Composites of Crosslinked Aggregates of Eversa® Transform and Magnetic Nanoparticles. Performance in the Ethanolysis of Soybean Oil. Catalysts 2020, 10, 817. [Google Scholar] [CrossRef]

- Vieira, A.C.; Cansian, A.B.M.; Guimarães, J.R.; Vieira, A.M.S.; Fernandez-Lafuente, R.; Tardioli, P.W. Performance of Liquid Eversa on Fatty Acid Ethyl Esters Production by Simultaneous Esterification/Transesterification of Low-to-High Acidity Feedstocks. Catalysts 2021, 11, 1486. [Google Scholar] [CrossRef]

- Maghraby, Y.R.; El-Shabasy, R.M.; Ibrahim, A.H.; El-Said Azzazy, H.M. Enzyme Immobilization Technologies and Industrial Applications. ACS Omega 2023, 8, 5184–5196. [Google Scholar] [CrossRef] [PubMed]

- Morais Júnior, W.G.; Moura, M.A.; Alves, M.P.; Fernández-Lorente, G.; Guisán, J.M.; Pessela, B.C. Influence of different immobilization techniques to improve the enantioselectivity of lipase from Geotrichum candidum applied on the resolution of mandelic acid. Mol. Catal. 2018, 458, 89–96. [Google Scholar] [CrossRef]

- de Souza, W.F.C.; Almeida, F.L.C.; de Melo, A.M.; Soares, A.S.P.; Forte, M.B.S.; de Castro, R.J.S.; Sato, H.H. Immobilization techniques on bioprocesses: Current applications regarding enzymes, microorganisms, and essential oils. Food Bioprocess Technol. 2022, 15, 1449–1476. [Google Scholar] [CrossRef]

- Almeida, F.L.C.; Prata, A.S.; Forte, M.B.S. Enzyme immobilization: What have we learned in the past five years? Biofuels Bioprod. Biorefining 2022, 16, 587–608. [Google Scholar] [CrossRef]

- Yushkova, E.D.; Nazarova, E.A.; Matyuhina, A.V.; Noskova, A.O.; Shavronskaya, D.O.; Vinogradov, V.V.; Skvortsova, N.N.; Krivoshapkina, E.F. Application of Immobilized Enzymes in Food Industry. J. Agric. Food Chem. 2019, 67, 11553–11567. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.H.; Jin, E.S.; Lee, J.H.; Hwang, E.T. Immobilization and Stabilization of Enzyme in Biomineralized Calcium Carbonate Microspheres. Front. Bioeng. Biotechnol. 2020, 8, 553591. [Google Scholar] [CrossRef]

- Homaei, A.A.; Sariri, R.; Vianello, F.; Stevanato, R. Enzyme immobilization: An update. J. Chem. Biol. 2013, 6, 185–205. [Google Scholar] [CrossRef]

- Remonatto, D.; Miotti, R.H., Jr.; Monti, R.; Bassan, J.C.; de Paula Veloso, A. Applications of immobilized lipases in enzymatic reactors: A review. Process Biochem. 2022, 114, 1–20. [Google Scholar] [CrossRef]

- Singh, P.; Kumar, S. Chapter 2—Microbial Enzyme in Food Biotechnology. In Enzymes in Food Biotechnology; Kuddus, M., Ed.; Academic Press: Cambridge, MA, USA, 2018; Volume 1, pp. 19–28. [Google Scholar] [CrossRef]

- Garcia-Quinto, E.; Aranda-Cañada, R.; Garcia-Garcia, P.; Fernández-Lorente, G. Use of Potential Immobilized Enzymes for the Modification of Liquid Foods in the Food Industry. Processes 2023, 11, 1840. [Google Scholar] [CrossRef]

- Hidouri, S.; Errachid, A.H.; Baussels, J.; Korpan, Y.I.; Ruiz-Sanchez, O.; Baccar, Z.M. Potentiometric sensing of histamine using immobilized enzymes on layered double hydroxides. J. Food Sci. Technol. 2021, 58, 2936–2942. [Google Scholar] [CrossRef]

- Han, J.; Zhang, T.; Zhou, Z.; Zhang, H. Development of a novel ultrasound- and biocrosslinking-enhanced immobilization strategy with application to food enzymes. Food Chem. 2023, 417, 135810. [Google Scholar] [CrossRef]

- Sampaio, C.S.; Angelotti, J.A.F.; Fernandez-Lafuente, R.; Hirata, D.B. Lipase immobilization via cross-linked enzyme aggregates: Problems and prospects—A review. Int. J. Biol. Macromol. 2022, 215, 434–449. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Quinto, E.; Garcia-Garcia, P.; Guisan, J.M.; Fernandez-Lorente, G. Enzymatic synthesis of mono- and disubstituted phospholipids by direct condensation of oleic acid and glycerophosphocholine with immobilized lipases and phospholipase. Food Chem. 2023, 4011, 134109. [Google Scholar] [CrossRef]

- Gonçalves, M.C.P.; Cansian, A.B.M.; Tardioli, P.W.; Saville, B.A. Production of sugars from mixed hardwoods for use in the synthesis of sugar fatty acid esters catalyzed by immobilized-stabilized derivatives of Candida antarctica lipase B. Biofuels Bioprod. Biorefining 2023. [Google Scholar] [CrossRef]

- Guimarães, J.R.; Carballares, D.; Rocha-Martin, J.; Alcântara, A.R.; Tardioli, P.W.; Fernandez-Lafuente, R. Heterofunctional Methacrylate Beads Bearing Octadecyl and Vinyl Sulfone Groups: Tricks to Obtain an Interfacially Activated Lipase from Thermomyces lanuginosus and Covalently Attached to the Support. Catalysts 2023, 13, 108. [Google Scholar] [CrossRef]

- Cordeiro, E.d.S.; Henriques, R.O.; Deucher, E.M.; de Oliveira, D.; Lerin, L.A.; Junior, A.F. Optimization, kinetic, and scaling-up of solvent-free lipase-catalyzed synthesis of ethylene glycol oleate emollient ester. Biotechnol. Appl. Bioquim. 2020, 10, 2067–2077. [Google Scholar] [CrossRef] [PubMed]

- García-Oliva, C.; Perona, A.; Rumbero, Á.; Hoyos, P.; Hernáiz, M.J. Enzymatic Synthesis and Molecular Modelling Studies of Rhamnose Esters Using Lipase from Pseudomonas stutzeri. Int. J. Mol. Sci. 2022, 23, 2239. [Google Scholar] [CrossRef]

- Cui, C.; Li, L.; Li, M. Improvement of lipase activity by synergistic immobilization on polyurethane and its application for large-scale synthesizing vitamin A palmitate. Prep. Biochem. Biotechnol. 2019, 49, 485–492. [Google Scholar] [CrossRef]

- Novaes, F.; Junior, I.; Sutili, F.; Marriott, P.; Bizzo, H.; Radler de Aquino Neto, F.; de Souza, R.; Rezende, C. Lipase-Catalysed Esters Synthesis of Cafestol and Kahweol. Food Chemistry 2018, 259, 226–233. [Google Scholar] [CrossRef]

- Chow, J.Y.; Shi Choo, K.L.; Lim, Y.P.; Ling, L.H.; Truc Nguyen, G.K.; Xue, B.; Chua, N.H.; Yew, W.S. Scalable Workflow for Green Manufacturing: Discovery of Bacterial Lipases for Biodiesel Production. ACS Sustain. Chem. Eng. 2021, 9, 13450–13459. [Google Scholar] [CrossRef]

- Colacicco, M.; Ciliberti, C.; Agrimi, G.; Biundo, A.; Pisano, I. Towards the Physiological Understanding of Yarrowia lipolytica Growth and Lipase Production Using Waste Cooking Oils. Energies 2022, 15, 5217. [Google Scholar] [CrossRef]

- Qi, H.; Du, Y.; Hu, G.; Zhang, L. Poly (Carboxybetaine Methacrylate)-Functionalized Magnetic Composite Particles: A Biofriendly Support for Lipase Immobilization. Int. J. Biol. Macromol. 2018, 107, 2660–2666. [Google Scholar] [CrossRef]

- Oliveira, F.; Salgado, J.M.; Pérez-Rodríguez, N.; Domínguez, J.M.; Venâncio, A.; Belo, I. Lipase production by solid-state fermentation of olive pomace in tray-type and pressurized bioreactors. J. Chem. Technol. Biotechnol. 2018, 93, 1312–1319. [Google Scholar] [CrossRef]

- Ismail, A.R.; El-Henawy, S.B.; Younis, S.A.; Betiha, M.A.; El-Gendy, N.S.; Azab, M.S.; Sedky, N.M. Statistical enhancement of lipase extracellular production by Bacillus stratosphericus PSP8 in a batch submerged fermentation process. J. Appl. Microbiol. 2018, 125, 1076–1093. [Google Scholar] [CrossRef] [PubMed]

- Fu, Y.; Lu, Z.; Ma, X.; Fang, K.; He, X.; Xu, H.; Hu, Y. One-Pot Cascade Synthesis of Benzopyrans and Dihydropyrano[c]Chromenes Catalyzed by Lipase TLIM. Bioorganic Chem. 2020, 99, 103888. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Zhang, Y.; Zheng, L.; Cui, X.; Huang, H.; Geng, X.; Xie, X. Regioselective acylation of resveratrol catalyzed by lipase under microwave. Green Chem. Lett. Rev. 2018, 11, 312–317. [Google Scholar] [CrossRef]

- Ping, L.; Yuan, X.; Zhang, M.; Chai, Y.; Shan, S. Improvement of Extracellular Lipase Production by a Newly Isolated Yarrowia Lipolytica Mutant and Its Application in the Biosynthesis of L-Ascorbyl Palmitate. Int. J. Biol. Macromol. 2018, 106, 302–311. [Google Scholar] [CrossRef]

- Bayout, I.; Bouzemi, N.; Guo, N.; Mao, X.; Serra, S.; Riva, S.; Secundo, F. Natural flavor ester synthesis catalyzed by lipases. Flavour Fragr J. 2020, 35, 209–218. [Google Scholar] [CrossRef]

- do Nascimento, F.V.; de Castro, A.M.; Secchi, A.R.; Coelho, M.A.Z. Insights into Media Supplementation in Solid-State Fermentation of Soybean Hulls by Yarrowia Lipolytica: Impact on Lipase Production in Tray and Insulated Packed-Bed Bioreactors. Biochem. Eng. J. 2021, 166, 107866. [Google Scholar] [CrossRef]

- de Meneses, A.C.; Sá, A.G.A.; Lerin, L.A.; Corazza, M.L.; de Araújo, P.H.H.; Sayer, C.; Oliveira, D. de Benzyl Butyrate Esterification Mediated by Immobilized Lipases: Evaluation of Batch and Fed-Batch Reactors to Overcome Lipase-Acid Deactivation. Process Biochem. 2019, 78, 50–57. [Google Scholar] [CrossRef]

- López-Fernández, J.; Benaiges, M.D.; Valero, F. Second- and Third-Generation Biodiesel Production with Immobilised Recombinant Rhizopus Oryzae Lipase: Influence of the Support, Substrate Acidity and Bioprocess Scale-Up. Bioresour. Technol. 2021, 334, 125233. [Google Scholar] [CrossRef] [PubMed]

| Keyword | Total Link Strength | Occurrences |

|---|---|---|

| Lipase | 784 | 147 |

| Industrial applications | 559 | 103 |

| Purification | 523 | 91 |

| Immobilization | 389 | 65 |

| Stability | 310 | 53 |

| Enzymes | 231 | 43 |

| Enzyme immobilization | 209 | 37 |

| Optimization | 191 | 34 |

| Lipases | 168 | 33 |

| Expression | 190 | 32 |

| Biochemical characterization | 181 | 29 |

| Biodiesel | 176 | 29 |

| Biocatalysis | 163 | 28 |

| Biodiesel production | 160 | 26 |

| Esterase | 146 | 26 |

| Hydrolysis | 158 | 26 |

| Enzyme | 164 | 25 |

| Microbial lipases | 146 | 25 |

| Alkaline lipase | 145 | 21 |

| Candida rugosa lipase | 127 | 21 |

| Oil | 126 | 20 |

| Covalent immobilization | 124 | 19 |

| Kinetic resolution | 123 | 19 |

| Thermostability | 123 | 19 |

| Cloning | 112 | 18 |

| Extracellular lipase | 128 | 18 |

| Identification | 118 | 18 |

| Adsorption | 112 | 17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

dos Santos, L.N.; Perna, R.F.; Vieira, A.C.; de Almeida, A.F.; Ferreira, N.R. Trends in the Use of Lipases: A Systematic Review and Bibliometric Analysis. Foods 2023, 12, 3058. https://doi.org/10.3390/foods12163058

dos Santos LN, Perna RF, Vieira AC, de Almeida AF, Ferreira NR. Trends in the Use of Lipases: A Systematic Review and Bibliometric Analysis. Foods. 2023; 12(16):3058. https://doi.org/10.3390/foods12163058

Chicago/Turabian Styledos Santos, Lucely Nogueira, Rafael Firmani Perna, Ana Carolina Vieira, Alex Fernando de Almeida, and Nelson Rosa Ferreira. 2023. "Trends in the Use of Lipases: A Systematic Review and Bibliometric Analysis" Foods 12, no. 16: 3058. https://doi.org/10.3390/foods12163058

APA Styledos Santos, L. N., Perna, R. F., Vieira, A. C., de Almeida, A. F., & Ferreira, N. R. (2023). Trends in the Use of Lipases: A Systematic Review and Bibliometric Analysis. Foods, 12(16), 3058. https://doi.org/10.3390/foods12163058