Fermentative Production of Diacylglycerol by Endophytic Fungi Screened from Taxus chinensis var. mairei

Abstract

:1. Introduction

2. Materials and Methods

2.1. Source of Plant Tissues

2.2. Isolation of Endophytic Fungi

2.3. Screening of DAG-Producing Endophytic Fungal Strains

2.3.1. Flask Cultivation

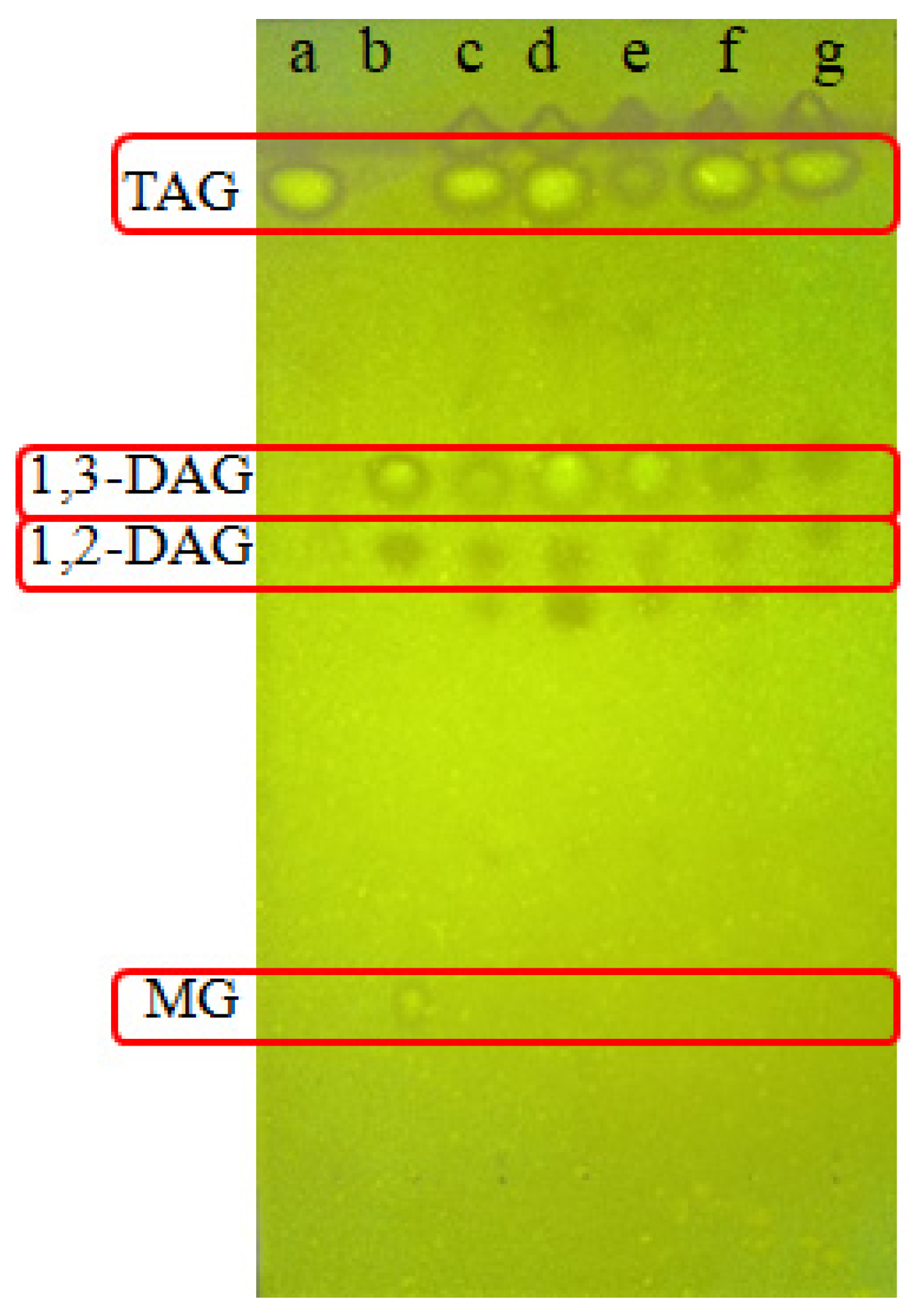

2.3.2. Screening of Lipid-Producing Endophytic Fungal Strains

2.3.3. Screening of DAG-Producing Endophytic Fungal Strains and Analysis of FA Composition

2.4. Biological Identification of DAG-Producing Endophytic Fungal Strains

2.4.1. DNA Extraction and Semi-Quantitative PCR

2.4.2. Phylogenetic Analysis

2.5. Evaluation of Effect of Culture Conditions on DAG Productivity

2.6. 1H NMR Analysis of the Extracted Lipids and Determination of DAG Yield

3. Results and Discussion

3.1. Isolation and Screening of DAG-Producing Endophytic Fungi

3.2. Identification of DAG-Producing Endophytic Fungi

3.3. FA compositions of Lipids and Their TLC Fractions from DAG-Producing Endophytic Fungi

3.4. 1H NMR Spectra of the Extracted Endophytic Fungal Lipids and Determination of DAG Yields

3.5. Effect of Fermentation Parameters on DAG Productivity

3.5.1. Effect of Fermentation Time

3.5.2. Effect of Inoculation Dosage

3.5.3. Effect of Temperature

3.5.4. Effect of Rotating Speed of Flasks

3.5.5. Effect of C/N Ratio

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, Y.Y.; Tang, T.K.; Phuah, E.T.; Tan, C.P.; Wang, Y.; Li, Y.; Cheong, L.Z.; Lai, O.M. Production, Safety, Health Effects and Applications of Diacylglycerol Functional Oil in Food Systems: A Review. Crit. Rev. Food Sci. Nutr. 2020, 60, 2509–2525. [Google Scholar] [CrossRef] [PubMed]

- Lee, A.; Yoo, H.J.; Kim, M.; Kim, M.; Choi, J.-H.; Lee, C.; Lee, J.H. Effects of Equivalent Medium-Chain Diacylglycerol or Long-Chain Triacylglycerol Oil Intake Via Muffins on Postpradial Triglycerides and Plasma Fatty Acids Levels. J. Func. Foods 2019, 53, 299–305. [Google Scholar] [CrossRef]

- Devi, B.L.A.P.; Gangadhar, K.N.; Prasad, R.B.N.; Sugasini, D.; Rao, Y.P.C.; Lokesh, B.R. Nutritionally Enriched 1,3-Diacylglycerol-Rich Oil: Low Calorie Fat with Hypolipidemic Effects in Rats. Food Chem. 2018, 248, 210–216. [Google Scholar] [CrossRef] [PubMed]

- Cooke, M.; Kazanietz, M.G. Overarching Roles of Diacylglycerol Signaling in Cancer Development and Antitumor Immunity. Sci. Signal. 2022, 15, eabo0264. [Google Scholar] [CrossRef] [PubMed]

- Cicero, N.; Albergamo, A.; Salvo, A.; Bua, G.D.; Bartolomeo, G.; Mangano, V.; Rotondo, A.; Di Stefano, V.; Di Bella, G.; Dugo, G. Chemical Characterization of a Variety of Cold-Pressed Gourmet Oils Available on the Brazilian Market. Food Res. Int. 2018, 109, 517–525. [Google Scholar] [CrossRef] [PubMed]

- Salvo, A.; Rotondo, A.; La Torre, G.L.; Cicero, N.; Dugo, G. Determination of 1,2/1,3-Diglycerides in Sicilian Extra-Virgin Olive Oils by 1H-NMR over a One-Year Storage Period. Nat. Prod. Res. 2017, 31, 822–828. [Google Scholar] [CrossRef] [PubMed]

- Ferretti, C.A.; Spotti, M.L.; Di Cosimo, J.I. Diglyceride-Rich Oils from Glycerolysis of Edible Vegetable Oils. Catal. Today 2018, 302, 233–241. [Google Scholar] [CrossRef]

- Palacios, D.; Ortega, N.; Rubio-Rodríguez, N.; Busto, M.D. Lipase-catalyzed Glycerolysis of Anchovy Oil in a Solvent-Free System: Simultaneous Optimization of Monoacylglycerol Synthesis and End-Product Oxidative Stability. Food Chem. 2019, 271, 372–379. [Google Scholar] [CrossRef]

- Huang, C.Q.; Lin, Z.P.; Zhang, Y.L.; Liu, Z.Y.; Tang, X.Y.; Li, C.Z.; Lin, L.; Huang, W.Q.; Ye, Y. Structure-Guided Preparation of Functional Oil Rich in 1,3-Diacylglycerols and Linoleic Acid from Camellia Oil by Combi-lipase. J. Sci. Food Agric. 2023, 103, 108–117. [Google Scholar] [CrossRef] [PubMed]

- Cho, H.U.; Park, J.M. Biodiesel Production by Various Oleaginous Microorganisms from Organic Wastes. Bioresour. Technol. 2018, 256, 502–508. [Google Scholar] [CrossRef]

- Mhlongo, S.I.; Ezeokoli, O.T.; Roopnarain, A.; Ndaba, B.; Sekoai, P.T.; Habimana, O.; Pohl, C.H. The Potential of Single-Cell Oils Derived from Filamentous Fungi as Alternative Feedstock Source for Biodiesel Production. Front. Microbiol. 2021, 12, 637381. [Google Scholar] [CrossRef]

- Vulevic, J.; Gibson, G.R. In Vitro Effects of Phosphatidylcholine and Transgalactooligosaccharides on the Production of 1,2-Sn-Diacylglycerol by Bifidobacterium Longum Biovar Infantis. J. Appl. Microbiol. 2008, 105, 1678–1685. [Google Scholar] [CrossRef] [PubMed]

- Vulevic, J.; McCartney, A.L.; Gee, J.M.; Johnson, I.T.; Gibson, G.R. Microbial Species Involved in Production of 1,2-Sn-Diacylglycerol and Effects of Phosphatidylcholine on Human Fecal Microbiota. Appl. Environ. Microbiol. 2004, 70, 5659–5666. [Google Scholar] [CrossRef] [Green Version]

- Sabzehzari, M.; Zeinali, M.; Naghavi, M.R. Alternative Sources and Metabolic Engineering of Taxol: Advances and Future Perspectives. Biotechnol. Adv. 2020, 43, 107565. [Google Scholar] [CrossRef]

- Wen, J.; Okyere, S.K.; Wang, S.; Wang, J.C.; Xie, L.; Ran, Y.A.; Hu, Y.C. Endophytic Fungi: An Effective Alternative Source of Plant-Derived Bioactive Compounds for Pharmacological Studies. J. Fungi 2022, 8, 205. [Google Scholar] [CrossRef]

- Destaillats, F.; Wolff, R.L.; Angers, P. A New Δ7-Polyunsaturated Fatty Acid in Taxus Spp. Seed Lipids, Dihomotaxoleic (7,11–20:2) Acid. Lipids 2001, 36, 319–321. [Google Scholar] [CrossRef] [PubMed]

- Tabaszewska, M.; Rutkowska, J.; Skoczylas, Ł.; Slupski, J.; Antoniewska, A.; Smolen, S.; Lukasiewica, M.; Baranowski, D.; Duda, I.; Pietsch, J. Red Arils of Taxus Baccata L.―A New Source of Valuable Fatty Acids and Nutrients. Molecules 2021, 26, 723. [Google Scholar] [CrossRef] [PubMed]

- Tuo, L.; Liu, F.; Yan, X.R.; Liu, Y. Bacillus taxi sp. Nov., a Novel Endophytic Bacterium Isolated from Root of Taxus chinensis (Pilger) Rehs. Int. J. Syst. Evol. Microbiol. 2020, 70, 481–486. [Google Scholar] [CrossRef]

- Ismaiel, A.A.; Ahmed, A.S.; Hassan, I.A.; El-Sayed, E.S.R.; Karam El-Din, A.A.K. Production of Paclitaxel with Anticancer Activity by Two Local Fungal Endophytes, Aspergillus Fumigatus and Alternaria Tenuissima. Appl. Microbiol. Biotechnol. 2017, 101, 5831–5846. [Google Scholar] [CrossRef] [PubMed]

- Cantellops, D.; Reid, A.P.; Eitenmiller, R.R.; Long, A.R. Determination of Lipids in Infant Formula Powder by Direct Extraction Methylation of Lipids and Fatty Acid Methyl Esters (FAME) Analysis by Gas Chromatography. J. AOAC Int. 1999, 82, 1128–1139. [Google Scholar] [CrossRef]

- Shah, A.M.; Mohamed, H.; Zhang, Z.C.; Song, Y.D. Isolation, Characterization and Fatty Acid Analysis of Gilbertella Persicaria DSR1: A Potential New Source of High Value Single-Cell Oil. Biomass Bioenergy 2021, 151, 106156. [Google Scholar] [CrossRef]

- Sales-Campos, H.; de Souza, P.R.; Peghini, B.C.; da Silva, J.S.; Cardoso, C.R. An Overview of the Modulatory Effects of Oleic Acid in Health and Disease. Mini-Rev. Med. Chem. 2013, 13, 201–210. [Google Scholar]

- San Martin, E.; Aovenza, A.; Peregrina, J.M.; Busto, J.H. Solvent-Based Strategy Improves the Direct Determination of Key Parameters in Edible Fats and Oils by 1H NMR. J. Sci. Food Agric. 2020, 100, 1726–1734. [Google Scholar] [CrossRef]

- Nieva-Echevarría, B.; Goicoechea, E.; Manzanos, M.J.; Guillén, M.D. Usefulness of 1H NMR in Assessing the Extent of Lipid Digestion. Food Chem. 2015, 179, 182–190. [Google Scholar] [CrossRef] [Green Version]

- Tang, F.F.; Green, H.S.; Wang, S.C.; Hatzakis, E. Analysis and Authentication of Avocado Oil Using High Resolution NMR Spectroscopy. Molecules 2021, 26, 310. [Google Scholar] [CrossRef]

- Sarpal, A.S.; Teixeira, C.M.L.L.; Silva, P.R.M.; Lima, G.M.; Silva, S.R.; Monteiro, T.V.; Cunha, V.S.; Daroda, R.J. Determination of Lipid Content of Oleaginous Microalgal Biomass by NMR Spectroscopic and GC–MS Techniques. Anal. Bioanal. Chem. 2015, 407, 3799–3816. [Google Scholar] [CrossRef] [PubMed]

- Sato, R.; Ara, S.; Yamazaki, H.; Ishiya, K.; Aburatani, S.; Takaku, H. Citrate-Mediated Acyl-CoA Synthesis is Required for the Promotion of Growth and Triacylglycerol Production in Oleaginous Yeast Lipomyces starkeyi. Microorganisms 2021, 9, 1693. [Google Scholar] [CrossRef] [PubMed]

- Takaku, H.; Matsuzawa, T.; Yaoi, K.; Yamazaki, H. Lipid Metabolism of the Oleaginous Yeast Lipomyces starkeyi. Appl. Microbiol. Biotechnol. 2020, 104, 6141–6148. [Google Scholar] [CrossRef] [PubMed]

- Fronimaki, P.; Spyros, A.; Christophoridou, S.; Dais, P. Determination of the Diglyceride Content in Greek Virgin Olive Oils and Some Commercial Olive Oils by Employing 31P NMR Spectroscopy. J. Agric. Food Chem. 2002, 50, 2207–2213. [Google Scholar] [CrossRef]

- Lu, H.Q.; Chen, H.Q.; Tang, X.; Yang, Q.; Zhang, H.; Chen, Y.Q.; Chen, W. Metabolomics Analysis Reveals the Role of Oxygen Control in the Nitrogen Limitation Induced Lipid Accumulation in Mortierella alpina. J. Biotechnol. 2021, 325, 325–333. [Google Scholar] [CrossRef]

- Yen, H.W.; Zhang, Z.Y. Effects of Dissolved Oxygen Level on Cell Growth and Total Lipid Accumulation in the Cultivation of Rhodotorula Glutinis. J. Biosci. Bioeng. 2011, 112, 71–74. [Google Scholar] [CrossRef] [PubMed]

- Lunt, S.Y.; Vander Heiden, M.G. Aerobic Glycolysis: Meeting the Metabolic Requirements of Cell Proliferation. Ann. Rev. Cell Dev. Biol. 2011, 27, 441–464. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, H.T.; Hu, B.; Liu, J.; Qian, H.; Xu, J.Z.; Zhang, W.G. Co-Production of Lipid, Exopolysaccharide and Single-Cell Protein by Sporidiobolus pararoseus under Ammonia Nitrogen-Limited Conditions. Bioproc. Biosyst. Eng. 2020, 43, 1403–1414. [Google Scholar] [CrossRef] [PubMed]

| Code | Tissue | Identification Result | Accession Number | Homology |

|---|---|---|---|---|

| MLP41 | Bark | Fusarium annulatum (F. annulatum) | OK325613 | 559/559 (100%) |

| MLG23 | Root | Trichoderma dorotheae (T. dorotheae) | OK315570 | 535/535 (100%) |

| MLY23 | Leaf | Colletotrichum aeschynomenes (C. aeschynomenes) | OK325610 | 530/531 (99.81%) |

| MLY31W | Leaf | Pestalotiopsis scoparia (P. scoparia) | OK325612 | 573/575 (99.65%) |

| MLGP11 | Root | Penicillium cataractarum (P. cataractarum) | OK325611 | 571/572 (99.83%) |

| FAs | Relative Percentage (%) | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MLP41 | MLG23 | MLY23 | MLY31W | MLGP11 | ||||||||||||||||

| Lipids | TAG | 1,2-DAG | 1,3-DAG | Lipids | TAG | 1,2-DAG | 1,3-DAG | Lipids | TAG | 1,2-DAG | 1,3-DAG | Lipids | TAG | 1,2-DAG | 1,3-DAG | Lipids | TAG | 1,2-DAG | 1,3-DAG | |

| C14:0 | 0.41 | 0.36 | 1.12 | nd | 0.003 | 0.51 | nd | nd | 0.56 | 1.25 | 3.08 | 1.74 | 0.42 | nd | nd | 0.49 | 0.54 | 0.18 | nd | nd |

| C15:0 | 0.31 | 0.53 | nd | nd | 0.43 | 0.81 | 0.64 | 0.43 | nd | 0.37 | 1.70 | 1.46 | nd | nd | nd | nd | 1.73 | 1.04 | 0.98 | nd |

| C16:0 | 21.58 | 28.45 | 20.24 | 24.82 | 19.08 | 25.21 | 27.82 | 25.97 | 31.97 | 31.61 | 35.11 | 34.13 | 29.09 | 34.24 | 21.80 | 19.15 | 17.63 | 24.55 | 23.33 | 24.43 |

| C16:1 | 1.14 | 2.04 | 2.38 | nd | 0.77 | 1.93 | 2.30 | 1.46 | 0.85 | 2.10 | 7.22 | 5.43 | 0.44 | nd | nd | 1.62 | 1.44 | 0.77 | 2.11 | 2.01 |

| C17:0 | 0.08 | nd | nd | nd | 0.40 | 0.52 | nd | nd | nd | nd | nd | nd | nd | nd | nd | nd | 1.25 | 0.33 | nd | nd |

| C17:1 | nd | nd | nd | nd | 0.59 | 1.37 | nd | nd | nd | nd | nd | nd | nd | nd | nd | nd | 0.70 | nd | nd | nd |

| C18:0 | 10.93 | 10.07 | 11.56 | 15.36 | 7.15 | 8.07 | 7.03 | 8.71 | 9.15 | 10.93 | 16.31 | 20.61 | 10.18 | 11.26 | 9.22 | 12.69 | 13.88 | 17.42 | 14.18 | 14.59 |

| C18:1 | 38.66 | 34.20 | 40.56 | 46.69 | 36.76 | 32.55 | 31.12 | 34.99 | 40.41 | 33.55 | 31.34 | 26.77 | 38.61 | 38.92 | 45.69 | 55.82 | 26.82 | 26.81 | 34.00 | 28.80 |

| C18:2 | 25.81 | 24.04 | 24.14 | 13.13 | 32.12 | 28.96 | 31.09 | 28.43 | 14.71 | 14.83 | 5.24 | 9.87 | 19.52 | 12.89 | 23.29 | 10.23 | 34.30 | 27.65 | 25.40 | 30.16 |

| C18:3 | nd | nd | nd | nd | 1.41 | nd | nd | nd | 1.34 | 2.20 | nd | nd | nd | nd | nd | nd | nd | nd | nd | nd |

| C20:0 | 0.46 | 0.09 | nd | nd | 0.32 | 0.08 | nd | nd | 0.46 | 1.47 | nd | nd | 1.16 | 2.09 | nd | nd | 1.72 | 0.53 | nd | nd |

| C22:0 | 0.61 | 0.21 | nd | nd | nd | nd | nd | nd | 0.55 | 1.69 | nd | nd | 0.58 | 0.60 | nd | nd | nd | 0.71 | nd | nd |

| C16 + C18 | 98.03 | 98.81 | 98.88 | 100.00 | 97.29 | 96.71 | 99.36 | 99.57 | 98.43 | 95.22 | 95.22 | 96.80 | 97.84 | 97.31 | 100.00 | 99.51 | 94.07 | 94.42 | 99.02 | 100.00 |

| SFA | 34.39 | 39.72 | 32.92 | 40.18 | 27.38 | 35.19 | 35.49 | 35.12 | 42.69 | 47.32 | 56.92 | 57.93 | 41.43 | 48.19 | 31.02 | 32.33 | 36.74 | 46.35 | 38.49 | 39.03 |

| MUFA | 39.80 | 36.24 | 42.94 | 46.69 | 39.09 | 35.85 | 33.42 | 36.45 | 41.26 | 35.65 | 38.56 | 32.20 | 39.05 | 38.92 | 45.69 | 57.44 | 28.95 | 26.79 | 36.11 | 30.81 |

| PUFA | 25.81 | 24.04 | 24.14 | 13.13 | 33.53 | 28.96 | 31.09 | 28.43 | 16.05 | 17.03 | 5.24 | 9.87 | 19.52 | 12.89 | 23.29 | 10.23 | 34.30 | 26.86 | 25.40 | 30.16 |

| UFA | 65.61 | 60.28 | 67.08 | 59.82 | 72.62 | 64.81 | 64.51 | 64.88 | 57.31 | 52.68 | 43.80 | 42.07 | 58.57 | 51.81 | 68.98 | 67.67 | 63.26 | 53.65 | 61.51 | 60.97 |

| Code | Chemical Shift (ppm) | Multiplicity | Type of Protons | Compound |

|---|---|---|---|---|

| A | 0.84–0.92 | t | –CH3 | Acyl groups and FA |

| B | 1.30 | m | –(CH2)n– | Acyl groups and FA |

| C | 1.61 | m | –OCOCH2CH2– | Acyl groups |

| D | 2.00–2.04 | m | –CH2CH=CH– | Acyl groups and FA |

| E | 2.28–2.38 | m | –OCOCH2– | Acyl groups and FA |

| F | 2.76 | m | –CH=CHCH2CH=CH– | Unsaturated ω-6 and ω-3 acyl groups and FA |

| G | 3.61, 3.69 | dd | –CH2OH | Glyceryl group in 1-MAG |

| H | 3.73 | m | –CH2OH | Glyceryl group in 1,2-DAG |

| I | 3.84 | m | –CH2OH | Glyceryl group in 2-MAG |

| J | 3.94 | m | –CHOHCH2OH | Glyceryl group in 1-MAG |

| K | 4.07 | m | –CHOH– | Glyceryl group in 1,3-DAG |

| L | 4.13 | dd | –CH2OCO– | Glyceryl group in 1,3-DAG |

| M | 4.14 | dd | –CH2OCO– | Glyceryl group in TAG |

| N | 4.18 | dd | –CH2OCO– | Glyceryl group in 1-MAG |

| O | 4.23 | dd | –CH2OCO– | Glyceryl group in 1,2-DAG |

| P | 4.29 | dd, dd | –CH2OCO– | Glyceryl group in TAG |

| Q | 5.08 | m | –CH(OCOR’)– | Glyceryl group in 1,2-DAG |

| R | 5.26 | m | –CH(OCOR’)– | Glyceryl group in TAG |

| S | 5.30–5.40 | m | –CH=CH– | Acyl groups and FA |

| T | 3.99 | dd | Undetermined | |

| U | 3.98 | dd | Undetermined | |

| V | 3.67 | m | Phospholipids |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, W.; Bi, H.; Peng, H.; Yang, L.; He, H.; Fu, G.; Liu, Y.; Wan, Y. Fermentative Production of Diacylglycerol by Endophytic Fungi Screened from Taxus chinensis var. mairei. Foods 2023, 12, 399. https://doi.org/10.3390/foods12020399

Xu W, Bi H, Peng H, Yang L, He H, Fu G, Liu Y, Wan Y. Fermentative Production of Diacylglycerol by Endophytic Fungi Screened from Taxus chinensis var. mairei. Foods. 2023; 12(2):399. https://doi.org/10.3390/foods12020399

Chicago/Turabian StyleXu, Wenqiang, Haoran Bi, Hong Peng, Ling Yang, Hongwei He, Guiming Fu, Yuhuan Liu, and Yin Wan. 2023. "Fermentative Production of Diacylglycerol by Endophytic Fungi Screened from Taxus chinensis var. mairei" Foods 12, no. 2: 399. https://doi.org/10.3390/foods12020399

APA StyleXu, W., Bi, H., Peng, H., Yang, L., He, H., Fu, G., Liu, Y., & Wan, Y. (2023). Fermentative Production of Diacylglycerol by Endophytic Fungi Screened from Taxus chinensis var. mairei. Foods, 12(2), 399. https://doi.org/10.3390/foods12020399