Carbon Footprint of the Pork Product Chain and Recent Advancements in Mitigation Strategies

Abstract

:1. Introduction

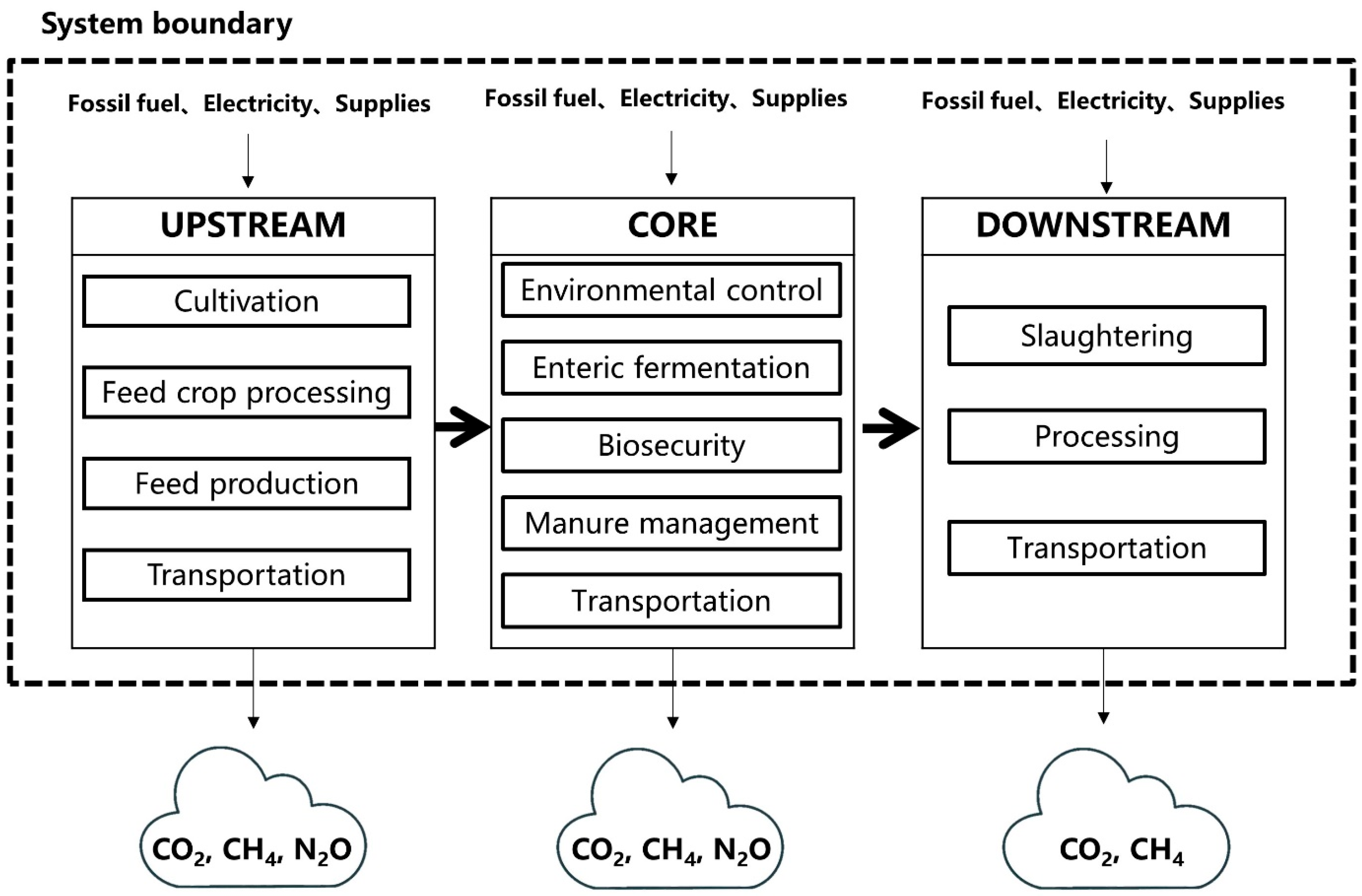

2. System Boundary of Pork Products

3. Source of GHG Emissions

3.1. Transportation

3.2. Feed Production

3.3. Pig Production

3.4. Respiration and Gut Fermentation

3.5. Manure Management

3.6. Wastewater and Harmless Treatment

3.7. Biosecurity

3.8. Slaughtering and Processing

4. Mitigation Strategies for Carbon Emission

4.1. Reducing Transportation Distance

4.2. Mitigation in Feed Crop Production

4.3. Renewable Energy Applications

4.4. Energy-Saving and High-Efficiency Feed Processing Technology

4.5. New Modes of Environmental Control

4.6. Reasonable Manure Management

4.7. Improve Pork Production Efficiency

- Adopting breeding goals: focused on increased feed efficiency and improved animal welfare that can lead to a reduction in the carbon footprint of pork production. The study compared two future scenarios, one reflecting the current breeding goal and the other reflecting a future breeding goal with the mentioned improvements; the results showed that the carbon footprint of the pork production system was 6.5% lower in the scenario with the alternative breeding goal compared to the one with the current breeding goal [59]. This suggests that by prioritizing feed efficiency and animal welfare, the pork industry can potentially produce pork with lower carbon emissions.

- Strengthen feeding management: Combined with the production model and local actual conditions, the standard operating procedures for pig production were formulated (establishing a stable workforce and deploy personnel according to production rhythm, implementing regulations on the use of farm hygiene products, strengthening biosecurity measures, and implementing effective management for the purification of epidemic diseases).

- Implement nutritional regulation methods: Adjusted nutrition based on the characteristics of different production stages to reduce carbon and nitrogen emissions in pig production. For example, the use of low-protein diets can reduce nitrogen and carbon content in pig manure, resulting in a significant reduction in GHG emissions during manure management processes [60,61]. The application of functional nutritional regulation techniques to improve feed conversion efficiency is key to reducing GHG emissions in the pig industry. Antimicrobial peptides, plant extracts, and functional substances can enhance the health and growth performance of pig herds [62,63,64,65], thereby strengthening immune function, reducing disease-related losses, and indirectly reducing the use of immunological healthcare products, thus lowering carbon emissions associated with their application.

5. Limitations of the Study

6. Areas for Further Research

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Nations Environment Programme. Emissions Gap Report (EGR) 2022: The Closing Window—Climate Crisis Calls for Rapid Transformation of Societies. 2022. Available online: https://www.unep.org/resources/emissions-gap-report-2022 (accessed on 8 October 2023).

- The Food and Agriculture Organization of the United Nations. Food and Agriculture Organization Statistics. 2020. Available online: https://www.fao.org/faostat/en/#data/GT (accessed on 1 November 2023).

- The Food and Agriculture Organization of the United Nations. Global Livestock Environmental Assessment Model Version 3. 2022. Available online: https://foodandagricultureorganization.shinyapps.io/GLEAMV3_Public/ (accessed on 8 October 2023).

- Zhou, Y.; Dong, H.; Xin, H.; Zhu, Z.; Huang, W.; Wang, Y. Carbon footprint assessment of a large-scale pig production system in northern China: A case study. Trans. ASABE 2018, 61, 1121–1131. [Google Scholar] [CrossRef]

- Chen, J.; Wang, S.; Ou, C.T.; Jiang, X. Study on carbon emission measurement and dynamic optimization of fresh meat supply chain. J. China Agric. Univ. 2020, 25, 165–182. [Google Scholar]

- Li, Q.; Gao, M.; Li, J. Carbon emissions inventory of farm size pig husbandry combining Manure-DNDC model and IPCC coefficient methodology. J. Clean. Prod. 2021, 320, 128854. [Google Scholar] [CrossRef]

- Li, J.; Li, Q.; Liu, L. Carbon emissions from smallholder pig production in China: A precise account based on farmers’ survey. Environ. Sci. Pollut. Res. 2022, 29, 25651–25664. [Google Scholar] [CrossRef] [PubMed]

- Long, W.; Wang, H.; Hou, Y.; Chadwick, D.; Ma, Y.; Cui, Z.; Zhang, F. Mitigation of Multiple Environmental Footprints for China’s Pig Production Using Different Land Use Strategies. Environ. Sci. Technol. 2021, 55, 4440–4451. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.; Zhang, X.; Xu, M.; Chang, Y. Greenhouse gas emissions of meat products in China: A provincial-level quantification. Resour. Conserv. Recycl. 2023, 190, 106843. [Google Scholar] [CrossRef]

- Shabir, I.; Dash, K.K.; Dar, A.H.; Pandey, V.K.; Fayaz, U.; Srivastava, S.; Nisha, R. Carbon footprints evaluation for sustainable food processing system development: A comprehensive review. Future Foods 2023, 7, 100215. [Google Scholar] [CrossRef]

- Fang, Z.C.; Huhe, T.L.; Yuan, R.L.; YUAN, R.L.; Wu, D.; Huang, X.; Yu, Z.X.; Lei, T.Z.; Chen, Y. Environmental impacts assessment of large-scale multi-floor pig farming systems. J. Ecol. Rural Environ. 2022, 38, 1491–1500. [Google Scholar]

- Alltech. Agri-Food Outlook. 2022. Available online: https://www.alltech.com/agri-food-outlook (accessed on 8 October 2023).

- Paris, B.; Vandorou, F.; Balafoutis, A.T.; Vaiopoulos, K.; Kyriakarakos, G.; Manolakos, D.; Papadakis, G. Energy use in open-field agriculture in the EU: A critical review recommending energy efficiency measures and renewable energy sources adoption. Renew. Sustain. Energy Rev. 2022, 158, 112098. [Google Scholar] [CrossRef]

- Costantino, A.; Comba, L.; Cornale, P.; Fabrizio, E. Energy impact of climate control in pig farming: Dynamic simulation and experimental validation. Appl. Energy 2022, 309, 118457. [Google Scholar] [CrossRef]

- Paris, B.; Vandorou, F.; Tyris, D.; Balafoutis, A.T.; Vaiopoulos, K.; Kyriakarakos, G.; Manolakos, D.; Papadakis, G. Energy use in the EU livestock sector: A review recommending energy efficiency measures and renewable energy sources adoption. Appl. Sci. 2022, 12, 2142. [Google Scholar] [CrossRef]

- Cai, Q.; Zeng, N.; Zhao, F.; Han, P.; Liu, D.; Lin, X.; Chen, J. The impact of human and livestock respiration on CO2 emissions from 14 global cities. Carbon Balance Manag. 2022, 17, 17. [Google Scholar] [CrossRef] [PubMed]

- Philippe, F.X.; Nicks, B. Review on greenhouse gas emissions from pig houses: Production of carbon dioxide, methane and nitrous oxide by animals and manure. Agric. Ecosyst. Environ. 2015, 199, 10–25. [Google Scholar] [CrossRef]

- Basak, J.K.; Kim, N.E.; Shahriar, S.A.; Paudel, B.; Moon, B.E.; Kim, H.T. Applicability of statistical and machine learning–based regression algorithms in modeling of carbon dioxide emission in experimental pig barns. Air Qual. Atmos. Health 2022, 15, 1899–1912. [Google Scholar] [CrossRef]

- Misiukiewicz, A.; Gao, M.; Filipiak, W.; Cieslak, A.; Patra, A.K.; Szumacher-Strabel, M. Methanogens and methane production in the digestive systems of nonruminant farm animals. Animal 2021, 15, 100060. [Google Scholar] [CrossRef] [PubMed]

- Mi, J.; Peng, H.; Wu, Y.; Wang, Y.; Liao, X. Diversity and community of methanogens in the large intestine of finishing pigs. BMC Microbiol. 2019, 19, 83. [Google Scholar] [CrossRef]

- Kuhla, B.; Viereck, G. Enteric methane emission factors, total emissions and intensities from Germany’s livestock in the late 19th century: A comparison with the today’s emission rates and intensities. Sci. Total Environ. 2022, 848, 157754. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change. Climate Change 2022: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2022. [Google Scholar]

- INRA. EvaPig® Evaluation of Pig Feeds–Equations and Coefficients; INRA (French National Institute for Agricultural Research): Paris, France; Ajinomoto Animal Nutrition Europe: Paris, France; AFZ (French Association of Zootechnie): Paris, France, 2020. [Google Scholar]

- Yuan, J.; Liu, Y.; Tang, R.L.; Li, G.X. A review of carbon and nitrogen losses and greenhouse gas emissions during livestock manure composting. J. Agro-Environ. Sci. 2021, 40, 2428–2438. [Google Scholar]

- Basak, J.K.; Arulmozhi, E.; Moon, B.E.; Bhujel, A.; Kim, H.T. Modelling methane emissions from pig manure using statistical and machine learning methods. Air Qual. Atmos. Health 2022, 15, 575–589. [Google Scholar] [CrossRef]

- Małgorzata, K.; Krystyna, M.; Anna, G.; Jolanta, S.; Katarzyna, W.; Danuta, D.; Anna, J.; Erik, M. Cycles of carbon, nitrogen and phosphorus in poultry manure management technologies—Environmental aspects. Crit. Rev. Environ. Sci. Technol. 2023, 53, 914–938. [Google Scholar]

- Kreidenweis, U.; Breier, J.; Herrmann, C.; Libra, J.; Prochnow, A. Greenhouse gas emissions from broiler manure treatment options are lowest in well-managed biogas production. J. Clean. Prod. 2021, 280, 124969. [Google Scholar] [CrossRef]

- Shen, Q.; Sun, H.; Yao, X.; Wu, Y.; Wang, X.; Chen, Y.; Tang, J. A comparative study of pig manure with different waste straws in an ectopic fermentation system with thermophilic bacteria during the aerobic process: Performance and microbial community dynamics. Bioresour. Technol. 2019, 281, 202–208. [Google Scholar] [CrossRef] [PubMed]

- Alarcón, L.V.; Allepuz, A.; Mateu, E. Biosecurity in pig farms: A review. Porc. Health Manag. 2021, 7, 5. [Google Scholar] [CrossRef] [PubMed]

- Scollo, A.; Perrucci, A.; Stella, M.C.; Ferrari, P.; Robino, P.; Nebbia, P. Biosecurity and Hygiene Procedures in Pig Farms: Effects of a Tailor-Made Approach as Monitored by Environmental Samples. Animals 2023, 13, 1262. [Google Scholar] [CrossRef] [PubMed]

- Stewart, S.C.; Dritz, S.S.; Woodworth, J.C.; Paulk, C.; Jones, C.K. A review of strategies to impact swine feed biosecurity. Anim. Health Res. Rev. 2020, 21, 61–68. [Google Scholar] [CrossRef] [PubMed]

- Davies, R.; Wales, A. Antimicrobial resistance on farms: A review including biosecurity and the potential role of disinfectants in resistance selection. Compr. Rev. Food Sci. Food Saf. 2019, 18, 753–774. [Google Scholar] [CrossRef] [PubMed]

- Naresh, K.S.; Chakabarti, B. Energy and Carbon Footprint of Food Industry. In Energy Footprints of the Food and Textile Sectors. Environmental Footprints and Eco-Design of Products and Processes; Muthu, S., Ed.; Springer: Singapore, 2019. [Google Scholar]

- Godde, C.M.; Mason-D’Croz, D.; Mayberry, D.E.; Thornton, P.K.; Herrero, M. Impacts of climate change on the livestock food supply chain; a review of the evidence. Glob. Food Secur. 2021, 28, 100488. [Google Scholar] [CrossRef]

- Liu, X.; Cai, Z.; Yuan, Z. Environmental burdens of small-scale intensive pig production in China. Sci. Total Environ. 2021, 770, 144720. [Google Scholar] [CrossRef]

- Trolle, E.; Nordman, M.; Lassen, A.D.; Colley, T.A.; Mogensen, L. Carbon footprint reduction by transitioning to a diet consistent with the Danish Climate-Friendly Dietary Guidelines: A comparison of different carbon footprint databases. Foods 2022, 11, 1119. [Google Scholar] [CrossRef]

- Nielsen, P.; Nielsen, A.; Weidema, B.; Dalgaard, R.; Halberg, N. LCA Food Database. Available online: www.lcafood.dk (accessed on 11 November 2023).

- Cui, Z.; Zhang, H.; Chen, X.; Zhang, C.; Ma, W.; Huang, C.; Zhang, W.; Mi, G.; Miao, Y.; Li, X.; et al. Pursuing sustainable productivity with millions of smallholder farmers. Nature 2018, 555, 363–366. [Google Scholar] [CrossRef]

- Bracken, C.J.; Lanigan, G.J.; Richards, K.G.; Müller, C.; Tracy, S.R.; Grant, J.; Krol, D.J.; Sheridan, H.; Lynch, M.B.; Grace, C.; et al. Sward composition and soil moisture conditions affect nitrous oxide emissions and soil nitrogen dynamics following urea-nitrogen application. Sci. Total Environ. 2020, 722, 137780. [Google Scholar] [CrossRef] [PubMed]

- Cummins, S.; Finn, J.A.; Richards, K.G.; Lanigan, G.J.; Grange, G.; Brophy, C.; Cardenas, L.M.; Misselbrook, T.H.; Reynolds, C.K.; Krol, D.J. Beneficial effects of multi-species mixtures on N2O emissions from intensively managed grassland swards. Sci. Total Environ. 2021, 792, 148163. [Google Scholar] [CrossRef] [PubMed]

- Klimczyk, M.; Siczek, A.; Schimmelpfennig, L. Improving the efficiency of urea-based fertilization leading to reduction in ammonia emission. Sci. Total Environ. 2021, 771, 145483. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Song, X.; Zhang, Y.; Wang, D.; Rees, R.M.; Ju, X. Using nitrification inhibitors and deep placement to tackle the trade-offs between NH3 and N2O emissions in global croplands. Glob. Change Biol. 2022, 28, 4409–4422. [Google Scholar] [CrossRef] [PubMed]

- Cowan, N.; Carnell, E.; Skiba, U.; Dragosits, U.; Drewer, J.; Levy, P. Nitrous oxide emission factors of mineral fertilisers in the UK and Ireland: A Bayesian analysis of 20 years of experimental data. Environ. Int. 2020, 135, 105366. [Google Scholar] [CrossRef]

- Holka, M.; Kowalska, J.; Jakubowska, M. Reducing Carbon Footprint of Agriculture—Can Organic Farming Help to Mitigate Climate Change? Agriculture 2022, 12, 1383. [Google Scholar] [CrossRef]

- Guo, H.; Xie, S.; Pan, C. The Impact of Planting Industry Structural Changes on Carbon Emissions in the Three Northeast Provinces of China. Int. J. Environ. Res. Public Health 2021, 18, 705. [Google Scholar] [CrossRef]

- Gorjian, S.; Ebadi, H.; Trommsdorff, M.; Sharon, H.; Demant, M.; Schindele, S. The advent of modern solar-powered electric agricultural machinery: A solution for sustainable farm operations. J. Clean. Prod. 2021, 292, 126030. [Google Scholar] [CrossRef]

- Eras, J.J.C.; Gutiérrez, A.S.; Ulloa, M.J.C. The temperature gradient of cereals as an optimization parameter of the milling process in hammermills. J. Clean. Prod. 2021, 297, 126685. [Google Scholar] [CrossRef]

- Guo, Z.H.; Huang, T.L. Construction of biosecurity system on pig farms under the normality of African swine fever. China Anim. Husb. 2021, 15, 60–65. [Google Scholar]

- Yang, P.; Wang, H.; Zhu, M.; Ma, Y. Evaluation of extrusion temperatures, pelleting parameters, and vitamin forms on vitamin stability in feed. Animals 2020, 10, 894. [Google Scholar] [CrossRef]

- Ignatkin, I.; Kazantsev, S.; Shevkun, N.; Skorokhodov, D.; Serov, N.; Alipichev, A.; Panchenko, V. Developing and testing the air cooling system of a combined climate control unit used in pig farming. Agriculture 2023, 13, 334. [Google Scholar] [CrossRef]

- Li, X.; Ye, Z.; Li, G.; Shen, P.; Zhu, S.; Feng, X. Environmental characteristics of a swine gestation barn with an innovative cooling pad system. Trans. Chin. Soc. Agric. Eng. 2020, 36, 238–245. [Google Scholar]

- Seidel, D.S.; Field, T.C.; Schinckel, A.P.; Stwalley, C.S.; Stwalley III, R.M. Effects of temperature probe orientation on the Purdue hog cooling pad data acquisition. Comput. Electron. Agric. 2020, 175, 105609. [Google Scholar] [CrossRef]

- Jeong, M.G.; Rathnayake, D.; Mun, H.S.; Dilawar, M.A.; Park, K.W.; Lee, S.R.; Yang, C.J. Effect of a sustainable air heat pump system on energy efficiency, housing environment, and productivity traits in a pig farm. Sustainability 2020, 12, 9772. [Google Scholar] [CrossRef]

- Wang, C.; Ma, X.; Shen, J.; Chen, D.; Zheng, L.; Ge, T.; Wu, J. Reduction in net greenhouse gas emissions through a combination of pig manure and reduced inorganic fertilizer application in a double-rice cropping system: Three-year results. Agric. Ecosyst. Environ. 2022, 326, 107799. [Google Scholar] [CrossRef]

- Yang, P.; Zhao, J. Fiber digestibility in growing pigs fed common fiber-rich ingredients–A systematic review. Ann. Anim. Sci. 2021, 22, 537–550. [Google Scholar] [CrossRef]

- Zalewska, M.; Błażejewska, A.; Czapko, A.; Popowska, M. Antibiotics and antibiotic resistance genes in animal manure–consequences of its application in agriculture. Front. Microbiol. 2021, 12, 640. [Google Scholar] [CrossRef] [PubMed]

- Dadrasnia, A.; de Bona Munoz, I.; Ya’nez, E.H.; Lamkaddam, I.U.; Mora, M.; Ponsa, S.; Ahmed, M.; Argelaguet, L.L.; Williams, P.M.; Oatley-Radcliffe, D.L. Sustainable nutrient recovery from animal manure: A review of current best practice technology and the potential for freeze concentration. J. Clean. Prod. 2021, 315, 128106. [Google Scholar] [CrossRef]

- Lan, W.; Yao, C.; Luo, F.; Jin, Z.; Lu, S.; Li, J.; Wang, X.; Hu, X. Effects of Application of Pig Manure on the Accumulation of Heavy Metals in Rice. Plants 2022, 11, 207. [Google Scholar] [CrossRef]

- Zira, S.; Olsen, H.F.; Rydhmer, L. Low carbon emissions in future pig production–does a new breeding goal matter? In Proceedings of 12th World Congress on Genetics Applied to Livestock Production (WCGALP): Technical and Species Orientated Innovations in Animal Breeding, and Contribution of Genetics to Solving Societal Challenges; Wageningen Academic Publishers: Wageningen, The Netherlands, 2022; pp. 139–142. [Google Scholar]

- Trabue, S.L.; Kerr, B.J.; Scoggin, K.D.; Andersen, D.; van Weelden, M. Swine diets impact manure characteristics and gas emissions: Part I protein level. Sci. Total Environ. 2021, 755 Pt 2, 142528. [Google Scholar] [CrossRef] [PubMed]

- Trabue, S.L.; Kerr, B.J.; Scoggin, K.D.; Andersen, D.; van Weelden, M. Swine diets impact manure characteristics and gas emissions: Part II protein source. Sci. Total Environ. 2021, 763, 144207. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.C.; Fu, J.; Zhu, L.Y.; Li, Z.; Wang, Y.Z.; Jin, M.L. Overall assessment of antimicrobial peptides in piglets: A set of meta-analyses. Animal 2020, 14, 2463–2471. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.; Ji, P.; Song, M.; Che, T.M.; Bravo, D.; Pettigrew, J.E.; Liu, Y. Dietary plant extracts modulate gene expression profiles in alveolar macrophages of pigs experimentally infected with porcine reproductive and respiratory syndrome virus. J. Anim. Sci. Biotechnol. 2020, 11, 74. [Google Scholar] [CrossRef] [PubMed]

- Kiernan, D.P.; O’Doherty, J.V.; Sweeney, T. The Effect of prebiotic supplements on the gastrointestinal microbiota and associated health parameters in pigs. Animals 2023, 13, 3012. [Google Scholar] [CrossRef] [PubMed]

- Liu, N.; Shen, H.; Zhang, F.; Liu, X.; Xiao, Q.; Jiang, Q.; Tan, B.; Ma, X. Applications and prospects of functional oligosaccharides in pig nutrition: A review. Anim. Nutr. 2023, 13, 206–215. [Google Scholar] [CrossRef]

| Species | GHG Emissions (Tg CO2 Equivalent/Year) | |||

|---|---|---|---|---|

| CO2 | CH4 | N2O | Total | |

| Buffalo | 89.29 (5.7%) | 329.53 (8.9%) | 94.53 (10.3%) | 513.35 (8.3%) |

| Cattle | 1029.35 (65.9%) | 2300.46 (61.9%) | 494.05 (54.0%) | 3823.86 (61.8%) |

| Chicken | 32.04 (2.1%) | 424.86 (11.4%) | 115.59 (12.6%) | 572.49 (9.2%) |

| Goat | 20.13 (1.3%) | 173.07 (4.7%) | 30.31 (3.3%) | 223.50 (3.6%) |

| Pig | 369.83 (23.7%) | 325.09 (8.8%) | 152.22 (16.7%) | 847.13 (13.7%) |

| Sheep | 22.02 (1.4%) | 160.70 (4.3%) | 27.44 (3.0%) | 210.15 (3.4%) |

| Total | 1562.66 (100%) | 3713.70 (100%) | 914.13 (100%) | 6190.48 (100%) |

| Item | Percentage | Emissions (Megagram) |

|---|---|---|

| Direct on farm energy (CO2) | 12.0 | 101,792,650.0 |

| Embedded on farm energy (CO2) | 8.2 | 69,774,277.0 |

| Enteric fermentation (CO2) | 33.2 | 281,072,770.7 |

| Feed (CO2) | 0.5 | 4,549,406.3 |

| Feed (CH4) | 6.0 | 50,422,302.7 |

| Feed (N2O) | 3.1 | 25,908,407.8 |

| Land use (CO2) | 3.2 | 26,893,778.6 |

| Manure (CH4) | 3.3 | 27,585,401.3 |

| Manure (N2O) | 28.5 | 241,017,553.3 |

| Post farm (CO2) | 2.1 | 18,104,037.9 |

| Total | 100.0 | 847,120,585.6 |

| Reference | Transportation | Feed Production | Pig Production | Enteric Fermentation | Manure Management | Slaughtering |

|---|---|---|---|---|---|---|

| [2] | 8.2% | 42.6% | 3.8% | 3.1% | 39.2% | - |

| [3] | - | 46.0% | 15.0% | 5.0% | 34.0% | - |

| [6] | 2.2% | 28.6% | 2.7% | 9.6% | 56.9% | - |

| [7] | 2.2% | 27.8% | 2.6% | 9.3% | 42.9% | - |

| [8] Smallholder | 5.0% | 26.0% | 17.0% | - | 50.0% | - |

| [8] Medium scale | 10.0% | 68.0% | 11.0% | - | 20.0% | - |

| [8] Industrial scale | 10.0% | 68.0% | 14.0% | - | 19.0% | - |

| [9] | - | 65.0% | 5.0% | 4.0% | 19.0% | 7.0% |

| Biosecurity Measure [29,31] | Carbon Footprint |

|---|---|

| Cleaning, disinfection, and drying of vehicles | Electricity, fuels, chemicals, and disinfectants |

| Quarantine, disinfection, and sampling to monitor pathogens of personnel entering | Disinfectant, reagents, and consumables |

| Disinfection, sampling, and testing of supplies | Electricity, disinfectants, reagents, and consumables |

| Quarantine for newly introduced pigs and sampling to monitor pathogens | Electricity, disinfectants, reagents, and consumables |

| Clean feed delivery truck | Electricity and fuels |

| Sick and dead pig treatment | Electricity, disinfectants, fuels, reagents, and consumables |

| Manure disposal and waste management | Electricity |

| Specific clothes and boots | Materials used and manufacturing processes |

| Full fencing around and closed farm area | Construction and maintenance processes |

| Strict control for entrance in farm | Disinfectants |

| Against birds | Materials used for the netting or mesh |

| Rodent control | Chemical usage |

| Impact Category | Unit | Pork | Tenderloin | Ham | Minced Meat |

|---|---|---|---|---|---|

| Global warming | kg CO2e | 2.25 | 4.52 | 2.90 | 2.66 |

| Acidification | g SO2e | 40 | 75 | 48 | 28 |

| Nutrient enrichment | g NO3e | 214 | 413 | 266 | 207 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, P.; Yu, M.; Ma, X.; Deng, D. Carbon Footprint of the Pork Product Chain and Recent Advancements in Mitigation Strategies. Foods 2023, 12, 4203. https://doi.org/10.3390/foods12234203

Yang P, Yu M, Ma X, Deng D. Carbon Footprint of the Pork Product Chain and Recent Advancements in Mitigation Strategies. Foods. 2023; 12(23):4203. https://doi.org/10.3390/foods12234203

Chicago/Turabian StyleYang, Pan, Miao Yu, Xianyong Ma, and Dun Deng. 2023. "Carbon Footprint of the Pork Product Chain and Recent Advancements in Mitigation Strategies" Foods 12, no. 23: 4203. https://doi.org/10.3390/foods12234203

APA StyleYang, P., Yu, M., Ma, X., & Deng, D. (2023). Carbon Footprint of the Pork Product Chain and Recent Advancements in Mitigation Strategies. Foods, 12(23), 4203. https://doi.org/10.3390/foods12234203