Internal Quality Assessment of East African Highland Cooking Banana (Musa spp.) Flour: Significance for Breeding and Industrial Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

Cooking Bananas and Preparation of Flour

2.2. Methods

2.2.1. Functional Properties

Swelling Power Capacity

Water Solubility

Water Absorption Capacity (WAC)

Water Absorption Index (WAI)

Freeze–Thawing Stability (% Syneresis)

2.2.2. Pasting Properties

2.2.3. Statistical Analysis

3. Results and Discussion

3.1. Functional Properties

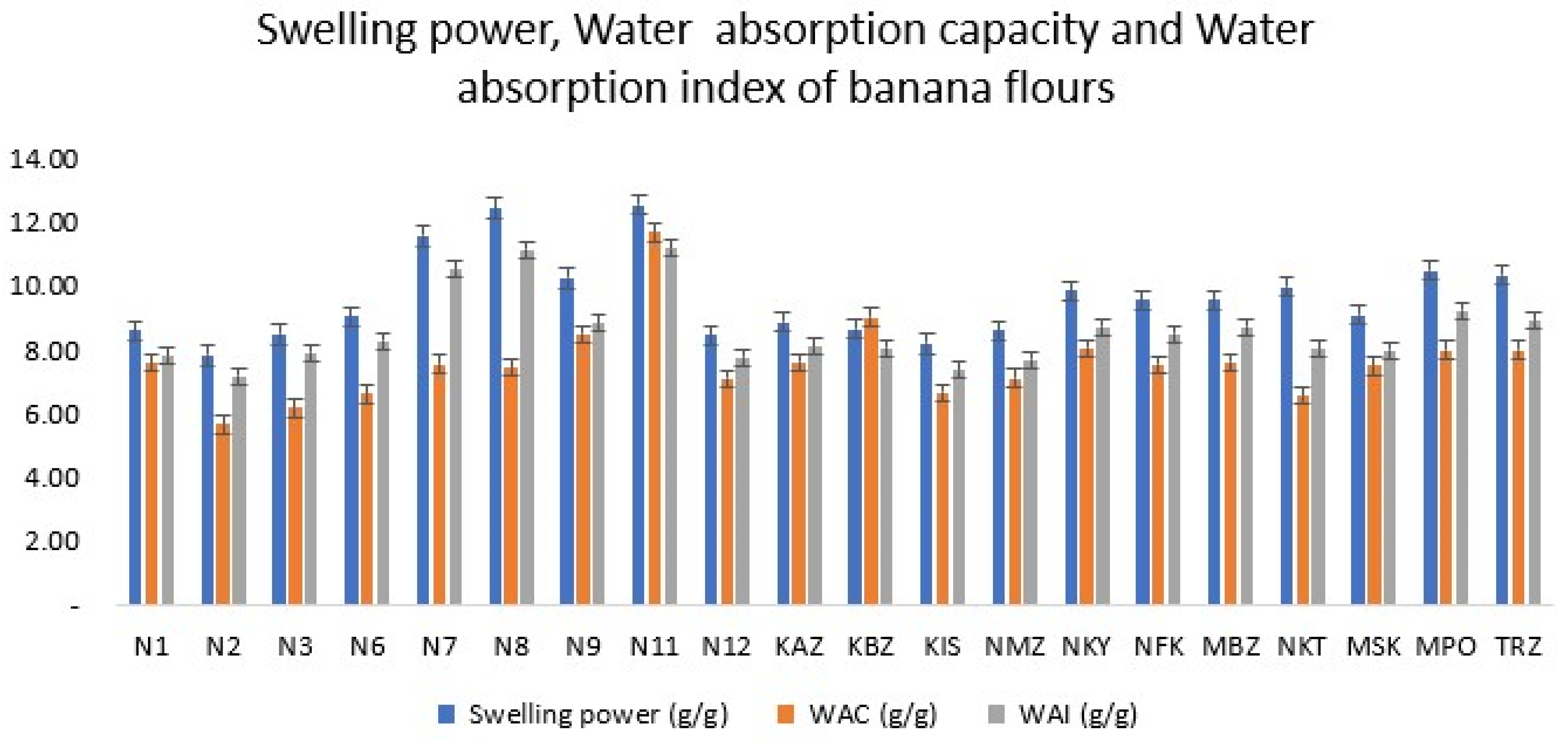

3.1.1. Swelling Power (SP)

3.1.2. Water Absorption Index (WAI)

3.1.3. Water Absorption Capacity (WAC)

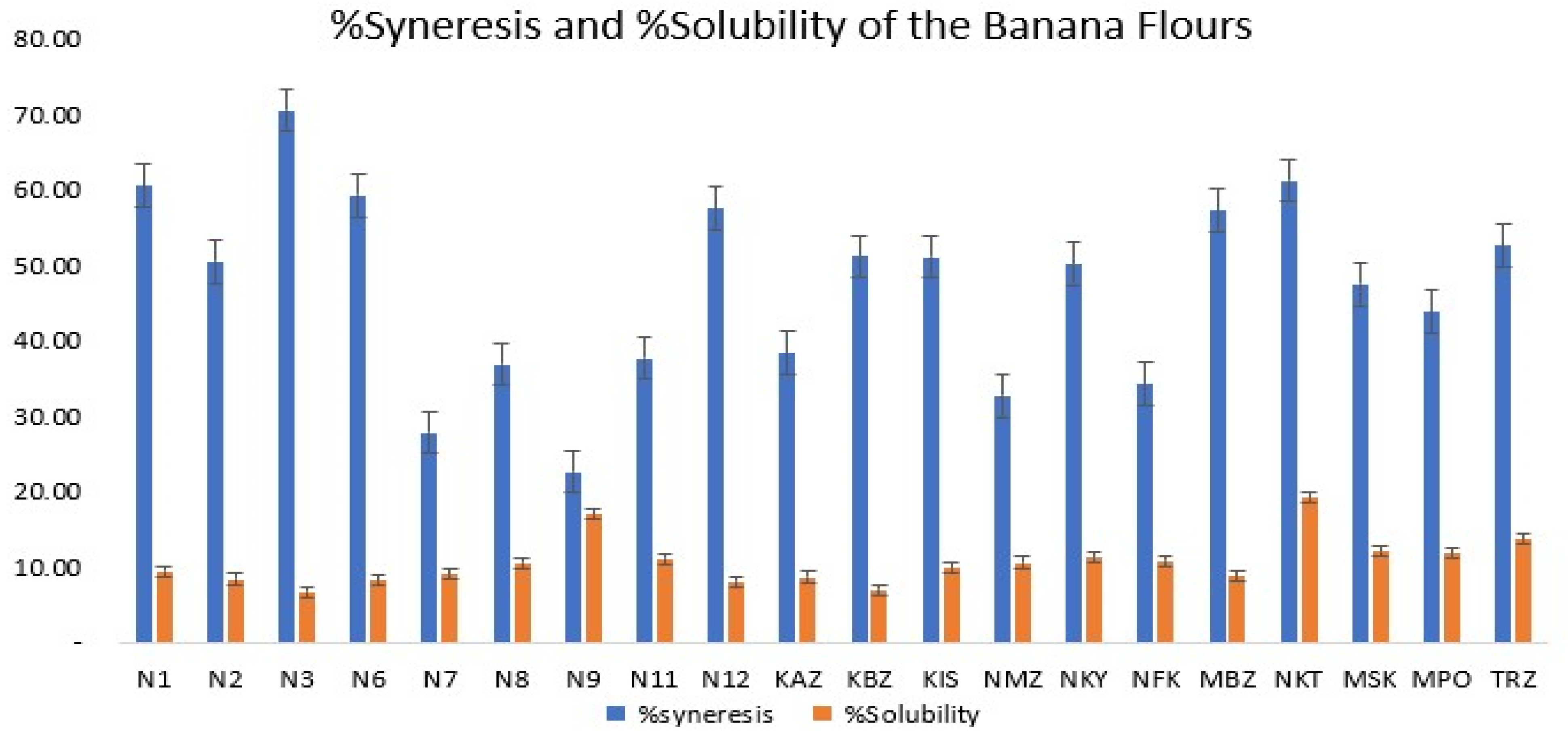

3.1.4. Freeze–Thawing Stability (Syneresis)

3.1.5. Solubility

3.2. Pasting Properties

3.2.1. Peak Viscosity (PV)

3.2.2. Trough Viscosity (TV)

3.2.3. Breakdown Viscosity (BDV)

3.2.4. Final Viscosity (FV)

3.2.5. Setback Viscosity (SB)

3.2.6. Peak Time

3.2.7. Pasting Temperature (PT)

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Karamura, D. Numerical Taxonomic Studies of the East African Highland Bananas (Musa AAA—East Africa) in Uganda. Ph.D. Thesis, Department of Agricultural Botany, University of Reading, Reading, France, 1999. [Google Scholar]

- Kikulwe, E.M.; Birol, E.; Wesseler, J.; Falck-Zepeda, J. A latent class approach to investigating demand for genetically modified banana in Uganda. Agric. Econ. 2011, 42, 547–560. [Google Scholar] [CrossRef]

- Dotto, J.; Matemu, A.O.; Ndakidemi, P.A. Potential of cooking bananas in addressing food security in East Africa. Int. J. Biosci. 2018, 13, 278–294. [Google Scholar]

- Nansamba, M.; Sibiya, J.; Tumuhimbise, R.; Karamura, D.; Kubiriba, J.; Karamura, E. Breeding banana (Musa spp.) for drought tolerance: A review. Plant Breed. 2020, 139, 685–696. [Google Scholar] [CrossRef]

- Adeniji, T.A.; Tenkouano, A.; Ezurike, J.N.; Ariyo, C.O.; Vroh-Bi, I. Value-adding post harvest processing of cooking bananas (Musa spp. AAB and ABB genome groups). Afr. J. Biotechnol. 2010, 9, 9135–9141. [Google Scholar]

- Tushemereirwe, W.; Kangire, A.; Ssekiwoko, F.; Offord, L.C.; Crozier, J.; Boa, E.; Rutherford, M.; Smith, J.J. First report of Xanthomonas campestris pv. musacearum on banana in Uganda. Plant Pathol. 2004, 53, 802. [Google Scholar] [CrossRef]

- Kubiriba, J.; Ssali, R.; Barekye, A.; Akankwasa, K.; Tushemereirwe, W.; Batte, M.; Karamura, E.; Karamura, D. The performance of East African highland bananas released in farmers’ fields and the need for their further improvement. Acta Hortic. 2016, 231–238. [Google Scholar] [CrossRef]

- Akankwasa, K.; Marimo, P.; Tumuhimbise, R.; Asasira, M.; Khakasa, E.; Mpirirwe, I.; Kleih, U.; Forsythe, L.; Fliedel, G.; Dufour, D.; et al. The East African highland cooking bananas ‘Matooke’ preferences of farmers and traders: Implications for variety development. Int. J. Food Sci. Technol. 2021, 56, 1124–1134. [Google Scholar] [CrossRef]

- Nowakunda, K.; Rubaihayo, P.R.; Ameny, M.A.; Tushemereirwe, W.K. Consumer acceptability of introduced bananas in Uganda. Infomusa 2000, 9, 22–25. [Google Scholar]

- Dufour, D.; Gibert, O.; Giraldo, A.; Sánchez, T.; Reynes, M.; Pain, J.-P.; González, A.; Fernández, A.; Díaz, A. Differentiation between cooking bananas and dessert bananas. 2. Thermal and functional characterization of cultivated Colombian Musaceae (Musa sp.). J. Agric. Food Chem. 2009, 57, 7870–7876. [Google Scholar] [CrossRef]

- Olatunde, G.O.; Arogundade, L.K.; Oluwaponmile, I.O. Chemical, functional and pasting properties of banana and plantain starches modified by pre-gelatinization, oxidation and acetylation. Cogent Food Agric. 2017, 3, 1283079. [Google Scholar] [CrossRef]

- Sanya, L.N.; Sseguya, H.; Kyazze, F.B.; Diiro, G.M.; Nakazi, F. The role of variety attributes in the uptake of new hybrid bananas among smallholder rural farmers in central Uganda. Agric. Food Secur. 2020, 9, 1–13. [Google Scholar] [CrossRef]

- Ruengsakulrach, S.; Srisuma, N.; Uebersax, M.A.; Hosfield, G.L.; Occeña, L.G. Early Generation Screening of Navy Bean Breeding lines by Canning Quality Assessment and Pasting Characteristics of Bean Flour. J. Food Qual. 1994, 17, 321–333. [Google Scholar] [CrossRef]

- Allahgholipour, M.; Ali, A.J.; Alinia, F.; Nagamine, T.; Kojima, Y. Relationship between rice grain amylose and pasting properties for breeding better quality rice varieties. Plant Breed. 2006, 125, 357–362. [Google Scholar] [CrossRef]

- Cozzolino, D. The use of the rapid visco analyser (RVA) in breeding and selection of cereals. J. Cereal Sci. 2016, 70, 282–290. [Google Scholar] [CrossRef]

- Fida, R.; Pramafisi, G.; Cahyana, Y. Application of banana starch and banana flour in various food product: A review. In IOP Conference Series: Earth and Environmental Science; IOP Publishing Ltd.: Bristol, UK, 2020. [Google Scholar] [CrossRef]

- Amini Khoozani, A.; Birch, J.; Bekhit, A.E.A. Production, application and health effects of banana pulp and peel flour in the food industry. J. Food Sci. Technol. 2019, 56, 548–559. [Google Scholar] [CrossRef]

- Anyasi, T.A.; Jideani, A.I.; Mchau, G.R. Functional properties and postharvest utilization of commercial and noncommercial banana cultivars. Compr. Rev. Food Sci. Food Saf. 2013, 12, 509–522. [Google Scholar] [CrossRef]

- Da Mota, R.V.; Lajolo, F.M.; Cordenunsi, B.R.; Ciacco, C. Composition and Functional Properties of Banana Flour from Different Varieties. Starch-Stärke 2000, 52, 63–68. [Google Scholar] [CrossRef]

- Fontes, S.d.M.; Cavalcanti, M.T.; Candeia, R.A.; Almeida, E.L. Characterization and study of functional properties of banana starch green variety of Mysore (Musa AAB—Mysore). Food Sci. Technol. 2017, 37, 224–231. [Google Scholar] [CrossRef]

- Salih, Z.A.; Siddeeg, A.; Taha, R.T.; Bushra, M.; Ammar, A.F.; Ali, A.O. Physicochemical and functional properties of pulp and peel flour of dried green and ripe banana (Cavendish). Int. J. Res. Agric. Sci. 2017, 4, 348–353. [Google Scholar]

- Ahmed, Z.F.R.; Taha, E.M.A.; Abdelkareem, N.A.A.; Mohamed, W.M. Postharvest Properties of Unripe Bananas and the Potential of Producing Economic Nutritious Products. Int. J. Fruit Sci. 2020, 20, S995–S1014. [Google Scholar] [CrossRef]

- Bertolini, A.C.; Bello-Pérez, L.A.; Méndez-Montealvo, G.; Almeida, C.A.S.; Lajolo, F. Rheological and functional properties of flours from banana pulp and peel. Starch-Stärke 2010, 62, 277–284. [Google Scholar] [CrossRef]

- Haslinda, W.H.; Cheng, L.H.; Chong, L.C.; Aziah, A.N. Chemical composition and physicochemical properties of green banana (Musa acuminate × balbisiana Colla cv. Awak) flour. Int. J. Food Sci. Nutr. 2009, 60, 232–239. [Google Scholar] [CrossRef]

- Cheok, C.Y.; Sulaiman, R.; Manan, N.A.; Zakora, A.J.; Chin, N.L.; Hussain, N. Pasting and physical properties of green banana flours and pastas. Int. Food Res. J. 2018, 25, 2585–2592. [Google Scholar]

- Tushemereirwe, W.K.; Batte, M.; Nyine, M.; Tumuhimbise, R.; Barekye, A.; Tendo, S.; Talengera, D.; Kubiriba, J.; Lorenzen, J.; Swennen, R.; et al. Performance of NARITA Hybrids in the Preliminary Yield Trials for Three Cycles in Uganda; IITA, NARO: Entebbe, Uganda, 2015. [Google Scholar]

- Dadzie, B.K.; Orchard, J.E. Routine Post Harvest Screening of Banana/Plantain Hybrids:Criteria and Methods. In INIBAP Technical Guidelines 2; International Plant Genetic Resources Institute: Rome, Italy; International Network for the Improvement of Banana and Plantain: Montpellier, France; ACP-EU Technical Centre for Agricultural and Rural Cooperation: Wageningen, The Netherlands, 1997. [Google Scholar]

- Yu, X.; Wang, J.; Zhang, J.; Wang, L.; Wang, Z.; Xiong, F. Physicochemical Properties of Starch Isolated from Bracken (Pteridium aquilinim) Rhizome. J. Food Sci. 2015, 80, C2717–C2724. [Google Scholar] [CrossRef] [PubMed]

- Marta, H.; Cahyana, Y.; Djali, M.; Arcot, J.; Tensiska, T. A comparative study on the physicochemical and pasting properties of starch and flour from different banana (Musa spp.) cultivars grown in Indonesia. Int. J. Food Prop. 2019, 22, 1562–1575. [Google Scholar] [CrossRef]

- Torruco-Uco, J.; Betancur-Ancona, D. Physicochemical and functional properties of makal (Xanthosoma yucatanensis) starch. Food Chem. 2007, 101, 1319–1326. [Google Scholar] [CrossRef]

- Kraithong, S.; Lee, S.; Rawdkuen, S. Physicochemical and functional properties of Thai organic rice flour. J. Cereal Sci. 2017, 79, 259–266. [Google Scholar] [CrossRef]

- Du, S.-K.; Jiang, H.; Yu, X.; Jane, J.-L. Physicochemical and functional properties of whole legume flour. LWT—Food Sci. Technol. 2013, 55, 308–313. [Google Scholar] [CrossRef]

- De Barros Mesquita, C.; Leonel, M.; Franco, C.M.L.; Leonel, S.; Garcia, E.L.; dos Santos, T.P.R. Characterization of banana starches obtained from cultivars grown in Brazil. Int. J. Biol. Macromol. 2016, 89, 632–639. [Google Scholar] [CrossRef]

- Alimi, B.A.; Workneh, T.S.; Sibomana, M.S. Effect of Hydrothermal Modifications on Functional, Pasting and Structural Properties of False Banana (Ensete ventricosum) Starch. Food Biophys. 2016, 11, 248–256. [Google Scholar] [CrossRef]

- Konik, C.M.; Miskelly, D.M.; Gras, P.W. Starch Swelling Power, Grain Hardness and Protein: Relationship to Sensory Properties of Japanese Noodles. Starch-Stärke 1993, 45, 139–144. [Google Scholar] [CrossRef]

- Anajekwu, E.O.; Maziya-Dixon, B.; Akinoso, R.; Awoyale, W.; Alamu, E.O. Physicochemical Properties and Total Carotenoid Content of High-Quality Unripe Plantain Flour from Varieties of Hybrid Plantain Cultivars. J. Chem. 2020, 2020, 5960346. [Google Scholar] [CrossRef]

- Li, J.Y.; Yeh, A.I. Relationships between thermal, rheological characteristics and swelling power for various starches. J. Food Eng. 2001, 50, 141–148. [Google Scholar] [CrossRef]

- Li, M.-C.; Chou, C.-F.; Hsu, S.-C.; Lin, J.-S. Physicochemical characteristics and resistant starch of different varieties of banana from Taiwan. Int. J. Food Prop. 2020, 23, 1168–1175. [Google Scholar] [CrossRef]

- Akubor, P.I.; Igba, T. Effect of pre gelatinization and annealing on the chemical composition, functional and pasting properties of starch prepared from unripe banana fruits. S. Asian J. Food Technol. Environ. 2019, 5, 807–816. [Google Scholar] [CrossRef]

- Ghribi, A.M.; Sila, A.; Gafsi, I.M.; Blecker, C.; Danthine, S.; Attia, H.; Bougatef, A.; Besbes, S. Structural, functional and ACE inhibitory properties of Water-Soluble Polysaccharides from Chickpea flours. Int. J. Biol. Macromol. 2015, 75, 276–282. [Google Scholar] [CrossRef]

- Torre-Gutiérrez, D.A.L.; Chel-Guerrero, L.A.; Betancur-Ancona, D. Functional properties of square banana (Musa balbisiana) starch. Food Chem. 2008, 106, 1138–1144. [Google Scholar] [CrossRef]

- Zheng, G.H.; Sosulski, F. Determination of Water Separation from Cooked Starch and Flour Pastes after Refrigeration and Freeze-thaw. J. Food Sci. 1998, 63, 134–139. [Google Scholar] [CrossRef]

- Zhang, P.; Whistler, R.L.; BeMiller, J.N.; Hamaker, B.R. Banana starch: Production, physicochemical properties, and digestibility—A review. Carbohydr. Polym. 2005, 59, 443–458. [Google Scholar] [CrossRef]

- Leonel, M.; Leonel, S.; dos Santos, T.P.R.; Souza, J.M.A.; Martins, R.C.; da Silva, M.S.C. Agronomic yield and starch properties of banana cultivars. Pesqui. Agropecuária Bras. 2021, 56, 02491. [Google Scholar] [CrossRef]

- Awuchi, C.G.; Igwe, V.S.; Echeta, C.K. The Functional Properties of Foods and Flours. Int. J. Adv. Acad. Res. Sci. Technol. Eng. 2019, 5, 139–160. [Google Scholar]

- China, M.A.H.; Amadi, G.A.; Ujong, A.E. Functional and pasting properties of wheat and cooking banana flour blends and their utilization in cookies production. Res. J. Food Sci. Nutr. 2022, 7, 59–67. [Google Scholar] [CrossRef]

- Kumar, R.; Khatkar, B.S. Thermal, pasting and morphological properties of starch granules of wheat (Triticum aestivum L.) varieties. J. Food Sci. Technol. 2017, 54, 2403–2410. [Google Scholar] [CrossRef] [PubMed]

- Balet, S.; Guelpa, A.; Fox, G.; Manley, M. Rapid Visco Analyser (RVA) as a Tool for Measuring Starch-Related Physiochemical Properties in Cereals: A Review. Food Anal. Methods 2019, 12, 2344–2360. [Google Scholar] [CrossRef]

| Cultivar | Cultivar Code | Clone Set | Cultivar Type | Date and Year of Harvest |

|---|---|---|---|---|

| Kazirakwe | KAZ | Nakabululu | Landrace | 3 November 2020 |

| Kibuzi | KBZ | Nakitembe | Landrace | 4 October 2022 |

| Kisansa | KIS | Musakala | Landrace | 16 December 2020 |

| Namwezi | NMZ | Nfuuka | Landrace | 25 February 2021 |

| Nakinyika | NKY | Nfuuka | Landrace | 13 September 2019 |

| Nakitembe | NKT | Nakitembe | Landrace | 16 February 2020 |

| Mpologoma | MPO | Musakala | Landrace | 13 September 2019 |

| Nfuuka | NFK | Nfuuka | Landrace | 18 February 2021 |

| Tereza | TRZ | Nfuuka | Landrace | 13 September 2019 |

| Mbwazirume | MBZ | Nakitembe | Landrace | 15 March 2022 |

| Musakala | MSK | Musakala | Landrace | 25 March 2022 |

| NARITA 1 | N1 | NA | Hybrid | 1 November 2022 |

| NARITA 2 | N2 | NA | Hybrid | 26 November 2018 |

| NARITA 3 | N3 | NA | Hybrid | 4 January 2017 |

| NARITA 6 | N6 | NA | Hybrid | 15 April 2019 |

| NARITA 7 | N7 | NA | Hybrid | 1 October 2019 |

| NARITA 8 | N8 | NA | Hybrid | 10 February 2021 |

| NARITA 9 | N9 | NA | Hybrid | 8 May 2018 |

| NARITA 11 | N11 | NA | Hybrid | 31 May 2022 |

| NARITA 12 | N12 | NA | Hybrid | 18 October 2018 |

| Sample Name | Sample Code | Swelling Power (g/g) | WAI (g/g) | WAC (g/g) | %Syneresis | %Solubility |

|---|---|---|---|---|---|---|

| NARITA1 | N1 | 8.85 ± 0.26 | 7.80 ± 0.21 | 7.58 ± 0.84 | 60.55 ± 3.85 | 9.45 ± 0.36 |

| NARITA2 | N2 | 7.83 ± 0.17 | 7.16 ± 0.17 | 5.66 ± 0.02 | 50.49 ± 2.12 | 8.39 ± 0.65 |

| NARITA3 | N3 | 8.64 ± 0.11 | 7.92 ± 0.11 | 6.18 ± 0.11 | 70.53 ± 1.25 | 6.66 ± 0.15 |

| NARITA6 | N6 | 9.42 ± 0.09 | 8.29 ± 0.09 | 6.62 ± 2.05 | 59.27 ± 1.19 | 8.24 ± 0.14 |

| NARITA7 | N7 | 9.99 ± 1.51 | 10.51 ± 1.51 | 7.54 ± 0.83 | 27.83 ± 0.18 | 9.04 ± 1.04 |

| NARITA8 | N8 | 12.02 ± 0.51 | 11.13 ± 0.51 | 7.44 ± 0.82 | 36.85 ± 1.01 | 10.49 ± 0.21 |

| NARITA9 | N9 | 8.56 ± 1.62 | 8.84 ± 1.62 | 8.48 ± 1.41 | 22.59 ± 1.01 | 13.16 ± 3.76 |

| NARITA11 | N11 | 11.94 ± 0.56 | 11.16 ± 0.56 | 11.68 ± 0.4 | 37.66 ± 0.13 | 11.04 ± 0.84 |

| NARITA12 | N12 | 7.95 ± 0.46 | 7.78 ± 0.36 | 7.09 ± 1.34 | 57.54 ± 1.21 | 7.99 ± 0.83 |

| KAZIRAKWE | KAZ | 8.66 ± 0.23 | 8.11 ± 0.40 | 7.61 ± 0.83 | 38.38 ± 0.19 | 8.67 ± 0.93 |

| KIBUZI | KBZ | 8.75 ± 0.46 | 8.05 ± 0.43 | 9.01 ± 1.65 | 51.19 ± 3.59 | 6.93 ± 0.09 |

| KISANSA | KIS | 9.34 ± 1.01 | 7.37 ± 0.78 | 6.64 ± 0.83 | 51.10 ± 4.71 | 9.88 ± 1.50 |

| MBWAZIRUME | MBZ | 9.27 ± 0.28 | 8.71 ± 0.20 | 7.60 ± 0.82 | 57.30 ± 8.56 | 8.71 ± 0.66 |

| MPOLOGOMA | MPO | 10.68 ± 0.46 | 9.24 ± 0.23 | 7.99 ± 0.77 | 37.66 ± 11.11 | 11.73 ± 2.47 |

| MUSAKALA | MSK | 9.32 ± 0.17 | 7.98 ± 0.16 | 7.49 ± 0.01 | 47.51 ± 2.69 | 12.02 ± 0.12 |

| NFUUKA | NFK | 9.40 ± 0.99 | 8.51 ± 0.79 | 7.54 ± 0.79 | 34.24 ± 2.37 | 10.82 ± 0.09 |

| NAKITEMBE | NKT | 10.83 ± 0.53 | 8.04 ± 0.50 | 6.55 ± 0.06 | 61.23 ± 15.04 | 19.14 ± 0.52 |

| NAKINYIKA | NKY | 9.97 ± 0.75 | 8.71 ± 0.29 | 8.05 ± 1.09 | 50.18 ± 12.85 | 11.19 ± 3.43 |

| NAMWEZI | NMZ | 9.12 ± 0.46 | 7.69 ± 0.41 | 7.10 ± 1.41 | 32.69 ± 0.83 | 10.58 ± 0.09 |

| TEREZA | TRZ | 10.65 ± 0.71 | 8.90 ± 0.51 | 7.99 ± 0.84 | 52.60 ± 0.93 | 13.73 ± 1.90 |

| Codes | Type | Peak Vis. | Trough Vis. | Breakdown Vis. | Final Vis. | Setback Vis. | Peak Time | Pasting Temp |

|---|---|---|---|---|---|---|---|---|

| N1 | Hybrid | 2835 ± 454.60 | 1598 ± 126.40 | 1235 ± 328.70 | 3690 ± 113.30 | 2092 ± 91.80 | 5.70 ± 0.30 | 79.69 ± 1.40 |

| N2 | Hybrid | 1451 ± 174.30 | 949 ± 102.60 | 883 ± 78.00 | 1355 ± 146.40 | 786 ± 44.10 | 4.65 ± 0.00 | 78.84 ± 0.40 |

| N3 | Hybrid | 2855 ± 364.20 | 1575 ± 171.10 | 1280 ± 205.80 | 3842 ± 431.3 | 2267 ± 275.4 | 5.50 ± 0.20 | 78.83 ± 0.40 |

| N6 | Hybrid | 3608 ± 562.90 | 1869 ± 293.40 | 2120 ± 269.40 | 3685 ± 301.20 | 2197 ± 7.80 | 4.93 ± 0.10 | 79.98 ± 0.00 |

| N7 | Hybrid | 3505 ± 269.40 | 1775 ± 100.90 | 2110 ± 201.2 | 3497 ± 191.50 | 2102 ± 170.80 | 4.82 ± 0.10 | 74.65 ± 2.80 |

| N8 | Hybrid | 2193 ± 122.90 | 1443 ± 400.20 | 1130 ± 722.7 | 2983 ± 1338.10 | 1920 ± 987.80 | 5.47 ± 0.20 | 81.08 ± 0.50 |

| N9 | Hybrid | 3281 ± 344.40 | 2140 ± 103.20 | 1141 ± 241.1 | 3362 ± 159.10 | 1222 ± 55.90 | 5.0 ± 0.10 | 79.85 ± 0.10 |

| N11 | Hybrid | 1697 ± 552.10 | 1193 ± 58.90 | 884 ± 493.5 | 2030 ± 513.70 | 1217 ± 455.00 | 5.27 ± 0.06 | 81.25 ± 3.70 |

| N12 | Hybrid | 2939 ± 192.00 | 1884 ± 134.50 | 1054 ± 103.5 | 3823 ± 200.80 | 1938 ± 91.80 | 5.68 ± 0.00 | 82.35 ± 0.00 |

| KAZ | Landrc | 2363 ± 227.00 | 1367 ± 54.40 | 1376 ± 172.5 | 3060 ± 146.40 | 2073 ± 91.90 | 5.2 ± 0.20 | 77.43 ± 0.10 |

| KBZ | Landrc | 1535 ± 14.80 | 976 ± 12.70 | 939 ± 2.10 | 1359 ± 9.90 | 763 ± 2.80 | 4.7 ± 0.00 | 77.85 ± 0.60 |

| KIS | Landrc | 457 ± 82.70 | 423 ± 72.80 | 414 ± 9.90 | 567 ± 97.60 | 525 ± 24.70 | 6.0 ± 0.20 | 81.05 ± 0.60 |

| NMZ | Landrc | 3155 ± 81.30 | 1904 ± 169.70 | 1251 ± 88.40 | 3637 ± 84.10 | 1733 ± 85.60 | 5.77 ± 0.10 | 79.90 ± 0.10 |

| NKYK | Landrc | 3980 ± 194.10 | 2081 ± 129.00 | 1949 ± 110.3 | 3511 ± 145.20 | 1483 ± 61.20 | 4.82 ± 0.00 | 77.68 ± 0.60 |

| NFK | Landrc | 3959 ± 142.10 | 1943 ± 36.10 | 2396 ± 106.1 | 4111 ± 48.10 | 2549 ± 12.00 | 5.10 ± 0.00 | 77.40 ± 0.10 |

| MBZ | Landrc | 2377 ± 360.10 | 1422 ± 99.80 | 1153 ± 522.80 | 2618 ± 172.50 | 1361 ± 317.50 | 5.48 ± 0.90 | 78.17 ± 1.80 |

| NKT | Landrc | 2703 ± 627.90 | 1606 ± 161.90 | 1478 ± 466.00 | 3034 ± 546.60 | 1808 ± 384.70 | 5.13 ± 0.20 | 77.85 ± 0.60 |

| MSK | Landrc | 6265 ± 52.30 | 4254 ± 67.90 | 1872 ± 72.80 | 5004 ± 24.00 | 809 ± 77.10 | 5.51 ± 0.40 | 78.16 ± 0.00 |

| MPO | Landrc | 2905 ± 50.20 | 1407 ± 178.40 | 1498 ± 176.40 | 3196 ± 130.30 | 1789 ± 303.00 | 5.02 ± 0.10 | 78.03 ± 0.50 |

| TRZ | Landrc | 2930 ± 517.90 | 1733 ± 309.40 | 1197 ± 231.30 | 3679 ± 139.00 | 1946 ± 320.60 | 5.58 ± 0.20 | 62.70 ± 13.50 |

| Peak Vis. | Trough Vis. | Breakdown Vis. | Final Vis. | Setback Vis. | Peak Time | Pasting T. | Swelling Power | %Solubility | WAC (g/g) | WAI (g/g) | %Syneresis | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Peak Vis. | 1 | 0.95 | 0.78 | 0.90 | 0.29 | −0.08 | −0.16 | 0.05 | 0.22 | −0.06 | 0.00 | −0.11 |

| Trough Vis. | 0.95 | 1 | 0.57 | 0.82 | 0.08 | 0.05 | −0.09 | 0.03 | 0.26 | −0.02 | −0.03 | −0.11 |

| BDV | 0.78 | 0.57 | 1 | 0.71 | 0.57 | −0.40 | −0.19 | 0.16 | 0.08 | −0.11 | 0.14 | −0.16 |

| Final Vis. | 0.90 | 0.82 | 0.71 | 1 | 0.62 | 0.12 | −0.20 | 0.09 | 0.18 | −0.11 | 0.05 | −0.03 |

| Setback | 0.29 | 0.08 | 0.57 | 0.62 | 1 | 0.04 | −0.19 | 0.18 | −0.05 | −0.17 | 0.20 | 0.04 |

| Peak Time | −0.08 | 0.05 | −0.40 | 0.12 | 0.04 | 1 | 0.07 | −0.16 | −0.02 | −0.12 | −0.17 | 0.22 |

| Pasting T. | −0.16 | −0.09 | −0.19 | −0.20 | −0.19 | 0.07 | 1 | −0.14 | −0.23 | −0.03 | −0.08 | −0.09 |

| Swelling P. | 0.05 | 0.03 | 0.16 | 0.09 | 0.18 | −0.16 | −0.14 | 1 | 0.35 | 0.60 | 0.97 | −0.49 |

| %Solubility | 0.22 | 0.26 | 0.08 | 0.18 | −0.05 | −0.02 | −0.23 | 0.35 | 1 | 0.13 | 0.13 | −0.25 |

| WAC (g/g) | −0.06 | −0.02 | −0.11 | −0.11 | −0.17 | −0.12 | −0.03 | 0.60 | 0.13 | 1 | 0.62 | −0.40 |

| WAI (g/g) | 0.00 | −0.03 | 0.14 | 0.05 | 0.20 | −0.17 | −0.08 | 0.97 | 0.13 | 0.62 | 1 | −0.49 |

| %Syneresis | −0.11 | −0.11 | −0.16 | −0.03 | 0.04 | 0.22 | −0.02 | −0.49 | −0.25 | −0.40 | −0.49 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khakasa, E.; Muyanja, C.; Mugabi, R.; Mukasa, Y.; Babirye, M.P.; Balikoowa, B.; Namanya, P.; Kubiriba, J.; Arinaitwe, I.K.; Nowakunda, K. Internal Quality Assessment of East African Highland Cooking Banana (Musa spp.) Flour: Significance for Breeding and Industrial Applications. Foods 2023, 12, 4323. https://doi.org/10.3390/foods12234323

Khakasa E, Muyanja C, Mugabi R, Mukasa Y, Babirye MP, Balikoowa B, Namanya P, Kubiriba J, Arinaitwe IK, Nowakunda K. Internal Quality Assessment of East African Highland Cooking Banana (Musa spp.) Flour: Significance for Breeding and Industrial Applications. Foods. 2023; 12(23):4323. https://doi.org/10.3390/foods12234323

Chicago/Turabian StyleKhakasa, Elizabeth, Charles Muyanja, Robert Mugabi, Yusuf Mukasa, Mary P. Babirye, Brian Balikoowa, Priver Namanya, Jerome Kubiriba, Ivan K. Arinaitwe, and Kephas Nowakunda. 2023. "Internal Quality Assessment of East African Highland Cooking Banana (Musa spp.) Flour: Significance for Breeding and Industrial Applications" Foods 12, no. 23: 4323. https://doi.org/10.3390/foods12234323

APA StyleKhakasa, E., Muyanja, C., Mugabi, R., Mukasa, Y., Babirye, M. P., Balikoowa, B., Namanya, P., Kubiriba, J., Arinaitwe, I. K., & Nowakunda, K. (2023). Internal Quality Assessment of East African Highland Cooking Banana (Musa spp.) Flour: Significance for Breeding and Industrial Applications. Foods, 12(23), 4323. https://doi.org/10.3390/foods12234323