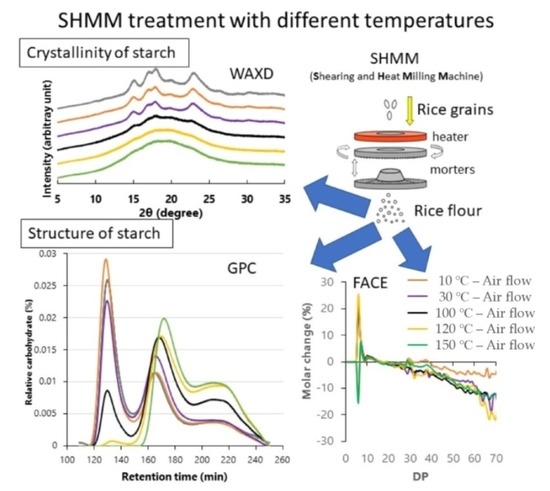

Effect of Shearing and Heat Milling Treatment Temperature on the Crystallinity, Thermal Properties, and Molecular Structure of Rice Starch

Abstract

:1. Introduction

2. Materials and Methods

2.1. Rice and Milling Conditions

2.2. Wide-Angle X-ray Diffraction

2.3. Analysis of the Thermal Properties of Starch

2.4. GPC of Undegraded Starch

2.5. GPC of Debranched Starch

2.6. Chain Length Distribution Analysis of Rice Starch

3. Results

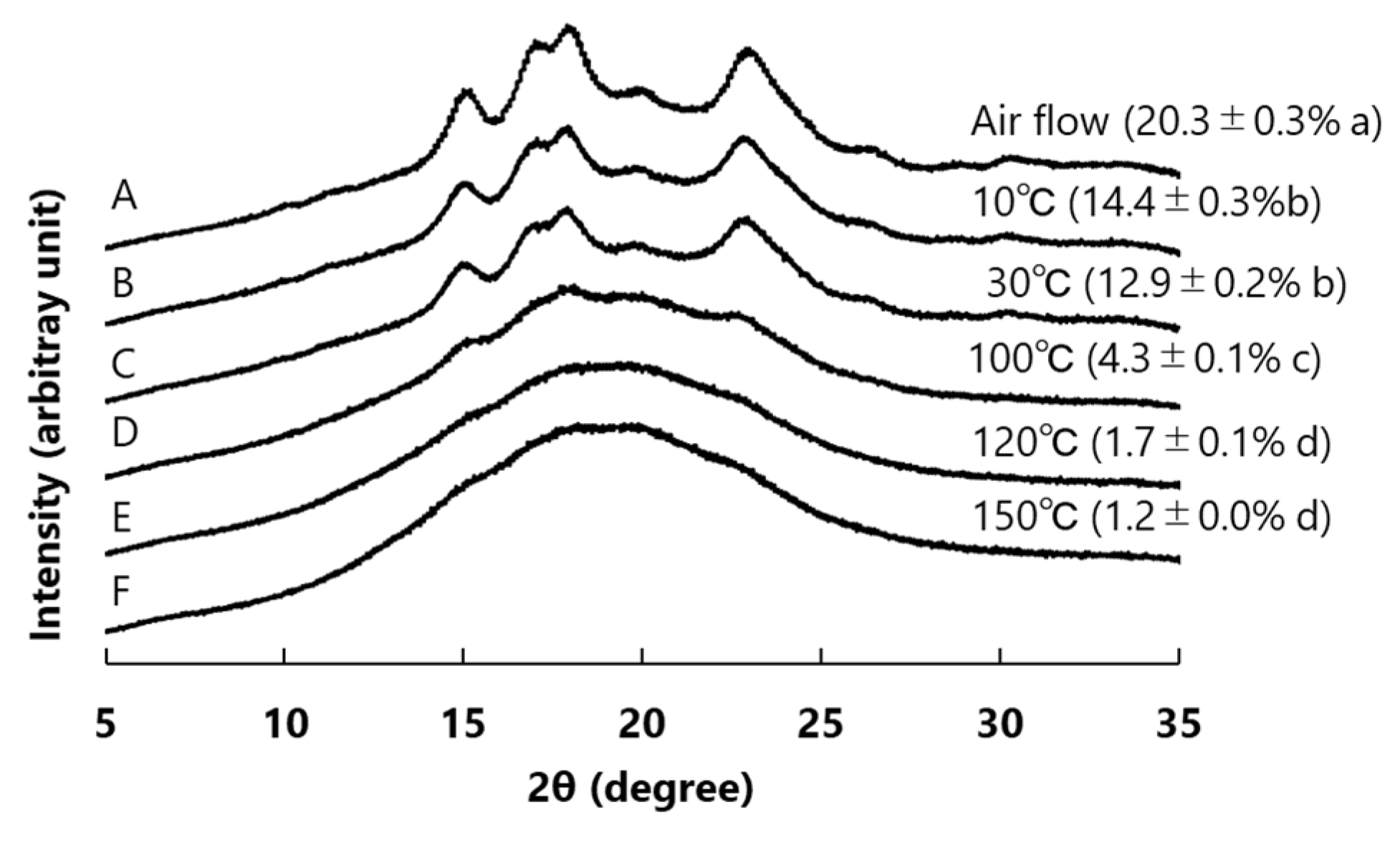

3.1. Effect of SHMM Treatment Temperature on the Crystallinity of Starch

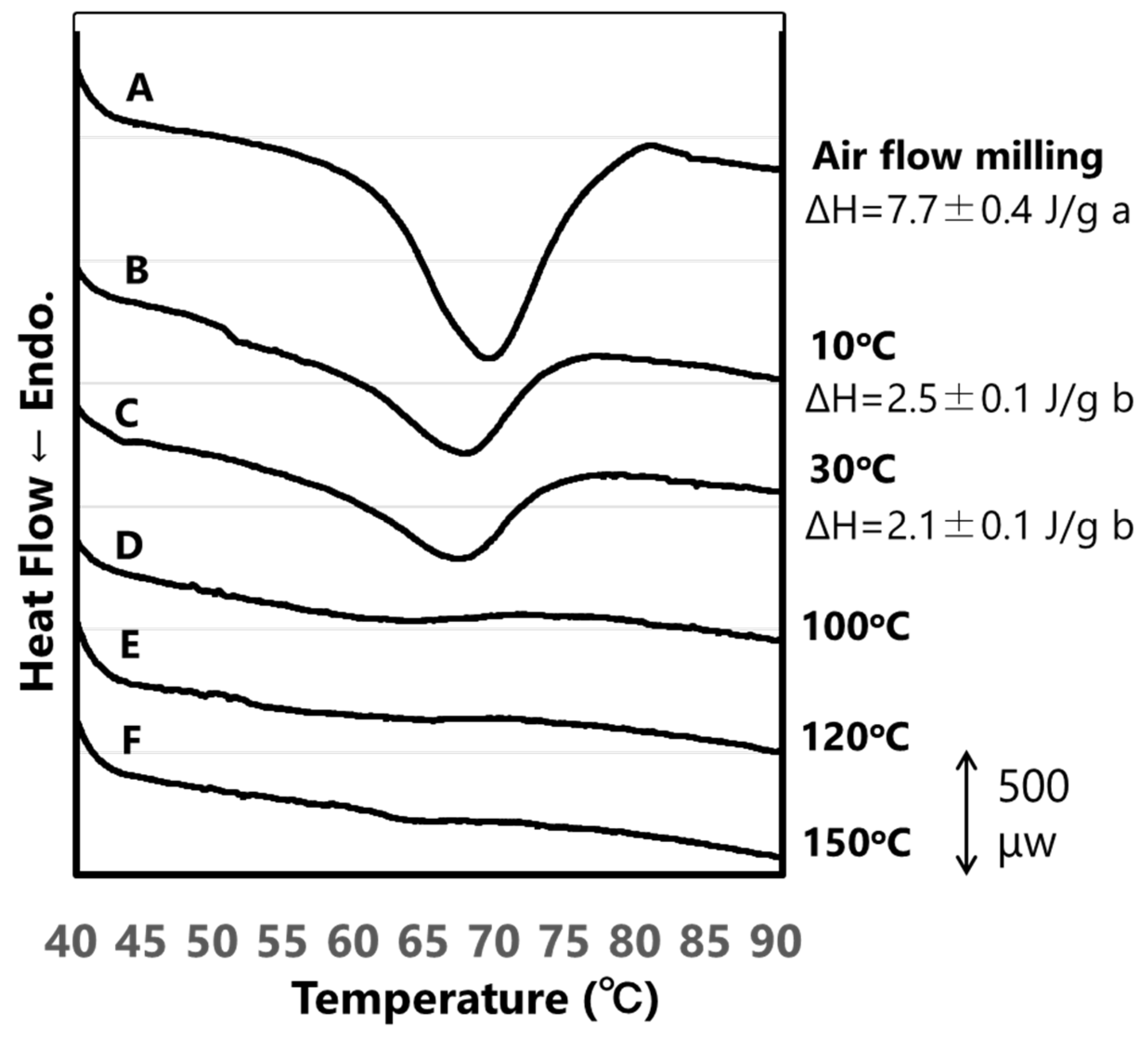

3.2. Effect of SHMM Treatment Temperature on the Thermal Properties of Starch

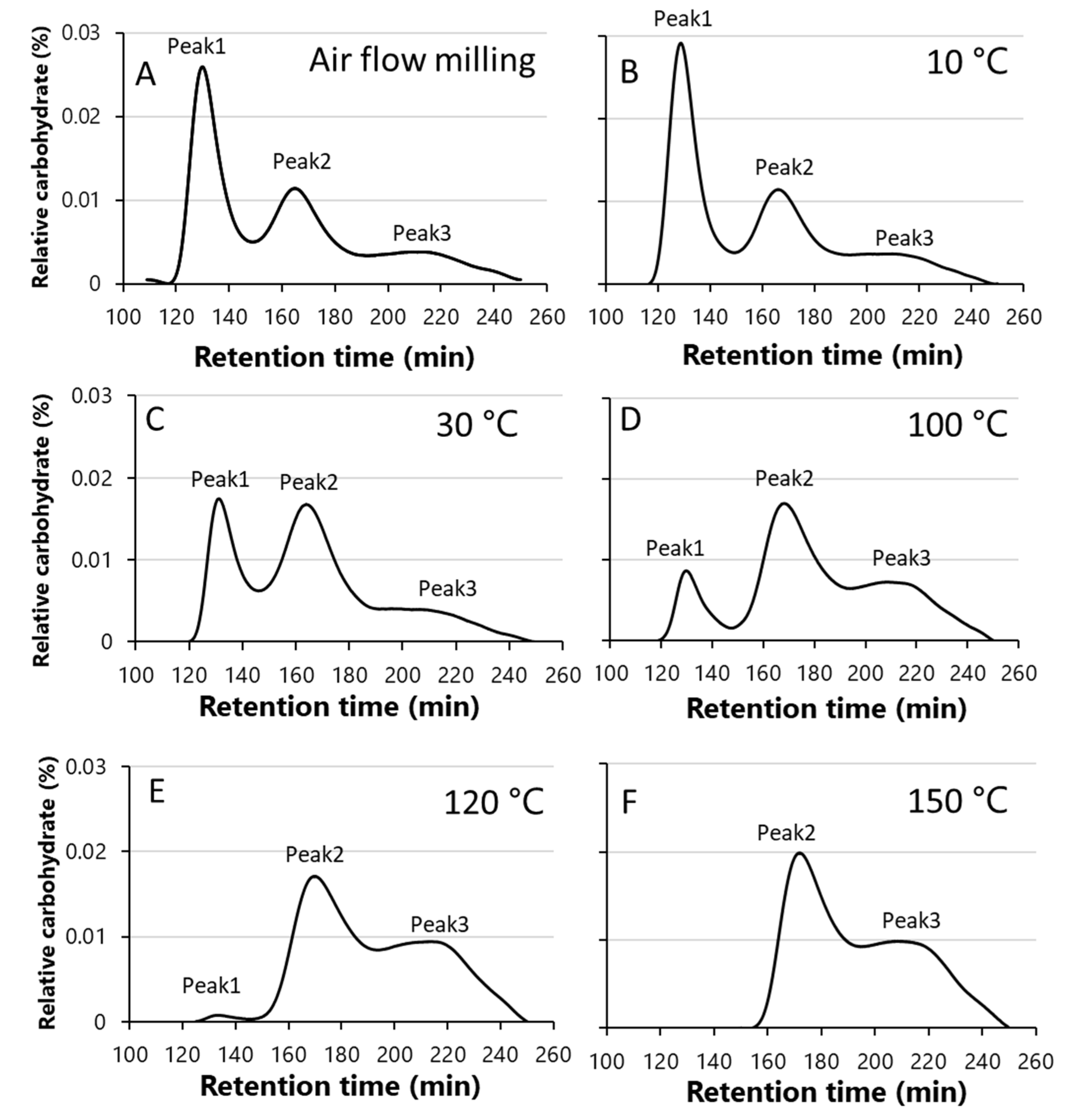

3.3. SHMM Treatment Temperature Effect on Starch Molecular Weight

3.4. Effect of SHMM Treatment Temperature on the Structure of Debranched Starch

3.5. Effect of SHMM Treatment Temperature on the Chain Length Distribution of Starch

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Rai, S.; Kaur, A.; Chopra, C.S. Gluten-free products for celiac susceptible people. Front. Nutr. 2018, 5, 116. [Google Scholar] [CrossRef]

- Horstmann, S.W.; Lynch, K.M.; Arendt, E.K. Starch characteristics linked to gluten-free products. Foods 2017, 6, 29. [Google Scholar] [CrossRef] [Green Version]

- Morrison, W.R.; Tester, R.F.; Gidley, M.J. Properties of damaged starch granules. II. Crystallinity, molecular order and gelatinization of ball-milled starches. J. Cereal Sci. 1994, 19, 209–217. [Google Scholar] [CrossRef]

- Takahashi, T.; Miura, M.; Ohisa, N.; Mori, K.; Kobayashi, S. Heat treatments of milled rice and properties of the flours. Cereal Chem. 2005, 82, 228–232. [Google Scholar] [CrossRef]

- Kuge, T.; Kitamura, S. Annealing of starch granules-warm water treatment and heat-moisture treatment. J. Jpn. Soc. Starch Sci. 1985, 32, 65–83. [Google Scholar] [CrossRef] [Green Version]

- Khunae, P.; Tran, T.; Sirivongpaisai, P. Effect of heat-moisture treatment on structural and thermal properties of rice starches differing in amylose content. Starch/Stärke 2007, 59, 593–599. [Google Scholar] [CrossRef]

- Yamada, T.; Kato, T.; Tamaki, S.; Teranishi, K.; Hisamitsu, M. Introduction of fatty acids to starch granules by ultra-high-pressure treatment. Starch/Stärke 1998, 50, 484–486. [Google Scholar] [CrossRef]

- Kadlec, P.; Kaasova, J.; Bubnik, Z. Chemical and physicochemical changes during microwave treatment of rice. Food Sci. Biotechnol. 2003, 12, 219–223. [Google Scholar]

- Bryant, R.J.; Kadan, R.S.; Champagune, E.T.; Vinyard, B.T.; Boykin, D. Functional and digestive characteristics of extruded rice flour. Cereal Chem. 2001, 78, 131–137. [Google Scholar] [CrossRef]

- Bao, J.; Corke, H. Pasting properties of γ-irradiated rice starches as affected by pH. J. Agric. Food Chem. 2002, 50, 336–341. [Google Scholar] [CrossRef]

- Katsuno, K.; Nishioka, A.; Koda, T.; Miyata, K.; Murasawa, G.; Nakamura, Y.; Inouchi, N. Novel method for producing amorphous rice flours by milling without adding water. Starch/Stärke 2010, 62, 475–479. [Google Scholar] [CrossRef]

- Murakami, S.; Ota, A.; Nishio, T.; Miyata, K.; Koda, T.; Nishioka, A. Effect of Strain Hardening Property on Baking Productivity of Rice Batter. Nihon Reologi Gakkaishi 2015, 43, 145–149. [Google Scholar] [CrossRef] [Green Version]

- Murakami, S.; Fujita, N.; Nakamura, Y.; Inouchi, N.; Oitome, N.F.; Koda, T.; Nishioka, A. Effects of shear and heat milling treatment on thermal properties and molecular structures of rice starch. Starch/Stärke 2017, 70, 1700164. [Google Scholar] [CrossRef]

- Nakamura, Y.; Kubo, A.; Shimamune, T.; Matsuda, T.; Harada, K.; Satoh, H. Correlation between activities of starch debranching enzyme and α-polyglucan structure in endosperms of sugary-1 mutants of rice. Plant J. 1997, 12, 143–153. [Google Scholar] [CrossRef]

- Kubo, A.; Fujita, N.; Harada, K.; Matsuda, T.; Satoh, H.; Nakamura, Y. The starch-debranching enzymesi soamylase and pullulanase are both involved in amylopectin biosynthesis in rice endosperm. Plant Physiol. 1999, 121, 399–409. [Google Scholar] [CrossRef] [Green Version]

- Fujita, N.; Kubo, A.; Suh, D.S.; Wong, K.S.; Jane, J.L.; Ozawa, K.; Takaiwa, F.; Inaba, Y.; Nakamura, Y. Antisense inhibition of isoamylase alters the structure of amylopectin and the physicochemical properties of starch in rice endosperm. Plant Cell Physiol. 2003, 44, 607–618. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yoo, S.H.; Jane, J.L. MWs and gyration radius of amylopectins determined by high-performance size-exclusion chromatography equipped with multi-angle laser-light scattering and refractive index detectors. Carbohydr. Polym. 2002, 49, 307–314. [Google Scholar] [CrossRef]

- Suzuki, N.; Hanashiro, I.; Fujita, N. Molecular weight distribution of whole starch in rice endosperm by gel-permeation chromatography. J. Appl. Glycosci. 2023, 70, 25–32. [Google Scholar]

- Toyosawa, Y.; Kawagoe, Y.; Matsushima, R.; Crofts, N.; Ogawa, M.; Fukuda, M.; Kumamaru, T.; Okazaki, Y.; Kusano, M.; Saito, K.; et al. Deficiency of starch synthase IIIa and IVb alters starch granule morphology from polyhedral to spherical in rice endosperm. Plant Physiol. 2016, 170, 1255–1270. [Google Scholar] [CrossRef] [Green Version]

- Fujita, N.; Hasegawa, H.; Taira, T. The isolation and characterization of a waxy mutant of diploid wheat (Triticum monococcum L.). Plant Sci. 2001, 160, 595–602. [Google Scholar] [CrossRef]

- O’Shea, M.G.; Morell, M.K. High resolution slab gel electrophoresis of 8-amino-1,3, 6-pyrenetrisulfonic acid (APTS) tagged oligosaccharides using a DNA sequencer. Electrophoresis 1996, 17, 681–686. [Google Scholar] [CrossRef]

- Fujita, N.; Hanashiro, I.; Suzuki, S.; Higuchi, T.; Toyosawa, Y.; Utsumi, Y.; Itoh, R.; Aihara, S.; Nakamura, Y. Elongated phytoglycogen chain length in transgenic rice endosperm expressing active starch synthase IIa affects the altered solubility and crystallinity of the storage α-glucan. J. Exp. Bot. 2012, 63, 5859–5872. [Google Scholar] [CrossRef] [Green Version]

- Crofts, N.; Satoh, Y.; Miura, S.; Hosaka, Y.; Abe, M.; Fujita, N. Active-type starch synthase (SS) IIa from indica rice partially complements the sugary-1 phenotype in japonica rice endosperm. Plant Mol. Biol. 2022, 108, 325–342. [Google Scholar] [CrossRef] [PubMed]

- Kasemsuwan, T.; Jane, J.; Schnable, P.; Stinard, P.; Robertson, D. Characterization of the dominant mutant amylose-extender (Ae1-5180) maize starch. Cereal Chem. 1995, 72, 457–464. [Google Scholar]

- Cooke, D.; Gidley, M.J. Loss of crystalline and molecular order during starch gelatinization origin of the enthalpic transition. Carbohydr. Res. 1992, 227, 103–112. [Google Scholar] [CrossRef]

- Nitta, H.; Hasebe, M.; Hosaka, Y.; Wakui, T.; Fujita, N. Physical properties and starch structure of ground rice puree. Food Sci. Technol. Res. 2019, 25, 499–505. [Google Scholar] [CrossRef]

| Sample | Milling Type 1 | Temperature |

|---|---|---|

| A | Air flow milling | - |

| B | SHMM | 10 °C |

| C | SHMM | 30 °C |

| D | SHMM | 100 °C |

| E | SHMM | 120 °C |

| F | SHMM | 150 °C |

| Milling Method | Frac. I (%) 1 | Frac. III/Frac. II 1 |

|---|---|---|

| Air flow milling | 18.4 + 1.9 a | 2.4 + 0.1 a |

| SHMM at 10 °C | 16.9 + 0.5 a | 2.3 + 0.1 a |

| SHMM at 30 °C | 16.2 + 0.5 a | 2.3 + 0.1 a |

| SHMM at 100 °C | 19.5 + 0.9 a | 2.6 + 0.2 a |

| SHMM at 120 °C | 17.0 + 1.9 a | 2.4 + 0.0 a |

| SHMM at 150 °C | 18.6 + 0.6 a | 2.1 + 0.1 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suzuki, N.; Abiko, M.; Yano, H.; Koda, T.; Nishioka, A.; Fujita, N. Effect of Shearing and Heat Milling Treatment Temperature on the Crystallinity, Thermal Properties, and Molecular Structure of Rice Starch. Foods 2023, 12, 1041. https://doi.org/10.3390/foods12051041

Suzuki N, Abiko M, Yano H, Koda T, Nishioka A, Fujita N. Effect of Shearing and Heat Milling Treatment Temperature on the Crystallinity, Thermal Properties, and Molecular Structure of Rice Starch. Foods. 2023; 12(5):1041. https://doi.org/10.3390/foods12051041

Chicago/Turabian StyleSuzuki, Naoto, Marin Abiko, Hiroko Yano, Tomonori Koda, Akihiro Nishioka, and Naoko Fujita. 2023. "Effect of Shearing and Heat Milling Treatment Temperature on the Crystallinity, Thermal Properties, and Molecular Structure of Rice Starch" Foods 12, no. 5: 1041. https://doi.org/10.3390/foods12051041

APA StyleSuzuki, N., Abiko, M., Yano, H., Koda, T., Nishioka, A., & Fujita, N. (2023). Effect of Shearing and Heat Milling Treatment Temperature on the Crystallinity, Thermal Properties, and Molecular Structure of Rice Starch. Foods, 12(5), 1041. https://doi.org/10.3390/foods12051041