Enhancing Gluten-Free Bread Production: Impact of Hydroxypropyl Methylcellulose, Psyllium Husk Fiber, and Xanthan Gum on Dough Characteristics and Bread Quality

Abstract

:1. Introduction

2. Materials and Methods

2.1. Formulations

2.1.1. Ingredients

2.1.2. Gluten-Free Breadmaking

2.2. Analysis

2.2.1. Rheological Properties

2.2.2. Extrusion Analysis

2.2.3. Physicochemical Analysis

2.2.4. Color Analysis

2.2.5. Texture Analysis

2.2.6. Image Analysis

2.2.7. Statistical Analysis

3. Results and Discussion

3.1. Dough Rheology Properties

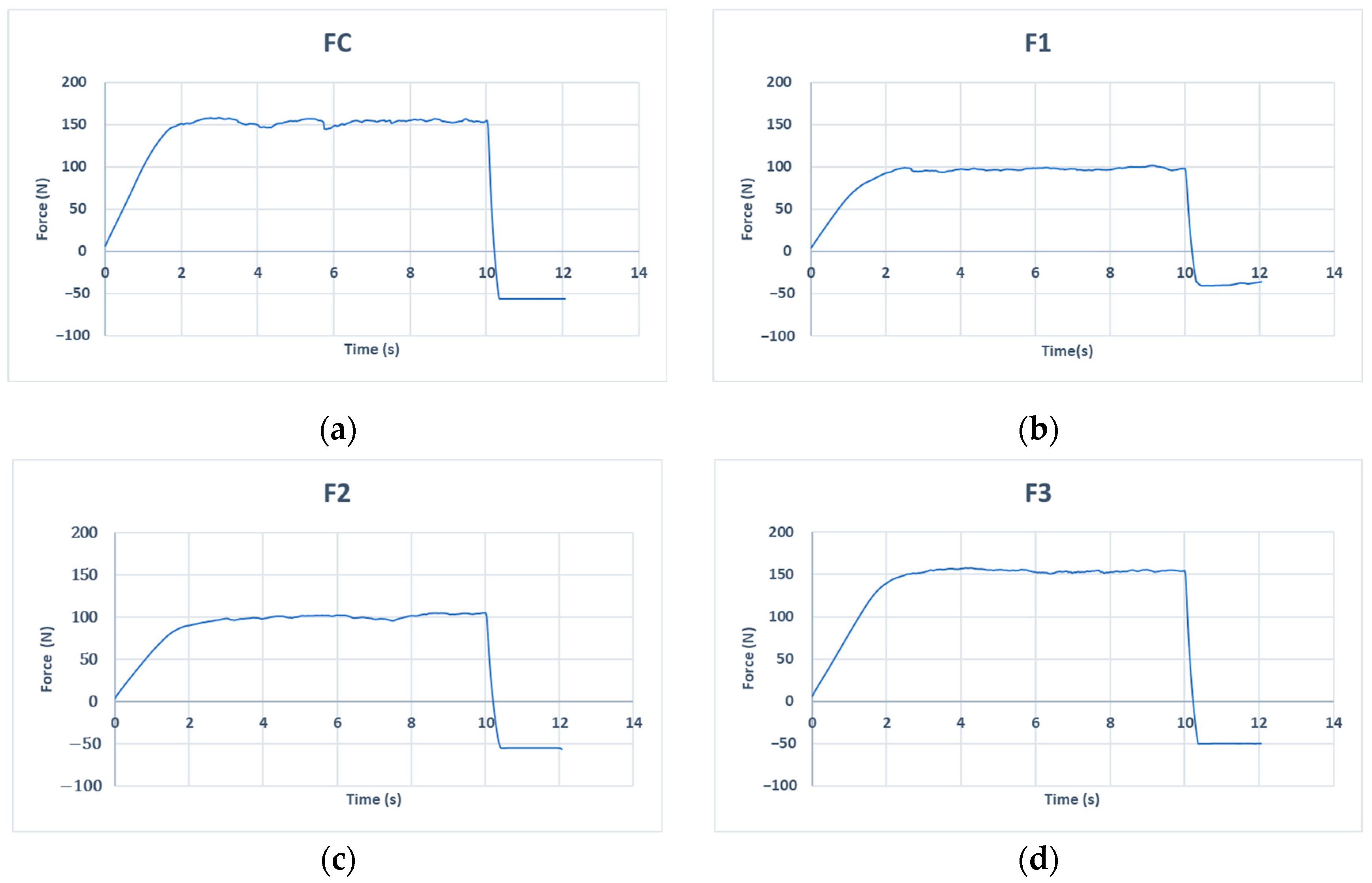

3.2. Dough Extrusion

3.3. Physicochemical Analysis

3.4. Color Analysis

3.5. Textural Characterization

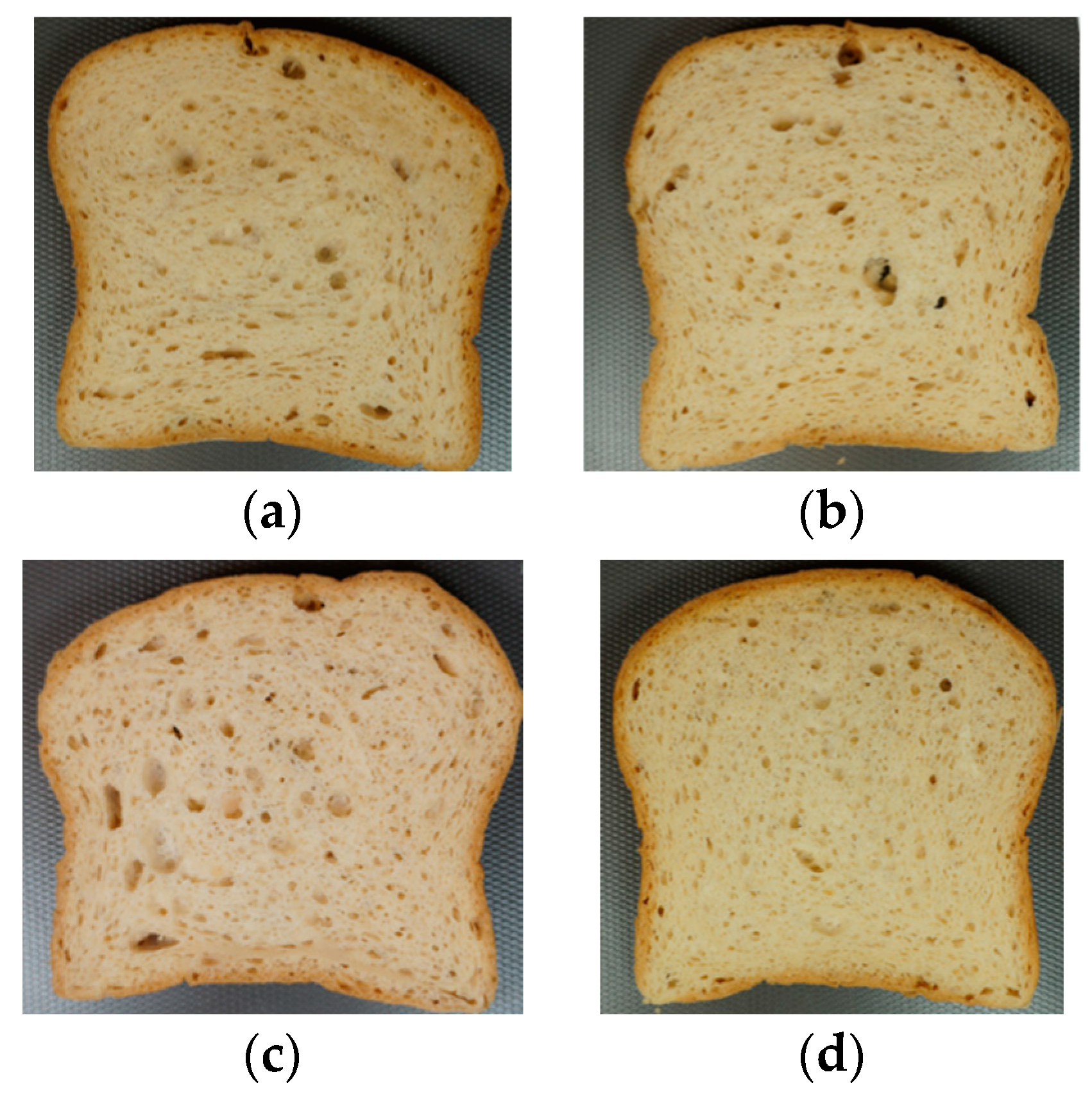

3.6. Image Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Puerta, P.; Laguna, L.; Vidal, L.; Ares, G.; Fiszman, S.; Tárrega, A. Co-occurrence networks of Twitter content after manual or automatic processing. A case-study on ‘gluten-free’. Food Qual. Prefer. 2020, 86, 103993. [Google Scholar] [CrossRef]

- Christoph, M.J.; Larson, N.; Hootman, K.C.; Miller, J.M.; Neumark-Sztainer, D. Who Values Gluten-Free? Dietary Intake, Behaviors, and Sociodemographic Characteristics of Young Adults Who Value Gluten-Free Food. J. Acad. Nutr. Diet. 2018, 118, 1389–1398. [Google Scholar] [CrossRef] [PubMed]

- Gao, Z.; Wang, G.; Zhang, J.; Guo, L.; Zhao, W. Psyllium Fibre Inclusion in Gluten-Free Buckwheat Dough Improves Dough Structure and Lowers Glycaemic Index of the Resulting Bread. Foods 2024, 13, 767. [Google Scholar] [CrossRef] [PubMed]

- Aguiar, E.V.; Santos, F.G.; Krupa-Kozak, U.; Capriles, V.D. Nutritional facts regarding commercially available gluten-free bread worldwide: Recent advances and future challenges. In Critical Reviews in Food Science and Nutrition; Taylor and Francis Ltd.: Abingdon, UK, 2023; Volume 63, pp. 693–705. [Google Scholar] [CrossRef]

- Reilly, N.R. The Gluten-Free Diet: Recognizing Fact, Fiction, and Fad. J. Pediatr. 2016, 175, 206–210. [Google Scholar] [CrossRef] [PubMed]

- Hartmann, C.; Hieke, S.; Taper, C.; Siegrist, M. European consumer healthiness evaluation of ‘Free-from’ labelled food products. Food Qual. Prefer. 2018, 68, 377–388. [Google Scholar] [CrossRef]

- Roman, L.; Belorio, M.; Gomez, M. Gluten-Free Breads: The Gap Between Research and Commercial Reality. In Comprehensive Reviews in Food Science and Food Safety; Blackwell Publishing Inc.: Malden, MA, USA, 2019; Volume 18, pp. 690–702. [Google Scholar] [CrossRef]

- Lammers, V.R.G.; Wolf, P.; Windhab, E.J. The rheology of batch and continuously prepared gluten-free bread dough in oscillatory and capillary shear flow. J. Food Sci. Technol. 2018, 55, 3077–3084. [Google Scholar] [CrossRef]

- Goode, K.; Matthew, N.; Unsworth, G.; Stephenson, G.; Beardsworth, A. Reducing waste on bread roll plants by application of novel technologies. In Energy Procedia; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; pp. 139–147. [Google Scholar] [CrossRef]

- Uthayakumaran, S.; Newberry, M.; Keentok, M.; Stoddard, F.L.; Bekes, F. Basic rheology of bread dough with modified protein content and glutenin-to-gliadin ratios. Cereal Chem. 2000, 77, 744–749. [Google Scholar] [CrossRef]

- Cauvain, S.P. Technology of Breadmaking, 2nd ed.; Springer: New York, NY, USA, 2007. [Google Scholar]

- Gómez, M. Gluten-free bakery products: Ingredients and processes. Adv. Food Nutr. Res. 2022, 99, 189–238. [Google Scholar] [CrossRef] [PubMed]

- Franco, E.A.N.; Sanches-Silva, A.; Ribeiro-Santos, R.; de Melo, N.R. Psyllium (Plantago ovata Forsk): From evidence of health benefits to its food application. In Trends in Food Science and Technology; Elsevier Ltd.: Amsterdam, The Netherlands, 2020; Volume 96, pp. 166–175. [Google Scholar] [CrossRef]

- Zandonadi, R.P.; Botelho, R.B.A.; Araújo, W.M.C. Psyllium as a Substitute for Gluten in Bread. J. Am. Diet. Assoc. 2009, 109, 1781–1784. [Google Scholar] [CrossRef]

- Filipčev, B.; Pojić, M.; Šimurina, O.; Mišan, A.; Mandić, A. Psyllium as an improver in gluten-free breads: Effect on volume, crumb texture, moisture binding and staling kinetics. LWT 2021, 151, 112156. [Google Scholar] [CrossRef]

- Ren, Y.; Linter, B.R.; Linforth, R.; Foster, T.J. A comprehensive investigation of gluten free bread dough rheology, proving and baking performance and bread qualities by response surface design and principal component analysis. Food Funct. 2020, 11, 5333–5345. [Google Scholar] [CrossRef] [PubMed]

- Mancebo, C.M.; Miguel, M.Á.S.; Martínez, M.M.; Gómez, M. Optimisation of rheological properties of gluten-free doughs with HPMC, psyllium and different levels of water. J. Cereal Sci. 2015, 61, 8–15. [Google Scholar] [CrossRef]

- Djordjević, M.; Šoronja-Simović, D.; Nikolić, I.; Djordjević, M.; Šereš, Z.; Milašinović-Šeremešić, M. Sugar beet and apple fibres coupled with hydroxypropylmethylcellulose as functional ingredients in gluten-free formulations: Rheological, technological and sensory aspects. Food Chem. 2019, 295, 189–197. [Google Scholar] [CrossRef] [PubMed]

- Bárcenas, M.E.; Rosell, C.M. Effect of HPMC addition on the microstructure, quality and aging of wheat bread. Food Hydrocoll. 2005, 19, 1037–1043. [Google Scholar] [CrossRef]

- Masure, H.G.; Fierens, E.; Delcour, J.A. Current and forward looking experimental approaches in gluten-free bread making research. J. Cereal Sci. 2016, 67, 92–111. [Google Scholar] [CrossRef]

- Hager, A.S.; Arendt, E.K. Influence of hydroxypropylmethylcellulose (HPMC), xanthan gum and their combination on loaf specific volume, crumb hardness and crumb grain characteristics of gluten-free breads based on rice, maize, teff and buckwheat. Food Hydrocoll. 2013, 32, 195–203. [Google Scholar] [CrossRef]

- Belorio, M.; Marcondes, G.; Gómez, M. Influence of psyllium versus xanthan gum in starch properties. Food Hydrocoll. 2020, 105, 105843. [Google Scholar] [CrossRef]

- Kim, Y.; Yokoyama, W.H. Physical and sensory properties of all-barley and all-oat breads with additional Hydroxypropyl Methylcellulose (HPMC) β-Glucan. J. Agric. Food Chem. 2011, 59, 741–746. [Google Scholar] [CrossRef] [PubMed]

- Sciarini, L.S.; Ribotta, P.D.; León, A.E.; Pérez, G.T. Effect of hydrocolloids on gluten-free batter properties and bread quality. Int. J. Food Sci. Technol. 2010, 45, 2306–2312. [Google Scholar] [CrossRef]

- Farahnaky, A.; Askari, H.; Majzoobi, M.; Mesbahi, G. The impact of concentration, temperature and pH on dynamic rheology of psyllium gels. J. Food Eng. 2010, 100, 294–301. [Google Scholar] [CrossRef]

- Lazaridou, A.; Duta, D.; Papageorgiou, M.; Belc, N.; Biliaderis, C.G. Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. J. Food Eng. 2007, 79, 1033–1047. [Google Scholar] [CrossRef]

- Demirkesen, I.; Mert, B.; Sumnu, G.; Sahin, S. Rheological properties of gluten-free bread formulations. J. Food Eng. 2010, 96, 295–303. [Google Scholar] [CrossRef]

- Hussain, S.; Keary, C.; Craig, D.Q.M. A Thermorheological investigation into the gelation and phase separation of hydroxypropyl methylcellulose aqueous systems. Polymer 2002, 43, 5623–5628. [Google Scholar] [CrossRef]

- Rosell, C.M.; Foegeding, A. Interaction of hydroxypropylmethylcellulose with gluten proteins: Small deformation properties during thermal treatment. Food Hydrocoll. 2007, 21, 1092–1100. [Google Scholar] [CrossRef]

- Sivaramakrishnan, H.P.; Senge, B.; Chattopadhyay, P.K. Rheological properties of rice dough for making rice bread. J. Food Eng. 2004, 62, 37–45. [Google Scholar] [CrossRef]

- Belorio, M.; Gómez, M. Effect of hydration on gluten-free breads made with hydroxypropyl methylcellulose in comparison with psyllium and xanthan gum. Foods 2020, 9, 1548. [Google Scholar] [CrossRef] [PubMed]

- García-Segovia, P.; García-Alcaraz, V.; Balasch-Parisi, S.; Martínez-Monzó, J. 3D printing of gels based on xanthan/konjac gums. Innov. Food Sci. Emerg. Technol. 2020, 64, 102343. [Google Scholar] [CrossRef]

- Encina-Zelada, C.R.; Cadavez, V.; Monteiro, F.; Teixeira, J.A.; Gonzales-Barron, U. Combined effect of xanthan gum and water content on physicochemical and textural properties of gluten-free batter and bread. Food Res. Int. 2018, 111, 544–555. [Google Scholar] [CrossRef] [PubMed]

- Bárcenas, M.E.; Benedito, C.; Rosell, C.M. Use of hydrocolloids as bread improvers in interrupted baking process with frozen storage. Food Hydrocoll. 2004, 18, 769–774. [Google Scholar] [CrossRef]

- Fratelli, C.; Muniz, D.G.; Santos, F.G.; Capriles, V.D. Modelling the effects of psyllium and water in gluten-free bread: An approach to improve the bread quality and glycemic response. J. Funct. Foods 2018, 42, 339–345. [Google Scholar] [CrossRef]

- Sabanis, D.; Tzia, C. Effect of hydrocolloids on selected properties of gluten-free dough and bread. Food Sci. Technol. Int. 2011, 17, 279–291. [Google Scholar] [CrossRef] [PubMed]

- Ziemichód, A.; Wójcik, M.; Różyło, R. Seeds of Plantago psyllium and Plantago ovata: Mineral composition, grinding, and use for gluten-free bread as substitutes for hydrocolloids. J. Food Process Eng. 2019, 42, e12931. [Google Scholar] [CrossRef]

- Tebben, L.; Li, Y. Effect of xanthan gum on dough properties and bread qualities made from whole wheat flour. Cereal Chem. 2019, 96, 263–272. [Google Scholar] [CrossRef]

- Pathare, P.B.; Opara, U.L.; Al-Said, F.A.J. Colour Measurement and Analysis in Fresh and Processed Foods: A Review. In Food and Bioprocess Technology; Springer Science and Business Media, LLC: Berlin/Heidelberg, Germany, 2013; Volume 6, pp. 36–60. [Google Scholar] [CrossRef]

- Gray, J.A.; Bemiller, J.N. Bread staling: Molecular basis and control. Compr. Rev. Food Sci. Food Saf. 2003, 2, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Roman, L.; Reguilon, M.P.; Gomez, M.; Martinez, M.M. Intermediate length amylose increases the crumb hardness of rice flour gluten-free breads. Food Hydrocoll. 2020, 100, 105451. [Google Scholar] [CrossRef]

- Roman, L.; Gomez, M.; Martinez, M.M. Mesoscale structuring of gluten-free bread with starch. In Current Opinion in Food Science; Elsevier Ltd.: Amsterdam, The Netherlands, 2021; Volume 38, pp. 189–195. [Google Scholar] [CrossRef]

- Puerta, P.; Laguna, L.; Villegas, B.; Rizo, A.; Fiszman, S.; Tarrega, A. Oral processing and dynamics of texture perception in commercial gluten-free breads. Food Res. Int. 2020, 134, 109233. [Google Scholar] [CrossRef] [PubMed]

- Crockett, R.; Ie, P.; Vodovotz, Y. How do xanthan and hydroxypropyl methylcellulose individually affect the physicochemical properties in a model gluten-free dough? J. Food Sci. 2011, 76, E274–E282. [Google Scholar] [CrossRef] [PubMed]

- Schober, T.J.; Messerschmidt, M.; Bean, S.R.; Park, S.H.; Arendt, E.K. Gluten-free bread from sorghum: Quality differences among hybrids. Cereal Chem. 2005, 82, 394–404. [Google Scholar] [CrossRef]

- Cappa, C.; Lucisano, M.; Mariotti, M. Influence of Psyllium, sugar beet fibre and water on gluten-free dough properties and bread quality. Carbohydr. Polym. 2013, 98, 1657–1666. [Google Scholar] [CrossRef]

- Morreale, F.; Garzón, R.; Rosell, C.M. Understanding the role of hydrocolloids viscosity and hydration in developing gluten-free bread. A study with hydroxypropylmethylcellulose. Food Hydrocoll. 2018, 77, 629–635. [Google Scholar] [CrossRef]

- Onyango, C.; Mutungi, C.; Unbehend, G.; Lindhauer, M.G. Modification of gluten-free sorghum batter and bread using maize, potato, cassava or rice starch. LWT 2011, 44, 681–686. [Google Scholar] [CrossRef]

- Guarda, A.; Rosell, C.M.; Benedito, C.; Galotto, M.J. Different hydrocolloids as bread improvers and antistaling agents. Food Hydrocoll. 2004, 18, 241–247. [Google Scholar] [CrossRef]

- Ashby, J.; Gibson, M.F.; Ashby, L.J. Cellular Solids: Structure & Properties; Pergamon Press: Elmsford, NY, USA, 1988. [Google Scholar]

- Peressini, D.; Pin, M.; Sensidoni, A. Rheology and breadmaking performance of rice-buckwheat batters supplemented with hydrocolloids. Food Hydrocoll. 2011, 25, 340–349. [Google Scholar] [CrossRef]

| Ingredient | Xanthan Gum (g) | HPMC (g) | Psyllium (g) | Water (g) |

|---|---|---|---|---|

| Formula | ||||

| FC | 3.2 | 3.6 | 9.8 | 159.7 |

| F1 | 3.2 | 4.4 | 9.8 | 164.0 |

| F2 | 3.2 | 3.6 | 13.2 | 173.6 |

| F3 | 0 | 3.6 | 9.8 | 148.5 |

| Formula | G″ Storage Modulus (Pa) | G″ Loss Modulus (Pa) | Tan δ (G″/G′) |

|---|---|---|---|

| FC | 11,410 ± 310 b | 3431 ± 60 b | 0.301 ± 0.003 b |

| F1 | 11,533 ± 25 b | 3517 ± 41 b | 0.305 ± 0.004 b |

| F2 | 11,210 ± 236 b | 3207 ± 106 a | 0.286 ± 0.005 a |

| F3 | 9305 ± 296 a | 3507 ± 179 b | 0.377 ± 0.007 c |

| Formula | Force (N) | Area (N·s) |

|---|---|---|

| FC | 135 ± 47 c | 949 ± 57 c |

| F1 | 88 ± 8 a | 621 ± 28 a |

| F2 | 101 ± 4 ab | 708 ± 211 ab |

| F3 | 129 ± 30 bc | 904 ± 331 bc |

| Formula | Dough xw (%) | Dough aw | Crust xw (%) | Crust aw | Crumb xw (%) | Crumb aw | Crumb pH |

|---|---|---|---|---|---|---|---|

| FC | 50.7 ± 1.5 ab | 0.911 ± 0.006 ab | 24.8 ± 3.4 a | 0.908 ± 0.016 b | 45.8 ± 1.7 ab | 0.937 ± 0.003 a | 5.13 ± 0.07 a |

| F1 | 51.9 ± 0.1 bc | 0.909 ± 0.004 ab | 26.5 ± 2.7 a | 0.899 ± 0.034 b | 45.5 ± 1.4 ab | 0.940 ± 0.004 b | 5.21 ± 0.16 b |

| F2 | 53.0 ± 0.1 c | 0.899 ± 0.013 a | 29.5 ± 6.3 a | 0.921 ± 0.018 c | 47.1 ± 1.7 b | 0.944 ± 0.002 c | 5.22 ± 0.07 b |

| F3 | 49.8 ± 0.2 a | 0.921 ± 0.014 b | 24.6 ± 7.3 a | 0.871 ± 0.028 a | 44.1 ± 2.6 a | 0.939 ± 0.007 ab | 5.32 ± 0.05 c |

| FC | F1 | F2 | F3 | |

|---|---|---|---|---|

| L* dough | 75.4 ± 0.4 b | 75.4 ± 0.2 b | 74.7 ± 0.3 a | 76.1 ± 0.3 c |

| a* dough | 0.30 ± 0.06 a | 0.33 ± 0.06 a | 0.48 ± 0.07 b | 0.56 ± 0.07 c |

| b* dough | 9.64 ± 0.15 a | 9.87 ± 0.13 b | 10.06 ± 0.15 c | 10.35 ± 0.25 d |

| ∆E dough | 0.46 ± 0.26 a | 0.83 ± 0.32 b | 1.19 ± 0.30 c | |

| L* crumb | 65 ± 2 a | 65 ± 2 a | 64 ± 3 a | 64 ± 3 a |

| a* crumb | 1.1 ± 0.3 b | 1.1 ± 0.3 b | 1.5 ± 0.4 c | 0.9 ± 0.4 a |

| b* crumb | 11.5 ± 0.9 c | 11.2 ± 0.8 bc | 11.0 ± 0.9 ab | 10.8 ± 1 a |

| ∆E crumb | 2.6 ± 1.6 a | 2.6 ± 1.5 a | 3.1 ± 1.8 a | |

| L* crust | 54 ± 3 b | 53 ± 3 b | 54 ± 3 b | 51 ± 2 a |

| a* crust | 9.6 ± 1.1 b | 9.3 ± 0.9 b | 8.7 ± 1.6 a | 9.6 ± 0.8 b |

| b* crust | 20.8 ± 2.5 b | 20.4 ± 1.9 b | 18.8 ± 2.8 a | 19.4 ± 2.4 a |

| ∆E crust | 4.4 ± 1.6 a | 4.6 ± 1.5 ab | 5.1 ± 1.8 b |

| Formula | Hardness (N) | Adhesiveness (N·s) | Cohesiveness | Gumminess (N) |

|---|---|---|---|---|

| FC | 58.9 ± 7.9 b | −0.04 ± 0.03 a | 0.60 ± 0.02 ab | 35.3 ± 4.9 b |

| F1 | 60.6 ± 10.2 b | −0.04 ± 0.03 a | 0.59 ± 0.13 a | 35.5 ± 9.6 b |

| F2 | 64.7 ± 13.8 b | −0.05 ± 0.02 a | 0.63 ± 0.05 b | 40.7 ± 7.5 c |

| F3 | 46.3 ± 11.6 a | −0.02 ± 0.02 b | 0.60 ± 0.04 ab | 27.8 ± 7.60 a |

| Formula | Number of Cells (Cells/cm2) | Mean Cell Size (cm2) |

|---|---|---|

| FC | 11 ± 2 b | 0.0083 ± 0.0004 a |

| F1 | 11 ± 2 b | 0.0083 ± 0.0007 a |

| F2 | 8 ± 4 a | 0.0084 ± 0.0007 a |

| F3 | 12 ± 1 c | 0.0082 ± 0.0007 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torres-Pérez, R.; Martínez-García, E.; Siguero-Tudela, M.M.; García-Segovia, P.; Martínez-Monzó, J.; Igual, M. Enhancing Gluten-Free Bread Production: Impact of Hydroxypropyl Methylcellulose, Psyllium Husk Fiber, and Xanthan Gum on Dough Characteristics and Bread Quality. Foods 2024, 13, 1691. https://doi.org/10.3390/foods13111691

Torres-Pérez R, Martínez-García E, Siguero-Tudela MM, García-Segovia P, Martínez-Monzó J, Igual M. Enhancing Gluten-Free Bread Production: Impact of Hydroxypropyl Methylcellulose, Psyllium Husk Fiber, and Xanthan Gum on Dough Characteristics and Bread Quality. Foods. 2024; 13(11):1691. https://doi.org/10.3390/foods13111691

Chicago/Turabian StyleTorres-Pérez, Ramón, Elena Martínez-García, Marta Maravilla Siguero-Tudela, Purificación García-Segovia, Javier Martínez-Monzó, and Marta Igual. 2024. "Enhancing Gluten-Free Bread Production: Impact of Hydroxypropyl Methylcellulose, Psyllium Husk Fiber, and Xanthan Gum on Dough Characteristics and Bread Quality" Foods 13, no. 11: 1691. https://doi.org/10.3390/foods13111691