A Comprehensive Review on Harnessing Soy Proteins in the Manufacture of Healthy Foods through Extrusion

Abstract

:1. Introduction

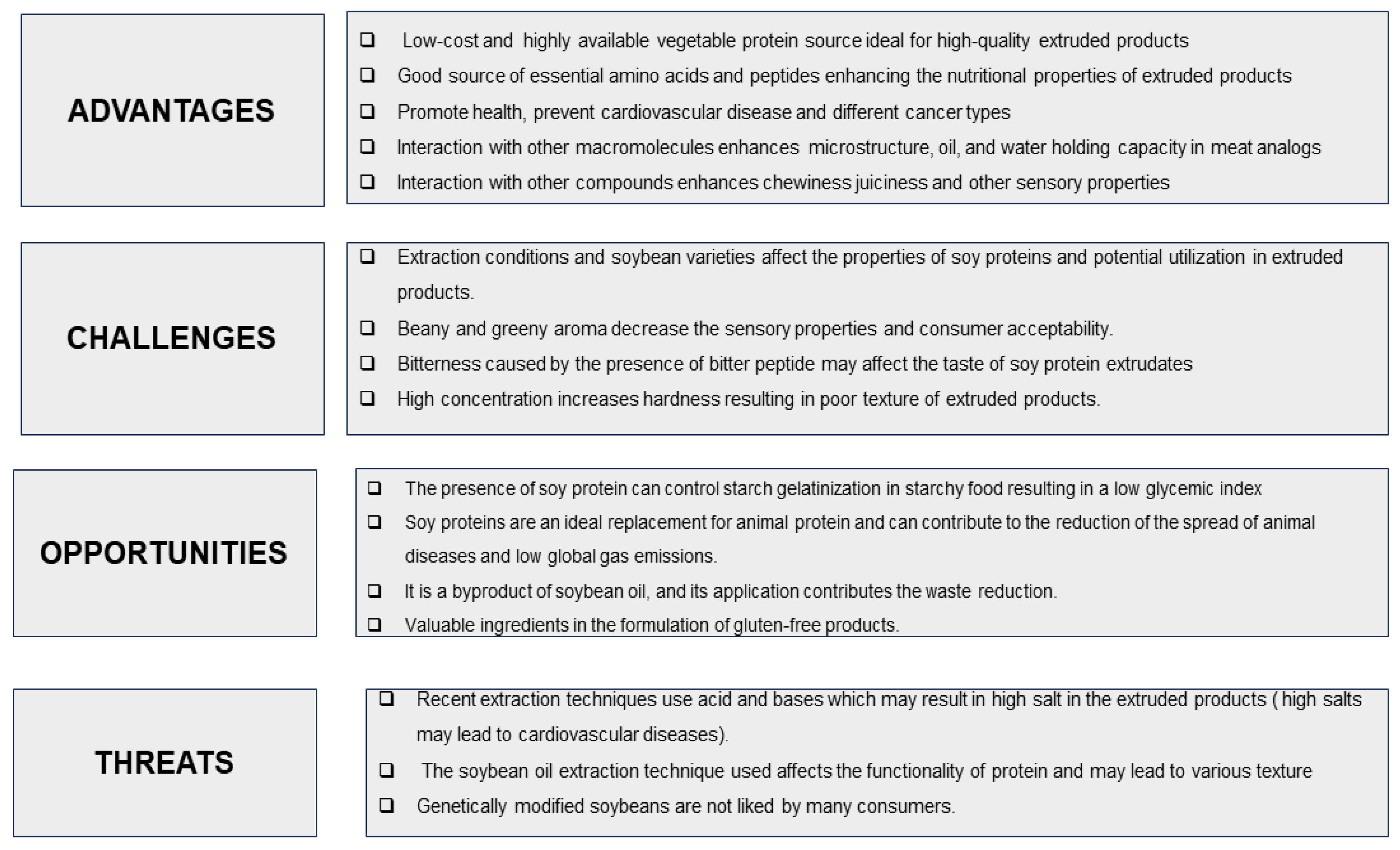

2. Soy Protein Properties and Biological Functions

2.1. Composition

2.2. Biological Functions

3. Challenges in the Utilization of Soy Proteins

3.1. Deficiency and Loss of Amino Acids

3.2. Beany and Grassy Flavor

4. Extrusion of Soy Proteins

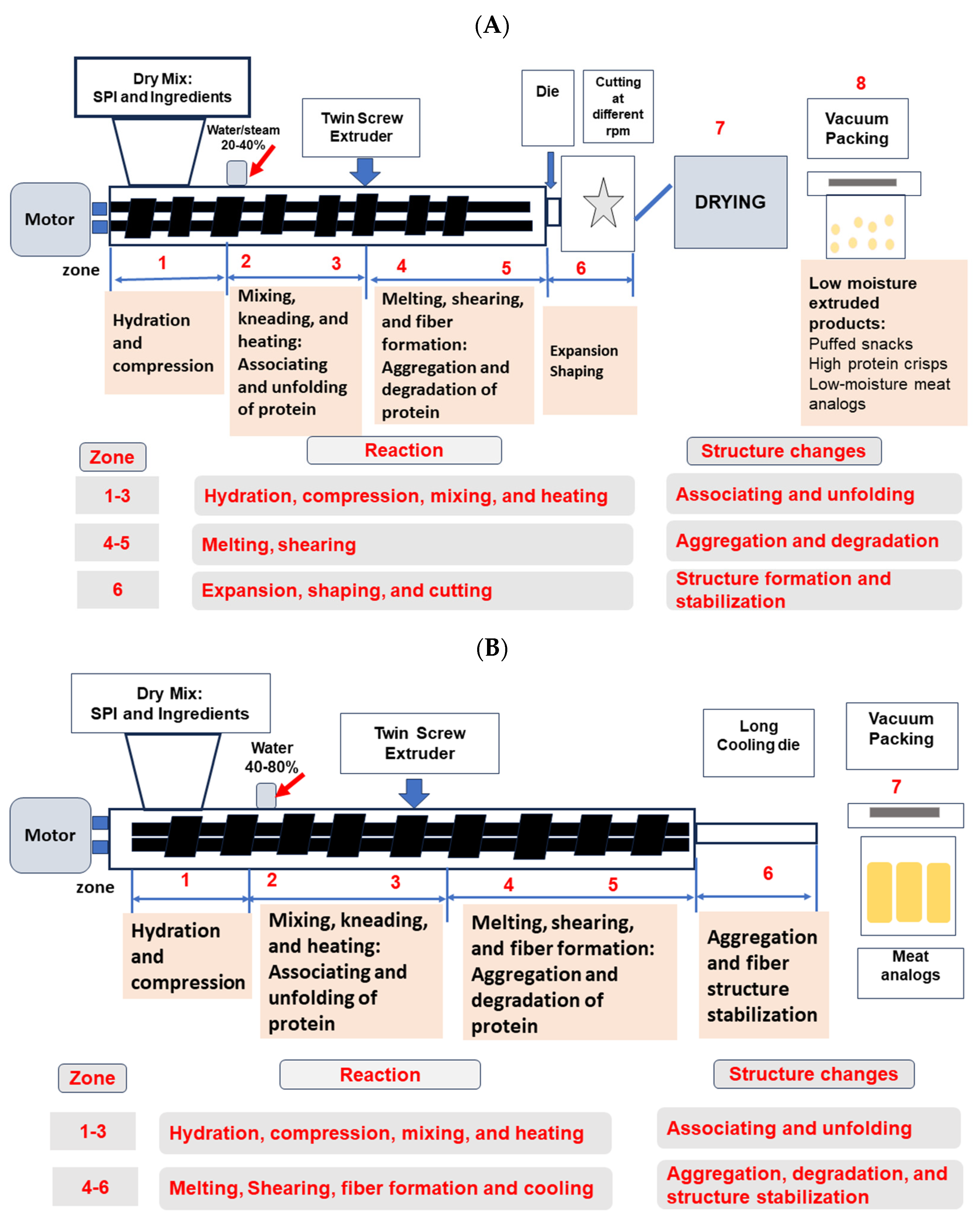

4.1. Low Moisture Extrusion

4.2. High Moisture Extrusion

5. Extrusion of Soy Protein-Based Blends

5.1. Low Moisture Extrusion of Soy Protein-Based Blends

5.2. High Moisture Extrusion of Soy Protein-Based Blends

6. Potential Application of Soy Protein and Soy Protein-Based Blends in Healthy Food Formulation through Extrusion

6.1. Application in Meat Analogs

6.2. Application in Snack Products Formulation

6.3. Application in Pasta Products Formulation

6.4. Application Cereal Breakfast Processing

7. Conclusions and Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Harastani, R.; James, L.J.; Walton, J.; Woolley, E. Tackling obesity: A knowledge-base to enable industrial food reformulation. Innov. Food Sci. Emerg. Technol. 2020, 64, 102433. [Google Scholar] [CrossRef]

- Naumann, S.; Schweiggert-Weisz, U.; Martin, A.; Schuster, M.; Eisner, P. Effects of extrusion processing on the physiochemical and functional properties of lupin kernel fibre. Food Hydrocoll. 2021, 111, 106222. [Google Scholar] [CrossRef]

- MacDonald, R.S.; Pryzbyszewski, J.; Hsieh, F.H. Soy protein isolate extruded with high moisture retains high nutritional quality. J. Agric. Food Chem. 2009, 57, 3550–3555. [Google Scholar] [CrossRef] [PubMed]

- Alam, M.S.; Kaur, J.; Khaira, H.; Gupta, K. Extrusion and Extruded Products: Changes in Quality Attributes as Affected by Extrusion Process Parameters: A Review. Crit. Rev. Food Sci. Nutr. 2015, 56, 445–473. [Google Scholar] [CrossRef] [PubMed]

- Cornet SH, V.; Snel SJ, E.; Schreuders FK, G.; van der Sman RG, M.; Beyrer, M.; van der Goot, A.J. Thermo-mechanical processing of plant proteins using shear cell and high-moisture extrusion cooking. Crit. Rev. Food Sci. Nutr. 2021, 1–18. [Google Scholar] [CrossRef] [PubMed]

- Leonard, W.; Zhang, P.; Ying, D.; Fang, Z. Application of extrusion technology in plant food processing byproducts: An overview. Compr. Rev. Food Sci. Food Saf. 2020, 19, 218–246. [Google Scholar] [CrossRef] [PubMed]

- Sui, X.; Zhang, T.; Jiang, L. Soy Protein: Molecular Structure Revisited and Recent Advances in Processing Technologies. Annu. Rev. Food Sci.Technol. 2021, 12, 1–29. [Google Scholar] [CrossRef] [PubMed]

- Tian, H.; Guo, G.; Fu, X.; Yao, Y.; Yuan, L.; Xiang, A. Fabrication, properties and applications of soy-protein-basedmaterials: A review. Int. J. Biol. Macromol. 2018, 120, 475–490. [Google Scholar] [CrossRef]

- Tang, C.H. Nano-architectural assembly of soy proteins: A promising strategy to fabricate nutraceutical nanovehicles. Adv. Colloid. Interface Sci. 2021, 291, 102402. [Google Scholar] [CrossRef]

- Nishinari, K.; Fang, Y.; Guo, S.; Phillips, G.O. Soy proteins: A review on composition, aggregation and emulsification. Food Hydrocoll. 2014, 39, 301–318. [Google Scholar] [CrossRef]

- Cai, J.-S.; Feng, J.-Y.; Ni, Z.-J.; Ma, R.-H.; Thakur, K.; Wang, S.; Hu, F.; Zhang, J.-G.; Wei, Z.-J. An update on the nutritional, functional, sensory characteristics of soy products, and applications of new processing strategies. Trends Food Sci. Technol. 2021, 112, 676–689. [Google Scholar] [CrossRef]

- Cai, J.S.; Zhu, Y.Y.; Ma, R.H.; Thakur, K.; Zhang, J.G.; Wei, Z.J. Effects of roasting level on physicochemical, sensory, and volatile profiles of soybeans using electronic nose and HS-SPME-GC-MS. Food Chem. 2021, 340, 127880. [Google Scholar] [CrossRef] [PubMed]

- Wofford, M.R.; Rebholz, C.M.; Reynolds, K.; Chen, J.; Chen, C.S.; Myers, L.; Xu, J.; Jones, D.W.; Whelton, P.K.; He, J. Effect of soy and milk protein supplementation on serum lipid levels: A randomized controlled trial. Eur. J. Clin. Nutr. 2012, 66, 419–425. [Google Scholar] [CrossRef] [PubMed]

- George, K.S.; Munoz, J.; Akhavan, N.S.; Foley, E.M.; Siebert, S.C.; Tenenbaum, G.; Khalil, D.A.; Chai, S.C.; Arjmandi, B.H. Is soy protein effective in reducing cholesterol and improving bone health? Food Funct. 2020, 11, 544–551. [Google Scholar] [CrossRef] [PubMed]

- Yeh, W.J.; Yang, H.Y.; Chen, J.R. Soy beta-conglycinin retards progression of diabetic nephropathy via modulating the insulin sensitivity and angiotensin-converting enzyme activity in rats fed with high salt diet. Food Funct. 2014, 5, 2898–2904. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.I.; Tseng, H.T.; Hsieh, C.C. Evaluating the impact of soy compounds on breast cancer using the data mining approach. Food Funct. 2020, 11, 4561–4570. [Google Scholar] [CrossRef] [PubMed]

- Kovacs-Nolan, J.; Zhang, H.; Ibuki, M.; Nakamori, T.; Yoshiura, K.; Turner, P.V.; Matsui, T.; Mine, Y. The PepT1-transportable soy tripeptide VPY reduces intestinal inflammation. Biochim. Biophys. Acta 2012, 1820, 1753–1763. [Google Scholar] [CrossRef]

- Zeng, B.; Wang, D.; Wang, H.; Chen, T.; Luo, J.; Xi, Q.; Sun, J.; Zhang, Y. Dietary Soy Protein Isolate Attenuates Intestinal Immunoglobulin and Mucin Expression in Young Mice Compared with Casein. Nutrients 2020, 12, 2739. [Google Scholar] [CrossRef]

- Krishnan, H.B.; Jez, J.M. Review: The promise and limits for enhancing sulfur-containing amino acid content of soybean seed. Plant Sci. 2018, 272, 14–21. [Google Scholar] [CrossRef]

- Stolt, E.; Olsen, T.; Elshorbagy, A.; Kozich, V.; van Greevenbroek, M.; Ovrebo, B.; Thoresen, M.; Refsum, H.; Retterstol, K.; Vinknes, K.J. Sulfur amino acid restriction, energy metabolism, and obesity: A study protocol of an 8-week randomized controlled dietary intervention with whole foods and amino acid supplements. J. Transl. Med. 2021, 19, 153. [Google Scholar] [CrossRef]

- Duque-Estrada, P.; Kyriakopoulou, K.; de Groot, W.; van der Goot, A.J.; Berton-Carabin, C.C. Oxidative stability of soy proteins: From ground soybeans to structured products. Food Chem. 2020, 318, 126499. [Google Scholar] [CrossRef] [PubMed]

- Estrada, P.D.; Berton-Carabin, C.C.; Schlangen, M.; Haagsma, A.; Pierucci, A.; van der Goot, A.J. Protein Oxidation in Plant Protein-Based Fibrous Products: Effects of Encapsulated Iron and Process Conditions. J. Agric. Food Chem. 2018, 66, 11105–11112. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, Q.; Zhang, N.; Bak, K.H.; Soladoye, O.P.; Aluko, R.E.; Fu, Y.; Zhang, Y. Insights into formation, detection and removal of the beany flavor in soybean protein. Trends Food Sci. Technol. 2021, 112, 336–347. [Google Scholar] [CrossRef]

- Shin, D.J.; Kim, W.; Kim, Y. Physicochemical and sensory properties of soy bread made with germinated, steamed, and roasted soy flour. Food Chem. 2013, 141, 517–523. [Google Scholar] [CrossRef] [PubMed]

- Chong, W.K.; Mah, S.Y.; Easa, A.M.; Tan, T.C. Thermal inactivation of lipoxygenase in soya bean using superheated steam to produce low beany flavour soya milk. J. Food Sci. Technol. 2019, 56, 4371–4379. [Google Scholar] [CrossRef] [PubMed]

- Navicha, W.B.; Hua, Y.; Masamba, K.; Kong, X.; Zhang, C. Optimization of soybean roasting parameters in developing nutritious and lipoxygenase-free soymilk. J. Food Meas. Charact. 2017, 11, 1899–1908. [Google Scholar] [CrossRef]

- Milani TM, G.; Menis ME, C.; Jordano, A.; Boscolo, M.; Conti-Silva, A.C. Pre-extrusion aromatization of a soy protein isolate using volatile compounds and flavor enhancers: Effects on physical characteristics, volatile retention and sensory characteristics of extrudates. Food Res. Int. 2014, 62, 375–381. [Google Scholar] [CrossRef]

- Dalbhagat, C.G.; Mahato, D.K.; Mishra, H.N. Effect of extrusion processing on physicochemical, functional and nutritional characteristics of rice and rice-based products: A review. Trends Food Sci. Technol. 2019, 85, 226–240. [Google Scholar] [CrossRef]

- Sahu, C.; Patel, S. Moisture sorption characteristics and quality changes during storage in defatted soy incorporated maize-millet based extruded product. LWT 2020, 133, 110153. [Google Scholar] [CrossRef]

- Fang, Y.; Zhang, B.; Wei, Y.; Li, S. Effects of specific mechanical energy on soy protein aggregation during extrusion process studied by size exclusion chromatography coupled with multi-angle laser light scattering. J. Food Eng. 2013, 115, 220–225. [Google Scholar] [CrossRef]

- Singh, S.K.; Singha, P.; Muthukumarappan, K. Modeling and optimizing the effect of extrusion processing parameters on nutritional properties of soy white flakes-based extrudates using response surface methodology. Anim. Feed Sci. Technol. 2019, 254, 114197. [Google Scholar] [CrossRef]

- Chen, F.L.; Wei, Y.M.; Zhang, B.; Ojokoh, A.O. System parameters and product properties response of soybean protein extruded at wide moisture range. J. Food Eng. 2010, 96, 208–213. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, L.; Liu, H.; Yoon, A.; Rizvi SS, H.; Wang, Q. Changes in conformation and quality of vegetable protein during texturization process by extrusion. Crit. Rev. Food Sci. Nutr. 2019, 59, 3267–3280. [Google Scholar] [CrossRef] [PubMed]

- Mozafarpour, R.; Koocheki, A.; Milani, E.; Varidi, M. Extruded soy protein as a novel emulsifier: Structure, interfacial activity and emulsifying property. Food Hydrocoll. 2019, 93, 361–373. [Google Scholar] [CrossRef]

- Zheng, H.; Yan, G.; Lee, Y.; Alcaraz, C.; Marquez, S.; de Mejia, E.G. Effect of the extrusion process on allergen reduction and the texture change of soybean protein isolate-corn and soybean flour-corn mixtures. Innov. Food Sci. Emerg. Technol. 2020, 64, 102421. [Google Scholar] [CrossRef]

- Wang, H.; van den Berg FW, J.; Zhang, W.; Czaja, T.P.; Zhang, L.; Jespersen, B.M.; Lametsch, R. Differences in physicochemical properties of high-moisture extrudates prepared from soy and pea protein isolates. Food Hydrocoll. 2022, 128, 107540. [Google Scholar] [CrossRef]

- Fu, L.; Wang, Z.; Adhikari, B.; He, Z.; Zeng, M.; Qin, F.; Chen, J. Soluble and insoluble fractions of soy protein isolate affect the properties of its high-moisture extrudates. Food Biosci. 2024, 59, 103850. [Google Scholar] [CrossRef]

- Pietsch, V.L.; Bühler, J.M.; Karbstein, H.P.; Emin, M.A. High moisture extrusion of soy protein concentrate: Influence of thermomechanical treatment on protein-protein interactions and rheological properties. J. Food Eng. 2019, 251, 11–18. [Google Scholar] [CrossRef]

- Zheng, Y.; Xu, J.; Sun, C.; Zhao, Y.; Cao, Y.; Lu, W.; Zhang, Y.; Fang, Y. Multihole nozzle-mediated high-moisture extrusion of soy proteins into fiber-rich structures. Food Hydrocoll. 2024, 151, 109819. [Google Scholar] [CrossRef]

- Fu, X.; Li, W.; Zhang, T.; Li, H.; Zang, M.; Liu, X. Effect of extrusion on the protein structure and digestibility of extruded soybean protein. J. Sci. Food Agric. 2024, 104, 2225–2232. [Google Scholar] [CrossRef]

- Chiang, J.H.; Loveday, S.M.; Hardacre, A.K.; Parker, M.E. Effects of soy protein to wheat gluten ratio on the physicochemical properties of extruded meat analogues. Food Struct. 2019, 19, 100102. [Google Scholar] [CrossRef]

- Palanisamy, M.; Töpfl, S.; Aganovic, K.; Berger, R.G. Influence of iota carrageenan addition on the properties of soya protein meat analogues. Lwt 2018, 87, 546–552. [Google Scholar] [CrossRef]

- Ye, X.; Su, X.; Xiao, T.; Lu, F.; Xie, T. High moisture extrusion of soybean protein isolate: Effect of beta-glucan on physicochemical properties of extrudates. Food Chem. 2024, 441, 138329. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, L.; Czaja, T.P.; Bakalis, S.; Zhang, W.; Lametsch, R. Structural characteristics of high-moisture extrudates with oil-in-water emulsions. Food Res. Int. 2022, 158, 111554. [Google Scholar] [CrossRef] [PubMed]

- Beck, S.M.; Knoerzer, K.; Foerster, M.; Mayo, S.; Philipp, C.; Arcot, J. Low moisture extrusion of pea protein and pea fibre fortified rice starch blends. J. Food Eng. 2018, 231, 61–71. [Google Scholar] [CrossRef]

- Arora, B.; Yoon, A.; Sriram, M.; Singha, P.; Rizvi, S.S.H. Reactive extrusion: A review of the physicochemical changes in food systems. Innov. Food Sci. Emerg. Technol. 2020, 64, 102429. [Google Scholar] [CrossRef]

- Tanger, C.; Schmidt, F.; Utz, F.; Kreissl, J.; Dawid, C.; Kulozik, U. Pea protein microparticulation using extrusion cooking: Influence of extrusion parameters and drying on microparticle characteristics and sensory by application in a model milk dessert. Innov. Food Sci. Emerg. Technol. 2021, 74, 102851. [Google Scholar] [CrossRef]

- Sun, C.; Fu, J.; Chang, Y.; Li, S.; Fang, Y. Structure Design for Improving the Characteristic Attributes of Extruded Plant-Based Meat Analogues. Food Biophys. 2021, 17, 137–149. [Google Scholar] [CrossRef]

- Fang, Y.; Zhang, B.; Wei, Y. Effects of the specific mechanical energy on the physicochemical properties of texturized soy protein during high-moisture extrusion cooking. J. Food Eng. 2014, 121, 32–38. [Google Scholar] [CrossRef]

- Su, X.; Li, F.; Gong, Y.; Dai, M.; Pan, W.; Zhang, B. Physical and chemical properties of soy protein isolates treated with sodium sulphite under low temperature extrusion. Int. J. Food Sci. Technol. 2021, 56, 4559–4567. [Google Scholar] [CrossRef]

- Emin, M.A.; Quevedo, M.; Wilhelm, M.; Karbstein, H.P. Analysis of the reaction behavior of highly concentrated plant proteins in extrusion-like conditions. Innov. Food Sci. Emerg. Technol. 2017, 44, 15–20. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, L.; Jiang, Y.; Faisal, S.; Wang, Q. A new insight into the high-moisture extrusion process of peanut protein: From the aspect of the orders and amount of energy input. J. Food Eng. 2020, 264, 109668. [Google Scholar] [CrossRef]

- Osen, R.; Toelstede, S.; Wild, F.; Eisner, P.; Schweiggert-Weisz, U. High moisture extrusion cooking of pea protein isolates: Raw material characteristics, extruder responses, and texture properties. J. Food Eng. 2014, 127, 67–74. [Google Scholar] [CrossRef]

- Guerrero, P.; Beatty, E.; Kerry, J.P.; de la Caba, K. Extrusion of soy protein with gelatin and sugars at low moisture content. J. Food Eng. 2012, 110, 53–59. [Google Scholar] [CrossRef]

- Offiah, V.; Kontogiorgos, V.; Falade, K.O. Extrusion processing of raw food materials and by-products: A review. Crit. Rev. Food Sci. Nutr. 2019, 59, 2979–2998. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, R.; Oterhals, Å.; Xue, Y.; Skodvin, T.; Samuelsen, T. A Impact of fish protein concentrate on apparent viscosity and physical properties of soy protein concentrate subjected to thermomechanical treatment. J. Food Eng. 2019, 259, 34–43. [Google Scholar] [CrossRef]

- Guo, Z.; Teng, F.; Huang, Z.; Lv, B.; Lv, X.; Babich, O.; Yu, W.; Li, Y.; Wang, Z.; Jiang, L. Effects of material characteristics on the structural characteristics and flavor substances retention of meat analogs. Food Hydrocoll. 2020, 105, 105752. [Google Scholar] [CrossRef]

- Yu, J.; Wang, X.-Y.; Li, D.; Wang, L.-J.; Wang, Y. Development of soy protein isolate emulsion gels as extrusion-based 3D food printing inks: Effect of polysaccharides incorporation. Food Hydrocoll. 2022, 131, 107824. [Google Scholar] [CrossRef]

- Jiménez-Munoz, L.M.; Tavares, G.M.; Corredig, M. Design future foods using plant protein blends for best nutritional and technological functionality. Trends Food Sci. Technol. 2021, 113, 139–150. [Google Scholar] [CrossRef]

- Han, X.M.; Xing, J.J.; Han, C.; Guo, X.N.; Zhu, K.X. The effects of extruded endogenous starch on the processing properties of gluten-free Tartary buckwheat noodles. Carbohydr. Polym. 2021, 267, 118170. [Google Scholar] [CrossRef]

- Kiiru, S.M.; Kinyuru, J.N.; Kiage, B.N.; Martin, A.; Marel, A.K.; Osen, R. Extrusion texturization of cricket flour and soy protein isolate: Influence of insect content, extrusion temperature, and moisture-level variation on textural properties. Food Sci. Nutr. 2020, 8, 4112–4120. [Google Scholar] [CrossRef]

- Sandoval Murillo, J.L.; Osen, R.; Hiermaier, S.; Ganzenmüller, G. Towards understanding the mechanism of fibrous texture formation during high-moisture extrusion of meat substitutes. J. Food Eng. 2019, 242, 8–20. [Google Scholar] [CrossRef]

- Dekkers, B.L.; Boom, R.M.; van der Goot, A.J. Structuring processes for meat analogues. Trends Food Sci. Technol. 2018, 81, 25–36. [Google Scholar] [CrossRef]

- Dekkers, B.L.; Nikiforidis, C.V.; van der Goot, A.J. Shear-induced fibrous structure formation from a pectin/SPI blend. Innov. Food Sci. Emerg. Technol. 2016, 36, 193–200. [Google Scholar] [CrossRef]

- Dou, W.; Zhang, X.; Zhao, Y.; Zhang, Y.; Jiang, L.; Sui, X. High moisture extrusion cooking on soy proteins: Importance influence of gums on promoting the fiber formation. Food Res. Int. 2022, 156, 111189. [Google Scholar] [CrossRef]

- de Boer, J.; Aiking, H. Strategies towards healthy and sustainable protein consumption: A transition framework at the levels of diets, dishes, and dish ingredients. Food Qual. Prefer. 2019, 73, 171–181. [Google Scholar] [CrossRef]

- Alae-Carew, C.; Green, R.; Stewart, C.; Cook, B.; Dangour, A.D.; Scheelbeek, P.F.D. The role of plant-based alternative foods in sustainable and healthy food systems: Consumption trends in the UK. Sci. Total Env. 2022, 807 Pt 3, 151041. [Google Scholar] [CrossRef]

- Kou, T.; Wang, Q.; Cai, J.; Song, J.; Du, B.; Zhao, K.; Ma, Y.; Geng, B.; Zhang, Y.; Han, X.; et al. Effect of soybean protein on blood pressure in postmenopausal women: A meta-analysis of randomized controlled trials. Food Funct. 2017, 8, 2663–2671. [Google Scholar] [CrossRef]

- Anzani, C.; Boukid, F.; Drummond, L.; Mullen, A.M.; Alvarez, C. Optimising the use of proteins from rich meat co-products and non-meat alternatives: Nutritional, technological and allergenicity challenges. Food Res. Int. 2020, 137, 109575. [Google Scholar] [CrossRef]

- Samard, S.; Maung, T.T.; Gu, B.Y.; Kim, M.H.; Ryu, G.H. Influences of extrusion parameters on physicochemical properties of textured vegetable proteins and its meatless burger patty. Food Sci. Biotechnol. 2021, 30, 395–403. [Google Scholar] [CrossRef]

- Lyu, X.; Ying, D.; Zhang, P.; Fang, Z. Effect of Whole Tomato Powder or Tomato Peel Powder Incorporation on the Color, Nutritional, and Textural Properties of Extruded High Moisture Meat Analogues. Food Bioprocess. Technol. 2023, 17, 231–244. [Google Scholar] [CrossRef]

- Ketnawa, S.; Chaijan, M.; Grossmann, L.; Rawdkuen, S. High-moisture soy protein-mushroom-based meat analogue: Physicochemical, structural properties and its application. Int. J. Food Sci. Technol. 2023, 59, 596–614. [Google Scholar] [CrossRef]

- Huang, Z.; Liu, Y.; An, H.; Kovacs, Z.; Abddollahi, M.; Sun, Z.; Zhang, G.; Li, C. Utilizing Haematococcus pluvialis to simulate animal meat color in high-moisture meat analogues: Texture quality and color stability. Food Res. Int. 2024, 175, 113685. [Google Scholar] [CrossRef]

- Pandey, S.; Kumar, A.; Rao, P.S. Optimization, modeling, and characterization study for the physicochemical properties of raw banana and defatted soy composite extrudates. Food Chem. 2021, 339, 127865. [Google Scholar] [CrossRef]

- Sharifi, S.; Majzoobi, M.; Farahnaky, A. Development of healthy extruded maize snacks; Effects of soybean flour and feed moisture content. Int. J. Food Sci. Technol. 2020, 56, 3179–3187. [Google Scholar] [CrossRef]

- Na-Nakorn, K.; Hamaker, B.R.; Tongta, S. Physicochemical and rheological properties of cooked extruded reformed rice with added protein or fiber. Lwt 2021, 151, 112196. [Google Scholar] [CrossRef]

- Bolarinwa, I.F.; Oyesiji, O.O. Gluten-free rice-soy pasta: Proximate composition, textural properties and sensory attributes. Heliyon 2021, 7, e06052. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Dou, W.; Zhang, X.; Zhao, Y.; Zhang, Y.; Jiang, L.; Sui, X. The development history and recent updates on soy protein-based meat alternatives. Trends Food Sci. Technol. 2021, 109, 702–710. [Google Scholar] [CrossRef]

- Herz, E.; Herz, L.; Dreher, J.; Gibis, M.; Ray, J.; Pibarot, P.; Schmitt, C.; Weiss, J. Influencing factors on the ability to assemble a complex meat analogue using a soy-protein-binder. Innov. Food Sci. Emerg. Technol. 2021, 73, 102806. [Google Scholar] [CrossRef]

- Zhou, H.; Hu, Y.; Tan, Y.; Zhang, Z.; McClements, D.J. Digestibility and gastrointestinal fate of meat versus plant-based meat analogs: An in vitro comparison. Food Chem. 2021, 364, 130439. [Google Scholar] [CrossRef]

- Turner-McGrievy, G.M.; Wirth, M.D.; Shivappa, N.; Wingard, E.E.; Fayad, R.; Wilcox, S.; Frongillo, E.A.; Hebert, J.R. Randomization to plant-based dietary approaches leads to larger short-term improvements in Dietary Inflammatory Index scores and macronutrient intake compared with diets that contain meat. Nutr. Res. 2015, 35, 97–106. [Google Scholar] [CrossRef] [PubMed]

- Schreuders, F.K.G.; Schlangen, M.; Kyriakopoulou, K.; Boom, R.M.; van der Goot, A.J. Texture methods for evaluating meat and meat analogue structures: A review. Food Control 2021, 127, 108103. [Google Scholar] [CrossRef]

- Ahmad, M.; Qureshi, S.; Akbar, M.H.; Siddiqui, S.A.; Gani, A.; Mushtaq, M.; Hassan, I.; Dhull, S. B Plant-based meat alternatives: Compositional analysis, current development and challenges. Appl. Food Res. 2022, 2, 100154. [Google Scholar] [CrossRef]

- Tas, A.A.; Shah, A.U. The replacement of cereals by legumes in extruded snack foods: Science, technology, and challenges. Trends Food Sci. Technol. 2021, 116, 701–711. [Google Scholar] [CrossRef]

- Gao, Y.; Li, X.; Dong, J.; Cao, Y.; Li, T.; Mielke, H.W. Snack foods and lead ingestion risks for school-aged children: A comparative evaluation of potentially toxic metals and children’s exposure response of blood lead, copper and zinc levels. Chemosphere 2020, 261, 127547. [Google Scholar] [CrossRef] [PubMed]

- Skoczek-Rubinska, A.; Bajerska, J. The consumption of energy dense snacks and some contextual factors of snacking may contribute to higher energy intake and body weight in adults. Nutr. Res. 2021, 96, 20–36. [Google Scholar] [CrossRef] [PubMed]

- Alam, M.S.; Pathania, S.; Sharma, A. Optimization of the extrusion process for development of high fibre soybean-rice ready-to-eat snacks using carrot pomace and cauliflower trimmings. Lwt 2016, 74, 135–144. [Google Scholar] [CrossRef]

- Makowska, A.; Zielińska-Dawidziak, M.; Niedzielski, P.; Michalak, M. Effect of extrusion conditions on iron stability and physical and textural properties of corn snacks enriched with soybean ferritin. Int. J. Food Sci. Technol. 2018, 53, 296–303. [Google Scholar] [CrossRef]

- Suri, S.; Dutta, A.; Chandra Shahi, N.; Raghuvanshi, R.S.; Singh, A.; Chopra, C.S. Numerical optimization of process parameters of ready-to-eat (RTE) iron-rich extruded snacks for anemic population. Lwt 2020, 134, 110164. [Google Scholar] [CrossRef]

- van der Sman, R.G.M.; Broeze, J. Structuring of indirectly expanded snacks based on potato ingredients: A review. J. Food Eng. 2013, 114, 413–425. [Google Scholar] [CrossRef]

- Menis-Henrique, M.E.C.; Scarton, M.; Piran MV, F.; Clerici, M.T.P.S. Cereal fiber: Extrusion modifications for food industry. Curr. Opin. Food Sci. 2020, 33, 141–148. [Google Scholar] [CrossRef]

- Ferreira, S.M.; Capriles, V.D.; Conti-Silva, A.C. Inulin as an ingredient for improvement of glycemic response and sensory acceptance of breakfast cereals. Food Hydrocoll. 2021, 114, 106582. [Google Scholar] [CrossRef]

- Abbie, E.; Francois, M.E.; Chang, C.R.; Barry, J.C.; Little, J. P A low-carbohydrate protein-rich bedtime snack to control fasting and nocturnal glucose in type 2 diabetes: A randomized trial. Clin. Nutr. 2020, 39, 3601–3606. [Google Scholar] [CrossRef] [PubMed]

- Rafiq, A.; Sharma, S.; Singh, B. In vitro, starch digestibility, degree of gelatinization and functional properties of twin screw prepared cereal-legume pasta. J. Cereal Sci. 2017, 74, 279–287. [Google Scholar] [CrossRef]

- Carpentieri, S.; Larrea-Wachtendorff, D.; Donsì, F.; Ferrari, G. Functionalization of pasta through the incorporation of bioactive compounds from agri-food by-products: Fundamentals, opportunities, and drawbacks. Trends Food Sci. Technol. 2022, 122, 49–65. [Google Scholar] [CrossRef]

- Gangola, M.P.; Ramadoss, B.R.; Jaiswal, S.; Chan, C.; Mollard, R.; Fabek, H.; Tulbek, M.; Jones, P.; Sanchez-Hernandez, D.; Anderson, G.H.; et al. Faba bean meal, starch or protein fortification of durum wheat pasta differentially influence noodle composition, starch structure and in vitro digestibility. Food Chem. 2021, 349, 129167. [Google Scholar] [CrossRef] [PubMed]

- Reddy Surasani, V.K.; Singh, A.; Gupta, A.; Sharma, S. Functionality and cooking characteristics of pasta supplemented with protein isolate from pangas processing waste. Lwt 2019, 111, 443–448. [Google Scholar] [CrossRef]

- Detchewa, P.; Thongngam, M.; Jane, J.L.; Naivikul, O. Preparation of gluten-free rice spaghetti with soy protein isolate using twin-screw extrusion. J. Food Sci. Technol. 2016, 53, 3485–3494. [Google Scholar] [CrossRef]

- Khatkar, A.B.; Kaur, A.; Khatkar, S.K.; Bala, M.; Maan, S.; Tyagi, S.K. Valorization of ultrasound assisted restructured soy protein: Impact on the quality characteristics of instant noodles. Lwt 2021, 147, 111599. [Google Scholar] [CrossRef]

- Marengo, M.; Amoah, I.; Carpen, A.; Benedetti, S.; Zanoletti, M.; Buratti, S.; Lutterodt, H.E.; Johnson, P.T.; Manful, J.; Marti, A.; et al. Enriching gluten-free rice pasta with soybean and sweet potato flours. J. Food Sci. Technol. 2018, 55, 2641–2648. [Google Scholar] [CrossRef]

- Ciccoritti, R.; Nocente, F.; Sgrulletta, D.; Gazza, L. Cooking quality, biochemical and technological characteristics of bran-enriched pasta obtained by a novel pasta-making process. Lwt 2019, 101, 10–16. [Google Scholar] [CrossRef]

- Lamacchia, C.; Baiano, A.; Lamparelli, S.; Padalino, L.; La Notte, E.; Luccia, A.D. Study on the interactions between soy and semolina proteins during pasta making. Food Res. Int. 2010, 43, 1049–1056. [Google Scholar] [CrossRef]

- Chávez-Murillo, C.E.; Aceves-Flores, M.S.; Verástegui-Quevedo, M.; Rosa-Millán, J. Influence of starch and protein molecular interactions on the in vitro digestion characteristics of biscuits partially substituted with pulse flours. Int. J. Food Sci. Technol. 2021, 56, 3388–3399. [Google Scholar] [CrossRef]

- Gallegos-Infante, J.A.; Rocha-Guzman, N.E.; Gonzalez-Laredo, R.F.; Ochoa-Martínez, L.A.; Corzo, N.; Bello-Perez, L.A.; Medina-Torres, L.; Peralta-Alvarez, L.E. Quality of spaghetti pasta containing Mexican common bean flour (Phaseolus vulgaris L.). Food Chem. 2010, 119, 1544–1549. [Google Scholar] [CrossRef]

- De Arcangelis, E.; Cuomo, F.; Trivisonno, M.C.; Marconi, E.; Messia, M.C. Gelatinization and pasta making conditions for buckwheat gluten-free pasta. J. Cereal Sci. 2020, 95, 103073. [Google Scholar] [CrossRef]

- Rubin, E.B.; Viscuso, M.R.; Moleski, S.M. Maintaining a Balanced Diet While Gluten-Free: Treatment Options. Curr. Treat. Options Gastroenterol. 2020, 18, 699–717. [Google Scholar] [CrossRef]

- De Brier, N.; Gomand, S.V.; Joye, I.J.; Pareyt, B.; Courtin, C.M.; Delcour, J.A. The impact of pearling as a treatment prior to wheat roller milling on the texture and structure of bran-rich breakfast flakes. LWT—Food Sci. Technol. 2015, 62, 668–674. [Google Scholar] [CrossRef]

- Himat, A.S.; Gautam, S.; Chavez Garcia, J.P.; Vidrio-Sahagún, A.X.; Liu, Z.; Bressler, D.; Vasanthan, T. Starch-based novel ingredients for low glycemic food formulation. Bioact. Carbohydr. Diet. Fibre 2021, 26, 100275. [Google Scholar] [CrossRef]

| Extrusion Conditions | Major Findings | Reference | |||||

|---|---|---|---|---|---|---|---|

| Composition | Screw Speed | Feed Rate | Temperature | Moisture Content | |||

| Soy Protein Purity | Others | ||||||

| % | % | RPM | Kg/h | °C | % | ||

| 80 | 0 | 180 | 40 | 110, 130 and 160 | 18–25 | 7S and 11S disappeared at 18% Moisture content. 7S and 11S decreased at 130–160 °C. Solubility at 25% moisture extrusion and hydrophobicity at 18% were lowered. At 130–160 °C, the alpha helix decreased. | [34] |

| 90 | Volatile compounds 4.14, 3.75 and 3.46 mL | 170 | 2.7 | 50, 90, 120, 130, 150 and 170 | 30–40 | The addition of volatile compounds decreased the expansion rate at 35% moisture/150 °C and 40% moisture/130 °C. 30% moisture/170 °C favored the reduction of the dough viscosity, allowing greater interactions between the volatiles and the protein matrix. | [27] |

| 40.8–41.4 | - | 320 | 2.5 | 55–95, 70–110, 85–125, 100–140, 110–150 | 15–27 | The nitrogen solubility index increased when extrusion temperature and moisture changed from 150 to 110 °C and 27 to 15 °C, respectively. Gel-forming ability increased when the extrusion temperature changed from 150 to 110 °C. Oil holding capacity improved in samples extruded at 110 °C. | [31] |

| 94.3 | Soy flour, Corn flour 7, soy fibers 2, 18 | 200 and 400 | 20 | 30, 75, 120, 130 and 140 | 20 and 40 | Changing the moisture from 20 to 40% decreased the water-holding capacity and the specific volume of the extrudates. Increasing the moisture content decreased the expansion ratio. High screw speed and temperature significantly decreased the whiteness. | [35] |

| 90 | - | 200 | 0.3 | 40, 60, 90, 105, 120, 120 and 90 | 60 | Lightness decreased, and redness increased when the temperature changed from 120–160 °C. Bands near 100 kDa in SPI disappeared after extrusion. 7S disappeared, and 11S was more intense following extrusion. | [36] |

| 90.3–92.8 | - | 180 | 0.3 | 25, 40, 60, 90, 130, 140, and 110 °C | 50 | The soluble Soy protein isolate portion showed a compact and smooth gel structure, indicating that SSPI alone was unable to create a distinct fibrous structure. High content of insoluble soy protein, the fibrous structures in the extruded SPI became more pronounced. | [37] |

| 67 | - | 150, 500 and 800 | 15 | 40, 60, 100, 100, 100 and 100–160 | 60 | At ≥180 rpm and ≥100 °C high water evaporation and no formation of anisotropic texture. At =180 rpm and 100–132 °C there was a formation of anisotropic texture. | [38] |

| 92 | - | 175 | 35, 60, 90, 120, 145, 145, 145, and 120 Cooling at 60 to 20 °C | 65 | Lowering a cooling die temperature from 60 °C to 40 °C, the cross-fiber structure of samples became richer with a defined orientation. When the cooling temperature dropped from 60 °C to 20 °C, the expansion ratios of textured vegetable decreased significantly. | [39] | |

| 90 and 70 | - | 30–160 | 1.4 | 110, 140, 150, 160, 170, 180, and 190 | 60 | Better textural properties and the highest fibrous degree at 160 °C and 30 rpm. Extrusion reduced the ordered secondary structure and increased the disordered structure of soy proteins. | [40] |

| 70 | Wheat gluten 0–30, wheat starch 2.7, pumpkin powder 3 | 400 | 2.8 | 20, 50, 80, 110, 150, 180 and 150 | 66 | 30% wheat gluten increased the lightness, hardness, chewiness, texturization, and fibrous structure. | [41] |

| 66.5 | iota carrageenan (0.75–3) | 50 | 6 | 60, 135, 125 and 20 | 60 | Iota carrageenan addition did not affect the color. Iota carrageenan improved the hardness and water-holding capacity of the extrudates. 1.5% iota carrageenan has better physical, textural, and sensorial properties. | [42] |

| 90.12 | β-glucan 1,2,3,4 and 5 | 300 | - | 60, 80,120, 150, 150, and 50 | 60 | The hardness, cohesiveness, and chewiness of the extrudates increased due to β-glucanx, however, at 4% addition, the product attributes decreased. Addition of β-glucan preserved the bands of 7S and 11S due to molecular interaction and crosslinking effect. Large molecular weight bands 50–100 kDa were observed in samples with β-glucan The inclusion of 4% BG changed β-sheet into α-helical structures. This increased α-helical structures and decreased the content of β-turn and β-sheet, promoting the development of a stable and orderly structure of BG and SPI. | [43] |

| 90 | Wheat gluten 30% and maize oil 4.6–11% | 400 | 0.3 | 40, 60, 90, 115, 140, 140, and 140. Cooling at 40 °C | 60 | oil direct addition approach could not be used to obtain the expected fibrous structure of SPI-WG extrudates O/W emulsion promoted the generation of fibrous structures in SPI-WG extrudates. The fibrous structure could be maintained in SPI-WG extrudates with oil contents up to 8.0% | [44] |

| Feed Composition | Extrusion Conditions | Products | Findings | References | |||||

|---|---|---|---|---|---|---|---|---|---|

| Soy Protein | Others | Extruder Type | Feeding | Screw Speed | Temp | Moisture | |||

| % | % | Kg/h | RPM | ℃ | % | ||||

| 20 | Wheat Gluten 20 and starch 5 | Co-rotating twin-screw extruder | 6 | 200 | 130, 150, and 130 | 40–50 | Meat analogs | Meat analogs at 50% moisture content and 130℃ die Temperature showed texturized properties with the highest water absorption capacity and integrity index. | [70] |

| 80–90 | Whole Tomato Powder 5–20%, Tomato Peel Powder 10% | Co-rotating twin screw extruder | 3 | 300 | 30, 60, 100, and 90 | 60 | Meat analogs | Tomato peel powder led to a soft texture and color improvement. 20% whole tomato powder led to poor textural properties. | [71] |

| 15–60 | Mushroom Protein 15–45 | Co-rotating twin-screw extruder | 2.28 | 500 | 50, 80, 120, 140, 140, 120, and 50 | 65 | Meat analogs | Mushroom Protein led to a significant change in darker and brown. The addition of mushroom protein up to 25% showed excellent sensory properties. Mushroom protein decreased the oil and water holding capacity. | [72] |

| 33 | Soybean meal 43%, Gluten 24%, Wheat starch 8%, and Haematococcus pluvialis (HP) (0.25~1.25%) as a colorant | Co-rotating twin-screw extruder | 3.2 | 280 | 30, 90, 120, 140, 150, 160, and cooling at 60 °C | 50 | Meat analogs | Low levels of HP promoted the flexible and disordered regions within the protein secondary structure, while excessive HP addition was unfavorable for protein cross-linking. The maximal texturization degree was obtained at 0.75% HP 1% HP had a color similar to fresh beef sirloin. | [73] |

| 10–40 | Wheat gluten 10–40, Natural flavor powder 1% | Co-rotating twin-screw extruder | 6 | 20, 50, 80, 150, 140, 100, 80, and 60 °C | 50–80 | Meat analogs | Soy protein and wheat gluten affected the microstructure of meat analogs. Soy protein isolate and wheat gluten ratio and moisture content affected the flavor retention. | [60] | |

| 16–32 | Raw Banana | Co-rotating twin-screw extruder | 15 | 200–300 | 60, 70, and 80 °C | 10–20 | Snacks | The optimum conditions for the extrudate were found at the screw speed of 200 rpm, barrel temperature of 80 °C, moisture content of 10%, and defatted soy flour content of 32%. | [74] |

| 5–20 | Maize grit | Single-screw extruder | 100 | 170 | 50, 100, and 150 | 17–24 | Snacks | < 20% soybean flour and feed moisture content resulted in snacks with improved nutritional value and physical properties. | [75] |

| 20 | Maize Bran 20%, 20% resistant maltodextrin | Twin-screw extruder | 0.5 | 30 | 70, 90, 90, and 70 °C. | 28 | Reformulated rice | High concentrations of soy protein increased the hardness. SPI delayed starch gelatinization during cooking. | [76] |

| 10–30 | Tapioca Flour 20, rice flour 20–60 | Single-screw extruder | - | - | 60 | 10–12 | Pasta | (30% soybean protein pasta) had the lowest sensory value. Rice pasta enriched with 15% soybean protein was highly ranked for sensory attributes. | [77] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Y.; Liu, L.; Sun, B.; Zhu, Y.; Lv, M.; Li, Y.; Zhu, X. A Comprehensive Review on Harnessing Soy Proteins in the Manufacture of Healthy Foods through Extrusion. Foods 2024, 13, 2215. https://doi.org/10.3390/foods13142215

Huang Y, Liu L, Sun B, Zhu Y, Lv M, Li Y, Zhu X. A Comprehensive Review on Harnessing Soy Proteins in the Manufacture of Healthy Foods through Extrusion. Foods. 2024; 13(14):2215. https://doi.org/10.3390/foods13142215

Chicago/Turabian StyleHuang, Yuyang, Linlin Liu, Bingyu Sun, Ying Zhu, Mingshou Lv, Yang Li, and Xiuqing Zhu. 2024. "A Comprehensive Review on Harnessing Soy Proteins in the Manufacture of Healthy Foods through Extrusion" Foods 13, no. 14: 2215. https://doi.org/10.3390/foods13142215