Cheese Whey Protein and Blueberry Juice Mixed Fermentation Enhance the Freeze-Resistance of Lactic Acid Bacteria in the Freeze-Drying Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Freeze-Drying Condition

2.4. Determination of Bacterial Survival Rate

2.5. Fourier Transform Infrared Spectroscopy (FTIR) Analysis

2.6. SEM Analysis

3. Results and Discussion

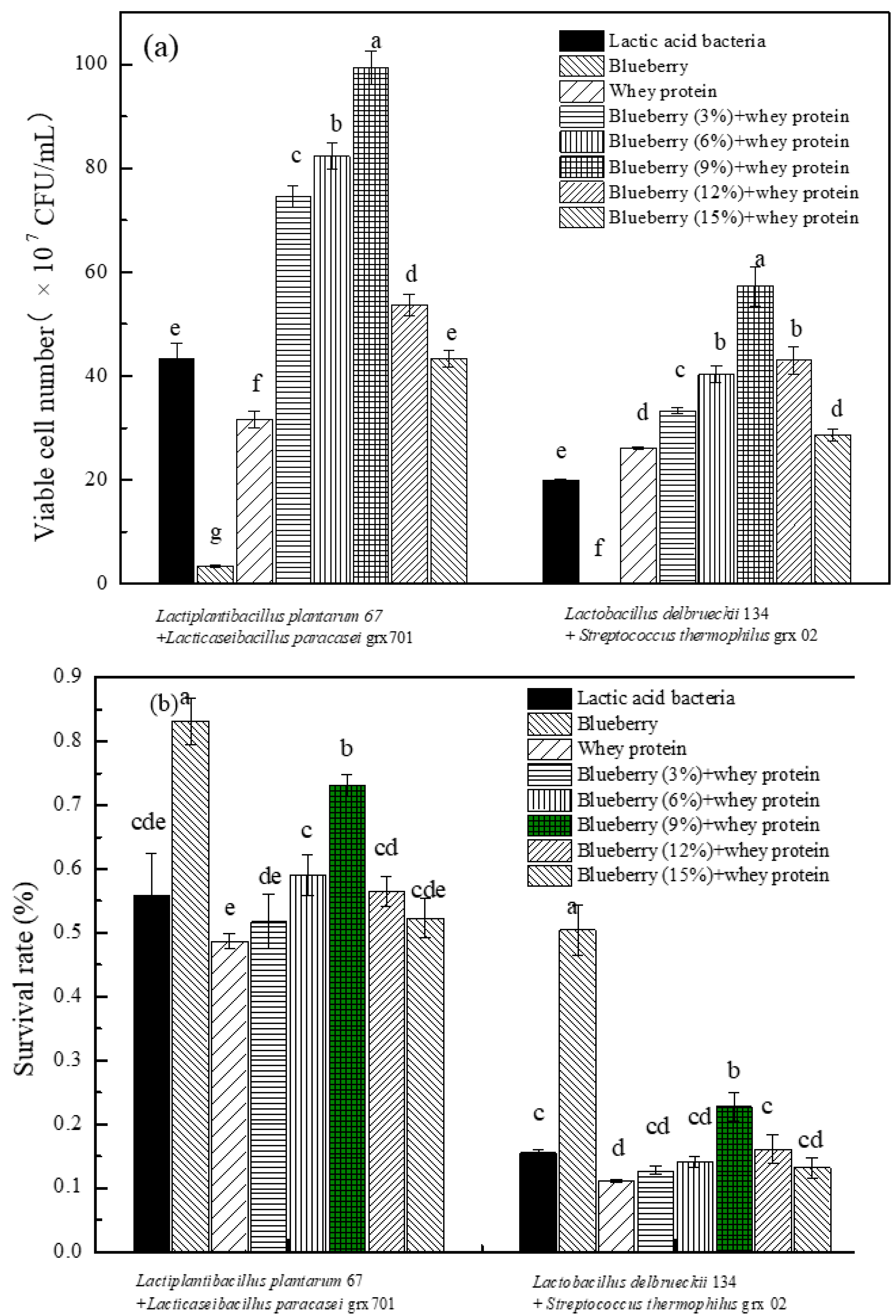

3.1. The Survival of Bacteria at Different Fermented Condition

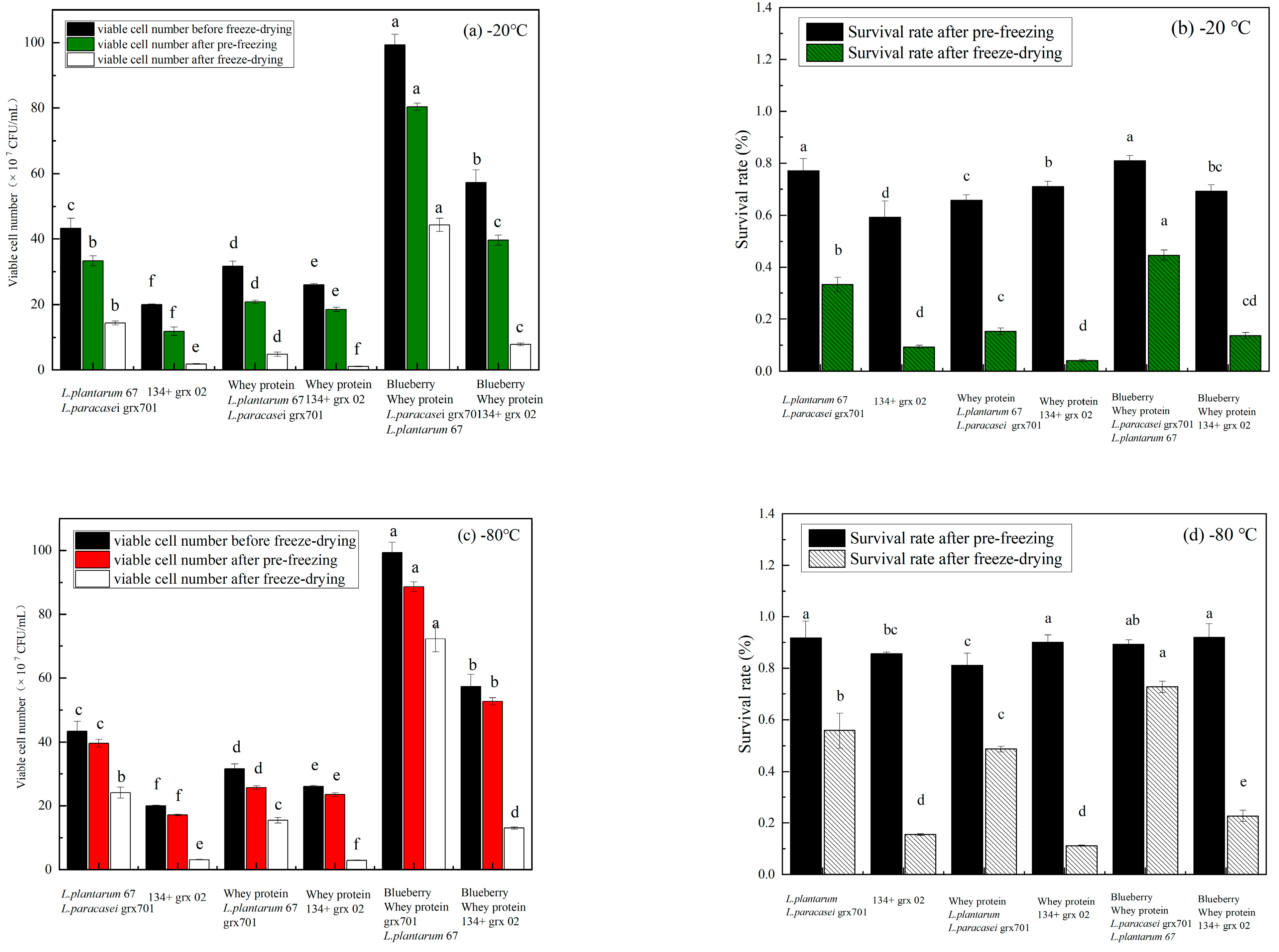

3.2. Effect of Pre-Freezing Temperature on the Lactobacilli Activity

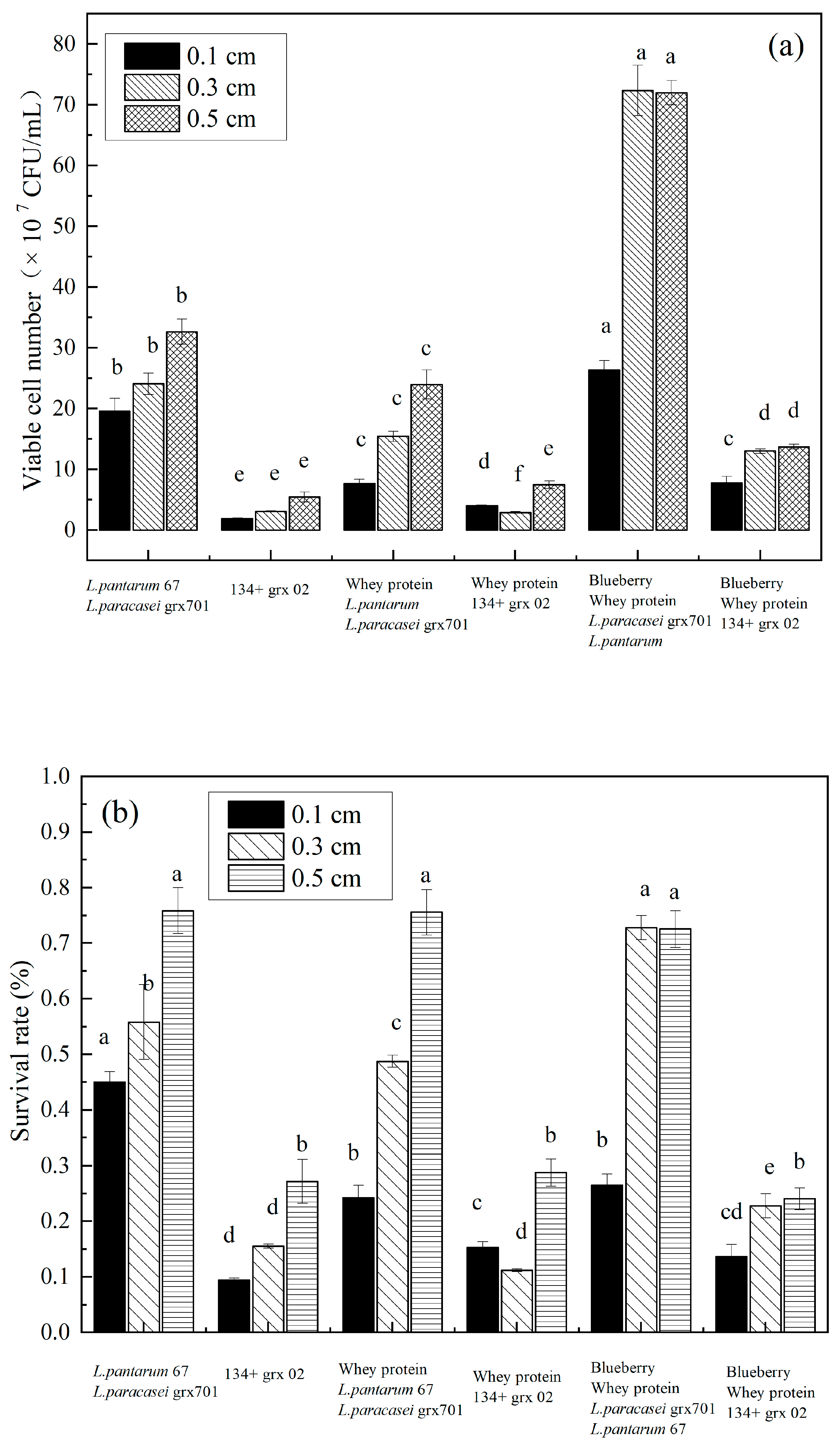

3.3. Effect of Freeze-Drying Thickness on the Bacterial Activity

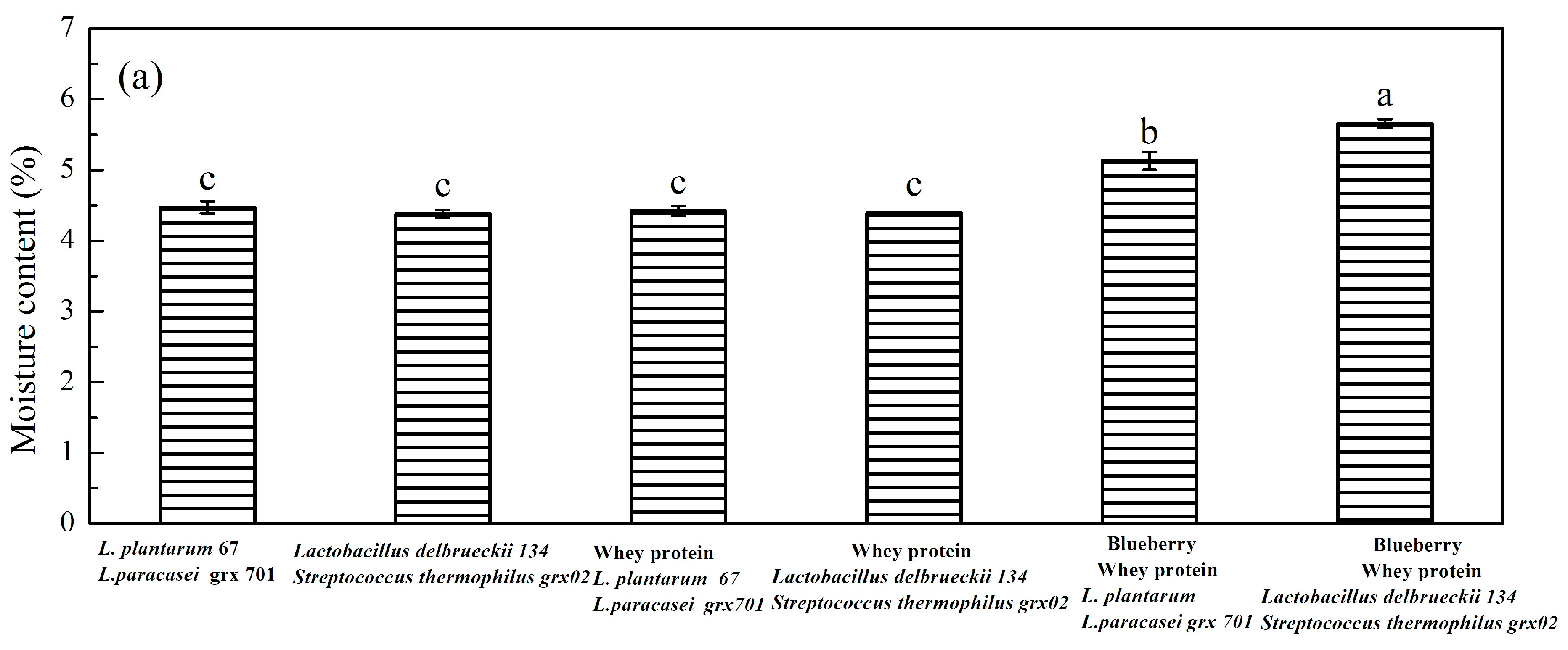

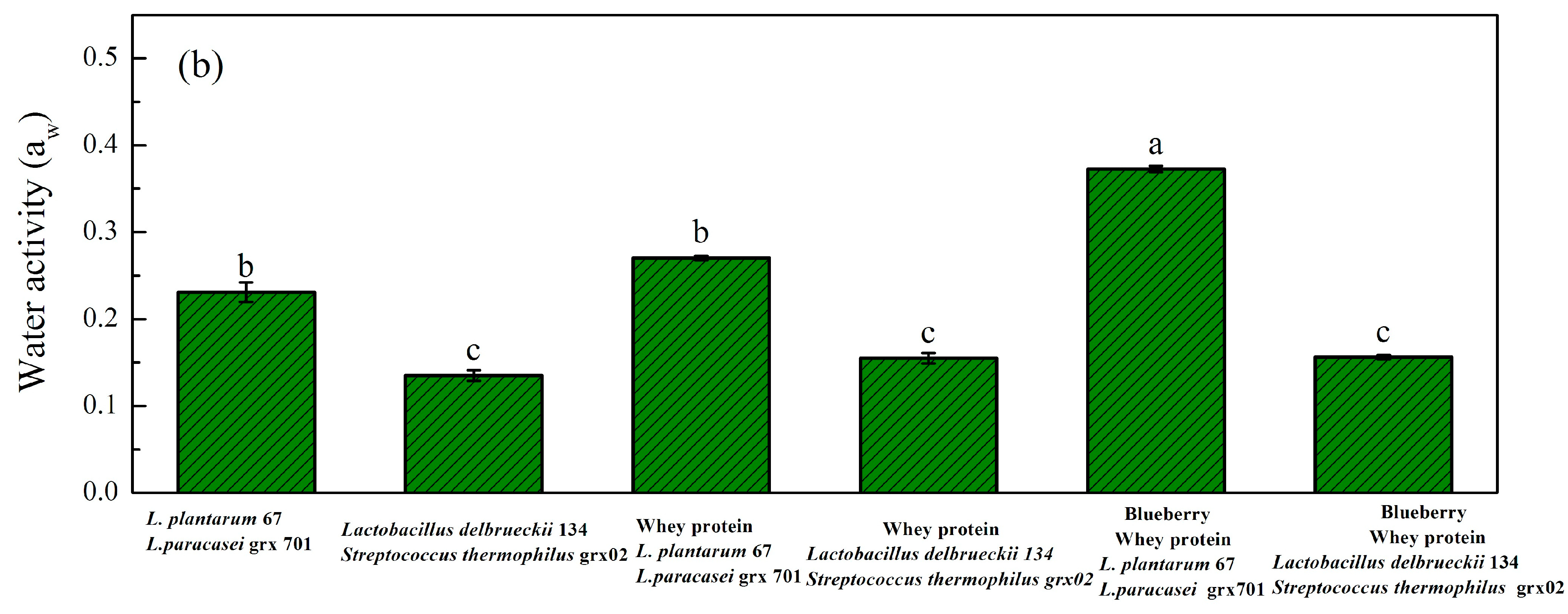

3.4. The Water Activity of Freeze-Dried Powders

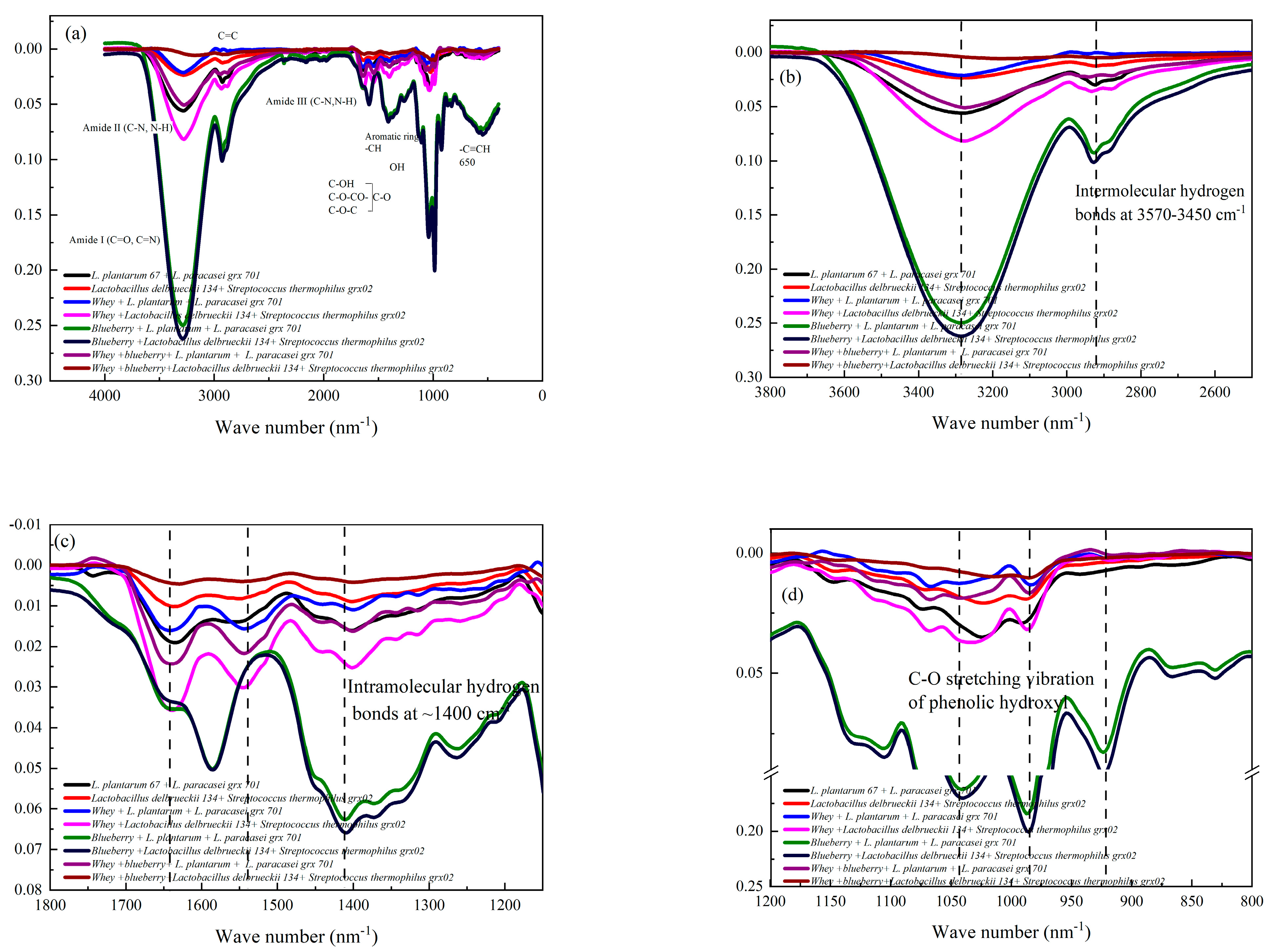

3.5. Analysis of Blueberry–Whey Protein Mixed Fermentation Bacteria by FTIR

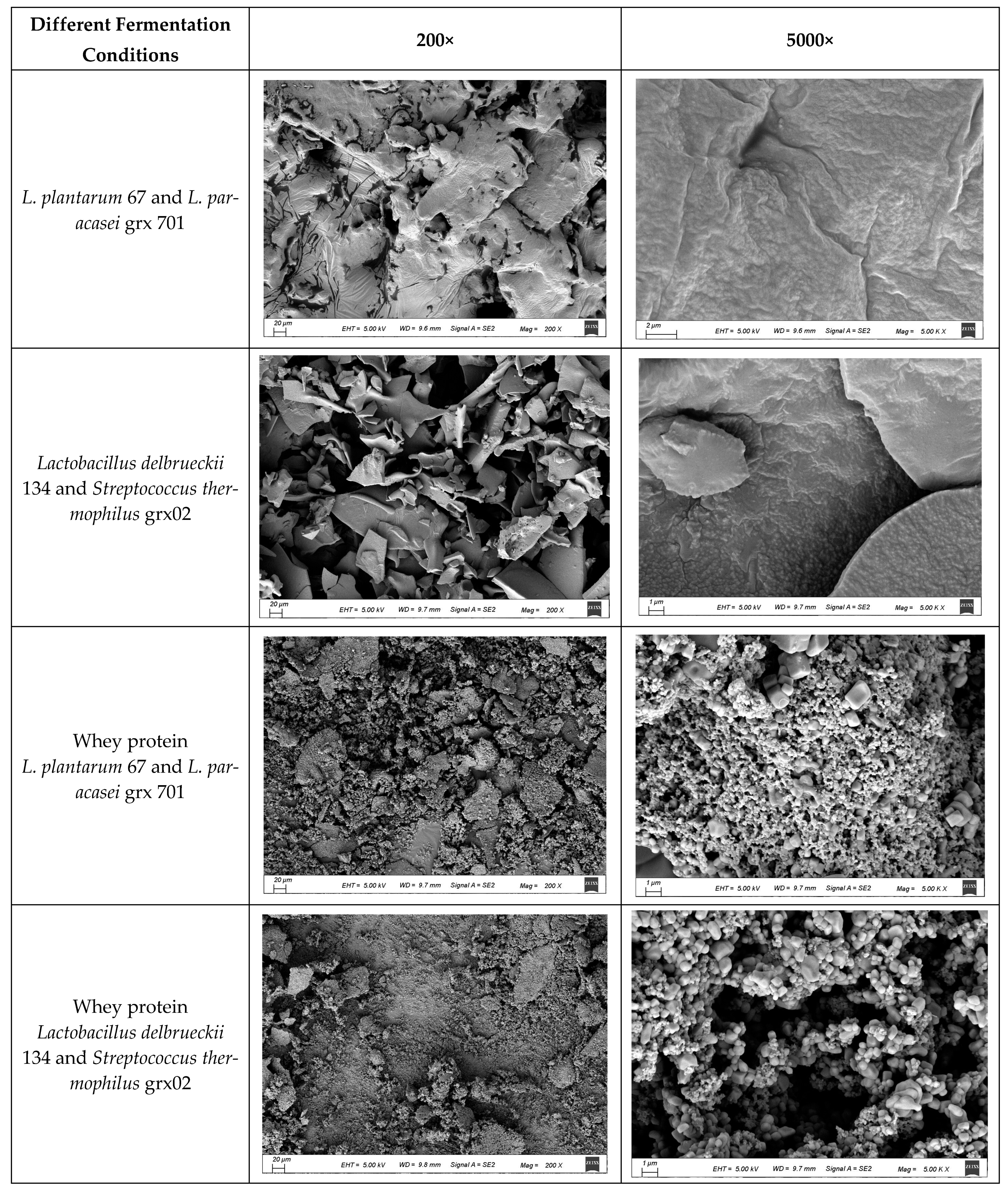

3.6. Surface Morphology of Freeze-Dried Powder

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, H.; Huang, P.; Hao, L.; Che, Y.; Dong, S.; Wang, Z.; Wu, C. Enhancing viability of dried lactic acid bacteria prepared by freeze drying and spray drying via heat preadaptation. Food Microbiol. 2023, 112, 104239. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Sun, R.; Yang, Y.; Yang, Y.; He, Y.; Gong, X.; Zheng, Y.; E, J.; Yao, C.; Zhang, Q.; et al. Calcium ions enhanced freeze-drying and spray-drying resistance of Lactiplantibacillus plantarum LIP-1 by regulation of cell wall surface proteins and related enzymes expression. LWT 2023, 189, 115460. [Google Scholar] [CrossRef]

- Cheng, Z.; Yan, X.; Wu, J.; Weng, P.; Wu, Z. Effects of freeze drying in complex lyoprotectants on the survival, and membrane fatty acid composition of Lactobacillus plantarum L1 and Lactobacillus fermentum L2. Cryobiology 2022, 105, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Cao, R.; Sogabe, T.; Mikajiri, S.; Kawai, K. Effects of sucrose, carnosine, and their mixture on the glass transition behavior and storage stability of freeze-dried lactic acid bacteria at various water activities. Cryobiology 2022, 106, 131–138. [Google Scholar] [CrossRef] [PubMed]

- Peng, C.; Liu, B.; Chen, Z. Protective effects of enzymatic hydrolysis products of pomelo peel cellulose on Lactobacillus plantarum during freeze-drying process. Appl. Food Res. 2023, 3, 100301. [Google Scholar] [CrossRef]

- Chen, B.; Wang, X.; Li, P.; Feng, X.; Mao, Z.; Wei, J.; Lin, X.; Li, X.; Wang, L. Exploring the protective effects of freeze-dried Lactobacillus rhamnosus under optimized cryoprotectants formulation. LWT 2023, 173, 114295. [Google Scholar] [CrossRef]

- Hua, T.-C.; Liu, B.-L.; Zhang, H. 6—Protective Agents and Additives for Freeze-drying of Pharmaceutical Products. In Freeze-Drying of Pharmaceutical and Food Products; Woodhead Publishing: Cambridge, UK, 2010; pp. 170–186. [Google Scholar]

- Zhou, W.; Mao, B.; Tang, X.; Zhang, Q.; Zhao, J.; Chen, W.; Cui, S. Cyclopropane fatty acid and accumulation of glutamate contributed to higher freeze-drying resistance for Bifidobacterium animalis than Bifidobacterium adolescentis. Food Biosci. 2023, 56, 103353. [Google Scholar] [CrossRef]

- Tian, Y.; He, Z.; He, L.; Li, C.; Qiao, S.; Tao, H.; Wang, X.; Zeng, X.; Tian, Y. Effect of freeze-dried protectants on the survival rate and fermentation performance of fermented milk’s directed vat set starters. Cryobiology 2024, 114, 104811. [Google Scholar] [CrossRef]

- Li, X.; Yi, J.; He, J.; Dong, J.; Duan, X. Comparative evaluation of quality characteristics of fermented napa cabbage subjected to hot air drying, vacuum freeze drying, and microwave freeze drying. LWT 2024, 192, 115740. [Google Scholar] [CrossRef]

- Wang, H.; Huang, T.; Liu, K.; Yu, J.; Yao, G.; Zhang, W.; Zhang, H.; Sun, T. Protective effects of whey protein hydrolysate on Bifidobacterium animalis ssp. lactis Probio-M8 during freeze-drying and storage. J. Dairy Sci. 2022, 105, 7308–7321. [Google Scholar] [CrossRef]

- Shen, X.; Sun, X.; Xie, Q.; Liu, H.; Zhao, Y.; Pan, Y.; Hwang, C.-A.; Wu, V.C.H. Antimicrobial effect of blueberry (Vaccinium corymbosum L.) extracts against the growth of Listeria monocytogenes and Salmonella Enteritidis. Food Control 2014, 35, 159–165. [Google Scholar] [CrossRef]

- Sánchez-Patán, F.; Barroso, E.; van de Wiele, T.; Jiménez-Girón, A.; Martín-Alvarez, P.J.; Moreno-Arribas, M.V.; Martínez-Cuesta, M.C.; Peláez, C.; Requena, T.; Bartolomé, B. Comparative in vitro fermentations of cranberry and grape seed polyphenols with colonic microbiota. Food Chem. 2015, 183, 273–282. [Google Scholar] [CrossRef] [PubMed]

- Yu, Q.; Wang, W.; Liu, X.; Shen, W.; Gu, R.; Tang, C. The Antioxidant Activity and Protection of Probiotic Bacteria in the In Vitro Gastrointestinal Digestion of a Blueberry Juice and Whey Protein Fermentation System. Fermentation 2023, 9, 335. [Google Scholar] [CrossRef]

- Wu, Y.; Li, S.; Tao, Y.; Li, D.; Han, Y.; Show, P.L.; Wen, G.; Zhou, J. Fermentation of Blueberry and Blackberry Juices Using Lactobacillus plantarum, Streptococcus thermophilus and Bifidobacterium bifidum: Growth of Probiotics, Metabolism of Phenolics, Antioxidant Capacity in Vitro and Sensory Evaluation. Food Chem. 2021, 348, 129083. [Google Scholar] [CrossRef] [PubMed]

- Santivarangkna, C.; Kulozik, U.; Foerst, P. Inactivation mechanisms of lactic acid starter cultures preserved by drying processes. J. Appl. Microbiol. 2008, 105, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Wang, R.; Yang, Y.; E, J.; Wang, J. Effects of different pre-freezing temperatures on the freeze-drying survival rate and stability during room temperature storage of Lactiplantibacillus plantarum LIP-1. Food Biosci. 2022, 50, 102087. [Google Scholar] [CrossRef]

- Rockinger, U.; Funk, M.; Winter, G. Current Approaches of Preservation of Cells During (freeze-) Drying. J. Pharm. Sci. 2021, 110, 2873–2893. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.-L.; Jang, J.-H.; Amani, M.; Yan, W.-M. Numerical and experimental study on the heat and mass transfer of kiwifruit during vacuum freeze-drying process. Alex. Eng. J. 2023, 73, 427–442. [Google Scholar] [CrossRef]

- Chen, B.-L.; Lin, G.-S.; Amani, M.; Yan, W.-M. Microwave-assisted freeze drying of pineapple: Kinetic, product quality, and energy consumption. Case Stud. Therm. Eng. 2023, 41, 102682. [Google Scholar] [CrossRef]

- Doi, T.; Wang, M.; McClements, D.J. Impact of proteins and polysaccharides on flavor release from oil-in-water emulsions during simulated cooking. Food Res. Int. 2019, 125, 108549. [Google Scholar] [CrossRef]

- Li, B.; Li, H.; Song, B.; Tian, J.; Gao, N.; Zhang, Y.; Shu, C. Protective effects of fermented blueberry juice with probiotics on alcohol-induced stomach mucosa injury in rats. Food Biosci. 2023, 55, 102974. [Google Scholar] [CrossRef]

- Li, Y.; Liu, G.; Liao, N.; Xu, F.; Wang, J.; Shao, D.; Jiang, C.; Shi, J. Construction of walnut protein/tea polyphenol/alginate complex for enhancing heat and gastrointestinal tolerance of lactic acid bacteria. Food Hydrocoll. 2024, 149, 109523. [Google Scholar] [CrossRef]

- Chevalier, L.M.; Rioux, L.-E.; Angers, P.; Turgeon, S.L. Study of the interactions between pectin in a blueberry puree and whey proteins: Functionality and application. Food Hydrocoll. 2019, 87, 61–70. [Google Scholar] [CrossRef]

- Nemzer, B.; Vargas, L.; Xia, X.; Sintara, M.; Feng, H. Phytochemical and physical properties of blueberries, tart cherries, strawberries, and cranberries as affected by different drying methods. Food Chem. 2018, 262, 242–250. [Google Scholar] [CrossRef] [PubMed]

- Díaz-Álvarez, R.; Carpentieri, S.; Ferrari, G.; Pataro, G.; Segura-Ponce, L. Effect of high-voltage electrical discharge (HVED) at high frequency on vacuum freeze-drying time and physicochemical properties of blueberries. J. Food Eng. 2024, 365, 111815. [Google Scholar] [CrossRef]

- Araujo-Díaz, S.B.; Leyva-Porras, C.; Aguirre-Bañuelos, P.; Álvarez-Salas, C.; Saavedra-Leos, Z. Evaluation of the physical properties and conservation of the antioxidants content, employing inulin and maltodextrin in the spray drying of blueberry juice. Carbohydr. Polym. 2017, 167, 317–325. [Google Scholar] [CrossRef] [PubMed]

- Passot, S.; Cenard, S.; Douania, I.; Tréléa, I.C.; Fonseca, F. Critical water activity and amorphous state for optimal preservation of lyophilised lactic acid bacteria. Food Chem. 2012, 132, 1699–1705. [Google Scholar] [CrossRef]

- Xue, Z.P.; Cu, X.; Xu, K.; Peng, J.H.; Liu, H.R.; Zhao, R.T.; Wang, Z.; Wang, T.; Xu, Z.S. The effect of glutathione biosynthesis of Streptococcus thermophilus ST-1 on cocultured Lactobacillus delbrueckii ssp. bulgaricus ATCC11842. J. Dairy Sci. 2023, 106, 884–896. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, N.L.; Alexandre, A.C.S.; Silva, S.H.; Figueiredo, J.d.A.; Rodrigues, A.A.; de Resende, J.V. Drying efficiency and quality preservation of blackberries (Rubus spp. variety Tupy) in the near and mid-infrared-assisted freeze-drying. Food Chem. Adv. 2023, 3, 100550. [Google Scholar] [CrossRef]

- Wang, W.-Q.; Sheng, H.-B.; Zhou, J.-Y.; Yuan, P.-P.; Zhang, X.-F.; Lu, M.-L.; Gu, R.-X. The Effect of a Variable Initial pH on the Structure and Rheological Properties of Whey Protein and Monosaccharide Gelation via the Maillard Reaction. Int. Dairy J. 2021, 113, 104896. [Google Scholar] [CrossRef]

- Gedik, O.; Karahan, A.G. Properties and Stability of Lactiplantibacillus plantarum Ab6-25 and Saccharomyces boulardii T8-3c Single and Double-Layered Microcapsules Containing Na-Alginate and/or Demineralized Whey Powder with Lactobionic Acid. Int. J. Biol. Macromol. 2024, 271, 132406. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Zhang, J.; Yu, Q.; Zhou, J.; Lu, M.; Gu, R.; Huang, Y. Structural and Compositional Changes of Whey Protein and Blueberry Juice Fermented Using Lactobacillus plantarum or Lactobacillus casei during Fermentation. RSC Adv. 2021, 11, 26291–26302. [Google Scholar] [CrossRef]

- Amiri, S.; Teymorlouei, M.J.; Bari, M.R.; Khaledabad, M.A. Development of Lactobacillus acidophilus La5-Loaded Whey Protein Isolate/Lactose Bionanocomposite Powder by Electrospraying: A Strategy for Entrapment. Food Biosci. 2021, 43, 101222. [Google Scholar] [CrossRef]

- Zang, Z.; Tian, J.; Chou, S.; Lang, Y.; Tang, S.; Yang, S.; Yang, Y.; Jin, Z.; Chen, W.; Liu, X. Investigation on the Interaction Mechanisms for Stability of Preheated Whey Protein Isolate with Anthocyanins from Blueberry. Int. J. Biol. Macromol. 2024, 255, 127880. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Liu, X.; Shao, Y.; Guo, Y.; Gu, R.; Wang, W. Cheese Whey Protein and Blueberry Juice Mixed Fermentation Enhance the Freeze-Resistance of Lactic Acid Bacteria in the Freeze-Drying Process. Foods 2024, 13, 2260. https://doi.org/10.3390/foods13142260

Wang Y, Liu X, Shao Y, Guo Y, Gu R, Wang W. Cheese Whey Protein and Blueberry Juice Mixed Fermentation Enhance the Freeze-Resistance of Lactic Acid Bacteria in the Freeze-Drying Process. Foods. 2024; 13(14):2260. https://doi.org/10.3390/foods13142260

Chicago/Turabian StyleWang, Yuxian, Xian Liu, Yufeng Shao, Yaozu Guo, Ruixia Gu, and Wenqiong Wang. 2024. "Cheese Whey Protein and Blueberry Juice Mixed Fermentation Enhance the Freeze-Resistance of Lactic Acid Bacteria in the Freeze-Drying Process" Foods 13, no. 14: 2260. https://doi.org/10.3390/foods13142260