Optimization of Pectin Extraction from Melon Peel as a New Source of Pectin and Pectin Hydrolysate with Prebiotic Potential

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Melon Peel

2.2. Extraction of Pectin from Melon Peel

2.3. Optimization of the Pectin Extraction Conditions of Melon Peel Using the Response Surface Methodology (RSM)

2.4. Properties of Pectin Extract from Melon Peel

2.5. Prebiotic Properties of Extracted Pectin and Pectin Hydrolysate (PEH)

2.5.1. Preparation of Pectin and Pectin Hydrolysate from Melon Peel

2.5.2. Preparation of Probiotics

2.5.3. Effect of the DE of Pectin and PEH on the Growth of Probiotics

2.5.4. Evaluation of Prebiotic Activity Score (PAS)

2.6. Statistical Analysis

3. Results

3.1. Optimization of Pectin Extraction from Melon Peel

3.1.1. Model Fitting and Statistical Analysis

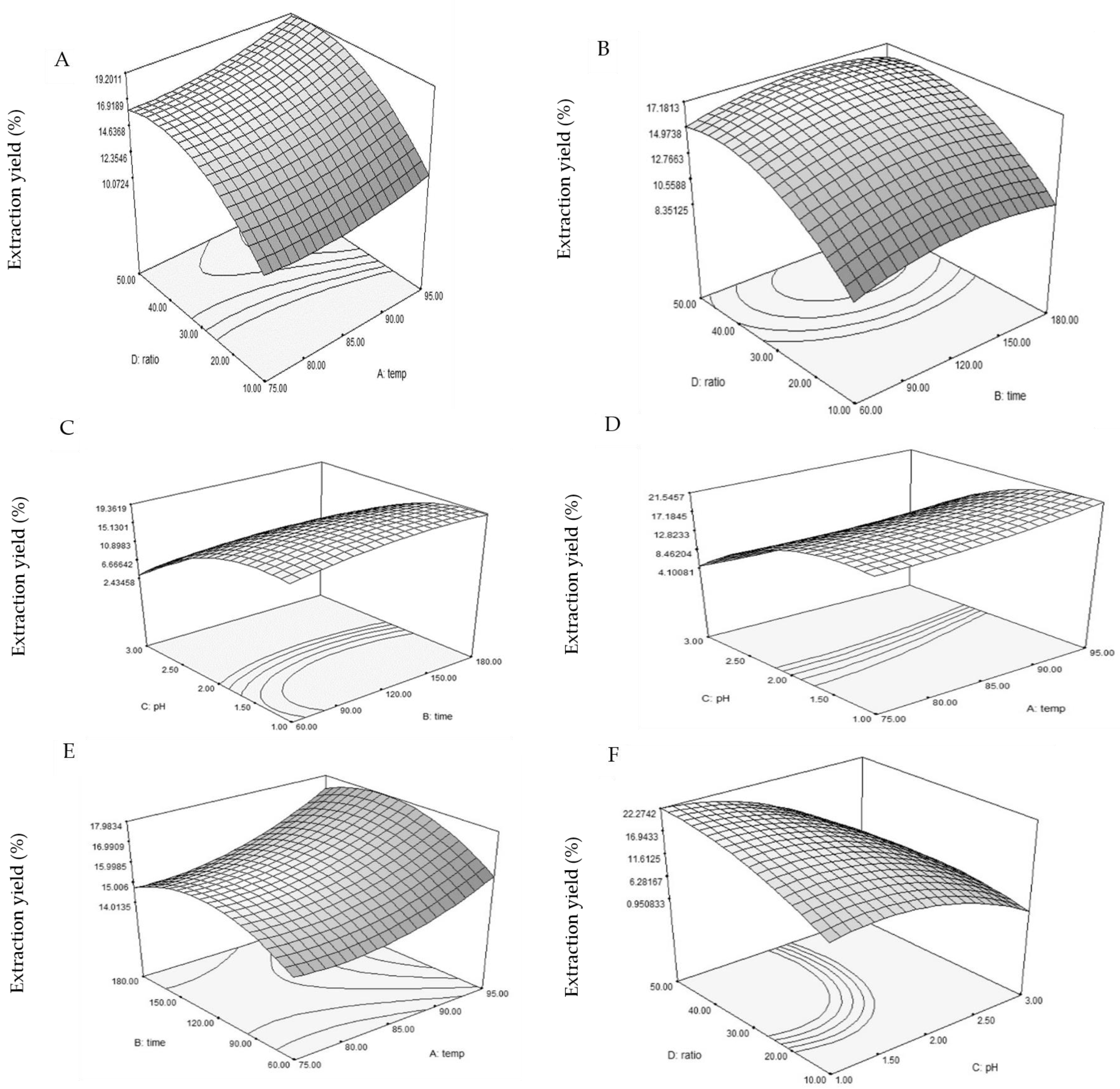

3.1.2. The Relationship between Factor Variables and Extraction Yield

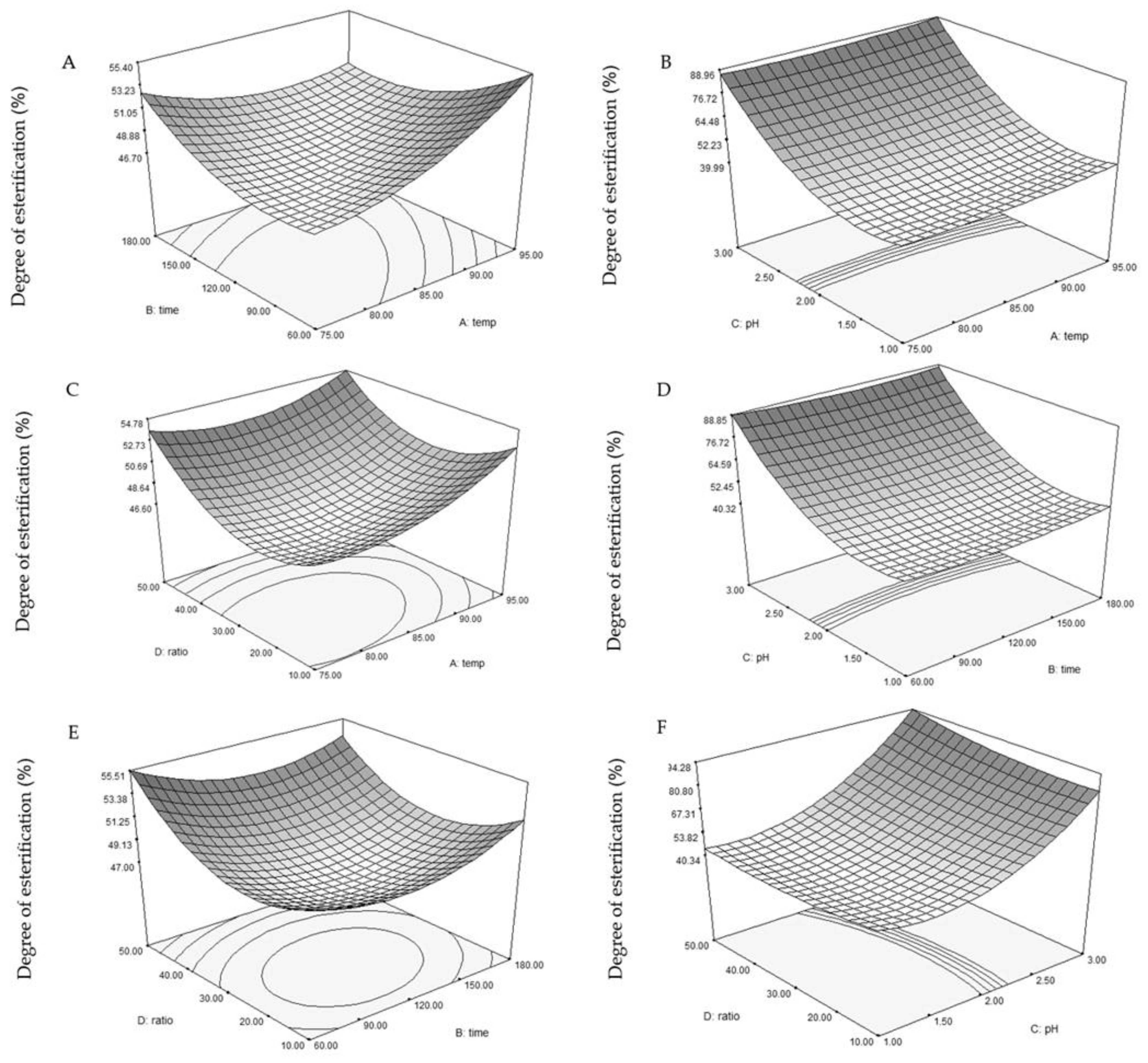

3.1.3. The Relationship between Factor Variables and DE

3.2. Optimization Conditions of Factor Variables for the Yield and DE

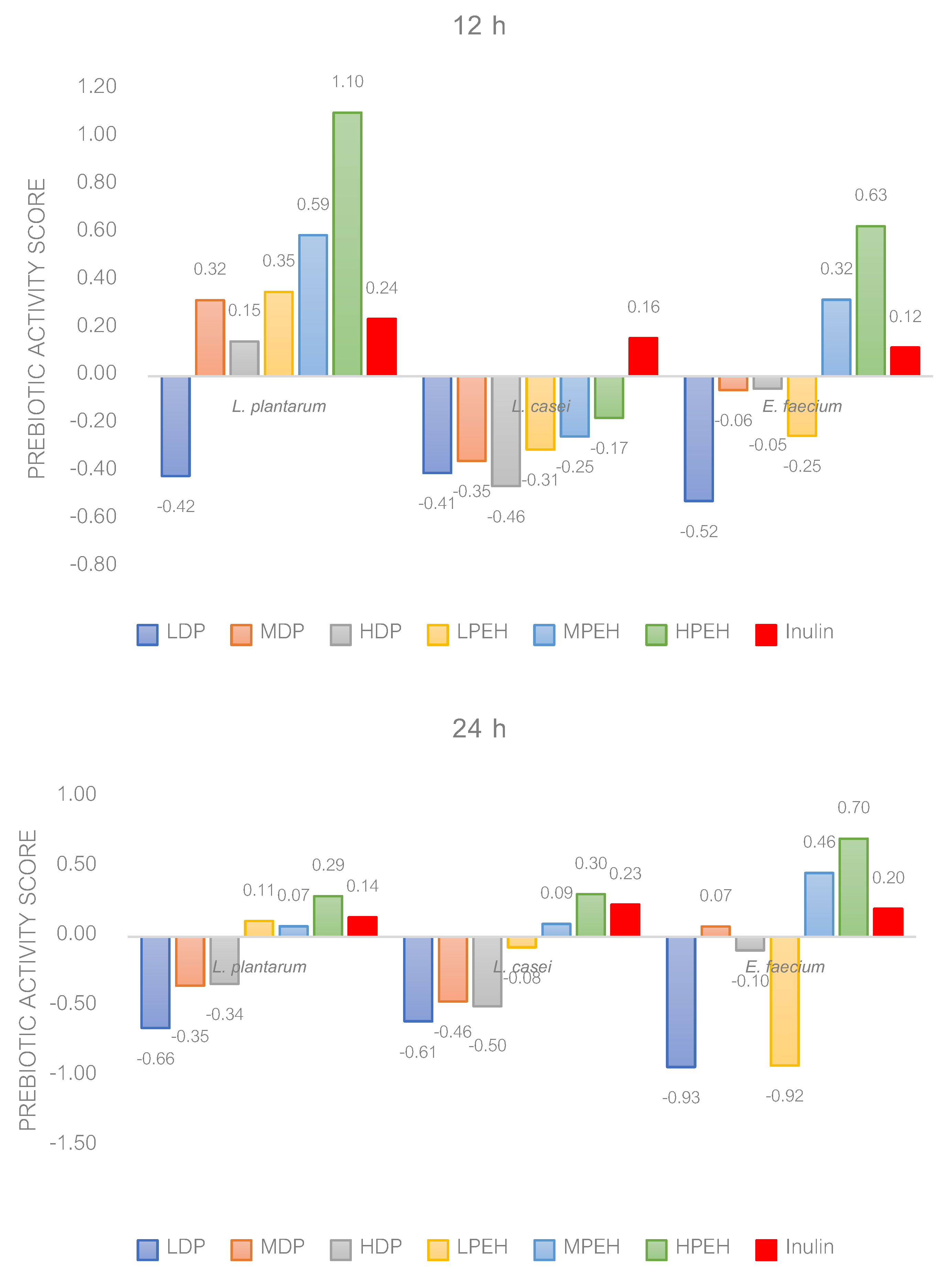

3.3. Prebiotic Properties of Extracted Pectin and PEH on Growth of Probiotics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Davani-Davari, D.; Negahdaripour, M.; Karimzadeh, I.; Seifan, M.; Mohkam, M.; Masoumi, S.J.; Berenjian, A.; Ghasemi, Y. Prebiotics: Definition, types, sources, mechanisms, and cinical applications. Food 2019, 8, 92. [Google Scholar] [CrossRef]

- Ho, Y.-Y.; Lin, C.-M.; Wu, M.-C. Evaluation of the prebiotic effects of citrus pectin hydrolysate. J. Food Drug Anal. 2017, 25, 550–558. [Google Scholar] [CrossRef]

- Gomez, B.; Pelaez, C.; Martinez-cuesta, M.C.; Parajo, J.C.; Alonso, J.L.; Requena, T. Emerging prebiotics obtained from lemon and sugar beet byproducts: Evaluation of their in vitro fermentability by probiotic bacteria. LWT Food Sci. Technol. 2019, 109, 17–25. [Google Scholar] [CrossRef]

- Larsen, N.; de Souza, C.B.; Krych, L.; Cahu, T.B.; Wiese, M.; Kot, W.; Hansen, K.M.; Blennow, A.; Venema, K.; Jespersen, L. Potential of Pectins to beneficially modulate the gut microbiota depends on their structural properties. Front. Microbiol. 2019, 10, 223. [Google Scholar] [CrossRef]

- Zhang, S.; Hu, H.; Wang, L.; Liu, F.; Pan, S. Preparation and prebiotic potential of pectin oligosaccharides obtained from citrus peel pectin. Food Chem. 2018, 244, 232–237. [Google Scholar] [CrossRef]

- Pradi, B.; Baldassarre, S.; Babbar, N.; Elena, B.; Vandezande, P.; Hermans, D.; Bruggeman, G.; Gatti, M.; Elst, K.; Sforza, S. Pectin oligosaccharides from sugar beet pulp: Molecular characterization and potential prebiotic activity. Food Funct. 2018, 10, 223. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, T. Pectin Oligosaccharides enhance α2,6-sialylation modification that promotes apoptosis of bladder cancer cells by targeting the hedgehog pathway. Cell Biochem. Biophys. 2021, 79, 719–728. [Google Scholar] [CrossRef]

- Tan, H.; Chen, W.; Liu, Q.; Yang, G.; Li, K. Pectin oligosaccharides ameliorate colon cancer by regulating oxidative stress- and inflammation-activated signaling pathways. Front. Immunol. 2018, 9, 1504. [Google Scholar] [CrossRef]

- Gomez, B.; Gullon, B.; Yanez, R.; Schols, H.; Alonso, J.L. Prebiotic potential of pectins and pectic oligosaccharides derived from lemon peel wastes and sugar beet pulp: A comparative evaluation. J. Funct. Foods 2016, 20, 108–121. [Google Scholar] [CrossRef]

- Chatterjee, E.; Manuel, G.A.S.; Hassan, S. Effect of fruit pectin on growth of lactic acid bacteria. J. Prob. Health 2016, 4, 147–150. [Google Scholar] [CrossRef]

- Wongkaew, M.; Tinpovong, B.; Sringarm, K.; Leksawasdi, N.; Jantanasakulwong, K.; Rachtanapun, P.; Hanmoungjai, P.; Sommano, S.R. Crude pectic oligosaccharide recovery from Thai Chok Anan mango peel using pectinolytic enzyme hydrolysis. Foods 2021, 10, 627. [Google Scholar] [CrossRef] [PubMed]

- Olano-Martin, E.; Gibson, G.R.; Rastall, R.A. Comparison of the in vitro bifidogenic properties of pectins and pectic-oligosaccharides. J. Appl. Microbiol. 2002, 93, 505–511. [Google Scholar] [CrossRef] [PubMed]

- Department of Agriculture Extension, 2017, Cantaloupe in 2016. Available online: http://www.agriinfo.doae.go.th/year60/plant/rortor/veget/18.pdf (accessed on 12 January 2019).

- Mallek-Ayadi, S.; Bahloul, N.; Kechaou, N. Characterization, phenolic compounds and functional properties of Cucumis melo L. peels. Food Chem. 2017, 221, 1691–1697. [Google Scholar] [CrossRef] [PubMed]

- Gomez-Garcia, R.; Camposa, D.A.; Oliveiraa, A.; Aguilarb, C.N.; Madureiraa, A.R.; Pintado, M. A chemical valorisation of melon peels towards functional food ingredients: Bioactives profile and antioxidant properties. Food Chem. 2021, 335, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Gomez-Garcia, R.; Sanchez-Gutierrez, M.; Freitas-Costa, C.; Vilas-Boas, A.A.; Campos, D.A.; Aguilar, C.N.; Madureira, A.R.; Pintado, M. Prebiotic effect, bioactive compounds and antioxidant capacity of melon peel (Cucumis melo L. inodorus) flour subjected to in vitro gastrointestinal digestion and human faecal fermentation. Food Res. Int. 2022, 154, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Chan, S.Y.; Choo, W.S. Effect of extraction conditions on the yield and chemical properties of pectin from cocoa husks. Food Chem. 2013, 141, 3752–3758. [Google Scholar] [CrossRef] [PubMed]

- Raji, Z.; Khodaiyan, F.; Rezaei, K.; Kiani, H.; Hosseini, S.S. Extraction optimization and physicochemical properties of pectin from melon peel. Int. J. Biol. Macromol. 2017, 98, 709–716. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.A.; Butt, M.S.; Randhawa, M.A.; Karim, R.; Sultan, M.T.; Ahmed, W. Extraction and characterization of pectin from grapefruit (Duncan cultivar) and its utilization as gelling agent. Int. Food Res. J. 2014, 21, 2195–2199. [Google Scholar]

- Prakash Maran, J.; Manikandan, S.; Thirugnanasambandham, K.; Vigna Nivetha, C.; Dinesh, R. Box-Behnken design based statistical modeling for ultrasound-assisted extraction of corn silk polysaccharide. Carbohydr. Polym. 2013, 92, 604–611. [Google Scholar] [CrossRef]

- Mohamed, H. Extraction and characterization of pectin from grapefruit peels. MOJ Food Process. Technol. 2016, 2, 31–38. [Google Scholar] [CrossRef]

- Thitiratsakul, B.; Anprung, P. Prebiotic activity score and bioactive compounds in longan (Dimocarpus longan Lour.): Influence of pectinase in enzyme-assisted extraction. J. Food Sci. Technol. 2014, 51, 1947–1955. [Google Scholar] [CrossRef] [PubMed]

- Anprung, P.; Sangthawan, S. Prebiotic activity and bioactive compounds of the enzymatically depolymerized Thailand-grown mangosteen aril. J. Food Res. 2012, 1, 268–276. [Google Scholar] [CrossRef]

- Marin, F.R.; Soler-Rivas, C.; Benavente-Garcia, O.; Castillo, J.; Perez-Alvarez, J.A. By-products from different citrus processes as a source of customized functional fibres. Food Chem. 2007, 100, 736–741. [Google Scholar] [CrossRef]

- Liew, S.O.; Chin, N.L.; Yusof, Y.A. Extraction and characterization of pectin from passion fruit peels. Agric. Agric. Sci. Procedia. 2014, 2, 231–236. [Google Scholar] [CrossRef]

- Khan, M.; Bibi, N.; Zeb, A. Optimization of process conditions for pectin extraction from citrus peel. Sci. Tech. Dev. 2015, 34, 9–15. [Google Scholar] [CrossRef][Green Version]

- Hashmi, S.H.; Ghatge, P.; Machewad, G.M.; Pawar, S. Studies on extraction of essential oil and pectin from sweet orange. J. Food Proc. Tech. 2012, 1, 1–3. [Google Scholar] [CrossRef]

- Dehankar, P.B.; Patil, N.S.; Mane, P.; Mane, J. Recycling of orange peel as pectin—A valuable product. Int. J. Inf. Fut. Res. 2015, 2, 3041–3048. [Google Scholar]

- Hundie, K.B.; Akuma, D.A. Extraction and Characterization of pectin from lemon waste for commercial applications. J. Text. Cloth. Sci. Appl. 2021, 8, 1111–1120. [Google Scholar]

- Homayoonfal, M.; Khodaiyan, F.; Mousavi, M. Modelling and optimizing physicochemical features of walnut-oil beverage emulsions by implementation of response surface methodology: Effect of preparation conditions on emulsion stability. Food Chem. 2015, 174, 649–659. [Google Scholar] [CrossRef] [PubMed]

- Balasubramani, P.; Palaniswamy, P.T.; Visvanathan, R.; Thirupathi, V.; Subbarayan, A.; Prakash Maran, J. Microencapsulation of garlic oleoresin using maltodextrin as wall material by spray drying technology. Int. J. Biol. Macromol. 2015, 72, 210–217. [Google Scholar] [CrossRef]

- Chaharbaghi, E.; Khodaiyan, F.; Hosseini, S.S. Optimization of pectin extraction from pistachio green hull as a new source. Carbohydr. Polym. 2017, 173, 107–113. [Google Scholar] [CrossRef] [PubMed]

- Prakash Maran, J.; Sivakumar, V.; Thirugnanasambandham, K.; Sridhar, R. Optimization of microwave assisted extraction of pectin from orange peel. Carbohydr. Polym. 2013, 97, 703–709. [Google Scholar] [CrossRef]

- Shivamathi, C.S.; Gunaseelan, S.; Soosai, M.R.; Vignesh, N.S.; Varalakshmi, P.; Kumar, R.S.; Ganesh Moorthy, I.M. Process optimization and characterization of pectin derived from underexploited pineapple peel biowaste as a value-added product. Food Hydrocoll. 2022, 123, 107141. [Google Scholar] [CrossRef]

- Canteri-Schemin, M.H.; Fertonani, H.C.R.; Waszczynskyj, N.; Wosiacki, G. Extraction of pectin from apple pomace. Braz. Arch. Biol. Technol. 2005, 48, 259–266. [Google Scholar] [CrossRef]

- Yapo, B.M.; Robert, C.; Etienne, I.; Wathelet, B.; Paquot, M. Effect of extraction conditions on the yield, purity and surface properties of sugar beet pulp pectin extracts. Food Chem. 2007, 100, 1356–1364. [Google Scholar] [CrossRef]

- Prakash Maran, J.; Mekala, V.; Manikandan, S. Modeling and optimization of ultrasound-assisted extraction of polysaccharide from Cucurbita moschata. Carbohydr. Polym. 2013, 92, 2018–2026. [Google Scholar] [CrossRef]

- Moorthy, I.G.; Maran, J.P.; Surya, S.M.; Naganyashree, S.; Shivamathi, C.S. Response surface optimization of ultrasound assisted extraction of pectin from pomegranate peel. Int. J. Biol. Macromol. 2015, 72, 1323–1328. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Zhai, W. Optimization of microwave-assisted extraction of anthocyanins from purple corn (Zea mays L.) cob and identification with HPLC-MS. Innov. Food Sci. Emerg. Technol. 2010, 11, 470–476. [Google Scholar] [CrossRef]

- Pagan, J.; Ibarz, A.; Llorca, M.; Pagan, A.; Barbosa-Canovas, G.V. Extraction and characterization of pectin from stored peach pomace. Food Res. Int. 2001, 34, 605–612. [Google Scholar] [CrossRef]

- Chen, Y.; Xie, M.Y.; Gong, X.F. Microwave-assisted extraction used for the isolation of total triterpenoid saponins from Ganoderma atrum. J. Food Eng. 2007, 81, 162–170. [Google Scholar] [CrossRef]

- Zheng, X.; Yin, F.; Liu, C.; Xu, X. Effect of process parameters of microwave assisted extraction (MAE) on polysaccharides yield from pumpkin. J. Northeast Agric. Univ. 2011, 18, 79–86. [Google Scholar] [CrossRef]

- Hosseini, S.S.; Khodaiyan, F.; Yarmand, M.S. Aqueous extraction of pectin from sour orange peel and its preliminary physicochemical properties. Int. J. Biol. Macromol. 2016, 82, 920–926. [Google Scholar] [CrossRef] [PubMed]

- Yang, P.Y.; Wong, C.J.; Woo, K.K. Optimization of pectin extraction from peel of dragon fruit (Hylocereus polyrhizus). Asian J. Biol. Sci. 2011, 4, 189–195. [Google Scholar]

- Li, W.J.; Fan, Z.G.; Wu, Y.Y.; Jiang, Z.G.; Shi, R.C. Eco-friendly extraction and physicochemical properties of pectin from jackfruit peel waste with subcritical water. J. Sci. Food Agric. 2019, 99, 5283–5292. [Google Scholar] [CrossRef] [PubMed]

- Vriesmann, L.C.; Teofilo, R.F.; Perkowicz, C.L. Extraction and characterization of pectin from cacao pod husks (Theobroma cacao L.) with citric acid. LWT Food Sci. Technol. 2012, 49, 108–116. [Google Scholar] [CrossRef]

- Gullon, B.; Gomez, B.; Martínez-Sabajanes, M.; Yanez, R.; Parajó, J.C.; Alonso, J.L. Pectic oligosaccharides: Manufacture and functional properties. Trends Food Sci. Technol. 2013, 30, 153–161. [Google Scholar] [CrossRef]

| Source | Sum of Squares | DF | Mean Square | F-Value | p-Value | Source | Sum of Squares | DF | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (A) Yield | (B) DE | ||||||||||

| Model | 1015.57 | 14 | 72.54 | 22.26 | <0.0001 * | Model | 7673.79 | 14 | 548.13 | 63.15 | <0.0001 * |

| X1 | 13.98 | 1 | 13.98 | 4.29 | 0.0573 | X1 | 25.42 | 1 | 25.42 | 2.93 | 0.1091 |

| X2 | 3.34 | 1 | 3.34 | 1.02 | 0.3286 | X2 | 0.0046 | 1 | 0.0046 | 0.0005 | 0.9819 |

| X3 | 652.10 | 1 | 652.10 | 200.09 | <0.0001 * | X3 | 5635.77 | 1 | 5635.77 | 649.33 | <0.0001 * |

| X4 | 129.89 | 1 | 129.89 | 39.86 | <0.0001 * | X4 | 35.59 | 1 | 35.59 | 4.10 | 0.0624 |

| X12 | 3.31 | 1 | 3.31 | 1.01 | 0.3309 | X12 | 21.44 | 1 | 21.44 | 2.47 | 0.1384 |

| X22 | 10.64 | 1 | 10.64 | 3.27 | 0.0923 | X22 | 34.52 | 1 | 34.52 | 3.98 | 0.0660 |

| X32 | 136.64 | 1 | 136.64 | 41.93 | <0.0001 * | X32 | 1882.18 | 1 | 1882.18 | 216.86 | <0.0001 * |

| X42 | 42.34 | 1 | 42.34 | 12.99 | 0.0029 * | X42 | 78.04 | 1 | 78.04 | 8.99 | 0.0096 * |

| X1 X2 | 0.19 | 1 | 0.19 | 0.058 | 0.8131 | X1 X2 | 27.79 | 1 | 27.79 | 3.20 | 0.0952 |

| X1 X3 | 2.81 | 1 | 2.81 | 0.86 | 0.3692 | X1 X3 | 0.20 | 1 | 0.20 | 0.023 | 0.8815 |

| X1 X4 | 0.62 | 1 | 0.62 | 0.19 | 0.6703 | X1 X4 | 3.18 | 1 | 3.18 | 0.37 | 0.5545 |

| X2 X3 | 3.48 | 1 | 3.48 | 1.07 | 0.3191 | X2 X3 | 1.70 | 1 | 1.70 | 0.20 | 0.6648 |

| X2 X4 | 0.024 | 1 | 0.024 | 0.0074 | 0.9328 | X2 X4 | 2.70 | 1 | 2.70 | 0.31 | 0.5861 |

| X3 X4 | 28.62 | 1 | 28.62 | 8.78 | 0.0103 * | X3 X4 | 40.42 | 1 | 40.42 | 4.66 | 0.0488 * |

| Residual | 45.63 | 14 | 3.26 | Residual | 121.51 | 14 | 8.68 | ||||

| Lack of Fit | 42.43 | 10 | 4.24 | 5.32 | 0.0608 | Lack of Fit | 99.46 | 10 | 9.95 | 1.80 | 0.2992 |

| Pure Error | 3.19 | 4 | 0.80 | Pure Error | 22.05 | 4 | 5.51 | ||||

| Total | 1061.19 | 28 | Total | 7795.30 | 28 | ||||||

| Std. Dev. | 1.81 | R-Squared | 0.9570 | Std. Dev. | 2.95 | R-Squared | 0.9844 | ||||

| Mean | 12.89 | Adj R-Squared | 0.9140 | Mean | 57.40 | Adj R-Squared | 0.9688 | ||||

| C.V. | 14.00 | Pred R-Squared | 0.7650 | C.V. | 5.13 | Pred R-Squared | 0.9221 | ||||

| PRESS | 249.40 | Adeq Precision | 16.424 | PRESS | 607.35 | Adeq Precision | 24.341 |

| Optimal Condition | Response | Characteristics | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Predicted Value | Measure Value | ||||||||||

| Temp (°C) | Time (min) | pH | Ratio (mL/g) | Yield (%) | DE (%) | Yield (%) | DE (%) | Eq.wt (g) | MeO (%) | AUA (%) | |

| LDP | 85 | 166 | 1 | 50 | 22.83 | 45.20 | 21.42 ± 1.45 | 46.17 ± 0.71 | 210.55 ± 3.13 | 12.63 ± 0.55 | 13.05 ± 1.41 |

| MDP | 85 | 120 | 2.2 | 50 | 14.22 | 60.00 | 12.02 ± 2.74 | 56.65 ± 1.03 | 303.10 ± 6.49 | 13.37 ± 0.27 | 55.30 ± 12.90 |

| HDP | 85 | 90 | 2.7 | 50 | 7.28 | 80.00 | 6.53 ± 1.06 | 88.38 ± 0.71 | 2678.57 ± 252.54 | 8.84 ± 0.22 | 78.43 ± 5.48 |

| Supplements | L. plantarum TISTR 877 | L. casei TISTR 390 | E. faecium TISTR 1027 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Time (h) | Time (h) | Time (h) | |||||||

| 0 | 24 | 36 | 0 | 24 | 36 | 0 | 24 | 36 | |

| LDP | 4.28 ± 0.05 a | 6.84 ± 0.03 e | 8.53 ± 0.07 d | 4.36 ± 0.12 bc | 6.58 ± 0.33 d | 7.16 ± 0.08 c | 4.31 ± 0.03 bc | 6.07 ± 0.06 f | 7.43 ± 0.09 d |

| MDP | 4.25 ± 0.02 a | 7.18 ± 0.03 d | 8.67 ± 0.01 c | 4.38 ± 0.03 abc | 7.36 ± 0.09 bc | 7.20 ± 0.17 cd | 4.22 ± 0.03 d | 6.46 ± 0.11 de | 7.79 ± 0.07 c |

| HDP | 4.25 ± 0.02 a | 7.15 ± 0.09 d | 8.66 ± 0.07 c | 4.49 ± 0.02 ab | 7.44 ± 0.09 b | 7.39 ± 0.12 c | 4.32 ± 0.07 bc | 7.47 ± 0.12 c | 8.39 ± 0.06 b |

| LPEH | 4.26 ± 0.05 a | 7.90 ± 0.03 c | 8.85 ± 0.03 b | 4.39 ± 0.02 abc | 6.99 ± 0.27 c | 8.34 ± 0.04 b | 4.31 ± 0.05 bc | 6.33 ± 0.14 e | 7.73 ± 0.03 cd |

| MPEH | 4.27 ± 0.01 a | 8.42 ± 0.02 a | 9.21 ± 0.07 a | 4.48 ± 0.00 ab | 7.61 ± 0.01 b | 8.46 ± 0.05 b | 4.44 ± 0.00 a | 7.78 ± 0.05 b | 9.05 ± 0.04 a |

| HPEH | 4.25 ± 0.05 a | 8.30 ± 0.01 b | 9.11 ± 0.03 a | 4.51 ± 0.07 a | 8.29 ± 0.01 a | 8.72 ± 0.02 a | 4.39 ± 0.00 ab | 8.17 ± 0.07 a | 9.16 ± 0.06 a |

| Positive control | 4.30 ± 0.02 a | 8.28 ± 0.01 b | 9.18 ± 0.01 a | 4.33 ± 0.06 c | 7.99 ± 0.04 a | 8.73 ± 0.16 a | 4.43 ± 0.05 a | 8.28 ± 0.02 a | 9.09 ± 0.12 a |

| Negative control | 4.22 ± 0.03 a | 7.20 ± 0.03 d | 8.29 ± 0.07 e | 4.35 ± 0.02 bc | 7.50 ± 0.12 b | 8.37 ± 0.08 b | 4.26 ± 0.00 cd | 6.64 ± 0.04 d | 8.35 ± 0.00 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bilraheem, S.; Srinuanpan, S.; Cheirsilp, B.; Upaichit, A.; Kawai, F.; Thumarat, U. Optimization of Pectin Extraction from Melon Peel as a New Source of Pectin and Pectin Hydrolysate with Prebiotic Potential. Foods 2024, 13, 2554. https://doi.org/10.3390/foods13162554

Bilraheem S, Srinuanpan S, Cheirsilp B, Upaichit A, Kawai F, Thumarat U. Optimization of Pectin Extraction from Melon Peel as a New Source of Pectin and Pectin Hydrolysate with Prebiotic Potential. Foods. 2024; 13(16):2554. https://doi.org/10.3390/foods13162554

Chicago/Turabian StyleBilraheem, Saroya, Sirasit Srinuanpan, Benjamas Cheirsilp, Apichat Upaichit, Fusako Kawai, and Uschara Thumarat. 2024. "Optimization of Pectin Extraction from Melon Peel as a New Source of Pectin and Pectin Hydrolysate with Prebiotic Potential" Foods 13, no. 16: 2554. https://doi.org/10.3390/foods13162554

APA StyleBilraheem, S., Srinuanpan, S., Cheirsilp, B., Upaichit, A., Kawai, F., & Thumarat, U. (2024). Optimization of Pectin Extraction from Melon Peel as a New Source of Pectin and Pectin Hydrolysate with Prebiotic Potential. Foods, 13(16), 2554. https://doi.org/10.3390/foods13162554