Wheat Germ as Partial or Total Substitutive of Lean Meat in Low-Fat Cooked Sausages

Abstract

1. Introduction

2. Materials and Methods

2.1. Food Materials and Additives

2.2. Sausage Manufacture

2.3. Jelly and Fat Separation

2.4. Emulsion Stability

2.5. Proximate Composition Analysis

2.6. Texture and Color

2.7. Fatty Acid Profile and Fat Oxidation Stability

2.8. Sensory Analysis Evaluation

2.9. Statistical Analysis

3. Results and Discussion

3.1. Emulsion Characteristics

3.2. Proximate Composition

3.3. Color and Texture

3.4. Fatty Acid Profile

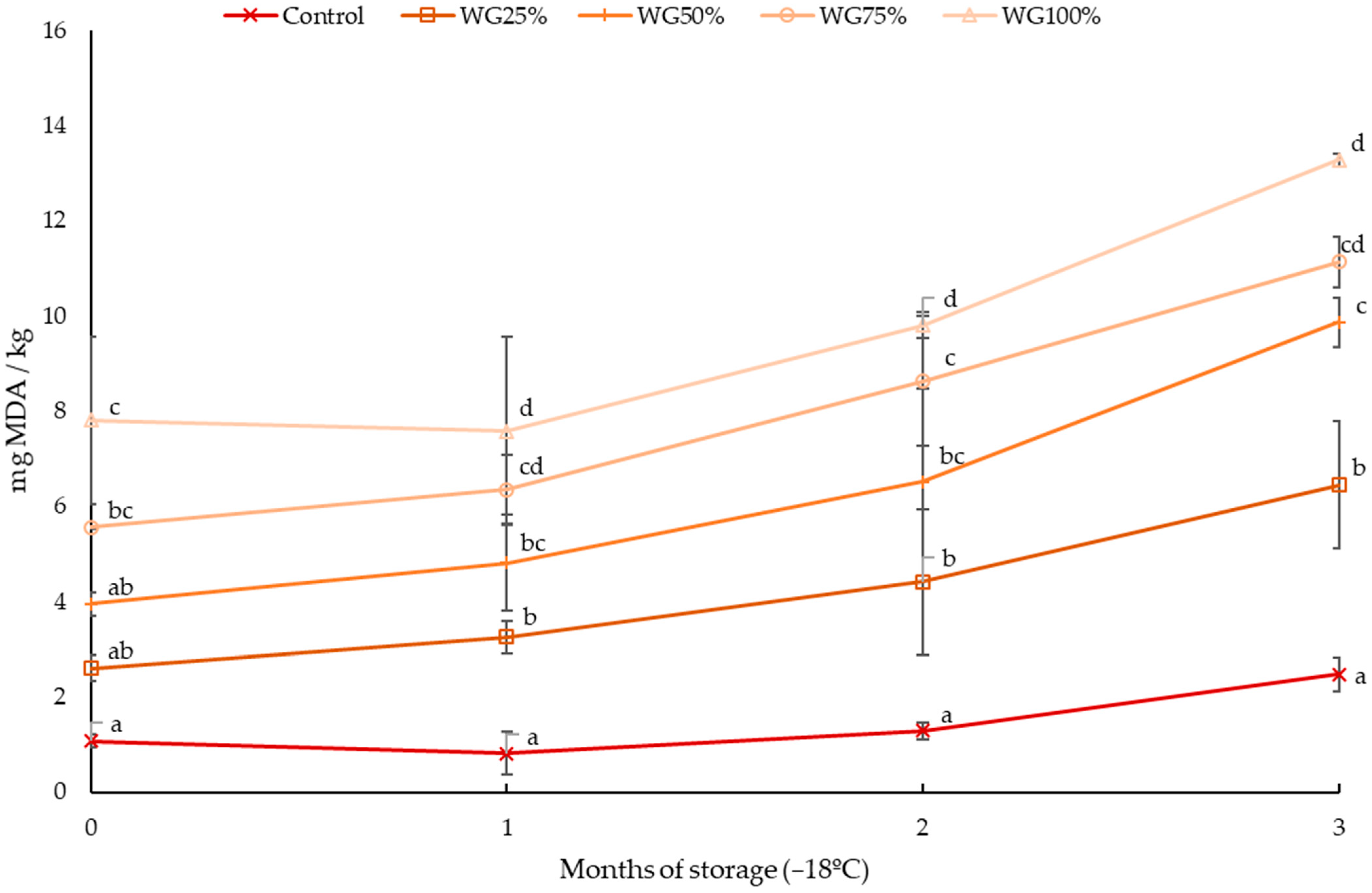

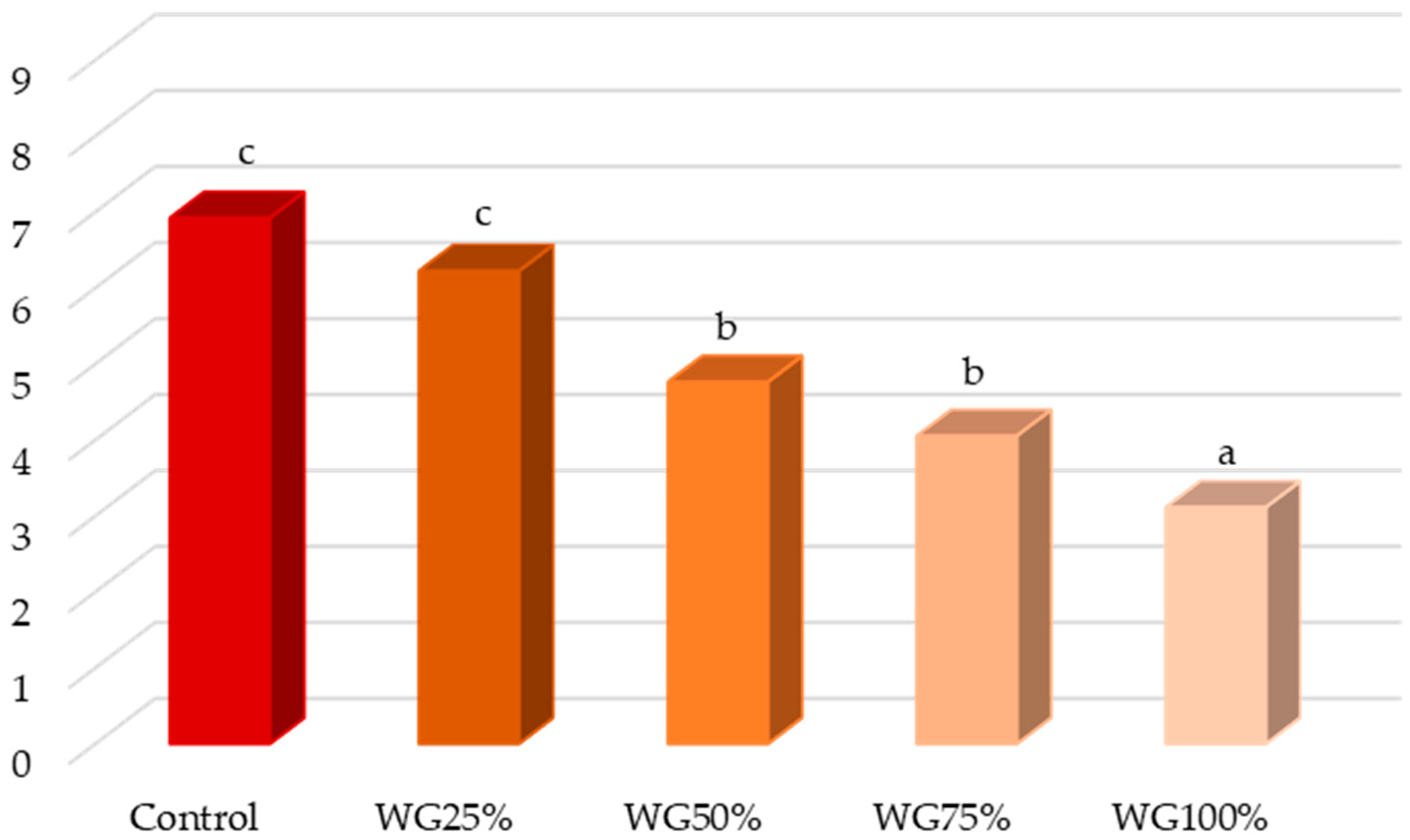

3.5. Fat Oxidation

3.6. Sensory Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Godfray, H.C.J.; Aveyard, P.; Garnett, T.; Hall, J.W.; Key, T.J.; Lorimer, J.; Pierrehumbert, R.T.; Scarborough, P.; Springmann, M.; Jebb, S.A. Meat Consumption, Health, and the Environment. Science 2018, 361, eaam5324. [Google Scholar] [CrossRef] [PubMed]

- Geiker, N.R.W.; Bertram, H.C.; Mejborn, H.; Dragsted, L.O.; Kristensen, L.; Carrascal, J.R.; Bügel, S.; Astrup, A. Meat and Human Health—Current Knowledge and Research Gaps. Foods 2021, 10, 1556. [Google Scholar] [CrossRef] [PubMed]

- Ekmekcioglu, C.; Wallner, P.; Kundi, M.; Weisz, U.; Haas, W.; Hutter, H.-P. Red Meat, Diseases, and Healthy Alternatives: A Critical Review. Crit. Rev. Food Sci. Nutr. 2018, 58, 247–261. [Google Scholar] [CrossRef]

- Hedenus, F.; Wirsenius, S.; Johansson, D.J.A. The Importance of Reduced Meat and Dairy Consumption for Meeting Stringent Climate Change Targets. Clim. Chang. 2014, 124, 79–91. [Google Scholar] [CrossRef]

- Graham, T.; Abrahamse, W. Communicating the Climate Impacts of Meat Consumption: The Effect of Values and Message Framing. Glob. Environ. Chang. 2017, 44, 98–108. [Google Scholar] [CrossRef]

- Huis, A.V.; Van Itterbeeck, J.; Klunder, H.; Mertens, E.; Halloran, A.; Muir, G.; Vantomme, P. Edible Insect, Future Prospect for Food and Feed Security; Food and Agriculture Organization of the United Nations: Rome, Italy, 2013; pp. 1–154. [Google Scholar]

- Reis, G.G.; Heidemann, M.S.; Borini, F.M.; Molento, C.F.M. Livestock Value Chain in Transition: Cultivated (Cell-Based) Meat and the Need for Breakthrough Capabilities. Technol. Soc. 2020, 62, 101286. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, Y.; Badar, I.H.; Xia, X.; Kong, B.; Chen, Q. Prospects of Artificial Meat: Opportunities and Challenges around Consumer Acceptance. Trends Food Sci. Technol. 2021, 116, 434–444. [Google Scholar] [CrossRef]

- Ahmad, M.; Qureshi, S.; Akbar, M.H.; Siddiqui, S.A.; Gani, A.; Mushtaq, M.; Hassan, I.; Dhull, S.B. Plant-Based Meat Alternatives: Compositional Analysis, Current Development and Challenges. Appl. Food Res. 2022, 2, 100154. [Google Scholar] [CrossRef]

- Berghout, J.A.M.; Boom, R.M.; van der Goot, A.J. Understanding the Differences in Gelling Properties between Lupin Protein Isolate and Soy Protein Isolate. Food Hydrocoll. 2015, 43, 465–472. [Google Scholar] [CrossRef]

- Ladjal Ettoumi, Y.; Chibane, M.; Romero, A. Emulsifying Properties of Legume Proteins at Acidic Conditions: Effect of Protein Concentration and Ionic Strength. LWT—Food Sci. Technol. 2016, 66, 260–266. [Google Scholar] [CrossRef]

- Kumar, P.; Chatli, M.K.; Mehta, N.; Singh, P.; Malav, O.P.; Verma, A.K. Meat Analogues: Health Promising Sustainable Meat Substitutes. Crit. Rev. Food Sci. Nutr. 2017, 57, 923–932. [Google Scholar] [CrossRef] [PubMed]

- De Angelis, D.; Kaleda, A.; Pasqualone, A.; Vaikma, H.; Tamm, M.; Tammik, M.-L.; Squeo, G.; Summo, C. Physicochemical and Sensorial Evaluation of Meat Analogues Produced from Dry-Fractionated Pea and Oat Proteins. Foods 2020, 9, 1754. [Google Scholar] [CrossRef] [PubMed]

- Pantoa, T.; Baricevic-Jones, I.; Suwannaporn, P.; Kadowaki, M.; Kubota, M.; Roytrakul, S.; Mills, E.N.C. Young Rice Protein as a New Source of Low Allergenic Plant-Base Protein. J. Cereal Sci. 2020, 93, 102970. [Google Scholar] [CrossRef]

- Singh, M.; Trivedi, N.; Enamala, M.K.; Kuppam, C.; Parikh, P.; Nikolova, M.P.; Chavali, M. Plant-Based Meat Analogue (PBMA) as a Sustainable Food: A Concise Review. Eur. Food Res. Technol. 2021, 247, 2499–2526. [Google Scholar] [CrossRef]

- Petrusán, J.-I.; Rawel, H.; Huschek, G. Protein-Rich Vegetal Sources and Trends in Human Nutrition: A Review. Curr. Top. Pept. Protein Res. 2016, 17, 1–19. [Google Scholar]

- Onwezen, M.C.; Bouwman, E.P.; Reinders, M.J.; Dagevos, H. A Systematic Review on Consumer Acceptance of Alternative Proteins: Pulses, Algae, Insects, Plant-Based Meat Alternatives, and Cultured Meat. Appetite 2021, 159, 105058. [Google Scholar] [CrossRef] [PubMed]

- Kumar, P.; Sharma, B.D.; Kumar, R.R.; Kumar, A. Optimization of the Level of Wheat Gluten in Analogue Meat Nuggets. Indian J. Anim. Res. 2012, 21, 54–59. [Google Scholar]

- Ghafoor, K.; Özcan, M.M.; AL-Juhaımı, F.; Babıker, E.E.; Sarker, Z.I.; Ahmed, I.A.M.; Ahmed, M.A. Nutritional Composition, Extraction, and Utilization of Wheat Germ Oil: A Review. Eur. J. Lipid Sci. Technol. 2017, 119, 1600160. [Google Scholar] [CrossRef]

- Zhu, K.-X.; Zhou, H.-M.; Qian, H.-F. Proteins Extracted from Defatted Wheat Germ: Nutritional and Structural Properties. Cereal Chem. 2006, 83, 69–75. [Google Scholar] [CrossRef]

- Shewry, P.R.; Powers, S.; Field, J.M.; Fido, R.J.; Jones, H.D.; Arnold, G.M.; West, J.; Lazzeri, P.A.; Barcelo, P.; Barro, F.; et al. Comparative Field Performance over 3 Years and Two Sites of Transgenic Wheat Lines Expressing HMW Subunit Transgenes. Theor. Appl. Genet. 2006, 113, 128–136. [Google Scholar] [CrossRef]

- Shewry, P.R. The HEALTHGRAIN Programme Opens New Opportunities for Improving Wheat for Nutrition and Health. Nutr. Bull. 2009, 34, 225–231. [Google Scholar] [CrossRef]

- Shewry Jones, P.R. Transgenic Wheat: Where Do We Stand after the First 12 Years? Ann. Appl. Biol. 2005, 147, 1–14. [Google Scholar] [CrossRef]

- Gili, R.D.; Palavecino, P.M.; Cecilia Penci, M.; Martinez, M.L.; Ribotta, P.D. Wheat Germ Stabilization by Infrared Radiation. J. Food Sci. Technol. 2017, 54, 71–81. [Google Scholar] [CrossRef] [PubMed]

- Ge, Y.; Sun, A.; Ni, Y.; Cai, T. Some Nutritional and Functional Properties of Defatted Wheat Germ Protein. J. Agric. Food Chem. 2000, 48, 6215–6218. [Google Scholar] [CrossRef] [PubMed]

- Youssef, H.M.K.E. Assessment of Gross Chemical Composition, Mineral Composition, Vitamin Composition and Amino Acids Composition of Wheat Biscuits and Wheat Germ Fortified Biscuits. Food Nutr. Sci. 2015, 6, 845–853. [Google Scholar] [CrossRef]

- Mueller, T.; Voigt, W. Fermented Wheat Germ Extract—Nutritional Supplement or Anticancer Drug? Nutr. J. 2011, 10, 89. [Google Scholar] [CrossRef] [PubMed]

- Fadel, H.H.M.; Abdel Mageed, M.A.; Lotfy, S.N. Quality and Flavour Stability of Coffee Substitute Prepared by Extrusion of Wheat Germ and Chicory Roots. Amino Acids 2008, 34, 307–314. [Google Scholar] [CrossRef] [PubMed]

- Barros, J.C.; Munekata, P.E.S.; de Carvalho, F.A.L.; Domínguez, R.; Trindade, M.A.; Pateiro, M.; Lorenzo, J.M. Healthy Beef Burgers: Effect of Animal Fat Replacement by Algal and Wheat Germ Oil Emulsions. Meat Sci. 2021, 173, 108396. [Google Scholar] [CrossRef]

- Serdaroğlu, M.; Özsümer, M.S. Effects of soy protein, whey powder and wheat gluten on quality characteristics of cooked beef sausages formulated with 5, 10 and 20% fat. Electron. J. Pol. Agric. 2003, 6, 3. [Google Scholar]

- Elbakheet, S.I.; Elgasim, E.A.; Algadi, M.Z.; Si, E.; Ea, E.; Mz, A. Utilization of Wheat Germ Flour in the Processing of Beef Sausage. Adv. Food Process Technol. 2018, 10, 100001. [Google Scholar]

- Güngör, E.; Gökoğlu, N. Determination of Microbial Contamination Sources at a Frankfurter Sausage Processing Line. Turk. J. Vet. Anim. Sci. 2010, 34, 53–59. [Google Scholar] [CrossRef]

- Polizer Rocha, Y.J.; Lapa-Guimarães, J.; de Noronha, R.L.F.; Trindade, M.A. Evaluation of Consumers’ Perception Regarding Frankfurter Sausages with Different Healthiness Attributes. J. Sens. Stud. 2018, 33, e12468. [Google Scholar] [CrossRef]

- González-Viñas, M.A.; Caballero, A.B.; Gallego, I.; García Ruiz, A. Evaluation of the Physico-Chemical, Rheological and Sensory Characteristics of Commercially Available Frankfurters in Spain and Consumer Preferences. Meat Sci. 2004, 67, 633–641. [Google Scholar] [CrossRef] [PubMed]

- Franco, D.; Martins, A.; López-Pedrouso, M.; Purriños, L.; Cerqueira, M.; Vicente, A.; Pastrana, L.; Zapata, C.; Lorenzo, J. Strategy towards Replacing Pork Backfat with a Linseed Oleogel in Frankfurter Sausages and Its Evaluation on Physicochemical, Nutritional, and Sensory Characteristics. Foods 2019, 8, 366. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.-J.; Jung, E.-H.; Lee, S.-H.; Kim, J.-H.; Lee, J.-J.; Choi, Y.-I. Effect of Replacing Pork Fat with Vegetable Oils on Quality Properties of Emulsion-Type Pork Sausages. Food Sci. Anim. Resour. 2015, 35, 130–136. [Google Scholar] [CrossRef] [PubMed]

- Badar, I.H.; Liu, H.; Chen, Q.; Xia, X.; Kong, B. Future Trends of Processed Meat Products Concerning Perceived Healthiness: A Review. Compr. Rev. Food Sci. Food Saf. 2021, 20, 4739–4778. [Google Scholar] [CrossRef] [PubMed]

- Younis, K.; Ashfaq, A.; Ahmad, A.; Anjum, Z.; Yousuf, O. A Critical Review Focusing the Effect of Ingredients on the Textural Properties of Plant-based Meat Products. J. Texture Stud. 2023, 54, 365–382. [Google Scholar] [CrossRef] [PubMed]

- Zamuz, S.; Purriños, L.; Galvez, F.; Zdolec, N.; Muchenje, V.; Barba, F.J.; Lorenzo, J.M. Influence of the Addition of Different Origin Sources of Protein on Meat Products Sensory Acceptance. J. Food Process. Preserv. 2019, 43, e13940. [Google Scholar] [CrossRef]

- Corrêa, P.F.; Silva, C.F.d.; Ferreira, J.P.; Guerra, J.M.C. Vegetable-Based Frankfurter Sausage Production by Different Emulsion Gels and Assessment of Physical-Chemical, Microbiological and Nutritional Properties. Food Chem. Adv. 2023, 3, 100354. [Google Scholar] [CrossRef]

- Revilla, I.; Santos, S.; Hernández-Jiménez, M.; Vivar-Quintana, A.M. The Effects of the Progressive Replacement of Meat with Texturized Pea Protein in Low-Fat Frankfurters Made with Olive Oil. Foods 2022, 11, 923. [Google Scholar] [CrossRef]

- Mazumder, M.; Sujintonniti, N.; Chaum, P.; Ketnawa, S.; Rawdkuen, S. Developments of Plant-Based Emulsion-Type Sausage by Using Grey Oyster Mushrooms and Chickpeas. Foods 2023, 12, 1564. [Google Scholar] [CrossRef] [PubMed]

- Marçal, C.; Pinto, C.A.; Silva, A.M.S.; Monteiro, C.; Saraiva, J.A.; Cardoso, S.M. Macroalgae-Fortified Sausages: Nutritional and Quality Aspects Influenced by Non-Thermal High-Pressure Processing. Foods 2021, 10, 209. [Google Scholar] [CrossRef] [PubMed]

- Lurueña-Martínez, M.A.; Revilla, I.; Vivar-Quintana, A.M. Effect of locust bean/xantham gum addition and replacement of pork fat with olive oil on the quality characteristics of low-fat frankfurters. Meat. Sci. 2004, 68, 383–389. [Google Scholar] [CrossRef]

- Official Methods of Analysis, 15 th ed.; Helrich, K., Ed.; Association of Official Analytical Chemist: Washington, DC, USA, 1990. [Google Scholar]

- Hughes, E.; Cofrades, S.; Troy, D.J. Effects of Fat Level, Oat Fibre and Carrageenan on Frankfurters Formulated with 5, 12 and 30% Fat. Meat Sci. 1997, 45, 273–281. [Google Scholar] [CrossRef] [PubMed]

- Folch, J.; Lees, M.; Stanley, G.H.S. A Simple Method for the Isolation and Purification of Total Lipides From Animal Tissues. J. Biol. Chem. 1957, 226, 497–509. [Google Scholar] [CrossRef]

- Buege, J.A.; Aust, S.D. [30] Microsomal Lipid Peroxidation. Methods Enzymol. 1978, 52, 302–310. [Google Scholar] [PubMed]

- Thushan Sanjeewa, W.G.; Wanasundara, J.P.D.; Pietrasik, Z.; Shand, P.J. Characterization of Chickpea (Cicer arietinum L.) Flours and Application in Low-Fat Pork Bologna as a Model System. Food Res. Int. 2010, 43, 617–626. [Google Scholar] [CrossRef]

- Jones, L.J.; Tung, M.A. Functional Properties of Modified Oilseed Protein Concentrates and Isolates. Can. Inst. Food Sci. Technol. J. 1983, 16, 57–62. [Google Scholar] [CrossRef]

- Flores Llovera, M.; Giner, E.; Fiszman, S.; Salvador, A.; Flores, J. Effect of a New Emulsifier Containing Sodium Stearoyl-2-Lactylate and Carrageenan on the Functionality of Meat Emulsion Systems. Meat Sci. 2007, 76, 9–18. [Google Scholar] [CrossRef] [PubMed]

- Ahmedna, M.; Prinyawiwatkul, W.; Rao, R.M. Solubilized Wheat Protein Isolate: Functional Properties and Potential Food Applications. J. Agric. Food Chem. 1999, 47, 1340–1345. [Google Scholar] [CrossRef] [PubMed]

- Kamani, M.H.; Meera, M.S.; Bhaskar, N.; Modi, V.K. Partial and Total Replacement of Meat by Plant-Based Proteins in Chicken Sausage: Evaluation of Mechanical, Physico-Chemical and Sensory Characteristics. J. Food Sci. Technol. 2019, 56, 2660–2669. [Google Scholar] [CrossRef] [PubMed]

- Gnanasambandam, R.; Zayas, J.F. Quality Characteristics of Meat Batters and Frankfurters Containing Wheat Germ Protein Flour. J. Food Qual. 1994, 17, 129–142. [Google Scholar] [CrossRef]

- El- Sayed, S.M.; Farag, S.E.; El-Sayed, S.A.M. Utilization of Some Chicken Edible Internal Organs and Wheat Germ in Production of Sausage. J. Food Dairy Sci. 2018, 9, 353–358. [Google Scholar] [CrossRef]

- İbanoǧlu, E. Kinetic Study on Colour Changes in Wheat Germ Due to Heat. J. Food Eng. 2002, 51, 209–213. [Google Scholar] [CrossRef]

- Govari, M.; Pexara, A. Nitrates and Nitrites in Meat Products. J. Hell. Vet. Med. Soc. 2015, 66, 127–140. [Google Scholar] [CrossRef]

- García, M.L.; Dominguez, R.; Galvez, M.D.; Casas, C.; Selgas, M.D. Utilization of Cereal and Fruit Fibres in Low Fat Dry Fermented Sausages. Meat Sci. 2002, 60, 227–236. [Google Scholar] [CrossRef] [PubMed]

- Viuda-Martos, M.; Ruiz-Navajas, Y.; Fernández-López, J.; Pérez-Álvarez, J.A. Effect of Orange Dietary Fibre, Oregano Essential Oil and Packaging Conditions on Shelf-Life of Bologna Sausages. Food Control 2010, 21, 436–443. [Google Scholar] [CrossRef]

- Thebaudin, J.Y.; Lefebvre, A.C.; Harrington, M.; Bourgeois, C.M. Dietary Fibres: Nutritional and Technological Interest. Trends Food Sci. Technol. 1997, 8, 41–48. [Google Scholar] [CrossRef]

- Backers, T.; Noli, B. Dietary Fibers Meat Processing. Int. Food Mark. Technol. 1997, 12, 4–8. [Google Scholar]

- Cofrades, S.; Guerra, M.A.; Carballo, J.; Fernández-Martín, F.; Colmenero, F.J. Plasma Protein and Soy Fiber Content Effect on Bologna Sausage Properties as Influenced by Fat Level. J. Food Sci. 2000, 65, 281–287. [Google Scholar] [CrossRef]

- Fernández-Ginés, J.M.; Fernández-López, J.; Sayas-Barberá, E.; Sendra, E.; Pérez-Alvarez, J.A. Effect of Storage Conditions on Quality Characteristics of Bologna Sausages Made with Citrus Fiber. J. Food Sci. 2003, 68, 710–714. [Google Scholar] [CrossRef]

- Abd EL-Rahman, A.M.M. Utilization of Wheat Germ as Natural Antioxidant and Fat Mimetic to Increase ShelfLife in Beef Sausage and as Lowering Cholesterol in Rats. Middle East J. 2015, 4, 555–563. [Google Scholar]

- Hidayat, B.T.; Wea, A.; Andriati, N. Physicochemical, Sensory Attributes and Protein Profile by SDS-PAGE of Beef Sausage Substituted with Texturized Vegetable Protein. Food Res. 2017, 2, 20–31. [Google Scholar] [CrossRef] [PubMed]

- Wood, J.D.; Enser, M.; Fisher, A.V.; Nute, G.R.; Sheard, P.R.; Richardson, R.I.; Hughes, S.I.; Whittington, F.M. Fat Deposition, Fatty Acid Composition and Meat Quality: A Review. Meat Sci. 2008, 78, 343–358. [Google Scholar] [CrossRef]

- Connor, W.E. Importance of N−3 Fatty Acids in Health and Disease. Am. J. Clin. Nutr. 2000, 71, 171S–175S. [Google Scholar] [CrossRef]

- Liput, K.P.; Lepczyński, A.; Ogłuszka, M.; Nawrocka, A.; Poławska, E.; Grzesiak, A.; Ślaska, B.; Pareek, C.S.; Czarnik, U.; Pierzchała, M. Effects of Dietary n–3 and n–6 Polyunsaturated Fatty Acids in Inflammation and Cancerogenesis. Int. J. Mol. Sci. 2021, 22, 6965. [Google Scholar] [CrossRef] [PubMed]

- WHO/FAO Expert Consultation. Global Report on Diet, Nutrition and Prevention of Chronic Diseases. World Health Organ. Tech. Rep. Ser. 2003, 916, 1–149. [Google Scholar]

- Coutinho de Oliveira, T.L.; Malfitano de Carvalho, S.; de Araújo Soares, R.; Andrade, M.A.; Cardoso, M.d.G.; Ramos, E.M.; Piccoli, R.H. Antioxidant Effects of Satureja montana L. Essential Oil on TBARS and Color of Mortadella-Type Sausages Formulated with Different Levels of Sodium Nitrite. LWT—Food Sci. Technol. 2012, 45, 204–212. [Google Scholar] [CrossRef]

- Kaczmarek, A.; Cegielska-Radziejewska, R.; Szablewski, T.; Zabielski, J. TBARS and Microbial Growth Predicative Models of Pork Sausage Stored at Different Temperatures. Czech J. Food Sci. 2015, 33, 320–325. [Google Scholar] [CrossRef]

- Marzocchi, S.; Caboni, M.F.; Greco Miani, M.; Pasini, F. Wheat Germ and Lipid Oxidation: An Open Issue. Foods 2022, 11, 1032. [Google Scholar] [CrossRef]

- Lee, J.; Sung, J.-M.; Cho, H.J.; Woo, S.-H.; Kang, M.-C.; Yong, H.I.; Kim, T.-K.; Lee, H.; Choi, Y.-S. Natural Extracts as Inhibitors of Microorganisms and Lipid Oxidation in Emulsion Sausage during Storage. Food Sci. Anim. Resour. 2021, 41, 1060. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Zhao, L.; Chen, H.; Sun, D.; Deng, B.; Li, J.; Liu, Y.; Wang, F. Inactivation of Lipase and Lipoxygenase of Wheat Germ with Temperature-Controlled Short Wave Infrared Radiation and Its Effect on Storage Stability and Quality of Wheat Germ Oil. PLoS ONE 2016, 11, e0167330. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Chi, C.; Zhou, S.; Jiang, Y. Comparison of Wheat Germ and Oil Characteristics and Stability by Different Stabilization Techniques. LWT 2024, 191, 115664. [Google Scholar] [CrossRef]

- Roux, S.; Petit, M.; Baeza, E.; Bastianelli, D.; Tillard, E.; Arnaud, E. Kinetics of Malonaldehyde Content in Enriched Chicken Meat during Isothermal Cooking. Eur. J. Lipid Sci. Technol. 2014, 116, 153–159. [Google Scholar] [CrossRef]

- Ferrari, C.K.B.; Torres, E.A.F.S. Lipid Oxidation and Quality Parameters of Sausages Marketed Locally in the Town of Săo Paulo (Brazil). Czech J. Food Sci. 2002, 20, 144–150. [Google Scholar] [CrossRef]

- Roldan, M.; Antequera, T.; Armenteros, M.; Ruiz, J. Effect of Different Temperature–Time Combinations on Lipid and Protein Oxidation of Sous-Vide Cooked Lamb Loins. Food Chem. 2014, 149, 129–136. [Google Scholar] [CrossRef]

- Globisch, M.; Kaden, D.; Henle, T. 4-Hydroxy-2-Nonenal (4-HNE) and Its Lipation Product 2-Pentylpyrrole Lysine (2-PPL) in Peanuts. J. Agric. Food Chem. 2015, 63, 5273–5281. [Google Scholar] [CrossRef] [PubMed]

- Revilla, I.; Quintana, A.M.V. The Effect of Different Paprika Types on the Ripening Process and Quality of Dry Sausages. Int. J. Food Sci. Technol. 2005, 40, 411–417. [Google Scholar] [CrossRef]

- Wenjiao, F.; Yongkui, Z.; Yunchuan, C.; Junxiu, S.; Yuwen, Y. TBARS Predictive Models of Pork Sausages Stored at Different Temperatures. Meat Sci. 2014, 96, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Fernández, J.; Pérez-Álvarez, J.A.; Fernández-López, J.A. Thiobarbituric Acid Test for Monitoring Lipid Oxidation in Meat. Food Chem. 1997, 59, 345–353. [Google Scholar] [CrossRef]

| Ingredients | Control | WG25% | WG50% | WG75% | WG100% |

|---|---|---|---|---|---|

| Lean pork | 40 | 30 | 20 | 10 | 0 |

| Wheat germ | 0 | 10 | 20 | 30 | 40 |

| Olive oil | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 |

| Locust bean/Xanthan gum | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

| Ice | 36 | 36 | 36 | 36 | 36 |

| Polyphosphate | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Nitrite salt 1 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 |

| Potato starch | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| Soy protein | 2 | 2 | 2 | 2 | 2 |

| Sodium ascorbate | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| Dextrose | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 |

| Sodium lactate | 1 | 1 | 1 | 1 | 1 |

| Flavorings | 2 | 2 | 2 | 2 | 2 |

| Onion | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 |

| Garlic | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| Pepper | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| Control | WG25% | WG50% | WG75% | WG100% | p-Value | |

|---|---|---|---|---|---|---|

| Back extrusion force (N) | 3.80 ± 0.78 a | 5.56 ± 0.59 a | 9.61 ± 2.24 a,b | 17.48 ± 7.20 b | 32.18 ± 15.25 c | 0.000 |

| Back extrusion area (N·s) | 28.70 ± 5.67 a | 20.82 ± 12.13 a | 21.55 ± 12.76 a | 67.79 ± 43.74 a | 134.97 ± 89.16 b | 0.001 |

| %TEF | 4.14 ± 0.75 b | 3.92 ± 1.53 b | 2.55 ± 0.81 a | 1.24 ± 1.27 a | 1.41 ± 0.54 a | 0.000 |

| %Fat | 2.92 ± 1.68 a | 3.27 ± 0.99 a | 6.32 ± 2.14 b | 6.51 ± 0.62 b | 6.56 ± 0.67 b | 0.000 |

| Jelly/fat separation (%) | 0.193 ± 0.13 b | 0.074 ± 0.07 a | 0.013 ± 0.01 a | 0.005 ± 0.01 a | 0.003 ± 0.01 a | 0.000 |

| Wheat Germ | Control | WG25% | WG50% | WG75% | WG100% | p-Value | |

|---|---|---|---|---|---|---|---|

| Moisture (%) | 8.37 ± 0.18 | 61.88 ± 3.20 c | 56.86 ± 4.20 c | 48.67 ± 2.59 b | 45.47 ± 3.94 a,b | 39.87 ± 5.98 a | 0.000 |

| Total fat (%) | 7.64 ± 0.13 | 12.26 ± 1.53 b | 9.21 ± 1.43 a | 8.96 ± 1.12 a | 8.09 ± 0.85 a | 7.92 ± 1.00 a | 0.000 |

| Protein (%) | 25.75 ± 0.21 | 11.51 ± 0.84 a | 10.90 ± 1.15 a | 12.20 ± 0.95 a | 12.11 ± 3.26 a | 13.27 ± 1.34 a | 0.226 |

| Ash (%) | 4.30 ± 0.03 | 3.29 ± 0.35 a | 3.39 ± 0.35 a | 3.60 ± 0.16 a | 3.93 ± 0.18 a | 4.70 ± 0.68 b | 0.001 |

| Fiber (%) | 24.90 ± 0.85 | 2.23 ± 0.95 a | 3.70 ± 0.29 a | 6.25 ± 1.67 b | 7.45 ± 1.65 b,c | 9.63 ± 1.64 c | 0.000 |

| Carbohydrate (%) | 29.05 ± 0.92 | 8.53 ± 0.27 a | 15.94 ± 1.66 b | 20.07 ± 1.11 bc | 21.96 ± 2.78 b,c | 24.61 ± 3.56 c | 0.005 |

| Starch (%) | 17.45 ± 0.35 | 3.29 ± 0.37 a | 5.04 ± 0.24 b | 6.68 ± 0.02 c | 7.75 ± 0.63 d | 9.89 ± 0.15 e | 0.000 |

| Control | WG25% | WG50% | WG75% | WG100% | p-Value | |

|---|---|---|---|---|---|---|

| L* | 64.24 ± 1.65 e | 59.04 ± 1.39 d | 56.82 ± 1.37 c | 51.10 ± 0.71 b | 45.50 ± 1.50 a | 0.000 |

| a* | 19.50 ± 0.38 b | 15.92 ± 0.69 a | 15.94 ± 0.80 a | 16.03 ± 1.93 a | 15.20 ± 1.39 a | 0.000 |

| b* | 30.90 ± 1.25 a,b | 22.88 ± 2.68 a | 31.07 ± 1.88 a,b | 33.51 ± 5.85 b | 31.39 ± 5.69 a,b | 0.069 |

| Hardness (g) | 1964.63 ± 509.48 a | 1901.98 ± 264.14 a | 2947.78 ± 556.36 b | 3698.22 ± 370.19 c | 4947.98 ± 334.02 d | 0.000 |

| Adhesiveness (g·mm) | −1.32 ± 1.83 a | −0.43 ± 0.79 a | −0.88 ± 1.42 a | −0.11 ± 0.08 a | −0.30 ± 0.57 a | 0.682 |

| Springiness (mm) | 0.95 ± 0.15 d | 0.86 ± 0.05 c | 0.80 ± 0.05 c | 0.70 ± 0.07 b | 0.62 ± 0.40 a | 0.000 |

| Cohesiveness | 0.76 ± 0.04 d | 0.68 ± 0.05 c | 0.64 ± 0.09 b | 0.62 ± 0.06 b | 0.53 ± 0.05 a | 0.000 |

| Gumminess (g) | 1478.49 ± 315.29 a | 1297.29 ± 186.77 a | 1887.94 ± 508.74 b | 2277.53 ± 181.36 c | 2624.37 ± 210.53 d | 0.000 |

| Chewiness (g·mm) | 1426.65 ± 535.57 b | 1121.46 ± 203.04 a | 1532.16 ± 487.62 b | 1611.54 ± 269.10 b | 1622.40 ± 135.70 b | 0.000 |

| Wheat Germ | Control | WG25% | WG50% | WG75% | WG100% | p-Value | |

|---|---|---|---|---|---|---|---|

| C6:0 | 14.96 ± 1.54 | 5.22 ± 3.1 | 2.35 ± 3.22 | 10.44 ± 5.30 | 2.81 ± 4.01 | 5.08 ± 1.34 | 0.433 |

| C8:0 | 21.14 ± 2.00 | 0.90 ± 0.79 | n.d. | n.d. | 1.18 ± 0.42 | n.d. | 0.318 |

| C10:0 | 0.68 ± 0.15 | 5.36 b ± 1.94 | 3.92 a,b ± 1.11 | 4.31 a,b ± 1.05 | 2.61 a,b ± 0.25 | 1.78 a ± 0.27 | 0.014 |

| C11:0 | 0.80 ± 0.10 | n.d | n.d | 8.21 ± 1.21 | n.d | 0.86 ± 0.10 | 0.267 |

| C12:0 | 0.96 ± 0.51 | 5.10 b ± 1.79 | 4.04 a,b ± 1.21 | 3.74 a,b ± 0.85 | 2.36 a,b ± 0.53 | 1.81 a ± 0.12 | 0.015 |

| C13:0 | 1.51 ± 0.07 | 9.94 ± 4.99 | 2.36 ± 0.42 | 7.77 ± 3.77 | 2.39 ± 1.32 | 0.54 ± 0.44 | 0.648 |

| C14:0 | 7.19 ± 0.46 | 53.90 c ± 12.30 | 37.14 b ± 12.16 | 28.33 a,b ± 3.00 | 18.49 a ± 2.55 | 11.21 a ± 0.95 | 0.003 |

| C14:1n5 | 1.08 ± 0.54 | 4.27 ± 1.30 | 2.82 ± 0.56 | 3.63 ± 1.39 | 3.23 ± 0.40 | 1.29 ± 0.23 | 0.126 |

| C15:0 | 3.83 ± 0.23 | 5.41 ± 1.11 | 1.64 ± 1.32 | 2.78 ± 1.18 | 2.02 ± 0.48 | 2.34 ± 1.06 | 0.074 |

| C15:1 | 0.65 ± 0.92 | 10.41 ± 3.90 | 18.77 ± 0.45 | 17.15 ± 3.33 | 15.82 ± 3.15 | 15.97 ± 3.74 | 0.797 |

| C16:0 | 995.55 ± 2.31 | 2676.53 ± 176.70 | 2115.01 ± 157.75 | 2057.07 ± 87.73 | 1990.97 ± 151.52 | 1660.24 ± 138.83 | 0.243 |

| C16:1 | 9.12 ± 0.17 | 33.24 ± 6.97 | 25.16 ± 6.80 | 21.18 ± 2.35 | 85.44 ± 9.18 | 84.24 ± 6.11 | 0.405 |

| C17:0 | 10.23 ± 0.42 | 246.36 c ± 67.13 | 187.49 b ± 12.93 | 163.02 b ± 8.68 | 10.21 a ± 2.80 | 3.22 a ± 0.28 | 0.000 |

| C17:1 | 1.31 ± 0.08 | 32.92 ± 10.37 | 29.61 ± 1.63 | 25.42 ± 2.51 | 25.48 ± 6.31 | 17.64 ± 1.37 | 0.170 |

| C18:0 | 1.61 ± 0.11 | 852.51 d ± 157.12 | 3.20 a ± 0.61 | 159.68 b ± 70.10 | 433.10 c ± 169.12 | 190.74 b ± 68.48 | 0.006 |

| C18:1n9t | 7.75 ± 0.52 | 66.85 ± 13.33 | 82.50 ± 11.75 | 75.79 ± 8.02 | 75.60 ± 11.37 | 61.13 ± 5.92 | 0.801 |

| C18:1n9c | 607.34 ± 6.80 | 10632.17 d ± 976.65 | 8265.09 c ± 640.41 | 7823.80 b,c ± 102.05 | 7443.37 b ± 160.31 | 5970.93 a ± 149.21 | 0.041 |

| C18:2n6t | 2.59 ± 0.17 | 5.23 ± 1.72 | 11.05 ± 3.24 | 4.08 ± 1.69 | 2.41 ± 0.57 | 2.05 ± 0.83 | 0.265 |

| C18:2 n6 | 631.43 ± 19.85 | 1800.35 a,b ± 157.53 | 1730.40 a ± 104.29 | 1943.42 b ± 107.54 | 2272.04 b,c ± 195.27 | 2053.26 b ± 194.59 | 0.050 |

| C20:0 | 6.28 ± 6.67 | 73.37 ± 16.49 | 56.71 ± 1.57 | 56.38 ± 0.82 | 54.75 ± 5.11 | 43.67 ± 1.95 | 0.214 |

| C18:3 n6 | 8.79 ± 0.60 | 7.95 ± 1.57 | 6.85 ± 0.82 | 9.49 ± 2.11 | 6.70 ± 1.95 | 6.21 ± 0.73 | 0.553 |

| C20:1 n9 | 23.25 ± 0.87 | 75.27 ± 8.22 | 64.54 ± 5.00 | 68.97 ± 10.56 | 67.88 ± 8.67 | 59.28 ± 6.27 | 0.781 |

| C18:3 n3 | 59.31 ± 26.72 | 124.39 a ± 16.88 | 144.42 a ± 16.77 | 194.20 a,b ± 13.90 | 257.27 b ± 28.25 | 247.16 b ± 28.72 | 0.001 |

| C21:0 | 7.85 ± 0.55 | 4.48 ± 1.57 | 4.78 ± 1.82 | 4.53 ± 1.16 | 2.15 ± 0.81 | 3.60 ± 1.62 | 0.371 |

| C20:2 n6 | 7.94 ± 0.31 | 56.44 ± 11.21 | 59.29 ± 6.37 | 33.47 ± 11.91 | 33.22 ± 8.59 | 36.55 ± 10.14 | 0.262 |

| C22:0 | 7.19 ± 1.56 | 23.57 ± 4.10 | 20.92 ± 1.48 | 4.12 ± 1.94 | 11.49 ± 3.28 | 8.75 ± 2.62 | 0.051 |

| C20:3 n6 | 1.93 ± 0.25 | 8.26 ± 3.54 | 8.88 ± 4.45 | 4.72 ± 1.57 | 3.52 ± 1.85 | 20.54 ± 10.09 | 0.451 |

| C22:1 n9 | 18.21 ± 0.97 | 37.45 ± 10.67 | 42.44 ± 3.25 | 24.63 ± 6.33 | 31.71 ± 7.11 | 34.99 ± 10.56 | 0.716 |

| C20:3 n3 | 3.32 ± 0.19 | 3.79 ± 0.77 | 3.59 ± 0.70 | 2.52 ± 0.32 | 12.69 ± 6.59 | 2.00 ± 1.73 | 0.371 |

| C23:0 | 1.79 ± 0.05 | 46.97 d ± 13.16 | 28.76 c ± 0.98 | 15.46 b ± 3.97 | 13.88 b ± 3.35 | 0.47 a ± 0.82 | 0.000 |

| C20:4 n6 | 7.43 ± 0.28 | 11.15 ± 3.10 | 13.30 ± 0.05 | 13.92 ± 3.07 | 10.29 ± 1.03 | 13.76 ± 2.76 | 0.964 |

| C22:2 n6 | 4.50 ± 0.42 | 6.79 ± 1.19 | 1.17 ± 1.66 | 1.53 ± 1.34 | 2.14 ± 0.30 | 2.50 ± 0.52 | 0.715 |

| C24:0 | 8.43 ± 6.65 | n.d | n.d. | 5.94 ± 2.26 | 3.72 ± 1.28 | n.d. | 0.468 |

| C20:5 n3 | 7.89 ± 0.15 | 9.15 ± 2.72 | 8.57 ± 1.11 | 4.62 ± 2.43 | 8.21 ± 2.79 | 7.86 ± 1.67 | 0.475 |

| C24:1 n9 | 14.05 ± 6.90 | 18.78 ± 10.42 | 4.89 ± 2.21 | 4.53 ± 0.22 | 5.90 ± 1.05 | 5.28 ± 0.38 | 0.705 |

| C22:4 n3 | 6.60 ± 0.42 | 12.47 b ± 2.1 | 8.27 a,b ± 1.13 | 4.14 a ± 0.46 | 3.24 a ± 1.35 | 2.51 a ± 0.51 | 0.001 |

| C22:5 n3 | 10.43 ± 1.21 | 29.54 ± 4.76 | 7.39 ± 1.65 | 22.14 ± 4.97 | 3.33 ± 0.85 | 2.27 ± 0.13 | 0.464 |

| C22:6 n3 | 8.91 ± 7.99 | n.d | n.d. | n.d. | n.d. | 5.69 ± 0.86 | 0.397 |

| SFA | 1089.99 ± 21.06 | 4009.63 b ± 284.87 | 2472.06 a ± 199.56 | 2531.79 a ± 164.90 | 2552.14 a ± 132.65 | 1934.30 a ± 78.26 | 0.050 |

| MUFA | 711.38 ± 6.37 | 10905.05 c ± 495.25 | 8539.21 b ± 444.24 | 8064.70 b ± 210.10 | 7751.77 b ± 271.76 | 6247.99 a ± 267.74 | 0.005 |

| PUFA | 732.47 ± 49.24 | 1981.82 ± 271.09 | 1999.80 ± 146.07 | 2338.65 ± 157.68 | 2617.71 ± 132.80 | 2405.14 ± 173.66 | 0.052 |

| n6 | 34.46 ± 6.26 | 1941.42 ± 252.30 | 1920.86 ± 234.40 | 2197.81 ± 151.51 | 2405.79 ± 110.82 | 2194.85 ± 125.46 | 0.810 |

| n3 | 702.56 ± 26.76 | 137.34 a ± 53.32 | 156.57 a ± 19.57 | 201.34 a,b ± 10.79 | 278.17 b ± 19.45 | 257.02 b ± 10.92 | 0.001 |

| P/S | 0.67 ± 0.05 | 0.55 a ± 0.02 | 0.81 b ± 0.01 | 0.93 b ± 0.14 | 1.03 b,c ± 0.08 | 1.25 c ± 0.21 | 0.000 |

| n6/n3 | 29.08 ± 2.39 | 13.81 c ± 0.78 | 12.27 c ± 0.04 | 10.90 b ± 0.92 | 8.65 a ± 0.58 | 8.55 a ± 0.16 | 0.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez-Fernández, M.; Revilla, I.; Rodrigo, P.; López-Calabozo, R.; Vivar-Quintana, A.M. Wheat Germ as Partial or Total Substitutive of Lean Meat in Low-Fat Cooked Sausages. Foods 2025, 14, 178. https://doi.org/10.3390/foods14020178

Rodríguez-Fernández M, Revilla I, Rodrigo P, López-Calabozo R, Vivar-Quintana AM. Wheat Germ as Partial or Total Substitutive of Lean Meat in Low-Fat Cooked Sausages. Foods. 2025; 14(2):178. https://doi.org/10.3390/foods14020178

Chicago/Turabian StyleRodríguez-Fernández, Marta, Isabel Revilla, Pablo Rodrigo, Rocío López-Calabozo, and Ana María Vivar-Quintana. 2025. "Wheat Germ as Partial or Total Substitutive of Lean Meat in Low-Fat Cooked Sausages" Foods 14, no. 2: 178. https://doi.org/10.3390/foods14020178

APA StyleRodríguez-Fernández, M., Revilla, I., Rodrigo, P., López-Calabozo, R., & Vivar-Quintana, A. M. (2025). Wheat Germ as Partial or Total Substitutive of Lean Meat in Low-Fat Cooked Sausages. Foods, 14(2), 178. https://doi.org/10.3390/foods14020178