Potential Impact of Oat Ingredient Type on Oral Fragmentation of Biscuits and Oro-Digestibility of Starch—An In Vitro Approach

Abstract

:1. Introduction

2. Materials and Methods

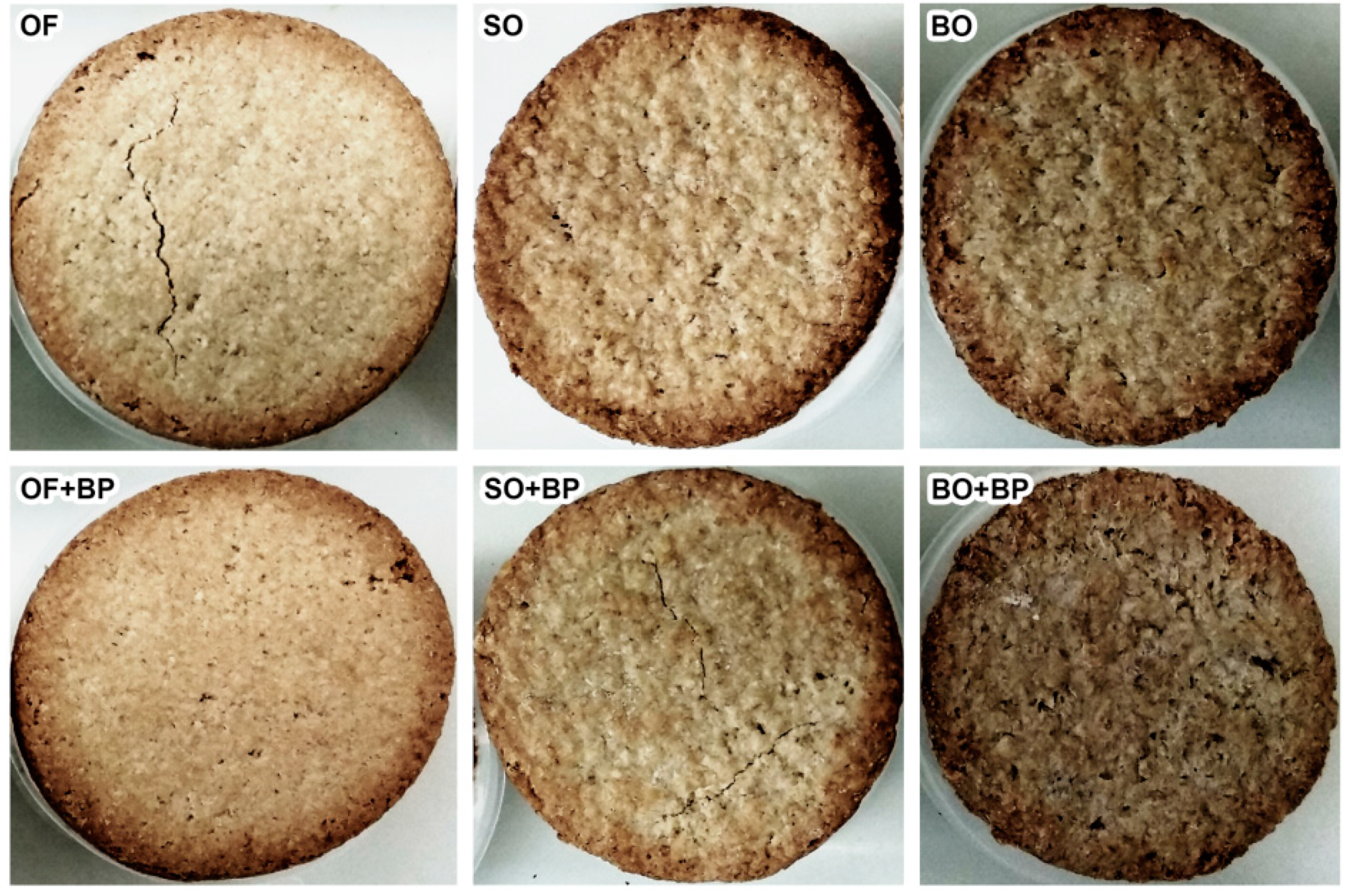

2.1. Samples

2.2. Instrumental Texture of Samples

2.3. In Vitro Fragmentation

2.4. In Vitro Starch Oro-Digestion

2.5. Statistical Data Analysis

3. Results

3.1. Instrumental Texture of Oat Biscuits

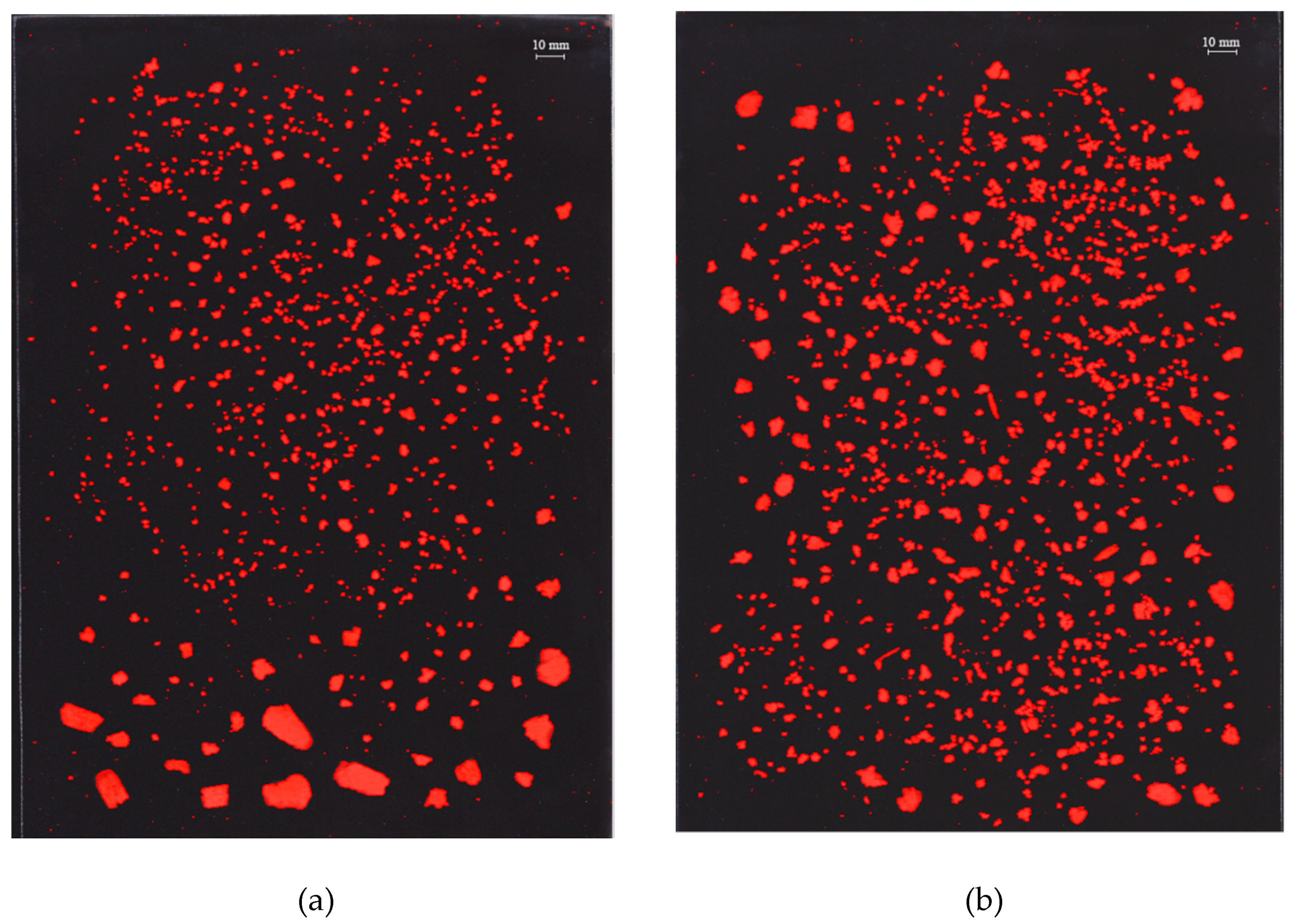

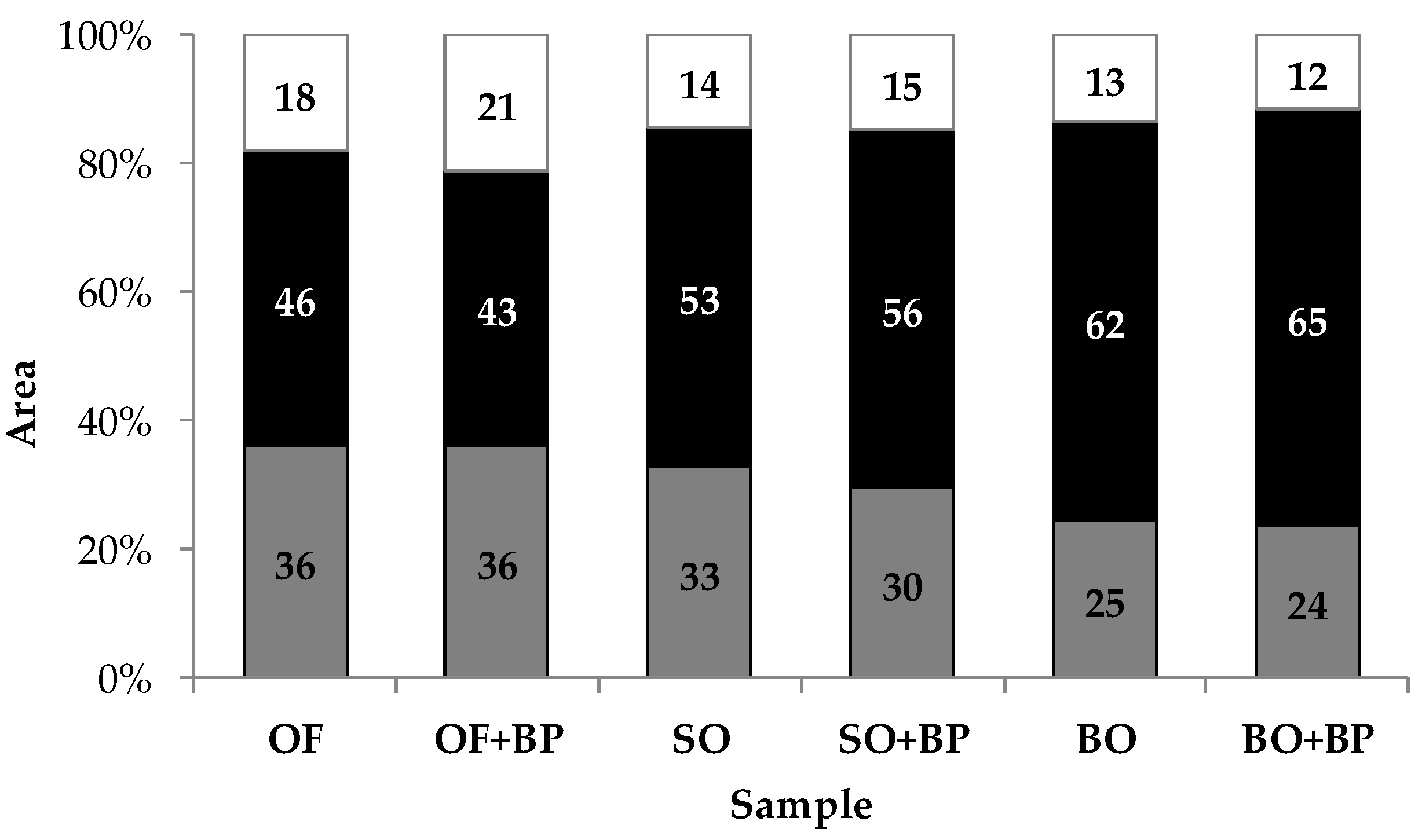

3.2. Particle Size Pattern

3.3. In Vitro Starch Hydrolysis

4. Discussion

4.1. Instrumental Texture of Biscuits

4.2. Particle Size Pattern

4.3. In Vitro Starch Oral Hydrolysis

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Koç, H.; Vinyard, C.J.; Essick, G.K.; Foegeding, E.A. Food oral processing: Conversion of food structure to textural perception. Annu. Rev. Food Sci. Technol. 2013, 4, 237–266. [Google Scholar] [CrossRef]

- Young, A.K.; Cheong, J.N.; Foster, K.D.; Hedderley, D.I.; Morgenstern, M.P.; James, B.J. Exploring the links between texture perception and bolus properties throughout oral processing. Part 2: Bolus mechanical and rheological properties. J. Text. Stud. 2016, 47, 474–483. [Google Scholar] [CrossRef]

- Feron, G.; Salles, C. Food oral processing in humans: Links between physiological parameters, release of flavour stimuli and flavour perception of food. Int. J. Food Stud. 2018, 7, 1–12. [Google Scholar]

- Gao, J.; Wang, Y.; Dong, Z.; Zhou, W. Structural and mechanical characteristics of bread and their impact on oral processing: A review. Int. J. Food Sci. Technol. 2018, 53, 858–872. [Google Scholar] [CrossRef]

- Hoebler, C.; Devaux, M.-F.; Karinthi, A.; Belleville, C.; Barry, J.-L. Particle size of solid food after human mastication and in vitro simulation of oral breakdown. Int. J. Food Sci. Nutr. 2000, 51, 353–366. [Google Scholar] [CrossRef] [PubMed]

- Mishra, S.; Hardacre, A.; Monro, J. Food structure and carbohydrate digestibility. In Carbohydrates—Comprehensive Studies on Glycobiology and Glycotechnology; Chang, C.-F., Ed.; InTech: Rijeka, Croatia, 2012; pp. 289–316. [Google Scholar]

- Hutchings, J.B.; Lillford, P.J. The Perception of Food Texture—The Philosophy of the Breakdown Path. J. Tex. Stud. 1988, 19, 103–115. [Google Scholar] [CrossRef]

- Hoebler, C.; Karinthi, A.; Devaux, M.-F.; Guillon, F.; Gallant, D.J.G.; Bouchet, B.; Melegary, C.; Barry, J.-L. Physical and chemical transformations of cereal food during oral digestion in human subjects. Br. J. Nutr. 1998, 80, 429–436. [Google Scholar] [CrossRef]

- Freitas, D.; Le Feunteun, S.; Panouillé, M.; Souchon, I. The important role of salivary α-amylase in the gastric digestion of wheat bread starch. Food Funct. 2018, 9, 200–208. [Google Scholar] [CrossRef]

- Foschia, M.; Peressini, D.; Sensidoni, A.; Brennan, M.A.; Brennan, C.S. Mastication or masceration: Does the preparation of sample affect the predictive in vitro glycemic response of pasta? Starch 2014, 66, 1096–1102. [Google Scholar] [CrossRef]

- Devezeaux de Lavergne, M.; van de Velde, F.; Stieger, M. Bolus matters: The influence of food oral breakdown on dynamic texture perception. Food Funct. 2017, 8, 464–480. [Google Scholar] [CrossRef]

- Panouillé, M.; Saint-Eve, A.; Souchon, I. Instrumental methods for bolus characterization during oral processing to understand food perceptions. Curr. Opin. Food Sci. 2016, 9, 42–49. [Google Scholar] [CrossRef]

- Peyron, M.A.; Mishellany, A.; Woda, A. Particle size distribution of food boluses after mastication of six natural foods. J. Dent. Res. 2004, 83, 578–582. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Wong, J.X.; Lim, J.C.S.; Henry, J.; Zhou, W. Influence of bread structure on human oral processing. J. Food Eng. 2015, 167, 147–155. [Google Scholar] [CrossRef]

- Tournier, C.; Devezeaux de Lavergne, M.; van de Velde, F.; Stieger, M.; Salles, C.; Bertrand, D. Investigation of oral gels breakdown using image analysis. Food Hydrocoll. 2017, 63, 67–76. [Google Scholar] [CrossRef]

- Chen, J.; Khandelwal, N.; Liu, Z.; Funami, T. Influences of food hardness on the particle size distribution of food boluses. Arch. Oral Biol. 2013, 58, 293–298. [Google Scholar] [CrossRef] [PubMed]

- Engelen, L.; Fontijn-Tekamp, A.; van der Bilt, A. The influence of product and oral characteristics on swallowing. Arch. Oral Biol. 2005, 50, 739–746. [Google Scholar] [CrossRef]

- Jalabert-Malbos, M.L.; Mishellany-Dutour, A.; Woda, A.; Peyron, M.A. Particle size distribution in the food bolus after mastication of natural foods. Food Qual. Pref. 2007, 18, 803–812. [Google Scholar] [CrossRef]

- Alam, S.A.; Pentikäinen, S.; Närväinen, J.; Holopainen-Mantila, U.; Poutanen, K.; Sozer, N. Effects of structural and mechanical textural properties of brittle cereal foams on mechanisms of oral breakdown. Food Res. Int. 2017, 96, 1–11. [Google Scholar] [CrossRef]

- Rodrigues, S.A.; Young, A.K.; James, B.J.; Morgenstern, M.P. Structural changes within a biscuit bolus during mastication. J. Tex. Stud. 2014, 45, 89–96. [Google Scholar] [CrossRef]

- Agrawal, K.R.; Lucas, P.W.; Prinz, J.F.; Bruce, I.C. Mechanical properties of foods responsible for resisting food breakdown in the human mouth. Arch. Oral Biol. 1997, 42, 1–9. [Google Scholar] [CrossRef]

- Fiszman, S.; Tarrega, A. The dynamics of texture perception of hard solid food: A review of the contribution of the temporal dominance of sensations technique. J. Tex. Stud. 2018, 49, 202–212. [Google Scholar] [CrossRef]

- Chen, J. Food oral processing: Mechanisms and implications of food oral destruction. Trends Food Sci. Technol. 2015, 45, 222–228. [Google Scholar] [CrossRef]

- Ferry, A.L.S.; Mitchell, J.R.; Hort, J.; Hill, S.E.; Taylor, A.J.; Lagarrigue, S.; Vallès-Pàmies, B. In-mouth amylase activity can reduce perception of saltiness in starch-thickened foods. J. Agric. Food Chem. 2006, 54, 8869–8873. [Google Scholar] [CrossRef]

- Read, N.W.; Welch, L.; Austen, C.J.; Barnish, C.; Bartlett, C.E.; Baxter, A.J.; Brown, G.; Compton, M.E.; Hume, K.E.; Storie, I.; Worlding, J. Swallowing food without chewing; a simple way to reduce postprandial glycaemia. Br. J. Nutr. 1986, 55, 43–47. [Google Scholar] [CrossRef] [Green Version]

- Nordlund, E.; Katina, K.; Mykkänen, H.; Poutanen, K. Distinct characteristics of rye and wheat breads impact on their in vitro gastric disintegration and in vivo glucose and insulin responses. Foods 2016, 5, 24. [Google Scholar] [CrossRef]

- Gao, J.; Lin, S.; Jin, X.; Wang, Y.; Ying, J.; Dong, Z.; Zhou, W. In vitro digestion of bread: How is it influenced by the bolus characteristics? J. Text. Stud. in press. [CrossRef]

- Chen, J.S.; Karlsson, C.; Povey, M. Acoustic envelope detector for crispness assessment of biscuits. J. Text. Stud. 2005, 36, 139–156. [Google Scholar] [CrossRef]

- Mishellany-Dutour, A.; Peyron, M.-A.; Croze, J.; François, O.; Hartmann, C.; Alric, M.; Woda, A. Comparison of food boluses prepared in vivo and by the AM2 mastication simulator. Food Qual. Pref. 2011, 22, 326–331. [Google Scholar] [CrossRef]

- Jourdren, S.; Panouillé, M.; Saint-Eve, A.; Déléris, I.; Forest, D.; Lejeune, P.; Souchon, I. Breakdown pathways during oral processing of different breads: Impact of crumb and crust structures. Food Funct. 2016, 7, 1446–1457. [Google Scholar] [CrossRef]

- Sozer, N.; Cicerelli, L.; Heinio, R.-L.; Poutanen, K. Effect of wheat bran addition on in vitro starch digestibility, physico-mechanical and sensory properties of biscuits. J. Cereal Sci. 2014, 60, 105–113. [Google Scholar] [CrossRef]

- Marzec, A.; Ziółkowski, T. Structure analysis of selected cereal products in the aspect of their acoustic properties. Pol. J. Food Nutr. Sci. 2007, 57, 89–93. [Google Scholar]

- Varela, P.; Aguilera, J.M.; Fiszman, S. Quantification of fracture properties and microstructural features of roasted Marcona almonds by image analysis. LWT-Food Sci. Technol. 2008, 41, 10–17. [Google Scholar] [CrossRef] [Green Version]

- Varela, P.; Salvador, A.; Fiszman, S. On the assessment of fracture in brittle foods: The case of roasted almonds. Food Res. Int. 2008, 41, 544–551. [Google Scholar] [CrossRef]

- Chauvin, M.A.; Younce, F.; Ross, C.; Swanson, B. Standard scales for crispness, crackliness and crunchiness in dry and wet foods: Relationship with acoustical determinations. J. Text. Stud. 2008, 39, 345–368. [Google Scholar] [CrossRef]

- Alam, S.A.; Pentikäinen, S.; Närväinen, J.; Katina, K.; Poutanen, K.; Sozer, N. The effect of structure and texture on the breakdown pattern during mastication and impacts on in vitro starch digestibility of high fibre rye extrudates. Food Funct. 2019, in press. [Google Scholar] [CrossRef] [PubMed]

- Pentikainen, S.; Sozer, N.; Narvainen, J.; Ylatalo, S.; Teppola, P.; Jurvelin, J.; Holopainen-Mantila, U.; Torronen, R.; Aura, A.M.; Poutanen, K. Effects of wheat and rye bread structure on mastication process and bolus properties. Food Res. Int. 2014, 66, 356–364. [Google Scholar] [CrossRef]

- Assad-Bustillos, M.; Tournier, C.; Feron, G. Fragmentation of two soft cereal products during oral processing in the elderly: Impact of product properties and oral health status. Food Hydrocoll. 2019, 91, 153–165. [Google Scholar] [CrossRef]

- Lapis, T.J.; Penner, M.H.; Balto, A.S.; Lim, J. Oral digestion and perception of starch: Effects of cooking, tasting time, and salivary α-amylase activity. Chem. Senses 2017, 42, 635–645. [Google Scholar] [CrossRef]

- Tamura, M.; Okazaki, Y.; Kumagai, C.; Ogawa, Y. The importance of an oral digestion step in evaluating simulated in vitro digestibility of starch from cooked rice grain. Food Res. Int. 2017, 94, 6–12. [Google Scholar] [CrossRef]

- Nantanga, K.K.M.; Bertoft, E.; Seetharaman, K. Structures of human salivary amylase hydrolysates from starch processed at two water concentrations. Starch 2013, 65, 637–644. [Google Scholar] [CrossRef]

| Sample 1 | MF (N) | SMF (N/s) | NSP (>8 dB) | NSP (>12 dB) |

|---|---|---|---|---|

| OF | 9.6 ± 1.5 a,b | 7.1 ± 0.5 a | 12 ± 3 a | 1 ± 1 a |

| OF+BP | 11.3 ± 2.0 a | 7.6 ± 1.2 a | 24 ± 8 b | 6 ± 4 b |

| SO | 9.9 ± 0.8 a,b | 6.3 ± 0.9 a,b | 28 ± 3 b,c | 5 ± 3 b |

| SO+BP | 8.3 ± 0.8 b,c | 6.4 ± 0.9 a | 26 ± 6 b,c | 7 ± 2 b,c |

| BO | 6.8 ± 2.6 c | 4.9 ± 1.5 b,c | 34 ± 11 c,d | 10 ± 4 c,d |

| BO+BP | 6.3 ± 2.0 c | 4.1 ± 1.1 c | 41 ± 7 d | 13 ± 2 d |

| Sample 1 | a25 (mm2) | a50 (mm2) | a75 (mm2)a | a75/a25 |

|---|---|---|---|---|

| OF | 3.5 ± 0.7 a | 9.4 ± 2.8 a | 29.1 ± 7.5 a | 8.2 ± 0.6 a,b |

| OF+BP | 3.3 ± 0.1 a | 8.9 ± 1.5 a | 33.6 ± 6.3 a | 10.2 ± 1.8 a |

| SO | 3.8 ± 0.3 a,b | 9.2 ± 0.4 a | 23.2 ± 2.5 a | 6.1 ± 0.2 b |

| SO+BP | 4.1 ± 0.1 a,b | 10.0 ± 1.1 a | 22.8 ± 0.6 a | 5.5 ± 0.2 b |

| BO | 5.0 ± 0.6 b,c | 10.8 ± 1.4 a | 25.9 ± 2.7 a | 5.2 ± 0.1 b |

| BO+BP | 5.4 ± 0.8 c | 12.1 ± 2.5 a | 22.9 ± 0.9 a | 4.3 ± 0.5 b |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gamero, A.; Nguyen, Q.C.; Varela, P.; Fiszman, S.; Tarrega, A.; Rizo, A. Potential Impact of Oat Ingredient Type on Oral Fragmentation of Biscuits and Oro-Digestibility of Starch—An In Vitro Approach. Foods 2019, 8, 148. https://doi.org/10.3390/foods8050148

Gamero A, Nguyen QC, Varela P, Fiszman S, Tarrega A, Rizo A. Potential Impact of Oat Ingredient Type on Oral Fragmentation of Biscuits and Oro-Digestibility of Starch—An In Vitro Approach. Foods. 2019; 8(5):148. https://doi.org/10.3390/foods8050148

Chicago/Turabian StyleGamero, Amparo, Quoc Cuong Nguyen, Paula Varela, Susana Fiszman, Amparo Tarrega, and Arantxa Rizo. 2019. "Potential Impact of Oat Ingredient Type on Oral Fragmentation of Biscuits and Oro-Digestibility of Starch—An In Vitro Approach" Foods 8, no. 5: 148. https://doi.org/10.3390/foods8050148

APA StyleGamero, A., Nguyen, Q. C., Varela, P., Fiszman, S., Tarrega, A., & Rizo, A. (2019). Potential Impact of Oat Ingredient Type on Oral Fragmentation of Biscuits and Oro-Digestibility of Starch—An In Vitro Approach. Foods, 8(5), 148. https://doi.org/10.3390/foods8050148