High Fibre Gluten-Free Fresh Pasta with Tiger Nut, Chickpea and Fenugreek: Technofunctional, Sensory and Nutritional Properties

Abstract

1. Introduction

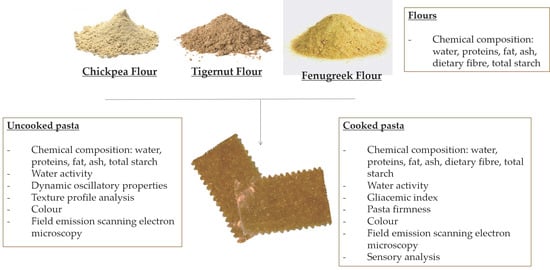

2. Materials and Methods

2.1. Materials

2.2. Pasta Preparation and Experimental Design

2.3. Pasta Cooking

2.4. Chemical Composition of Raw Materials and Uncooked and Cooked Pasta

2.5. Water Activity of Uncooked and Cooked Pasta

2.6. Glycaemic Index—In Vitro Starch Digestibility of Cooked Pasta

2.7. Rheological Properties of Dough and Pasta: Fundamental and Empirical Properties

2.7.1. Dynamic Oscillatory Properties

2.7.2. Empirical Rheological Tests: TPA and Firmness

2.8. Colour of Pasta

2.9. Cooking Properties

2.10. Field Emission Scanning Electron Microscopy

2.11. Sensory Analysis

2.12. Statistical Analysis

3. Results and Discussion

3.1. Chemical Composition and Water Activity (aw)

3.2. In Vitro Digestion of the Cooked Pasta

3.3. Rheological Properties of Dough and Cooked Pasta

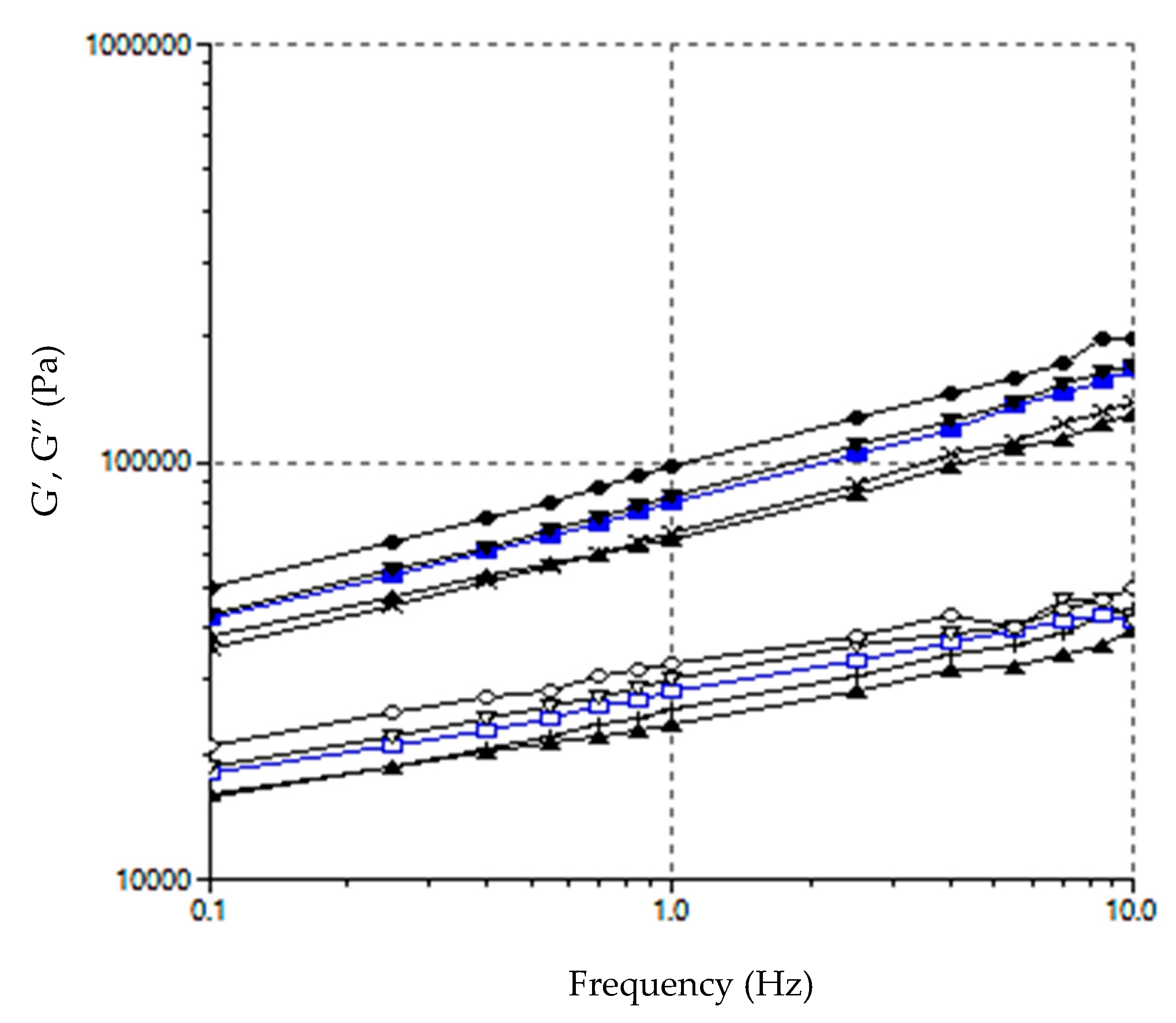

Dynamic Oscillatory Properties

3.4. Colour of the Uncooked and Cooked Pastas

3.5. Cooking Properties

3.6. Sensory Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lamacchia, C.; Camarca, A.; Picascia, S.; Di Luccia, A.; Gianfrani, C. Cereal-based gluten-free food: How to reconcile nutritional and technological properties of wheat proteins with safety for celiac disease patients. Nutrients 2014, 6, 575–590. [Google Scholar] [CrossRef] [PubMed]

- Capriles, V.D.; dos Santos, F.G.; Arêas, J.A.G. Gluten-free breadmaking: Improving nutritional and bioactive compounds. J. Cereal Sci. 2016, 67, 83–91. [Google Scholar] [CrossRef]

- Hager, A.S.; Wolter, A.; Czerny, M.; Bez, J.; Zannini, E.; Arendt, E.K.; Czerny, M. Investigation of product quality, sensory profile and ultrastructure of breads made from a range of commercial gluten-free flours compared to their wheat counterparts. Eur. Food Res. Technol. 2012, 235, 333–344. [Google Scholar] [CrossRef]

- Miranda, J.; Lasa, A.; Bustamante, M.A.; Churruca, I.; Simon, E. Nutritional Differences Between a Gluten-free Diet and a Diet Containing Equivalent Products with Gluten. Plant Foods Hum. Nutr. 2014, 69, 182–187. [Google Scholar] [CrossRef]

- Giuberti, G.; Gallo, A.; Cerioli, C.; Fortunati, P.; Masoero, F. Cooking quality and starch digestibility of gluten free pasta using new bean flour. Food Chem. 2015, 175, 43–49. [Google Scholar] [CrossRef]

- Berti, C.; Riso, P.; Monti, L.D.; Porrini, M. In vitro starch digestibility and in vivo glucose response of gluten-free foods and their gluten counterparts. Eur. J. Nutr. 2004, 43, 198–204. [Google Scholar] [CrossRef]

- Akirov, A.; Pinhas-Hamiel, O. Co-occurrence of type 1 diabetes mellitus and celiac disease. World J. Diabetes 2015, 6, 707–714. [Google Scholar] [CrossRef]

- Brennan, C.S.; Tudorica, C.M. Evaluation of potential mechanisms by which dietary fibre additions reduce the predicted glycaemic index of fresh pastas. Int. J. Food Sci. Technol. 2008, 43, 2151–2162. [Google Scholar] [CrossRef]

- Wójtowicz, A.; Mościcki, L. Influence of legume type and addition level on quality characteristics, texture and microstructure of enriched precooked pasta. LWT Food Sci. Technol. 2014, 59, 1175–1185. [Google Scholar] [CrossRef]

- Jukanti, A.K.; Gaur, P.M.; Gowda, C.L.L.; Chibbar, R.N. Nutritional quality and health benefits of chickpeas (Cicer arietinum L.): A review. Br. J. Nutr. 2012, 108, 11–26. [Google Scholar] [CrossRef]

- Turco, I.; Bacchetti, T.; Morresi, C.; Padalinoc, L.; Ferretti, G. Polyphenols and the glycaemic index of legume pasta. Food Funct. 2019, 10, 5931–5938. [Google Scholar] [CrossRef] [PubMed]

- Basch, E.; Ulbricht, C.; Kuo, G.; Szapary, P.; Smith, M. Therapeutic applications of fenugreek. Altern. Med. Rev. 2003, 8, 20–27. [Google Scholar] [PubMed]

- Jyotsna, R.; Indrani, D.; Sai Manohar, R.; Venkateswara Rao, G. Effect of fenugreek (Trigonella foenum graecum L.) on the textural characteristics and microstructure of vermicelli from triticum durum wheat semolina. J. Food Process. Preserv. 2011, 35, 320–326. [Google Scholar] [CrossRef]

- Shirani, G.; Ganesharanee, R. Extruded products with Fenugreek (Trigonella foenum-graecium) chickpea and rice: Physical properties, sensory acceptability and glycaemic index. J. Food Eng. 2009, 90, 44–52. [Google Scholar] [CrossRef]

- Sharma, H.R.; Chauchan, G.S. Effect of stabilized rice bran-fenugreek blends on the quality of breads and cookies. J. Food Sci. Technol. 2002, 39, 225–233. [Google Scholar]

- Sánchez-Zapata, E.; Fernández-López, J.; Angel Pérez-Alvarez, J. Tiger Nut (Cyperus esculentus) Commercialization: Health Aspects, Composition, Properties, and Food Applications. Compr. Rev. Food Sci. Food Saf. 2012, 11, 366–377. [Google Scholar] [CrossRef]

- Chinma, C.E.; Abu, J.O.; Abubakar, Y.A. Effect of tigernut (Cyperus esculentus) flour addition on the quality of wheat-based cake. Int. J. Food Sci. Technol. 2010, 45, 1746–1752. [Google Scholar] [CrossRef]

- Aguilar, N.; Albanell, E.; Miñarro, B.; Capellas, M. Chickpea and tiger nut flours as alternatives to emulsifier and shortening in gluten-free bread. LWT Food Sci. Technol. 2015, 62, 225–232. [Google Scholar] [CrossRef]

- AACC. Approved Methods of the American Association of Cereal Chemists, 10th ed.; American Association of Cereal Chemists: St. Paul, MN, USA, 2005. [Google Scholar]

- AOAC. AOAC. AOAC Official Method 996.11 Starch (Total) in Cereal Products. In Official Methods of Analysis of AOAC International (OMA); AOAC International: Gaithersburg, MD, USA, 2005. [Google Scholar]

- Englyst, K.N.; Vinoy, S.; Englyst, H.N.; Lang, V. Glycaemic index of cereal products explained by their content of rapidly and slowly available glucose. Br. J. Nutr. 2003, 89, 329–339. [Google Scholar] [CrossRef]

- Goñi, I.; Garcia-AIonso, A.; Saura-Calixto, F. A starch hydrolysis procedure to estimate glycemic index. Nutr. Res. 1997, 17, 427–437. [Google Scholar] [CrossRef]

- Mahasukhonthachat, K.; Sopade, P.A.; Gidley, M.J. Kinetics of starch digestion in sorghum as affected by particle size. J. Food Eng. 2010, 96, 18–28. [Google Scholar] [CrossRef]

- Granfeldt, Y.; Björck, I.; Drews, A.; Towar, J. An in vitro procedure based on chewing to predict metabolic responses to starch in cereal and legume products. Eur. J. Clin. Nutr. 1992, 46, 649–660. [Google Scholar] [CrossRef] [PubMed]

- Sreerama, Y.N.; Sashikala, V.B.; Pratape, V.M.; Singh, V. Nutrients and antinutrients in cowpea and horse gram flours in comparison to chickpea flour: Evaluation of their flour functionality. Food Chem. 2012, 131, 462–468. [Google Scholar] [CrossRef]

- Martín-Esparza, M.E.; Raigón, M.D.; Raga, A.; Albors, A. High fibre tiger nut pasta and xanthan gum: Cooking quality, microstructure, physico-chemical properties and consumer acceptance. Food Sci. Biotechnol. 2018, 27, 1075–1084. [Google Scholar] [CrossRef] [PubMed]

- Rajarajeswari, A.; Vijayalakshmi, P.; Sadiq, A.M. Influence of Trigonella Foenum Graecum (Fenugreek) in Alloxan Induced Diabetic Rats. Bioscan 2012, 7, 395–400. [Google Scholar]

- Mudgil, D.; Barak, S. Composition, properties and health benefits of indigestible carbohydrate polymers as dietary fiber: A review. Int. J. Biol. Macromol. 2013, 61, 1–6. [Google Scholar] [CrossRef]

- Regulation (EC) No. 1924/2006 of the European Parliament and of the Council of 20 December 2006 on nutrition and health claims made on foods. Off. J. Eur. Union 2006, L404, 9–25.

- Roberts, K.T.; Cui, S.W.; Wu, Y.; Williams, S.A.; Wang, C.; Graham, T. Physicochemical evaluation of fenugreek gum and extrusion modified fenugreek gum and effects on starch degradation in bread. Bioact. Carbohydr. Diet. Fibre 2014, 4, 176–183. [Google Scholar] [CrossRef]

- Neelakantan, N.; Narayanan, M.; De Souza, R.J.; Van Dam, R.M. Effect of fenugreek (Trigonella foenum-graecum L.) intake on glycemia: A meta-analysis of clinical trials. Nutr. J. 2014, 13, 7. [Google Scholar] [CrossRef]

- Guillon, F.; Champ, M. Structural and physical properties of dietary fibers, and consequences of processing on human physiology. Food Res. Int. 2000, 33, 233–245. [Google Scholar] [CrossRef]

- Hager, A.S.; Czerny, M.; Bez, J.; Zannini, E.; Arendt, E.K. Starch properties, invitro digestibility and sensory evaluation of fresh egg pasta produced from oat, teff and wheat flour. J. Cereal Sci. 2013, 58, 156–163. [Google Scholar] [CrossRef]

- Lu, X.; Brennan, M.A.; Serventi, L.; Liu, J.; Guan, W.; Brennan, C.S. Addition of mushroom powder to pasta enhances the antioxidant content and modulates the predictive glycaemic response of pasta. Food Chem. 2018, 264, 199–209. [Google Scholar] [CrossRef] [PubMed]

- Sozer, N. Rheological properties of rice pasta dough supplemented with proteins and gums. Food Hydrocoll. 2009, 23, 849–855. [Google Scholar] [CrossRef]

- Larrosa, V.; Lorenzo, G.; Zaritzky, N.; Califano, A. Optimization of rheological properties of gluten-free pasta dough using mixture design. J. Cereal Sci. 2013, 57, 520–526. [Google Scholar] [CrossRef]

- Georgopoulos, T.; Larsson, H.; Eliasson, A.C. A comparison of the rheological properties of wheat flour dough and its gluten prepared by ultracentrifugation. Food Hydrocoll. 2004, 18, 143–151. [Google Scholar] [CrossRef]

- Fiorda, F.A.; Soares, M.S.; da Silva, F.A.; Grosmann, M.V.E.; Souto, L.R.F. Microestructure, texture and colour of gluten-free pasta made with amaranth flour, cassava starch and cassava bagasse. LWT Food Sci. Technol. 2013, 54, 132–138. [Google Scholar] [CrossRef]

- Nowacka, M.; Tylewicz, U.; Tappi, S.; Siroli, L.; Lanciotti, R.; Romani, S.; Witrowa-Rajchert, D. Ultrasound assisted osmotic dehydration of organic cranberries (Vaccinium oxycoccus): Study on quality parameters evolution during storage. Food Control 2018, 93, 40–47. [Google Scholar] [CrossRef]

- Chauhan, G.S.; Sharma, H.R. Physico-chemical and rheological quality characteristics of fenugreek (Trigonella foenum graecum L.) supplemented wheat flour. J. Food Sci. Technol. 2000, 37, 87–90. [Google Scholar]

- Bouasla, A.; Wójtowicz, A.; Zidoune, M.N. Gluten-free precooked rice pasta enriched with legumes flours: Physical properties, texture, sensory attributes and microstructure. LWT Food Sci. Technol. 2017, 75, 569–577. [Google Scholar] [CrossRef]

- Laleg, K.; Cassan, D.; Barron, C.; Prabhasankar, P.; Micard, V. Structural, culinary, nutritional and anti-nutritional properties of high protein, gluten free, 100% legume pasta. PLoS ONE 2016, 11, 1–19. [Google Scholar] [CrossRef]

- Kaur, G.; Sharma, S.; Nagi, H.P.S.; Dar, B.N. Functional properties of pasta enriched with variable cereal brans. J. Food Sci. Technol. 2012, 49, 467–474. [Google Scholar] [CrossRef] [PubMed]

- Wani, S.A.; Kumar, P. Fenugreek enriched extruded product: Optimization of ingredients using response surface methodology. Int. Food Res. J. 2016, 23, 18–25. [Google Scholar]

| CPF | TNF | FF | |

|---|---|---|---|

| Water | 9.33 ± 0.01 c | 6.4 ± 0.2 a | 7.96 ± 0.08 b |

| Proteins | 23.70 ± 0.09 c | 3.7 ± 1.5 a | 20.7 ± 0.3 b |

| Fat | 4.31 ± 0.03 a | 21.44 ± 0.06 c | 5.31 ± 0.05 b |

| Ashes | 3.2984 ± 0.0007 b | 2.516 ± 0.004 a | 4.3685 ± 0.0004 c |

| Dietary Fibre | |||

| SDF | 6 ± 3 a | 3.5 ± 1.3 a | 25 ± 2 b |

| IDF | 23.9 ± 0.6 b | 16.6 ± 0.8 a | 23 ± 3 b |

| Total | 30 ± 3 a | 20 ± 2 a | 48 ± 5 b |

| Total starch | 33.6 ± 1.5 c | 18 ± 4 b | 0.4 ± 0.2 a |

| Before Cooking | |||||

|---|---|---|---|---|---|

| 0FF | 2.5FF | 5FF | 7.5FF | 10FF | |

| Water1 | 25.7 ± 0.2 a.A | 27.7 ± 0.5 c.A | 27.656 ± 0.101 c.A | 26.4 ± 0.2 b.A | 27.2 ± 0.3 c.A |

| Protein | 12.12 ± 0.06 a.A | 12.589 ± 0.012 b.A | 13.6 ± 0.2 c.A | 13.8 ± 0.2 c.A | 14.45 ± 0.19 d.A |

| Fat | 14.42 ± 0.07 d.A | 14.234 ± 0.113 c.A | 13.447 ± 0.014 b.A | 13.30 ± 0.04 b.A | 12.50 ± 0.03 a.A |

| Ash | 2.6571 ± 0.0003 a.A | 2.8366 ± 0.0008 ab.A | 2.7927 ± 0.0013 ab.A | 2.8849 ± 0.0008 b.A | 2.9134 ± 0.0004 b.A |

| Dietary Fibre | |||||

| SDF | 4.86 * | 5.55 * | 6.10 * | 6.54 * | 7.16 * |

| IDF | 20.76 * | 21.51 * | 21.66 * | 21.47 * | 21.87 * |

| Total | 25.61 * | 27.06 * | 27.76 * | 28.00 * | 29.02 * |

| Total starch | 29.3 ± 0.5 b.A | 28.5 ± 0.7 ab.A | 29 ± 2 ab.A | 27.7 ± 0.4 a.A | 27.9 ± 0.3 ab.A |

| After Cooking | |||||

| 0FF | 2.5FF | 5FF | 7.5FF | 10FF | |

| Water1 | 58 ± 2 a.B | 60.7 ± 0.5 b.B | 57.83 ± 1.09 a.B | 60.83 ± 1.12 b.B | 58.9 ± 1.3 ab.B |

| Proteins | 13.04 ± 0.02 b.B | 13.4 ± 0.2 c.B | 10.98 ± 0.14 a.B | 14.79 ± 0.13 d.B | 14.67 ± 0.03 d.A |

| Fat | 15.89 ± 0.04 c.B | 15.2 ± 0.4 b.A | 14.85 ± 0.04 b.B | 13.18 ± 0.02 a.A | 12.80 ± 0.04 a.B |

| Ashes | 2.419 ± 0.003 a.A | 2.464 ± 0.005 a.A | 2.242 ± 0.002 a.A | 2.614 ± 0.004 a.A | 2.680 ± 0.003 a.A |

| Fibre | |||||

| SDF | 3 ± 2 a | 3.5 ± 0.4 a | 4.2 ± 1.2 a | 4.3 ± 0.6 a | 4.9 ± 1.3 a |

| IDF | 19.2 ± 1.3 a | 20 ± 3 a | 22 ± 5 a | 24 ± 4 a | 22.4 ± 1.8 a |

| Total | 22.31 ± 3.69 a | 23 ± 3 a | 26 ± 6 a | 29 ± 4 a | 27.3 ± 0.6 a |

| Total starch | 32.6 ± 0.9 c.B | 30.6 ± 1.3 bc.B | 29 ± 2 ab.A | 28.4 ± 1.5 ab.A | 27.8 ± 1.7 a.A |

| Formulation | eGI |

|---|---|

| 0FF | 46.9 ± 0.9 c |

| 2.5FF | 44.6 ± 1.4 bc |

| 5FF | 46.56 ± 0.97 c |

| 7.5FF | 41.62 ± 1.12 b |

| 10FF | 36.3 ± 1.7 a |

| Formulation | G′ (Pa) | G″ (Pa) |

|---|---|---|

| 0FF | 64,736 ± 2155 c | 23,500 ± 170 c |

| 2.5FF | 66,908 ± 2739 c | 24,688 ± 1228 c |

| 5FF | 80,263 ± 1794 b | 27,430 ± 800 b |

| 7.5FF | 85,373 ± 5016 b | 30,110 ± 1432 a |

| 10FF | 105,236 ± 7217 a | 31,900 ± 809 a |

| Formulation | ||||

|---|---|---|---|---|

| K’ [Pa sn] | a | K″ [Pa sn] | b | |

| 0FF | 66,259 ± 2551 c | 0.279 ± 0.015 ab | 23,684 ± 301 d | 0.198 ± 0.015 ab |

| 2.5FF | 67,653 ± 3021 c | 0.279 ± 0.006 a | 24,570 ± 1310 d | 0.22 ± 0.01 a |

| 5FF | 81,638 ± 2119 b | 0.293 ± 0.008 ab | 27,145 ± 650 c | 0.192 ± 0.012 b |

| 7.5FF | 86,431 ± 4996 b | 0.2923 ± 0.0114 ab | 29,472 ± 1190 b | 0.193 ± 0.008 b |

| 10FF | 106,227 ± 7809 a | 0.27 ± 0.02 b | 31,504 ± 499 a | 0.156 ± 0.019 c |

| Formulation | Hardness (N) | Adhesiveness (N·s) | Resilience | Cohesiveness | Springiness | Firmness (N) | |

|---|---|---|---|---|---|---|---|

| UC | C | ||||||

| 0FF | 172 ± 14 a | −0.34 ± 0.09 b | 0.116 ± 0.014 a | 0.243 ± 0.019 a | 0.24 ± 0.02 a | 21 ± 3 a. A | 28 ± 4 a b. A |

| 2.5FF | 215 ± 30 b | −0.61 ± 0.17 a b | 0.14 ± 0.02 a b | 0.281 ± 0.007 b | 0.28 ± 0.04 a b | 25 ± 3 a. A | 25.3 ± 1.2 a. A |

| 5FF | 267 ± 7 c | −0.8 ± 0.3 a b | 0.154 ± 0.012 b c | 0.287 ± 0.009 b | 0.308 ± 0.008 b | 25 ± 3 a. A | 31.1 ± 0.7 b. B |

| 7.5FF | 279 ± 14 c | −1.1 ± 0.7 a | 0.15 ± 0.02 b c | 0.29 ± 0.03 b | 0.34 ± 0.03 b | 31.3 ± 0.8 b. B | 27 ± 2 a b. A |

| 10FF | 313 ± 10 d | −1.13 ± 0.17 a | 0.17 ± 0.02 c | 0.33 ± 0.02 c | 0.44 ± 0.09 c | 36.4 ± 1.9 c. B | 29 ± 3 a b. A |

| Formulation | L* | a* | b* | C*ab | h*ab | ∆E*1 | ∆E*2 | |

|---|---|---|---|---|---|---|---|---|

| UC | 0FF | 48.6 ± 0.2 b | 8.72 ± 0.02 c | 26.24 ± 0.11 d | 26.652 ± 0.102 d | 71.62 ± 0.08 c | - | - |

| 2.5FF | 48.2 ± 0.2 b | 8.83 ± 0.05 cd | 26.9 ± 0.2 d | 28.3 ± 0.2 d | 71.819 ± 0.109 c | 0.80 ± 0.12 a | - | |

| 5FF | 46.8 ± 0.2 a | 8.99 ± 0.12 cd | 26.48 ± 0.15 d | 27.96 ± 0.13 d | 71.2 ± 0.3 bc | 1.9 ± 0.5 ab | - | |

| 7.5FF | 46.3 ± 0.3 a | 9.47 ± 0.08 e | 26.7 ± 0.5 d | 28.3 ± 0.5 d | 70.4 ± 0.3 a | 2.5 ± 0.2 b | - | |

| 10FF | 46.3 ± 0.3 a | 9.2 ± 0.3 de | 26.1 ± 0.5 d | 27.7 ± 0.5 d | 70.6 ± 0.4 ab | 2.4 ± 0.4 b | - | |

| C | 0FF | 60.7 ± 0.2 f | 4.692 ± 0.017 ab | 20.0 ± 0.7 c | 20.6 ± 0.6 c | 76.8 ± 0.5 f | - | 14.86 |

| 2.5FF | 57.1 ± 0.9 e | 4.4 ± 0.4 a | 17.9 ± 1.4 a | 18.4 ± 1.4 a | 76.13 ± 0.14 de | 4.4 ± 0.6 b | 14.42 | |

| 5FF | 55.5 ± 0.6 d | 4.60 ± 0.09 ab | 17.9 ± 0.6 a | 18.5 ± 0.6 a | 75.6 ± 0.2 de | 5.7 ± 0.3 ab | 13.98 | |

| 7.5FF | 54.8 ± 1.4 cd | 4.8 ± 0.5 b | 18.8 ± 0.9 ab | 19.39 ± 1.05 ab | 75.6 ± 0.8 d | 6.13 ± 1.16 ab | 13.57 | |

| 10FF | 53.8 ± 1.2 c | 4.8 ± 0.2 b | 19.8 ± 0.3 bc | 20.3 ± 0.3 bc | 76.2 ± 0.5 ef | 6.89 ± 1.19 b | 11.78 |

| Formulation | WAI (g/g) | SI (cm3/cm3) | CL (%) |

|---|---|---|---|

| 0FF | 0.700 ± 0.018 ab | 0.33 ± 0.02 a | 7.3 ± 0.5 a |

| 2.5FF | 0.71 ± 0.05 bc | 0.5090 ± 0.1004 b | 6.7 ± 0.8 a |

| 5FF | 0.66 ± 0.04 a | 0.7 ± 0.2 bc | 6.252 ± 0.109 a |

| 7.5FF | 0.74 ± 0.03 bc | 0.75 ± 0.08 c | 6.36 ± 0.17 a |

| 10FF | 0.74 ± 0.04 c | 0.76 ± 0.15 c | 5.9 ± 0.6 a |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Llavata, B.; Albors, A.; Martin-Esparza, M.E. High Fibre Gluten-Free Fresh Pasta with Tiger Nut, Chickpea and Fenugreek: Technofunctional, Sensory and Nutritional Properties. Foods 2020, 9, 11. https://doi.org/10.3390/foods9010011

Llavata B, Albors A, Martin-Esparza ME. High Fibre Gluten-Free Fresh Pasta with Tiger Nut, Chickpea and Fenugreek: Technofunctional, Sensory and Nutritional Properties. Foods. 2020; 9(1):11. https://doi.org/10.3390/foods9010011

Chicago/Turabian StyleLlavata, Beatriz, Ana Albors, and M. Eugenia Martin-Esparza. 2020. "High Fibre Gluten-Free Fresh Pasta with Tiger Nut, Chickpea and Fenugreek: Technofunctional, Sensory and Nutritional Properties" Foods 9, no. 1: 11. https://doi.org/10.3390/foods9010011

APA StyleLlavata, B., Albors, A., & Martin-Esparza, M. E. (2020). High Fibre Gluten-Free Fresh Pasta with Tiger Nut, Chickpea and Fenugreek: Technofunctional, Sensory and Nutritional Properties. Foods, 9(1), 11. https://doi.org/10.3390/foods9010011