Effect of Innovative Food Processing Technologies on the Physicochemical and Nutritional Properties and Quality of Non-Dairy Plant-Based Beverages

Abstract

1. Introduction

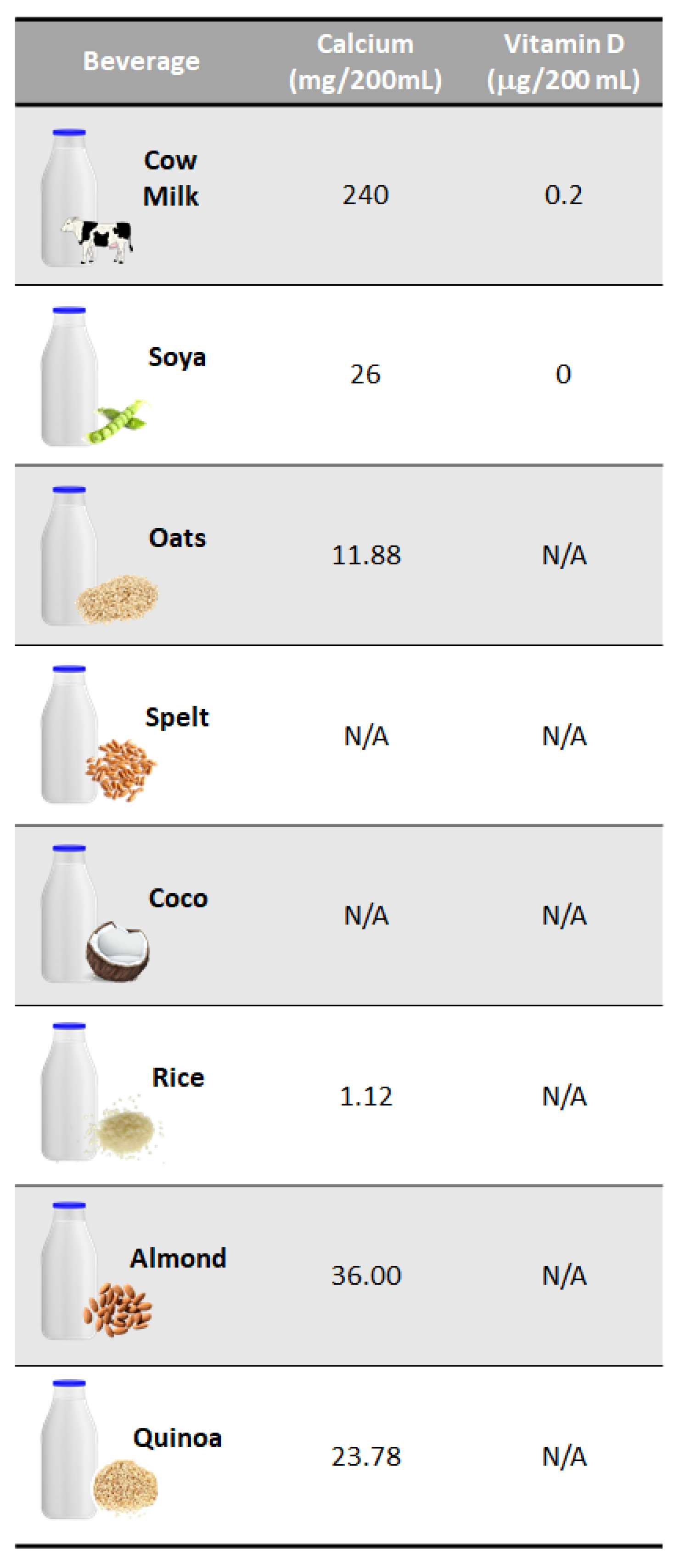

2. The Nutritional and Bioactive Composition of the Most Commonly Consumed Plant-Based Beverages

3. Application of Various Innovative Technologies for the Processing of Plant-Based Beverages

3.1. High-Hydrostatic-Pressure Processing

3.2. High-Pressure Homogenization

3.3. Other Innovative Processing Technologies

4. Effect of Innovative Processing Methods on Off-Flavor, Stability, and Shelf Life of Plant-Based Beverages

4.1. Removal and Prevention of Off-Flavor Generation

4.2. Improving Product Stability

4.3. Shelf Life Improvement

5. Challenges and Recommendations for Future Studies

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Markets and Markets Dairy Alternative (Milk) Market by Type (Soy, Almond, Rice), Formulation (Plain, Flavored, Sweetened, Unsweetened), Channel (Supermarket, Health Store, Pharmacy, Convenience Store) & Geography—Global Trends & Forecast to 2018. Available online: https://www.marketsandmarkets.com/Market-Reports/dairy-alternative-plant-milk-beverages-market-677.html (accessed on 3 March 2020).

- Silva, A.R.A.; Silva, M.M.N.; Ribeiro, B.D. Health issues and technological aspects of plant-based alternative milk. Food Res. Int. 2020, 131, 108972. [Google Scholar] [CrossRef]

- Research and Markets Global Dairy Products Market Report 2019, Forecast to 2025-Growing DEMAND for dairy Alternatives Hampering Growth. Available online: https://markets.businessinsider.com/news/stocks/global-dairy-products-market-report-2019-forecast-to-2025-growing-demand-for-dairy-alternatives-hampering-growth-1028592785 (accessed on 3 March 2020).

- Research and Markets $35+ Billion Dairy Alternatives Market & Consumption Report, 2020–2026; Research and Markeds: Dublin, Ireland, 2020.

- Sethi, S.; Rahul, S.K.T.; Anurag, R.K. Plant-based milk alternatives an emerging segment of functional beverages: A review. J. Food Sci. Technol. 2016, 53, 3408–3423. [Google Scholar] [CrossRef]

- Barba, F.J.; Carbonell-Capella, J.M.; Esteve, M.J.; Frígola, A. Automating a 96-well microtiter plate assay for quick analysis of chemically available lysine in foods. Food Anal. Methods 2013, 6, 1258–1264. [Google Scholar] [CrossRef]

- Roselló-Soto, E.; Poojary, M.M.; Barba, F.J.; Koubaa, M.; Lorenzo, J.M.; Mañes, J.; Moltó, J.C. Thermal and non-thermal preservation techniques of tiger nuts’ beverage “horchata de chufa”. Implications for food safety, nutritional and quality properties. Food Res. Int. 2018, 105, 945–951. [Google Scholar] [CrossRef]

- Welch, R.W. Oats in human nutrition and health. In The Oat Crop-Production and Utilization; Welch, R.W., Ed.; Springer: Dordrecht, The Netherlands, 1995; pp. 443–479. [Google Scholar]

- Pineli, L.L.O.; Botelho, R.B.A.; Zandonadi, R.P.; Solorzano, J.L.; de Oliveira, G.T.; Reis, C.E.G.; Teixeira, D.S. Low glycemic index and increased protein content in a novel quinoa milk. LWT-Food Sci. Technol. 2015, 63, 1261–1267. [Google Scholar] [CrossRef]

- Omoni, A.O.; Aluko, R.E. Soybean foods and their benefits: Potential mechanisms of action. Nutr. Rev. 2005, 63, 272–283. [Google Scholar] [CrossRef]

- Namiki, M. Nutraceutical functions of sesame: A review. Crit. Rev. FoodScience Nutr. 2007, 47, 651–673. [Google Scholar] [CrossRef]

- Shahidi, F.; Ambigaipalan, P. Omega-3 polyunsaturated fatty acids and their health benefits. Annu. Rev. Food Sci. Technol. 2018, 9, 345–381. [Google Scholar] [CrossRef]

- Kumar, V.; Sinha, A.K.; Makkar, H.P.S.; Becker, K. Dietary roles of phytate and phytase in human nutrition: A review. Food Chem. 2010, 120, 945–959. [Google Scholar] [CrossRef]

- Dhakal, S.; Liu, C.; Zhang, Y.; Roux, K.H.; Sathe, S.K.; Balasubramaniam, V.M. Effect of high pressure processing on the immunoreactivity of almond milk. Food Res. Int. 2014, 62, 215–222. [Google Scholar] [CrossRef]

- USDA. USDA Nutrient Database for Standard Reference, Release; USDA: Washington, DC, USA, 2019.

- Truswell, A.S. Cereal grains and coronary heart disease. Eur. J. Clin. Nutr. 2006, 56, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Deswal, A.; Deora, N.S.; Mishra, H.N. Optimization of enzymatic production process of oat milk using response surface methodology. Food Bioprocess Technol. 2014, 7, 610–618. [Google Scholar] [CrossRef]

- Biswas, S.; Sircar, D.; Mitra, A.; De, B. Phenolic constituents and antioxidant properties of some varieties of Indian rice. Nutr. Food Sci. 2013, 41, 123–135. [Google Scholar] [CrossRef]

- Faccin, G.L.; Vieira, N.; Miotto, L.A.; Barreto, P.L.M.; Amante, E.R. Chemical, sensorial and rheological properties of a new organic rice bran beverage. Rice Sci. 2009, 16, 226–234. [Google Scholar] [CrossRef]

- Mitchell, C.R.; Mitchell, P.R.; Nissenbaum, R. Nutritional Rice Milk Production. U.S. Patent 4744992, 1988. [Google Scholar]

- Seow, C.C.; Gwee, C.N. Review coconut milk: Chemistry and technology. Int. J. Food Sci. Technol. 1997, 32, 189–201. [Google Scholar] [CrossRef]

- Bernat, N.; Cháfer, M.; Rodríguez-García, J.; Chiralt, A.; González-Martínez, C. Effect of high pressure homogenisation and heat treatment on physical properties and stability of almond and hazelnut milks. LWT-Food Sci. Technol. 2015, 62, 488–496. [Google Scholar] [CrossRef]

- Sousa, A.; Bolanz, K.A.K. Nutritional implications of an increasing consumption of non-dairy plant-based beverages instead of cow’s milk in Switzerland. Adv. Dairy Res. 2017, 5. [Google Scholar] [CrossRef]

- Soxhlet, F. Supposed conversion of starch into sugar by water at a high temperature. J. Chem. Soc. Abstr. 1881, 42, 554–557. [Google Scholar]

- Balasubramaniam, V.M.; Martínez-Monteagudo, S.I.; Gupta, R. Principles and application of high pressure–based technologies in the food industry. Annu. Rev. Food Sci. Technol. 2015, 6, 435–462. [Google Scholar] [CrossRef]

- Dhakal, S.; Giusti, M.M.; Balasubramaniam, V.M. Effect of high pressure processing on dispersive and aggregative properties of almond milk. J. Sci. Food Agric. 2016, 3821–3830. [Google Scholar] [CrossRef]

- Manassero, C.A.; Vaudagna, S.R.; Sancho, A.M.; Añón, M.C.; Speroni, F. Combined high hydrostatic pressure and thermal treatments fully inactivate trypsin inhibitors and lipoxygenase and improve protein solubility and physical stability of calcium-added soymilk. Innov. Food Sci. Emerg. Technol. 2016, 35, 86–95. [Google Scholar] [CrossRef]

- Valencia-Flores, D.C.; Hern, M.; Guamis, B.; Ferragut, V. Comparing the effects of ultra-high-pressure homogenization and conventional thermal treatments on the microbiological, physical, and chemical quality of almond beverages. J. Food Sci. 2013, 78, 199–205. [Google Scholar] [CrossRef]

- Cruz, N.; Capellas, M.; Hernández, M.; Trujillo, A.J.; Guamis, B.; Ferragut, V. Ultra high pressure homogenization of soymilk: Microbiological, physicochemical and microstructural characteristics. Food Res. Int. 2007, 40, 725–732. [Google Scholar] [CrossRef]

- Briviba, K.; Gräf, V.; Walz, E.; Guamis, B.; Butz, P. Ultra high pressure homogenization of almond milk: Physico-chemical and physiological effects. Food Chem. 2016, 192, 82–89. [Google Scholar] [CrossRef]

- Cruz, N.; Capellas, M.; Jaramillo, D.P.; Trujillo, A.J.; Guamis, B.; Ferragut, V. Soymilk treated by ultra high-pressure homogenization: Acid coagulation properties and characteristics of a soy-yogurt product. Food Hydrocoll. 2009, 23, 490–496. [Google Scholar] [CrossRef]

- Ferragut, V.; Hernandez-Herrero, M.; Veciana-Nogues, M.T.; Borras-Suarez, M.; Gonzalez-Linares, J.; Vidal-Carou, M.C.; Guamis, B. Ultra-high-pressure homogenization (UHPH) system for producing high-quality vegetable-based beverages: Physicochemical, microbiological, nutritional and toxicological characteristics. J. Sci. Food Agric. 2015, 95, 953–961. [Google Scholar] [CrossRef]

- Toro-Funes, N.; Bosch-Fusté, J.; Veciana-Nogués, M.T.; Vidal-Carou, M.C. Effect of ultra high pressure homogenization treatment on the bioactive compounds of soya milk. Food Chem. 2014, 152, 597–602. [Google Scholar] [CrossRef]

- Poliseli-Scopel, F.H.; Gallardo-Chacón, J.-J.; Juan, B.; Guamis, B.; Ferragut, V. Characterisation of volatile profile in soymilk treated by ultra high pressure homogenisation. Food Chem. 2013, 141, 2541–2548. [Google Scholar] [CrossRef]

- Pérez-González, M.; Gallardo-Chacón, J.J.; Valencia-Flores, D.; Ferragut, V. Optimization of a Headspace SPME GC–MS methodology for the analysis of processed almond beverages. Food Anal. Methods 2015, 8, 612–623. [Google Scholar] [CrossRef]

- Poliseli-Scopel, F.H.; Hernández-Herrero, M.; Guamis, B.; Ferragut, V. Comparison of ultra high pressure homogenization and conventional thermal treatments on the microbiological, physical and chemical quality of soymilk. LWT-Food Sci. Technol. 2012, 46, 42–48. [Google Scholar] [CrossRef]

- Poliseli-Scopel, F.H.; Hernández-Herrero, M.; Guamis, B.; Ferragut, V. Sterilization and aseptic packaging of soymilk treated by ultra high pressure homogenization. In Innovative Food Science and Emerging Technologies; Elsevier Ltd.: Amsterdam, The Netherlands, 2014; Volume 22, pp. 81–88. [Google Scholar]

- Toro-Funes, N.; Bosch-Fusté, J.; Veciana-Nogués, M.T.; Vidal-Carou, M.C. Influence of ultra-high-pressure homogenization treatment on the phytosterols, tocopherols, and polyamines of almond beverage. J. Agric. Food Chem. 2014, 62, 9539–9543. [Google Scholar] [CrossRef]

- Toro-Funes, N.; Bosch-Fusté, J.; Latorre-Moratalla, M.L.; Veciana-Nogués, M.T.; Vidal-Carou, M.C. Isoflavone profile and protein quality during storage of sterilised soymilk treated by ultra high pressure homogenisation. Food Chem. 2015, 167, 78–83. [Google Scholar] [CrossRef]

- Jafari, S.M.; He, Y.; Bhandari, B. Production of sub-micron emulsions by ultrasound and microfluidization techniques. J. Food Eng. 2007, 82, 478–488. [Google Scholar] [CrossRef]

- Iswarin, S.J.; Permadi, B. Coconut milk’s fat breaking by means of ultrasound. Int. J. Basic Appl. Sci. 2012, 12, 1–5. [Google Scholar]

- Cortés, C.; Esteve, M.J.; Frígola, A.; Torregrosa, F. Quality characteristics of horchata (a Spanish vegetable beverage) treated with pulsed electric fields during shelf-life. Food Chem. 2005, 91, 319–325. [Google Scholar] [CrossRef]

- Xiang, B. Effects of pulsed electric fields on structural modification and rheological properties for selected food proteins. Ph.D. Thesis, Sainte-Anne-de-Bellevue, McGill University, Montreal, AB, Canada, 2008. [Google Scholar]

- Barba, F.J.; Parniakov, O.; Pereira, S.A.; Wiktor, A.; Grimi, N.; Boussetta, N.; Saraiva, J.A.; Raso, J.; Martin-Belloso, O.; Witrowa-Rajchert, D.; et al. Current applications and new opportunities for the use of pulsed electric fields in food science and industry. Food Res. Int. 2015, 77, 773–798. [Google Scholar] [CrossRef]

- Puértolas, E.; Koubaa, M.; Barba, F.J. An overview of the impact of electrotechnologies for the recovery of oil and high-value compounds from vegetable oil industry: Energy and economic cost implications. Food Res. Int. 2016, 80, 19–26. [Google Scholar] [CrossRef]

- Koubaa, M.; Barba, F.J.; Kovačević, D.B.; Putnik, P.; Santos, M.D.; Queirós, R.P.; Moreira, S.A.; Inácio, R.S.; Fidalgo, L.G.; Saraiva, J.A. Pulsed Electric Field Processing of Fruit Juices. In Fruit Juices-Extraction, Composition, Quality and Analysis; Rajauria, G., Tiwari, B.K., Eds.; Academic Press: Cambridge, MA, USA, 2018; pp. 437–449. ISBN 9780128022306. [Google Scholar]

- Gabrić, D.; Barba, F.; Roohinejad, S.; Gharibzahedi, S.M.T.; Radojčin, M.; Putnik, P.; Kovačević, D.B. Pulsed electric fields as an alternative to thermal processing for preservation of nutritive and physicochemical properties of beverages: A review. J. Food Process Eng. 2018, 41, e12638. [Google Scholar] [CrossRef]

- Ma, L.; Li, B.; Han, F.; Yan, S.; Wang, L.; Sun, J. Evaluation of the chemical quality traits of soybean seeds, as related to sensory attributes of soymilk. Food Chem. 2015, 173, 694–701. [Google Scholar] [CrossRef]

- Abagoshu, N.A.; Ibrahim, A.M.; Teka, T.A.; Mekonnen, T.B. Effect of soybean varieties and processing methods on nutritional and sensory properties of soymilk. J. Food Process. Preserv. 2017, 41, 1–9. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, S.; Liu, Z.; Chang, S.K.C. Off-flavor related volatiles in soymilk as affected by soybean variety, grinding, and heat-processing methods. J. Agric. Food Chem. 2012, 60, 7457–7462. [Google Scholar] [CrossRef] [PubMed]

- Blagden, T.; Gilliland, S.E. Reduction of levels of volatile components associated with the “Beany” flavor in soymilk by Lactobacilli and Streptococci. J. Food Sci. 2005, 70, M186–M189. [Google Scholar] [CrossRef]

- Lv, Y.-C.; Song, H.-L.; Li, X.; Wu, L.; Guo, S.-T. Influence of blanching and grinding process with hot water on beany and non-beany flavor in soymilk. J. Food Sci. 2011, 76, S20–S25. [Google Scholar] [CrossRef] [PubMed]

- Tripathi, M.K.; Mangaraj, S.; Kumar, M.; Sinha, L.K.; Giri, S.K.; Ali, N. Effect of processing condition on the quality and beany flavour of soymilk. Curr. Sci. 2015, 109, 1164–1171. [Google Scholar]

- Gul, O.; Atalar, I.; Mortas, M.; Turker, F.; Fehmi, S. Application of TOPSIS methodology to determine optimum hazelnut cake concentration and high pressure homogenization condition for hazelnut milk production based on physicochemical, structural and sensory properties. J. Food Meas. Charact. 2018, 12, 2404–2415. [Google Scholar] [CrossRef]

- Ukwuru, M.U.; Ogbodo, A.C. Effect of processing treatment on the quality of tigernut milk. Pakistan J. Nutr. 2011, 10, 95–100. [Google Scholar] [CrossRef]

- Giri, S.K.; Mangaraj, S. Processing influences on composition and quality attributes of soymilk and its powder. Food Eng. Rev. 2012, 4, 149–164. [Google Scholar] [CrossRef]

- Codina-Torrella, I.; Guamis, B.; Zamora, A.; Quevedo, J.M.; Trujillo, A.J. Microbiological stabilization of tiger nuts’ milk beverage using ultra-high pressure homogenization. A preliminary study on microbial shelf-life extension. Food Microbiol. 2018, 69, 143–150. [Google Scholar] [CrossRef]

- Smith, K.; Mendonca, A.; Jung, S. Impact of high-pressure processing on microbial shelf-life and protein stability of refrigerated soymilk. Food Microbiol. 2009, 26, 794–800. [Google Scholar] [CrossRef]

- Li, Y.-Q.; Tian, W.-L.; Mo, H.-Z.; Zhang, Y.-L.; Zhao, X.-Z. Effects of pulsed electric field processing on quality characteristics and microbial inactivation of soymilk. Food Bioprocess Technol. 2013, 6, 1907–1916. [Google Scholar] [CrossRef]

- Selma, M.V.; Fernández, P.S.; Valero, M.; Salmerón, M.C. Control of Enterobacter aerogenes by high-intensity, pulsed electric fields in horchata, a Spanish low-acid vegetable beverage. Food Microbiol. 2003, 20, 105–110. [Google Scholar] [CrossRef]

- Uemura, K.; Takahashi, C.; Kobayashi, I. Inactivation of Bacillus subtilis spores in soybean milk by radio-frequency flash heating. J. Food Eng. 2010, 100, 622–626. [Google Scholar] [CrossRef]

- Guo, Y.; Ma, M.; Jiang, F.; Jiang, W.; Wang, H.; Du, S. kui Protein quality and antioxidant properties of soymilk derived from black soybean after in vitro simulated gastrointestinal digestion. Int. J. Food Sci. Technol. 2020, 55, 720–728. [Google Scholar] [CrossRef]

- Mylan, J.; Morris, C.; Beech, E.; Geels, F.W. Rage against the regime: Niche-regime interactions in the societal embedding of plant-based milk. Environ. Innov. Soc. Transit. 2019, 31, 233–247. [Google Scholar] [CrossRef]

| Type of Milk | Calories (kcal) | Protein (g) | Lipids (g) | Total Carbohydrates (g) | Functional Compounds | Characteristics | Reference |

|---|---|---|---|---|---|---|---|

| Cow’s milk | 61 | 3.15 | 3.25 | 4.8 | - | - | [15] |

| Oat | 80 | 2.5 | 4 | - | β-Glucan | Antinutritional compounds such as phytates | [8,16,17] |

| Rice | 130 | 1 | 2 | 27 | Phytosterols (β-sitosterol and γ-oryzanol) | Poor emulsion stability due to high starch content | [9,18,19,20] |

| Quinoa | 104 | 4.5 | 6 | 9 | Manganese, Phosphorous | - | [9] |

| Soy | 80 | 7 | 4 | 4 | Isoflavones, Phytosterols | Beany flavor due to the action of lipoxygenase on unsaturated fatty acids | [10] |

| Almond | 40 | 1 | 3 | 2 | α-Tocopherol, Arabinose | Presence of allergenic protein amandin | [5,14] |

| Coconut | 80 | <1 | 5 | 7 | Lauric acid, Vitamin E | - | [21] |

| Hazelnut | 124 | 1.4 | 6 | 14 | Catechin | - | [22] |

| Sesame | 140 | 1.5 | 6 | 16.5 | Lignans (sesamin, sesamolin, sesaminol) | Antinutritional factors such as oxalate | [11] |

| Hemp | 70 | 2 | 6 | 1 | Omega 3-fatty acids | - | [5] |

| Novel Method | Plant-Based Milks | Treatment Conditions | Inference | Reference |

|---|---|---|---|---|

| High hydrostatic pressure (HHP) | Almond milk | HHP (450 and 600 MPa for 0, 30, 60, 180, 300, and 600 s at 30 °C) and traditional thermal processing (0, 30, 180, and 300 s at 72, 85, and 99 °C). | Induced the aggregation and coagulation of almond proteins; higher aggregation than conventional heat treatment (72 and 85 °C) | [26] |

| Soymilk enriched with calcium | HHP (500–700 MPa at 73–95 °C) and traditional thermal processing (80, 85, 90, 95 °C at 0.1 MPa) | Inhibited the activity of trypsin inhibitors and lipoxygenase; improved protein solubility, viscosity, and stability (up to 5 days) | [27] | |

| High-pressure (HPH)/Ultra-high-pressure homogenization (UHPH) | Almond milk | UHPH (350 MPa at 85 °C). | No significant reduction in vitamins B1 and B2. Reduction in anti-protein antigens by 99.8% was achieved | [30] |

| UHPH (200 MPa at 55 °C and 300 MPa at 75 °C) | No significant difference in chemical composition, essential amino acid, lysine content (limiting amino acid in almond milk) | [32] | ||

| UHPH (200 and 300 MPa at 55 °C, 65 °C and 75 °C) | Increased total phytosterols content; reduced the total tocopherol content | [38] | ||

| HPH (150, 300, 450, and 600 MPa, 30 °C, up to 600 s) and traditional thermal processing (up to 300 s at 72, 85, and 99 °C) | Reduced protein solubility (up to 70%) and amandin immunoreactivity | [14] | ||

| Soy yogurt | HPH (200–300 MPa at 40–50 °C) | Improved physiochemical properties (e.g., firmness) of the yogurts (milk treated by HPH) | [31] | |

| Soymilk | UHPH (200–300 MPa) | Improved stability during storage | [29] | |

| UHPH (200 MPa, 55 or 75 °C and 300 MPa, 80 °C) | Reduced hexanal formation using 200 MPa | [34] | ||

| UHPH (200–300 MPa, 55–75 °C) | No effect on isoflavone profile after processing and protein digestibility during storage | [33,38] | ||

| UHPH-treated soymilk (200 MPa, 55–75 °C) and thermal pasteurization (90 °C, 30 s) | Improved color and colloidal stability; reduced hydroperoxide index values and trypsin activity | [36,37] | ||

| UHPH (300 MPa and 75 °C of inlet temperature) and UHT sterilization (142 °C, 6 s) | No significant difference in isoflavones extractability, protein digestibility | [39] | ||

| Ultrasonication (US) | Coconut milk | US power levels (2.5 to 7.0 W) and treatment time (5 to 25 min) | Droplet diameter was reduced by increasing US power and time | [41] |

| Pulsed Electric Field (PEF) | Tiger nut milk | PEF pulse time (100 µs and 475 µs) and electric field intensity (20 kV/cm and 35 kV/cm) | No change in fat content (3.04%) throughout the storage period; reduced formation of lipid oxidation products | [42] |

| Soymilk | PEF with electric field intensities (18, 20, and 22 kV/cm), number of pulses (25, 50, 75, and 100), capacitance from the discharge capacitor of 0.33 L and pulse frequency of 0.5 Hz at 26 °C | Increased viscosity (22 kV/cm with 100 pulses) | [43] |

| Novel Method | Plant-Based Milks | Treatment Conditions | Antimicrobial Effect | Reference |

|---|---|---|---|---|

| Ultrahigh pressure homogenization | Tiger nut milk | 200 and 300 MPa at 40 °C | Total inhibition of Enterobacteriaceae, Lactobacillus, molds, and yeasts growth; partial inhibition of psychrotrophs and aerobic mesophiles growth, no effect on mesophilic spores | [57] |

| Soymilk | 200 and 300 MPa at 40 °C | Drastic reduction on total count, spores, and enterobacteria counts by both treatments | [29] | |

| 200 and 300 MPa, 55–75 °C | Complete inhibition of total bacteria, total spores and Bacillus cereus growth by 200 MPa at 75 °C and 300 MPa at 55–75 °C | [36] | ||

| 200 MPa, 55 and 75 °C | 200 MPa at 75 °C inhibited the growth of total bacteria and total spores during 28 days of refrigerated storage | [34] | ||

| 300 MPa at 80 °C | Complete inhibition of mesophilic and thermophilic bacteria | [37] | ||

| Almond milk | 200 and 300 MPa, 55–75 °C | Destruction of total bacteria, total spores, and Bacillus cereus growth by 200 MPa at 75 °C and 300 MPa at 55–75 °C | [28] | |

| High-pressure processing | Soymilk | 400–600 MPa, 25 and 75 °C, 1 and 5 min | Inhibition of total bacterial growth up to 4 days; 400–600 MPa at 75 °C caused total inhibition of aerobic bacteria for 28 days | [58] |

| Pulsed electric fields | Soymilk | 20–40 kV/cm, 0–547 µs | Inactivation of Escherichia coli and Staphylococcus aureus was proportional to increasing strength and treatment time | [59] |

| High-intensity pulsed electric fields | Horchata | 2.5–3 MV/m, 50–300 µs, 5–16 °C | Treatments increase the lag phase of Enterobacter aerogenes inoculated to horchata | [60] |

| Radio-frequency flash heating | Soymilk | 3.5–28 MHz | 4 log reduction in Bacillus subtilis spores by 28 MHz | [61] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Munekata, P.E.S.; Domínguez, R.; Budaraju, S.; Roselló-Soto, E.; Barba, F.J.; Mallikarjunan, K.; Roohinejad, S.; Lorenzo, J.M. Effect of Innovative Food Processing Technologies on the Physicochemical and Nutritional Properties and Quality of Non-Dairy Plant-Based Beverages. Foods 2020, 9, 288. https://doi.org/10.3390/foods9030288

Munekata PES, Domínguez R, Budaraju S, Roselló-Soto E, Barba FJ, Mallikarjunan K, Roohinejad S, Lorenzo JM. Effect of Innovative Food Processing Technologies on the Physicochemical and Nutritional Properties and Quality of Non-Dairy Plant-Based Beverages. Foods. 2020; 9(3):288. https://doi.org/10.3390/foods9030288

Chicago/Turabian StyleMunekata, Paulo E. S., Rubén Domínguez, Sravanthi Budaraju, Elena Roselló-Soto, Francisco J. Barba, Kumar Mallikarjunan, Shahin Roohinejad, and José M. Lorenzo. 2020. "Effect of Innovative Food Processing Technologies on the Physicochemical and Nutritional Properties and Quality of Non-Dairy Plant-Based Beverages" Foods 9, no. 3: 288. https://doi.org/10.3390/foods9030288

APA StyleMunekata, P. E. S., Domínguez, R., Budaraju, S., Roselló-Soto, E., Barba, F. J., Mallikarjunan, K., Roohinejad, S., & Lorenzo, J. M. (2020). Effect of Innovative Food Processing Technologies on the Physicochemical and Nutritional Properties and Quality of Non-Dairy Plant-Based Beverages. Foods, 9(3), 288. https://doi.org/10.3390/foods9030288