Wearable Soft Robots: Case Study of Using Shape Memory Alloys in Rehabilitation

Abstract

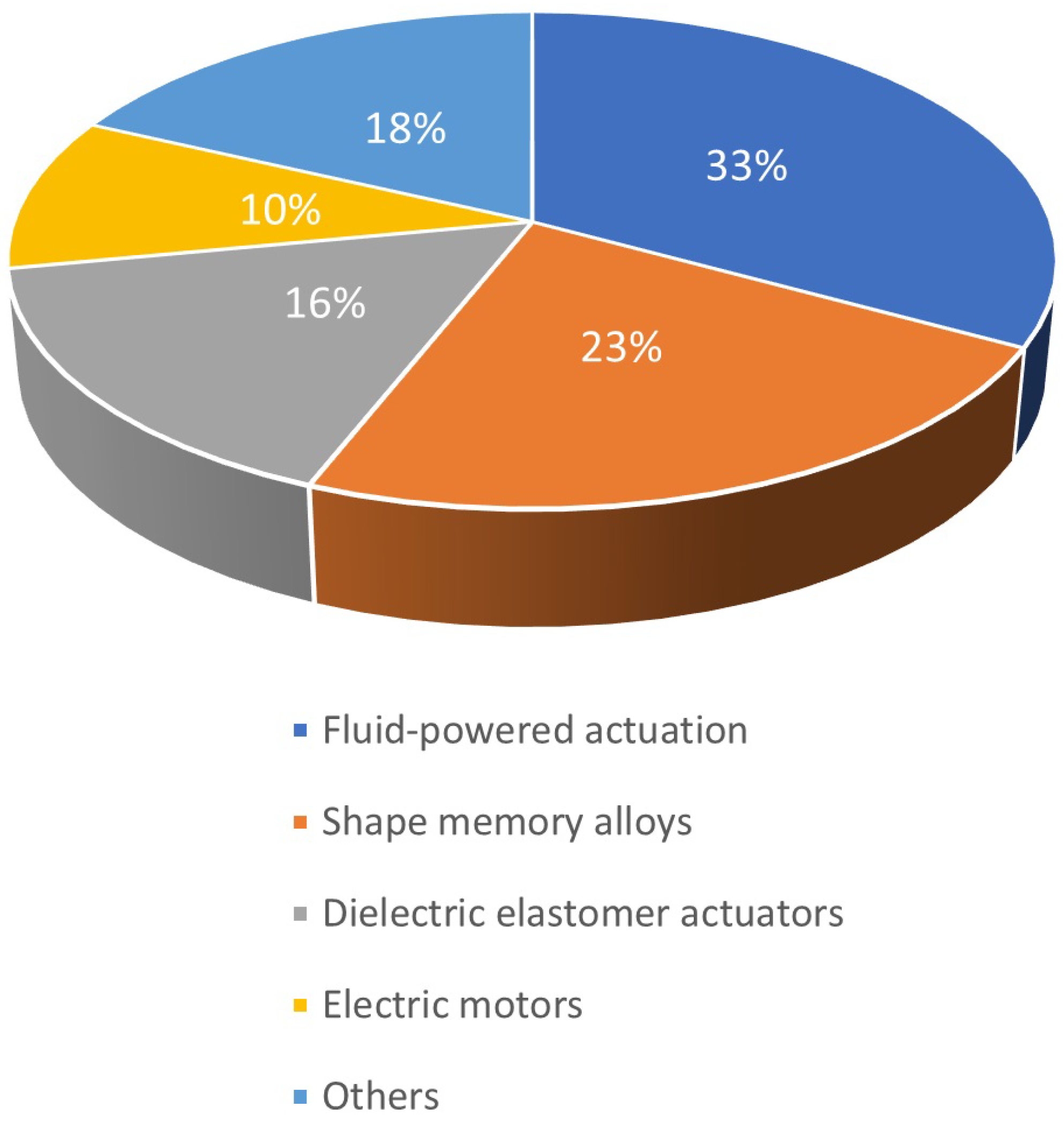

1. Introduction

1.1. Research Gap

1.2. Novelty

- It discusses SMA-based devices for the upper limb and lower limb that are in the prototype phase. It also discusses the challenges that these devices are facing to provide insight into developing a more effective SMA-based rehabilitation device.

- It elaborates on the design standards of joint movement assistive devices, covering a range of fields including (but not limited to) SMA configuration, actuation techniques, and cooling mechanisms.

- In addition to conventional exoskeletons, it discusses SMA-based smart fabrics, which are the state of the art in the field.

- This paper discusses efforts to implement the physical human–robotic interaction (PHRI) in the design of wearables for rehabilitation.

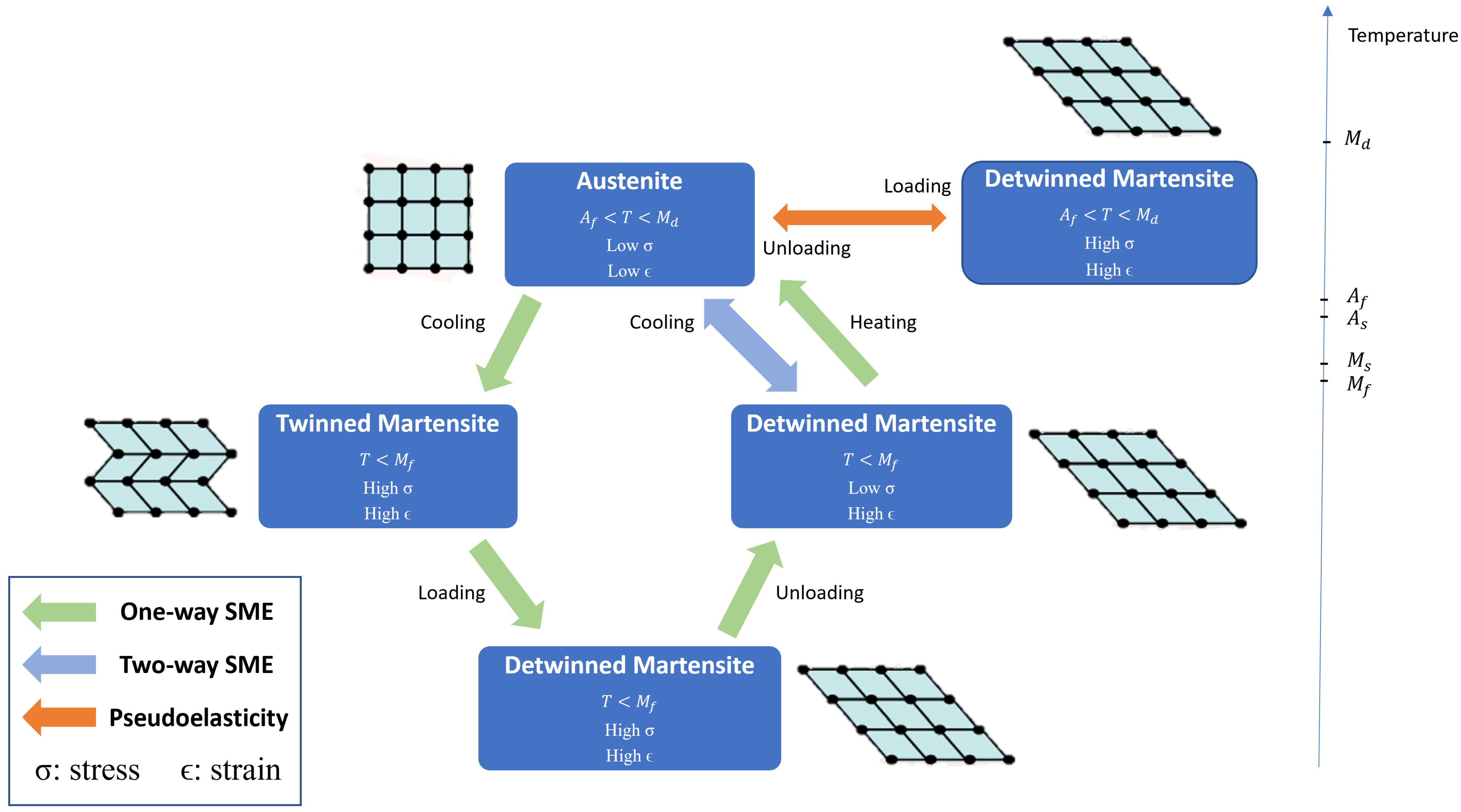

2. Shape Memory Effect and Pseudoelasticity

3. Shape Memory Alloy-Based Actuators

3.1. Design

3.2. Environmental Influences

3.3. Advantages

3.3.1. High Energy Density

3.3.2. Pseudoelasticity

3.3.3. Cost-Effectiveness of SMA-Based Devices

3.4. Challenges and Suggested Solutions

3.4.1. Hysteresis

3.4.2. Work Frequency

3.4.3. Energy Efficiency

3.4.4. Fatigue Property

3.5. Influencing Factors for Design of Variables

3.5.1. Physical Human–Robot Interaction (pHRI)

3.5.2. Control Mechanism

4. Applications of SMAs in Exoskeletons

- How SMAs have featured in the design of the device.

- The target organ and the intended motion achieved.

- The challenges encountered during the use of these devices.

4.1. Upper Limb

4.1.1. Forearm and Hand Rehabilitation Exoskeleton with 3 Degrees of Freedom (DOF)

4.1.2. EDGES SMA-Based Actuator

4.1.3. Advanced Service Laboratories (ASR) Glove for Hand Rehabilitation

4.1.4. Bowden Cable-Based SMA Actuator

4.1.5. Four-Bar Link Mechanism-Based SMA Finger Actuator

- The operation would cover the entire range of finger motion.

- The rotation speed ratio of the PIP and MCP joint would be between 3 and 4.

- The input torque would be as small as possible.

- To satisfy all the constraints, lengths were calculated through kinematic analysis for a gear ratio of 2:1 of the proposed structure.

- The fingers are initially kept straight.

- SMA-I automatically contracts when heated, forcing R1 to rotate clockwise.

- When SMA-II is heated, it contracts, rotating R1 anticlockwise to return the exoskeleton back to its initial state.

4.1.6. Tube-Encased SMA Coil Wrist Actuator

4.2. Lower Limb

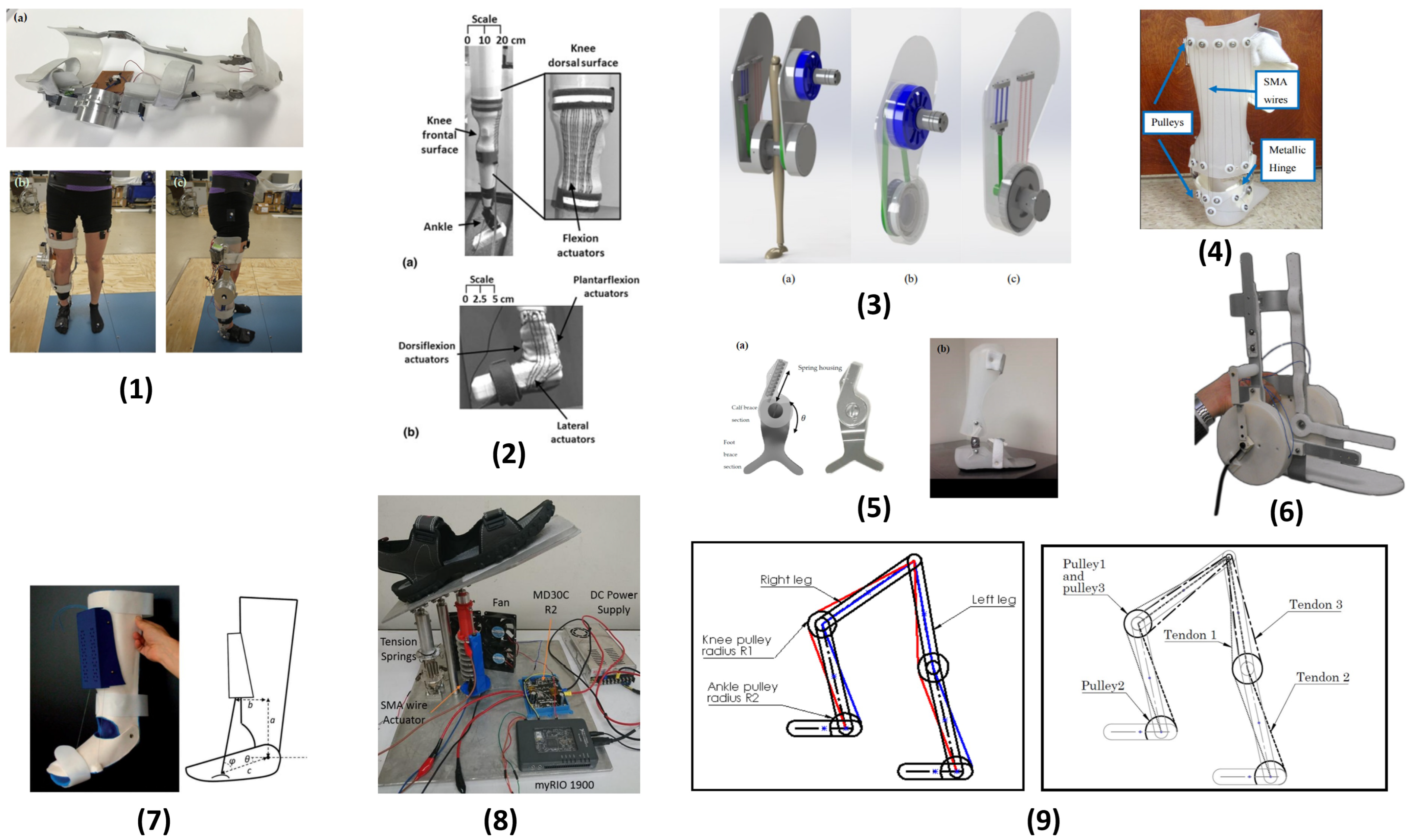

4.2.1. SMA-Driven Knee Module in Knee–Ankle Foot Orthosis (KAFO)

4.2.2. Active Soft Orthotic (ASO) for the Knee and Ankle Joints Using SMA Wire

4.2.3. Hybrid-Driven Knee Orthosis (KO) with SMA Actuator

4.2.4. SMA Pulley-Driven Hinged Active Ankle Foot Orthosis (AAFO)

4.2.5. Superelastic Hinge AFO (HAFO)

4.2.6. Lower Limb Exerciser with Intelligent Alloys (Leia)

4.2.7. SHADE: SMA Wire-Driven Ankle Rehabilitation Device

4.2.8. Platform-Type Ankle Rehabilitation Robot

4.2.9. Tendon-Driven Exoskeleton

5. Applications of SMAs in Smart Textiles

Recent Advancements in Smart Clothing Using SMA-Based Actuators

6. Conclusions

- Light weight, small size, easy to attach, and simple structure.

- Main degrees of freedom (DOF) for each joint to be supported.

- To accommodate sudden failures, a safety mechanism must be in place.

- The target organ to be able to freely interact with the environment.

Author Contributions

Funding

Conflicts of Interest

References

- Cieza, A.; Causey, K.; Kamenov, K.; Hanson, S.W.; Chatterji, S.; Vos, T. Global estimates of the need for rehabilitation based on the Global Burden of Disease study 2019: A systematic analysis for the Global Burden of Disease Study 2019. Lancet 2020, 396, 2006–2017. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization. Musculoskeletal Conditions. 2019. Available online: https://www.who.int/news-room/fact-sheets/detail/musculoskeletal-conditions (accessed on 2 January 2025).

- van Dijsseldonk, R.B.; Vriezekolk, J.E.; Keijsers, N.L.W.; Geurts, A.C.H.; van Nes, I.J.W. Needs and Wishes for the Future Exoskeleton: An Interview Study Among People with Spinal Cord Injury with Community-based Exoskeleton Experience. Res. Sq. 2020. preprint. [Google Scholar] [CrossRef]

- Schmitt, F.; Piccin, O.; Barbé, L.; Bayle, B. Soft robots manufacturing: A review. Front. Robot. AI 2018, 5, 84. [Google Scholar] [CrossRef] [PubMed]

- Mirvakili, S.M.; Pazukha, A.; Sikkema, W.; Sinclair, C.W.; Spinks, G.M.; Baughman, R.H.; Madden, J.D. Niobium nanowire yarns and their application as artificial muscles. Adv. Funct. Mater. 2013, 23, 4311–4316. [Google Scholar] [CrossRef]

- Mirvakili, S.M.; Hunter, I.W. Artificial muscles: Mechanisms, applications, and challenges. Adv. Mater. 2018, 30, 1704407. [Google Scholar] [CrossRef]

- Pan, M.; Yuan, C.; Liang, X.; Dong, T.; Liu, T.; Zhang, J.; Zou, J.; Yang, H.; Bowen, C. Soft actuators and robotic devices for rehabilitation and assistance. Adv. Intell. Syst. 2022, 4, 2100140. [Google Scholar] [CrossRef]

- Gopura, R.; Bandara, D.; Kiguchi, K.; Mann, G.K. Developments in hardware systems of active upper-limb exoskeleton robots: A review. Robot. Auton. Syst. 2016, 75, 203–220. [Google Scholar] [CrossRef]

- Gao, X.; Yang, J.; Wu, J.; Xin, X.; Li, Z.; Yuan, X.; Dong, S. Piezoelectric Actuators and Motors: Materials, Designs, and Applications. Adv. Mater. Technol. 2019, 5, 1900716. [Google Scholar] [CrossRef]

- Martini, E.; Crea, S.; Parri, A.; Bastiani, L.; Faraguna, U.; McKinney, Z.; Vitiello, N. Gait Training Using a Robotic Hip Exoskeleton Improves Metabolic Gait Efficiency in the Elderly. Sci. Rep. 2019, 9, 7157. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, Y.; Li, M.; Chen, E.; Mu, W.; Fisher, R.; Yin, R. Wearable Actuators: An Overview. Textiles 2021, 1, 283–321. [Google Scholar] [CrossRef]

- Gonz’alez, A.; Garc’ia, L.; Kilby, J.; McNair, P. Soft Wearable Rehabilitation Robots with Artificial Muscles Based on Smart Materials: A Review. Adv. Intell. Syst. 2023, 5, 2200159. [Google Scholar] [CrossRef]

- Srivastava, R.; Alsamhi, S.; Murray, N.; Devine, D. Shape Memory Alloy-Based Wearables: A Review, and Conceptual Frameworks on HCI and HRI in Industry 4.0. Sensors 2022, 22, 6802. [Google Scholar] [CrossRef] [PubMed]

- Ge, J.; Zhang, J.; Chen, D.; Dong, T. A Lightweight Passive Ankle Exoskeleton Adjusted Stiffness by Shape Memory Alloy. Robot. Intell. Autom. 2024, 44, 830–840. [Google Scholar] [CrossRef]

- Mohd Jani, J.; Leary, M.; Subic, A. Designing Shape Memory Alloy Linear Actuators: A Review. J. Intell. Mater. Syst. Struct. 2017, 28, 1699–1718. [Google Scholar] [CrossRef]

- Díaz, I.; Gil, J.J.; Sánchez, E. Lower-limb robotic rehabilitation: Literature review and challenges. J. Robot. 2011, 2011, 759764. [Google Scholar] [CrossRef]

- Lo, H.S.; Xie, S.Q. Exoskeleton robots for upper-limb rehabilitation: State of the art and future prospects. Med. Eng. Phys. 2012, 34, 261–268. [Google Scholar] [CrossRef] [PubMed]

- Aliman, N.; Ramli, R.; Haris, S.M. Design and development of lower limb exoskeletons: A survey. Robot. Auton. Syst. 2017, 95, 102–116. [Google Scholar] [CrossRef]

- Chu, C.Y.; Patterson, R.M. Soft robotic devices for hand rehabilitation and assistance: A narrative review. J. Neuroeng. Rehabil. 2018, 15, 9. [Google Scholar] [CrossRef]

- Meng, Q.; Zeng, Q.; Xie, Q.; Fei, C.; Kong, B.; Lu, X.; Wang, H.; Yu, H. Flexible lower limb exoskeleton systems: A review. NeuroRehabilitation 2022, 50, 367–390. [Google Scholar] [CrossRef]

- Zhang, Y.; Lu, M. A review of recent advancements in soft and flexible robots for medical applications. Int. J. Med. Robot. Comput. Assist. Surg. 2020, 16, e2096. [Google Scholar] [CrossRef]

- Copaci, D.; Arias, J.; Moreno, L.; Blanco, D. Shape Memory Alloy (SMA)-Based Exoskeletons for Upper Limb Rehabilitation. In Rehabilitation of the Human Bone-Muscle System; IntechOpen: London, UK, 2022. [Google Scholar]

- Zhao, C. Shape memory stainless steels. Adv. Mater. Process. 2001, 159, 33–35. [Google Scholar]

- Jani, J.M.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. (1980–2015) 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Kohl, M. Shape Memory Microactuators; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2004. [Google Scholar]

- Huang, W. On the selection of shape memory alloys for actuators. Mater. Des. 2002, 23, 11–19. [Google Scholar] [CrossRef]

- Shi, M.; Yeatman, E.M. A comparative review of artificial muscles for microsystem applications. Microsyst. Nanoeng. 2021, 7, 95. [Google Scholar] [CrossRef] [PubMed]

- Mirvakili, S.M.; Hunter, I.W. Fast torsional artificial muscles from NiTi twisted yarns. ACS Appl. Mater. Interfaces 2017, 9, 16321–16326. [Google Scholar] [CrossRef]

- Meling, T.R.; Ødegaard, J. The effect of temperature on the elastic responses to longitudinal torsion of rectangular nickel titanium archwires. Angle Orthod. 1998, 68, 357–368. [Google Scholar]

- Huang, W.; Toh, W. Training two-way shape memory alloy by reheat treatment. J. Mater. Sci. Lett. 2000, 17, 1549–1550. [Google Scholar] [CrossRef]

- Perkins, J.; Hodgson, D. The two-way shape memory effect. In Engineering Aspects of Shape Memory Alloys; Butterworth-Heinemann: Oxford, UK, 1990; pp. 195–206. [Google Scholar]

- Schroeder, T.; Wayman, C. The two-way shape memory effect and other “training” phenomena in Cu Zn single crystals. Scr. Metall. 1977, 11, 225–230. [Google Scholar] [CrossRef]

- Ma, J.; Karaman, I.; Noebe, R.D. High temperature shape memory alloys. Int. Mater. Rev. 2010, 55, 257–315. [Google Scholar] [CrossRef]

- Otsuka, K.; Wayman, C.M. Shape Memory Materials; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Golgouneh, A.; Holschuh, B.; Dunne, L. A controllable biomimetic SMA-actuated robotic arm. In Proceedings of the 2020 8th IEEE RAS/EMBS International Conference for Biomedical Robotics and Biomechatronics (BioRob), New York, NY, USA, 29 November–1 December 2020; pp. 152–157. [Google Scholar]

- Golgouneh, A.; Li, J.; Abel, J.; Dunne, L.E. A Smart Controllable SMA-Based Tourniquet. In Proceedings of the ASME 2021 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, Virtual Online, 14–15 September 2021; Volume 85499, p. V001T03A002. [Google Scholar]

- Dynalloy, Inc. Makers of Dynamic Alloys. Available online: https://www.dynalloy.com/tech_data_wire.php# (accessed on 15 July 2022).

- Motzki, P.; Gorges, T.; Kappel, M.; Schmidt, M.; Rizzello, G.; Seelecke, S. High-speed and high-efficiency shape memory alloy actuation. Smart Mater. Struct. 2018, 27, 075047. [Google Scholar] [CrossRef]

- Sobrinho, J.; Cunha, M.; Emiliavaca, A.; Souto, C.; R’ies, A. A Compact Rotary Motor Actuated by Shape Memory Alloy Mini Springs. J. Intell. Mater. Syst. Struct. 2020, 31, 1808–1820. [Google Scholar] [CrossRef]

- Arias Guadalupe, J.; Copaci, D.; Serrano del Cerro, D.; Moreno, L.; Blanco, D. Efficiency analysis of SMA-based actuators: Possibilities of configuration according to the application. Actuators 2021, 10, 63. [Google Scholar] [CrossRef]

- Van Humbeeck, J. Non-medical applications of shape memory alloys. Mater. Sci. Eng. A 1999, 273, 134–148. [Google Scholar] [CrossRef]

- Villoslada, A.; Escudero, N.; Mart’in, F.; Caballero, A.; Rivera, C.; Collado, M.; Moreno, L. Position Control of a Shape Memory Alloy Actuator Using a Four-Term Bilinear PID Controller. Sens. Actuators A Phys. 2015, 236, 257–272. [Google Scholar] [CrossRef]

- Kim, C.; Kim, G.; Lee, Y.; Lee, G.; Han, S.; Kang, D.; Koo, S.H.; Koh, J.-S. Shape memory alloy actuator-embedded smart clothes for ankle assistance. Smart Mater. Struct. 2020, 29, 055003. [Google Scholar] [CrossRef]

- Wilson, E.; Assaf, T.; Pearson, M.; Rossiter, J.; Anderson, S.; Porrill, J.; Dean, P. Cerebellar-Inspired Algorithm for Adaptive Control of Nonlinear Dielectric Elastomer-Based Artificial Muscle. J. R. Soc. Interface 2016, 13, 20160547. [Google Scholar] [CrossRef]

- Flemming, L.; Johnson, D.; Mascaro, S. Optimal Control of Multi-Input SMA Actuator Arrays Using Graph Theory. In Proceedings of the IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 6109–6114. [Google Scholar] [CrossRef]

- Buehler, W.J.; Wang, F.E. A summary of recent research on the nitinol alloys and their potential application in ocean engineering. Ocean Eng. 1968, 1, 105–120. [Google Scholar] [CrossRef]

- Liu, Y. Shape Memory Alloys: Manufacture, Properties and Applications; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2010; pp. 361–369. [Google Scholar]

- Zareie, S.; Zabihollah, A. Hysteresis Behavior of Pre-Strained Shape Memory Alloy Wires Subject to Cyclic Loadings: An Experimental Investigation. In Emerging Trends in Mechatronics; IntechOpen: London, UK, 2020; p. 151. [Google Scholar]

- Pathak, A.; Brei, D.; Luntz, J. Transformation strain based method for characterization of convective heat transfer from shape memory alloy wires. Smart Mater. Struct. 2010, 19, 035005. [Google Scholar] [CrossRef]

- Loh, C.S.; Yokoi, H.; Arai, T. New shape memory alloy actuator: Design and application in the prosthetic hand. In Proceedings of the 2005 IEEE Engineering in Medicine and Biology 27th Annual Conference, Shanghai, China, 17–18 January 2006; pp. 6900–6903. [Google Scholar]

- Utter, B. Enhancing the actuation frequency of shape memory alloy wire by vibration-enhanced cooling. J. Intell. Mater. Syst. Struct. 2019, 30, 3177–3189. [Google Scholar] [CrossRef]

- Lara-Quintanilla, A.; Bersee, H. Active cooling and strain-ratios to increase the actuation frequency of SMA wires. Shape Mem. Superelasticity 2015, 1, 460–467. [Google Scholar] [CrossRef]

- Hunter, I.; Lafontaine, S.; Hollerbach, J.; Hunter, P. Fast reversible NiTi fibers for use in microrobotics. In Proceedings of the 1991 IEEE Micro Electro Mechanical Systems—MEMS, Nara, Japan, 30 December 1990–2 January 1991; Volume 91, pp. 166–170. [Google Scholar]

- Furuya, Y.; Shimada, H. Shape memory actuators for robotic applications. Mater. Des. 1991, 12, 21–28. [Google Scholar] [CrossRef]

- Cheng, S.S.; Kim, Y.; Desai, J.P. Modeling and characterization of shape memory alloy springs with water cooling strategy in a neurosurgical robot. J. Intell. Mater. Syst. Struct. 2017, 28, 2167–2183. [Google Scholar] [CrossRef]

- Leary, M.; Mac, J.; Mazur, M.; Schiavone, F.; Subic, A. Enhanced shape memory alloy actuators. In Sustainable Automotive Technologies 2010: Proceedings of the 2nd International Conference; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Gorbet, R.B.; Russell, R.A. A novel differential shape memory alloy actuator for position control. Robotica 1995, 13, 423–430. [Google Scholar] [CrossRef]

- Motzki, P. Efficient SMA actuation—Design and control concepts. Proceedings 2020, 64, 20. [Google Scholar] [CrossRef]

- Wilkes, K.E.; Liaw, P.K.; Wilkes, K.E. The fatigue behavior of shape-memory alloys. JOM 2000, 52, 45–51. [Google Scholar] [CrossRef]

- Morin, C.; Moumni, Z.; Zaki, W. Thermomechanical coupling in shape memory alloys under cyclic loadings: Experimental analysis and constitutive modeling. Int. J. Plast. 2011, 27, 1959–1980. [Google Scholar] [CrossRef]

- Bertacchini, O.W.; Lagoudas, D.C.; Patoor, E. Fatigue life characterization of shape memory alloys undergoing thermomechanical cyclic loading. In Proceedings of the Smart Structures and Materials 2003: Active Materials: Behavior and Mechanics, San Diego, CA, USA, 2–6 March 2003; Volume 5053, pp. 612–624. [Google Scholar]

- DesRoches, R.; McCormick, J.; Delemont, M. Cyclic properties of superelastic shape memory alloy wires and bars. J. Struct. Eng. 2004, 130, 38–46. [Google Scholar] [CrossRef]

- Zhao, T.; Kang, G. Experimental study and life prediction on fatigue failure of NiTi shape memory alloy under multi-axial one-way shape memory cyclic loadings. Int. J. Fatigue 2022, 155, 106609. [Google Scholar] [CrossRef]

- Gall, K.; Maier, H. Cyclic deformation mechanisms in precipitated NiTi shape memory alloys. Acta Mater. 2002, 50, 4643–4657. [Google Scholar] [CrossRef]

- Mahtabi, M.J.; Shamsaei, N.; Elahinia, M.H. Fatigue of shape memory alloys. In Shape Memory Alloy Actuators: Design, Fabrication and Experimental Evaluation; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2016. [Google Scholar]

- Sgambitterra, E.; Magarò, P.; Niccoli, F.; Renzo, D.; Maletta, C. Novel insight into the strain-life fatigue properties of pseudoelastic NiTi shape memory alloys. Smart Mater. Struct. 2019, 28, 10LT03. [Google Scholar] [CrossRef]

- Furuichi, Y.; Tobushi, H.; Ikawa, T.; Matsui, R. Fatigue properties of a TiNi shape-memory alloy wire subjected to bending with various strain ratios. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2003, 217, 93–99. [Google Scholar] [CrossRef]

- Lagoudas, D.; Miller, D.; Rong, L.; Kumar, P. Thermomechanical fatigue of shape memory alloys. Smart Mater. Struct. 2009, 18, 085021. [Google Scholar] [CrossRef]

- Yin, H.; He, Y.; Moumni, Z.; Sun, Q. Effects of grain size on tensile fatigue life of nanostructured NiTi shape memory alloy. Int. J. Fatigue 2016, 88, 166–177. [Google Scholar] [CrossRef]

- Wagner, M.F.; Nayan, N.; Ramamurty, U. Healing of fatigue damage in NiTi shape memory alloys. J. Phys. D Appl. Phys. 2008, 41, 185408. [Google Scholar] [CrossRef]

- Karakoc, O.; Hayrettin, C.; Canadinc, D.; Karaman, I. Role of applied stress level on the actuation fatigue behavior of NiTiHf high temperature shape memory alloys. Acta Mater. 2018, 153, 156–168. [Google Scholar] [CrossRef]

- Bertacchini, O.W.; Lagoudas, D.C.; Calkins, F.T.; Mabe, J.H. Thermomechanical cyclic loading and fatigue life characterization of nickel rich NiTi shape-memory alloy actuators. In Proceedings of the Behavior and Mechanics of Multifunctional and Composite Materials 2008, San Diego, CA, USA, 9–13 March 2008; Volume 6929, pp. 238–248. [Google Scholar]

- Wang, Z.; Xu, L.; Sun, X.; Shi, M.; Liu, J. Fatigue behavior of glass-fiber-reinforced epoxy composites embedded with shape memory alloy wires. Compos. Struct. 2017, 178, 311–319. [Google Scholar] [CrossRef]

- Bayati, P.; Jahadakbar, A.; Barati, M.; Nematollahi, M.; Saint-Sulpice, L.; Haghshenas, M.; Chirani, S.A.; Mahtabi, M.J.; Elahinia, M. Toward low and high cycle fatigue behavior of SLM-fabricated NiTi: Considering the effect of build orientation and employing a self-heating approach. Int. J. Mech. Sci. 2020, 185, 105878. [Google Scholar] [CrossRef]

- Markopoulos, A.; Pressas, I.; Manolakos, D. Manufacturing processes of shape memory alloys. In Materials Forming and Machining; Elsevier: Amsterdam, The Netherlands, 2016; pp. 155–180. [Google Scholar]

- Torra, V.; Isalgue, A.; Auguet, C.; Carreras, G.; Lovey, F.C.; Soul, H.; Terriault, P. Damping in civil engineering using SMA. The fatigue behavior and stability of CuAlBe and NiTi alloys. J. Mater. Eng. Perform. 2009, 18, 738–745. [Google Scholar] [CrossRef]

- Treadway, J.; Abolmaali, A.; Lu, F.; Aswath, P. Tensile and fatigue behavior of superelastic shape memory rods. Mater. Des. 2015, 86, 105–113. [Google Scholar] [CrossRef]

- Saygili, H.H.; Tugrul, H.O.; Kockar, B. Effect of aging heat treatment on the high cycle fatigue life of Ni50.3Ti29.7Hf20 high-temperature shape memory alloy. Shape Mem. Superelasticity 2019, 5, 32–41. [Google Scholar] [CrossRef]

- Nayan, N.; Buravalla, V.; Ramamurty, U. Effect of mechanical cycling on the stress–strain response of a martensitic Nitinol shape memory alloy. Mater. Sci. Eng. A 2009, 525, 60–67. [Google Scholar] [CrossRef]

- Takeda, K.; Matsui, R.; Tobushi, H.; Homma, S.; Hattori, K. Enhancement of fatigue life in TiNi shape memory alloy by ultrasonic shot peening. Mater. Trans. 2015, 56, 513–518. [Google Scholar] [CrossRef]

- Nahavandi, D.; Alizadehsani, R.; Khosravi, A.; Acharya, U.R. Application of artificial intelligence in wearable devices: Opportunities and challenges. Comput. Methods Programs Biomed. 2022, 213, 106541. [Google Scholar] [CrossRef] [PubMed]

- Pérez Vidal, A.F.; Rumbo Morales, J.Y.; Ortiz Torres, G.; Sorcia Vázquez, F.d.J.; Cruz Rojas, A.; Brizuela Mendoza, J.A.; Rodríguez Cerda, J.C. Soft exoskeletons: Development, requirements, and challenges of the last decade. Actuators 2021, 10, 166. [Google Scholar] [CrossRef]

- John Varghese, R.; Mukherjee, G.; Deshpande, A. Designing Physical Human-Robot Interaction Interfaces: A Scalable Method for Simulation Based Design. Front. Neurorobot. 2022, 15, 187. [Google Scholar] [CrossRef] [PubMed]

- Schiele, A.; Van Der Helm, F.C. Kinematic design to improve ergonomics in human machine interaction. IEEE Trans. Neural Syst. Rehabil. Eng. 2006, 14, 456–469. [Google Scholar] [CrossRef]

- Agarwal, P.; Fox, J.; Yun, Y.; O’Malley, M.K.; Deshpande, A.D. An index finger exoskeleton with series elastic actuation for rehabilitation: Design, control and performance characterization. Int. J. Robot. Res. 2015, 34, 1747–1772. [Google Scholar] [CrossRef]

- Petron, A.J. Prosthetic Socket Design: From a Multi-Indenter Device for In Vivo Biomechanical Tissue Measurement to a Quasi-Passive Transtibial Socket Interface. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2016. [Google Scholar]

- Quinlivan, B.; Asbeck, A.; Wagner, D.; Ranzani, T.; Russo, S.; Walsh, C. Force transfer characterization of a soft exosuit for gait assistance. In Proceedings of the ASME 2015 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Boston, MA, USA, 2–5 August 2015; Volume 57120, p. V05AT08A049. [Google Scholar]

- Joey, Z.G.; Chang, L.; Pérez-Arancibia, N.O. Preisach-model-based position control of a shape-memory alloy linear actuator in the presence of time-varying stress. Mechatronics 2021, 73, 102452. [Google Scholar]

- Lacasse, S.; Terriault, P.; Simoneau, C.; Brailovski, V. Design, manufacturing, and testing of an adaptive composite panel with embedded shape memory alloy actuators. J. Intell. Mater. Syst. Struct. 2015, 26, 2055–2072. [Google Scholar] [CrossRef]

- Elahinia, M.H.; Ashrafiuon, H.; Ahmadian, M.; Tan, H. A temperature-based controller for a shape memory alloy actuator. J. Vib. Acoust. 2005, 127, 285–291. [Google Scholar] [CrossRef]

- Nath, T.; Singh, S.K. Nitinol shape memory alloy spring. Indian J. Eng. Mater. Sci. (IJEMS) 2021, 28, 446–453. [Google Scholar]

- Ikuta, K. Micro/miniature shape memory alloy actuator. In Proceedings of the IEEE International Conference on Robotics and Automation, Cincinnati, OH, USA, 13–18 May 1990; pp. 2156–2161. [Google Scholar]

- Jayender, J.; Patel, R.V.; Nikumb, S.; Ostojic, M. Modeling and control of shape memory alloy actuators. IEEE Trans. Control Syst. Technol. 2008, 16, 279–287. [Google Scholar] [CrossRef]

- Lange, G.; Lachmann, A.; Rahim, A.H.A.; Ismail, M.H.; Low, C.Y. Shape memory alloys as linear drives in robot hand actuation. Procedia Comput. Sci. 2015, 76, 168–173. [Google Scholar] [CrossRef][Green Version]

- Alcaide, J.O.; Pearson, L.; Rentschler, M.E. Design, modeling and control of a SMA-actuated biomimetic robot with novel functional skin. In Proceedings of the 2017 IEEE International Conference on Robotics and Automation (ICRA), Singapore, 29 May–3 June 2017; pp. 4338–4345. [Google Scholar]

- Awang Jumat, N.; Ogunwa, T.T.; Abdullah, E.J.; Chahl, J.; Romli, F.I.; Abdul Majid, D.L. Flapping actuation using temperature feedback control of coated shape memory alloy actuators. Microsyst. Technol. 2021, 27, 3299–3311. [Google Scholar] [CrossRef]

- Hope, J.; McDaid, A. Development of wearable wrist and forearm exoskeleton with shape memory alloy actuators. J. Intell. Robot. Syst. 2017, 86, 397. [Google Scholar] [CrossRef]

- Viscuso, S.; Pittaccio, S.; Caimmi, M.; Gasperini, G.; Pirovano, S.; Villa, E.; Besseghini, S.; Molteni, F. Pseudoelastic nitinol-based device for relaxation of spastic elbow in stroke patients. J. Mater. Eng. Perform. 2009, 18, 805–813. [Google Scholar] [CrossRef]

- Hadi, A.; Alipour, K.; Kazeminasab, S.; Elahinia, M. ASR glove: A wearable glove for hand assistance and rehabilitation using shape memory alloys. J. Intell. Mater. Syst. Struct. 2018, 29, 1575–1585. [Google Scholar] [CrossRef]

- Copaci, D.S.; Blanco, D.; Martin-Clemente, A.; Moreno, L. Flexible shape memory alloy actuators for soft robotics: Modelling and control. Int. J. Adv. Robot. Syst. 2020, 17, 1729881419886747. [Google Scholar] [CrossRef]

- Tang, T.; Zhang, D.; Xie, T.; Zhu, X. An exoskeleton system for hand rehabilitation driven by shape memory alloy. In Proceedings of the 2013 IEEE International Conference on Robotics and Biomimetics (ROBIO), Shenzhen, China, 12–14 December 2013; pp. 756–761. [Google Scholar]

- Jeong, J.; Yasir, I.B.; Han, J.; Park, C.H.; Bok, S.K.; Kyung, K.U. Design of shape memory alloy-based soft wearable robot for assisting wrist motion. Appl. Sci. 2019, 9, 4025. [Google Scholar] [CrossRef]

- Savi, M.A.; Pacheco, P.M.C.L.; Garcia, M.S.; Aguiar, R.A.A. Nonlinear geometric influence on the mechanical behavior of shape memory alloy helical springs. Smart Mater. Struct. 2015, 24, 035012. [Google Scholar] [CrossRef]

- An, S.M.; Ryu, J.; Cho, M.; Cho, K.J. Engineering design framework for a shape memory alloy coil spring actuator using a static two-state model. Smart Mater. Struct. 2012, 21, 055009. [Google Scholar] [CrossRef]

- Tian, F. A Superelastic Variable Stiffness Knee Actuator for a Knee-Ankle-Foot Orthosis. Ph.D. Thesis, University of Toledo, Toledo, OH, USA, 2015. [Google Scholar]

- Stirling, L.; Yu, C.H.; Miller, J.; Hawkes, E.; Wood, R.; Goldfield, E.; Nagpal, R. Applicability of shape memory alloy wire for an active, soft orthotic. J. Mater. Eng. Perform. 2011, 20, 658–662. [Google Scholar] [CrossRef]

- Sun, Z.; Zi, B.; Li, Y. Design and Modeling for Hybrid Driven Knee Orthosis with SMA actuator. In Proceedings of the 2021 27th International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Shanghai, China, 26–28 November 2021; pp. 127–132. [Google Scholar]

- Bhadane-Deshpande, M. Towards a Shape Memory Alloy Based Variable Stiffness Ankle Foot Orthosis. Ph.D. Thesis, The University of Toledo, Toledo, OH, USA, 2012. [Google Scholar]

- Amerinatanzi, A.; Zamanian, H.; Shayesteh Moghaddam, N.; Jahadakbar, A.; Elahinia, M. Application of the superelastic NiTi spring in ankle foot orthosis (AFO) to create normal ankle joint behavior. Bioengineering 2017, 4, 95. [Google Scholar] [CrossRef]

- Pittaccio, S.; Viscuso, S. An EMG-controlled SMA device for the rehabilitation of the ankle joint in post-acute stroke. J. Mater. Eng. Perform. 2011, 20, 666–670. [Google Scholar] [CrossRef]

- Pittaccio, S.; Viscuso, S. Shape memory actuators for medical rehabilitation and neuroscience. In Smart Actuation and Sensing Systems—Recent Advances and Future Challenges; InTech: London, UK, 2012; pp. 83–120. [Google Scholar]

- Hau, C.T.; Gouwanda, D.; Gopalai, A.A.; Yee, L.C.; Hanapiah, F.A.B. Design and development of platform ankle rehabilitation robot with Shape Memory Alloy based actuator. In Proceedings of the 2017 39th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Jeju, Republic of Korea, 11–15 July 2017; pp. 946–949. [Google Scholar]

- Joudzadeh, P.; Hadi, A.; Alipour, K. Conceptual design of a lower limb exoskeleton actuated by shape memory alloys for assisting elderly people in stair climbing. In Proceedings of the 2016 4th International Conference on Robotics and Mechatronics (ICROM), Tehran, Iran, 26–28 October 2016; pp. 530–535. [Google Scholar]

- Tian, F.; Elahinia, M.; Hefzy, M.S. A dynamic knee-ankle-foot orthosis with superelastic actuators. In Proceedings of the ASME 2013 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, Snowbird, UT, USA, 16–18 September 2013; Volume 56048, p. V002T06A005. [Google Scholar]

- Tian, F.; Hefzy, M.S.; Elahinia, M. Development of a dynamic knee actuator for a KAFO using superelastic alloys. In Proceedings of the ASME 2014 International Mechanical Engineering Congress and Exposition, Montreal, QC, Canada, 14–20 November 2014; Volume 46469, p. V003T03A065. [Google Scholar]

- Chan Vili, Y.Y. Investigating smart textiles based on shape memory materials. Text. Res. J. 2007, 77, 290–300. [Google Scholar] [CrossRef]

- Abel, J.; Luntz, J.; Brei, D. Hierarchical architecture of active knits. Smart Mater. Struct. 2013, 22, 125001. [Google Scholar] [CrossRef]

- Kiourti, A.; Volakis, J.L. Colorful textile antennas integrated into embroidered logos. J. Sens. Actuator Netw. 2015, 4, 371–377. [Google Scholar] [CrossRef]

- Maziz, A.; Concas, A.; Khaldi, A.; Stålhand, J.; Persson, N.K.; Jager, E.W. Knitting and weaving artificial muscles. Sci. Adv. 2017, 3, e1600327. [Google Scholar] [CrossRef]

- Mirabedini, A.; Aziz, S.; Spinks, G.M.; Foroughi, J. Wet-spun biofiber for torsional artificial muscles. Soft Robot. 2017, 4, 421–430. [Google Scholar] [CrossRef]

- Abel, J.; Luntz, J.; Brei, D. A two-dimensional analytical model and experimental validation of garter stitch knitted shape memory alloy actuator architecture. Smart Mater. Struct. 2012, 21, 085011. [Google Scholar] [CrossRef]

- Eschen, K.P. Multiscale Mechanics of Shape Memory Alloy Knitted Architectures. Ph.D. Thesis, University of Minnesota, Minneapolis, MN, USA, 2020. [Google Scholar]

- Granberry, R.; Abel, J.; Holschuh, B. Active knit compression stockings for the treatment of orthostatic hypotension. In Proceedings of the 2017 ACM International Symposium on Wearable Computers, Maui, HI, USA, 11–15 September 2017; pp. 186–191. [Google Scholar]

- Granberry, R.; Eschen, K.; Holschuh, B.; Abel, J. Functionally graded knitted actuators with NiTi-based Shape Memory Alloys for topographically self-fitting wearables. Adv. Mater. Technol. 2019, 4, 1900548. [Google Scholar] [CrossRef] [PubMed]

- Duvall, J.C.; Schleif, N.; Dunne, L.E.; Holschuh, B. Dynamic compression garments for sensory processing disorder treatment using integrated active materials. J. Med. Devices 2019, 13, 021001. [Google Scholar] [CrossRef]

- Holschuh, B.T.; Newman, D.J. Morphing compression garments for space medicine and extravehicular activity using active materials. Aerosp. Med. Hum. Perform. 2016, 87, 84–92. [Google Scholar] [CrossRef]

- Berzowska, J. Memory rich clothing: Second skins that communicate physical memory. In Proceedings of the 5th Conference on Creativity & Cognition, London, UK, 12–15 April 2005; pp. 32–40. [Google Scholar]

- Eschen, K.; Granberry, R.; Abel, J. Guidelines on the design, characterization, and operation of shape memory alloy knitted actuators. Smart Mater. Struct. 2020, 29, 035036. [Google Scholar] [CrossRef]

- Eschen, K.; Abel, J. Performance and prediction of large deformation contractile shape memory alloy knitted actuators. Smart Mater. Struct. 2018, 28, 025014. [Google Scholar] [CrossRef]

- Leaf, G. A property of a buckled elastic rod. Br. J. Appl. Phys. 1958, 9, 71. [Google Scholar] [CrossRef]

- Jung, W.K.; Lee, S.M.; Ahn, S.H.; Park, J. Development and assessment of a knitted shape memory alloy-based multifunctional elbow brace. J. Ind. Text. 2022, 51, 1989S–2009S. [Google Scholar] [CrossRef]

- Park, S.J.; Kim, U.; Park, C.H. A novel fabric muscle based on shape memory alloy springs. Soft Robot. 2020, 7, 321–331. [Google Scholar] [CrossRef]

- Park, S.J.; Park, C.H. Suit-type wearable robot powered by shape-memory-alloy-based fabric muscle. Sci. Rep. 2019, 9, 9157. [Google Scholar] [CrossRef]

- Golgouneh, A.; Beaudette, E.; Woelfle, H.; Li, B.; Subash, N.; Redhouse, A.J.; Jones, M.; Martin, T.; Lobo, M.A.; Holschuh, B.; et al. Design of a hybrid SMA-pneumatic based wearable upper limb exoskeleton. In Proceedings of the 2021 International Symposium on Wearable Computers, Virtual, 21–26 September 2021; pp. 179–183. [Google Scholar]

| Wire Diameter (mm) | Resistance (/m) | Activation Current (A) | Force (N) | Cooling Time 70 °C (s) | Cooling Time 90 °C (s) |

|---|---|---|---|---|---|

| 0.15 | 55.00 | 0.41 | 3.15 | 2.00 | 1.70 |

| 0.20 | 29.00 | 0.66 | 5.59 | 3.20 | 2.70 |

| 0.25 | 18.50 | 1.05 | 8.74 | 5.40 | 4.50 |

| 0.31 | 12.20 | 1.50 | 12.55 | 8.10 | 6.80 |

| 0.38 | 8.30 | 2.25 | 22.06 | 10.50 | 8.80 |

| 0.51 | 4.30 | 4.00 | 34.91 | 16.80 | 14.00 |

| Title | Target Organ | Target Motion/Application | Actuation Mechanism | Cooling Mechanism | Challenges |

|---|---|---|---|---|---|

| Forearm and hand rehabilitation exoskeleton with 3 degrees of freedom (DOF) [97] | Forearm and hand | Wrist flexion–extension and abduction–adduction | SMA wires actuating tendons in spring bias and differential configuration | Miniature fans embedded in the design |

|

| EDGES SMA-based actuator [98] | Elbow | Spastic elbow relaxation | Polycentric hinges controlled by SMA wires | Natural convection |

|

| Bowden cable-based SMA actuator [99] | Elbow | Elbow flexion–extension | SMA wire actuation with the Bowden tube acting as a flexible heat dissipater | Natural convection aided by a Bowden tube acting as a heat sink |

|

| Tube-encased SMA coil wrist actuator [100] | Wrist | Wrist flexion–extension and ulnar–radial deviation | SMA coil enclosed in a stretchable polymer (Ecoflex 00-30) tube | Coolant circulation system |

|

| Four-bar link mechanism-based SMA finger actuator [101] | Fingers | Finger abduction–adduction and extension–flexion | Four-bar link mechanism | Natural convection |

|

| ASR glove for hand rehabilitation [102] | Fingers | Finger abduction–adduction and extension–flexion | SMA wires actuating tendons connected to a platform on the forearm | Natural convection |

|

| Title | Target Organ | Target Motion/Application | Actuation Mechanism | Cooling Mechanism | Challenges |

|---|---|---|---|---|---|

| SMA-driven knee module in Knee–Ankle Foot Orthosis [105] | Knee | Knee extension–flexion | Parallel combination of a superelastic torsional rod and a torsional spring | Natural convection |

|

| Active Soft Orthotic (ASO) for the knee and ankle joints using SMA wire [106] | Knee and ankle | Ankle dorsiflexion–plantarflexion and knee extension–flexion | Four lines of SMA coils | Natural convection |

|

| Hybrid-Driven Knee Orthosis (KO) with SMA actuator [107] | Knee | Knee extension–flexion | Two antagonistic actuators connected and fixed on a knee joint shaft pulley by belt | Natural convection |

|

| SMA Pulley-driven hinged Active Ankle Foot Orthosis (AAFO) [108] | Ankle | Ankle dorsiflexion–plantarflexion | Three SMA springs transferring torque through pulleys | Natural convection |

|

| Superelastic hinge AFO (HAFO) [109] | Ankle | Ankle dorsiflexion–plantarflexion | Superelastic hinge for rotary using NiTi spring | Natural convection |

|

| Lower-Limb Exerciser with Intelligent Alloys (Leia) [110] | Ankle | Ankle dorsiflexion–plantarflexion | Rotary actuators on either side of the hinge | Natural convection |

|

| SHADE: SMA wire-driven ankle rehabilitation device [111] | Ankle | Ankle dorsiflexion–plantarflexion | Two linear actuators fixed between two thermoplastic shells connected at a hinge | Natural convection |

|

| Platform-type ankle rehabilitation robot [112] | Ankle | Ankle dorsiflexion–plantarflexion | Metal plates weaved with SMA wire | Forced convection using four conventional on–off fans |

|

| Tendon-driven exoskeleton [113] | Knee and ankle | Ankle dorsiflexion–plantarflexion and knee extension–flexion | SMA wires with pulleys | Natural convection |

|

| Sr. No. | Parameter | Value |

|---|---|---|

| 1 | Average Radius | 12 mm |

| 2 | SMA Spring Wire Radius | 0.5 mm |

| 3 | Number of effective coils | 28 |

| 4 | Spring length | 100 mm |

| Title | Target Organ | Target Motion/Application | Actuation Mechanism | Cooling Mechanism | Challenges |

|---|---|---|---|---|---|

| Smart clothing for ankle rehabilitation [43] | Ankle | Ankle dorsiflexion–plantarflexion | SMA wires crossing each other and anchored at two points | Natural convection |

|

| Multifunctional elbow brace (MFEB) [131] | Elbow | Thermal and pressure therapy | Knitted SMA wires clenching the fabric upon activation | Natural convection |

|

| Spring-based fabric muscle (SFM) [132] | Any | Multi-purpose | Four layers in series of five springs connected in parallel | Natural convection |

|

| Suit-Type Wearable Robot (STWR) [133] | Elbow | Elbow flexion–extension | Knitted SMA wires clenching the fabric upon activation | Natural convection |

|

| Pneumatic–SMA hybrid soft exoskeleton [134] | Shoulders and arms | Shoulder abduction | SMA springs housed in fabric braids to provide antagonistic elastic force | Natural convection |

|

| Stocking to provide compression treatment for orthostatic hypertension [123] | Shin | Compression treatment | SMA wires and aramid fibers interwoven at different ratios | Natural convection |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shami, Z.; Arslan, T.; Lomax, P. Wearable Soft Robots: Case Study of Using Shape Memory Alloys in Rehabilitation. Bioengineering 2025, 12, 276. https://doi.org/10.3390/bioengineering12030276

Shami Z, Arslan T, Lomax P. Wearable Soft Robots: Case Study of Using Shape Memory Alloys in Rehabilitation. Bioengineering. 2025; 12(3):276. https://doi.org/10.3390/bioengineering12030276

Chicago/Turabian StyleShami, Zain, Tughrul Arslan, and Peter Lomax. 2025. "Wearable Soft Robots: Case Study of Using Shape Memory Alloys in Rehabilitation" Bioengineering 12, no. 3: 276. https://doi.org/10.3390/bioengineering12030276

APA StyleShami, Z., Arslan, T., & Lomax, P. (2025). Wearable Soft Robots: Case Study of Using Shape Memory Alloys in Rehabilitation. Bioengineering, 12(3), 276. https://doi.org/10.3390/bioengineering12030276