Abstract

Cacao mucilage is a rich medium for microbial development due to the presence of various sugars, water, pectin, mineral salts, and yeasts of the Saccharomyces cerevisiae type. This study aims to provide added value to this commonly discarded residue, thereby contributing to the economic growth of the Rio Chila area in the Valencia Canton of Los Ríos Province. The methods applied for developing beer consist of malting, grinding, mashing, filtering, boiling, cooling, fermentation (during which cacao mucilage is added), and maturation, followed by physical–chemical analyses. The Fine aroma cacao mucilage presented values of 0.66% acidity, 7.63 °Brix, pH 4.43, absorbance 1.13, transmittance 23.67%, suspended solids 0.04 g: 2.66%, density 1.07 g/mL, turbidity 6.94 NTU, °GL 8.47% vol., foam quantity 1.70 cm, colorimetry L* 50.77, colorimetry a* 18.08, colorimetry b* 50.53, and bitterness degree 39.00. The analyses presented values within the normal parameters applied to beers at the national level (INEN standards). Escherichia coli, Salmonella, and total microorganisms showed no contamination in the microbiological analyses. In the sensory analyses, appearance, aroma, flavour, and mouthfeel were evaluated, with the best experiment being the combination of Fine aroma cacao with a concentration of 30% mucilage and added Cascade hops. This study took into account the concentrations of cacao mucilage (20% and 30%) from the varieties (Fine aroma and CCN-51), as well as the addition of the brewing hops Cascade and Northern Brewer. Regarding the physicochemical characteristics, adding this cacao derivative did not affect craft beer and conformed to the ranges of the NTE INEN 2262 standard. Thus, this research proposes an alternative use for cocoa mucilage, contributing to waste reduction and broadening its potential applications.

1. Introduction

In recent years, the Ecuadorian beer industry has shown significant growth, mainly in the craft beer market, where the process must be more careful because of the limited technology used in its production. The characteristics of this type of beer vary from those of commercial beers. Some important variation factors are the care and dedication of the brewmaster during production and carbonation, and the quality of barley [1]. The latter affects both physical and chemical characteristics [2]. Currently, beer is characterised by being a highly accepted product in European countries, where more than 90 L are consumed per year [3]. In Ecuador, 300 million litres are consumed annually, which is equivalent to 25 L per capita [4].

Craft beer production is classified as a small-scale process, with production subprocesses that combine the crafting of traditional recipes with a search for differentiation through new ingredients to create new styles [5]. Incorporating adjuncts as complements in beer brewing can have both negative and positive effects on the final product. It is necessary to understand the influence of adjuncts as partial replacements in beer through analytical methods to provide a high-quality product [6].

Craft beers offer a wide variety of flavours and aromas, largely determined by the type of yeast used. Ales, fermented at higher temperatures (15–24 °C) by Saccharomyces cerevisiae, typically feature more complex and fruity flavour profiles. On the other hand, lagers, fermented at lower temperatures (7–12 °C) by Saccharomyces pastorianus, are characterised by cleaner and more refreshing flavours. They are also called top-fermenting due to the surface position of the yeast in the fermenter [7]. The essential ingredients of craft beer are malt, water, hops, and yeast [8]. For the bitterness of craft beer, hops are used, whose primary role in brewing is the preservation of products derived from the isomerisation of beer resins by hops, the flavour of the beer from its essential oils and isomerisation products, and the increase in polyphenol levels in the wort and beer [9]. Among the different types of hops used in craft beer brewing, Northern Brewer 7.4% AA (alpha acids) stands out, and is used as a dual-purpose hop providing excellent medium bitterness properties and a pleasant aroma of grass and wood [10], and the American Cascade hop with data ranging from 2.3 to 10.2% AA in pellet form, characterised by a specific citrus, floral, and herbal aroma [11].

In addition, this type of American Pale beer acquires intense, varied, and tasty aromas [12]. The yeast Saccharomyces cerevisiae is directly responsible for beer fermentation, with the most favourable pH conditions for its activity ranging between 4.5 and 6.5 [13]. The cells of this type of yeast are tiny, so the carbon dioxide bubbles (CO2) produced during fermentation carry the particles to the top of the fermentation tank, where they clump together and perform their functions [14]. The first fermentation has a relatively short duration, lasting between two and five days [15]. Using a product or by-product containing sugars and yeasts can help carry out fermentation processes, as with cocoa mucilage.

Cocoa (Theobroma cacao L.) is a tree of Amazonian origin from the Malvaceae family, a shade-loving plant that generally requires abundant rainfall and shade conditions for its development, and it originates from complex ecological structures (rainforests) [16]. Currently, the three primary producers are the Ivory Coast (1,963,949 t), Ghana (947,632 t), and Indonesia (593,832 t), which contributed 66.73% of the world’s production [17], while 14% comes from Latin America, with Ecuador standing out at 4% and Brazil at 3% of the world’s production [18]. In Ecuador, two types of cocoa are cultivated: the Fine aroma cultivars and the CCN 51 clone. The first is mainly grown in agroforestry systems by small producers and some companies with extensions exceeding 120 ha. The sensory quality of Fine-aroma-type cocoa is recognised worldwide, and high prices are paid in the markets [19].

Cocoa seeds are surrounded by an aromatic pulp which comes from their teguments, called mucilage or baba, which is composed of spongy parenchymatous cells that contain sap cells rich in sugars (10–13%), pentoses (2–3%), citric acid (1–2%), and salts (8–10%) [20]. Countries such as Peru utilise cocoa mucilage’s benefits in producing products such as liquor, jam, and jellies, and the large amount of sugar that mucilage contains generates alcohol, becoming an input for making craft beer [21,22]. A central problem arises within cocoa production in Ecuador: the underutilisation of cocoa mucilage. It has been observed that farmers discard the mucilage that detaches from the cocoa seed, resulting in the waste of raw material. Among the factors or causes that lead to the waste of cocoa mucilage are the lack of knowledge among farmers and the lack of concern from organisations for the optimisation of this resource, the lack of awareness of the nutrient content and properties of the mucilage, and the optimisation of this resource to produce other derivatives [23,24]. The possible utilisation of cocoa mucilage could be the production of fermented beverages, as the yeast content, such as Saccharomyces cerevisiae cocoa mucilage, facilitates its adaptability in fermentation processes, in addition to containing acetic acid bacteria (AAB) and lactic acid bacteria (LAB) [25]. Furthermore, the chemical composition of this residue allows for the partial substitution of carbon sources in fermentative processes, such as beer and Ale malt.

The present study was conducted to evaluate an Ale-type craft beer with two types of hops (Cascade and Northern Brewer) and the use of cocoa mucilage (Theobroma cacao L.) from the Fine aroma and CCN-51 varieties as a partial substitute for malt through the analysis of physicochemical, microbiological, sensory, and statistical parameters to determine the added value of cocoa mucilage (commonly a residue) that generates sustainability in the cocoa industry in Los Ríos Province.

2. Materials and Methods

2.1. Raw Materials

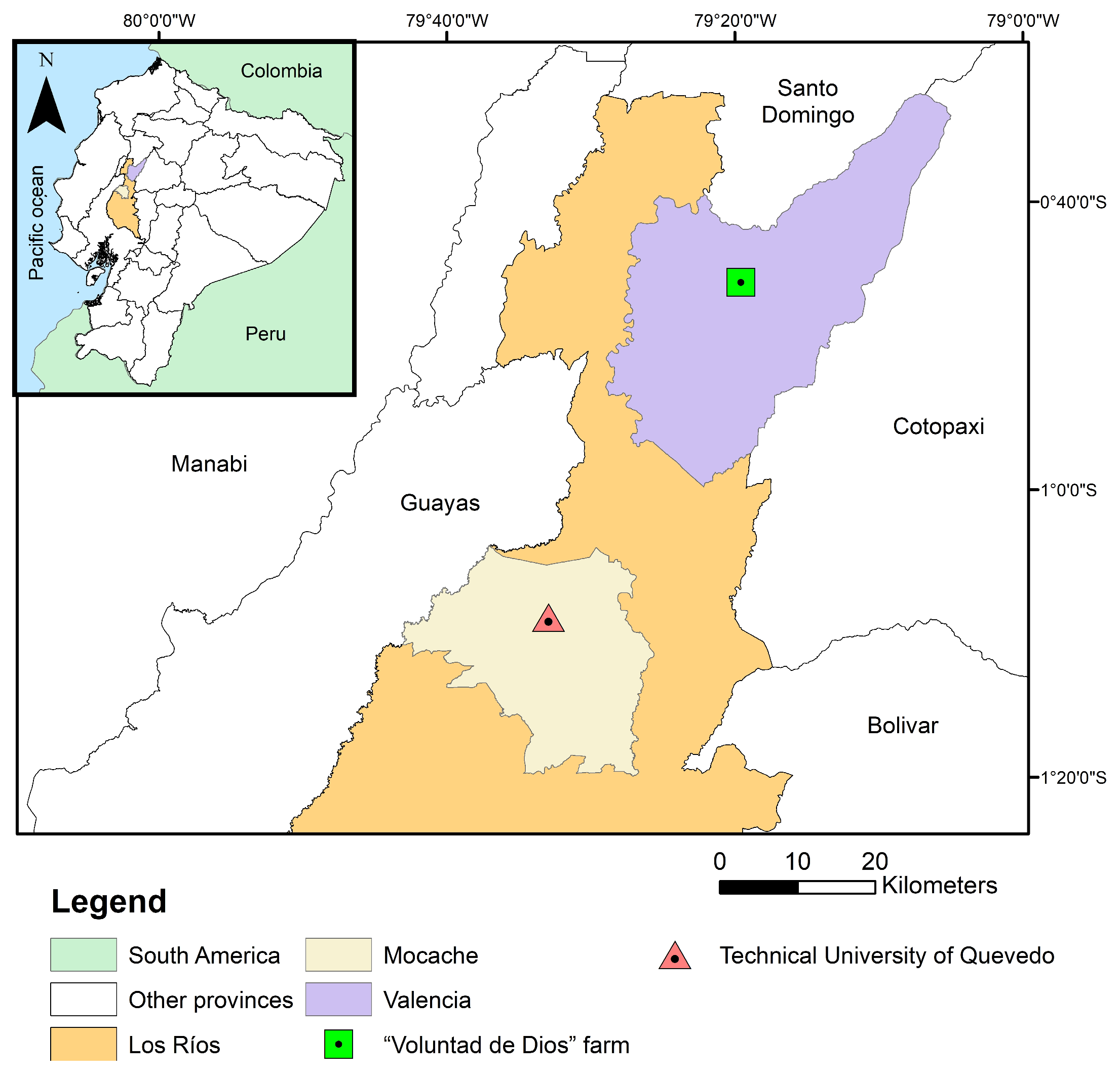

The raw materials used in this study were malt and pasteurised cocoa mucilage of the Fine aroma and CCN-51 varieties, which were distributed in an area of 10.000 m2, with 70% of the CCN-51 crop and 30% of Fine aroma, which were applied at concentrations of 20% and 30%. These concentrations were considered because, in previous research, similar concentrations were used, with excellent results in other types of beverages. Two types of hops (Cascade and Northern Brewer) were used to measure the degree of bitterness. To produce Ale-type craft beer with partial addition of mucilage, the cocoa mucilage from the two varieties was acquired from the “Voluntad de Dios” farm located in the Fumisa sector, via Camarones, Rio Chila precinct, situated in Los Ríos Province (121 m.a.s.l. dry tropical climate) (Figure 1). The yeast applied is a type of active dry yeast Saccharomyces cerevisiae for craft beer.

Figure 1.

Geographical location of the place where the cocoa mucilage, the main material of this research, was obtained. Geographical location of Experimental Campus ‘La María’, where all the tests of this research were carried out.

2.2. Design

In the present study, the effects on the production of craft beer of different varieties (CCN-51 and Fine aroma) and concentrations of mucilage (20% and 30%), as well as two types of hops (Cascade and Northern Brewer), were evaluated, resulting in eight different batches (Table 1). Additionally, there was a control batch of beer with hops (Cascade and Northern Brewer) without cocoa mucilage. Three independent replicates of each batch comprising cocoa varieties plus mucilage concentrations and types of hops were analysed.

Table 1.

Experimental units carried out within this study, with the description of cocoa type, mucilage concentration, and type of craft beer.

The following physicochemical analyses were performed: acidity, °Brix, pH, absorbance, transmittance, suspended solids, density, turbidity, °GL, foam quantity, colorimetry L* a* b*, and bitterness degree. The analyses of this study were carried out in the laboratories of bromatology, soils, introductory chemistry, biotechnologies, and ruminology, located at the campus of the Technical University of Quevedo, experimental farm “La María”, at km 7 ½ of the Quevedo–El Empalme road, San Felipe precinct, Mocache Canton, Los Ríos Province (Figure 1).

2.3. Craft Beer Production

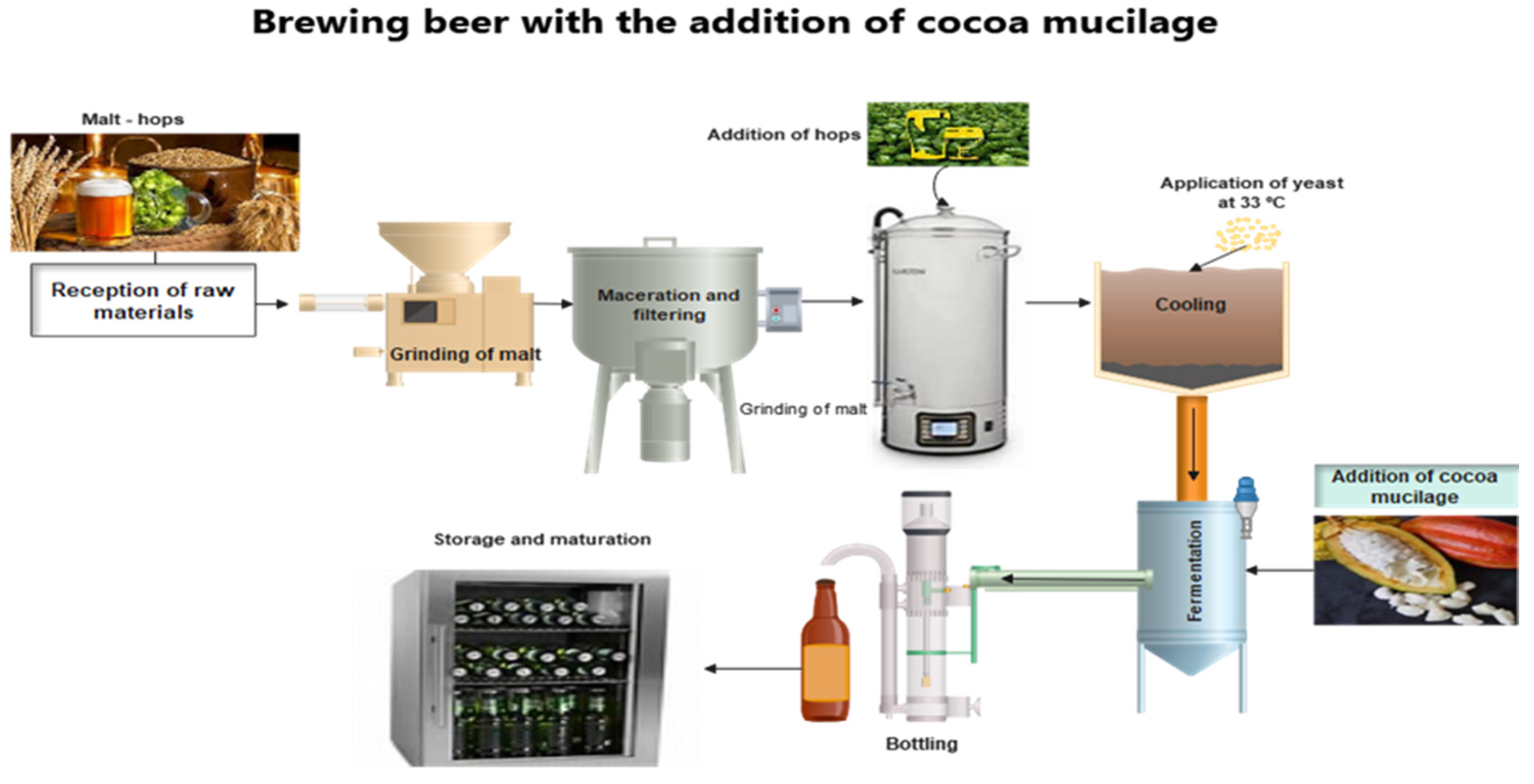

The primary operations carried out to produce the control craft beer are shown in Figure 2.

Figure 2.

Craft beer production.

- Malt, an essential element in the production of beer, is obtained through a process known as malting, which involves the regulated germination of barley grains. At this stage, a group of endogenous enzymes is activated, such as amylases and proteases, which play an essential role in the hydrolysis of starches and proteins during mashing, generating fermentable sugars and peptides that contribute to the taste and texture of the final beer.

- Grinding: The grains were ground by breaking the pericarp of barley malt in an electric mill. This action allows for easier extraction of the sugars contained in the malt.

- Mashing and filtration: The ground grains are mixed with water to form the wort, increasing the temperature gradually, starting at 40 °C, then 60 °C for 30 min, and, finally, 80 °C for 90 min. After mashing, the wort is filtered using a 20 L filter press, separating the liquid from the grains. The mashing curve follows enzyme activation temperatures to maximize sugar production.

- Boiling: The wort was boiled at 95 °C for 60 min, in order to sterilize it, coagulate proteins, and stop enzymatic activity. During this stage, 60 g of hops were added in two doses. The first addition (30 g) was made at the beginning of the boiling, contributing mainly to the bitterness of the beer. The second addition, with the remaining 30 g, was made halfway through the process, with constant stirring, to maximize the extraction of aromas and essential oils from the hops. In this step, two control batches were prepared, corresponding to the two types of hops evaluated.

- 5.

- Wort cooling: During the wort cooling, the temperature was reduced to 33 °C. Ale-type yeast Saccharomyces cerevisiae was added to 5.75 g of 20 L of wort. A clarifying agent (selafine) was also added in a proportion of 1 g in the 20 L of wort.

- 6.

- Beer fermentation: The wort was fermented for two weeks at a temperature of 25 ± 2 °C. Fermentation occurs because yeast consumes the sugars extracted from the malt and converts them into alcohol. In this process, the yeast also releases CO2, for which air-locked CO2 valves are placed. This process took place in a light-deprived environment for 15 days.

- 7.

- Bottling: Using a filling machine, the beer was bottled in 330 cc glass bottles. To preserve carbonic acid in the beer, filling was performed using a rechargeable automatic liquid dispenser, thus ensuring the quality of the beer.

- 8.

- Maturation: The resulting liquid required a maturation period of 15 days. During this period, the beer was subjected to low temperatures of 4 °C to stabilise the flavour and aroma, and the right balance between the different nuances was obtained.

- 9.

- Storage: Finally, the craft beer was refrigerated at 4 °C for six days.

2.4. Beer Production with the Addition of Cocoa Mucilage

The craft beer was brewed using the traditional method, with the exception of the addition of cocoa mucilage.

This ingredient was incorporated into the wort at the beginning of the fermentation of the wort in order to increase the aromatic complexity and modify the sugar profile. After cooking, the wort was cooled to 33 °C and inoculated with a yeast strain selected for this style of beer.

Fermentation: in this stage, the cocoa mucilage was added with the respective percentages of 20% and 30%. Alcohol production then decreases to obtain a final alcohol concentration of 6–7% by volume [26]. The bottling, maturation, and storage stages were carried out under the same controlled temperature and humidity conditions as the reference beer in order to ensure a fair comparison and to assess the impact of cocoa mucilage on the stability and flavour of the beer.

Recipe for the production of 20 L of beer:

- Base and special malt: 6.81 kg

- Hops: 62 g

- Yeast: 11.5 g

- Clarifying agent: 2 g

2.5. Analysis of Physicochemical Parameters

The NTE INEN 2262-2013 standards [27] (alcoholic beverages, beer, requirements) were considered to identify the physicochemical properties of the fermented beverage. All analyses were performed on three independent samples. For this purpose, the following parameters were determined:

- Measurement of soluble solids: this was conducted with the Pocket Refractometer from ATAGO, with a scale of 0–93%, and results were expressed in °Brix following the NTE INEN 1083 standard [28].

- Measurement of pH: A potentiometer was used at 26 °C (room temperature) and calibrated before use, following the Ecuadorian standard NTE INEN 2325 [29].

- Determination of titratable acidity (%): Via the titration of 10 mL of sample with 0.1 N NaOH using phenolphthalein as an indicator, expressed as a percentage of lactic acid for dairy products, applying the official AOAC 947.05 NTE INEN 2323 method, A.O.A.C. [30].

- Alcoholic degrees in (%): Using an alcoholmeter and applying the Ecuadorian technical standard 340 [31].

- Density: The pycnometer method was applied according to the NTE 349 standard [32].ɗ = m2 − m1/m3 − m1,ɗ = relative density at 20°/20 °C.m1 = mass of the empty pycnometer, in grams.m2 = mass of the pycnometer with the sample, in grams.m3 = mass of the pycnometer with distilled water, in grams.

- Colorimetry: The colour measurement was carried out using the CIE L*a*b* method [33] with a CHROMA METER CR 400 colorimeter, and each component is described below and measured in orthotropic units (OTU):L* defines the luminositya* red–green colour componentb* yellow–blue colour componentThe luminosity (L*), the red index (a*), and the yellow index (b*) with a photocolorimeter spectrum.

- Transmittance and absorbance (nm): A DR3900 HACH spectrophotometer series 1488262 (Manufacturer: HACH; city: Colorado; country: USA) was used, with a wavelength of 430 nanometres. The use of absorbance in performing spectra has the advantage of being directly proportional to the concentration of molecules in the sample; the ASBC method was applied [34].

- Bitterness degree (%): The bitterness was determined by the IBU (International Bitterness Unit) method of Glenn Tinshet.

- Foam quantity (cm): Adapted from the Non-Invasive Beer foam Evaluation Method (NIBEM) method, foam stability was assessed by pouring 300 mL of beer into a graduated cylinder. Once the foam stabilised, the time required for its maintenance and disappearance was measured. The NIBEM method measured the collapse of the foam generated when pouring the beer from the bottle into the glass. This period of descent was assessed by measuring three different heights adjusted by electrodes until the foam disappeared completely. The “NIBEM” method was used with a foam stability analyser-FSA, using the NI-BEM 1-CUBE method equipment (1-CUBE, Havlickuv Brod, Czech Republic) [35].

- Turbidity: The turbidity meter 2100 AN from the HACH brand. The results are expressed in NTU. NTU/FNU: Formazin Nephelometric Unit, measurement of total turbidity, permanent turbidity, and cold turbidity of the beer [36].

- Suspended solids (%): In total, 1 mL of sample was taken and placed in the Eppendorf tube, and then the tubes were placed in the centrifuge for 5 min at 13,000 rpm. Before centrifugation, the sample was weighed on an analytical balance. Then, it was weighed again to obtain the value consumed during centrifugation according to the Mexican standard [37].

2.6. Microbiological Analysis

These microorganisms were detected and counted to evaluate the microbiological quality and detect possible contaminations because the mucilage is in contact with different surfaces during harvesting, and microorganisms such as Escherichia coli and Salmonella were considered as the basis of analysis. Nutrient Agar was used as the culture medium, and the official AOAC 986.33 method was applied [38]. For the Agar medium, decimal dilutions of 0.1 mL of the sample dilutions 10-110-2 and 10-3 in triplicate were used. The stock solution was collected, and 900 μL of distilled water was placed in three Eppendorf tubes, followed by the addition of 100 μL of the stock solution (−1) to the first Eppendorf tube and placed in the Vortex equipment for shaking. From the first Eppendorf tube, 100 μL was extracted and transferred to the second Eppendorf tube (−2) for shaking. Finally, 100 μL was extracted from the second Eppendorf tube and placed in the third Eppendorf tube (−3). Subsequently, it was shaken to homogenise the mixture.

For the determination of Escherichia coli, MacConkey Agar was used, which was previously autoclaved with a K GEMMY brand autoclave. The plates were incubated at 37 °C for 48 h, and colony counting was performed according to the INEN 2667 standard [39].

Salmonella Shigella Agar was used for the Salmonella analysis, and this medium was autoclaved using a K GEMMY brand autoclave. The result of the analysis was determined in 48 h, and colony counting was performed according to the NTE 2802 standard [40].

2.7. Sensory Analysis

Sensory analysis was conducted by 18 untrained tasters aged between 30 and 45 years. Before the tasting, the components of each experiment and their concentrations of CCN-51 cocoa mucilage and Fine aroma, as well as two types of hops (Cascade and Northern Brewer), were explained. Each panellist was presented with 20 mL samples, with five different samples previously coded in each session. Nominal scales were applied to identify the characteristics of the fermented beverages. They use a 5-point scale for odour, colour, flavour, sweetness, and astringency (1 = very much dislike, 2 = slightly dislike, 3 = neutral, 4 = slightly like, 5 = very much like), which was found in the form of their respective ratings. The Institutional Review Board, comprising the Research Directorate and Faculty of Engineering and Production Sciences, approved the study.

2.8. Statistical Analysis

Statgraphics Centurion XVI software (Statgraphics Technologies, version 19, The Plains, VA, USA) was used for the statistical analysis of the data, and the diagrams were drawn using EdrawMax V12.5.2. Statgraphics Centurion XVI software (Wondershare Technology Co., Ltd., Vancouver, BC, Canada) was used for the statistical analysis of the data, while diagram drawing was performed using EdrawMax V12.5.2. Two-way ANOVA was used to evaluate the results of physical, microbiological, and sensory analyses. If different means were found, they were separated using Tukey’s post hoc test. The confidence interval used for the study was set at 95%, ensuring reliable evaluation of the statistical significance of the results.

3. Results and Discussion

3.1. Physicochemical Analysis

Table 2 shows the results of this study. These were found within the parameters established by the standard requirements [27], which report a minimum value of 3.5 and a maximum of 4.8 with respect to pH.

Table 2.

Physicochemical analysis of all the experimental units carried out in this study.

For the CCN-51 variety at 30% and Cascade hop with 4.43 (EU3), in acidity, it showed a significant difference with 0.66 (%) the EU4, in °Brix, the combination EU4 CCN-51 with a concentration of 30%, and the addition of Northern Brewer 7.63%; for absorbance, it showed a significant difference in the Fine aroma mucilage variety at 20% with Cascade hop 1.17 EU5; and in transmittance, it showed the Fine aroma variety at 30% and Northern Brewer with 23.67 EU8. Suspended solids show the most representative value when combining the Fine aroma variety at 20% with Cascade 0.04 EU5; regarding density in CCN-51 at a concentration of 30% with Northern Brewer hop 1.07 EU4, turbidity in Fine aroma at 20% with Northern Brewer 11.38 EU6 shows a significant difference, active in the control with 12.16 with Northern Brewer, alcoholic degrees with the combination of CCN-51 concentration at 20%, and Cascade 8.47 EU1. Foam quantity showed a significant difference for the Fine aroma variety at a concentration of 30% and Northern Brewer hop 1.7 cm EU8. Colorimetry in L showed a significant difference in Fine aroma at 30% with Northern Brewer 50.77 EU8. Colorimetry in a* did not show a significant difference; the highest value is from CCN-51 with a concentration of 30% and the addition of Cascade hop 22.98 EU3. Colorimetry in b* did not show a significant difference, with higher values in the Fine aroma at 30% with Northern Brewer hop 50.53 EU8, which showed a significant difference in bitterness degrees in the combination of CCN-51 at a concentration of 30% and with Northern Brewer hop 39.00 EU4.

3.1.1. pH

The results obtained in the present study were within the parameters established by the standard [27] requirements, which report a minimum value of 3.5 and a maximum of 4.8 with respect to pH. A value of 4.28 was determined in the control, which showed a significant difference with the beer made with mucilage from CCN-51 with a concentration at 30% and the addition of Cascade hop with a value of 4.43 variety CCN-51 + mucilage concentration 30% + Cascade hop (EU3). These values are similar to those found by [2] and [41], who determined acidic pH in craft beers ranges between 4.20 and 4.47, compared to the craft-beer-type Pale Ale with the partial addition of cocoa mucilage, which influences the pH of the mucilage.

3.1.2. Acidity

The control beer presented an acidity of 0.39%, which was lower than the rest of the experimental units. The highest value, 0.66%, was observed in the production with mucilage from the CCN51 variety + mucilage concentration 30% + Northern Brewer hop (EU4). Previous studies have shown a diversity of acidity values, such as [42], who found acidity values of 0.87%, while [43] and [15] found values ranging from 0.22 to 0.80%. According to the NTE INEN 2262 standard [27], the acidity should contain a maximum of 0.30%. These higher acidity values in the new formulations compared to the control may be due to the presence of mucilage, which has an acidity of 1.048%.

3.1.3. °Brix

Traditionally, the Plato degree is used to determine the concentration of sugars in beer wort. This measure indicates the grams of original extract per 100 g of wort at 20 °C. Although both scales (Plato and Brix) measure the concentration of dissolved solids, there are slight differences in their calculations. For this work, we decided to use the Brix scale, which is widely used in the food industry. The soluble solids of the control presented values of 7.63 °Brix, with significant increases in the rest of the beers, especially in the formulations with cocoa mucilage from the CCN51 variety + mucilage concentration 30% (EU2 and EU4), with values higher than 7.5 °Brix and with the application of Northern Brewer hop. This may be due to the soluble solid content of the cocoa mucilage with values of 11.30 °Brix. The variation in this parameter is reflected in previous works, where total soluble solid concentrations between 3.6 and 12 °Brix have been obtained [13,44,45].

3.1.4. Spectrum Colorimetry L a*b

Regarding the luminosity represented by the parameter L*, a maximum luminosity of 50.77 was determined, which corresponds (EU8) to the Fine aroma cocoa variety at 30% concentration with Northern Brewer hop, while the luminosity of the control beers was situated at values of 40.00. In general, the brews with cocoa mucilage of the Fine aroma variety presented higher luminosities than the brews with CCN5. Other works have placed the L* values in craft beers between 23 and 82.43 [46].

The colour values reflected on the red–green axis (a*) ranged between 18.0 and 22.98 units, with increases in red colour observed with the addition of cocoa mucilage, especially with the CCN-51 variety at both concentrations (20% and 30%), and no significant differences were found between the experiments and the control. Meanwhile, the colourations representative of the yellow–blue axis (b*) showed values ranging between 38.13 and 50.53. In general, it can be observed that the beers made with Fine aroma mucilage exhibited slightly more yellowish colourations due to being of a different colour than CCN-51 and the type of Pale Ale malt.

3.1.5. Bitterness Degrees

Regarding the bitterness degree, in the control, values of 30.62 IBU were obtained with significant differences from the 39.00 IBU of the formulation Fine aroma variety CCN-51 + mucilage concentration 30% + Northern Brewer hop (EU4). In general, it was observed that the formulations with CCN-51 and Northern Brewer hop increased the average bitterness values. IBU is a unit of measurement that corresponds to the number of iso-alpha acids isomerised during the wort boiling. Previous works have shown lower bitterness values than those found in the present work, such as [47,48,49], which observed values ranging between 16.60 and 22.43.

3.1.6. Density

Regarding the density, the control beer presented a value of 1.03 g/mL with a significant difference when compared to 1.07 g/mL corresponding to the experiment of the CCN-51 variety + 30% mucilage concentration + Northern Brewer hop, which is close to the result of 1.05 g/mL from the research of [15] and [44] with a result of 1.00 to 1.01 g/mL, and also in the research [42], whose value is 0.98. Additionally, when analysing the cocoa mucilage, it had a density of 1.05, and it was determined that the increase in the alcoholic degrees of the final product in the control applied with Cascade hops was influenced in this study.

3.1.7. Absorbance

Regarding the absorbance analysis [50], mentions in their study that they recorded a value of 29.25 in the experiment corresponding to the Fine aroma variety + 20% mucilage concentration + Cascade hop, which is within the values (6.3–37.20) reported by the research of [51]. They mention that beer made only with bread is very clear, as it does not contain any type of malt, so its colour on the EBC scale and its absorbance are close to 0, like the absorbance result of the research by [52] with a value of 1. In the beer with the partial addition of cocoa mucilage, we obtained a higher absorbance value according to the EBC scale. It is worth noting that the absorbance of Fine aroma cocoa mucilage was 45, which did not cause the beer to turn dark. On the contrary, this allowed the final product to clarify due to the partial addition of the mucilage, as mentioned in [53], stating that a natural clarifier like cocoa mucilage is a good technical alternative because it can replace certain artificial clarifiers [46]. Compared to the control beer, it has a lower value of 25.5.

Regarding the transmittance of the craft beer, a value of 23.67% was determined, which belongs to the Fine aroma variety + 30% mucilage concentration + Northern Brewer hop. This value is higher than the control beer result of 10.63%, showing a significant difference, as [52] mentions in their study that molecular absorption spectroscopy is based on the measurement of transmittance, defined as the ratio of light beam intensities passing through a sample to that of the same beam in the absence of the sample. Additionally, in their study [54], they mention that the colour of the beer mainly depends on the type or types of malts used during its production, in the malting process of the cereal, and a very complex set of chemical reactions, through the production of coloured melanoidins, that give the beer shades ranging from light yellow to very dark brown and even black.

3.1.8. Turbidity

Regarding the turbidity analysis, the control had a value of 12.16 NTU, showing a significant difference compared to the 6.94 NTU within the experiment, corresponding to CCN-51 + mucilage concentration 30% + Cascade, which is within the range (5.99 and 32.6 NTU) obtained in the research of [55]. In comparison with the turbidity analysis of CCN-51 cocoa mucilage, which showed a value of 9.343 NTU, it influenced the clarity of the craft beer since the mucilage has clarifying properties [56].

3.1.9. Alcohol Degrees

Regarding the alcoholic degrees, a significant difference was obtained: the control has a value of 4.38%, while the experimental unit presented a value of 8.47% in the combination of the CCN-51 variety + 30% mucilage concentration + Northern Brewer. This value is higher than the research of [6] with a value of 6.40%. In turn, the result of the Ale-type beer is within the NTE INEN 2262: 2013 standard [27], which meets the requirements of a minimum of 1.0% volume and a maximum of 10.00% volume of alcohol content. It should be clarified that the beer presents high alcohol values due to the percentage of CCN-51 cocoa mucilage, as this raw material contains sugars (11.30%) that predominate in the fermentation of the beer.

3.1.10. Foam Quantity

According to [55], in their research, they state that, for consumers to determine the quality of beer, the most important factor is foam formation because it gives the first impression to the consumer. It can be defined as a dispersion of gas bubbles in a continuous, liquid, or semi-solid phase, containing a soluble surface-active agent. In the analysis for determining the foam quantity in craft beer, values of 1.70 cm were presented. This corresponds to the experiment of the Fine aroma variety + 30% mucilage concentration + Northern Brewer hop, which shows values higher than the research of [56] with a value of 0.92 cm. In the control, it presented 1.30 cm, indicating a significant difference.

3.1.11. Suspended Solids

In the result of the corresponding analysis of suspended solids, a value of 0.04 g = 2.66% was obtained in the experiment of the Fine aroma variety + 20% mucilage concentration + Cascade hop, which was transformed into a percentage obtaining 2.66%, the same that is close to the percentage of 2.56% from the research of [15]. Furthermore, in comparison with the sediment analysis of the Fine aroma cocoa mucilage, which was 6.3%, this value determined that adding the mucilage generates an increase in the sedimentation of the Ale-type craft beer and relating the values with the control Ale-type beer with a value of 1.33%.

3.2. Microbiological Results and Analysis

Regarding the microbiological analysis represented in Table 3 on the Escherichia coli of the craft beer, it was determined that there was no presence of Salmonella in the final product. In the total microorganisms, values are presented in the combination of CCN-51 with a concentration of 30% and Cascade hop 9.33 CFU/mL, and in the combination of CCN-51 at a concentration of 30% with Northern Brewer 17.33 CFU/mL in the INEN 2262 standard, which presents a maximum of 10 CFU/mL.

Table 3.

Microbiological analysis of all the experimental units carried out in this study.

3.2.1. Escherichia coli

Regarding the analysis of Escherichia coli in craft beer, it was determined that there was no presence of it in any of the experiments studied. Similarly, in the NTE INEN 2262 standard [27], which requires a maximum of 10 CFU/mL, it can be observed that this study complies with the parameter of the mentioned standard. Additionally, in the study by [57], there was no presence of Escherichia coli in their final product. It is worth mentioning that no presence of Escherichia coli was observed in the cocoa mucilage because it underwent prior pasteurisation before being added to the wort.

3.2.2. Salmonella

In the microbiological standard for food [58], it mentions Salmonella in that, in cocoa derivatives, the presence of pathogenic or harmful germs for the consumer and the product itself is not allowed. Compared with the study on Salmonella in cocoa mucilage, no Salmonella is present; thus, our research complies with the standard, with values <10 CFU/mL, according to INEN 2802.

3.2.3. Total Microorganisms

In the research conducted by [15], it was shown that the averages are less than 10 CFU/mL compared to the Ale-type craft beer, which obtained a higher value of 5.81 corresponding to the experiment of the Fine aroma variety + 20% mucilage concentration + Northern Brewer hop. This could be caused by the characteristics of cocoa mucilage, which contains yeasts and bacteria, exceeding the values of the NTE INEN 2262:2013 standard, where the maximum value is <10 CFU/mL in pasteurised beer, while the other experiments and the control are below 10 CFU/mL, as mentioned in the INEN 2262 standard.

3.3. Sensorial Analysis

Regarding the sensory analyses in Table 4, it can be established that the combinations with 30% cocoa mucilage with the Fine aroma and CCN-51 varieties and incorporating Cascade hops proved to be optimal for brewing beer. The mucilage, thanks to its nutrient-rich composition, favoured a vigorous and efficient fermentation process, contributing to a greater production of alcohol and esters. In addition, its coagulant properties facilitated the natural clarification of the wort, resulting in crystalline and bright beer. The excellent carbonation obtained is attributed to the ability of the mucilage to retain carbon dioxide during fermentation, providing a persistent and pleasant effervescence in the mouth.

Table 4.

Sensory analysis of all the experimental units carried out in this study.

3.3.1. Appearance

In the appearance analysis, it was determined that the best treatment was the variety Fine aroma + mucilage concentration 30% + Cascade hops with a value of 4.40, which is close to the research of [59], where the values range between 2.47 and 3.83, presenting a significant difference with the control, which allows the Ale-type craft beer with the partial addition of mucilage to achieve excellent acceptability. At the same time, they approach the control values of 3.69 and 4.58, determining shades that resemble these beer styles.

3.3.2. Aroma

Regarding the aroma analysis, it was observed that the best treatment corresponds to the variety Fine aroma + 30% mucilage concentration + Cascade hops with a value of 4.33 [13], obtaining favourable results with values ranging between 1.8 and 4.35, which are close to the aforementioned treatment. In addition, these values are close to the control values of 3.87 and 4.62, which were more pleasant for the panellists, determining characteristic aromas for these beer styles and presenting a significant difference between the beers made with Fine aroma mucilage with 30% concentration and Cascade hops.

3.3.3. Flavour

In the flavour analysis, it was determined that the best treatment was found in the variety Fine aroma + mucilage concentration 30% + Cascade hops with a value of 4.33, which is close to the result of 1.55 to 4.65 of the present study, showing a significant difference [13]. The panellists highlighted a pleasant flavour of the beer, which is due to the addition of cocoa mucilage to the wort, acting as a flavour precursor to achieve better characteristics in the final product. As for the witnesses, values of 3.86 and 4.45 were determined, which are close to the results of this study, determining that the incorporation of this additive has characteristic flavours of these styles.

3.3.4. Mouthfeel

In the sensory analysis on the mouthfeel, a value of 4.27 was observed, corresponding to the treatment of the CCN-51 variety + 20% mucilage concentration + Cascade hops, which showed a significant difference. In the study by [13], its values ranged between 1.75 and 4.25. The tasters of the Ale-type craft beer with the partial addition of mucilage mentioned that they obtained a good sensation in the palate and tongue because the beer has predominant characteristics of cocoa mucilage, excellent carbonation, and is refreshing. The mouthfeel gives a bitter taste due to the concentration of alpha acids (AA%) of the hops. The values do not show a significant difference with each of the experimental units. Additionally, with respect to the controls, there was no significant difference, but the panellists determined that they had a moderate bitterness.

4. Conclusions

Through a study of the concentrations of cocoa mucilage at 20% and 30%, it was determined that the best option for the fermentative process of Ale-type beer with the partial addition of mucilage was 30% of the Fine aroma variety, as it presented better physicochemical and microbiological characteristics, which are within the ranges established by the NTE INEN 2262 standards and microbial standards for cocoa derivatives.

According to the results obtained regarding the percentage of hops in the production of Ale-type craft beer, it is concluded that the ideal for preparing craft beer is the addition of Cascade hop, as it provides very good characteristics such as flavour, aroma, appearance, and mouthfeel. Furthermore, combining it with 30% mucilage from the Fine aroma variety resulted in excellent impressions from the tasters.

Regarding physicochemical characteristics, adding this cocoa derivative did not affect craft beer. In the best treatment, the following were obtained: acidity 0.51%, 5.27 °Brix, pH 4.23, absorbance 1.13, transmittance 8%, suspended solids 0.02 g: 2.66%, density 1.06 g/mL, turbidity 11.27 NTU, °GL 7.93% vol., foam quantity 1.67 cm, colorimetry L* 46.55, colorimetry a* 19.31, colorimetry b* 48.14, and bitterness degree 29.73. In the microbiological analysis, despite having microorganism values in the two treatments, the INEN standard 2262:2013 does not permit these values.

The microbiological analyses showed no contamination with Escherichia coli and Salmonellae in all experiments, adhering to the INEN 2667 and INEN 2802 standards. This is because of the characteristics of cocoa mucilage, which inhibits the growth of microorganisms. The sensory analyses presented better results in appearance, aroma, flavour, and mouthfeel, providing excellent properties and characteristics, especially in appearance and flavour, due to the influence of cocoa mucilage.

In terms of organoleptic characteristics, the Fine aroma + mucilage concentration 30% + Cascade presented a better appearance, aroma, flavour, and mouthfeel, providing excellent properties and characteristics to the consumer. The beer’s appearance and flavour are influenced by mucilage. Additionally, the characteristics of cocoa mucilage strengthened the fermentation process, clarified it, and provided excellent carbonation to the final product.

Author Contributions

Conceptualisation, J.V.-B.; Formal analysis, J.S.P.-M.; Funding acquisition, J.V.-B.; Investigation, J.V.-B., J.S.P.-M., C.E.Z.-Z., M.d.G.C., A.R., A.H. and J.B.-B.; Methodology, J.V.-B., M.d.G.C., A.R. and A.H.; Project administration, J.V.-B.; Supervision, M.d.G.C., A.R., A.H. and J.B.-B.; Validation, J.V.-B., C.E.Z.-Z. and J.B.-B.; Writing—original draft, J.V.-B.; Writing—review and editing, J.V.-B., J.S.P.-M., C.E.Z.-Z., M.d.G.C., A.R. and J.B.-B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

This study was approved by the Institutional Review Board comprised of the Research Directorate and the Faculty of Engineering and Production Sciences. Ethic Committee Name: Committee of the Agroindustrial Engineering career (State Technical University of Quevedo), Approval Code: Memorandum No. UTEQ-FCIP-2022-0347-M.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Acknowledgments

To the Technical University of Quevedo for the availability of the laboratories for each of the analyses carried out, as well as the heads of each laboratory, to the director of the Research Unit for the approval of the project titled ‘Sustainability of the cocoa industry: use of cocoa residues to generate products that impact the socioeconomic sphere’.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Campoverde, R.J. Analysis of the Substitute Market Growth of Craft Beers. Espirales Rev. Multidiscip. Investig. 2019, 3, 71–80. [Google Scholar] [CrossRef]

- Guzmán-Ortiz, F.A. Valuation and Use of a New Variety of Barley for Brewing Craft Beer. Ing. Agrícola Y Biosist. 2019, 11, 81–95. [Google Scholar] [CrossRef]

- Camargo, B.A.; Portales, L. Motivations and Effects on Beer Consumption among Millennials: The Case of Monterrey and Its Metropolitan Area. Aposta. Rev. Cienc. Soc. 2020, 85, 31–47. [Google Scholar]

- López-Balladares, O.; Espinoza-Montero, P.J.; Fernández, L. Electrochemical Evaluation of Cd, Cu, and Fe in Different Brands of Craft Beers from Quito, Ecuador. Foods 2023, 12, 2264. [Google Scholar] [CrossRef] [PubMed]

- Pérez, R. Craft Brewing Industry in Quito and the Transformation of Beer Bagasse into Flour. Rev. Conectividad 2021, 2, 57–70. [Google Scholar] [CrossRef]

- Segobia Muñoz, S.A. Evaluation of the Addition of Rye (Secale cereale) in the Formulation of Belgian Pale Ale Craft Beer. Enfoque UTE 2022, 13, 14–28. [Google Scholar] [CrossRef]

- Castañeda, R.; Andrade-Cuvi, M.J.; Argüello, Y.; Vernaza, M.G. Effect of the Addition of Malted and Unmalted quinoa (Chenopodium quinoa Wild) in Ale Type Beer with Barley (Hordeum vulgare) Malt. Enfoque UTE 2018, 9, 15–26. [Google Scholar] [CrossRef]

- Pino Hurtado, M.S.; Gallardo Aguilar, I.; Pérez Pentón, M. Experimental Study of Maceration and Fermentation Stages for Obtainment Beer from Sorghum Malt. Rev. Cent. Azúcar 2018, 45, 52–64. [Google Scholar]

- Pérez-Gregorio, R. Phenolic Compounds and Functional Beverages. Beverages 2021, 7, 71. [Google Scholar] [CrossRef]

- Bettenhausen, H.M.; Benson, A.; Fisk, S.; Herb, D.; Hernandez, J.; Lim, J.; Queisser, S.H.; Shellhammer, T.H.; Vega, V.; Yao, L.; et al. Variation in Sensory Attributes and Volatile Compounds in Beers Brewed from Genetically Distinct Malts: An Integrated Sensory and Non-Targeted Metabolomics Approach. J. Am. Soc. Brew. Chem. 2020, 78, 136–152. [Google Scholar] [CrossRef]

- Krofta, K.; Mikyška, A.; Vrzal, T. Comparison of Phytochemical and Brewing Characteristics of Cascade and Kazbek Hop Cultivars. J. Food Compos. Anal. 2024, 135, 106680. [Google Scholar] [CrossRef]

- Villas Boas Mello, J.A.; Nogueira da Silva, J.L. Product Requirements for a Craft Beer Project. Innovar 2020, 30, 39–52. [Google Scholar] [CrossRef]

- Dos Santos, D.R.N.; Bilac, C.A.; Muratori Barbosa, T.; Orsi, D.C. Physicochemical Characterization of Craft Beers Produced with Passion Fruit (Passiflora edulis Sims). J. Exp. Agric. Int. 2022, 44, 16–23. [Google Scholar] [CrossRef]

- Baiano, A.; Grieco, F.; Fiore, A. Witbier Fermented by Sequential Inoculation of Schizosaccharomyces Pombe and Saccharomyces Cerevisiae: Influence of Starchy Ingredients and S. cerevisiae Strain Used for in-Bottle Refermentation. Beverages 2024, 10, 51. [Google Scholar] [CrossRef]

- Mendoza Balcázar, J.M.; Pihuave Calderón, L.F.; Velásquez Campozano, M.R. Comparative Analysis of the Nutritional Value of Craft Beer and Industrial Beer. Cienc. UNEMI 2022, 15, 61–72. [Google Scholar] [CrossRef]

- Espinosa-Alzate, J.A.; Ríos-Osorio, L.A. Agroecological Systems Characterization for the Cacao Crop Establishment (Theobroma cacao L.), in Afro-Descendant Communities of the Colombian Pacific (Tumaco—Nariño, Colombia). Acta Agronómica 2016, 65, 211–217. [Google Scholar] [CrossRef]

- Antolinez Sandoval, E.Y.; Almanza Merchán, P.J.; Barona Rodriguez, A.F.; Polanco Díaz, E.; Serrano Cely, P.A. Current State of Cocoa Plantation: A Review of Its Main Limitations. Cienc. Y Agric. 2020, 17, 1–11. [Google Scholar] [CrossRef]

- Alcívar-Córdova, K.S.; Quezada-Campoverde, J.M.; Barrezueta-Unda, S.; Garzón-Montealegre, V.J.; Carvaja-Romero, H. Economic Analysis of the Export of Cocoa in Ecuador During the Period 2014–2019. Polo Conoc. 2021, 6, 2430–2444. [Google Scholar] [CrossRef]

- García-Briones, A.R.; Pico-Pico, B.F.; Jaimez, R.E. The Cacaoproduction Chain in Ecuador: Resilience in the Different Production Actors. Novasinergia Rev. Digit. Cienc. Ing. Y Tecnol. 2021, 4, 152–172. [Google Scholar] [CrossRef]

- Cakmak, H.; Ilyasoglu-Buyukkestelli, H.; Sogut, E.; Ozyurt, V.H.; Gumus-Bonacina, C.E.; Simsek, S. A Review on Recent Advances of Plant Mucilages and Their Applications in Food Industry: Extraction, Functional Properties and Health Benefits. Food Hydrocoll. Health 2023, 3, 100131. [Google Scholar] [CrossRef]

- Pilligua-Pilligua, R.L.; Barre-Zambrano, R.L.; Mendoza-Gonzáles, A.E.; Delgado, E.; Mero-Santana, R. Influence of Cocoa Mucilage (Theobroma cacao) on the Physicochemical Characteristics of Artisanal Beer. Rev. Espamciencia 2021, 12, 25–32. [Google Scholar] [CrossRef]

- Bastidas, J.V.; Moreira, A.F.M.; Bayas, B.W.O.; Briones-Bitar, J. Cocoa Mucilage: A Novel Substrate for Fermented Tea-Based Beverages. Int. J. Des. Nat. Ecodyn. 2023, 18, 1169–1178. [Google Scholar] [CrossRef]

- Villarroel-Bastidas, J.V.; Angulo-Ortega, G.d.C.; Briones-Bitar, J. Reducing Sugars Degradation in Cocoa Mucilage to Produce Bioethanol. Rev. Fac. Ing. Univ. Antioq. 2022, 108, 98–106. [Google Scholar] [CrossRef]

- Bastidas, J.V.; Melo, W.A.B.; Briones-Bitar, J. Sustainability of the Cocoa Industry: Cocoa Waste Mucilage Use to Produce Fermented Beverages. Case Study in Los Ríos Province. Int. J. Sustain. Dev. Plan. 2022, 17, 1147–1152. [Google Scholar] [CrossRef]

- Mendes, A.H.d.L.; Dionísio, A.P.; Mouta, C.F.H.; Abreu, F.A.P.D.; Pinto, C.O.; Garruti, D.D.S.; Araújo, I.M. Sensory Acceptance and Characterization of Yoghurt Supplemented with Yacon Syrup and Cashew Apple Extract as a Source of Bioactive Compounds. Braz. J. Food Technol. 2019, 22, 15318. [Google Scholar] [CrossRef]

- Walker, G.; Stewart, G. Saccharomyces Cerevisiae in the Production of Fermented Beverages. Beverages 2016, 2, 30. [Google Scholar] [CrossRef]

- NTE-INEN NTE INEN 262: Alcoholic Beverages. Beer. Requirements. Available online: https://odaninkasiquito.wordpress.com/wp-content/uploads/2015/08/inen-2-262-cerveza.pdf (accessed on 12 September 2024).

- NTE-INEN NTE-INEN 1983_Soft Drinks: Determination of Soluble Solids. Available online: https://es.scribd.com/document/495027904/solidos-solubles-Brix-bg-1083 (accessed on 12 September 2024).

- NTE-INEN NTE-INEN 2325: Alcoholic Beverages: Beer PH Determination. Available online: https://silo.tips/download/republicofecuador-edictofgovernment-173 (accessed on 12 September 2024).

- AOAC. Official Methods of Analysis, 22nd ed.; AOAC: Rockville, MD, USA, 2023; Available online: https://www.aoac.org/official-methods-of-analysis/ (accessed on 12 September 2024).

- NTE-INEN NTE-INEN 340: Alcoholic Beverages: Determination of Ethyl Alcohol Content. Alcoholimetric Method (Gay-Lussac). Available online: https://www.studocu.com/ec/document/universidad-ute/sistemas-de-gestion-de-calidad/nte-inen-340-norma-inen-bebidas-alcoholicas-determinacion-del-contenido-de-alcohol-etilico/27483899 (accessed on 12 September 2024).

- NTE-INEN NTE-INEN 349: Alcoholic Beverages. Determination of Relative Density. Available online: https://www.studocu.com/gt/document/universidad-de-san-carlos-de-guatemala/legislacion-1/bebidas-alcoholicas-determinacion-de-acidez-341/24041983 (accessed on 12 September 2024).

- Koren, D.; Hegyesné Vecseri, B.; Kun-Farkas, G.; Urbin, Á.; Nyitrai, Á.; Sipos, L. How to Objectively Determine the Color of Beer? J. Food Sci. Technol. 2020, 57, 1183–1189. [Google Scholar] [CrossRef]

- Charmier, L.M.J.; McLoughlin, C.; McCleary, B.V. Diastatic Power and Maltose Value: A Method for the Measurement of Amylolytic Enzymes in Malt. J. Inst. Brew. 2021, 127, 327–344. [Google Scholar] [CrossRef]

- Wierenga, P.A.; Basheva, E.S.; Delahaije, R.J.B.M. Variations in Foam Collapse and Thin Film Stability with Constant Interfacial and Bulk Properties. Adv. Colloid Interface Sci. 2023, 312, 102845. [Google Scholar] [CrossRef]

- HACH. Measuring Total, Permanent and Chill Haze in Beer; HACH: Loveland, CO, USA, 2020. [Google Scholar]

- Mexican. Standard Water Analysis—Measurement of Salts and Solids Dissolved in Natural Water, Wastewaters and Treated Wastewaters—Test Method. Available online: https://www.gob.mx/cms/uploads/attachment/file/166146/nmx-aa-034-scfi-2015.pdf (accessed on 12 September 2024).

- AOAC. AOAC 986.33-1988(2002), Bacterial and Coliform Counts. Available online: https://epraise.com.tw/wp-content/uploads/2024/06/Petrifilm-ACCC_AOAC-OMA-986.33.pdf (accessed on 12 September 2024).

- NTE-INEN NTE INEN 2667 on the Determination and Identification of Escherichia Coli in Foods for Human and Animal Consumption. Available online: https://www.fao.org/faolex/results/details/es/c/LEX-FAOC123360/ (accessed on 12 September 2024).

- NTE-INEN NTE INEN 2802: Alcoholic Beverages. Cocktails or Mixed Alcoholic Beverages and Appetizers. Requirements. Available online: https://es.scribd.com/document/392769622/Nte-inen-2802-Bebidas-Alcoholicas-Cocteles-o-Bebidas-Alcoholicas (accessed on 12 September 2002).

- Vanderhaegen, B.; Neven, H.; Verachtert, H.; Derdelinckx, G. The Chemistry of Beer Aging—A Critical Review. Food Chem. 2006, 95, 357–381. [Google Scholar] [CrossRef]

- Luján Corro, M.; Vásquez Villalobos, V. Automatic Control with Fuzzy Logic of Home-Made Beer Production in Maceration and Cooking Stages. Sci. Agropecu. 2010, 1, 125–137. [Google Scholar] [CrossRef][Green Version]

- Capece, A.; Romaniello, R.; Pietrafesa, A.; Siesto, G.; Pietrafesa, R.; Zambuto, M.; Romano, P. Use of Saccharomyces cerevisiae Var. Boulardii in Co-Fermentations with S. cerevisiae for the Production of Craft Beers with Potential Healthy Value-Added. Int. J. Food Microbiol. 2018, 284, 22–30. [Google Scholar] [CrossRef]

- Viana, A.C.; Pimentel, T.C.; Borges do Vale, R.; Clementino, L.S.; Januario Ferreira, E.T.; Magnani, M.; dos Santos Lima, M. American Pale Ale Craft Beer: Influence of Brewer’s Yeast Strains on the Chemical Composition and Antioxidant Capacity. LWT 2021, 152, 112317. [Google Scholar] [CrossRef]

- Dabija, A.; Ciocan, M.E.; Chetrariu, A.; Codină, G.G. Buckwheat and Amaranth as Raw Materials for Brewing, a Review. Plants 2022, 11, 756. [Google Scholar] [CrossRef] [PubMed]

- Valencia Velasco, S.F.; Humberto Reyes, L.; Sánchez-Camargo, A. Development and Sensory Analysis of a Craft Beer Using a Non-Conventional Yeast; Universidad de los Andes: Bogotá, Colombia, 2022; 18p. [Google Scholar]

- Menárguez López, E. Determination of Physical-Chemical Parameters of Artisan Beer. Available online: https://core.ac.uk/download/pdf/235855634.pdf (accessed on 12 September 2024).

- Van Opstaele, F.; De Rouck, G.; De Clippeleer, J.; Aerts, G.; De Cooman, L. Analytical and Sensory Assessment of Hoppy Aroma and Bitterness of Conventionally Hopped and Advanced Hopped Pilsner Beers. Cerevisia 2011, 36, 47–59. [Google Scholar] [CrossRef]

- Yorke, J.; Cook, D.; Ford, R. Brewing with Unmalted Cereal Adjuncts: Sensory and Analytical Impacts on Beer Quality. Beverages 2021, 7, 4. [Google Scholar] [CrossRef]

- Humia, B.V.; Santos, K.S.; Barbosa, A.M.; Sawata, M.; Mendonça, M.d.C.; Padilha, F.F. Beer Molecules and Its Sensory and Biological Properties: A Review. Molecules 2019, 24, 1568. [Google Scholar] [CrossRef]

- Guido, L.F. Brewing and Craft Beer. Beverages 2019, 5, 51. [Google Scholar] [CrossRef]

- Maia, P.D.; dos Santos Baião, D.; da Silva, V.P.F.; Miguel, M.A.L.; Lacerda, E.C.Q.; de Araújo Calado, V.M.; da Silva Carneiro, C.; Finotelli, P.V.; Pierucci, A.P.T. Microencapsulation of a Craft Beer, Nutritional Composition, Antioxidant Stability, and Drink Acceptance. LWT 2020, 133, 110104. [Google Scholar] [CrossRef]

- Quezada-Moreno, W.; Gallardo-Aguilar, I. Clarification of Cane Juice Using Mucilaginous Plants. ICIDCA. Sobre Los Deriv. La Caña Azúcar 2014, 48, 41–48. [Google Scholar]

- Ministerio de Agricultura, Pesca y Alimentación. Socioeconomic Report on the Beer Sector in Spain. Available online: https://cerveceros.org/uploads/5b30d4612433a__Informe_Cerveceros_2017.pdf (accessed on 12 September 2024).

- Velastegui Montero, E.X. Feasibility Study for the Creation of a Microenterprise Dedicated to the Production of High Fermentation Craft Beer Flavored with Organic Coffee (Coffea arabica) and Bottled with Forced Carbonation, in the Canton of Quito; Universidad Técnica de Ambato: Ambato, Ecuador, 2023. [Google Scholar]

- Guevara Milla, R.E. Development of an American Pale Ale Craft Beer Using Sorghum (Sorghum bicolor) as Base Malt with Barley (Hordeum vulgare) and Sweetened with Honey; Escuela Agrícola Panamericano Zamorano: Tegucigalpa, Honduras, 2019. [Google Scholar]

- Canonico, L.; Zannini, E.; Ciani, M.; Comitini, F. Assessment of Non-Conventional Yeasts with Potential Probiotic for Protein-Fortified Craft Beer Production. LWT 2021, 145, 111361. [Google Scholar] [CrossRef]

- European Union Commission Microbiological Criteria for Outbreaks and Sampling Standards for Poultry Carcasses and Fresh Poultry Meat. Available online: https://www.boe.es/doue/2013/068/L00019-00023.pdf (accessed on 12 September 2024).

- Villamarín Chávez, R.A. Craft Beer Brewing Based on Specialty Coffee from the Province of Loja, Ecuador. Available online: https://www.dspace.uce.edu.ec/server/api/core/bitstreams/6c5adc8d-e9b1-4012-b207-35564ac191c7/content (accessed on 12 September 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).