Preparation and Characterization of Boza Enriched with Nonfat Dry Milk and Its Impact on the Fermentation Process

Abstract

:1. Introduction

2. Results and Discussion

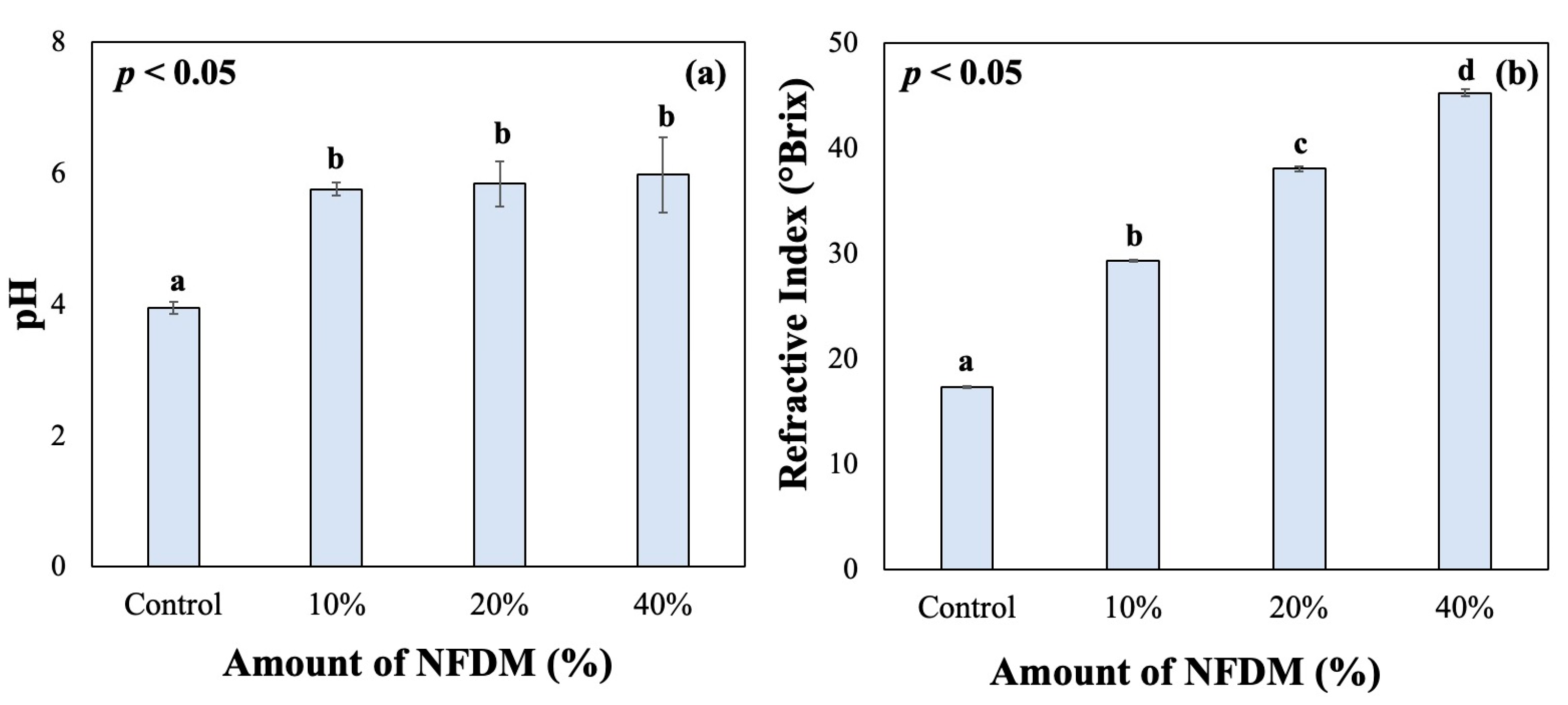

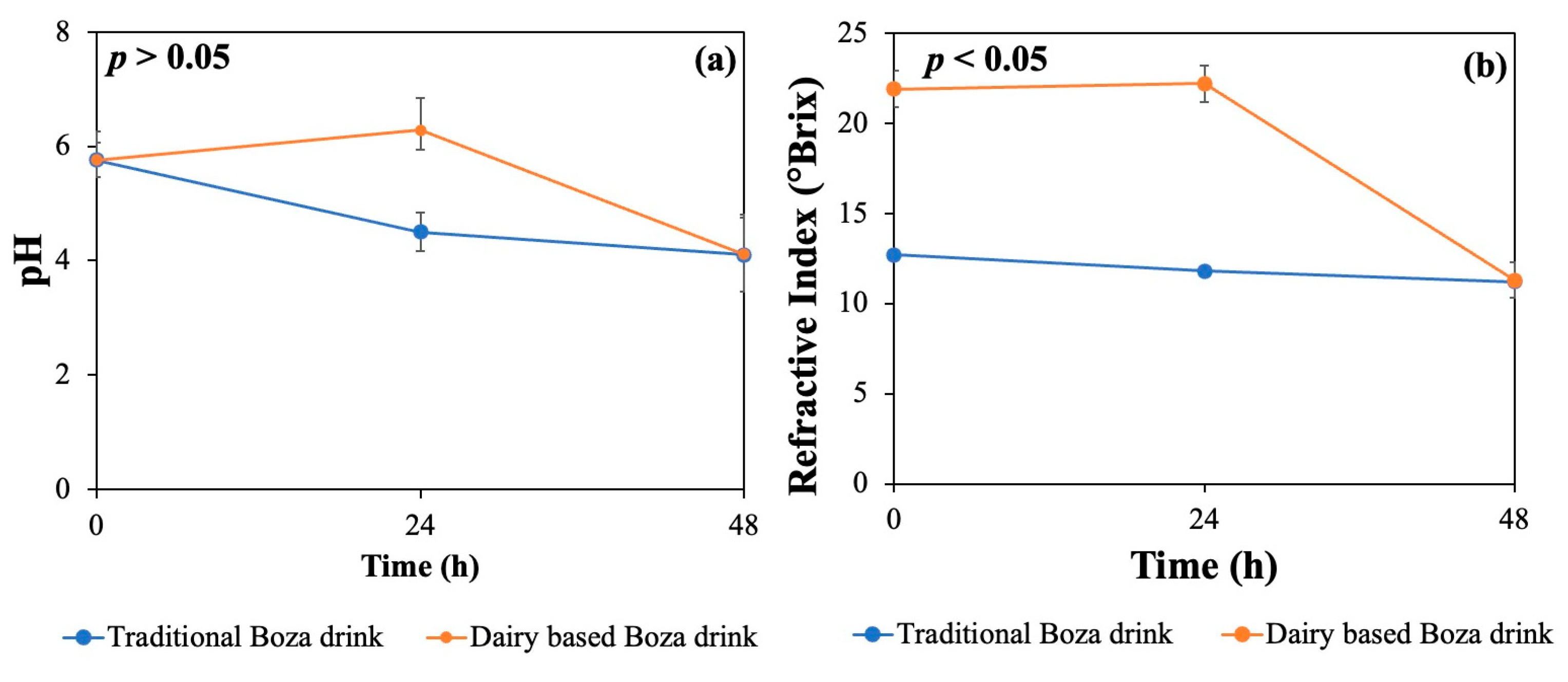

2.1. The pH and Refractive Index Results

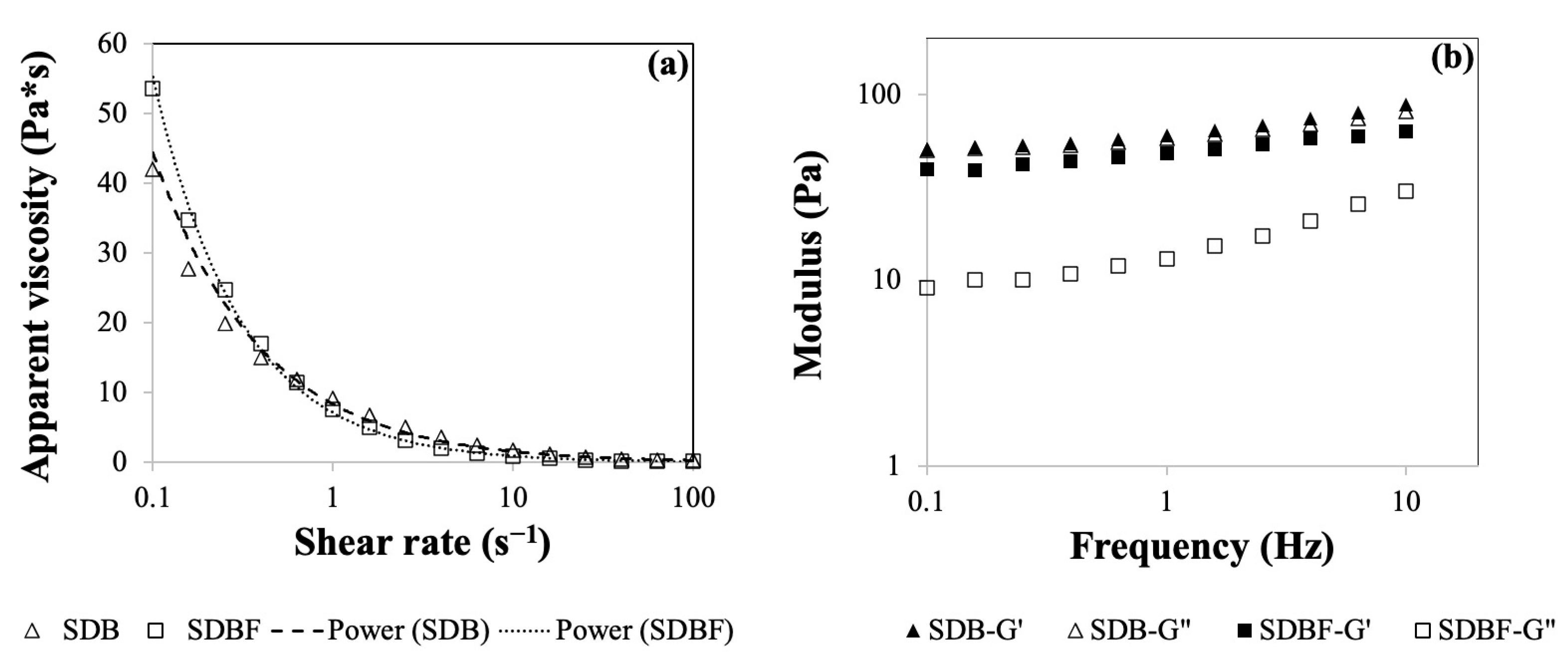

2.2. Rheological Properties of Dairy-Based Slurry and Boza

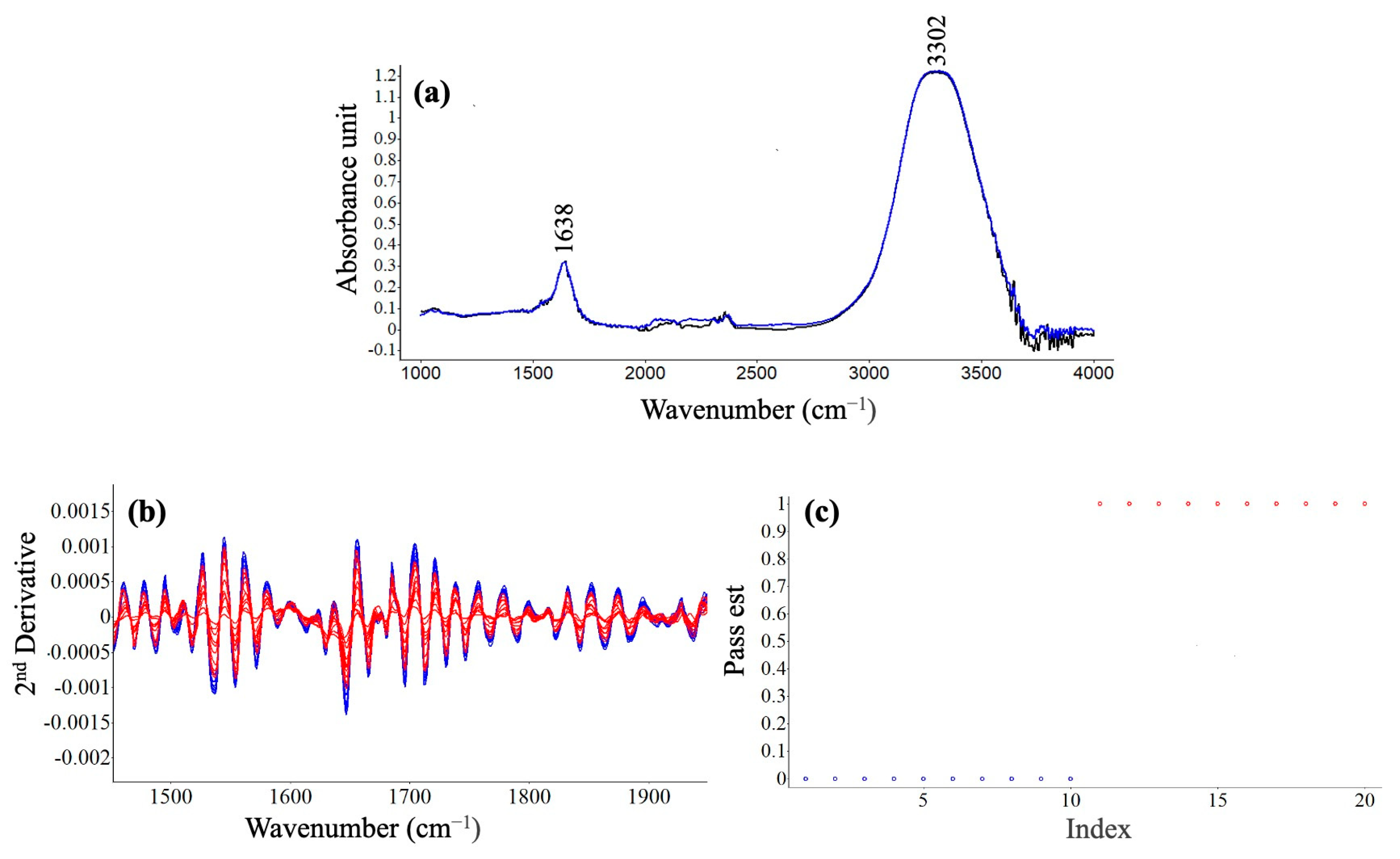

2.3. FTIR Spectroscopy

3. Conclusions

4. Materials and Methods

4.1. Materials

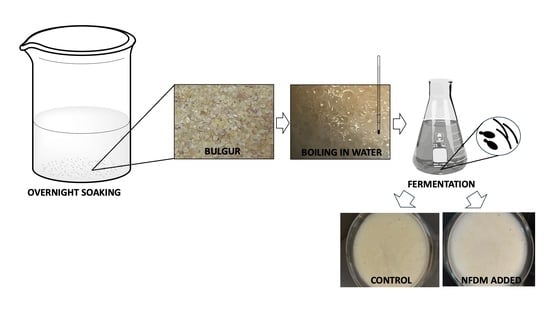

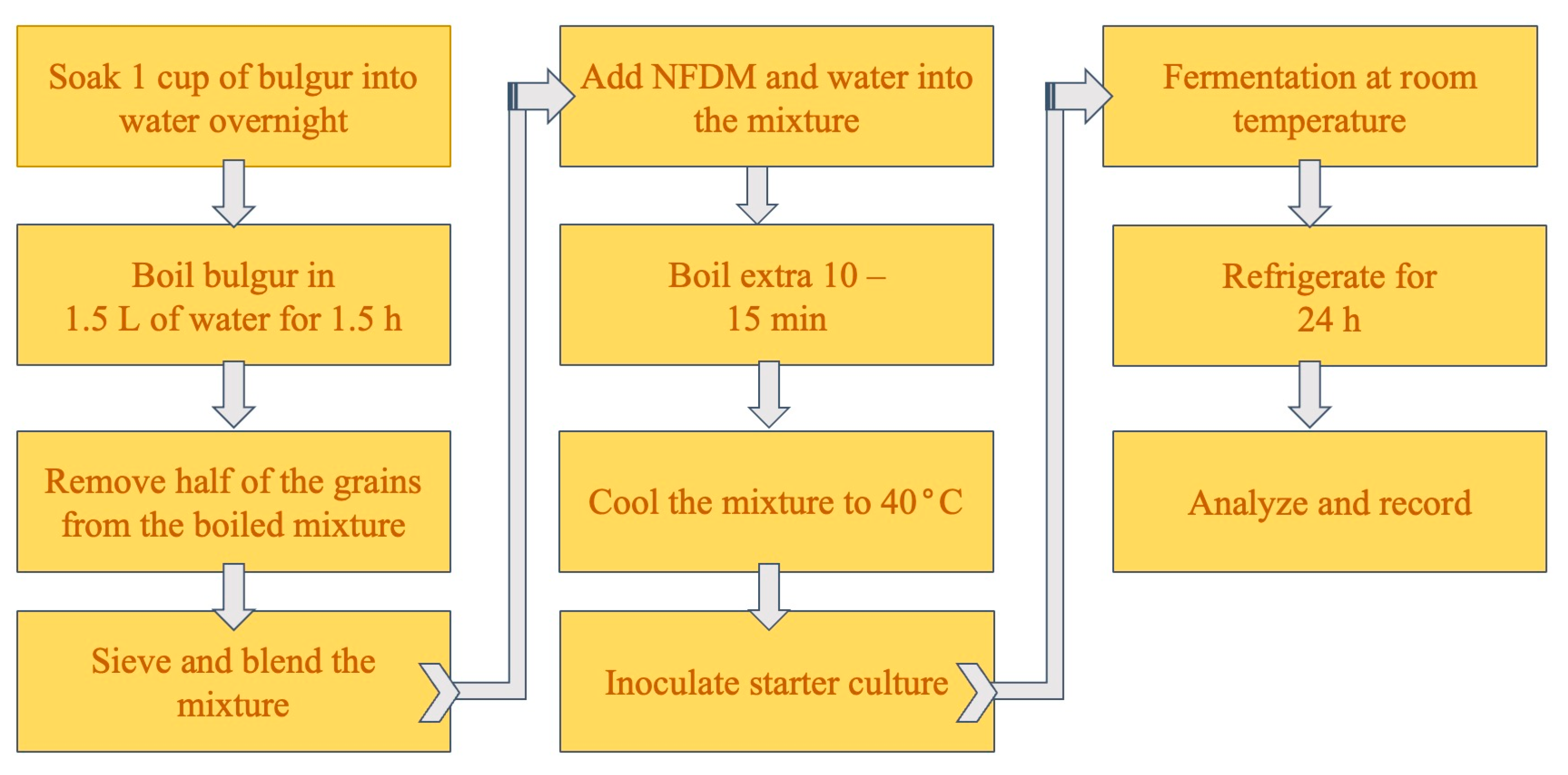

4.2. Boza Preparation

4.3. Dairy-Based Boza Preparation

4.4. The pH and Refractive Index Measurements

4.5. Rheological Measurements

4.6. FTIR Analysis of Dairy-Based Boza

4.7. Data Analysis and Statistics

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Amadou, I. Millet Based Fermented Beverages Processing. In Fermented Beverages; Elsevier: Amsterdam, The Netherlands, 2019; pp. 433–472. [Google Scholar]

- Setyowati, N.; Masyhuri; Mulyo, J.H.; Irham; Yudhistira, B. The Hidden Treasure of Wedang Uwuh, an Ethnic Traditional Drink from Java, Indonesia: Its Benefits and Innovations. Int. J. Gastron. Food Sci. 2023, 31, 100688. [Google Scholar] [CrossRef]

- Petrova, P.; Petrov, K. Traditional Cereal Beverage Boza: Fermentation Technology, Microbial Content and Healthy Effect. In Fermented Foods Part II Technological Interventions; Ray, R.C., Montet, D., Eds.; CRC Press Taylor & Franchis Group, LCC: Boca Raton, FL, USA, 2017; pp. 284–305. [Google Scholar]

- Vaudha, S.; Mishra, H. Non Dairy Probiotic Beverages. Int. Food Res. J. 2013, 20, 7–15. [Google Scholar]

- Hancioğlu, Ö.; Karapinar, M. Microflora of Boza, a Traditional Fermented Turkish Beverage. Int. J. Food Microbiol. 1997, 35, 271–274. [Google Scholar] [CrossRef] [PubMed]

- Leblanc, J.G.J.; Todorov, S.D. Bacteriocins Producing Lactic Acid Bacteria Isolated from Boza, a Traditional Fermented Beverage from Balkan Peninsula—From Isolation to Application. In Science against Microbial Pathogens: Communicating Current Research and Technological Advances; Formatex Research Center: Badajoz, Spain, 2011; pp. 1311–1320. ISBN 978-84-939843-2-8. [Google Scholar]

- Yeğin, S.; Üren, A. Biogenic Amine Content of Boza: A Traditional Cereal-Based, Fermented Turkish Beverage. Food Chem. 2008, 111, 983–987. [Google Scholar] [CrossRef]

- Caputo, L.; Quintieri, L.; Baruzzi, F.; Borcakli, M.; Morea, M. Molecular and Phenotypic Characterization of Pichia Fermentans Strains Found among Boza Yeasts. Food Res. Int. 2012, 48, 755–762. [Google Scholar] [CrossRef]

- Blandino, A.; Al-Aseeri, M.E.; Pandiella, S.S.; Cantero, D.; Webb, C. Cereal-Based Fermented Foods and Beverages. Food Res. Int. 2003, 36, 527–543. [Google Scholar] [CrossRef]

- Owens, C.E.; Fan, M.R.; Hart, A.J.; McKinley, G.H. On Oreology, the Fracture and Flow of “Milk’s Favorite Cookie®”. Phys. Fluids 2022, 34, 043107. [Google Scholar] [CrossRef]

- Muhammet, A.; Ersoz Tatlisu, N.B.; Toker, Ö.S.; Yilmaz, M.T.; Cankurt, H.; Durak, M.Z.; Sagdic, O. Microbiological, Steady, and Dynamic Rheological Characterization of Boza Samples: Temperature Sweep Tests and Applicability of the Cox–Merz Rule. Turk. J. Agric. For. 2014, 38, 377–387. [Google Scholar] [CrossRef]

- Genç, M.; Zorba, M.; Ova, G. Determination of Rheological Properties of Boza by Using Physical and Sensory Analysis. J. Food Eng. 2002, 52, 95–98. [Google Scholar] [CrossRef]

- Çelik, İ.; Işik, F.; Yilmaz, Y. Effect of Roasted Yellow Chickpea (Leblebi) Flour Addition on Chemical, Rheological and Sensory Properties of Boza. J. Food Process. Preserv. 2016, 40, 1400–1406. [Google Scholar] [CrossRef]

- Göncü, A.; Kuzumoğlu, Y.; Vardin, A.Y.; Çelik, İ.; Karaman, A.D. Evaluation of Physicochemical and Sensorial Properties of Gluten-free Boza Formulated with Chia and Quinoa Flours. Cereal Chem. 2023, 100, 1123–1131. [Google Scholar] [CrossRef]

- Liu, H.; Xu, X.; Cui, H.; Xu, J.; Yuan, Z.; Liu, J.; Li, C.; Li, J.; Zhu, D. Plant-Based Fermented Beverages and Key Emerging Processing Technologies. Food Rev. Int. 2023, 39, 5844–5863. [Google Scholar] [CrossRef]

- Marrero, S.C.; Martínez-Rodríguez, A.; Pérez, S.E.M.; Moya, S.P. New Trends and Applications in Fermented Beverages. In Fermented Beverages; Elsevier: Amsterdam, The Netherlands, 2019; pp. 31–66. [Google Scholar]

- Arslan-Tontul, S.; Erbas, M. Co-Culture Probiotic Fermentation of Protein-Enriched Cereal Medium (Boza). J. Am. Coll. Nutr. 2020, 39, 72–81. [Google Scholar] [CrossRef] [PubMed]

- Weijs, P.J.; Cynober, L.; DeLegge, M.; Kreymann, G.; Wernerman, J.; Wolfe, R.R. Proteins and Amino Acids Are Fundamental to Optimal Nutrition Support in Critically Ill Patients. Crit. Care 2014, 18, 591. [Google Scholar] [CrossRef] [PubMed]

- Hackney, K.J.; Trautman, K.; Johnson, N.; Mcgrath, R.; Stastny, S. Protein and Muscle Health during Aging: Benefits and Concerns Related to Animal-Based Protein. Anim. Front. 2019, 9, 12–17. [Google Scholar] [CrossRef] [PubMed]

- Wilding, P.; Lillford, P.J.; Regenstein, J.M. Functional Properties of Proteins in Foods. J. Chem. Technol. Biotechnol. Biotechnol. 1984, 34, 182–189. [Google Scholar] [CrossRef]

- Behera, S.S.; Panda, S.K. Ethnic and Industrial Probiotic Foods and Beverages: Efficacy and Acceptance. Curr. Opin. Food Sci. 2020, 32, 29–36. [Google Scholar] [CrossRef]

- Ferreira, I.; de Sousa Melo, D.; Menezes, A.G.T.; Fonseca, H.C.; de Assis, B.B.T.; Ramos, C.L.; Magnani, M.; Dias, D.R.; Schwan, R.F. Evaluation of Potentially Probiotic Yeasts and Lactiplantibacillus Plantarum in Co-Culture for the Elaboration of a Functional Plant-Based Fermented Beverage. Food Res. Int. 2022, 160, 111697. [Google Scholar] [CrossRef]

- Meichner, C.; Schedl, A.E.; Neuber, C.; Kreger, K.; Schmidt, H.-W.; Kador, L. Refractive-Index Determination of Solids from First- and Second-Order Critical Diffraction Angles of Periodic Surface Patterns. AIP Adv. 2015, 5, 087135. [Google Scholar] [CrossRef]

- Choi, I.; Li, N.; Vuia-Riser, J.; Carter, B.; Drake, M.; Zhong, Q. Neutral PH Nonfat Dry Milk Beverages with Turbidity Reduced by Sodium Hexametaphosphate: Physical and Sensory Properties during Storage. LWT 2021, 147, 111656. [Google Scholar] [CrossRef]

- Wilkowske, H.H. Relationship between Titratable Acidity and PH during Lactic Acid Fermentation in Reconstituted Nonfat Milk. J. Dairy Sci. 1954, 37, 22–29. [Google Scholar] [CrossRef]

- FAO. Off-Tastes in Raw and Reconstituted Milk; FAO: Roma, Italy, 2021; ISBN 92-5-101258-X. [Google Scholar]

- Steinkraus, K.H. Lactic Acid Fermentations. In Applications of Biotechnology to Traditional Fermented Foods; National Academy Press: Washington, DC, USA, 1992; ISBN 0309046858. [Google Scholar]

- Nwachukwu, E.; Achi, O.; Ijeoma, I. Lactic Acid Bacteria in Fermentation of Cereals for the Production of Indigenous Nigerian Foods. Afr. J. Food Sci. Technol. 2010, 1, 21–26. [Google Scholar]

- Muchtaridi, M.; Musfiroh, I.; Hambali, N.N.; Indrayati, W. Determination of Alcohol Contents of Fermentated Black Tape Ketan Based on Different Fermentation Time Using Specific Gravity, Refractive Index and GC-MS Methods. J. Microbiol. Biotechnol. food Sci. 2012, 2, 933–946. [Google Scholar]

- Lin, M.; Al-Holy, M.; Chang, S.-S.; Huang, Y.; Cavinato, A.G.; Kang, D.-H.; Rasco, B.A. Rapid Discrimination of Alicyclobacillus Strains in Apple Juice by Fourier Transform Infrared Spectroscopy. Int. J. Food Microbiol. 2005, 105, 369–376. [Google Scholar] [CrossRef] [PubMed]

- Kher, A.; Udabage, P.; McKinnon, I.; McNaughton, D.; Augustin, M.A. FTIR Investigation of Spray-Dried Milk Protein Concentrate Powders. Vib. Spectrosc. 2007, 44, 375–381. [Google Scholar] [CrossRef]

- Markoska, T.; Huppertz, T.; Grewal, M.K.; Vasiljevic, T. FTIR Analysis of Physiochemical Changes in Raw Skim Milk upon Concentration. LWT 2019, 102, 64–70. [Google Scholar] [CrossRef]

- Kohajdova, Z.; Karocicova, J. Fermentation of Cereals for Specific Purpose. J. Food Nutr. Res. 2007, 46, 51–57. [Google Scholar]

- Debebe, A.; Redi-Abshiro, M.; Chandravanshi, B.S. Non-Destructive Determination of Ethanol Levels in Fermented Alcoholic Beverages Using Fourier Transform Mid-Infrared Spectroscopy. Chem. Cent. J. 2017, 11, 27. [Google Scholar] [CrossRef]

- Tekin Pulatsü, E.; Sahin, S.; Sumnu, G. Characterization of Different Double-Emulsion Formulations Based on Food-Grade Emulsifiers and Stabilizers. J. Dispers. Sci. Technol. 2018, 39, 996–1002. [Google Scholar] [CrossRef]

- Pulatsu, E.; Su, J.W.; Lin, J.; Lin, M. Factors Affecting 3D Printing and Post-Processing Capacity of Cookie Dough. Innov. Food Sci. Emerg. Technol. 2020, 61, 102316. [Google Scholar] [CrossRef]

| Sample | Model Fitting Parameters for Viscometry and Oscillation | ||

|---|---|---|---|

| Model fitting parameters for viscometry | |||

| K | n | R2 | |

| SDB-F | 7.10 ± 0.43 a | 0.11 ± 0.05 a | 0.92 |

| SDB | 8.36 ± 0.38 a | 0.28 ± 0.01 a | 0.98 |

| Model fitting parameters for oscillation | |||

| a’ | b’ | R2 | |

| SDB-F | 41.16 ± 17.72 a | 1.39 ± 0.17 a | 0.96 |

| SDB | 47.04 ± 17.52 a | 1.35 ± 0.04 a | 0.93 |

| Model fitting parameters for oscillation | |||

| a” | b” | R2 | |

| SDB-F | 39.97 ± 17.57 a | 1.35 ± 0.16 a | 0.94 |

| SDB | 47.04 ± 17.52 a | 1.30 ± 0.03 a | 0.93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pulatsu, E.; Malik, S.; Lin, M.; Krishnaswamy, K.; Vardhanabhuti, B. Preparation and Characterization of Boza Enriched with Nonfat Dry Milk and Its Impact on the Fermentation Process. Gels 2024, 10, 22. https://doi.org/10.3390/gels10010022

Pulatsu E, Malik S, Lin M, Krishnaswamy K, Vardhanabhuti B. Preparation and Characterization of Boza Enriched with Nonfat Dry Milk and Its Impact on the Fermentation Process. Gels. 2024; 10(1):22. https://doi.org/10.3390/gels10010022

Chicago/Turabian StylePulatsu, Ezgi, Sargun Malik, Mengshi Lin, Kiruba Krishnaswamy, and Bongkosh Vardhanabhuti. 2024. "Preparation and Characterization of Boza Enriched with Nonfat Dry Milk and Its Impact on the Fermentation Process" Gels 10, no. 1: 22. https://doi.org/10.3390/gels10010022

APA StylePulatsu, E., Malik, S., Lin, M., Krishnaswamy, K., & Vardhanabhuti, B. (2024). Preparation and Characterization of Boza Enriched with Nonfat Dry Milk and Its Impact on the Fermentation Process. Gels, 10(1), 22. https://doi.org/10.3390/gels10010022