High-Performance Flexible Sensor with Sensitive Strain/Magnetic Dual-Mode Sensing Characteristics Based on Sodium Alginate and Carboxymethyl Cellulose

Abstract

1. Introduction

2. Results and Discussion

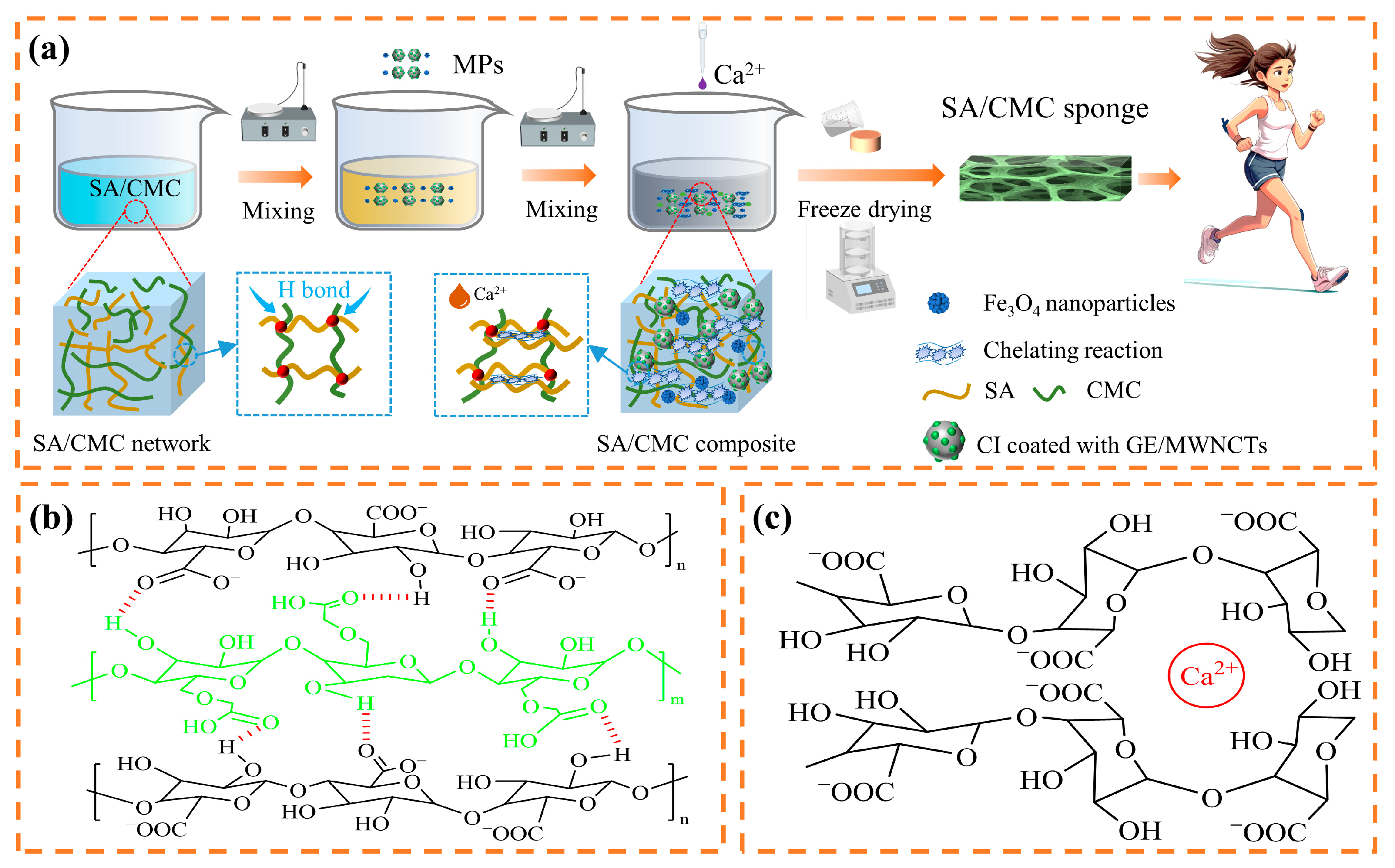

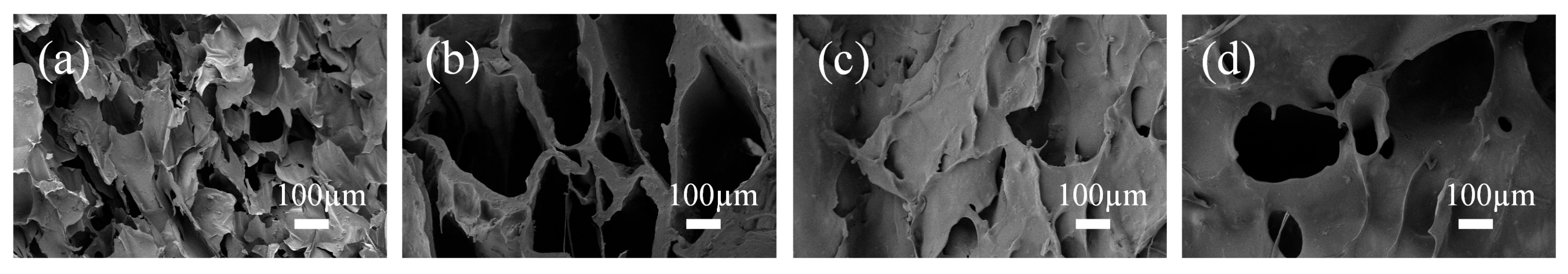

2.1. SA/CMC Porous Sponge Formation

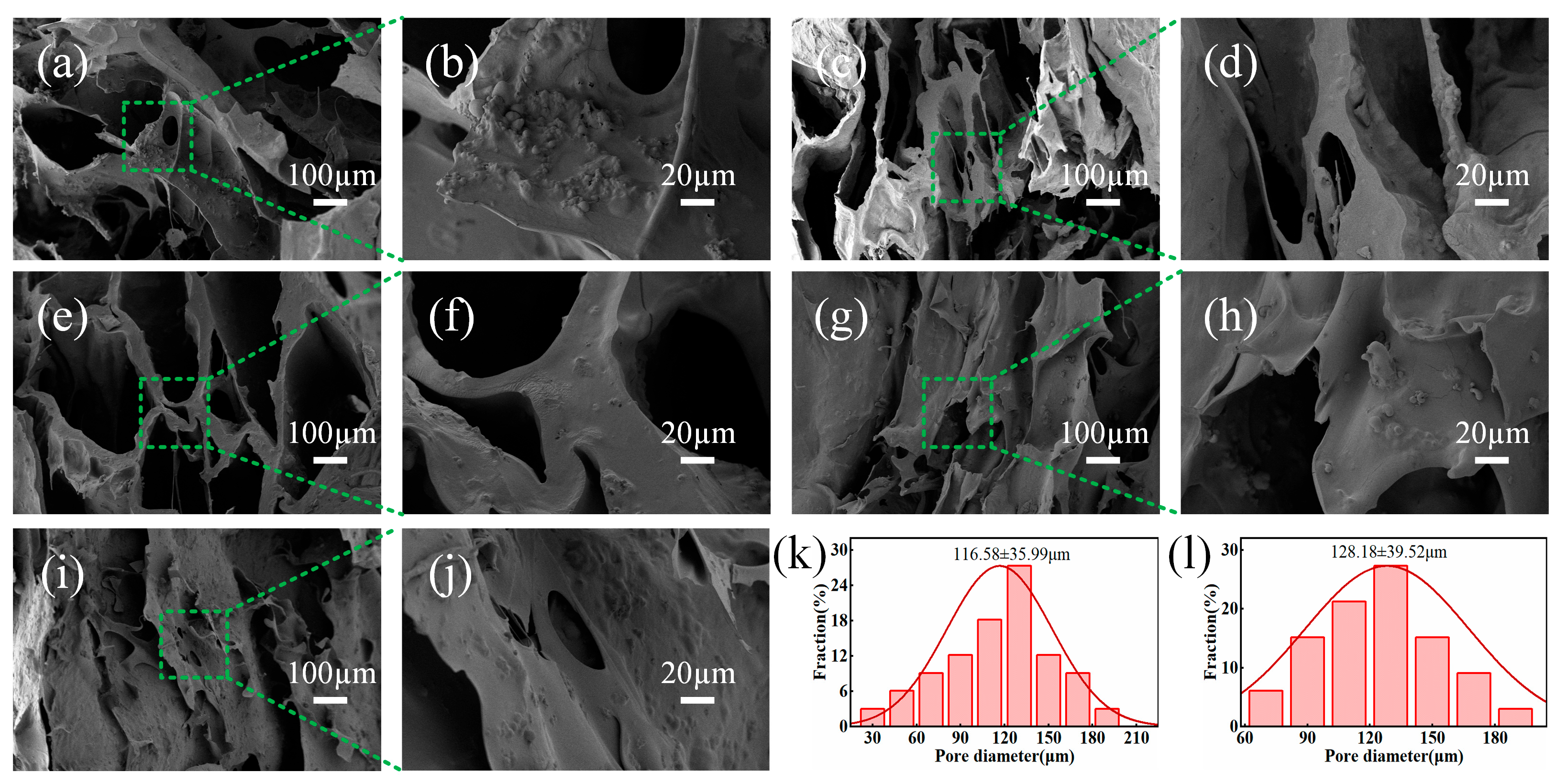

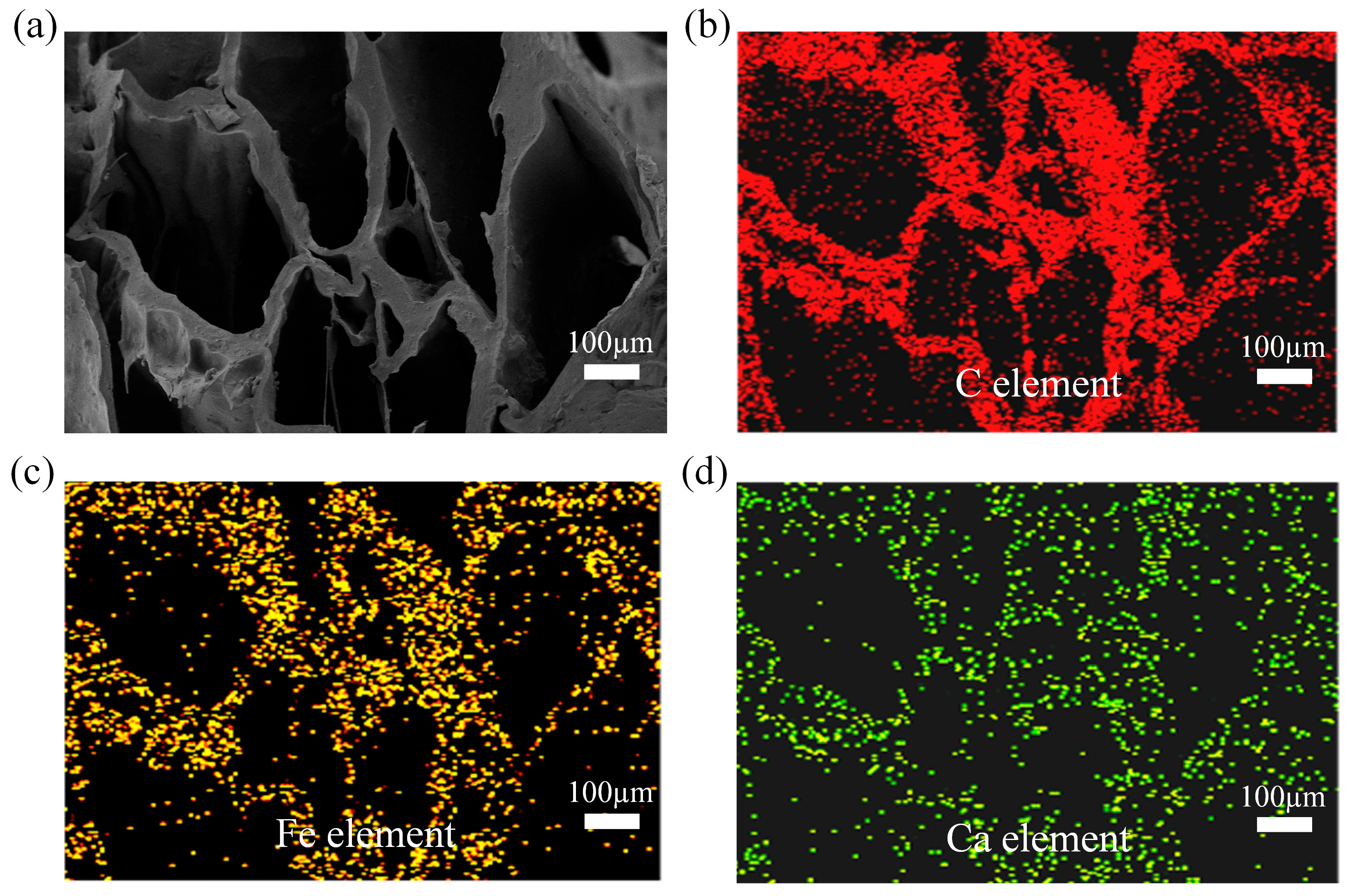

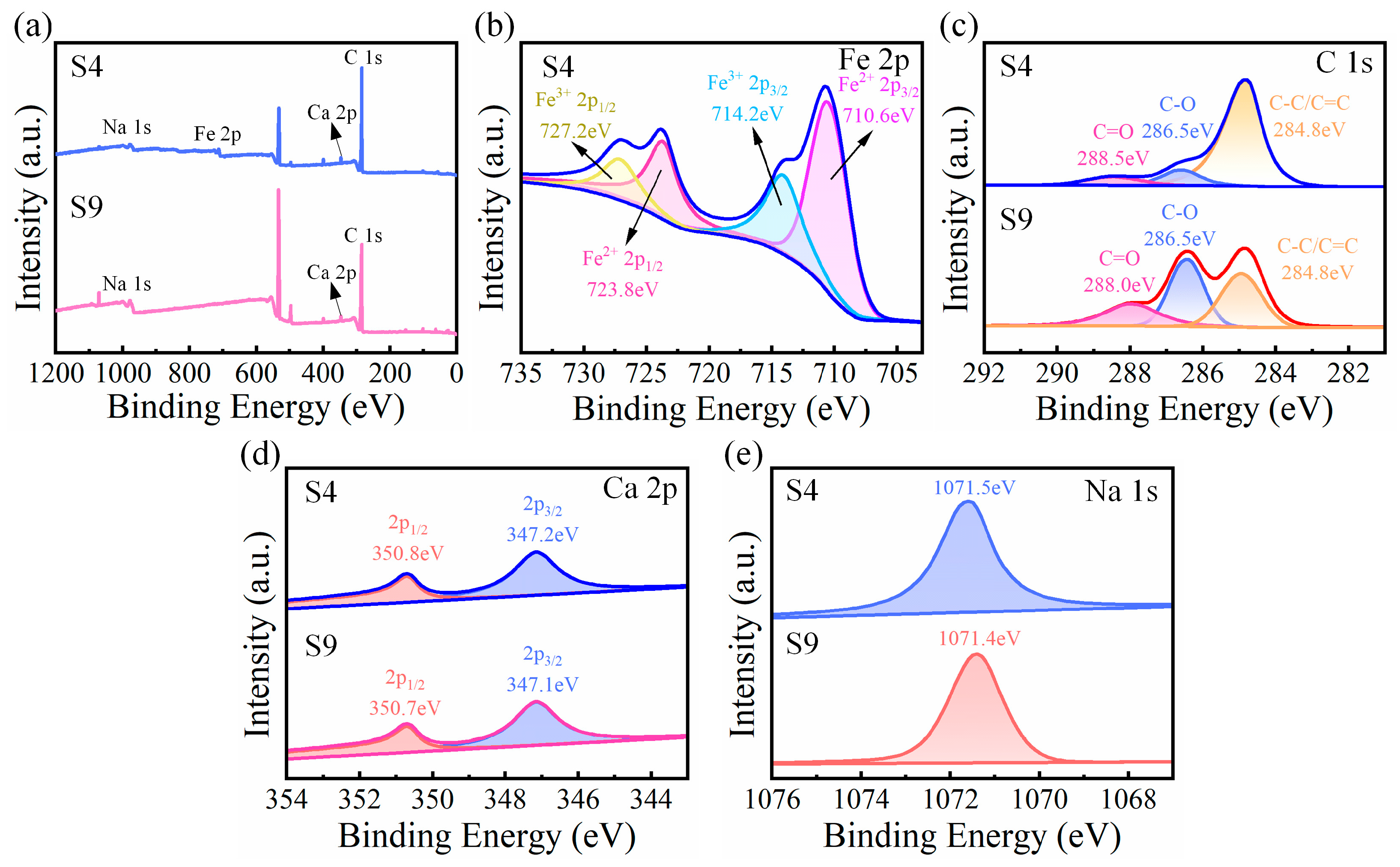

2.2. Material Characterization of the SA/CMC Porous Sponge

2.3. Mechanical Properties and Hydrophilicity of the SA/CMC Porous Sponge

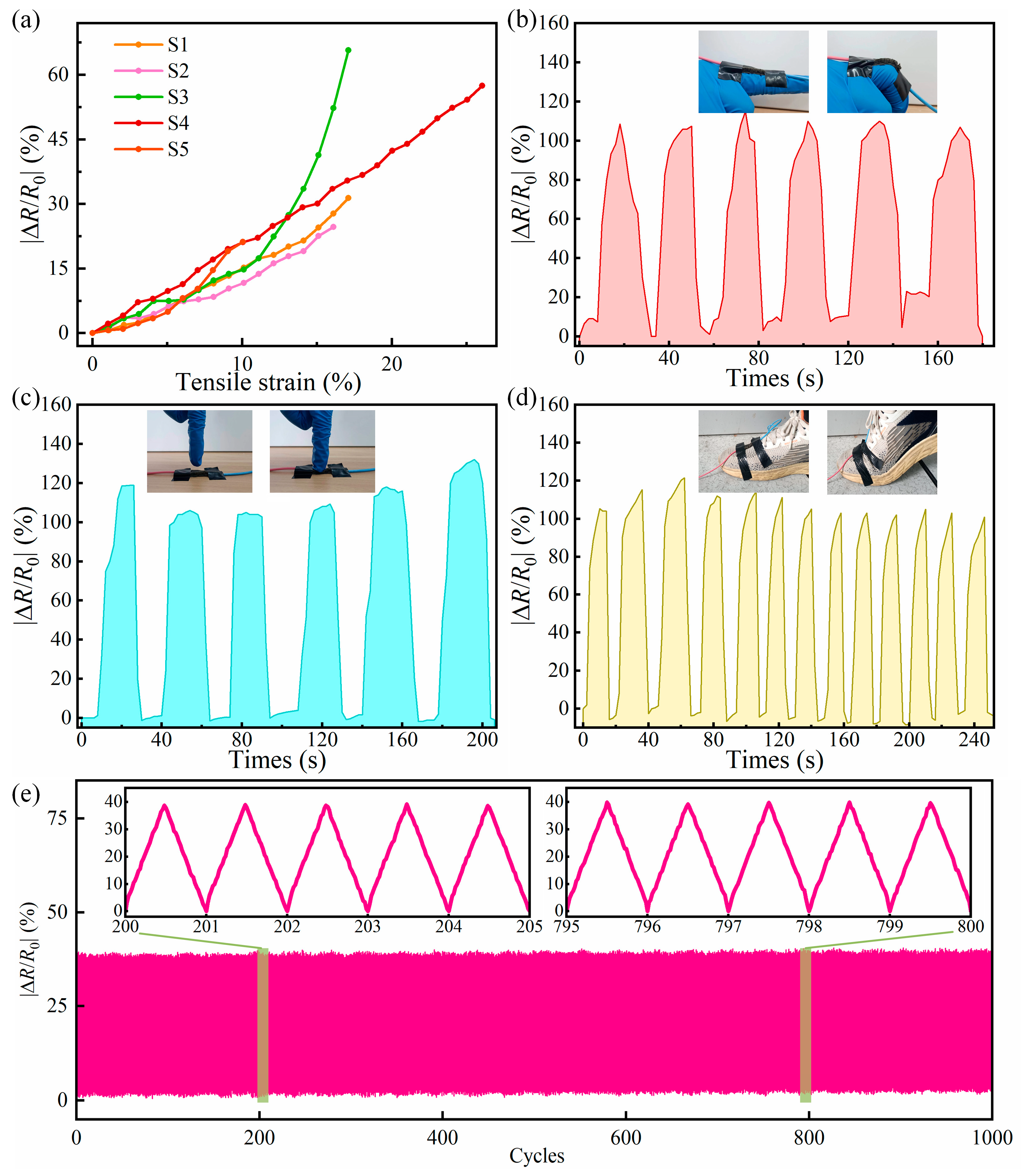

2.4. Strain and Magnetic Sensing Properties of SA/CMC Porous Sponge Sensors and Human Motion Detection Applications

2.5. Stimulus–Response Mechanism of SA/CMC Porous Sponge

2.6. Limitations and Future Work

3. Conclusions

4. Materials and Methods

4.1. Materials and Chemicals

4.2. Preparation of SA/CMC Porous Foams

4.3. Characterization

4.4. Performance Testing

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pistriţu, F.; Gheorghe, M.; Ion, M.; Brincoveanu, O.; Romanitan, C.; Suchea, M.P.; Schiopu, P.; Ionescu, O.N. On the Development of a New Flexible Pressure Sensor. Micromachines 2024, 15, 847. [Google Scholar] [CrossRef] [PubMed]

- Kaidarova, A.; Alsharif, N.; Oliveira, B.N.M.; Marengo, M.; Geraldi, N.R.; Duarte, C.M.; Kosel, J. Laser-printed, flexible graphene pressure sensors. Glob. Chall. 2020, 4, 2000001. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, M.; Yang, B.; Tan, J.; Ding, X. Highly compressible, thermally stable, light-weight, and robust aramid nanofibers/Ti3AlC2 MXene composite aerogel for sensitive pressure sensor. ACS Nano 2020, 14, 10633–10647. [Google Scholar] [CrossRef]

- Kumar, N.J.; Johnson, A.; Roggen, D.; Münzenrieder, N. A flexible capacitance strain sensor with stitched contact terminals. Adv. Mater. Technol. 2023, 8, 2200410. [Google Scholar] [CrossRef]

- Veeralingam, S.; Badhulika, S. Bi2S3/PVDF/Ppy-based freestanding, wearable, transient nanomembrane for ultrasensitive pressure, strain, and temperature sensing. ACS Appl. Bio Mater. 2020, 4, 14–23. [Google Scholar] [CrossRef]

- Amjadi, M.; Pichitpajongkit, A.; Lee, S.; Ryu, S.; Park, I. Highly stretchable and sensitive strain sensor based on silver nanowire–elastomer nanocomposite. ACS Nano 2014, 8, 5154–5163. [Google Scholar] [CrossRef] [PubMed]

- Usman, M.; Jamhour, N.; Hettinger, J.; Xue, W. Smart wearable flexible temperature sensor with compensation against bending and stretching effects. Sens. Actuators A Phys. 2023, 353, 114224. [Google Scholar] [CrossRef]

- Yamada, S.; Toshiyoshi, H. Temperature sensor with a water-dissolvable ionic gel for ionic skin. ACS Appl. Mater. Interfaces 2020, 12, 36449–36457. [Google Scholar] [CrossRef]

- Trung, T.Q.; Dang, T.M.L.; Ramasundaram, S.; Toi, P.T.; Park, S.Y.; Lee, N.-E. A stretchable strain-insensitive temperature sensor based on free-standing elastomeric composite fibers for on-body monitoring of skin temperature. ACS Appl. Mater. Interfaces 2018, 11, 2317–2327. [Google Scholar] [CrossRef]

- Chaudhary, P.; Verma, A.; Chaudhary, S.; Kumar, M.; Lin, M.-F.; Huang, Y.-C.; Chen, K.-L.; Yadav, B. Design of a Humidity Sensor for a PPE Kit Using a Flexible Paper Substrate. Langmuir 2024, 40, 9602–9612. [Google Scholar] [CrossRef]

- Ouda, E.; Yousf, N.; Morsy, M.; Duraia, E.-S.M. Flexible humidity sensor based on light-scribed graphene oxide. J. Mater. Sci. Mater. Electron. 2022, 33, 18241–18251. [Google Scholar] [CrossRef]

- Zhang, Z.; Lu, T.; Yang, D.; Lu, S.; Cai, R.; Tan, W. A high-wet-strength biofilm for readable and highly sensitive humidity sensors. Nano Lett. 2021, 21, 9030–9037. [Google Scholar] [CrossRef] [PubMed]

- Singh, E.; Meyyappan, M.; Nalwa, H.S. Flexible graphene-based wearable gas and chemical sensors. ACS Appl. Mater. Interfaces 2017, 9, 34544–34586. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Goel, N.; Hojamberdiev, M.; Kumar, M. Transition metal dichalcogenides-based flexible gas sensors. Sens. Actuators A Phys. 2020, 303, 111875. [Google Scholar] [CrossRef]

- Jia, L.-C.; Zhou, C.-G.; Dai, K.; Yan, D.-X.; Li, Z.-M. Facile fabrication of highly durable superhydrophobic strain sensors for subtle human motion detection. J. Mater. Sci. Technol. 2022, 110, 35–42. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, X.; Xiang, D.; Wu, Y.; Sun, D.; Shen, J.; Wang, M.; Zhao, C.; Li, H.; Li, Z. Highly stretchable, sensitive and wide linear responsive fabric-based strain sensors with a self-segregated carbon nanotube (CNT)/Polydimethylsiloxane (PDMS) coating. Prog. Nat. Sci. Mater. Int. 2022, 32, 34–42. [Google Scholar] [CrossRef]

- Ershad, F.; Patel, S.; Yu, C. Wearable bioelectronics fabricated in situ on skins. NPJ Flex. Electron. 2023, 7, 32. [Google Scholar] [CrossRef]

- Li, L.; Zhang, J.; Yang, C.; Huang, L.; Zhang, J.; Bai, J.; Redshaw, C.; Feng, X.; Cao, C.; Huo, N. Stimuli-responsive materials from ferrocene-based organic small molecule for wearable sensors. Small 2021, 17, 2103125. [Google Scholar] [CrossRef]

- Choi, S.; Han, S.I.; Jung, D.; Hwang, H.J.; Lim, C.; Bae, S.; Park, O.K.; Tschabrunn, C.M.; Lee, M.; Bae, S.Y. Highly conductive, stretchable and biocompatible Ag–Au core–sheath nanowire composite for wearable and implantable bioelectronics. Nat. Nanotechnol. 2018, 13, 1048–1056. [Google Scholar] [CrossRef] [PubMed]

- Kumar, V.; Park, S.-S. Stretchable Magneto-Mechanical Configurations with High Magnetic Sensitivity Based on “Gel-Type” Soft Rubber for Intelligent Applications. Gels 2024, 10, 80. [Google Scholar] [CrossRef]

- Liu, H.; Chu, H.; Yuan, H.; Li, D.; Deng, W.; Fu, Z.; Liu, R.; Liu, Y.; Han, Y.; Wang, Y. Bioinspired Multifunctional Self-Sensing Actuated Gradient Hydrogel for Soft-Hard Robot Remote Interaction. Nano-Micro Lett. 2024, 16, 69. [Google Scholar] [CrossRef]

- Sakhuja, N.; Kumar, R.; Katare, P.; Bhat, N. Structure-driven, flexible, multilayered, paper-based pressure sensor for human–machine interfacing. ACS Sustain. Chem. Eng. 2022, 10, 9697–9706. [Google Scholar] [CrossRef]

- Lyu, Q.; Gong, S.; Yin, J.; Dyson, J.M.; Cheng, W. Soft wearable healthcare materials and devices. Adv. Healthc. Mater. 2021, 10, 2100577. [Google Scholar] [CrossRef] [PubMed]

- Jung, G.; Lee, H.; Park, H.; Kim, J.; Kim, J.W.; Kim, D.S.; Keum, K.; Lee, Y.H.; Ha, J.S. Temperature-tolerant flexible supercapacitor integrated with a strain sensor using an organohydrogel for wearable electronics. Chem. Eng. J. 2022, 450, 138379. [Google Scholar] [CrossRef]

- Benarrait, R.; Ullah-Khan, M.; Terrien, J.; Al Hajjar, H.; Lamarque, F.; Dietzel, A. A Flexible Double-Sided Curvature Sensor Array for Use in Soft Robotics. Sensors 2024, 24, 3475. [Google Scholar] [CrossRef] [PubMed]

- Han, S.; Choi, J.; Seo, Y.P.; Park, I.J.; Choi, H.J.; Seo, Y. High-performance magnetorheological suspensions of pickering-emulsion-polymerized polystyrene/Fe3O4 particles with enhanced stability. Langmuir 2018, 34, 2807–2814. [Google Scholar] [CrossRef] [PubMed]

- Plachy, T.; Cvek, M.; Munster, L.; Hanulikova, B.; Suly, P.; Vesel, A.; Cheng, Q. Enhanced magnetorheological effect of suspensions based on carbonyl iron particles coated with poly (amidoamine) dendrons. Rheol. Acta 2021, 60, 263–276. [Google Scholar] [CrossRef]

- Park, Y.-J.; Choi, S.-B. Sensors and Sensing Devices Utilizing Electrorheological Fluids and Magnetorheological Materials—A Review. Sensors 2024, 24, 2842. [Google Scholar] [CrossRef]

- Rwei, S.-P.; Ranganathan, P.; Chiang, W.-Y.; Wang, T.-Y. The magnetorheological fluid of carbonyl iron suspension blended with grafted MWCNT or graphene. J. Magn. Magn. Mater. 2017, 443, 58–66. [Google Scholar] [CrossRef]

- Park, D.E.; Chae, H.S.; Choi, H.J.; Maity, A. Magnetite–polypyrrole core–shell structured microspheres and their dual stimuli-response under electric and magnetic fields. J. Mater. Chem. C 2015, 3, 3150–3158. [Google Scholar] [CrossRef]

- Yang, L.; Jia, H.; Wu, A.; Jiao, H.; Chen, X.; Kou, Y.; Dong, M. Particle aggregation and breakage kinetics in cemented paste backfill. Int. J. Miner. Metall. Mater. 2024, 31, 1965–1974. [Google Scholar]

- Fu, Y.; Yao, J.; Zhao, H.; Zhao, G.; Wan, Z.; Qiu, Y. Fabrication and magnetorheology of bidisperse magnetic microspheres coated with gelatin and multi-walled carbon nanotubes. Smart Mater. Struct. 2018, 27, 125001. [Google Scholar] [CrossRef]

- Yang, L.; Gao, Y.; Chen, H.; Jiao, H.; Dong, M.; Bier, T.A.; Kim, M. Three-dimensional concrete printing technology from a rheology perspective: A review. Adv. Cem. Res. 2024, 126, 72–86. [Google Scholar] [CrossRef]

- Thirumalai, D.; Santhamoorthy, M.; Kim, S.-C.; Lim, H.-R. Conductive Polymer-Based Hydrogels for Wearable Electrochemical Biosensors. Gels 2024, 10, 459. [Google Scholar] [CrossRef] [PubMed]

- Bodelot, L.; Voropaieff, J.-P.; Pössinger, T. Experimental investigation of the coupled magneto-mechanical response in magnetorheological elastomers. Exp. Mech. 2018, 58, 207–221. [Google Scholar] [CrossRef]

- Böse, H.; Ehrlich, J. Dielectric elastomer sensors with advanced designs and their applications. Actuators 2023, 12, 115. [Google Scholar] [CrossRef]

- Fu, Y.; Wang, S.; Wan, Z.; Tian, Y.; Wang, D.; Ma, Y.; Yang, L.; Wei, Z. Functional magnetic alginate/gelatin sponge-based flexible sensor with multi-mode response and discrimination detection properties for human motion monitoring. Carbohydr. Polym. 2024, 324, 121520. [Google Scholar] [CrossRef]

- Fu, Y.; Zhao, S.; Zhang, B.; Tian, Y.; Wang, D.; Ban, X.; Ma, Y.; Jiang, L.; Wan, Z.; Wei, Z. Multifunctional cross-sensitive magnetic alginate-chitosan-polyethylene oxide nanofiber sensor for human-machine interaction. Int. J. Biol. Macromol. 2024, 264, 130482. [Google Scholar] [CrossRef]

- Fu, Y.; Wang, S.; Wang, D.; Tian, Y.; Ban, X.; Wang, X.; Zhao, Z.; Wan, Z.; Wei, R. Flexible Multimodal Magnetoresistive Sensors Based on Alginate/Poly (vinyl alcohol) Foam with Stimulus Discriminability for Soft Electronics Using Machine Learning. ACS Appl. Mater. Interfaces 2024, 16, 21118–21132. [Google Scholar] [CrossRef]

- Fu, Y.; Wang, S.; Tian, Y.; Zhang, B.; Zhao, Z.; Wan, Z.; Chen, X.; Zhu, D.; Yang, L.; Wei, Z. A high-sensitivity and multi-response magnetic nanofiber-aerogel sensor with directionally aligned porous structure based on triple network for interactive human–machine interfaces. Chem. Eng. J. 2024, 497, 154441. [Google Scholar] [CrossRef]

- Stepanov, G.; Chertovich, A.; Kramarenko, E.Y. Magnetorheological and deformation properties of magnetically controlled elastomers with hard magnetic filler. J. Magn. Magn. Mater. 2012, 324, 3448–3451. [Google Scholar] [CrossRef]

- Ge, L.; Gong, X.; Wang, Y.; Xuan, S. The conductive three dimensional topological structure enhanced magnetorheological elastomer towards a strain sensor. Compos. Sci. Technol. 2016, 135, 92–99. [Google Scholar] [CrossRef]

- Fu, Y.; Yao, J.; Zhao, H.; Zhao, G.; Wan, Z.; Guo, R. A muscle-like magnetorheological actuator based on bidisperse magnetic particles enhanced flexible alginate-gelatin sponges. Smart Mater. Struct. 2019, 29, 015019. [Google Scholar] [CrossRef]

- Herren, B.; Webster, V.; Davidson, E.; Saha, M.C.; Altan, M.C.; Liu, Y. PDMS sponges with embedded carbon nanotubes as piezoresistive sensors for human motion detection. Nanomaterials 2021, 11, 1740. [Google Scholar] [CrossRef]

- Caillol, S. Special Issue “Natural Polymers and Biopolymers II”. Molecules 2020, 26, 112. [Google Scholar] [CrossRef] [PubMed]

- Thakur, S.; Sharma, B.; Verma, A.; Chaudhary, J.; Tamulevicius, S.; Thakur, V.K. Recent progress in sodium alginate based sustainable hydrogels for environmental applications. J. Clean. Prod. 2018, 198, 143–159. [Google Scholar] [CrossRef]

- Arefian, M.; Hojjati, M.; Tajzad, I.; Mokhtarzade, A.; Mazhar, M.; Jamavari, A. A review of Polyvinyl alcohol/Carboxymethyl cellulose (PVA/CMC) composites for various applications. J. Compos. Compd. 2020, 2, 69–76. [Google Scholar]

- Guo, X.; Wang, Y.; Qin, Y.; Shen, P.; Peng, Q. Structures, properties and application of alginic acid: A review. Int. J. Biol. Macromol. 2020, 162, 618–628. [Google Scholar] [CrossRef]

- Liu, X.; Wang, Y.; Liang, Z.; Lian, X.; Huang, D.; Hu, Y.; Wei, Y. Progress in preparation and application of sodium alginate microspheres. J. Biomed. Eng. Shengwu Yixue Gongchengxue Zazhi 2023, 40, 792–798. [Google Scholar]

- Zhang, H.; Song, Q.; Deng, Z.; Ren, J.; Xiang, X. Sodium alginate hydrogel toughened by guar gum for strain sensors. Polym. Bull. 2023, 81, 8045–8056. [Google Scholar] [CrossRef]

- Tang, Y.; Fang, Z.; Lee, H.-J. Exploring Applications and Preparation Techniques for Cellulose Hydrogels: A Comprehensive Review. Gels 2024, 10, 365. [Google Scholar] [CrossRef]

- Srirachya, N.; Boonkerd, K.; Kobayashi, T. Effective elongation properties of cellulose–natural rubber composite hydrogels having interconnected domain. J. Elastomers Plast. 2020, 52, 337–355. [Google Scholar] [CrossRef]

- Qin, X.; Zhao, Z.; Deng, J.; Zhao, Y.; Liang, S.; Yi, Y.; Li, J.; Wei, Y. Tough, conductive hydrogels based on gelatin and oxidized sodium carboxymethyl cellulose as flexible sensors. Carbohydr. Polym. 2024, 335, 121920. [Google Scholar] [CrossRef] [PubMed]

- Ding, L.; Xuan, S.; Feng, J.; Gong, X. Magnetic/conductive composite fibre: A multifunctional strain sensor with magnetically driven property. Compos. Part A Appl. Sci. Manuf. 2017, 100, 97–105. [Google Scholar] [CrossRef]

- Huang, P.; Li, Y.-Q.; Yu, X.-G.; Zhu, W.-B.; Nie, S.-Y.; Zhang, H.; Liu, J.-R.; Hu, N.; Fu, S.-Y. Bioinspired flexible and highly responsive dual-mode strain/magnetism composite sensor. ACS Appl. Mater. Interfaces 2018, 10, 11197–11203. [Google Scholar] [CrossRef]

- Ding, L.; Xuan, S.; Pei, L.; Wang, S.; Hu, T.; Zhang, S.; Gong, X. Stress and magnetic field bimode detection sensors based on flexible CI/CNTs–PDMS sponges. ACS Appl. Mater. Interfaces 2018, 10, 30774–30784. [Google Scholar] [CrossRef] [PubMed]

- Ding, L.; Pei, L.; Xuan, S.; Fan, X.; Cao, X.; Wang, Y.; Gong, X. Ultrasensitive multifunctional magnetoresistive strain sensor based on hair-like magnetization-induced pillar forests. Adv. Electron. Mater. 2020, 6, 1900653. [Google Scholar] [CrossRef]

- Jang, D.; Farooq, S.; Yoon, H.; Khalid, H. Design of a highly flexible and sensitive multi-functional polymeric sensor incorporating CNTs and carbonyl iron powder. Compos. Sci. Technol. 2021, 207, 108725. [Google Scholar] [CrossRef]

- Shu, Q.; Hu, T.; Xu, Z.; Zhang, J.; Fan, X.; Gong, X.; Xuan, S. Non-tensile piezoresistive sensor based on coaxial fiber with magnetoactive shell and conductive flax core. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106548. [Google Scholar] [CrossRef]

- Seo, Y.; Choi, H.J. Core–shell-structured Fe3O4 nanocomposite particles for high-performance/stable magnetorheological fluids: Preparation and characteristics. J. Korean Ceram. Soc. 2020, 57, 608–631. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties (GB/T 50081-2019). Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019.

| Materials | Stimuli | Advantages | Reference | |

|---|---|---|---|---|

| Lastex yarn (LY)/Ag/PDMS/CIP composite fiber | Strain | ~120.0% at 50% strain | Ideal flexibility, large deformation, and appropriate elasticity and sensing properties | [54] |

| Magnetic field | ~7.6% at 240 mT | |||

| Carbon-fiber aerogel (CFA)/Fe3O4 silicone composite | Strain | ~68% at 20% strain | Highly responsive and wide working frequency | [55] |

| Magnetic field | ~86% at 150 mT | |||

| Carbon nanotube (CNT)/CIP PDMS sponge | Strain | ~82.8% at 60% strain | High flexibility and low density | [56] |

| Magnetic field | ~3.6% at 144 mT | |||

| Ag/CIP PDMS pillar forest | Strain | ~99.6% at 60% strain | Fast response, excellent sensitivity, and high stability. | [57] |

| Magnetic field | ~0.9% at 170 mT | |||

| CNT/CIP polymeric composite | Strain | ~160% at 100% strain | High flexibility, good resistance change, and repeatability | [58] |

| Magnetic field | ~25% at 340 mT | |||

| AgNW/CIP/flax fiber/MRE fiber | Strain | ~19.8% at 16.2° strain | Ideal flexibility, stability, and sensing performance | [59] |

| Magnetic field | ~11.2% at 60 mT | |||

| SA/CMC porous sponge | Strain | ~57.5% at 26% strain | High flexibility, fast response, and high stability | This work |

| ~115% at 90° strain | ||||

| Magnetic field | ~50.2% at 240 mT |

| Porous Sponge Types | Sample | Mass Fraction (wt%) | Glycerol (wt%) | |

|---|---|---|---|---|

| SA | CMC | |||

| SA/CMC Porous Sponges | S1 | 1 | 3 | 2 |

| S2 | 2 | 3 | 2 | |

| S3 | 3 | 3 | 2 | |

| S4 | 3 | 2 | 2 | |

| S5 | 3 | 1 | 2 | |

| S6 | 3 | 2 | 0 | |

| S7 | 3 | 2 | 4 | |

| S8 | 3 | 2 | 6 | |

| SA/CMC Porous Sponges without MPs | S9 | 3 | 2 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Yue, L.; Fu, Y.; Wan, Z.; Wang, L.; Wei, Y.; Li, S. High-Performance Flexible Sensor with Sensitive Strain/Magnetic Dual-Mode Sensing Characteristics Based on Sodium Alginate and Carboxymethyl Cellulose. Gels 2024, 10, 555. https://doi.org/10.3390/gels10090555

Liu C, Yue L, Fu Y, Wan Z, Wang L, Wei Y, Li S. High-Performance Flexible Sensor with Sensitive Strain/Magnetic Dual-Mode Sensing Characteristics Based on Sodium Alginate and Carboxymethyl Cellulose. Gels. 2024; 10(9):555. https://doi.org/10.3390/gels10090555

Chicago/Turabian StyleLiu, Chong, Longwang Yue, Yu Fu, Zhenshuai Wan, Li Wang, Yangke Wei, and Sha Li. 2024. "High-Performance Flexible Sensor with Sensitive Strain/Magnetic Dual-Mode Sensing Characteristics Based on Sodium Alginate and Carboxymethyl Cellulose" Gels 10, no. 9: 555. https://doi.org/10.3390/gels10090555

APA StyleLiu, C., Yue, L., Fu, Y., Wan, Z., Wang, L., Wei, Y., & Li, S. (2024). High-Performance Flexible Sensor with Sensitive Strain/Magnetic Dual-Mode Sensing Characteristics Based on Sodium Alginate and Carboxymethyl Cellulose. Gels, 10(9), 555. https://doi.org/10.3390/gels10090555