Growth Potential of Selected Yeast Strains Cultivated on Xylose-Based Media Mimicking Lignocellulosic Wastewater Streams: High Production of Microbial Lipids by Rhodosporidium toruloides

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials and Microorganisms

2.2. Fermentations for SCO Production

2.3. Analytical Methods

3. Results and Discussion

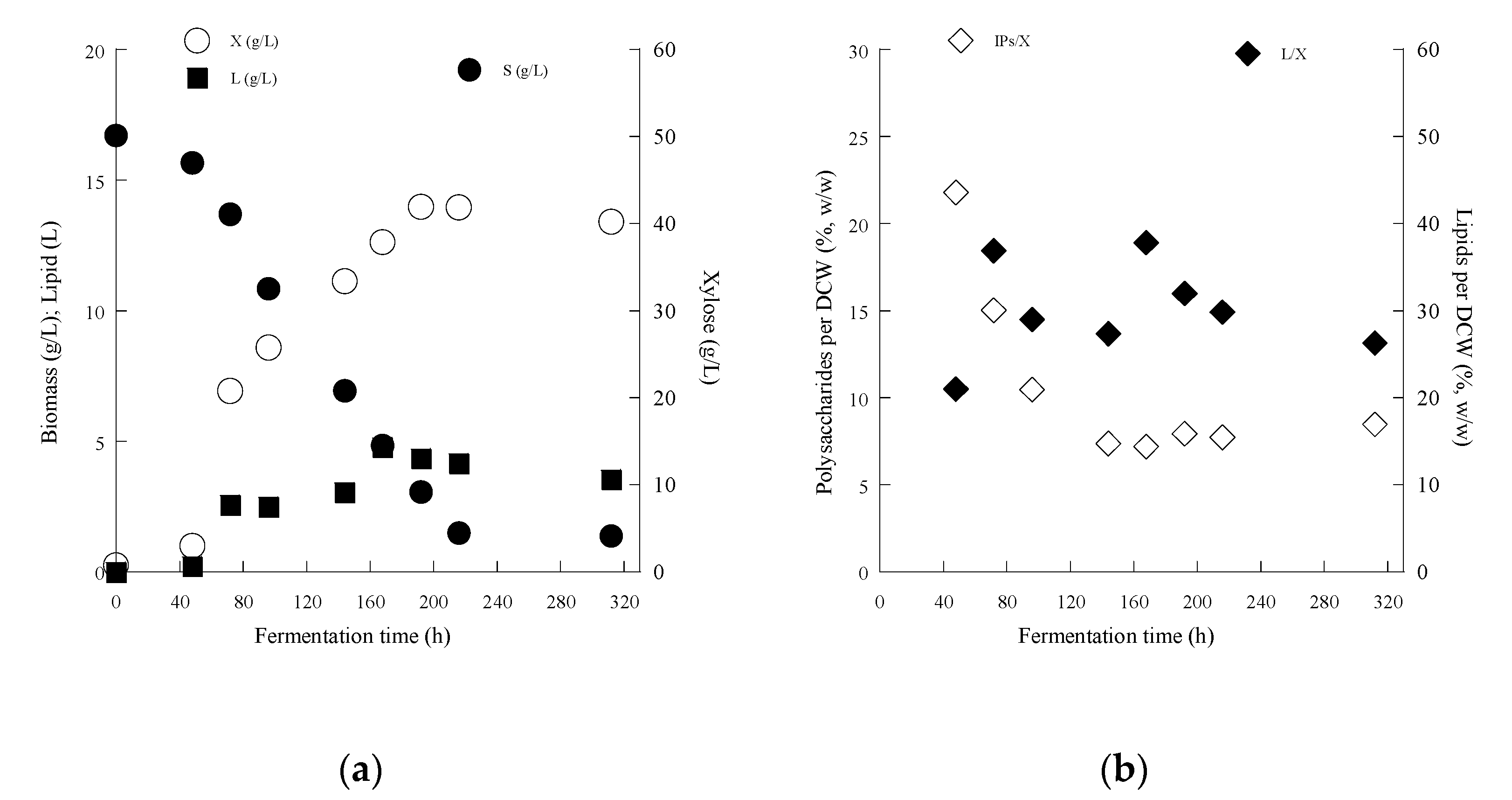

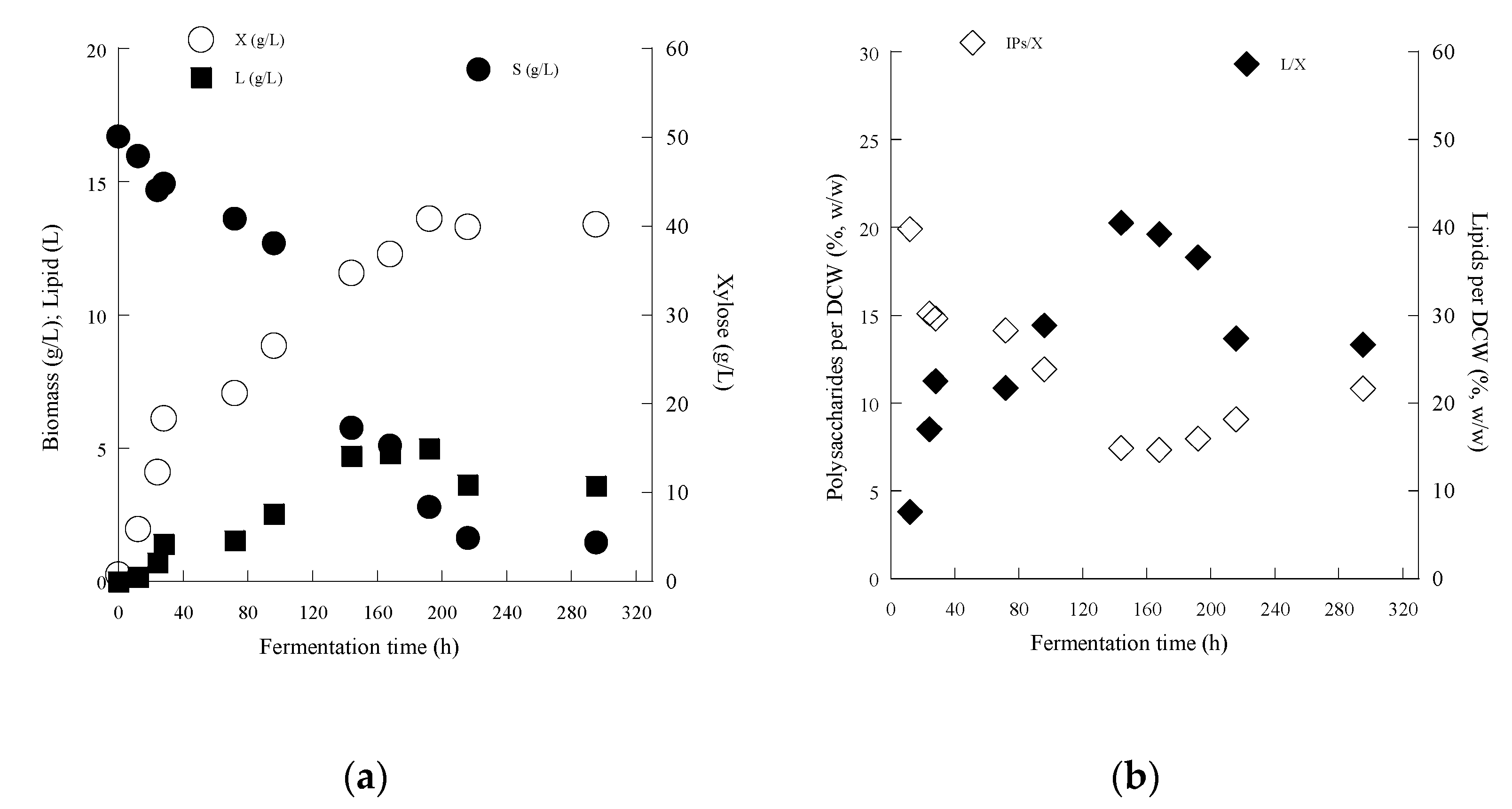

3.1. Screening of Microorganisms for SCO Production

3.2. Effect of LS Supplementation on Fermentation Efficiency

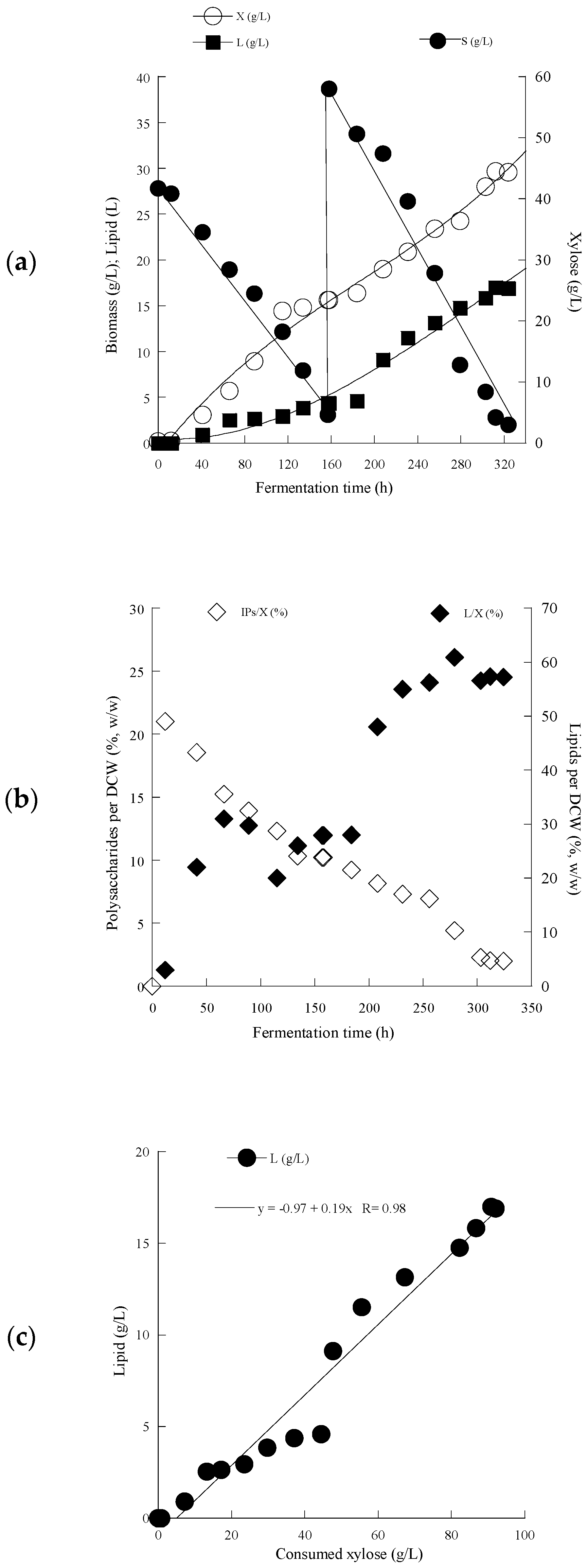

3.3. Fed-Batch Fermentation

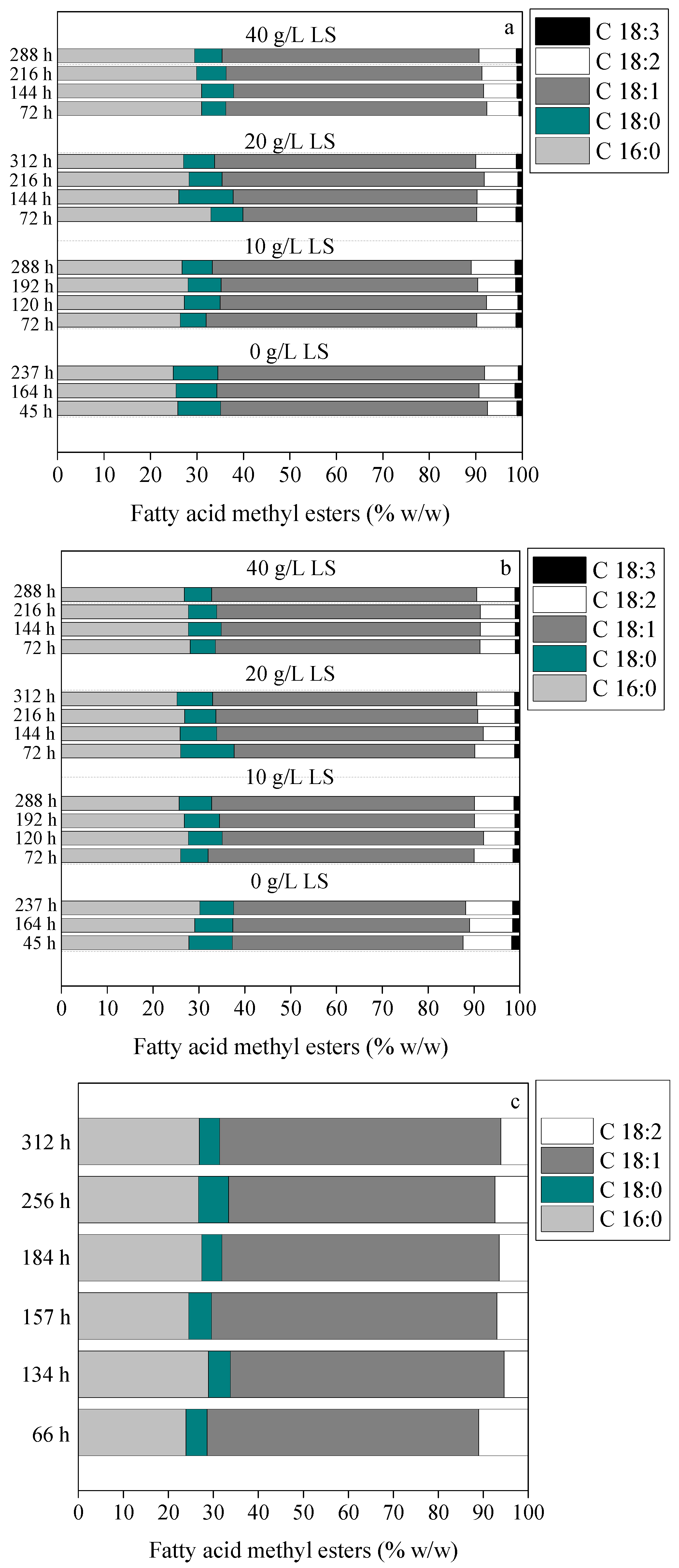

3.4. Total Fatty Acid Profile of Cellular Lipids

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Narisetty, V.; Cox, R.; Bommareddy, R.; Agrawal, D.; Ahmad, E.; Pant, K.K.; Chandel, A.K.; Bhatia, S.K.; Kumar, D.; Binod, P.; et al. Valorisation of Xylose to Renewable Fuels and Chemicals, an Essential Step in Augmenting the Commercial Viability of Lignocellulosic Biorefineries. Sustain. Energy Fuels 2022, 6, 29–65. [Google Scholar] [CrossRef]

- Valdés, G.; Mendonça, R.T.; Aggelis, G. Lignocellulosic Biomass as a Substrate for Oleaginous Microorganisms: A Review. Appl. Sci. 2020, 10, 7698. [Google Scholar] [CrossRef]

- Hazeena, S.H.; Sindhu, R.; Pandey, A.; Binod, P. Lignocellulosic Bio-Refinery Approach for Microbial 2,3-Butanediol Production. Bioresour. Technol. 2020, 302, 122873. [Google Scholar] [CrossRef]

- Diamantopoulou, P.; Stoforos, N.G.; Xenopoulos, E.; Sarris, D.; Psarianos, D.; Philippoussis, A.; Papanikolaou, S. Lipid Production by Cryptococcus curvatus Growing on Commercial Xylose and Subsequent Valorization of Fermentation Waste-Waters for the Production of Edible and Medicinal Mushrooms. Biochem. Eng. J. 2020, 162, 107706. [Google Scholar] [CrossRef]

- Diamantopoulou, P.; Filippousi, R.; Antoniou, D.; Varfi, E.; Xenopoulos, E.; Sarris, D.; Papanikolaou, S. Production of Added-Value Microbial Metabolites during Growth of Yeast Strains on Media Composed of Biodiesel-Derived Crude Glycerol and Glycerol/Xylose Blends. FEMS Microbiol. Lett. 2020, 367, fnaa063. [Google Scholar] [CrossRef]

- Alexandri, M.; Vlysidis, A.; Papapostolou, H.; Tverezovskaya, O.; Tverezovskiy, V.; Kookos, I.K.; Koutinas, A. Downstream Separation and Purification of Succinic Acid from Fermentation Broths Using Spent Sulphite Liquor as Feedstock. Sep. Purif. Technol. 2019, 209, 666–675. [Google Scholar] [CrossRef]

- Tsouko, E.; Papadaki, A.; Papanikolaou, S.; Danezis, G.P.; Georgiou, C.A.; Freire, D.M.G.; Koutinas, A. Enzymatic Production of Isopropyl and 2-Ethylhexyl Esters Using γ-Linolenic Acid Rich Fungal Oil Produced from Spent Sulphite Liquor. Biochem. Eng. J. 2021, 169, 107956. [Google Scholar] [CrossRef]

- Alén, R. Pulp Mills and Wood-Based Biorefineries. In Industrial Biorefineries & White Biotechnology; Elsevier: Amsterdam, The Netherlands, 2015; pp. 91–126. [Google Scholar] [CrossRef]

- He, Q.; Chen, H. Increased Efficiency of Butanol Production from Spent Sulfite Liquor by Removal of Fermentation Inhibitors. J. Clean. Prod. 2020, 263, 121356. [Google Scholar] [CrossRef]

- Hoheneder, R.; Fitz, E.; Bischof, R.H.; Russmayer, H.; Ferrero, P.; Peacock, S.; Sauer, M. Efficient Conversion of Hemicellulose Sugars from Spent Sulfite Liquor into Optically Pure L-Lactic Acid by Enterococcus Mundtii. Bioresour. Technol. 2021, 333, 125215. [Google Scholar] [CrossRef]

- Pereira, J.; Queirós, D.; Lemos, P.C.; Rossetti, S.; Serafim, L.S. Enrichment of a Mixed Microbial Culture of PHA-Storing Microorganisms by Using Fermented Hardwood Spent Sulfite Liquor. New Biotechnol. 2020, 56, 79–86. [Google Scholar] [CrossRef]

- Papanikolaou, S.; Aggelis, G. Lipids of Oleaginous Yeasts. Part II: Technology and Potential Applications. Eur. J. Lipid Sci. Technol. 2011, 113, 1052–1073. [Google Scholar] [CrossRef]

- Saini, R.; Hegde, K.; Brar, S.K.; Vezina, P. Advanced Biofuel Production and Road to Commercialization: An Insight into Bioconversion Potential of Rhodosporidium sp. Biomass Bioenergy 2020, 132, 105439. [Google Scholar] [CrossRef]

- Athenaki, M.; Gardeli, C.; Diamantopoulou, P.; Tchakouteu, S.S.; Sarris, D.; Philippoussis, A.; Papanikolaou, S. Lipids from Yeasts and Fungi: Physiology, Production and Analytical Considerations. J. Appl. Microbiol. 2018, 124, 336–367. [Google Scholar] [CrossRef]

- Liu, Z.; Feist, A.M.; Dragone, G.; Mussatto, S.I. Lipid and Carotenoid Production from Wheat Straw Hydrolysates by Different Oleaginous Yeasts. J. Clean. Prod. 2020, 249, 119308. [Google Scholar] [CrossRef]

- Matsakas, L.; Novak, K.; Enman, J.; Christakopoulos, P.; Rova, U. Acetate-Detoxification of Wood Hydrolysates with Alkali Tolerant Bacillus sp. as a Strategy to Enhance the Lipid Production from Rhodosporidium toruloides. Bioresour. Technol. 2017, 242, 287–294. [Google Scholar] [CrossRef]

- Hartel, R.W.; von Elbe, J.H.; Hofberger, R. Fats, Oils and Emulsifiers. In Confectionery Science and Technology; Springer International Publishing: Cham, Switzerland, 2018; pp. 85–124. [Google Scholar] [CrossRef]

- Saran, S.; Mathur, A.; Dalal, J.; Saxena, R.K. Process Optimization for Cultivation and Oil Accumulation in an Oleaginous Yeast Rhodosporidium toruloides A29. Fuel 2017, 188, 324–331. [Google Scholar] [CrossRef]

- Tsouko, E.; Papadaki, A.; Carmona-Cabello, M.; Dorado, M.; Freire, D.M.G.; Papanikolaou, S.; Koutinas, A.A. Bioconversion of Agro-Residues into Microbial Oil-Based Oleochemicals Employing Packed Bed Bioreactor. Sustainability 2022, 14, 14135. [Google Scholar] [CrossRef]

- Xenopoulos, E.; Giannikakis, I.; Chatzifragkou, A.; Koutinas, A.; Papanikolaou, S. Lipid Production by Yeasts Growing on Commercial Xylose in Submerged Cultures with Process Water Being Partially Replaced by Olive Mill Wastewaters. Processes 2020, 8, 819. [Google Scholar] [CrossRef]

- Filippousi, R.; Tsouko, E.; Mordini, K.; Ladakis, D.; Koutinas, A.A.; Aggelis, G.; Papanikolaou, S. Sustainable Arabitol Production by a Newly Isolated Debaryomyces prosopidis Strain Cultivated on Biodiesel-Derived Glycerol. Carbon Resour. Convers. 2022, 5, 92–99. [Google Scholar] [CrossRef]

- Papanikolaou, S.; Chevalot, I.; Komaitis, M.; Aggelis, G.; Marc, I. Kinetic profile of the cellular lipid composition in an oleaginous Yarrowia lipolytica capable of producing a cocoa-butter substitute from industrial fats. Antonie Van Leeuwenhoek 2001, 80, 215–224. [Google Scholar] [CrossRef]

- Folch, J.; Lees, M.; Slane-Stanley, J. A simple method for the isolation and purification of total lipids from animal tissues. J. Biol. Chem. 1957, 226, 497–509. [Google Scholar] [CrossRef]

- Sarantou, S.; Stoforos, N.G.; Kalantzi, O.; Papanikolaou, S. Biotechnological Valorization of Biodiesel-Derived Glycerol: Trials with the Non-Conventional Yeasts Yarrowia lipolytica and Rhodosporidium sp. Carbon Resour. Convers. 2021, 4, 61–75. [Google Scholar] [CrossRef]

- Argyropoulos, D.; Psallida, C.; Sitareniou, P.; Flemetakis, E.; Diamantopoulou, P. Biochemical Evaluation of Agaricus and Pleurotus Strains in Batch Cultures for Production Optimization of Valuable Metabolites. Microorganisms 2022, 10, 964. [Google Scholar] [CrossRef] [PubMed]

- Miller, G.L. Use of Dinitrosalicylic Acid Reagent for Determination of Reducing Sugar. Anal. Chem. 1959, 31, 426–428. [Google Scholar] [CrossRef]

- Papanikolaou, S.; Aggelis, G. Sources of Microbial Oils with Emphasis to Mortierella (Umbelopsis) isabellina Fungus. World J. Microbiol. Biotechnol. 2019, 35, 63. [Google Scholar] [CrossRef] [PubMed]

- Filippousi, R.; Diamantopoulou, P.; Stavropoulou, M.; Makris, D.P.; Papanikolaou, S. Lipid Production by Rhodosporidium toruloides from Biodiesel-Derived Glycerol in Shake Flasks and Bioreactor: Impact of Initial C/N Molar Ratio and Added Onion-Peel Extract. Process Biochem. 2022, 123, 52–62. [Google Scholar] [CrossRef]

- Tchakouteu, S.S.; Chatzifragkou, A.; Kalantzi, O.; Koutinas, A.A.; Aggelis, G.; Papanikolaou, S. Oleaginous Yeast Cryptococcus curvatus Exhibits Interplay between Biosynthesis of Intracellular Sugars and Lipids. Eur. J. Lipid Sci. Technol. 2015, 117, 657–672. [Google Scholar] [CrossRef]

- Tchakouteu, S.S.; Kopsahelis, N.; Chatzifragkou, A.; Kalantzi, O.; Stoforos, N.G.; Koutinas, A.A.; Aggelis, G.; Papanikolaou, S. Rhodosporidium toruloides Cultivated in NaCl-Enriched Glucose-Based Media: Adaptation Dynamics and Lipid Production. Eng. Life Sci. 2017, 17, 237–248. [Google Scholar] [CrossRef]

- Tchakouteu, S.S.; Kalantzi, O.; Gardeli, C.; Koutinas, A.A.; Aggelis, G.; Papanikolaou, S. Lipid Production by Yeasts Growing on Biodiesel-Derived Crude Glycerol: Strain Selection and Impact of Substrate Concentration on the Fermentation Efficiency. J. Appl. Microbiol. 2015, 118, 911–927. [Google Scholar] [CrossRef]

- Sarris, D.; Papanikolaou, S. Biotechnological Production of Ethanol: Biochemistry, Processes and Technologies. Eng. Life Sci. 2016, 16, 307–329. [Google Scholar] [CrossRef]

- Tsakona, S.; Skiadaresis, A.G.; Kopsahelis, N.; Chatzifragkou, A.; Papanikolaou, S.; Kookos, I.K.; Koutinas, A.A. Valorisation of Side Streams from Wheat Milling and Confectionery Industries for Consolidated Production and Extraction of Microbial Lipids. Food Chem. 2016, 198, 85–92. [Google Scholar] [CrossRef] [PubMed]

- Harde, S.M.; Wang, Z.; Horne, M.; Zhu, J.Y.; Pan, X. Microbial Lipid Production from SPORL-Pretreated Douglas Fir by Mortierella isabellina. Fuel 2016, 175, 64–74. [Google Scholar] [CrossRef]

- Xu, J.; Liu, D. Exploitation of Genus Rhodosporidium for Microbial Lipid Production. World J. Microbiol. Biotechnol. 2017, 33, 54. [Google Scholar] [CrossRef] [PubMed]

- Makri, A.; Fakas, S.; Aggelis, G. Metabolic Activities of Biotechnological Interest in Yarrowia lipolytica Grown on Glycerol in Repeated Batch Cultures. Bioresour. Technol. 2010, 101, 2351–2358. [Google Scholar] [CrossRef] [PubMed]

- Papanikolaou, S.; Komaitis, M.; Aggelis, G. Single Cell Oil (SCO) Production by Mortierella isabellina Grown on High-Sugar Content Media. Bioresour. Technol. 2004, 95, 287–291. [Google Scholar] [CrossRef]

- Serrano-Carreon, L.; Hathout, Y.; Bensoussan, M.; Belin, J.-M. Lipid accumulation in Trichoderma species. FEMS Microbiol. Lett. 1992, 93, 181–187. [Google Scholar] [CrossRef]

- Gardeli, C.; Athenaki, M.; Xenopoulos, E.; Mallouchos, A.; Koutinas, A.A.; Aggelis, G.; Papanikolaou, S. Lipid Production and Characterization by Mortierella (Umbelopsis) Isabellina Cultivated on Lignocellulosic Sugars. J. Appl. Microbiol. 2017, 123, 1461–1477. [Google Scholar] [CrossRef]

- D’Annibale, A.; Sermanni, G.G.; Federici, F.; Petruccioli, M. Olive-Mill Wastewaters: A Promising Substrate for Microbial Lipase Production. Bioresour. Technol. 2006, 97, 1828–1833. [Google Scholar] [CrossRef]

- Sarris, D.; Stoforos, N.G.; Mallouchos, A.; Kookos, I.K.; Koutinas, A.A.; Aggelis, G.; Papanikolaou, S. Production of Added-Value Metabolites by Yarrowia lipolytica Growing in Olive Mill Wastewater-Based Media under Aseptic and Non-Aseptic Conditions. Eng. Life Sci. 2017, 17, 695–709. [Google Scholar] [CrossRef]

- Tzirita, M.; Kremmyda, M.; Sarris, D.; Koutinas, A.A.; Papanikolaou, S. Effect of Salt Addition upon the Production of Metabolic Compounds by Yarrowia lipolytica Cultivated on Biodiesel-Derived Glycerol Diluted with Olive-Mill Wastewaters. Energies 2019, 12, 3649. [Google Scholar] [CrossRef]

- Dourou, M.; Kancelista, A.; Juszczyk, P.; Sarris, D.; Bellou, S.; Triantaphyllidou, I.-E.; Rywinska, A.; Papanikolaou, S.; Aggelis, G. Bioconversion of Olive Mill Wastewater into High-Added Value Products. J. Clean. Prod. 2016, 139, 957–969. [Google Scholar] [CrossRef]

- Zhang, Y.; Bao, J. Tolerance of Trichosporon cutaneum to Lignin Derived Phenolic Aldehydes Facilitate the Cell Growth and Cellulosic Lipid Accumulation. J. Biotechnol. 2022, 343, 32–37. [Google Scholar] [CrossRef] [PubMed]

- Sarris, D.; Rapti, A.; Papafotis, N.; Koutinas, A.A.; Papanikolaou, S. Production of Added-Value Chemical Compounds through Bioconversions of Olive-Mill Wastewaters Blended with Crude Glycerol by a Yarrowia lipolytica Strain. Molecules 2019, 24, 222. [Google Scholar] [CrossRef] [PubMed]

- Bellou, S.; Makri, A.; Sarris, D.; Michos, K.; Rentoumi, P.; Celik, A.; Papanikolaou, S.; Aggelis, G. The Olive Mill Wastewater as Substrate for Single Cell Oil Production by Zygomycetes. J. Biotechnol. 2014, 170, 50–59. [Google Scholar] [CrossRef]

- Karamerou, E.E.; Theodoropoulos, C.; Webb, C. Evaluating Feeding Strategies for Microbial Oil Production from Glycerol by Rhodotorula glutinis. Eng. Life Sci. 2017, 17, 314–324. [Google Scholar] [CrossRef]

- Osorio-González, C.S.; Hegde, K.; Ferreira, P.; Brar, S.K.; Kermanshahipour, A.; Soccol, C.R.; Avalos-Ramírez, A. Lipid Production in Rhodosporidium toruloides Using C-6 and C-5 Wood Hydrolysate: A Comparative Study. Biomass Bioenergy 2019, 130, 105355. [Google Scholar] [CrossRef]

- Bonturi, N.; Crucello, A.; Viana, A.J.C.; Miranda, E.A. Microbial Oil Production in Sugarcane Bagasse Hemicellulosic Hydrolysate without Nutrient Supplementation by a Rhodosporidium toruloides Adapted Strain. Process Biochem. 2017, 57, 16–25. [Google Scholar] [CrossRef]

- Slininger, P.J.; Dien, B.S.; Kurtzman, C.P.; Moser, B.R.; Bakota, E.L.; Thompson, S.R.; O’Bryan, P.J.; Cotta, M.A.; Balan, V.; Jin, M.; et al. Comparative Lipid Production by Oleaginous Yeasts in Hydrolyzates of Lignocellulosic Biomass and Process Strategy for High Titers: High Titer Lipid Production by Yeasts in Lignocellulosic Hydrolyzates. Biotechnol. Bioeng. 2016, 113, 1676–1690. [Google Scholar] [CrossRef]

- Yu, X.; Zheng, Y.; Dorgan, K.M.; Chen, S. Oil Production by Oleaginous Yeasts Using the Hydrolysate from Pretreatment of Wheat Straw with Dilute Sulfuric Acid. Bioresour. Technol. 2011, 102, 6134–6140. [Google Scholar] [CrossRef]

- Filippousi, R.; Antoniou, D.; Tryfinopoulou, P.; Nisiotou, A.A.; Nychas, G.-J.; Koutinas, A.A.; Papanikolaou, S. Isolation, Identification and Screening of Yeasts towards Their Ability to Assimilate Biodiesel-derived Crude Glycerol: Microbial Production of Polyols, Endopolysaccharides and Lipid. J. Appl. Microbiol. 2019, 127, 1080–1100. [Google Scholar] [CrossRef]

- Kopsahelis, N.; Dimou, C.; Papadaki, A.; Xenopoulos, E.; Kyraleou, M.; Kallithraka, S.; Kotseridis, Y.; Papanikolaou, S.; Koutinas, A.A. Refining of Wine Lees and Cheese Whey for the Production of Microbial Oil, Polyphenol-Rich Extracts and Value-Added Co-Products: Restructuring Wineries and Dairy Industry into Novel Biorefineries. J. Chem. Technol. Biotechnol. 2018, 93, 257–268. [Google Scholar] [CrossRef]

- Bellou, S.; Triantaphyllidou, I.-E.; Aggeli, D.; Elazzazy, A.M.; Baeshen, M.N.; Aggelis, G. Microbial Oils as Food Additives: Recent Approaches for Improving Microbial Oil Production and Its Polyunsaturated Fatty Acid Content. Curr. Opin. Biotechnol. 2016, 37, 24–35. [Google Scholar] [CrossRef] [PubMed]

- Shah, A.M.; Yang, W.; Mohamed, H.; Zhang, Y.; Song, Y. Microbes: A Hidden Treasure of Polyunsaturated Fatty Acids. Front. Nutr. 2022, 9, 827837. [Google Scholar] [CrossRef] [PubMed]

- Patel, A.; Sindhu, D.K.; Arora, N.; Singh, R.P.; Pruthi, V.; Pruthi, P.A. Biodiesel Production from Non-Edible Lignocellulosic Biomass of Cassia fistula L. Fruit Pulp Using Oleaginous Yeast Rhodosporidium kratochvilovae HIMPA1. Bioresour. Technol. 2015, 197, 91–98. [Google Scholar] [CrossRef] [PubMed]

- Saad, N.; Abdeshahian, P.; Kalil, M.S.; Wan Yusoff, W.M.; Abdul Hamid, A. Optimization of Aeration and Agitation Rate for Lipid and Gamma Linolenic Acid Production by Cunninghamella bainieri 2A1 in Submerged Fermentation Using Response Surface Methodology. Sci. World J. 2014, 2014, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Singh, M. Essential Fatty Acids, DHA and Human Brain. Indian J. Pediatr. 2005, 72, 239–242. [Google Scholar] [CrossRef] [PubMed]

- Čertík, M.; Adamechová, Z.; Laoteng, K. Microbial Production of γ-Linolenic Acid: Submerged versus Solid-State Fermentations. Food Sci. Biotechnol. 2012, 21, 921–926. [Google Scholar] [CrossRef]

- Cipolatti, E.P.; Remedi, R.D.; dos Santos Sá, C.; Rodrigues, A.B.; Gonçalves Ramos, J.M.; Veiga Burkert, C.A.; Furlong, E.B.; Fernandes de Medeiros Burkert, J. Use of Agroindustrial Byproducts as Substrate for Production of Carotenoids with Antioxidant Potential by Wild Yeasts. Biocatal. Agric. Biotechnol. 2019, 20, 101208. [Google Scholar] [CrossRef]

- Papadaki, A.; Cipolatti, E.P.; Aguieiras, E.C.G.; Cerqueira Pinto, M.C.; Kopsahelis, N.; Freire, D.M.G.; Mandala, I.; Koutinas, A.A. Development of Microbial Oil Wax-Based Oleogel with Potential Application in Food Formulations. Food Bioprocess Technol. 2019, 12, 899–909. [Google Scholar] [CrossRef]

- Paximada, P.; Echegoyen, Y.; Koutinas, A.A.; Mandala, I.G.; Lagaron, J.M. Encapsulation of Hydrophilic and Lipophilized Catechin into Nanoparticles through Emulsion Electrospraying. Food Hydrocoll. 2017, 64, 123–132. [Google Scholar] [CrossRef]

| Strain | Time (h) | Scons (g/L) | X (g/L) | L (g/L) | IPs (g/L) | |

|---|---|---|---|---|---|---|

| Candida oleophila ATCC-20177 | 210 | a | 52.1 ± 2.5 | 13.1 ± 0.52 | 0.31 ± 0.01 | 4.6 ± 0.13 |

| 270 | b | 52.5 ± 2.7 | 12.0 ± 0.43 | 1.15 ± 0.04 | 4.4 ± 0.20 | |

| 170 | c | 45.9 ± 3.1 | 11.5 ± 0.17 | 0.21 ± 0.01 | 4.9 ± 0.14 | |

| Metschnikowia pulcherrima LFMB Y-2 | 415 | a, c | 51.5 ± 2.9 | 8.1 ± 0.38 | 0.19 ± 0.01 | 3.5 ± 0.16 |

| 141 | b | 21.8 ± 1.8 | 6.7 ± 0.23 | 0.52 ± 0.02 | 3.3 ± 0.13 | |

| Cryptococcus curvatus NRRL Y-1511 | 225 | a, b, c | 48.9 ± 2.2 | 17.1 ± 0.75 | 3.60 ± 0.14 | 4.8 ± 0.14 |

| Cryptococcus curvatus ATCC 20509 | 160 | a, b, c | 51.1 ± 2.0 | 16.2 ± 0.61 | 3.41 ± 0.11 | 5.2 ± 0.16 |

| R. toruloides Y 27012 | 237 | a, b, c | 43.0 ± 1.9 | 11.4 ± 0.37 | 2.5 ± 0.10 | 2.2 ± 0.11 |

| R. toruloides DSM 4444 | 288 | a | 43.2 ± 2.1 | 11.6 ± 0.39 | 2.6 ± 0.11 | 2.3 ± 0.10 |

| 192 | b, c | 34.6 ± 2.7 | 9.8 ± 0.39 | 2.7 ± 0.12 | 2.9 ± 0.12 |

| LS (g/L) | Time (h) | X (g/L) | L (g/L) | IPs (g/L) | YL/X (g/g) | YX/S (g/g) | Xylose Consumed (%, w/w) | |

|---|---|---|---|---|---|---|---|---|

| R. toruloides NRRL Y-27012 | ||||||||

| 10 | 216 | a | 12.6 ± 0.60 | 3.8 ± 0.15 | 1.2 ± 0.01 | 0.32 | 0.30 | 81.4 |

| 168 | b, c | 10.8 ± 0.51 | 3.9 ± 0.17 | 1.5 ± 0.05 | 0.36 | 0.36 | 63.1 | |

| 20 | 192 | a, b, c | 13.6 ± 0.62 | 5.0 ± 0.17 | 1.5 ± 0.04 | 0.37 | 0.33 | 83.1 |

| 40 | 216 | a, b, c | 14.6 ± 0.63 | 2.7 ± 0.12 | 1.6 ± 0.06 | 0.19 | 0.36 | 81.3 |

| R. toruloides DSM 4444 | ||||||||

| 10 | 216 | a, b, c | 12.3 ± 0.58 | 4.1 ± 0.18 | 2.3 ± 0.11 | 0.34 | 0.30 | 86.4 |

| 20 | 192 | a, c | 14.0 ± 0.49 | 4.4 ± 0.31 | 1.1 ± 0.01 | 0.31 | 0.34 | 82.1 |

| 168 | b | 12.6 ± 0.53 | 4.8 ± 0.22 | 0.9 ± 0.01 | 0.38 | 0.36 | 71.3 | |

| 40 | 216 | a, b, c | 14.7 ± 0.70 | 2.4 ± 0.11 | 0.9 ± 0.02 | 0.16 | 0.36 | 81.0 |

| Strain | Substrate | Mode | X (g/L) | SCO (g/L) | YL/X (% w/w) | Reference |

|---|---|---|---|---|---|---|

| NRRL Y-27012 | Commercial xylose with LS | Fed-batch | 29.7 | 17.0 | 57.0 | This study |

| NRRL Y-1091 | Xylose | Batch | 2.8–6.3 | 0.1–2.2 | 2.6–35.1 | [15] |

| Wheat straw | 10.7 | 1.0 | 9.4 | |||

| DSM 4444 | Xylose | Batch | 21.1 | 7.7 | 36.5 | [5] |

| NRRL-7191 | Xylose | Batch | 92.0 | 29.4 | 32.0 | [48] |

| CCT 0783 adapted | Xylose | Batch | 12.1 | 5.8 | 48.2 | [49] |

| Sugarcane bagasse | 8.5–10.7 | 3.7–4.5 | 34.6–52.8 | |||

| NCYC 1576 | Wood chips | Batch | 7.1–7.5 | 1.8–2.8 | 24–39 | [16] |

| NRRLY-1091 | Switchgrass | 2-stage-batch | 42.6 | 26.2 | 56.7 | [50] |

| ATCC 10788 | Detoxified wheat straw | Batch | 9.9 | 2.4 | 24.6 | [51] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Michou, S.; Tsouko, E.; Vastaroucha, E.-S.; Diamantopoulou, P.; Papanikolaou, S. Growth Potential of Selected Yeast Strains Cultivated on Xylose-Based Media Mimicking Lignocellulosic Wastewater Streams: High Production of Microbial Lipids by Rhodosporidium toruloides. Fermentation 2022, 8, 713. https://doi.org/10.3390/fermentation8120713

Michou S, Tsouko E, Vastaroucha E-S, Diamantopoulou P, Papanikolaou S. Growth Potential of Selected Yeast Strains Cultivated on Xylose-Based Media Mimicking Lignocellulosic Wastewater Streams: High Production of Microbial Lipids by Rhodosporidium toruloides. Fermentation. 2022; 8(12):713. https://doi.org/10.3390/fermentation8120713

Chicago/Turabian StyleMichou, Savvoula, Erminta Tsouko, Eleni-Stavroula Vastaroucha, Panagiota Diamantopoulou, and Seraphim Papanikolaou. 2022. "Growth Potential of Selected Yeast Strains Cultivated on Xylose-Based Media Mimicking Lignocellulosic Wastewater Streams: High Production of Microbial Lipids by Rhodosporidium toruloides" Fermentation 8, no. 12: 713. https://doi.org/10.3390/fermentation8120713

APA StyleMichou, S., Tsouko, E., Vastaroucha, E.-S., Diamantopoulou, P., & Papanikolaou, S. (2022). Growth Potential of Selected Yeast Strains Cultivated on Xylose-Based Media Mimicking Lignocellulosic Wastewater Streams: High Production of Microbial Lipids by Rhodosporidium toruloides. Fermentation, 8(12), 713. https://doi.org/10.3390/fermentation8120713