The Preparation Processes and Influencing Factors of Biofuel Production from Kitchen Waste

Abstract

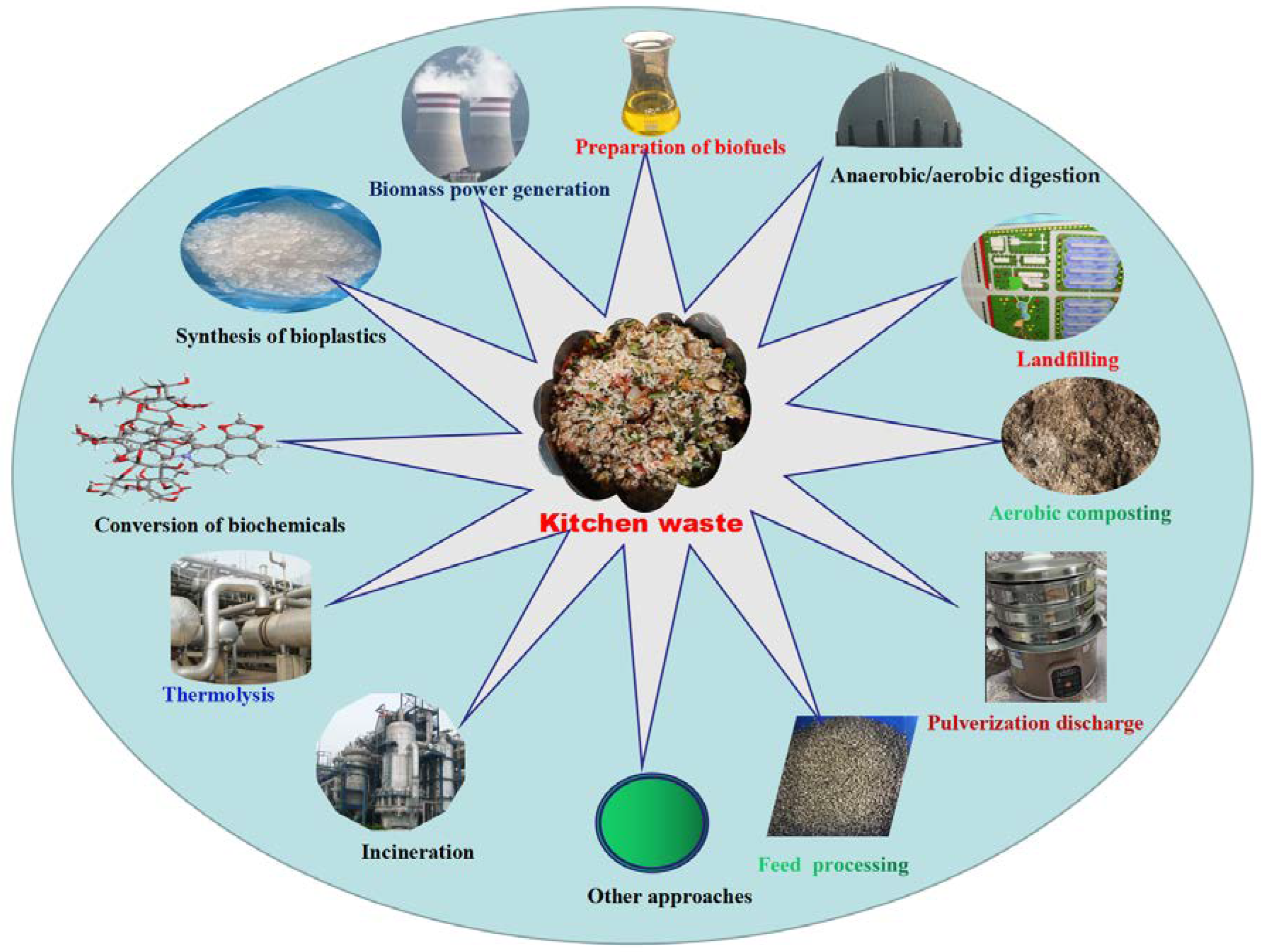

1. Introduction

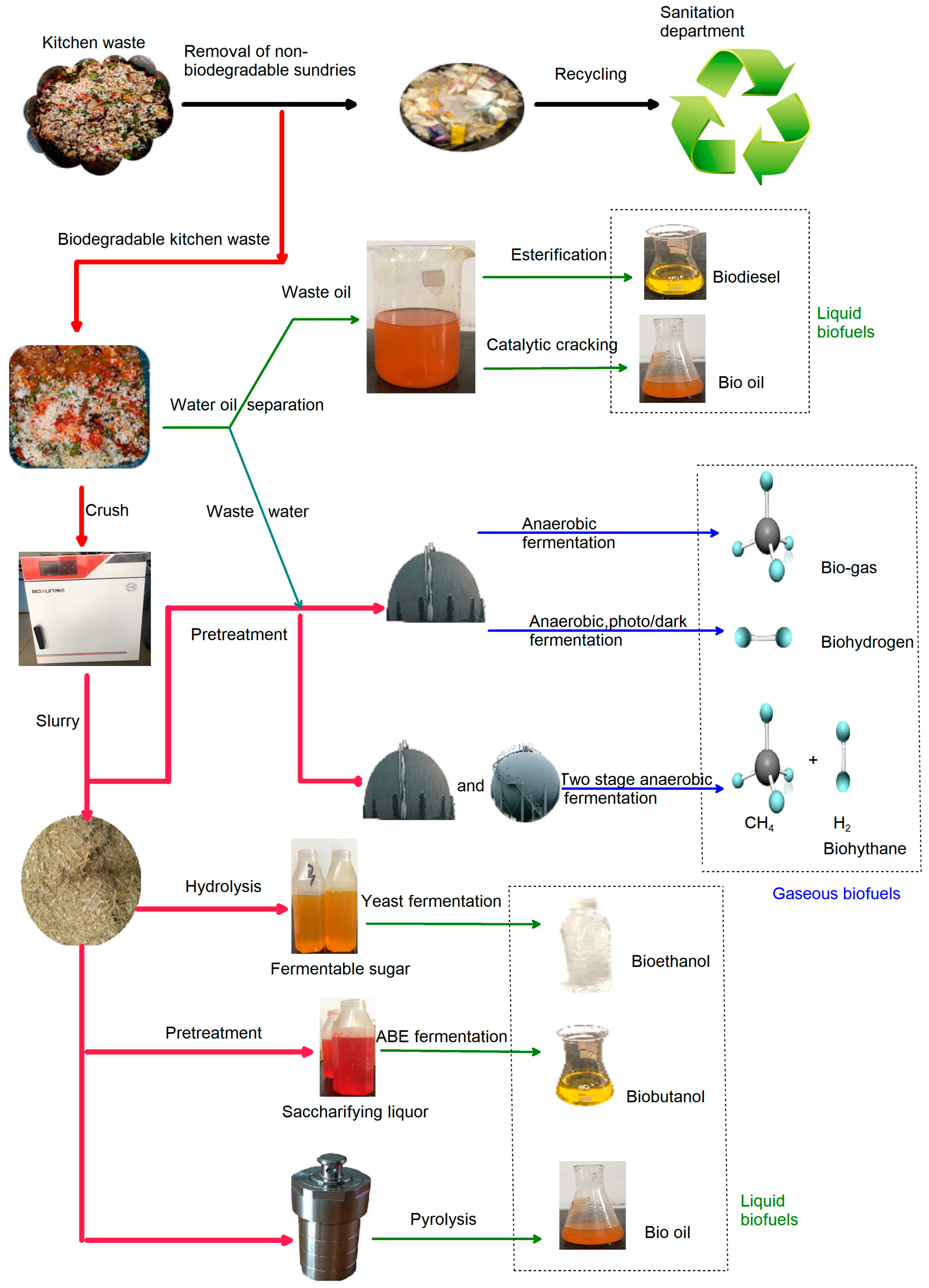

2. Sorting of Sundries and Solid–Liquid Separation in Kitchen Waste

2.1. Sorting

2.2. Solid–Liquid Separation

3. Preparation of Gaseous Biofuels from Kitchen Waste

3.1. Biogas

3.2. Biohythane

3.3. Biohydrogen

4. Preparation of Liquid Fuels with Kitchen Waste

4.1. Bioethanol

4.2. Biobutanol

| Fuel | Gasoline | 1-Butanol | 2-Butanol | tert-Butanol | Isobutanol | Ethanol | Methanol | Diesel | Biodiesel |

|---|---|---|---|---|---|---|---|---|---|

| Composition | C4-C12 | C4H9OH | C4H9OH | C4H9OH | C4H9OH | C2H5OH | CH3OH | C12-C25 | C14-C24 |

| Energy density (MJ/L) | 32 | 29.2 | 29.07 | 37.16 | 28.87 | 19.6 | 16 | 39 | 31–33 |

| Vapor pressure (kPa) at 20 °C | 0.7–207 | 0.67 | 1.33 | 4.13 | 1.17 | 7.58 | 12.8 | <0.07 | <0.07 |

| Vapor pressure of mixture with gasoline (kPa) | 53.8–103.4 | 44.1 | — | — | 46.9 | 138 | 800 | — | |

| Air : fuel ratio | 14.6 | 11.2 | — | — | — | 9.0 | 6.5 | — | 12.5 |

| Heat of vaporization (MJ/kg) | 0.36 | 0.43 | — | — | — | 0.92 | 1.16 | — | — |

| Research octane number | 84–99 | 96 | 101 | 105 | 113 | 129 | 112–136 | — | — |

| Motor octane number | 81–89 | 78 | 32 | 89 | 94 | 102 | 97–104 | — | — |

| Cetane number * | 0–10 | 25 | — | — | — | 5–8 | 4 | 40–55 | 48–65 |

| Density (g/mL) at 20 °C | 0.72–0.78 | 0.809 | 0.806 | 0.789 | 0.802 | 0.789 | 0.792 | 0.82–0.86 | 0.82–0.86 |

| Flash point (°C) | −45 to −38 | 35 | 35 | 11 | 27.8 | 14 | 11.1 | 65–88 | 65–88 |

| Boiling point (°C) | 25–215 | 117.7 | 99.5 | 82.4 | 108 | 78.5 | 64.5 | 180–370 | 180–370 |

| Flammability (% vol) | 0.6–8 | 1.4–11.2 | 1.7–9.8 | 2.4–8.0 | 1.2–10.9 | 3.3–19 | 6–36.5 | 1.5–7.6 | 1.5–7.6 |

| Self-ignition temperature (°C) | 427 | 343 | 406.3 | 477.8 | 415.6 | 363 | 473 | 220 | 220 |

| Viscosity (mpa.s, 25 °C) | 0.4–0.8 | 2.544 | 3.096 | 3.411 | 4.312 | 1.096 | 0.545 | 1.9–4.1 | 1.9–4.1 |

| Freezing temperature (°C) | <−60 | −89.5 | −115 | 23–26 | −108 | −114.5 | −97.6 | −30 to −9.9 | 7.5 to −16 |

| Hygroscopicity | Low | Low | — | — | Low | High | High | Very low | Very low |

| Compatibility with existing infrastructure | Yes | Yes | — | — | Yes | No | No | Yes | No |

4.3. Biodiesel

4.4. Bio-Oil

5. Conclusions and Future Directions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ABE | acetone:butanol:ethanol |

| AD | anaerobic digestion |

| C/N | carbon-to-nitrogen ratio |

| CNG | compressed natural gas |

| COD | chemical oxygen demand |

| EDTA | ethylene diamine tetraacetic acid |

| FW | food waste |

| LHV | lower heating value |

| LNG | liquefied natural gas |

| LPG | liquefied petroleum gas |

| MON | motor octane number |

| OL | organic load |

| RON | research octane number |

| TAN | total ammonia nitrogen |

| TS | total solid |

| VFA | volatile fatty (aliphatic) acid |

| VS | volatile solid |

| WCO | waste cooking oil |

References

- Mahapatra, S.; Kumar, D.; Singh, B.; Sachan, P.K. Biofuels and their sources of production: A review on cleaner sustainable alternative against conventional fuel, in the framework of the food and energy nexus. Energy Nexus 2021, 4, 100036. [Google Scholar] [CrossRef]

- Akinwumi, A.R.; Nwinyi, O.C.; Ayeni, A.O.; Ahuekwe, E.F.; Chukwu, M.N. An overview of the production and prospect of polyhydroxyalkanote (PHA)-based biofuels: Opportunities and limitations. Sci. Afr. 2022, 16, e01233. [Google Scholar] [CrossRef]

- Mohan, R.; Ray, P. Indian Monetary Policy in the Time of Inflation Targeting and Demonetization. Asian Econ. Policy Rev. 2019, 14, 67–92. [Google Scholar] [CrossRef]

- Shams Esfandabadi, Z.; Ranjbari, M.; Scagnelli, S. The imbalance of food and biofuel markets amid Ukraine-Russia crisis: A systems thinking perspective. Biofuel Res. J. 2022, 9, 1640–1647. [Google Scholar] [CrossRef]

- Lan, Z. Study on Biofuels Development and its Impacts; Wuhan University of Technology: Wuhan, China, 2009. [Google Scholar]

- Ko, J.K.; Lee, J.H.; Jung, J.H.; Lee, S.-M. Recent advances and future directions in plant and yeast engineering to improve lignocellulosic biofuel production. Renew. Sustain. Energy Rev. 2020, 134, 110390. [Google Scholar] [CrossRef]

- Soltanian, S.; Aghbashlo, M.; Almasi, F.; Hosseinzadeh-Bandbafha, H.; Nizami, A.-S.; Ok, Y.S.; Lam, S.S.; Tabatabaei, M. A critical review of the effects of pretreatment methods on the exergetic aspects of lignocellulosic biofuels. Energy Convers. Manag. 2020, 212, 112792. [Google Scholar] [CrossRef]

- Ambaye, T.G.; Vaccari, M.; Bonilla-Petriciolet, A.; Prasad, S.; van Hullebusch, E.D.; Rtimi, S. Emerging technologies for biofuel production: A critical review on recent progress, challenges and perspectives. J. Environ. Manag. 2021, 290, 112627. [Google Scholar] [CrossRef] [PubMed]

- Ebadian, M.; van Dyk, S.; McMillan, J.D.; Saddler, J. Biofuels policies that have encouraged their production and use: An international perspective. Energy Policy 2020, 147, 111906. [Google Scholar] [CrossRef]

- Ashani, P.N.; Shafiei, M.; Karimi, K. Biobutanol production from municipal solid waste: Technical and economic analysis. Bioresour. Technol. 2020, 308, 123267. [Google Scholar] [CrossRef]

- Beig, B.; Riaz, M.; Raza Naqvi, S.; Hassan, M.; Zheng, Z.; Karimi, K.; Pugazhendhi, A.; Atabani, A.E.; Thuy Lan Chi, N. Current challenges and innovative developments in pretreatment of lignocellulosic residues for biofuel production: A review. Fuel 2021, 287, 119670. [Google Scholar] [CrossRef]

- Ab Rasid, N.S.; Shamjuddin, A.; Abdul Rahman, A.Z.; Amin, N.A.S. Recent advances in green pre-treatment methods of lignocellulosic biomass for enhanced biofuel production. J. Clean. Prod. 2021, 321, 129038. [Google Scholar] [CrossRef]

- Boro, M.; Verma, A.K.; Chettri, D.; Yata, V.K.; Verma, A.K. Strategies involved in biofuel production from agro-based lignocellulose biomass. Environ. Technol. Innov. 2022, 28, 102679. [Google Scholar] [CrossRef]

- Sawasdee, V.; Pisutpaisal, N. Potential of Napier grass Pak Chong 1 as feedstock for biofuel production. Energy Rep. 2021, 7, 519–526. [Google Scholar] [CrossRef]

- Echaroj, S.; Pannucharoenwong, N.; Duanguppama, K.; Santikunaporn, M.; Rattanadecho, P. Supercritical ethanol liquefaction of rice husk to bio-fuel over modified graphene oxide. Energy Rep. 2022, 8, 173–183. [Google Scholar] [CrossRef]

- Usmani, Z.; Sharma, M.; Awasthi, A.K.; Sivakumar, N.; Lukk, T.; Pecoraro, L.; Thakur, V.K.; Roberts, D.; Newbold, J.; Gupta, V.K. Bioprocessing of waste biomass for sustainable product development and minimizing environmental impact. Bioresour. Technol. 2021, 322, 124548. [Google Scholar] [CrossRef] [PubMed]

- Viswanathan, K.; Ikhsan Taipabu, M.; Wu, W. Novel Petit grain bitter orange waste peel oil biofuel investigation in diesel engine with modified fuel injection pressure and bowl geometry. Fuel 2022, 319, 123660. [Google Scholar] [CrossRef]

- Srivastava, N.; Srivastava, M.; Abd_Allah, E.F.; Singh, R.; Hashem, A.; Gupta, V.K. Biohydrogen production using kitchen waste as the potential substrate: A sustainable approach. Chemosphere 2021, 271, 129537. [Google Scholar] [CrossRef] [PubMed]

- Suzihaque, M.U.H.; Syazwina, N.; Alwi, H.; Ibrahim, U.K.; Abdullah, S.; Haron, N. A sustainability study of the processing of kitchen waste as a potential source of biofuel: Biodiesel production from waste cooking oil (WCO). Mater. Today: Proc. 2022, 63, S484–S489. [Google Scholar] [CrossRef]

- Norouzian Baghani, A.; Sadjadi, S.; Yaghmaeian, K.; Hossein Mahvi, A.; Yunesian, M.; Nabizadeh, R. Solid alcohol biofuel based on waste cooking oil: Preparation, properties, micromorphology, heating value optimization and its application as candle wax. Renew. Energy 2022, 192, 617–630. [Google Scholar] [CrossRef]

- Ajay, C.M.; Mohan, S.; Dinesha, P. Decentralized energy from portable biogas digesters using domestic kitchen waste: A review. Waste Manag. 2021, 125, 10–26. [Google Scholar] [CrossRef]

- Kanchanatip, E.; Chansiriwat, W.; Palalerd, S.; Khunphonoi, R.; Kumsaen, T.; Wantala, K. Light biofuel production from waste cooking oil via pyrolytic catalysis cracking over modified Thai dolomite catalysts. Carbon Resour. Convers. 2022, 5, 177–184. [Google Scholar] [CrossRef]

- He, M.; Xu, C.; Li, B.; Hu, T.; Shi, Z. The influence of ventilation rate on nitrogen conversion and N2O releasing in composting of kitchen waste. J. Ningbo Univ. 2021, 34, 114–120. [Google Scholar]

- Zhao, C.; Xin, L.; Xu, X.; Qin, Y.; Wu, W. Dynamics of antibiotics and antibiotic resistance genes in four types of kitchen waste composting processes. J. Hazard. Mater. 2022, 424, 127526. [Google Scholar] [CrossRef]

- Kim, S.; Mostafa, A.; Im, S.; Lee, M.-K.; Kang, S.; Na, J.-G.; Kim, D.-H. Production of high-calorific biogas from food waste by integrating two approaches: Autogenerative high-pressure and hydrogen injection. Water Res. 2021, 194, 116920. [Google Scholar] [CrossRef] [PubMed]

- Negri, C.; Ricci, M.; Zilio, M.; D’Imporzano, G.; Qiao, W.; Dong, R.; Adani, F. Anaerobic digestion of food waste for bio-energy production in China and Southeast Asia: A review. Renew. Sustain. Energy Rev. 2020, 133, 110138. [Google Scholar] [CrossRef]

- Yukesh Kannah, R.; Merrylin, J.; Poornima Devi, T.; Kavitha, S.; Sivashanmugam, P.; Kumar, G.; Rajesh Banu, J. Food waste valorization: Biofuels and value added product recovery. Bioresour. Technol. Rep. 2020, 11, 100524. [Google Scholar] [CrossRef]

- De Medina-Salas, L.; Castillo-González, E.; Giraldi-Díaz, M.R.; Jamed-Boza, L.O. Valorisation of the organic fraction of municipal solid waste. Waste Manag. Res. 2018, 37, 59–73. [Google Scholar] [CrossRef]

- Sharma, P.; Gaur, V.K.; Sirohi, R.; Varjani, S.; Hyoun Kim, S.; Wong, J.W.C. Sustainable processing of food waste for production of bio-based products for circular bioeconomy. Bioresour. Technol. 2021, 325, 124684. [Google Scholar] [CrossRef]

- Miao, Z. Study on Co-Production of Biogas and Fuel Oil for Kitchen Waste; Kunming University of Science and Technology: Kunming, China, 2019. [Google Scholar]

- Bing, J.; Luo, E.; Jing, Y.; Li, Y.; Liu, D. Research on Construction Status of Kitchen Waste Resource Utilization System in China. Environ. Sci. Manag 2018, 43, 39–43. [Google Scholar]

- Hafid, H.S.; Rahman, N.A.A.; Shah, U.K.M.; Baharuddin, A.S.; Ariff, A.B. Feasibility of using kitchen waste as future substrate for bioethanol production: A review. Renew. Sustain. Energy Rev. 2017, 74, 671–686. [Google Scholar] [CrossRef]

- Li, M.; Li, F.; Zhou, J.; Yuan, Q.; Hu, N. Fallen leaves are superior to tree pruning as bulking agents in aerobic composting disposing kitchen waste. Bioresour. Technol. 2022, 346, 126374. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Long, F.; Cao, X.; Zhao, J.; Liu, P.; Xu, J. Catalytic cracking of waste cooking oil followed with hydro-isomerization for high-quality biofuel production. J. Clean. Prod. 2022, 345, 131027. [Google Scholar] [CrossRef]

- Singh, A.; Singhania, R.R.; Soam, S.; Chen, C.-W.; Haldar, D.; Varjani, S.; Chang, J.-S.; Dong, C.-D.; Patel, A.K. Production of bioethanol from food waste: Status and perspectives. Bioresour. Technol. 2022, 360, 127651. [Google Scholar] [CrossRef] [PubMed]

- Anastasiou, E.; Lorentz, K.O.; Stein, G.J.; Mitchell, P.D. Prehistoric schistosomiasis parasite found in the Middle East. Lancet Infect. Dis. 2014, 14, 553–554. [Google Scholar] [CrossRef]

- Sharma, P.; Gaur, V.K.; Kim, S.H.; Pandey, A. Microbial strategies for bio-transforming food waste into resources. Bioresour. Technol. 2020, 299, 122580. [Google Scholar] [CrossRef]

- Shi, S.; Gao, M.; Wang, J.; Zhen, J.; Yuan, Y.; Tian, D. Study on bio-butanol production from food waste by abe fermentation. Environ. Eng 2017, 35, 117–121. [Google Scholar] [CrossRef]

- Hoàng, T.Y.; Khoo, K.S.; Ngọc, H.L.T.; Thu, Q.T.T.; Thị, T.Đ.; Thu, H.Đ.T.; Hoàng, H.C.; Chinthalapati, S.; Lay, C.-H.; Show, P.L. Sustainable cultivation via waste soybean extract for higher vaccenic acid production by purple non-sulfur bacteria. Clean Technol. Environ. Policy 2021, 23, 103–112. [Google Scholar] [CrossRef]

- Yadav, A. Biofuel from waste cooking oil of hospitality laboratory. Mater. Today Proc. 2021, 57, 2121–2123. [Google Scholar] [CrossRef]

- Ginni, G.; Adish Kumar, S.; Mohamed Usman, T.M.; Pakonyi, P.; Rajesh Banu, J. Chapter 13—Integrated biorefineries of food waste. In Food Waste to Valuable Resources; Banu, J.R., Kumar, G., Gunasekaran, M., Kavitha, S., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 275–298. [Google Scholar]

- Chen, B. Food Waste pretreatment technologies. Environ. Sanit. Eng. 2015, 23, 10–12. [Google Scholar]

- Ban, F.; Sun, X.; Liu, X.; Li, M. Introduction to a food waste treatment project with automatic sorting, solid-liquid separation, and oil-water separation process. Environ. Eng. 2016, 34, 145. [Google Scholar] [CrossRef]

- Wu, Y.; Qin, Z.; Li, H.; Cui, J.; He, Q.; Zhang, H.; Zhang, H.; Yang, L. Effect of two-stage separation on the removal of sundries in kitchen waste. Guanndong Chem. Ind. 2022, 49, 109–110, 122. [Google Scholar]

- Sindhu, R.; Gnansounou, E.; Rebello, S.; Binod, P.; Varjani, S.; Thakur, I.S.; Nair, R.B.; Pandey, A. Conversion of food and kitchen waste to value-added products. J. Environ. Manag. 2019, 241, 619–630. [Google Scholar] [CrossRef] [PubMed]

- Bhatia, R.K.; Ramadoss, G.; Jain, A.K.; Dhiman, R.K.; Bhatia, S.K.; Bhatt, A.K. Conversion of Waste Biomass into Gaseous Fuel: Present Status and Challenges in India. BioEnergy Res. 2020, 13, 1046–1068. [Google Scholar] [CrossRef]

- Gao, Y. Study on the Domestication of Propionic Acid Methanogens and the Enhancement of Anaerobic Fermentation of Food Waste; Northeast Agricultural University: Harbin, China, 2018. [Google Scholar]

- Pasalari, H.; Gholami, M.; Rezaee, A.; Esrafili, A.; Farzadkia, M. Perspectives on microbial community in anaerobic digestion with emphasis on environmental parameters: A systematic review. Chemosphere 2021, 270, 128618. [Google Scholar] [CrossRef]

- Caruso, M.C.; Braghieri, A.; Capece, A.; Napolitano, F.; Romano, P.; Galgano, F.; Altieri, G.; Genovese, F. Recent Updates on the Use of Agro-Food Waste for Biogas Production. Appl. Sci. 2019, 9, 1217. [Google Scholar] [CrossRef]

- Kothari, R.; Pandey, A.K.; Kumar, S.; Tyagi, V.V.; Tyagi, S.K. Different aspects of dry anaerobic digestion for bio-energy: An overview. Renew. Sustain. Energy Rev. 2014, 39, 174–195. [Google Scholar] [CrossRef]

- Ma, Y.; Gu, J.; Liu, Y. Evaluation of anaerobic digestion of food waste and waste activated sludge: Soluble COD versus its chemical composition. Sci. Total Environ. 2018, 643, 21–27. [Google Scholar] [CrossRef]

- Ma, Y.; Liu, Y. Turning food waste to energy and resources towards a great environmental and economic sustainability: An innovative integrated biological approach. Biotechnol. Adv. 2019, 37, 107414. [Google Scholar] [CrossRef]

- Panepinto, D.; Genon, G. Analysis of the extrusion as a pretreatment for the anaerobic digestion process. Ind. Crops Prod. 2016, 83, 206–212. [Google Scholar] [CrossRef]

- Dahiya, S.; Kumar, A.N.; Shanthi Sravan, J.; Chatterjee, S.; Sarkar, O.; Mohan, S.V. Food waste biorefinery: Sustainable strategy for circular bioeconomy. Bioresour. Technol. 2018, 248, 2–12. [Google Scholar] [CrossRef]

- Ariunbaatar, J.; Panico, A.; Frunzo, L.; Esposito, G.; Lens, P.N.L.; Pirozzi, F. Enhanced anaerobic digestion of food waste by thermal and ozonation pretreatment methods. J. Environ. Manag. 2014, 146, 142–149. [Google Scholar] [CrossRef] [PubMed]

- Ariunbaatar, J.; Panico, A.; Yeh, D.H.; Pirozzi, F.; Lens, P.N.L.; Esposito, G. Enhanced mesophilic anaerobic digestion of food waste by thermal pretreatment: Substrate versus digestate heating. Waste Manag. 2015, 46, 176–181. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Jin, Y. Effects of thermal pretreatment on acidification phase during two-phase batch anaerobic digestion of kitchen waste. Renew. Energy 2015, 77, 550–557. [Google Scholar] [CrossRef]

- Ma, J.; Duong, T.H.; Smits, M.; Verstraete, W.; Carballa, M. Enhanced biomethanation of kitchen waste by different pre-treatments. Bioresour. Technol. 2011, 102, 592–599. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H. Study on Anaerobic Digestion of Food Waste: Effect of Pretreatment; Zhejiang University: Hangzhou, China, 2018. [Google Scholar]

- Feng, L.; LI, R. Efficiency of anaerobic digestion of kitchen waste by low intensity ultrasound pretreatment. Chin. J. Environ. Eng. 2012, 6, 3280–3286. [Google Scholar]

- Sun, Y. Effect of Different Pretretments on Fermentative Hydrogen and Methane Production from Food Waste and Mechanism Investigation; Beijing University of Chemical Technology: Beijing, China, 2013. [Google Scholar]

- Linyi, C.; Yujie, Q.; Buqing, C.; Chenglong, W.; Shaohong, Z.; Renglu, C.; Shaohua, Y.; Lan, Y.; Zhiju, L. Enhancing degradation and biogas production during anaerobic digestion of food waste using alkali pretreatment. Environ. Res. 2020, 188, 109743. [Google Scholar] [CrossRef]

- Wang, P.; Wang, X.; Chen, X.; Ren, L. Effects of bentonite on antibiotic resistance genes in biogas slurry and residue from thermophilic and mesophilic anaerobic digestion of food waste. Bioresour. Technol. 2021, 336, 125322. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, W.; Zhang, H.; Wang, Z.; Fan, C.; Zang, L. Recent achievements in enhancing anaerobic digestion with carbon-based functional materials. Bioresour. Technol. 2018, 266, 555–567. [Google Scholar] [CrossRef]

- Zhang, D.; Duan, N.; Tian, H.; Lin, C.; Zhang, Y.; Liu, Z. Comparing two enhancing methods for improving kitchen waste anaerobic digestion: Bentonite addition and autoclaved de-oiling pretreatment. Process Saf. Environ. Prot. 2018, 115, 116–124. [Google Scholar] [CrossRef]

- Yin, X. Optimization of Anaerobic Fermentation Process with Mixed Materials of Kitchen Waste and Vetiveria Zizanioides; Nanyang Normal University: Nanyang, China, 2018. [Google Scholar]

- Yi, L.; Rao, L.; Wang, X.; Wang, H. Effect of ventilation on nitrogen conversion and nitrogen loss in kitchen waste compost. J. Cent. South Univ. 2012, 43, 1584–1588. [Google Scholar]

- Enzmann, F.; Mayer, F.; Rother, M.; Holtmann, D. Methanogens: Biochemical background and biotechnological applications. AMB Express 2018, 8, 1. [Google Scholar] [CrossRef] [PubMed]

- Oren, A. Microbial life at high salt concentrations: Phylogenetic and metabolic diversity. Saline Syst. 2008, 4, 2. [Google Scholar] [CrossRef] [PubMed]

- Yuan, H.; Zhu, N. Progress in inhibition mechanisms and process control of intermediates and by-products in sewage sludge anaerobic digestion. Renew. Sustain. Energy Rev. 2016, 58, 429–438. [Google Scholar] [CrossRef]

- Akindele, A.A.; Sartaj, M. The toxicity effects of ammonia on anaerobic digestion of organic fraction of municipal solid waste. Waste Manag. 2018, 71, 757–766. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Angelidaki, I. Submersible microbial desalination cell for simultaneous ammonia recovery and electricity production from anaerobic reactors containing high levels of ammonia. Bioresour. Technol. 2015, 177, 233–239. [Google Scholar] [CrossRef] [PubMed]

- Ma, S. Study on Biochar Promoting Anaerobic Digestion of Gas Production from Kitchen Waste; Huazhong University of Science and Technology: Wuhan, China, 2018. [Google Scholar]

- Qi, Q.; Sun, C.; Zhang, J.; He, Y.; Wah Tong, Y. Internal enhancement mechanism of biochar with graphene structure in anaerobic digestion: The bioavailability of trace elements and potential direct interspecies electron transfer. Chem. Eng. J. 2021, 406, 126833. [Google Scholar] [CrossRef]

- Choong, Y.Y.; Norli, I.; Abdullah, A.Z.; Yhaya, M.F. Impacts of trace element supplementation on the performance of anaerobic digestion process: A critical review. Bioresour. Technol. 2016, 209, 369–379. [Google Scholar] [CrossRef]

- Wei, T.; Wen, H.; Chen, J. The effect of zero-valent iron acclimated sludge on methane production from kitchen wastes by anaerobic digestion. Hubei Agr. Sci. 2016, 55, 3618–3621. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, Z.; Meng, X.; Ding, q.; Zhang, H. Effects of Fe2+ dosing methods on anaerobic digestion of kitchen waste. Appl. Chem. Ind. 2019, 48, 838–840. [Google Scholar] [CrossRef]

- Bolzonella, D.; Battista, F.; Cavinato, C.; Gottardo, M.; Micolucci, F.; Lyberatos, G.; Pavan, P. Recent developments in biohythane production from household food wastes: A review. Bioresour. Technol. 2018, 257, 311–319. [Google Scholar] [CrossRef]

- David, B.; Federico, B.; Cristina, C.; Marco, G.; Federico, M.; Paolo, P. Chapter 13—Biohythane Production from Food Wastes. In Biohydrogen, 2nd ed.; Pandey, A., Mohan, S.V., Chang, J.-S., Hallenbeck, P.C., Larroche, C., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 347–368. [Google Scholar]

- Si, B.; Liu, Z.; Zhang, Y.; Li, J.; Shen, R.; Zhu, Z.; Xing, X. Towards biohythane production from biomass: Influence of operational stage on anaerobic fermentation and microbial community. Int. J. Hydrogrn Energy 2016, 41, 4429–4438. [Google Scholar] [CrossRef]

- Abreu, A.A.; Tavares, F.; Alves, M.M.; Pereira, M.A. Boosting dark fermentation with co-cultures of extreme thermophiles for biohythane production from garden waste. Bioresour. Technol. 2016, 219, 132–138. [Google Scholar] [CrossRef] [PubMed]

- Pasupuleti, S.B.; Venkata Mohan, S. Single-stage fermentation process for high-value biohythane production with the treatment of distillery spent-wash. Bioresour. Technol. 2015, 189, 177–185. [Google Scholar] [CrossRef]

- Vo, T.-P.; Lay, C.-H.; Lin, C.-Y. Effects of hydraulic retention time on biohythane production via single-stage anaerobic fermentation in a two-compartment bioreactor. Bioresour. Technol. 2019, 292, 121869. [Google Scholar] [CrossRef] [PubMed]

- Ta, D.T.; Lin, C.-Y.; Ta, T.M.N.; Chu, C.-Y. Biohythane production via single-stage anaerobic fermentation using entrapped hydrogenic and methanogenic bacteria. Bioresour. Technol. 2020, 300, 122702. [Google Scholar] [CrossRef] [PubMed]

- Chen, X. Ammonia Nitrogen Characteristics and Control Strategies for Two-Phase Anaerobic Digestion of Food Waste; Zhejiang University: Hangzhou, China, 2014. [Google Scholar]

- Sarkar, O.; Venkata Mohan, S. Pre-aeration of food waste to augment acidogenic process at higher organic load: Valorizing biohydrogen, volatile fatty acids and biohythane. Bioresour. Technol. 2017, 242, 68–76. [Google Scholar] [CrossRef]

- Dong, L.; Cao, G.; Zhao, L.; Liu, B.; Ren, N. Alkali/urea pretreatment of rice straw at low temperature for enhanced biological hydrogen production. Bioresour. Technol. 2018, 267, 71–76. [Google Scholar] [CrossRef]

- Stępień, Z. A Comprehensive Overview of Hydrogen-Fueled Internal Combustion Engines: Achievements and Future Challenges. Energies 2021, 14, 6504. [Google Scholar] [CrossRef]

- Capurso, T.; Stefanizzi, M.; Torresi, M.; Camporeale, S.M. Perspective of the role of hydrogen in the 21st century energy transition. Energy Convers. Manag. 2022, 251, 114898. [Google Scholar] [CrossRef]

- The Engineering ToolBox. Fuels-Higher and Lower Calorific Values. Available online: https://www.engineeringtoolbox.com (accessed on 1 February 2023).

- Liu, X.; Bao, Z.; Pen, J.; Yang, L.; Shi, Y.; Liu, H. Review of biohydrogen production by anaerobic fermentation of food waste. J. Tianjin Agric. Univ. 2017, 24, 95–99. [Google Scholar]

- Putatunda, C.; Behl, M.; Solanki, P.; Sharma, S.; Bhatia, S.K.; Walia, A.; Bhatia, R.K. Current challenges and future technology in photofermentation-driven biohydrogen production by utilizing algae and bacteria. Int. J. Hydrogrn Energy, 2022; in press. [Google Scholar] [CrossRef]

- Saravanan, A.; Senthil Kumar, P.; Khoo, K.S.; Show, P.-L.; Femina Carolin, C.; Fetcia Jackulin, C.; Jeevanantham, S.; Karishma, S.; Show, K.-Y.; Lee, D.-J.; et al. Biohydrogen from organic wastes as a clean and environment-friendly energy source: Production pathways, feedstock types, and future prospects. Bioresour. Technol. 2021, 342, 126021. [Google Scholar] [CrossRef] [PubMed]

- Zeng, X. tudies on hydrogen production from kitchen waste by sequential dark-and photo-fermentation. Environ. Sci. Manag. 2013, 38, 152–155. [Google Scholar]

- Wainaina, S.; Lukitawesa; Kumar Awasthi, M.; Taherzadeh, M.J. Bioengineering of anaerobic digestion for volatile fatty acids, hydrogen or methane production: A critical review. Bioengineered 2019, 10, 437–458. [Google Scholar] [CrossRef]

- Mishra, P.; Wahid, Z.A.; Karim, A.; Pant, K.K.; Ghosh, P.; Kumar, D.; Singh, L. Chronological perspective on fermentative-hydrogen from hypothesis in early nineteenth century to recent developments: A review. Biomass Convers. Biorefin. 2022, 12, 3711–3723. [Google Scholar] [CrossRef]

- Kumar, G.; Mathimani, T.; Rene, E.R.; Pugazhendhi, A. Application of nanotechnology in dark fermentation for enhanced biohydrogen production using inorganic nanoparticles. Int. J. Hydrogrn Energy 2019, 44, 13106–13113. [Google Scholar] [CrossRef]

- Maxa, D.; Rychtera, M.; Linhova, M.; Fribert, P.; Muzikova, Z.; Lipovský, J.; Paulová, L.; Pospisil, M.; Sebor, G.; Melzoch, K. Perspectives of Biobutanol Production and Use; InTech: Rijeka, Croatia, 2011. [Google Scholar]

- Bajpai, P. (Ed.) Global Production of Bioethanol. In Developments in Bioethanol; Springer: Singapore, 2021; pp. 177–196. [Google Scholar]

- Ma, H.; Wang, Q.; Qian, D.; Gong, L.; Zhang, W. The utilization of acid-tolerant bacteria on ethanol production from kitchen garbage. Renew. Energy 2009, 34, 1466–1470. [Google Scholar] [CrossRef]

- Chatterjee, S.; Venkata Mohan, S. Fungal biorefinery for sustainable resource recovery from waste. Bioresour. Technol. 2022, 345, 126443. [Google Scholar] [CrossRef]

- Uçkun Kiran, E.; Trzcinski, A.P.; Ng, W.J.; Liu, Y. Bioconversion of food waste to energy: A review. Fuel 2014, 134, 389–399. [Google Scholar] [CrossRef]

- Zhang, Q. Fuel ethanol production from kitchen garbage by simultaneous Saccharification and fermentation (SSF). Chem. Ind. Eng. Prog. 2015, 34, 91–94. [Google Scholar] [CrossRef]

- Hong, Y.S.; Yoon, H.H. Ethanol production from food residues. Biomass Bioenergy 2011, 35, 3271–3275. [Google Scholar] [CrossRef]

- Jiang, L.; Guo, D.; Yuan, K.; Du, A.; Chen, G. Secondary catalytic hydrolysis reaction of fuel ethanol production from kitchen garbag. Renew. Energ. Source 2012, 30, 66–69. [Google Scholar] [CrossRef]

- Amaro, H.M.; Guedes, A.C.; Malcata, F.X. Advances and perspectives in using microalgae to produce biodiesel. Appl. Energy 2011, 88, 3402–3410. [Google Scholar] [CrossRef]

- Sakuragi, H.; Kuroda, K.; Ueda, M. Molecular breeding of advanced microorganisms for biofuel production. J. Biomed. Biotechnol. 2011, 2011, 416931. [Google Scholar] [CrossRef]

- Lee, S.Y.; Sankaran, R.; Chew, K.W.; Tan, C.H.; Krishnamoorthy, R.; Chu, D.-T.; Show, P.-L. Waste to bioenergy: A review on the recent conversion technologies. BMC Energy 2019, 1, 4. [Google Scholar] [CrossRef]

- Ranjan, A.; Moholkar, V.S. Biobutanol: Science, engineering, and economics. Int. J. Energy Res. 2012, 36, 277–323. [Google Scholar] [CrossRef]

- Abo, B.O.; Gao, M.; Wu, C.; Zhu, W.; Wang, Q. A review on characteristics of food waste and their use in butanol production. Rev. Environ. Health 2019, 34, 447–457. [Google Scholar] [CrossRef] [PubMed]

- Ndaba, B.; Chiyanzu, I.; Marx, S. n-Butanol derived from biochemical and chemical routes: A review. Biotechnol. Rep. 2015, 8, 1–9. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, M.; Abo, B.O.; Wang, F.; Wang, Q. Bio-butanol production from direct fermentation of kitchen wastes. Environ. Eng. 2019, 37, 137–142. [Google Scholar] [CrossRef]

- Inui, M.; Suda, M.; Kimura, S.; Yasuda, K.; Suzuki, H.; Toda, H.; Yamamoto, S.; Okino, S.; Suzuki, N.; Yukawa, H. Expression of Clostridium acetobutylicum butanol synthetic genes in Escherichia coli. Appl. Microbiol. Biotechnol. 2008, 77, 1305–1316. [Google Scholar] [CrossRef]

- Pugazhendhi, A.; Mathimani, T.; Varjani, S.; Rene, E.R.; Kumar, G.; Kim, S.-H.; Ponnusamy, V.K.; Yoon, J.-J. Biobutanol as a promising liquid fuel for the future-recent updates and perspectives. Fuel 2019, 253, 637–646. [Google Scholar] [CrossRef]

- Bankar, S.B.; Survase, S.A.; Ojamo, H.; Granström, T. Biobutanol: The outlook of an academic and industrialist. RSC Adv. 2013, 3, 24734–24757. [Google Scholar] [CrossRef]

- Lee, S.Y.; Park, J.H.; Jang, S.H.; Nielsen, L.K.; Kim, J.; Jung, K.S. Fermentative butanol production by clostridia. Biotechnol. Bioeng. 2008, 101, 209–228. [Google Scholar] [CrossRef]

- Veza, I.; Muhamad Said, M.F.; Latiff, Z.A. Recent advances in butanol production by acetone-butanol-ethanol (ABE) fermentation. Biomass Bioenergy 2021, 144, 105919. [Google Scholar] [CrossRef]

- Rathour, R.K.; Ahuja, V.; Bhatia, R.K.; Bhatt, A.K. Biobutanol: New era of biofuels. Int. J. Energy Res. 2018, 42, 4532–4545. [Google Scholar] [CrossRef]

- Huang, H.; Singh, V.; Qureshi, N. Butanol production from food waste: A novel process for producing sustainable energy and reducing environmental pollution. Biotechnol. Biofuels 2015, 8, 147. [Google Scholar] [CrossRef] [PubMed]

- Jang, Y.-S.; Malaviya, A.; Cho, C.; Lee, J.; Lee, S.Y. Butanol production from renewable biomass by clostridia. Bioresour. Technol. 2012, 123, 653–663. [Google Scholar] [CrossRef]

- Bruder, M.; Moo-Young, M.; Chung, D.A.; Chou, C.P. Elimination of carbon catabolite repression in Clostridium acetobutylicum—A journey toward simultaneous use of xylose and glucose. Appl. Microbiol. Biotechnol. 2015, 99, 7579–7588. [Google Scholar] [CrossRef]

- Hanif, M.A.; Nisar, S.; Akhtar, M.N.; Nisar, N.; Rashid, N. Optimized production and advanced assessment of biodiesel: A review. Int. J. Energy Res. 2018, 42, 2070–2083. [Google Scholar] [CrossRef]

- Zhong, C.; Liang, K.; Li, A. Preparation of biodiesel from kitchen waste assisted by microwave. Mod. Chem. Ind. 2019, 39, 144–148. [Google Scholar] [CrossRef]

- Han, S.; Kim, G.-Y.; Han, J.-I. Biodiesel production from oleaginous yeast, Cryptococcus sp. by using banana peel as carbon source. Energy Rep. 2019, 5, 1077–1081. [Google Scholar] [CrossRef]

- Fei, Q.; O’Brien, M.; Nelson, R.; Chen, X.; Lowell, A.; Dowe, N. Enhanced lipid production by Rhodosporidium toruloides using different fed-batch feeding strategies with lignocellulosic hydrolysate as the sole carbon source. Biotechnol. Biofuels 2016, 9, 130. [Google Scholar] [CrossRef]

- Xiong, X.; Yu, I.K.M.; Tsang, D.C.W.; Bolan, N.S.; Sik Ok, Y.; Igalavithana, A.D.; Kirkham, M.B.; Kim, K.-H.; Vikrant, K. Value-added chemicals from food supply chain wastes: State-of-the-art review and future prospects. Chem. Eng. J. 2019, 375, 121983. [Google Scholar] [CrossRef]

- Karmee, S.K. Liquid biofuels from food waste: Current trends, prospect and limitation. Renew. Sustain. Energy Rev. 2016, 53, 945–953. [Google Scholar] [CrossRef]

- Leung, D.Y.C.; Wu, X.; Leung, M.K.H. A review on biodiesel production using catalyzed transesterification. Appl. Energy 2010, 87, 1083–1095. [Google Scholar] [CrossRef]

- Ueki, Y.; Saiki, S.; Hoshina, H.; Seko, N. Biodiesel fuel production from waste cooking oil using radiation-grafted fibrous catalysts. Radiat. Phys. Chem. 2018, 143, 41–46. [Google Scholar] [CrossRef]

- Edith, O.; Janius, R.; Yunus, R. Factors Affecting the Cold Flow Behaviour of Biodiesel and Methods for Improvement—A Review. Pertanika J. Sci. Technol. 2012, 20, 1–14. [Google Scholar]

- Verma, P.; Sharma, M.P.; Dwivedi, G. Evaluation and enhancement of cold flow properties of palm oil and its biodiesel. Energy Rep. 2016, 2, 8–13. [Google Scholar] [CrossRef]

- Focke, W.W.; Westhuizen, I.v.d.; Grobler, A.B.L.; Nshoane, K.T.; Reddy, J.K.; Luyt, A.S. The effect of synthetic antioxidants on the oxidative stability of biodiesel. Fuel 2012, 94, 227–233. [Google Scholar] [CrossRef]

- Amran, N.A.; Bello, U.; Hazwan Ruslan, M.S. The role of antioxidants in improving biodiesel’s oxidative stability, poor cold flow properties, and the effects of the duo on engine performance: A review. Heliyon 2022, 8, e09846. [Google Scholar] [CrossRef]

- Heater, B.S.; Chan, W.S.; Lee, M.M.; Chan, M.A.-O. Directed evolution of a genetically encoded immobilized lipase for the efficient production of biodiesel from waste cooking oil. Biotechnol. Biofuels 2019, 12, 165. [Google Scholar] [CrossRef] [PubMed]

- Tian, K.; Tai, K.; Chua, B.J.W.; Li, Z. Directed evolution of Thermomyces lanuginosus lipase to enhance methanol tolerance for efficient production of biodiesel from waste grease. Bioresour. Technol. 2017, 245, 1491–1497. [Google Scholar] [CrossRef] [PubMed]

- Praserttaweeporn, K.; Vitidsant, T.; Charusiri, W. Ni-modified dolomite for the catalytic deoxygenation of pyrolyzed softwood and non-wood to produce bio-oil. Results Eng. 2022, 14, 100461. [Google Scholar] [CrossRef]

- Wakatuntu, J.; Olupot, P.W.; Jjagwe, J.; Menya, E.; Okure, M. Optimization of pyrolysis conditions for production of rice husk-based bio-oil as an energy carrier. Results Eng. 2023, 17, 100947. [Google Scholar] [CrossRef]

- Makarfi Isa, Y.; Ganda, E.T. Bio-oil as a potential source of petroleum range fuels. Renew. Sustain. Energy Rev. 2018, 81, 69–75. [Google Scholar] [CrossRef]

- Kumar, A.; Yadav, P.; Reddy, S.N. Catalytic (copper) hydrothermal liquefaction for lignin to produce high quality bio-oil and nano Cu carbon hybrids material. Chem. Eng. Sci. 2023, 270, 118548. [Google Scholar] [CrossRef]

- Zhao, K.; Li, W.; Yu, Y.; Chen, G.; Yan, B.; Cheng, Z.; Zhao, H.; Fang, Y. Speciation and transformation of nitrogen in the hydrothermal liquefaction of wastewater-treated duckweed for the bio-oil production. Renew. Energy 2023, 204, 661–670. [Google Scholar] [CrossRef]

- Déniel, M.; Haarlemmer, G.; Roubaud, A.; Weiss-Hortala, E.; Fages, J. Energy valorisation of food processing residues and model compounds by hydrothermal liquefaction. Renew. Sustain. Energy Rev. 2016, 54, 1632–1652. [Google Scholar] [CrossRef]

- Shu, D. Study on Bio-Oil/Char Production from Kitchen Food Waste by Hydrothermal Treatment; Zhejiang University: Hangzhou, China, 2019. [Google Scholar]

- Akhtar, J.; Amin, N.A.S. A review on process conditions for optimum bio-oil yield in hydrothermal liquefaction of biomass. Renew. Sustain. Energy Rev. 2011, 15, 1615–1624. [Google Scholar] [CrossRef]

| Pretreatment | Treatment Conditions | Enhancement Effects | Possible Mechanisms | Reference |

|---|---|---|---|---|

| Thermal | Pretreatment temperatures: 80, 100, 70, 120 and 140 °C, respectively. | Cumulative biomethane production was enhanced by 22.2%, 18.9%, 9.9%, 7.5% and 3.8%, respectively. | Degradation of complex molecules, as well as the solubilization of recalcitrant particles, making the substrate more available for the anaerobes | [55] |

| Cumulative biomethane production was enhanced by

| A higher solubilization of COD due to various physical and microbial processes | [56] | |

| Increasing extent of total biomethane production:

| Both excessively low and excessively high thermal hydrolysis temperatures cannot effectively promote biogas production | [57] | |

| A pre-heating of 30 min to 120 °C + 30 min autoclaving at 120 °C + 30 min cooling to room temperature | A 24% increase in biogas production (65% CH4) | Thermal hydrolysis disintegrates the cell membranes | [58] | |

| Ultrasonic | Ultrasonic fequency: 20, 25 and 30 kHz; Pre-treatment time: 8, 12 and 16 min; Power density: 650, 975 and1300 W/L | The total methane production increased by 17.87% on average and 34.48% at its peak | Destroy the structure of cell membrane and promote the release of cell contents | [59] |

| Ultrasonic strength: 250 W Treatment time: 40 min | The cumulative gas production increased by 42.6%, and the methane concentration increased from 51.25% to 58.8% | Agitation effect to promote mixture; destroys cell wall by ultrasonic cavitation | [60] | |

| Acid | Acidified with HCl (10 N) at room temperature until pH 2, 24 h of contact time | A 48% increase in biogas production (65% CH4) | Promote the dissolution of organic matter | [58] |

| Adjusted the pH to 3.5 with HCl | The cumulative methane yield increased by 9.1% | [61] | ||

| Thermo-acid | Acidified with HCl (10 N) at room temperature until pH 2, 24 h of contact time, 30 min pre-heating to 12 °C + 30 min autoclaving at 120 °C + 30 min cooling to room temperature | A 40% increase in biogas production (65% CH4) | Promote the dissolution of organic matter | [58] |

| Pressure–depressure | Pressurized to 10 bar with CO2 as pressurizing gas. After a few minutes of contact time, the depressurization was released to 1 bar. | A 48% increase in biogas production (65% CH4) | Physically break up the microbial cell walls | [58] |

| Freeze–thaw | Frozen to 8 °C. After 6 h, the frozen KW was thawed in a thermal oven at 55 ± 2 °C for 30 min. | A 56% increase in biogas production (65% CH4) | Freezing the material at a low temperature provokes cell disruption due to intracellular ice crystals formation, causing damage to cell membranes | [58] |

| Alkali | Addition of 1% CaO | Biogas yield increases 30.67% Methane yield increases 15.49% | The damage of chemical bonds by Ca2+ increased the ability to break down complex compounds into soluble protein, monomeric sugars and other simpler compounds | [62] |

| Bentonite | Total of 3 g/L and 5 g/L of bentonite in mesophilic and thermophilic digestion, respectively | Methane production increased by 68.52% and 56.79%, respectively | Bentonite with large surface area and porous property could provide a sufficient habitat for microorganism growth. Moreover, due to its high adsorption capacity and constructional cations, bentonite was a suitable additive for promoting AD performance | [63] |

| Adding bentonite at organic loading rate of 1.39 g VS L−1 d−1. (VS, volatile solid) | Enhanced by 17.7% methane production | Bentonite contains many metal ions, providing necessary elements for the microorganism. Metal ions can be used as energy supplements to change the cell permeability, promoting microorganism to absorb nutrients selectively | [64] |

| OL (g COD/L) | 60 (Control) | 60 | 70 | 80 | 90 | 100 |

| Biohythane (L) | 128.7 | 144 | 156 | 156 | 159 | 163 |

| VFA (mg/L, 36 h of the cycle operation) | 4596 | 5087 | 5869 | 6155 | 6466 | 6754 |

| Fuel | CNG | LNG | LPG | H2 | CH4 |

|---|---|---|---|---|---|

| LHV (MJ/kg) | 47.45 | 51.85 | 46.30 | 120.0 | 50.2 |

| Research octane number | >127 | >127 | 109 | Not established | 107 |

| Motor octane number | 122 | 122 | 96 | Not established | - |

| Boiling point (°C) | — | −162 | −42.09 | −252.8 | −161.5 |

| Explosion limits (% vol) | 5–15 | 5–15 | 2.1–9.5 | 4.0–74.2 | 5.0–15.4 |

| Self-ignition temperature (°C) | 650 | 650 | 450 | 580 | 538 |

| Optimal Parameters | Value | Bio-Oil Characteristics | Value |

|---|---|---|---|

| Kitchen waste:water (g:mL) | 30:240 | Yield (%) | >43 |

| Reaction temperature (°C) | 300–320 | Higher heating value (MJ/kg) | 37 |

| Residence time (min) | 20–40 | Gas oil fraction (%) | >50 |

| Reaction pressure (MPa) | 8–11 | Viscosity (Pa.s) | <1.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, X.; Zhang, W.; Ha, X.; Li, N.; Chen, S.; Xing, H.; Yang, J. The Preparation Processes and Influencing Factors of Biofuel Production from Kitchen Waste. Fermentation 2023, 9, 247. https://doi.org/10.3390/fermentation9030247

Xiong X, Zhang W, Ha X, Li N, Chen S, Xing H, Yang J. The Preparation Processes and Influencing Factors of Biofuel Production from Kitchen Waste. Fermentation. 2023; 9(3):247. https://doi.org/10.3390/fermentation9030247

Chicago/Turabian StyleXiong, Xiaoli, Wenxing Zhang, Xia Ha, Ning Li, Shengming Chen, Hongwei Xing, and Jing Yang. 2023. "The Preparation Processes and Influencing Factors of Biofuel Production from Kitchen Waste" Fermentation 9, no. 3: 247. https://doi.org/10.3390/fermentation9030247

APA StyleXiong, X., Zhang, W., Ha, X., Li, N., Chen, S., Xing, H., & Yang, J. (2023). The Preparation Processes and Influencing Factors of Biofuel Production from Kitchen Waste. Fermentation, 9(3), 247. https://doi.org/10.3390/fermentation9030247