Abstract

Several EU initiatives and directives emphasize waste reduction and immediate reuse at the source. This study introduces a novel on-site recycling method for transforming printing house paper waste into high-quality, eco-friendly cardboard without mixing it with lower-quality or heterogeneous waste streams. Instead of traditional water- and energy-intensive recycling processes, the proposed dry defibration method involves mechanical grinding, spray-on binder application, and heat pressing, significantly reducing the ecological footprint. The process was optimized using environmentally safe binders, such as poly(vinyl alcohol), sodium alginate, sorbitol, cellulose nanofibrils, and water, applied at low concentrations. A binder-to-dry-pulp ratio of 160 wt.% offered the best balance, yielding cardboard properties comparable or superior to those obtained by traditional methods. Focusing on book covers, the method demonstrated a 50% reduction in GHG emissions compared to conventional paper recycling and purchased cardboard use. The findings highlight the potential of localized, resource-efficient recycling processes to support sustainable production practices within the printing industry.

1. Introduction

Paper recycling is a vital component of modern environmental sustainability, with the potential to conserve natural resources [1], reduce energy consumption, and mitigate greenhouse gas emissions [2]. Worldwide, the paper industry is one of the most active industrial sectors [3], while it is undergoing a transformation to address the environmental impacts of virgin pulp production [4]. This industry accounts for a significant portion of manufacturing output in numerous countries and also represents one of the most resource-intensive sectors, consuming vast amounts of water and energy [5], reflecting its extensive economic and environmental footprint [6]. For instance, the production of paper and board was responsible for approximately 6% of the global energy consumption in 2017 [7], and just under 2% of total industrial emissions in 2022 [8], underscoring the substantial impact of the industry [9].

Paper recycling has been around for many years, with limited developments, relying on established methods encompassing mechanical pulping, chemical pulping, and deinking, each pivotal in transforming post-consumer waste into high-quality recycled paper [10]. These conventional processes, while foundational, are not devoid of limitations, particularly in terms of water use, environmental impact [11,12], and energy demands [13]. Moreover, the centralization of recycling processes often results in the mixing of waste streams with varying compositions and qualities, which can degrade the mechanical properties of recycled products. Avoiding such mixing by recycling homogenous paper waste directly at its source can ensure higher-quality output, minimize contamination, and simplify processing [14].

Emerging technologies in paper recycling signify a shift towards more sustainable methodologies, emphasizing reductions in water and energy usage. Innovations in dry defibration and dry paper forming techniques present new avenues for paper recycling, promising enhancements in efficiency and sustainability [15,16]. Furthermore, the exploration of circular economy models and the adoption of “green” binder technologies underscore a broader industry move towards environmental responsibility, supported by the progress of adhesion science [17,18,19]. The modeling of different recycling and incineration technologies reveals significant variations in environmental impacts, highlighting the importance of selecting the right technology parameters and defining system boundaries clearly to ensure accurate environmental impact assessments [20]. The benefits of avoiding waste stream mixing, combined with the scalability of decentralized systems, align with the goals of the Waste Framework Directive (2008/98/EC) and the Circular Economy Action Plan. On-site paper recycling processes are encouraged as part of these efforts to minimize waste generation at its source. It has also been demonstrated that localized recycling systems improve economic sustainability by reducing transportation and logistical costs [21].

This transition is not without its challenges, encompassing market acceptance, economic viability, and the scalability of disruptive technologies. Successful integration of novel recycling methods into the circular economy necessitates overcoming logistic hurdles and addressing sustainable economic frameworks [22].

The drive towards energy efficiency in paper recycling encompasses a holistic approach to optimizing machinery and operational practices. Water reduction, waste heat recovery, process optimization by engineering experts, and the exploration of renewable energy sources further exemplify this commitment to sustainability [23,24,25,26].

While several studies have explored advancements in paper recycling methods, particularly dry defibration and fiber processing, significant gaps still remain in the literature. Previous research has investigated dry fiber processing techniques, but these studies did not fully address the challenges related to binder application and the mechanical properties of the resulting materials [15,27]. The durability and strength of recycled products using eco-friendly binders, such as poly(vinyl alcohol) (PVA) or sodium alginate, have not been thoroughly examined in comparison to traditional wet methods [28,29]. The scalability and economic viability remain concerns, with researchers raising questions about the practical implementation of these technologies on an industrial scale [27,30].

Our study aims to address these gaps by providing a holistic approach, starting from the relationship between the properties of a specific paper waste, the composition of recycled cellulose fiber (RCF)-based cardboard derived from that waste and its mechanical properties, as well as evaluating the environmental and economic benefits of the dry defibration process. In our investigation, RCF sheets were produced from pre-consumer waste and a known blend of paper waste from a local printing house, processed through a hammer mill, and subsequently formed into sheets at 180 °C. Environmentally safe binders were studied for their facilitated cohesion of RCF sheets, and the economic and environmental impact of the proposed local recycling were assessed.

2. Results and Discussion

It is not enough for a recycling process to be more environmentally friendly. In order to become a viable alternative, the process must also yield products or materials with properties that are at least on par with those they aim to replace. Benefits like reduced energy consumption or superior product qualities can be additional bonuses.

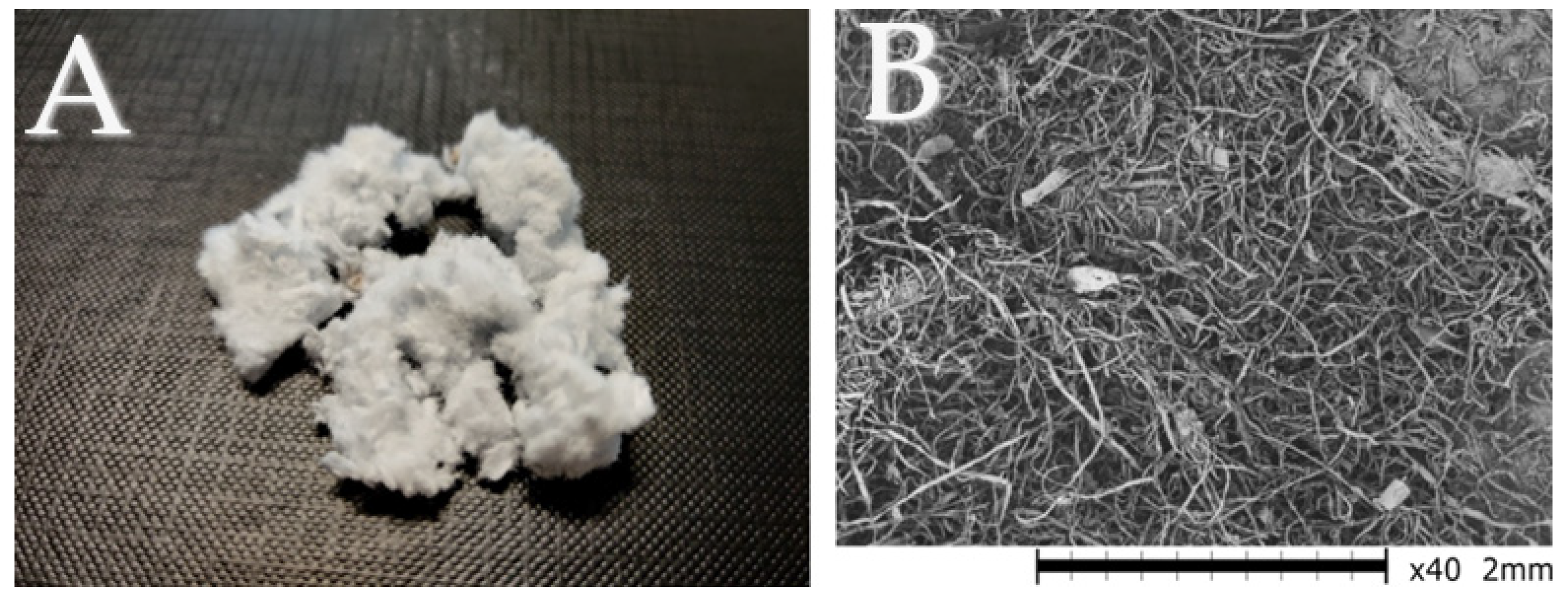

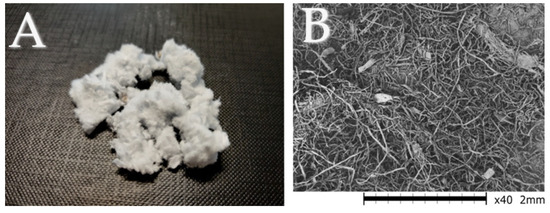

The traditional defibration method is deeply rooted, as it allows for the separation of cellulose fibers with minimal impact to their length or coarseness. The process has guided fiber processing for centuries [31]. The use of water as a debonding and bonding medium plays a central role in this system, facilitating efficient fiber separation. For a dry defibration process to become a viable alternative, the quality of the resulting fibers (Figure 1) should not deteriorate significantly either. A hammer mill was chosen for defibration based on preliminary experiments with a variety of different mill types. The fiber length, coarseness, and fibrillation of the loosened and separated cellulose fibers from the dry defibration process were analyzed and compared to those of the fibers in the original, unprocessed paper (Table 1).

Figure 1.

(A) Image of dry pulp from paper waste via dry defibration process in the collector of the hammer mill; (B) SEM image (40× magnification) of the RCFs after dry defibration in a hammer mill.

Table 1.

Comparison of fiber characteristics in original paper and dry defibrated RCF.

The arithmetic average fiber length of the dry-defibrated sample was just 4.4% shorter than in the source paper. This minor reduction suggests that the dry defibration technique effectively preserves fiber length with minimal shortening compared to traditional methods [32]. The reduction is even lower when comparing the length-weighted and the weight-weighted average fiber lengths of the dry-defibrated fibers with those of the original paper samples.

The fibers from the dry-defibrated sample had 8.3% higher coarseness compared to those from the source paper. This increase in coarseness may be related to the fibers being more curled and crushed, which could make the RCF sheets weaker in terms of tension but stronger in tear resistance [33].

The fibrillation percentage for the dry-defibrated paper was 1.65%, slightly lower than that of the original paper (1.73%). Fibrillation refers to the process where cellulose fibers break down into smaller fibrils, increasing surface area. In this case, the lower fibrillation percentage suggests that the hammer mill process removes existing fibrils from the fiber surfaces rather than creating new ones, which could explain the slight reduction in average fiber length observed during milling as the wet method retains the fibrillation.

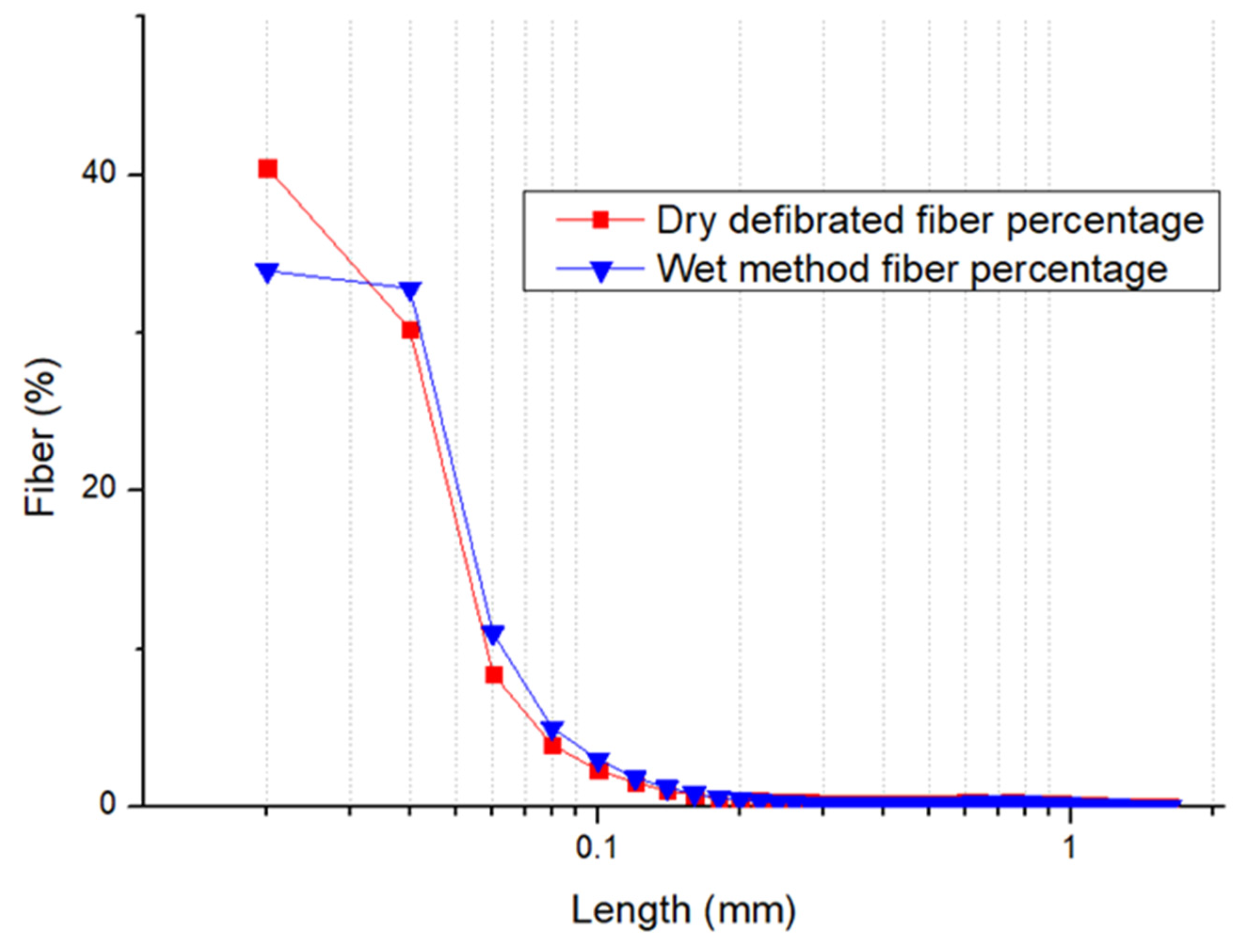

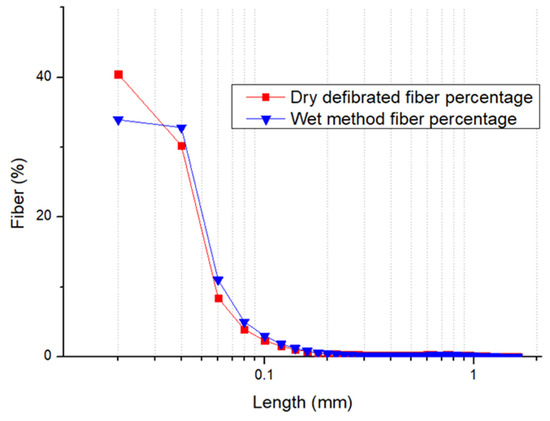

The comparison of the fiber length distribution of paper fibers after dry and wet defibration processes (Figure 2) reveals that the two distribution curves are similar, with the fibers shorter than 0.2 mm predominating in both cases. A slight difference can be observed in the proportion of fibers shorter than 0.05 mm, where the percentage is marginally higher in the case of dry defibration. These observations support the presumption that a hammer mill preserves the original fiber length, which is crucial for the mechanical properties of the new recycled material, though it may lead to the separation of a fraction of existing fibrils from the fiber surfaces.

Figure 2.

Fiber length distribution of paper fibers after dry and wet defibration processes.

High fiber quality retention after milling is a prerequisite for achieving products of high strength from recycled material. However, the fibers still need to be consistently bound together. Dry processes require a binder to facilitate the binding of the cellulose fibers separated by milling. All the binders reported in this study stand out for their hydrogen-bond forming capabilities, but their nature and molecule/particle sizes vary significantly. Water without any additives was also tested as a binder, relying on its natural capacity to bond fibers through hydrogen bonding.

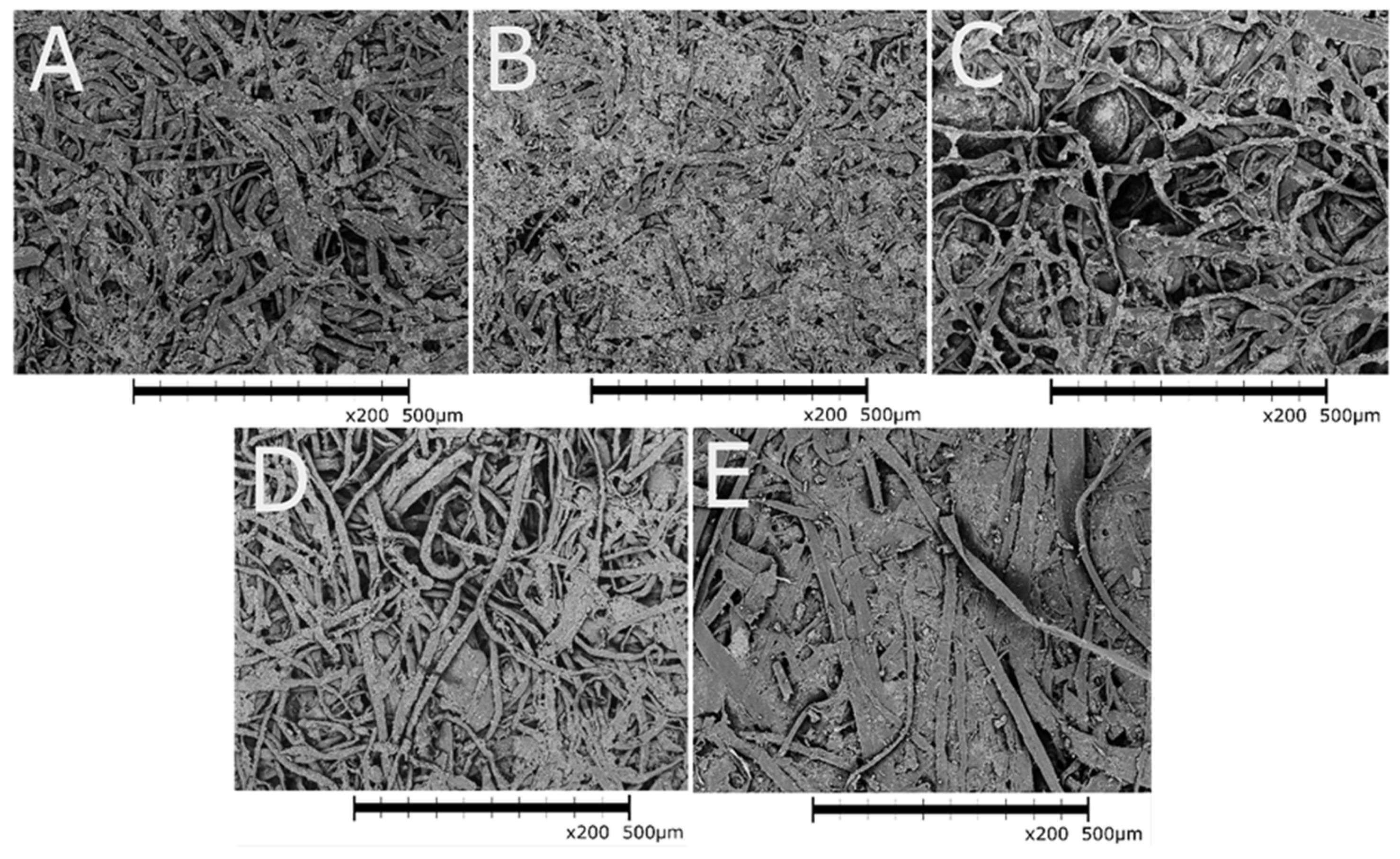

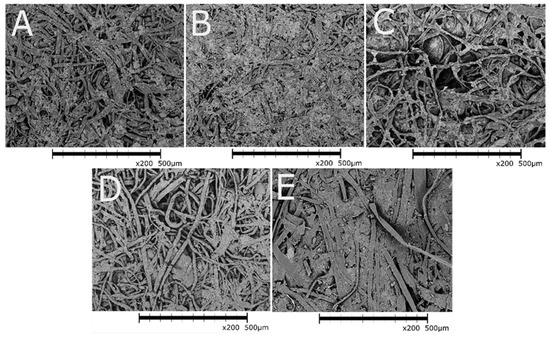

SEM micrographs (Figure 3) provide a detailed view of the fiber network and binder distribution for the cardboard samples. The reference commercial Eska cardboard shows a compact and uniform fiber structure with minimal gaps—image analysis shows a porosity of 25%. The 1% and 2% PVA samples exhibit similar characteristics, with a homogeneous and well-integrated fiber structure and fewer visible gaps between the fibers. Image analysis shows the porosity of the samples to be 27% and 29% for the 1% and 2% PVA boards, which is like the commercial cardboard.

Figure 3.

SEM micrographs (200× magnification) of RCF cardboard samples with different binders (binder-to-pulp ratio 160%): (A) 1% PVA, (B) 2% PVA, (C) 0.5% sodium alginate, and (D) water; (E) reference commercial cardboard (Eska).

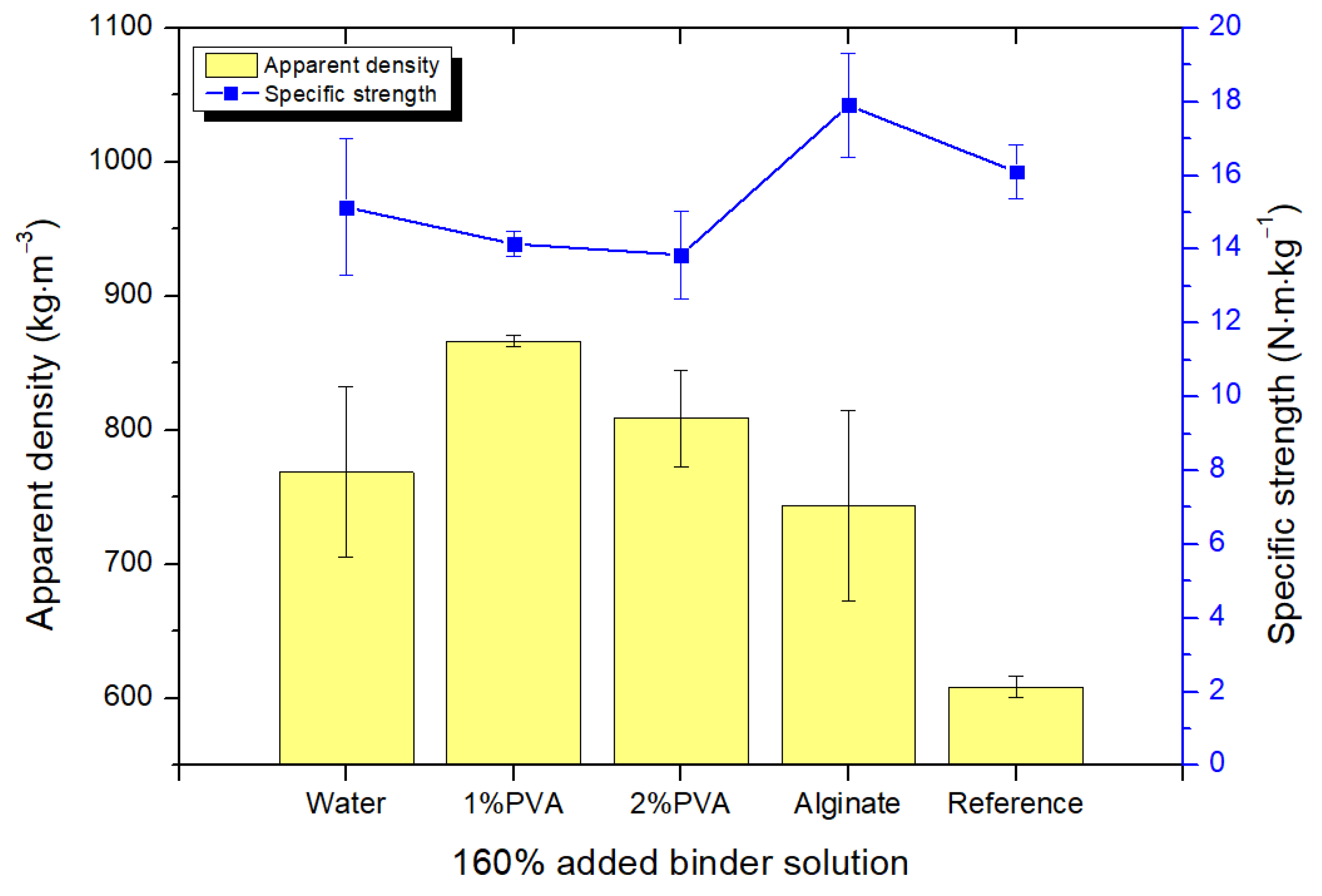

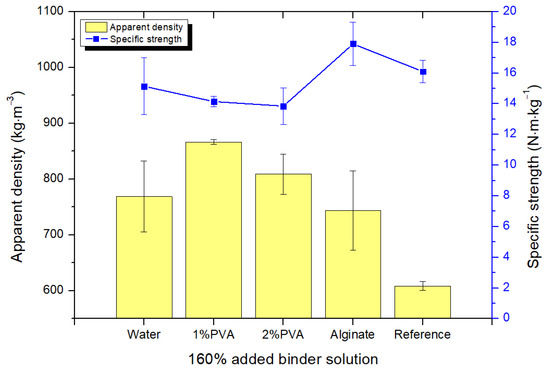

In contrast, the alginate sample exhibited a less uniform structure with visible voids in the fiber network with a porosity of 37%. This outcome is expected due to the tendency of sodium alginate to swell in water and shrink during drying, which can leave gaps in the material [34]. Despite these voids, the alginate binder demonstrated better fiber cohesion and integration compared to the water-based sample, which showed large gaps and poor bonding between fibers. The water sample also exhibited a porosity of 37%. Among all binders tested, the PVA samples and commercial cardboard exhibited the most uniform and well-bonded fiber networks, highlighting PVA’s strong performance as a binder. The comparison of the tensile properties of the fabricated RCF cardboards with different binders showed that cardboards with sodium alginate had the highest specific strength (18 N·m·kg−1), outperforming those with other binders analyzed in this study (Figure 4).

Figure 4.

Apparent density and specific strength of RCF Cardboard with different binders (water, 1% PVA, 2% PVA, and 0.5% sodium alginate) at 160% solution ratios, compared to a commercial reference.

Sodium alginate demonstrated promise as an effective binder for recycled cellulose fiber (RCF) cardboard, yielding high tensile strength despite the presence of visible voids in the structure (Figure 3). Previous research has indicated that alginate addition can enhance the mechanical strength of cellulose, likely due to its ability to improve fiber adhesion within the matrix [35]. While the exact bonding mechanism in such non-crosslinked systems is not fully understood, it is possible that the natural affinity of alginate for cellulose contributes to improved fiber integration and cohesion, thereby enhancing the structural integrity of the cardboard. The observed variability in tensile strength across samples highlights challenges in achieving consistent quality, suggesting that further process optimization may be necessary to reduce void formation and ensure uniform mechanical properties.

As seen in Figure 4, 1% PVA stood out for its ease of use and consistent performance, making it ideal for straightforward applications. As the 1% PVA solution proved to offer the most consistent results, the next thing to establish was the optimal ratio of the binder solution mass to that of the dry pulp. Water as a binder was used as the reference, as there are no concentration aspects to consider.

In addition to tensile strength, stiffness was evaluated to assess structural rigidity. The stiffness values varied depending on the binder type, with sodium alginate and 2% PVA yielding a stiffness of 265 N/mm and 214 N/mm, respectively, while just water bonded and 1% PVA RCF showed lower stiffness values of 99 N/mm and 160 N/mm. The reference material had a stiffness of 295 N/mm. The increased stiffness observed in the 2% PVA and sodium alginate samples suggests stronger fiber bonding, while samples with water-only treatment exhibited lower stiffness, indicating reduced inter-fiber cohesion.

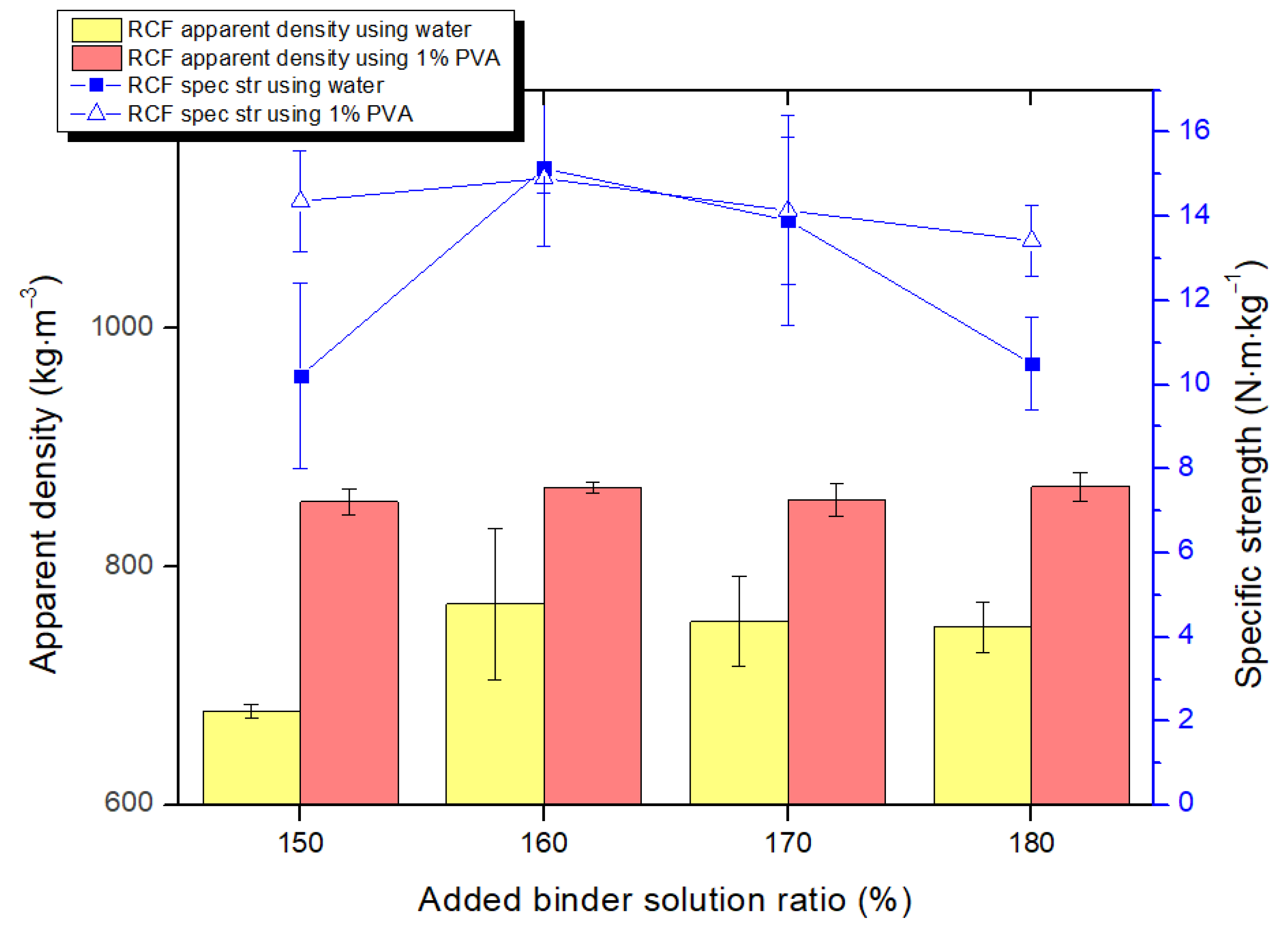

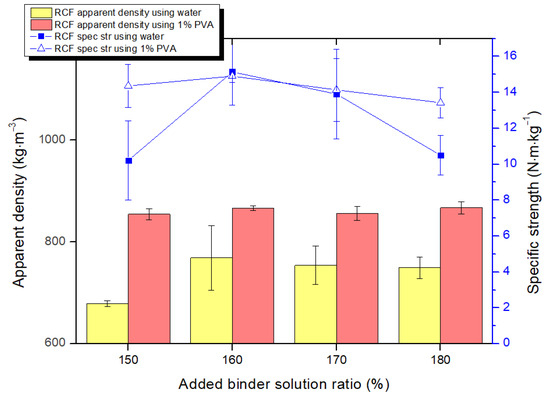

The ratio of binder solution to the mass of dry pulp was varied from 150% to 180% based on preliminary experiments. The resulting RCF cardboard samples were analyzed for their apparent density and tensile strength (Figure 5).

Figure 5.

Tensile strength of RCF cardboard samples with binder solution ratios of 150–180%, using 1% PVA solution and water as binders.

For both binders, the highest tensile strength was observed when using a binder ratio of 160% (Figure 5). Using water as the sole binder allows for the fabrication of compact RCF cardboard samples with tensile strength comparable to those prepared with additional polymeric binders. However, these water-bound samples exhibit greater sensitivity to moisture. By optimizing the liquid content using only water, we can determine the most efficient ratio of liquid to dry fibers. It was anticipated that the addition of 1% PVA would follow a similar trend, enhancing tensile strength, and indeed, the results confirmed this expectation.

The experimental results show that picking a 160% binder-to-pulp ratio effectively improves cardboard strength, balancing binder performance and sustainability. This ratio meets the performance standards of commercial products, indicating that the dry defibration method offers a viable, water- and energy-saving alternative to traditional cardboard production. The even distribution of the PVA binder, as seen in Figure 3, supports the observed improvements in mechanical properties, aligning closely with the commercial reference in terms of fiber bonding.

Despite the promising properties of CNF in other applications [36,37,38], the high variability in measurement uncertainty of samples using CNF as the binder prevented these results from being reliably represented in the graph. The RCF cardboard samples with CNF did not exhibit sufficient mechanical strength to be measured correctly, making them unsuitable for potential use in applications such as bookbinding covers. Similarly, sorbitol-based binder solutions also performed poorly, failing to provide materials with a consistent tensile strength value. These results indicate that CNF and sorbitol may still have potential but in other contexts or application techniques. In the framework of the current study, alginate, PVA, and even just water were proved to be superior primary binders for producing durable, high-strength RCF cardboards suitable for industrial applications such as bookbinding.

CO2 Footprint Analysis

In comparing the environmental impacts of the dry defibration method with traditional paper recycling methods, the key focus is on the CO2 footprint of each process. Traditional paper recycling methods, such as mechanical and chemical pulping, are energy-intensive processes that also require substantial amounts of water and chemicals. These processes typically involve deinking, pulping, and reprocessing, which contribute significantly to CO2 emissions due to the high energy consumption of machinery and the chemical treatments used. Traditional recycling methods involve the use of energy for heating, mechanical pulping, and drying, contributing to high CO2 emissions. It is estimated that traditional methods can emit up to 1947 kg of CO2 per ton of paper recycled [27]. The water-intensive nature of traditional methods not only increases the CO2 footprint through energy used for water heating and pumping but also introduces chemical effluents that may lead to further environmental impacts if not managed properly.

The dry defibration process uses clearly less water compared to traditional recycling methods. Traditional recycling processes can use between 10 to 20 m3 of water per ton of paper [11], depending on the technology and efficiency of the plant. For example, Eska reports using approximately 1.8 m3 of water per ton of product, while our dry defibration process uses approximately 1.6 m3 of water per ton of cardboard. Regional variations in recycling technology and energy sources significantly impact greenhouse gas (GHG) emissions, validating the need for localized, efficient methods like the one developed in this study [39].

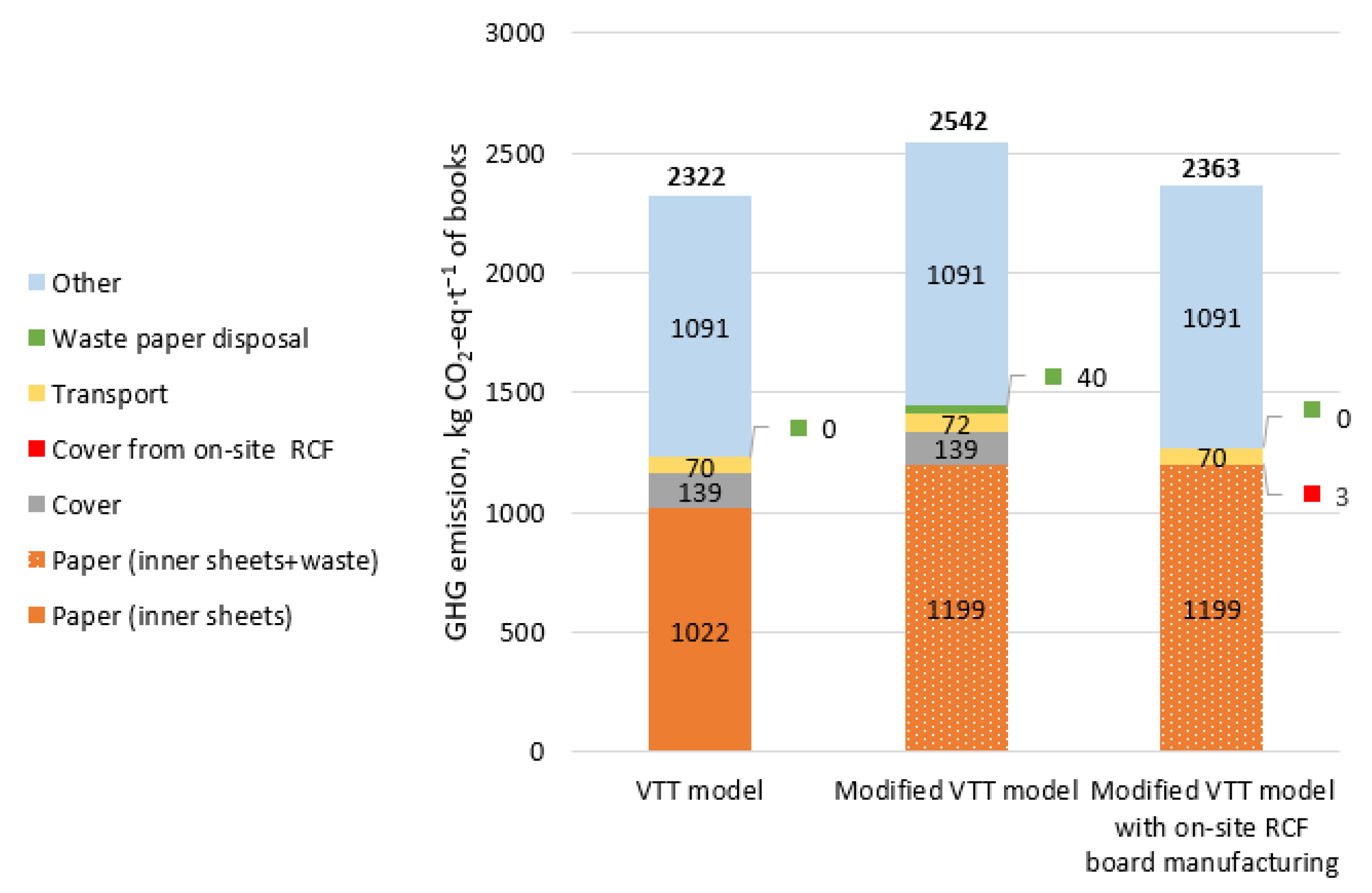

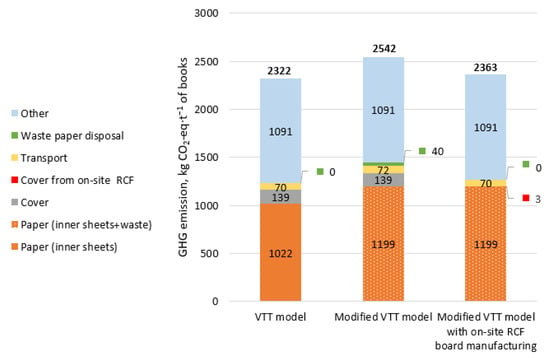

In order to establish how these aspects translate to carbon footprint reduction for a printing house that aims to convert locally generated waste paper into cover board on-site using the proposed RCF cardboard fabrication method, the carbon footprint of a hardcover book was calculated and compared to that of the production of a similar one with externally sourced hardcover and waste paper management. The used calculation model follows the approach by the Finnish research institute VTT, where the carbon footprint of a hardcover book (sheetfed offset printed) from cradle to the gate of the printing house was found to be 2322 kg CO2-eq per ton of books (Figure 6, VTT model), which translates to 1161 g CO2-eq per book, assuming the book weighs 500 g and contains 316 pages (14 × 21 cm) [40]. In the VTT model of print product life cycle, the GHG emissions associated with waste paper from cutting sheets from the paper roll, as well as its transportation and waste management, are not included. The GHG emissions related to the book cover (including the cardboard, cover sheet, and jacket) form 6% of the total GHG emissions of a book [40], but we also need to take into account the reduction of GHG emissions due to the on-site dry recycling of paper waste at the printing house.

Figure 6.

Comparison of GHG emissions of printed hardcover books with purchased covers and RCF cardboard covers.

In our case study, the local print house generates 17% of waste paper, equivalent in total to the mass of purchased book covers. Incorporating paper waste and the corresponding waste management into the VTT model raises the GHG emissions to 2542 kg CO2-eq per ton of books, with the cover component accounting for 5.5% of the total emissions (Figure 6, Comparison of GHG emissions of printed hardcover books with purchased covers and RCF cardboard covers, modified VTT model). By manufacturing covers on-site from RCF, the GHG emissions from the purchased covers, transport, and waste paper management become void (Figure 6, Modified VTT model with on-site RCF cardboard manufacturing). The GHG emissions for on-site RCF cardboard manufacturing were calculated using IPCC (Intergovernmental Panel on Climate Change) guidelines and the 2023 Estonian Ministry of Climate model [41] (for a detailed explanation about GHG emission calculations, please see Electronic Supplementary Information). In our case study, the print house uses 100% renewable energy for production, resulting in zero energy-related (defibration, mechanical pressing, heating) GHG emissions per ton of books, given the emission factor of 0.000 t CO2-eq·MWh−1 for renewable energy [41,42]. The emissions for covers made from on-site RCF are minimal, consisting only of emissions from polyvinyl alcohol (PVA) production [43] and municipal water supply [44]. The dry process eliminates the footprint related to wastewater management.

When manufacturing cardboard on-site from print house waste paper, the overall GHG emissions per ton of books decreased by 7% compared to externally sourced cardboard for covers and managing paper waste. Focusing solely on the book cover component, a comparison of the GHG emissions reveals that on-site RCF cardboard manufacturing results in a 50% reduction in GHG emissions compared to waste paper management and the use of purchased cardboard.

3. Materials and Methods

3.1. Preparation of RCF Cardboard Samples

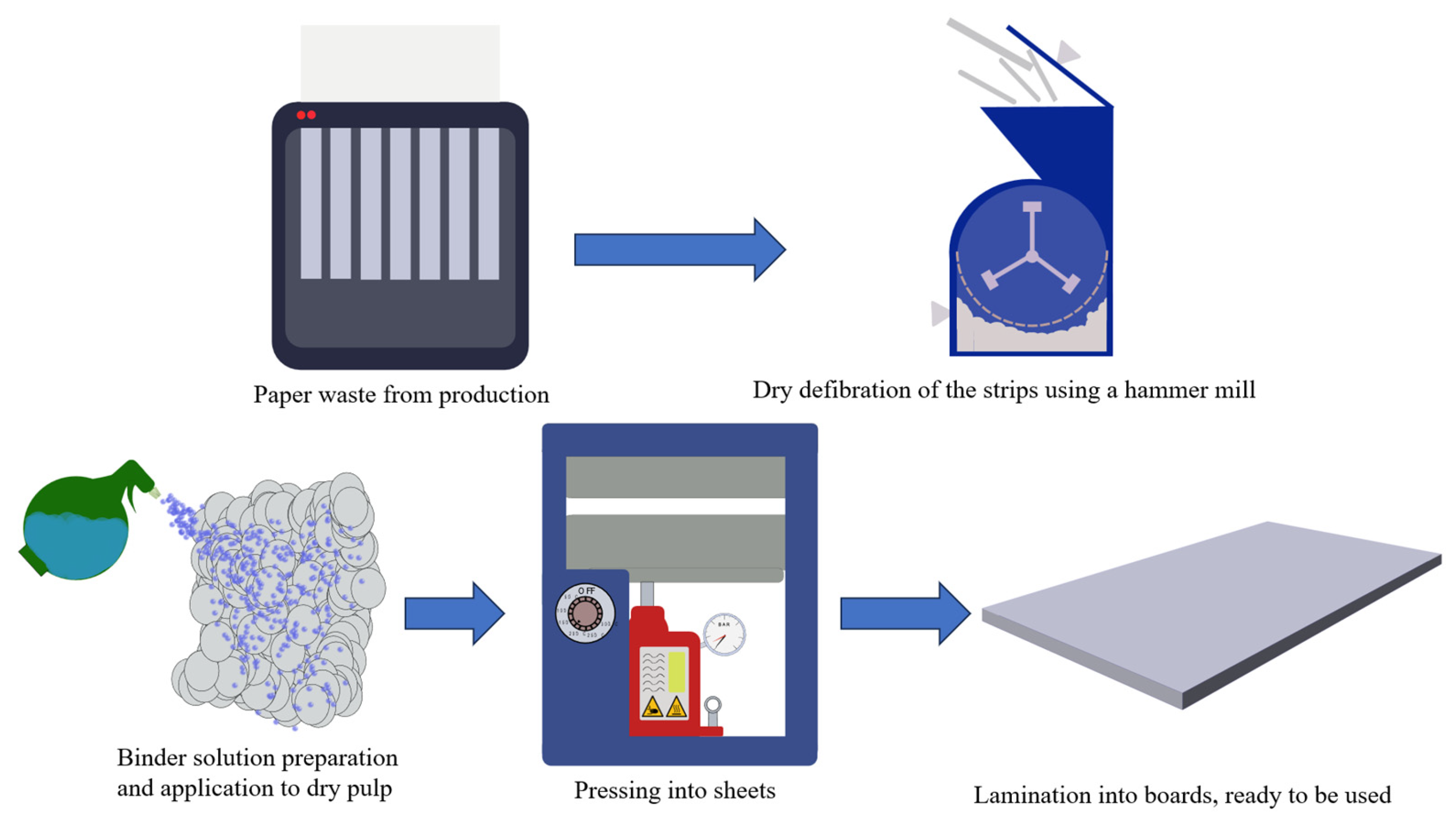

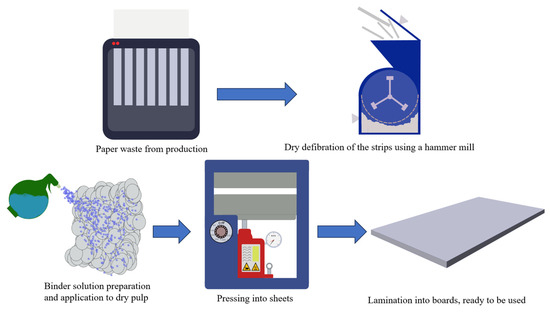

A schematic of the applied cardboard fabrication process is presented in Figure 7. The materials used and the individual steps of fabrication are described below in detail.

Figure 7.

Schematic representation of the cardboard fabrication process used in this study. The process involves mechanical grinding of paper waste followed by binder application and heat pressing at 180 °C.

Edge trimmings from a local printing house were the starting material for all experiments. Five to ten tons of such paper waste is generated by the printing house daily. Just two types of paper are used in the printing house: Amber Graphic (uncoated fine paper) and G-silk (coated paper), products of Arctic Paper (Sweden). The paper waste used in the experiments comprised an equal mix of 50% Amber Graphic and 50% G-silk, providing a consistent base material. This composition mirrors the average waste profile of the printing industry, offering insights into the recyclability of mixed paper waste streams.

3.2. Dry Defibration

The edge trimmings paper waste consisted of long thin strips with dimensions of 3 × 25 cm. The dry defibration process involved grinding the paper waste into fine fibers using a repurposed hammer mill (CP300*180, Zhengzhou Yingwang Machinery Co., Zhengzhou, China) specifically chosen for its ability to minimize fiber length reduction during defibration. The hammer mill screen used had holes measuring 6 mm in diameter.

3.3. Binders

From a larger pool of binder candidates, four materials were selected for their ability to interlink with cellulose matrix via hydrogen bonds while showing promising binding performance in preliminary trials: PVA, sodium alginate, sorbitol, CNFs, and water was used as comparison. These materials were chosen based on their non-toxic nature and biodegradability. Although starch is one of the most widely used and environmentally friendly binders in the paper industry, it was not considered for this study due to its poor solubility and limited compatibility with the dry defibration process.

PVA solutions at concentrations of 10%, 2%, and 1% were prepared by dispersing PVA (Mw 130 000 g/mol, 99+% hydrolyzed, Aldrich) in water (MilliQ) at room temperature followed by raising the temperature to 80 °C while constantly mixing the solution for 3 h.

A 0.5% sodium alginate solution was obtained by dissolving sodium alginate (Viscosity 350–550 mPa*s (1% at 20 °C), Thermo Scientific) in water (MilliQ) at room temperature (30 min until complete dissolution).

To prepare the 3% sorbitol solution, sorbitol (95%, BLD Pharmatech GmbH) was dissolved in water (MilliQ) at room temperature (30 min until complete dissolution). CNFs (2–3 mm length, 10–20 nm width, PowderNano, Jena, Germany) were dispersed in water to create a 1% stable suspension.

The binder concentrations for each solution—PVA, sodium alginate, sorbitol, and CNFs—were chosen based on their individual binding performance in preliminary experiments. PVA concentrations were selected due to their strong film-forming and binding ability [45], with concentrations below 1% proving insufficient for effective fiber cohesion. Concentrations above 2% were not feasible for spray-on application, as the solution became too viscous. Sodium alginate was tested only at 0.5% concentration because higher concentrations made the solution too viscous for application, while lower concentrations led to inconsistent results. Sorbitol was used at a concentration of 3% to maximize its adhesive properties while avoiding excessive softening of the material. CNFs were used at a 1% concentration due to their excellent reinforcement capabilities, even at lower concentrations, as reported in the literature [37]. For comparison, RCF sheets were also prepared using only MilliQ water in predetermined proportions.

The binder-to-dry pulp ratio was chosen instead of a dry binder-to-dry fiber ratio because one of the tested “binders” was pure water, which played a role in fiber bonding even though it contained no solid binder. Water facilitates hydrogen bonding between cellulose fibers during drying, contributing to the cohesion of the recycled cardboard. Additionally, since PVA and sodium alginate were applied as solutions, reporting the binder as a solution-to-pulp ratio allowed for a consistent comparison across all binder types while also reflecting the practical application process used in industrial settings.

To assess the impact of binder ratio on the mechanical properties of the produced cardboard, a systematic approach was employed to mix varying ratios of binder solutions and dry pulp. The percentage values (150%, 160%, 170%, and 180%) represent the mass of the binder solution in relation to the mass of the dry pulp. These specific ratios reported here were selected based on preliminary experiments: ratios below 150% led to insufficient fiber cohesion, resulting in weaker mechanical properties and a lack of structural integrity in the recycled cardboard, while above 180%, the pulp became overly saturated, impeding the structural integrity and the drying process. For reference, these solution-based binder ratios correspond to the following dry binder-to-dry fiber percentages:

- 1% PVA solutions: 1.5%, 1.6%, 1.7%, and 1.8% (dry PVA per dry fiber)

- 2% PVA solutions: 3.0%, 3.2%, 3.4%, and 3.6% (dry PVA per dry fiber)

- 0.5% sodium alginate solutions: 0.75%, 0.8%, 0.85%, and 0.9% (dry alginate per dry fiber)

3.4. Forming of RCF Cardboards

The dry pulp was laid on a flat surface and sprayed with a binder solution. The treated pulp was then formed into sheets using a custom heated plate press, concurrently evaporating excess water, activating the binder, and compressing the fibers together. The heat of the plate press was 180 ± 5 °C, the applied pressure was 25 bars, and the pressure was applied for 60 s. The conditions were predetermined experimentally to achieve optimal strength and uniformity of the RCF sheets. Three individual RCF sheets were adhered together with 10% PVA aqueous solution, applying 20 bar pressure at room temperature for 30 min to yield bookbinding cardboard samples for mechanical testing. The basis weight of the cardboard samples used for mechanical testing was around 1200 ± 50 g/m2 and was consistent across all samples.

3.5. Characterization

The fiber characteristics, including length, coarseness, and fibrillation, were measured using the Valmet Fiber Image Analyzer (Valmet FS5, Espoo, Finland). The purpose of these measurements was to assess the impact of the dry defibration process on fiber integrity, as these characteristics significantly influence the mechanical properties of the RCF cardboard. The fiber length distribution was assessed according to the ISO 16065-2:2014 standard [46]. As a comparison, the original paper was processed using wet disintegration according to ISO-5263 [47]. The fibers were dispersed in water and analyzed the same way as the dry-defibrated fibers. The fiber length measurements recorded fiber lengths at 0.02 mm intervals from 0.00–0.02 mm to 2 mm. Longer fiber lengths were not present in the samples. This resulted in approximately 100 measurement intervals being recorded.

The morphology of the cardboard samples was studied using scanning electron microscopy (SEM, TM-3000, Hitachi High-Technologies Corporation, Tokyo, Japan) at 15 kV, for which the samples were sputter-coated with a 6 nm thick gold layer (Leica EM ACE600 Sputter Coater, Wetzlar, Germany). The average fiber length of the samples and the cross-section of the torn test samples were analyzed. Porosity was evaluated from the SEM micrographs using ImageJ version 1.54g software.

The apparent density of cardboard samples was calculated based on the mass and the dimensions of the samples. The tensile strength and cantilever stiffness of the cardboard samples were measured using a motorized test stand (model AEL-A-1000, Goyojo, 3–1000 N range, Aliyiqi, Wenzhou, China). The tensile strength was measured at 20 mm·min−1 (test speed) following the procedures of ISO 1924-2:2008 [48] standard. The test specimens were die-cut from a flat sheet of material and were free of ragged edges. The RCF cardboard specimens were secured using a screw-type jagged plate grip that exerted uniform pressure across the gripping surface. Before the measurements, the samples were conditioned in a climate chamber (Constant Temperature and Humidity Test Machine, Kenton, Guangzhou, China) for 24 h at 23 °C and 50% relative humidity, following the procedures in the ISO 187:2022 [49]. All measurements were performed in triplicate, and the expanded measurement uncertainty for each RCF sample was calculated. The expanded measurement uncertainty was U (density, molded) = 3 kg·m−3, with a confidence interval of 95% (k = 1.9). For tensile strength and stiffness, the expanded measurement uncertainty varied depending on the binder used, reflecting the variability in the mechanical properties. However, in all cases, the confidence interval was maintained at 95%, indicating excellent reproducibility of the RCF cardboard.

To evaluate the environmental benefits of the proposed RCF cardboard fabrication method, greenhouse gas emissions were calculated for a hardcover book produced using cover cardboard fabricated on-site from locally generated waste paper. This was then compared to the carbon footprint of a hardcover book made from purchased materials, along with the management of the remaining waste paper. Each binder and process should undergo a thorough environmental impact assessment to ensure that the benefits are genuinely sustainable.

3.6. CO2 Footprint Analysis

The CO2 footprint of manufacturing hardcover books with book covers made from on-site fabricated RCF cardboard was calculated using the life cycle assessment (LCA) methodology. The analysis was based on a model by VTT Technical Research Centre of Finland Ltd. (VTT-Valtion Teknillinen Tutkimuskeskus), which calculated greenhouse gas emissions from cradle to gate for hardcover books [40]. The modified model used in this work applied the same main assumptions and system boundaries to ensure fair comparison. Details of the elements included in the greenhouse gas emissions for the manufacturing of covers from on-site fabricated RCF cardboard [50], the emission factors [41,43,44,51,52] used in the calculations, and the processes and assumptions related to book production [40] are provided in the Electronic Supplementary Information file.

4. Conclusions

The dry defibration method developed in this study demonstrates a practical and environmentally friendly solution for on-site recycling of paper waste. By grinding waste paper into fine fibers with a hammer mill and applying binders through a spray-on method, this approach produces high-quality recycled cellulose fiber (RCF) cardboard with tensile strength comparable to commercial bookbinding boards. Unlike traditional water-intensive methods, the dry defibration process significantly reduces water consumption and achieves a 50% reduction in greenhouse gas (GHG) emissions from the cover production and recycling steps alone. When applied to the production of a 500g hardcover book, this method reduces total GHG emissions by 7%. A key advantage of this system lies in the immediate reuse of homogeneous, high-quality paper waste directly at the source, avoiding contamination with low-quality or mixed waste streams. This ensures a consistent feedstock and maintains the high mechanical and structural properties of the resulting cardboard. The findings emphasize the potential of localized recycling processes to minimize environmental impact, reduce logistical costs, and contribute to circular economy principles. This study provides a framework for industries such as printing houses to adopt sustainable practices, transforming pre-consumer waste into valuable resources while meeting the demands of a low-carbon future.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/recycling10020067/s1, Table S1: Comparison of greenhouse gas (GHG) emission values across life cycle stages of a printed book from cradle to gate; Table S2: GHG emissions for on-site recycled cellulose fiber (RCF) cardboard manufacturing.

Author Contributions

K.J.L.: Conceptualization, methodology, investigation, writing—original draft preparation, and data curation. T.T.: Supervision, writing—review and editing, validation, project administration, resources, and funding acquisition. A.-L.P.: writing—review and editing, validation, investigation. D.d.S.C. and L.U.: Formal analysis and investigation. T.V.: visualization and funding acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Estonian Research Council (grant TEM-TA56).

Data Availability Statement

The data that support the findings of this study are available from the corresponding author, K.J. Levin, upon request.

Conflicts of Interest

Author Tanel Venderström was employed by the company Print Best. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| PVA | Poly(vinyl alcohol) |

| GHG | Greenhouse gas |

| SEM | Scanning electron microscope |

| RCF | Recycled cellulose fiber |

| CNF | Cellulose nanofiber |

References

- Van Ewijk, S.; Stegemann, J.A.; Ekins, P. Global Life Cycle Paper Flows, Recycling Metrics, and Material Efficiency. J. Ind. Ecol. 2018, 22, 686–693. [Google Scholar] [CrossRef]

- Laurijssen, J.; Marsidi, M.; Westenbroek, A.; Worrell, E.; Faaij, A. Paper and biomass for energy? Resour. Conserv. Recycl. 2010, 54, 1208–1218. [Google Scholar] [CrossRef]

- Bajpai, P. Paper and Paperboard Industry. In Pulp and Paper Industry; Elsevier: Amsterdam, The Netherlands, 2015; pp. 13–24. [Google Scholar] [CrossRef]

- Shang, D.; Lu, H.; Liu, C.; Wang, D.; Diao, G. Evaluating the green development level of global paper industry from 2000-2030 based on a market-extended LCA model. J. Clean. Prod. 2022, 380, 135108. [Google Scholar] [CrossRef]

- Amândio, M.S.T.; Pereira, J.M.; Rocha, J.M.S.; Serafim, L.S.; Xavier, A.M.R.B. Getting Value from Pulp and Paper Industry Wastes: On the Way to Sustainability and Circular Economy. Energies 2022, 15, 4105. [Google Scholar] [CrossRef]

- Molina-Sánchez, E.; Leyva-Díaz, J.C.; Cortés-García, F.J.; Molina-Moreno, V. Proposal of Sustainability Indicators for the Waste Management from the Paper Industry within the Circular Economy Model. Water 2018, 10, 1014. [Google Scholar] [CrossRef]

- Lipiäinen, S.; Kuparinen, K.; Sermyagina, E.; Vakkilainen, E. Pulp and paper industry in energy transition: Towards energy-efficient and low carbon operation in Finland and Sweden. Sustain. Prod. Consum. 2022, 29, 421–431. [Google Scholar] [CrossRef]

- IEA. Tracking Clean Energy Progress 2023. Paris, Jul. 2023. Available online: https://www.iea.org/reports/tracking-clean-energy-progress-2023 (accessed on 20 April 2024).

- Sopelana, A.; Auriault, C.; Bansal, A.; Fifer, K.; Paiva, H.; Maurice, C.; Westin, G.; Rios, J.; Oleaga, A.; Cañas, A. Innovative Circular Economy Models for the European Pulp and Paper Industry: A Reference Framework for a Resource Recovery Scenario. Sustainability 2021, 13, 10285. [Google Scholar] [CrossRef]

- Recovered Paper and Recycled Fibers. In Handbook of Pulp; Wiley-VCH: Weinheim, Germany, 2006; pp. 1147–1190.

- Olejnik, K. Water Consumption in Paper Industry—Reduction Capabilities and the Consequences. In Security of Industrial Water Supply and Management; Atimtay, A.T., Sikdar, S.K., Eds.; NATO Science for Peace and Security Series C: Environmental Security; Springer: Dordrecht, The Netherlands, 2011; pp. 113–129. [Google Scholar] [CrossRef]

- Han, N.; Zhang, J.; Hoang, M.; Gray, S.; Xie, Z. A review of process and wastewater reuse in the recycled paper industry. Environ. Technol. Innov. 2021, 24, 101860. [Google Scholar] [CrossRef]

- Jacobs. Pulp and Paper Industry: Energy Bandwidth Study, USA. 2006. Available online: https://www.energy.gov/eere/amo/articles/itp-forest-products-report-aiche-pulp-and-paper-industry-energy-bandwidth-study (accessed on 5 May 2024).

- Pivnenko, K.; Eriksson, E.; Astrup, T.F. Waste paper for recycling: Overview and identification of potentially critical substances. Waste Manag. 2015, 45, 134–142. [Google Scholar] [CrossRef]

- Nakamura, M. Development of The Dry Paper Recycling Technology which Realizes a New Ofice Papermaking System. Jpn. TAPPI J. 2018, 72, 786–792. [Google Scholar] [CrossRef][Green Version]

- CEPI. DryPulp for Cureformed Paper. EP2876207A1, 27 May 2015. Available online: https://patents.google.com/patent/EP2876207A1/en (accessed on 10 November 2023).

- Georgiadis, P. An integrated System Dynamics model for strategic capacity planning in closed-loop recycling networks: A dynamic analysis for the paper industry. Simul. Model. Pract. Theory 2013, 32, 116–137. [Google Scholar] [CrossRef]

- Flory, A.R.; Requesens, D.V.; Devaiah, S.P.; Teoh, K.T.; Mansfield, S.D.; E Hood, E. Development of a green binder system for paper products. BMC Biotechnol. 2013, 13, 28. [Google Scholar] [CrossRef] [PubMed]

- Rizzi, P.; Danesi, S. Policies for the Circular Economy: The Case of Paper Industry. Symphonya 2021, 1, 76–84. [Google Scholar] [CrossRef]

- Merrild, H.; Damgaard, A.; Christensen, T.H. Life cycle assessment of waste paper management: The importance of technology data and system boundaries in assessing recycling and incineration. Resour. Conserv. Recycl. 2008, 52, 1391–1398. [Google Scholar] [CrossRef]

- Yang, G.; Zhou, C.; Wang, W.; Ma, S.; Liu, H.; Liu, Y.; Zhao, Z. Recycling sustainability of waste paper industry in Beijing City: An analysis based on value chain and GIS model. Waste Manag. 2020, 106, 62–70. [Google Scholar] [CrossRef]

- Kvasha, N.; Bolotnikova, O.; Malevskaia-Malevich, E. Biotechnological Basis of the Pulp and Paper Industry Circular Economic System. Economies 2023, 11, 302. [Google Scholar] [CrossRef]

- Gregor-Svetec, D.; Možina, K.; Blaznik, B.; Urbas, R.; Brodnjak, U.V.; Golob, G. “Efficient Paper Recycling”, University of Ljubljana, Faculty of Natural Sciences and Engineering, Ljubljana, Slovenia. 2013. Available online: https://dk.upce.cz/server/api/core/bitstreams/b6b1022f-db19-4a5b-a2b8-8d80a4d88d59/content (accessed on 4 April 2025).

- Worrell, E.; Martin, N.; Anglani, N.; Einstein, D.; Khrushch, M.; Price, L. Opportunities to Improve energy Efficiency in the U.S. Pulp and Paper Industry; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2001. [Google Scholar]

- Li, L.; Zhu, J.; Zeng, Z. New Approach for Recycling Office Waste Paper: An Efficient and Recyclable Material for Oily Wastewater Treatment. ACS Appl. Mater. Interfaces 2020, 12, 55894–55902. [Google Scholar] [CrossRef]

- Jin, E.; van Ewijk, S.; Kanaoka, K.S.; Alamerew, Y.A.; Lin, H.; Cao, Z.; Jabarivelisdeh, B.; Ehmann, K.F.; Chertow, M.R.; Masanet, E. Sustainability assessment and pathways for U.S. domestic paper recycling. Resour. Conserv. Recycl. 2023, 199, 107249. [Google Scholar] [CrossRef]

- Ono, Y.; Hayashi, M.; Yokoyama, K.; Okamura, T.; Itsubo, N. Environmental Assessment of Innovative Paper Recycling Technology Using Product Lifecycle Perspectives. Resources 2020, 9, 23. [Google Scholar] [CrossRef]

- Altay, B.N.; Klass, C.; Chen, T.; Fleck, A.; Aydemir, C.; Karademir, A.; Fleming, P.D. The effect of green biobased binder on structural, mechanical, liquid absorption and wetting properties of coated papers. Clean. Eng. Technol. 2021, 5, 100274. [Google Scholar] [CrossRef]

- Chen, Q.; Zuo, W.; Xie, Z.; Liu, W.; Lu, M.; Qiu, X.; Habib, S.; Jing, Y.; Zhang, X.; Yu, N.; et al. Design of sodium alginate/PVA based high-efficiency recycled rewritten film by water-soluble-regeneration. Cellulose 2023, 30, 7865–7875. [Google Scholar] [CrossRef]

- Defalque, C.M.; Marins, F.A.S.; da Silva, A.F.; Rodríguez, E.Y.A. A review of waste paper recycling networks focusing on quantitative methods and sustainability. J. Mater. Cycles Waste Manag. 2021, 23, 55–76. [Google Scholar] [CrossRef]

- Shen, J.; Zhang, M. Disassembly, refinement, and reassembly: From ancient papermaking to modern materials processing. J. Bioresour. Bioprod. 2025, 10, 7–13. [Google Scholar] [CrossRef]

- Yang, X.; Berglund, L.A. Recycling without Fiber Degradation—Strong Paper Structures for 3D Forming Based on Nanostructurally Tailored Wood Holocellulose Fibers. ACS Sustain. Chem. Eng. 2020, 8, 1146–1154. [Google Scholar] [CrossRef]

- Seth, R. Fibre Quality Factors in Papermaking—II The Importance of Fibre Coarseness. MRS Proc. 1990, 197, 143. [Google Scholar] [CrossRef]

- Mazur, K.; Buchner, R.; Bonn, M.; Hunger, J. Hydration of Sodium Alginate in Aqueous Solution. Macromolecules 2014, 47, 771–776. [Google Scholar] [CrossRef]

- Chang, C.; Duan, B.; Zhang, L. Fabrication and characterization of novel macroporous cellulose–alginate hydrogels. Polymer 2009, 50, 5467–5473. [Google Scholar] [CrossRef]

- Shivyari, N.Y.; Tajvidi, M.; Bousfield, D.W.; Gardner, D.J. Production and Characterization of Laminates of Paper and Cellulose Nanofibrils. ACS Appl. Mater. Interfaces 2016, 8, 25520–25528. [Google Scholar] [CrossRef]

- Amini, E.; Tajvidi, M.; Gardner, D.J.; Bousfield, D.W. Utilization of Cellulose Nanofibrils as a Binder for Particleboard Manufacture. BioResources 2017, 12, 4093–4110. [Google Scholar] [CrossRef]

- Antony, T.; Cherian, R.M.; Varghese, R.T.; Kargarzadeh, H.; Ponnamma, D.; Chirayil, C.J.; Thomas, S. Sustainable green packaging based on nanocellulose composites-present and future. Cellulose 2023, 30, 10559–10593. [Google Scholar] [CrossRef]

- Provost-Savard, A.; Legros, R.; Majeau-Bettez, G. Parametrized regionalization of paper recycling life-cycle assessment. Waste Manag. 2023, 156, 84–96. [Google Scholar] [CrossRef]

- Pihkola, H. Carbon Footprint and Environmental Impacts of Print Products from Cradle to Grave. Results from the LEADER Project (Part 1); VTT: Espoo, Finland, 2010. [Google Scholar]

- Organisatsioonide KHG Jalajälg | Kliimaministeerium. Available online: https://kliimaministeerium.ee/rohereform-kliima/rohereform/organisatsioonide-khg-jalajalg (accessed on 28 August 2024).

- Bastos, J.; Monforti-Ferrario, F.; Melica, G. GHG Emission Factors for Local Energy Use. January 2024. Available online: http://data.europa.eu/89h/72fac2b2-aa63-4dc1-ade3-4e56b37e4b7c (accessed on 28 August 2024).

- Kiilto. Kiilto Sustainability Report 2023. 2023. Available online: https://www.kiilto.com/wp-content/uploads/2024/04/kiilto_sustainability_report_2023.pdf (accessed on 20 January 2025).

- Greenhouse Gas Reporting: Conversion Factors. 2024. Available online: https://www.gov.uk/government/publications/greenhouse-gas-reporting-conversion-factors-2024 (accessed on 20 January 2025).

- Singh, V.; Bachala, S.K.; Madan, M.; Ahuja, A.; Rastogi, V.K. A comprehensive comparison between synthetic and bio-based wet-strength additives for paper manufacturing. Cellulose 2024, 31, 4645–4679. [Google Scholar] [CrossRef]

- ISO 16065-2:2014(E); ISO, Pulps—Determination of Fibre Length by Automated Optical Analysis — Part 2: Unpolarized Light Method. ISO: Geneva, Switzerland, 2014.

- ISO 5263-1:2004(E); ISO, Pulps—Laboratory Wet Disintegration — Part 1: Disintegration of Chemical Pulps. ISO: Geneva, Switzerland, 2004.

- ISO 1924-2:2008; ISO, Paper and Board—Determination of Tensile Properties—Part 2: Constant Rate of Elongation Method (20 mm/min). ISO: Geneva, Switzerland, 2008.

- ISO 187:2022; ISO, Paper, Board and Pulps—Standard Atmosphere for Conditioning and Testing and Procedure for Monitoring the Atmosphere and Conditioning of Samples. ISO: Geneva, Switzerland, 2022.

- CEPI. Framework for Carbon Footprints for Paper and Board Products. 2017. Available online: https://www.cepi.org/wp-content/uploads/2021/02/ENV-17-035.pdf (accessed on 12 November 2024).

- Vullo, E.L.; Monforti-Ferrario, F.; Palermo, V.; Bertoldi, P. Greenhouse Gases Emission Factors for Local Emission Inventories: Covenant of Mayors Databases. LU: Publications Office. 2022. Available online: https://data.europa.eu/doi/10.2760/776442 (accessed on 19 March 2025).

- Eggleston, S.; Buendia, L.; Miwa, K.; Ngara, T.; Tanabe, K. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Institute for Global Environmental Strategies (IGES) for the IPCC: Hayama, Japan, 2006. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).