Abstract

Electronic waste (e-waste) is the fastest-growing waste stream on the planet, yet it remains critically under-addressed in global waste management and recycling efforts. The rapid pace of technological advancement has led to increased consumption of electronic devices, many of which are challenging and costly to recycle efficiently. Insufficient infrastructure for e-waste recycling has resulted in large quantities being exported to countries with minimal waste management capabilities. In these regions, waste is often processed manually, exposing workers to hazardous materials and toxic elements commonly found in electronic components, leading to serious health risks. E-waste consists primarily of fibrous composite materials and plastics mixed with valuable metals and reusable components. While metals are often recovered, the remaining materials are typically discarded, contributing to significant environmental harm. Addressing e-waste challenges requires more than just technological solutions. In the United States, limited policies promote large-scale reuse and recycling practices, particularly among corporations. To build a sustainable approach, a combination of next-generation, cost-effective chemical recycling technologies and forward-thinking policy reforms will be essential for the effective management and reduction of e-waste. This paper explores the global generation and composition of e-waste, highlighting its environmental and health impacts due to improper handling and disposal. It reviews current and emerging recycling technologies while examining the challenges and opportunities in e-waste management. Finally, it discusses sustainable solutions and future directions for improving e-waste recycling through innovative technologies and policy reforms, concluding with recommendations for a circular economy approach.

1. Introduction

As technology advances rapidly, it brings with it a significant challenge: electronic waste (e-waste). E-waste has become one of the largest and fastest-growing sources of pollution globally, driven by the booming electronics manufacturing industry. It was reported by the Global E-Waste Monitor (2024) that 62 million tonnes of e-waste were produced in 2022 and the generation of e-waste is on track to rise to 82 million tonnes in 2030 [1]. Waste electrical and electronic equipment (WEEE) poses a serious issue due to its complex mix of materials, making recycling both difficult and resource-intensive [2].

Many modern electronic products are designed with shorter lifecycles, making disposal more frequent. Tech companies frequently release new models, leading to a rapid turnover of devices. The rapid turnover of electronic devices, especially due to consumer demand for newer models of smartphones, wearables, etc., has led to an unprecedented surge in e-waste generation.

Although recycling electronic equipment is challenging, the core problem lies in inadequate waste management practices. Alarmingly, only about 25% of WEEE is recycled in the U.S., with the remainder often illegally exported, discarded, or ‘donated’ to developing countries with limited infrastructure for proper handling [3]. In these regions, valuable materials, such as those in circuit boards and batteries, are recovered, but much of the waste is processed improperly [4]. This leads to the contamination of the environment and increased health risks [5].

While processing e-waste is technically possible, it is often prohibitively expensive and requires significant investment for large-scale recycling. Exporting e-waste to developing countries is a cheaper alternative, seemingly benefiting both parties—developed nations offload their waste, and developing countries recover valuable materials to boost their economies. However, this system is deeply flawed, as it prioritizes cost savings over environmental safety and ethical waste management [4].

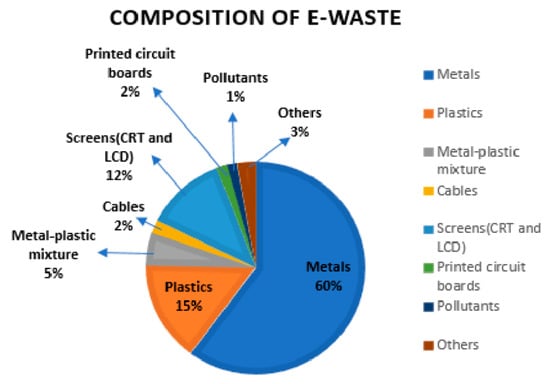

E-waste is hazardous, often containing up to 60% valuable metals, like copper, aluminum, gold, and iron, alongside nearly 3% toxic substances [5,6]. The extraction of these valuable materials leaves behind large amounts of plastic and polymer waste, which many developing countries lack the infrastructure to manage safely. Consequently, this waste is frequently buried, burned, or dumped into local water sources, causing long-term contamination of the air, soil, and waterways [7].

To tackle the vast challenge of electronic waste, a comprehensive and multi-faceted approach is needed. Solutions include enhancing recycling infrastructure in developed countries and designing electronics that are easier to recycle and reuse [8]. No single strategy will resolve this issue, but coordinated efforts that combine technological advancements, policy reforms, and global collaboration are crucial for effective long-term management.

Global consumption of electronic equipment has surged in recent decades, leading to a parallel rise in e-waste generation. The main sources of e-waste include home appliances, medical equipment, office machines, and industrial equipment [9]. Leading contributors to e-waste generation include major economies, such as the USA, China, Russia, and Japan. In the U.S., states like Minnesota, Oregon, and Washington report the highest per capita e-waste collection, ranging from 5.9 to 6.4 pounds per person [10]. Exporting e-waste remains cheaper than domestic recycling, contributing to illegal shipments to developing countries where improper handling poses severe environmental and societal risks.

E-waste also poses significant global environmental challenges due to hazardous chemicals, such as lead, mercury, cadmium, and arsenic, which contribute to severe environmental degradation [11]. Addressing this issue requires effective and sustainable disposal strategies, especially in countries with the highest e-waste generation. While metal recovery from WEEE offers economic benefits, widespread recycling is still limited due to the lack of comprehensive federal policies mandating e-waste recycling and recovery technologies.

Many electronic devices contain materials that are no longer in use but still hold value to produce other goods. Unfortunately, much of this e-waste is improperly disposed of, posing significant risks to public health due to hazardous materials. India, for example, faces a major e-waste issue, with the Associated Chambers of Commerce of India estimating that the country generates 25% of global e-waste annually [11]. The mismanagement of this waste exacerbates environmental and health risks. Various e-waste management strategies, such as pyrometallurgical and bio-metallurgical processing, enable the recovery of valuable metals from electronic scrap [12,13]. While physical separation methods are more convenient, they often result in high metal loss and contribute to the problem of brominated flame-retardant (BFR) dust. Recycling technology aims to transform e-waste into secondary resources, mitigating its environmental impact.

Efficient recycling of WEEE presents a significant challenge not only for the recycling industry but also due to inadequate collection infrastructures and a lack of consumer awareness about the potential for recycling electronics [14]. Many systems struggle to manage e-waste properly, primarily because of hazardous substances and heavy metals. WEEE is often perceived as a cost burden in production, prompting many systems to opt for the cheapest disposal methods. Governments are enforcing more sustainable practices, but many companies still face difficulties in adapting to these criteria. The concept of Extended Producer Responsibility (EPR) helps to drive change by encouraging companies to improve their waste recycling practices. EPR policies promote environmental considerations in the design of electronic products, extending their lifecycle and reducing their overall environmental impact [15].

This study examines the difficulties associated with electronic waste while researching sustainable methods, such as implementing AI (artificial intelligence) for its efficient management. The research goals involve studying the harmful effects of inappropriate e-waste disposal practices on the environment and health, evaluating international recycling systems and policies together with their effectiveness, and discovering technological innovations that improve e-waste recycling processes. This research emphasizes the importance of EPR for sustainable e-waste management while providing proposals to strengthen the recycling system in developing nations where improper waste handling persists.

2. Global Generation and Composition of Electronic Waste

As highlighted earlier, the rapid expansion of technology has led to an equally rapid increase in electronic waste, making it the fastest-growing waste stream globally [16]. A common misconception is that e-waste mainly results from large industrial equipment, whereas it often originates from short-lived consumer and industrial electronics. For example, the rise of digital currencies, such as Bitcoin, has fueled the use of specialized computers called ‘miners’ that validate transactions. These machines require frequent hardware replacements due to wear and technological advancements [17]. Once obsolete, the discarded components become bulky, difficult-to-manage waste, a challenge mirrored across the globe with various electronic devices that require regular upgrades or replacements.

To better understand e-waste generation, it is essential to examine its primary drivers. Technological and economic advancements continually introduce new devices, rendering older ones obsolete and contributing to a steady cycle of waste. For perspective, global e-waste reached 53.6 million tonnes in 2019, a 21% increase since 2015, highlighting the rapid pace of technological turnover. E-waste generation also varies significantly by region, with Asia accounting for 46.4% of global e-waste, followed by the Americas at 24.4% [8].

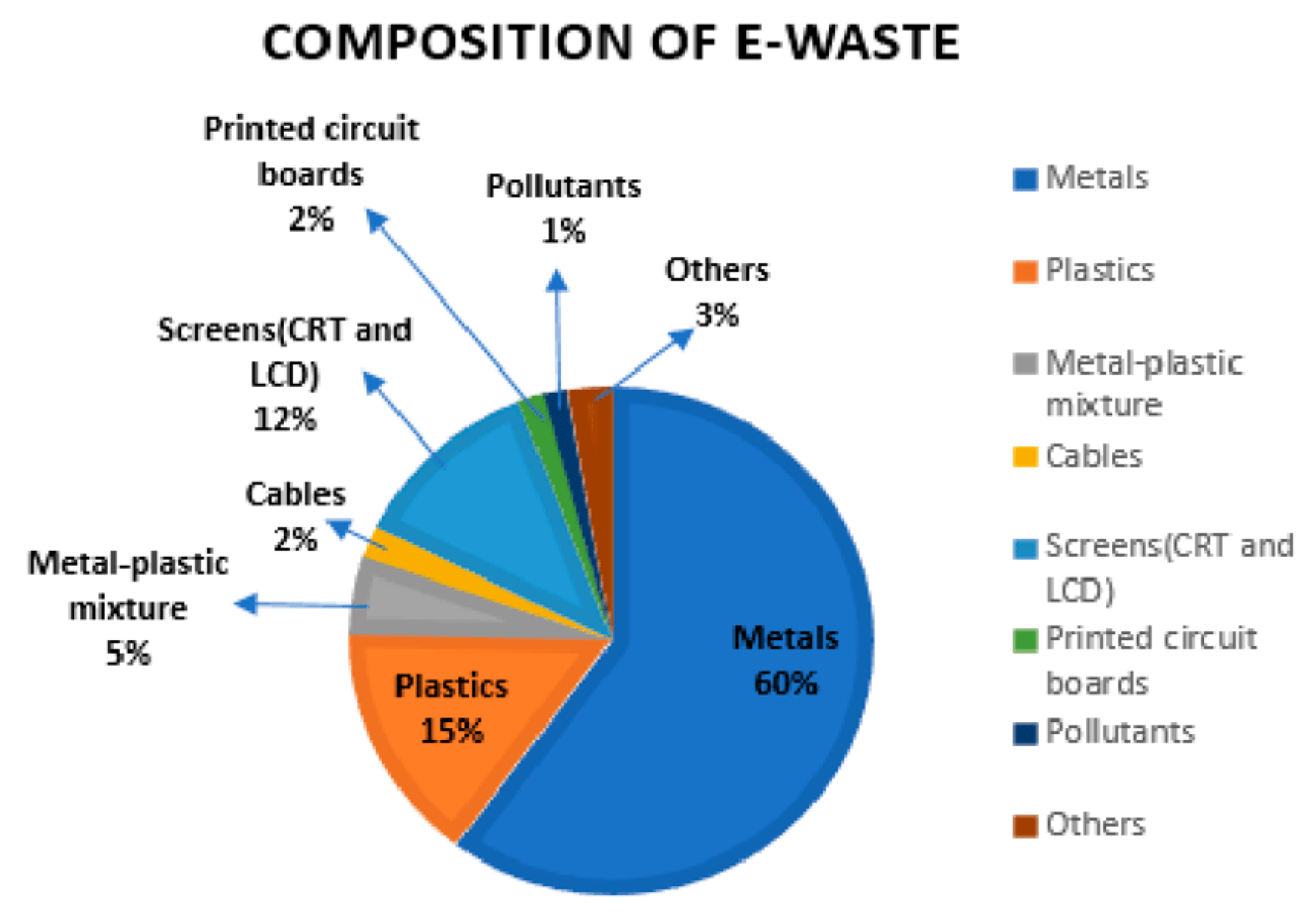

E-waste consists of both hazardous and valuable components. On the valuable side, raw materials, such as metals, glass, and plastics, can be recovered through proper recycling. Approximately 60% of e-waste is composed of recyclable metals, while 15% consists of plastics. However, only 17.4% of global e-waste is collected for recycling due to the complex and costly methods required for material recovery. Techniques like acid stripping, incineration, and acid baths are often necessary to extract valuable metals, making the process resource-intensive [8]. As a result, many companies opt for landfilling instead of investing in proper recycling infrastructure. Adding to the challenge, the diverse and complex compositions of e-waste make it difficult to identify and separate valuable materials from hazardous ones. Toxic substances in e-waste can pose significant health risks, contributing to the widespread practice of discarding e-waste rather than safely processing it.

The challenges in managing e-waste and the opportunities for material recovery are crucial factors in sustainable production. Valuable metals, like copper, silver, and gold, are present within e-waste and can be recovered and reintegrated into manufacturing processes. Countries with more advanced economies, like the United States, have stricter guidelines for handling e-waste than developing countries. Countries with developing economies still need better regulations to address the increasing problem of e-waste effectively. The research work by Chatterjee and Abraham [18] explores many global and regional circumstances of e-waste generation, emphasizing that the amount of e-waste is increasing at a much faster rate than municipal waste. Countries with large e-waste generation struggle both with the legal and illegal disposal of e-waste, in addition to the fact that a key solution would be the implementation of EPR.

E-waste management is an increasingly important topic as e-waste continues to grow worldwide. Several approaches have been put in place in multiple countries to manage e-waste efficiently, and Switzerland was among the first to innovate structures for e-waste handling. In Switzerland, organizations, such as the Swiss Foundation for Waste Management and the Swiss Association for Information, Communication, and Organization Technology, thoroughly handle recycling using the Producer Responsibility Organization [18]. Despite the regulated process, the way e-waste is handled differs greatly between many developed and developing nations. Some formal organizations in less developed countries operate with eco-friendly recycling methods, but their presence remains limited.

Government intervention, or the lack thereof, plays a significant role in the global e-waste crisis. Many developing countries still lack proper legislation to regulate e-waste management, leading to improper disposal practices. In such regions, e-waste is often discarded in landfills or handled by self-employed individuals who risk their health by manually sorting and recycling materials without adequate safety measures. Many middle- and low-income countries are managed by informal sectors, allowing waste to accumulate without proper treatment or consequences. Formal collection and recycling of e-waste remains minimal, while informal channels, which pose health risks, handle the majority. Without proper regulations, e-waste enters unregulated sectors where the extraction of valuable materials occurs without concern for environmental or human health consequences [1]. This mismanagement extends beyond local environments, as improperly discarded e-waste can travel long distances through ocean currents, spreading pollution across the globe. However, some countries, such as Nigeria, have begun taking proactive steps to address the issue through improved policies and recycling efforts [19].

In recent years, Nigeria has made efforts to strengthen its legislation, focusing on enhancing the reuse and recycling of e-waste. Historically, the country has relied on outdated technology imported from more developed nations, often in the form of secondhand equipment. To break free from this dependence, the Nigerian government has been working to advance its information and communication technology (ICT) sector, aiming for more sustainable, durable technological solutions [19]. However, a significant challenge persists—rapid technological advancements continue to drive frequent equipment turnover, making it difficult to achieve long-term sustainability.

Since the discovery of electricity, technological advancements have transformed daily life and offered countless benefits; however, they have also introduced significant challenges, particularly with the rise of electronic waste. Almost every invention has been adapted to function with electricity, which brings convenience but raises concerns about what happens when devices become obsolete. While some electronics may be donated, resold, or passed down, most eventually reach the end of their usable life and are discarded. The rapid pace of technological progress accelerates this cycle. A 1999 study by the National Safety Council showed that a standard household PC became obsolete within 4.5 years in 1992, with predictions that this lifespan would be reduced to just two years by 2005. A 2010 study by Busheri further revealed that over 180 million monitors and televisions become obsolete annually, with the rate of disposal now outpacing production [20]. This trend extends beyond computers—smaller, low-cost electronic items, like digital clocks, kitchen appliances, and calculators, often have even shorter lifespans, making them significant contributors to the growing crisis.

E-waste is a complex issue that cannot be resolved solely through policy changes or by simply improving recycling practices. A more comprehensive approach involves rethinking the entire lifecycle of electronic devices, starting from their design and manufacturing stages. To address this challenge, the Life Cycle Assessment (LCA) system was introduced in 1990, aimed at guiding engineers and designers to develop electronics that are easier to recycle and repurpose safely. By evaluating the environmental impact of a product from its creation to its end-of-life, LCA promotes sustainability-driven innovation in product design. While its adoption has been most prominent in Western Europe, studies have shown promising results in reducing e-waste and encouraging more circular manufacturing practices [21].

3. Health and Environmental Impact of Electronic Waste

E-waste poses significant threats not only to the environment but also to human health. Improper disposal, such as illegal dumping into water bodies or open landfills, can severely degrade soil and water quality. When e-waste decomposes or is incinerated, hazardous chemicals are released into the air, water, and soil, contaminating natural resources and making them unsafe for consumption or exposure.

As shown in Figure 1, metals constitute the largest portion of e-waste. These include ferrous metals, like iron and steel; non-ferrous valuable metals, such as gold, silver, platinum, aluminum, zinc, palladium, and copper; and toxic non-ferrous metals, like lead, nickel, mercury, and cadmium [22].

Figure 1.

The composition of e-waste. Reproduced with permission from [22].

E-waste contains numerous hazardous and toxic chemicals, including mercury, lead, nickel, cadmium, polybrominated flame retardants, barium, and lithium. These substances can cause severe damage to vital organs, such as the brain, lungs, liver, heart, kidneys, and skeletal system. Table 1 provides a comprehensive overview of harmful compounds present in e-waste, their sources, and their associated health risks [23]. Exposure to these toxins through inhalation, ingestion, or dermal absorption can also impair the nervous and reproductive systems, potentially leading to chronic diseases and congenital disabilities [24,25].

Residents living near e-waste recycling facilities face significant health risks due to exposure to contaminants through soil, dust, air, water, and food sources. Vulnerable populations, including pregnant women, infants, and children, are particularly at risk, with exposure to e-waste pollutants linked to conditions such as obesity, asthma, and neurodevelopmental disorders [25]. Documented health effects include adverse pregnancy outcomes (stillbirth, preterm birth, and low birth weight), reduced lung capacity, stunted growth, and impaired cognitive development [23]. Evidence also suggests a correlation between high levels of nickel, thallium, and mitochondrial DNA damage with increased cancer risk, with nickel, a persistent toxic element in the body, identified as a potential carcinogen [26]. The health consequences of e-waste exposure are alarming, with early deaths attributed to e-waste pollution projected to rise from 300,000 to over one million by 2022 [27]. Additionally, burning e-waste releases harmful particulate matter into the atmosphere, heightening the risk of cancer, chronic illnesses, and ecological harm [24,28]. Without a significant reduction in e-waste generation and improved management strategies, the threat to public health will continue to escalate.

Table 1.

Harmful compounds in e-waste, their sources, and health impacts. Adapted with permission from [29].

Table 1.

Harmful compounds in e-waste, their sources, and health impacts. Adapted with permission from [29].

| Toxic Constituent | Source of Exposure | Health Impact from High Exposure |

|---|---|---|

| Polybrominated diphenyl ether (PBDE) | Fire retardants, plastic housing, keyboards, cable insulation | Hormonal disorders, thyroid dysfunction |

| Polychlorinated biphenyl (PCB) | Capacitors, coolants, motors, dielectric fluids, transformers, lubricants | Thyroid dysfunction, liver damage, carcinogenic in animals |

| Chromium (Cr) | Corrosion-resistant films, memory tapes, disks, hardeners for housings | Lung dysfunction, reproductive issues, DNA damage |

| Lead (Pb) | Printed circuit boards (PCBs), monitors, bulbs, CRTs, cabling | Brain damage, nervous system issues, kidney and blood disorders |

| Nickel (Ni) | Batteries, computer housings, CRTs, PCBs | Allergic reactions, bronchitis, reduced lung function, lung cancer |

| Copper (Cu) | Wires, PCBs | Headaches, dizziness, eye, nose, and mouth irritation |

| Cadmium (Cd) | Semiconductor chips, infrared detectors, printer inks, toners, Ni-Cd batteries | Kidney and liver toxicity, neural damage, irreversible health effects |

| Mercury (Hg) | Batteries, backlight bulbs, flat panel displays, switches, thermostats | Brain damage, kidney failure, fetal harm |

| Arsenic (As) | Light-emitting diodes (LEDs) | Skin diseases, lung cancer, impaired nerve signaling |

| Antimony (Sb) | CRT glass, plastic housings, solder alloys | Stomach pain, vomiting, diarrhea, stomach ulcers |

| Barium (Ba) | Spark plugs, fluorescent lamps, CRT tubes | Brain swelling, muscle weakness, heart, liver, and spleen damage |

| Beryllium (Be) | Power supply boxes, motherboards, relays, finger clips | Berylliosis, lung cancer, skin disease |

| Selenium (Se) | Older photocopiers | Silicosis from prolonged exposure |

When e-waste decomposes, hazardous substances, like lead, mercury, and cadmium, can leach into the soil, contaminating the land essential for plant growth and harming both local ecosystems and communities. Improper disposal practices, such as dumping e-waste in landfills or illegal disposal on open ground, allow toxic metals and flame retardants to seep into the soil and groundwater, threatening food safety and public health. Contaminated soil weakens crops, making them more susceptible to absorbing toxins, which can pose health risks to consumers and reduce agricultural productivity [24,30].

Large particles released during the burning, shredding, or dismantling of e-waste often settle quickly into the soil, further compounding contamination. The extent of soil pollution depends on factors like soil composition, pH levels, temperature, and type. Many of these toxins have long half-lives, persisting in the environment and affecting plants and soil microbes over extended periods. Wildlife feeding on affected plants may suffer from internal health complications or even death due to toxin ingestion [24].

Scavenging animals drawn to e-waste in landfills and dumpsters face increased risks of exposure to hazardous materials, leading to potential injury or fatality. As plants and animals suffer from e-waste contamination, entire ecosystems can become destabilized, potentially reducing biodiversity and pushing some species toward endangerment or extinction [24,31].

E-waste pollution also threatens water sources, contaminating rivers, lakes, ponds, seas, and oceans, which harms aquatic life and endangers the health of communities relying on these waters for drinking and fishing. As e-waste decomposes, toxic metals, like mercury, lead, barium, and lithium, can leach into groundwater and eventually flow into nearby water bodies, causing acidification and toxification that disrupt aquatic ecosystems, endangering plants and wildlife. These pollutants can also infiltrate the water supplies that many communities depend on, posing significant health risks, especially during hot summer months when clean water is critical for hydration. Even when landfills, dumps, or recycling plants are located miles away from water sources, the persistent nature of these contaminants makes it difficult to find clean, safe drinking water [24,30].

In rural areas of South China, metal concentrations in groundwater near e-waste sites have been measured at levels 1.3 to 140 times higher than the country’s national safety guidelines, posing serious health risks for families using the water for drinking and cooking. At an abandoned e-waste recycling site in Longtang, China, heavy metals, like cadmium and copper, have severely acidified and contaminated local pond water. Additionally, aggressive e-waste recycling practices, such as acid stripping with strong oxidizing acids, including aqua regia, have been linked to soil acidification and the release of toxic leachates, further contaminating water and sediment in parts of China and India [32].

Improper disposal of e-waste—through burning, melting, disassembling, or shredding—releases harmful pollutants into the atmosphere, contributing to air pollution and respiratory illnesses. Toxic chemicals, including acids and desoldering agents, are often used to extract valuable metals, like copper, silver, and gold, from e-waste. However, the release of these substances can degrade air quality, endanger numerous plant and animal species, and disrupt biodiversity in affected regions. Over time, airborne pollutants can also contaminate soil and water, causing long-term ecological damage [24,28,31]. A striking example of this impact occurred in Guiyu, China, where an informal e-waste recycling hub emerged for the recovery of precious metals. This unregulated activity resulted in dangerously high levels of airborne lead, which not only affected the air but also contaminated local water and soil. Consequently, residents and wildlife in the area have experienced severe neurological damage and other health issues [24,28]. Additionally, e-waste pollution significantly contributes to warming, as the release of certain greenhouse gases and persistent organic pollutants further accelerates climate change.

The decomposition, incineration, and manufacturing of e-waste release significant amounts of carbon dioxide (CO2) into the atmosphere, contributing to ozone layer depletion and global warming. For instance, the production of just one ton of laptops can generate up to 10 tonnes of CO2 emissions. Most of a device’s carbon footprint occurs during manufacturing, even before it reaches the consumer. Therefore, reducing carbon-intensive manufacturing processes—such as using recycled raw materials—and extending product lifespans are critical to minimizing environmental impact [33].

Data from the Global E-waste Statistics Partnership (GESP) indicates that proper collection and recycling of just 17.4% of e-waste prevented approximately 15 million tonnes of CO2 emissions from entering the atmosphere. However, the continued rise in CO2 emissions from improperly managed e-waste highlights its significant contribution to climate change, often underestimated. Discarding outdated devices in landfills may seem convenient, but it can severely harm both the environment and human health [34].

Improper disposal of e-waste can lead to severe long-term ecological consequences. E-waste represents a modern environmental hazard, where the risks associated with Information and Communication Technology (ICT) are embedded in everyday life. The toxic substances present in electronic products, such as heavy metals and flame retardants, threaten both human health and the environment not only when discarded but throughout their lifecycle. However, these risks become more pronounced and visible once products reach the waste stage. Globally, nearly 80% of e-waste is mismanaged, often handled in informal settings in developing countries, such as China, Nigeria, Ghana, India, and Vietnam [35]. The rapid advancement of electronic technologies, especially ICTs, raises the potential for catastrophic environmental and health impacts if proper e-waste management practices are not adopted. Many countries lack strict legislation for handling e-waste, leading to widespread pollution as toxins are released into the air, soil, and groundwater during unsafe disassembly and incineration processes [36]. Unfortunately, these risks are often ignored or minimized until a significant waste management failure occurs, at which point the damage is often irreversible. Addressing these challenges requires proactive global efforts, stricter regulations, and increased public awareness to prevent long-term harm.

Table 2 highlights three critical strategies for addressing e-waste pollution and promoting recovery and development. The severe ecological impacts of soil, water, and air pollution emphasize the urgency of these strategies. As outlined in Table 2, e-waste contains various toxic substances, including heavy metals, such as lead, mercury, and cadmium, which can leach into the soil, causing long-lasting environmental damage. In China, the rise in e-waste due to increasing production and imports exacerbates the problem. Specifically, in Guiyu, China, studies on soil pollution revealed that levels of lead, cadmium, copper, and chromium exceeded the Grade I safety standards by more than tenfold [37]. Once contaminated, soil can remain toxic for decades, making it difficult for healthy vegetation to thrive, further harming the ecosystem. The persistent nature of soil contamination underscores the urgency of acting. Moreover, these toxic substances can enter the food chain when plants absorb them, which are then consumed by animals and humans, leading to significant public health risks. Addressing these challenges requires sustained efforts and immediate intervention.

Table 2.

Global electronic waste issues, proposed implementation plans, and intervention measures from a landscape architecture perspective.

Groundwater quality is a critical environmental issue with far-reaching consequences for ecological health. The deterioration of water quality is becoming an increasingly urgent concern, largely due to the improper management of electronic waste. Toxic substances, such as lead, mercury, and cadmium, which are common in soil pollution, are often disposed of in landfills and left exposed in uncontrolled environments, leading to contamination of both groundwater and surface water. On a global scale, e-waste contributes to approximately 70% of the leachate heavy metals found in landfills [44]. Groundwater serves as a vital source of drinking water, and when heavy metals infiltrate these reserves, they pose serious health risks to humans and animals who consume the contaminated water. Additionally, polluted water threatens aquatic life and disrupts biodiversity, especially when prolonged exposure to these harmful substances is not addressed. The release of such pollutants can lead to a wide range of health problems, from respiratory issues to the ingestion of carcinogens, increasing the risk of cancer in both humans and wildlife.

E-waste is a significant source of emissions of polybrominated diphenyl ethers (PBDEs), which are commonly used as flame retardants in various electronic products. These chemicals pose serious and often irreversible health risks. Moreover, thermal treatment methods, such as burning or incinerating e-waste, can exacerbate the problem by releasing even more toxic congeners into the environment. A study conducted in Thailand examined PBDE concentrations in areas where e-waste is disposed of, revealing that tri-PBDE levels were detectable in sampling sites and increased with distance from the e-waste disposal locations [45]. Burning electronic waste, a widespread informal practice in many developing countries, releases harmful fumes containing carcinogenic substances, contributing to respiratory issues, particularly for local wildlife and nearby communities. In conclusion, the improper handling and disposal of e-waste leads to a cumulative impact on soil, water, and air quality, with devastating consequences for both human health and ecological systems.

4. Current and Emerging E-Waste Recycling Technology

The need for advanced recycling technologies remains critical, as the lack of efficient and scalable e-waste recycling facilities contributes significantly to the growing global waste crisis. This issue has been widely documented, drawing attention from policymakers, engineers, and manufacturers alike. In recent years, mounting pressure to develop sustainable recycling solutions, particularly for composite materials, has intensified [46]. Composite materials, typically consisting of polymeric and metallic components, share recycling challenges like those of electronic waste. Various industries employ comparable recycling frameworks, highlighting the potential for cross-sector innovation. One such framework, the Technology Readiness Level (TRL), assesses the maturity of technologies and has been applied to evaluate the lifecycle of wind turbine blades to determine their recycling viability and cost-effectiveness [46]. Implementing a similar framework for e-waste could significantly improve recycling strategies, emphasizing the importance of a well-structured, long-term plan for sustainable resource management.

An effective recycling plan is both a necessity and a luxury in addressing the current e-waste crisis. Given the diverse range of electronic waste, multiple recycling approaches are essential to handle various components effectively. Printed circuit boards (PCBs), among the most common components in electronics, are particularly challenging to recycle due to their complex mix of organic materials, glass fibers, and valuable metals [47]. The PCB recycling process generally involves three critical stages: pretreatment, physical recycling, and chemical recycling. Pretreatment involves cleaning, disassembling reusable and hazardous parts, and mechanically separating materials through shredding and classification techniques. Physical recycling follows, focusing on material recovery through refining and purification processes. Chemical recycling is the final stage, often employing methods such as pyrolysis, thermolysis, and gasification to break down remaining components and extract valuable elements [47]. The complexity of PCB recycling highlights the pressing need for efficient, scalable recycling technologies to mitigate the growing e-waste problem.

Pyrolysis is a prominent chemical process for managing plastic waste, capable of converting plastics into valuable fuels, chemicals, and even new plastics. While promising, the technology still requires further refinement to optimize efficiency and scalability [36]. During pyrolysis, long-chain polymer molecules are thermally decomposed into smaller hydrocarbon fractions, producing oils and gases that serve as valuable precursors for fuel and chemical production. These outputs can be further processed to generate usable fuels and industrial gases. Although the process involves high operational costs, the value of the recovered oils and gases presents a significant opportunity for pyrolysis to become a more economically sustainable method of plastic recycling [48].

Composite and fibrous materials are among the most difficult to recycle due to their complex structures and manufacturing processes. Carbon fiber, a widely used fibrous composite material, is produced through a thermosetting process where heat hardens the fibers into a lightweight, rigid structure with aligned fibers. However, conventional recycling methods often degrade the material, leaving the fibers misaligned and fluffy, which significantly reduces their structural integrity and performance [49]. Thermolysis, an advanced chemical recycling technique, offers a more effective approach by preserving the fiber’s alignment and structural properties. By carefully adjusting temperature and pressure conditions, thermolysis can be applied to various types of fibrous composite materials, making it one of the most mature and efficient recycling methods for such challenging materials [49].

Gasification involves the reaction of plastic waste with a gasifying agent, such as air or steam, at elevated temperatures ranging from 500 to 1200 degrees Celsius. This high-temperature process breaks down plastics into a flammable synthetic gas, commonly known as syngas. Syngas, primarily composed of hydrogen and carbon monoxide, can be used as a fuel for electricity generation or as a feedstock for producing chemicals and other materials. While it is not typically used as a direct fuel source like gasoline, its versatility makes it valuable for energy recovery and industrial applications. Gasification has been extensively developed and refined over the years, making it a highly effective method for reducing plastic waste [50].

These methods offer effective strategies for managing existing plastic waste and guiding future decisions on plastic disposal. However, a significant challenge remains—addressing the plastic waste already polluting our environment. Biodegradation is a natural process in which microorganisms break down materials into carbon dioxide, water, and other simpler compounds. While all materials undergo biodegradation over time, the rate varies greatly [51]. Organic materials, like paper and cloth, decompose relatively quickly, while plastics and metals persist for much longer, contributing to long-term pollution. This disparity explains the increasing shift toward biodegradable alternatives, such as paper straws, cups, and containers, over traditional plastic products. Though biodegradation primarily involves biological activity breaking down materials, both biotic (biological) and abiotic (non-biological) factors influence the process. Factors such as temperature, humidity, and the presence of oxygen play critical roles, alongside microbial activity. By understanding and manipulating these factors, it is possible to accelerate the biodegradation of persistent materials, like plastics, presenting a promising pathway to mitigate plastic pollution more effectively.

Various factors, including temperature, climate, mechanical forces, and chemical conditions, influence the biodegradation process. In natural biodegradation, the sun’s heat and ultraviolet (UV) rays play a crucial role in breaking down materials to a state where microorganisms can metabolize them fully. By studying these natural processes, we gain valuable insights into what makes a material more biodegradable. This knowledge enables us to design new materials, such as bioplastics, that degrade more easily and efficiently. Bioplastics, derived from renewable sources, represent a promising solution for reducing e-waste. These materials maintain many of the essential properties of traditional plastics, such as durability and versatility, while offering the added benefit of semi-rapid biodegradation once discarded [51]. Bioplastics are already widely used in everyday applications, including food-grade materials, and their integration into electronic components could significantly mitigate e-waste challenges. The growing emphasis on bioplastics provides a hopeful pathway for more sustainable waste management practices in the future.

Increasing investments in biotechnology are essential for minimizing the improper disposal of electronic waste. Governments and large corporations should prioritize these efforts to promote sustainable waste management practices. Emerging biotechnological approaches, such as bioleaching and biosorption, have shown significant promise in the recovery of valuable metals from electronic waste. Bioleaching, for example, has been investigated for its effectiveness in extracting copper from e-waste. A study on metallurgical processing using bioleaching reported a copper recovery efficiency of 24% based on the total copper content, highlighting the potential of the process but also the need for further optimization to maximize metal recovery [52]. Complementary electrochemical methods have also demonstrated effectiveness in copper recovery. In a study using ammonia-based solutions, electrodeposition was explored to determine how copper concentration and ammonia salt levels influenced the process. The results indicated that higher copper concentrations led to greater ion availability for electrochemical charge transfer, slightly reducing the charge transfer coefficient but significantly increasing the transfer rate constant. This ultimately accelerated the overall metallurgical processing efficiency [53].

Biodegradation can be accelerated using a combination of chemical and mechanical processes. One effective and relatively inexpensive method for chemically breaking down plastics is the use of deep eutectic solvents (DESs). DESs are mixtures commonly composed of ammonium, phosphonium, or sulfonium salts, combined with a hydrogen bond donor and a hydrogen bond acceptor. Depending on their composition, DESs can be categorized into various types based on their chemical properties and applications [51]. DESs are particularly effective at dissolving plastics due to their strong solvent capabilities. Their unique chemistry, often rich in Lewis acids, allows them to act as catalysts for a wide range of organic reactions. Lewis acids, which accept electron pairs, enhance the degradation process by promoting the breakdown of polymer structures, making DES a promising tool for accelerating plastic biodegradation.

In addition to biotechnology, the integration of AI into IoT (Internet of Things) technology provides a hopeful move toward ecological balance, helping to address the growing problem of e-waste. IoT devices, which transmit data on the internet or other communication networks for certain applications [54], may be highly valuable in improving waste management. IoT-enabled smart tracking systems can improve waste collection efficiency by monitoring device lifespans and guiding users toward responsible disposal options and guiding people to responsible disposal choices. Additionally, IoT-enabled recycling facilities can streamline sorting and processing through complete automated material identification, considerably increasing the recovery rate of valuable resources. As technology rapidly advances, the application of AI and IoT to improve e-waste management will be crucial for dealing with the increasing demand for sustainable recycling solutions.

5. Challenges and Opportunities in E-Waste Management

Given the widespread awareness of e-waste issues, one might question why more effective solutions have yet to be widely implemented. However, several complex obstacles hinder the optimal management of the current e-waste crisis. At the same time, these challenges present opportunities for innovation, many of which are already being explored.

In recent years, e-waste concerns have gained unprecedented attention as the rapid expansion of electronic devices continues to reshape modern society. The constant advancement in technology has led to a surge in obsolete electronics, often discarded without proper disposal methods. This accumulation mirrors patterns seen in high-income countries, like the United States, where outdated devices are rapidly piling up, exacerbating the waste problem. The environmental threats posed by poor e-waste management, particularly the mismanagement of information storage media, create only a temporary and misleading sense of control. Yet, despite these hurdles, the growing awareness of e-waste hazards offers a platform for the development of innovative strategies to manage end-of-life products and promote sustainable practices in e-waste conservation.

A significant challenge in e-waste management is the contribution of the informal recycling sector to the infrastructure gap. In many regions, especially in developing countries, e-waste is often handled by informal recyclers, who lack the proper tools, protective measures, and facilities to manage the toxic constituents of electronic devices safely. These workers frequently resort to hazardous techniques, such as open burning or acid application, to extract valuable components, which not only release harmful pollutants into the environment but also expose workers to serious health risks. In many third-world countries, the informal sector conducts most e-waste recycling, driven by economic necessity and the lack of formal recycling systems. This practice persists because formal infrastructure remains insufficient, while developed countries often export their e-waste to these regions, further straining local capacity to manage the waste responsibly. Addressing the dangers posed by informal e-waste recycling requires both immediate and long-term solutions. Investments in safe treatment systems, worker protections, and properly equipped recycling facilities are crucial to mitigating health risks and environmental damage. Bridging the infrastructure gap demands financial commitments and international cooperation to establish sustainable recycling methods that protect both people and the planet.

There are challenges in trying to implement EPR, an essential tool for managing e-waste in developing countries, particularly in the absence of formal recycling infrastructure. Collective investment in recycling facilities can enhance infrastructure development. A Nash bargaining model is used in determining the optimal use of recycled contacts in the supply chain between original equipment manufacturers and waste management firms. This issue arises due to a conflict of interest where recycling materials attract environmentally conscious consumers while firms rely on the resale of recyclable content for revenue [55]. It is influenced by regulatory interventions, market dynamics, and technological investment, which emphasizes the government-coordinated sustainability efforts. Joint investment reduces individual costs, leading to suboptimal recycling capacity and efficiency due to conflicting producer incentives. A case study from China’s e-waste recycling alliance illustrates these dynamics. The findings suggest a tradeoff between promoting recycling infrastructure and incentivizing better product design, requiring careful policy considerations for EPR implementation [56].

Effective e-waste management must also adhere to data protection guidelines, as discarded electronic devices can still retain sensitive information. Careless disposal and recovery of such devices can lead to significant data breaches, exposing private, corporate, and government documents. Many devices enter the waste stream without proper removal or wiping of hard disk drives, putting confidential information at serious risk. This dual threat to privacy and economic security underscores the urgent need for safer e-waste recycling practices, including advanced data wiping and secure hardware destruction before disposal. For organizations, failure to properly manage data storage devices can result in severe consequences, such as the loss of proprietary information, reputational damage, and costly civil penalties for violating data protection laws. Addressing these security concerns also presents a business opportunity for companies specializing in secure e-waste disposal. Services like certified data destruction and hardware shredding not only enhance data security but also offer cost-effective solutions that can generate additional revenue streams within the e-waste management sector.

A case study of Recykal, a fully cloud-based and technologically advanced waste management company operating in Hyderabad, India, points out the definite role of producer responsibility organizations (PROs) in implementing EPR. In India, Recykal has efficiently transferred several of its EPR duties, which link multiple manufacturers, users, and certain recyclers, as the problem of increasing mishandling of e-waste. The success of Recykal’s approach can be attributed to several key factors: market expansion, economies of scale, and reduction of uncertainty in waste management processes. Recykal facilitates important tasks such as collecting, recycling, and reporting, ensuring that e-waste is dealt with in a sustainable way. This framework ensures that rules are followed and offers more clarity, better efficiency, and more accountability to the waste management field while keeping the same number of people employed. The Recykal case makes it clear that technology use and parties working together may help EPR programs function efficiently, especially in growing countries, like India [57].

Several economic challenges hinder effective e-waste management. Proper recycling, particularly within formal frameworks, is often prohibitively expensive for some companies and governments. As a result, e-waste is either discarded improperly or outsourced to the informal sector, where low wages and inadequate safety measures lead to hazardous waste handling practices. Furthermore, the toxic yet valuable composition of electronic products necessitates specialized technologies for safe and efficient material separation and recovery, which can be costly for recycling centers to acquire and implement. Table 3 shows the key challenges, opportunities, and solutions for e-waste management. Despite these challenges, the e-waste recycling market presents significant growth potential. To overcome these financial barriers and promote safer, more efficient recycling practices, governments and businesses must consider incentives, subsidies, and legislative measures. Organizations that invest in sustainable solutions and address these economic constraints will not only contribute to environmental protection but also gain a competitive advantage in this expanding market.

Table 3.

Key challenges, opportunities, and solutions for enhancing e-waste management.

Innovative waste treatment and management strategies are crucial for addressing the challenges of e-waste mismanagement. Existing approaches, like metallurgical processing through biotechnology, have shown promise; they often fall short in terms of efficiency and recovery rates for heavy metals. Advancing more effective technologies can significantly improve success in e-waste recycling. One such emerging solution involves the application of artificial intelligence techniques (AITs) to optimize e-waste management [65]. A recent study explored an AIT-based model employing a multi-level hierarchical cluster structure designed to streamline the classification of electronic waste. This model accounts for the diverse environmental and physical characteristics of e-waste, emphasizing risk assessment and toxic exposure mitigation. By enhancing the precision and scalability of waste classification, AIT offers a more comprehensive framework for improving e-waste management practices [66].

In summary, the e-waste management industry faces both significant challenges and promising opportunities. Key concerns include worker safety, environmental protection, and the widespread lack of proper infrastructure in developing countries, often leading wealthier nations to export their waste to regions with insufficient resources for safe processing. However, this complex issue also presents opportunities for meaningful progress. Investing in advanced recycling facilities, enforcing stricter regulations, and adopting cutting-edge technologies are essential steps toward improving the industry’s safety and efficiency. Critical areas, such as data security, demand particular attention, especially for organizations, like governments, that handle sensitive information, as unmanaged e-waste can become a target for data breaches. Economic barriers continue to hinder progress, yet targeted policies, including financial incentives and subsidies, can help drive the growth of safer and more effective e-waste management systems worldwide. As the digital age expands, the demand for sustainable e-waste management will only grow, creating a valuable space for forward-thinking companies to make a lasting positive impact.

6. Sustainable Solutions and Future Directions

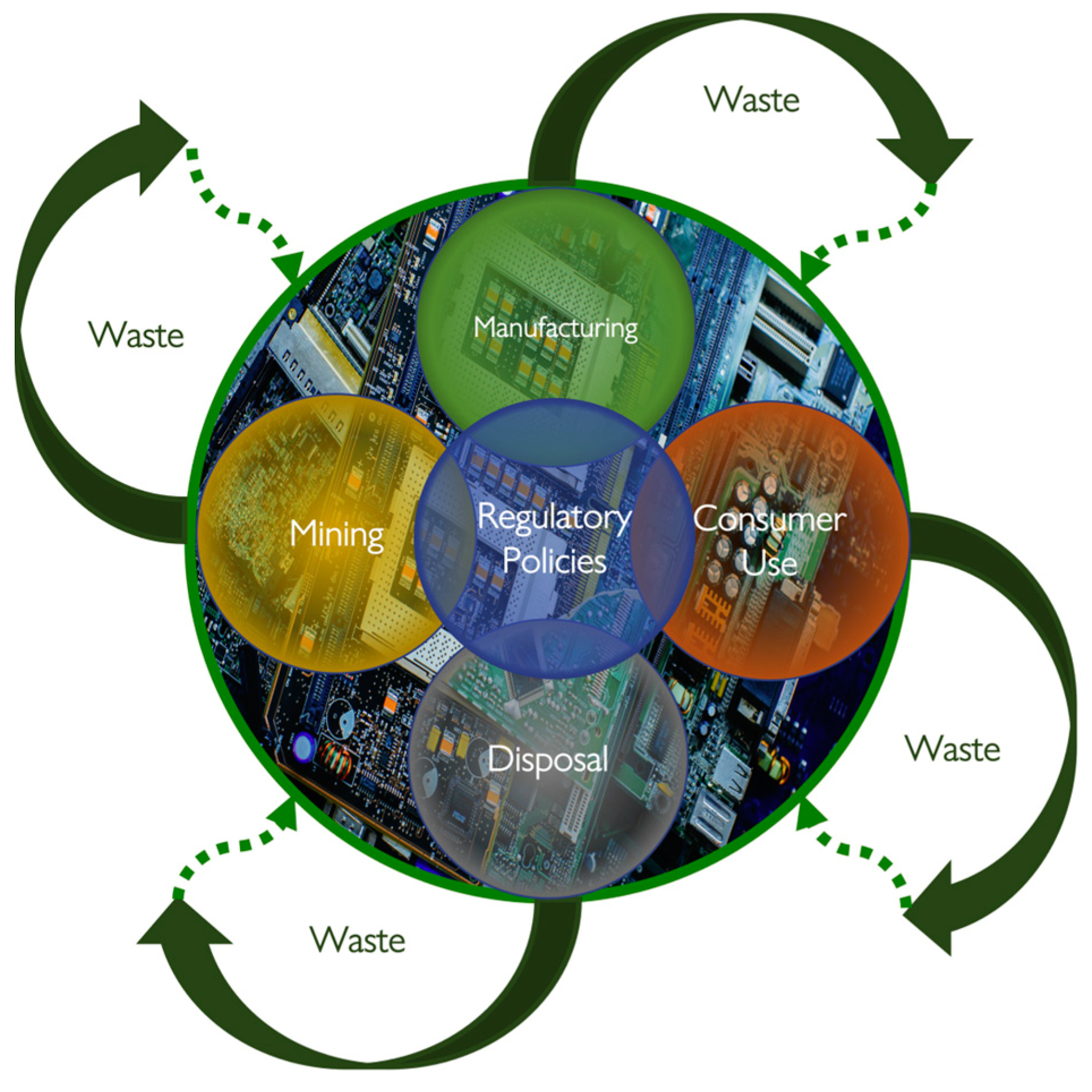

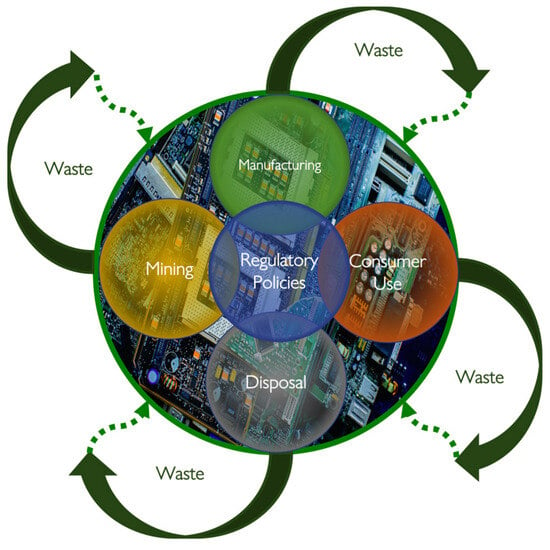

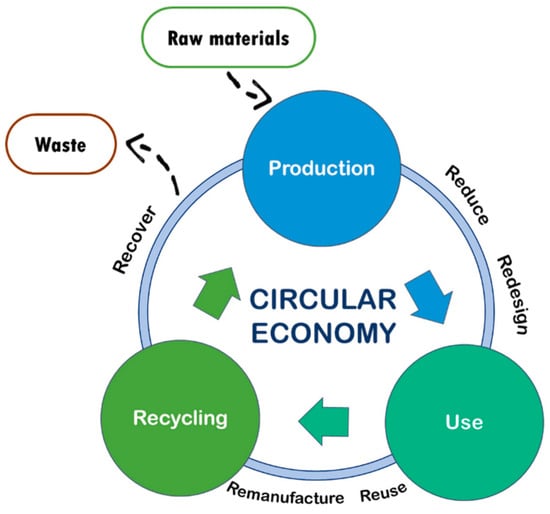

Implementing circular economy models in e-waste management presents a transformative pathway toward sustainable resource utilization and waste reduction. This approach emphasizes the continuous reuse, refurbishment, and recycling of electronic components, extending the lifespan of devices while minimizing the demand for raw materials. By slowing the depletion of natural resources and reducing waste generation, circular strategies can significantly lower annual greenhouse gas emissions compared to traditional linear models, which prioritize disposal after use. Embracing circular practices not only conserves resources but also fosters long-term environmental and economic sustainability. Figure 2 provides a comprehensive representation of the circular economy for electronic products.

Figure 2.

Transforming e-waste into a circular economy. Reproduced with permission from [67].

At its core are regulatory policies, which serve as a foundation for promoting sustainable practices throughout every phase of the electronic product lifecycle. Effective policy implementation requires coordination at local, national, regional, and international levels to prevent gaps that could compromise the success of circular economy efforts. The model is structured around four key stages: mining, manufacturing, consumer use, and disposal. Each stage plays a vital role in reducing the environmental impact of electronic devices by facilitating resource recovery, reuse, and recycling. Encircling the entire process, waste loops back from each stage, emphasizing continuous opportunities for material recovery and the minimization of resource depletion.

Various circular economy models have emerged to further reduce e-waste and pollution. Electrical and electronic product manufacturers play a crucial role throughout all phases of a product’s life cycle. However, assessing the full environmental impact can be challenging due to the complexity and number of stages involved. To address this, it has been proposed that design principles focusing on finish, material selection, and technological integration be implemented to raise awareness among designers and encourage innovative, eco-friendly solutions. Products could be designed with integrated information technology systems capable of storing essential data, such as product identification and material composition, to support effective recycling and reuse across multiple life cycles [68]. Implementing eco-design as a standard environmental consideration in electronic manufacturing would be a significant step toward minimizing waste and optimizing resource efficiency.

A multi-criteria decision-making (MCDM) approach to selecting the most effective circular economy strategies for e-waste and equipment management is essential [69]. Given the complexity of e-waste management, several factors—environmental, economic, social, and technical—must be considered. MCDM offers a structured framework that helps analyze these factors by assigning weights based on their relative importance. This hierarchical process allows for a clear visualization of the cause-and-effect relationships between criteria, enabling a deeper understanding of how various factors in WEEE management interact. By using MCDM, the selection and prioritization of circular economy strategies, such as the 9Rs (refuse, rethink, reduce, reuse, repair, refurbish, remanufacture, repurpose, recycle, and recover), can be optimized [70]. The 9Rs aim to achieve three main goals: maximizing the efficiency of product use and manufacturing, extending the lifespan of products and components, and ensuring the effective application of materials. The MCDM approach thus provides a valuable tool for identifying the most impactful strategies to reduce e-waste and enhance sustainability.

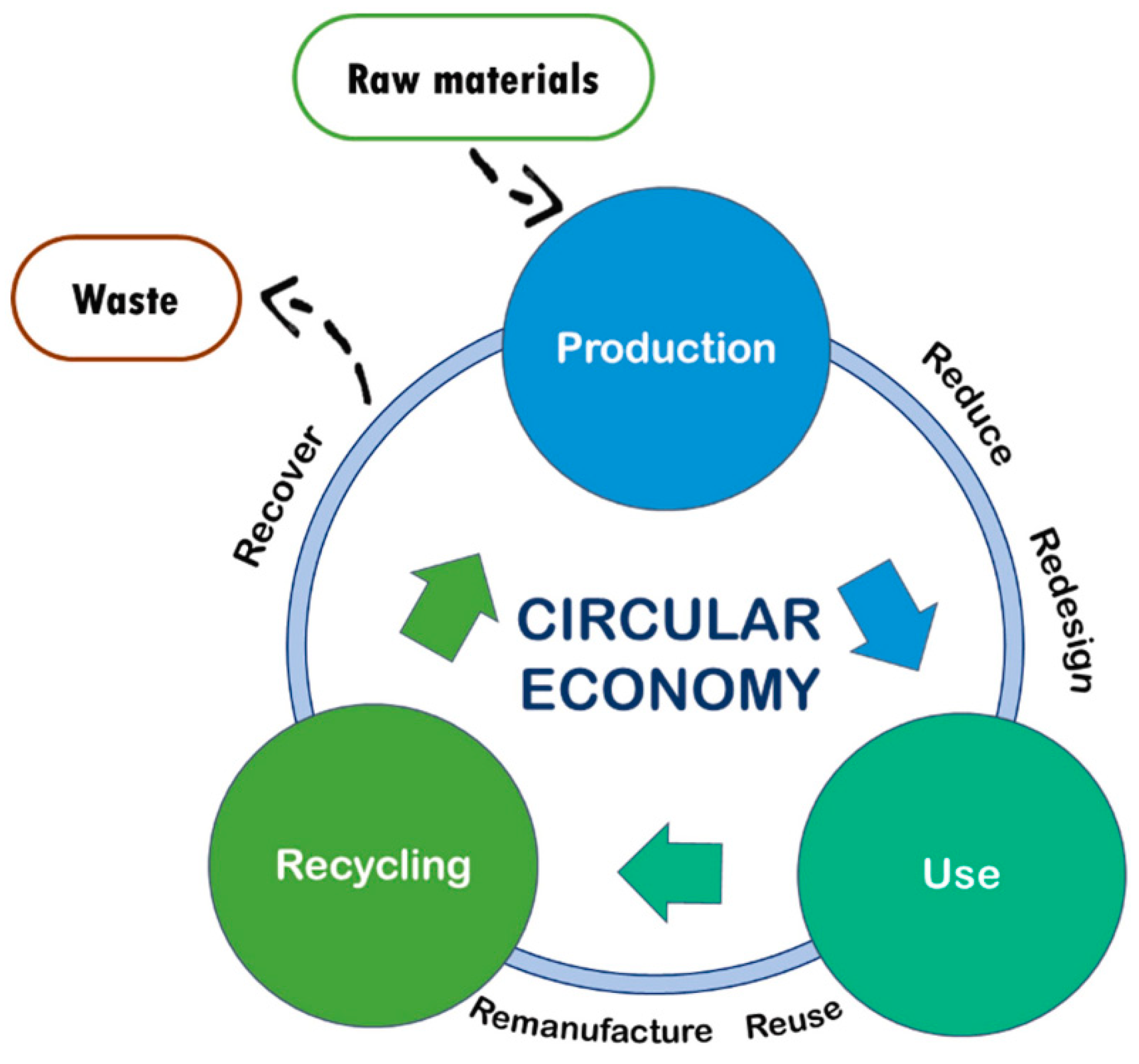

Figure 3 above illustrates the core stages of the circular economy: production, distribution, consumption, collection, redesign, reuse, recovery, and recycling. In the final stage, recycling converts collected e-waste into raw materials, closing the loop and feeding the cycle back into the design phase. This process minimizes non-recyclable waste, significantly reducing the amount of residual waste sent to landfills. Overall, circular economy models for e-waste focus on shifting from a traditional linear system to a closed-loop approach, where electronic components are continually reused and recycled, fostering sustainability and reducing environmental impact.

Figure 3.

General scheme of circular economy. Reproduced with permission from [71].

With the full incorporation of circular supply chains, manufacturers voluntarily start to include circular thinking in their supply management. This approach is particularly important in the EEE area, as it relies heavily on vital natural materials, such as rare earth metals, which are becoming more difficult to obtain due to the increasing demand for electronics [72]. If businesses create systems guaranteeing these materials can be reused, recycled, and repurposed, they can greatly lower the ecological effect of removing resources while also keeping material at its greatest worth.

Circular economy business models are being innovated inside the EEE sector when companies use strategies for extending how long their products last. If businesses make more durable goods, they can cut down on the frequency of consumer purchases, helping in the handling of a major cause of electronic waste [72]. For instance, some companies are focused on making products that last longer and are easier to repair, and this decreases the need to dispose of them and encourages parts to be reused. From an ecological perspective, this method is quite helpful. Additionally, it cultivates large worth for companies by expanding customer devotion and diminishing the requirement to replace products so frequently.

Large corporations in the electronics industry are feeling pressure to address the environmental impact of their products. Apple, a prominent digital goods and services company, provides one clear instance of circular economy ideas for their digital goods. They have implemented an entirely closed-loop system where they aim to considerably reduce the need for resource mining, striving for virtually zero waste across the complete lifecycle of their products. The company’s main project, the Liam robot, is an automatic dismantling device made for the quick retrieval and arrangement of materials from used iPhones, which would otherwise be misplaced or degrade over time [73]. This process aligns with the principles of circular economy by extending the lifespan of raw materials. In addition to this, it guarantees that they are reused as well as recycled in future production cycles. Apple’s dedication to overall resource recovery tackles many ecological issues and increases the quantifiable financial worth of most reused parts, promoting additional effective resource utilization and aiding its continuing business expansion. In this way, the circular economy model supports Apple in keeping its place in the attention economy by showing the company as ecologically conscious while promoting the continued buying and use of more new products.

7. Innovative Technologies for E-Waste Recycling

As technology and innovation continue to advance, new solutions for addressing e-waste emerge. One promising avenue is the integration of AI, which offers a wide range of potential applications for reducing e-waste. AI, a technology that uses computers and software to understand and learn from specific environments, can be applied to a variety of functions—from answering tech support queries to autonomously controlling vehicles [74]. In the context of electronic waste, AI can enhance various stages of the process, from product design to recycling.

To explore the role of artificial intelligence in reducing electronic waste, it is important to first consider the design phase before products even become waste. During product design, numerous factors must be considered, with functionality often taking precedence over considerations like ease of disposal. However, AI is increasingly being utilized to support the design process in many companies. By rapidly analyzing previous products, AI can create multiple prototypes that incorporate the best features of earlier designs—something that would be nearly impossible for a human to do [75]. When applied to reducing electronic waste, AI can enhance product designs by optimizing the ease of disassembly and identifying which components are most suitable for reuse or recycling. For example, AI can analyze a range of existing products and recommend design changes that make it easier to disassemble components, simplifying the recycling and disposal process [76].

Another innovative approach involves using machine learning to assess specific products and identify which components can be made modular, allowing for easy replacement rather than discarding the entire device. This reduces e-waste by extending the lifespan of individual components. Additionally, AI can be integrated directly into the product itself. By using sensors and algorithms, the device can predict the remaining lifespan of its components [77]. This proactive information could prompt users to repair or maintain their products before they fail completely. A prime example of this is found in modern smartphones, like the iPhone, which tracks battery health and notifies users when it is time to replace the battery. This not only helps preserve the device but also reduces unnecessary waste, benefiting both the environment and consumers’ wallets [78].

AI can also play a pivotal role in optimizing the disposal and collection of electronic waste. When a product reaches the end of its life and is discarded at a collection point, AI can analyze data to identify trends, such as which locations generate higher volumes of specific waste types [79]. For instance, if a particular site consistently collects more lithium-ion batteries than others, AI can notify the company, enabling them to tailor their recycling efforts and resources to focus more on lithium-ion battery processing at that location. Additionally, AI can streamline collection logistics by determining the most efficient pickup schedules. If certain locations accumulate waste faster than others, AI can recommend more frequent collections while reducing unnecessary pickups at lower-volume sites [80]. These optimized collection routines not only lower operational costs but also improve resource allocation, allowing companies to invest in other critical aspects of e-waste management.

A large portion of India’s e-waste generation arises from local electronics, but current disposal and recycling efforts mainly focus on commercial and mercantile sectors. Many consumers show an absence of awareness regarding proper disposal methods, resulting in e-waste being discarded among general household waste. Current research has been done on machine learning and robotics for waste classification, emphasizing their potential in improving waste segregation efficiency. Despite deep learning models being used to categorize common waste, more study is necessary concerning their application of residential e-waste gathering. This research puts forward rCubeBot, a special mobile robot system created for recognizing, gathering, and sorting specific e-waste from respective homes. This robot, fixed to city dump trucks, independently navigates through pickup locations, catches pictures of trash objects, and uses a CNN-based (convolutional neural network) identification system with 96% precision for the recognition of electronic reuse [81]. The robotic arm systematically picks up and puts the specified garbage inside another area within the vehicle, so it lessens how much manual hand sorting is needed. The deployment of this kind of system could foster a 20% lessening in waste management costs throughout five years while additionally protecting waste workers against hazardous conditions [81]. Integrating robotic automation into existing waste collection infrastructure presents a scalable, cost-effective, and minimally intrusive solution to the household e-waste crisis, targeting greater efficiency as well as sustainability throughout urban waste management.

An interesting study on recent advances in IoT-enabled systems and LPWAN (low-power wide-area network) integrates edge AI to optimize e-waste collection and recycling processes. This system improves highly effective monitoring, increases the overall speed of data transmission, and actively encourages further consumer participation in e-waste disposal initiatives. LPWAN supports monitoring much sooner than collection, and this helps waste management organizations considerably optimize logistics by using smart bins equipped with sensors to precisely measure e-waste amounts. These units dependably send amounts of information to highly protected systems on the internet. AI analytics in those systems accurately forecast collection schedules, which reduces functional costs while improving total productivity [54]. This IoT-based e-waste management solution represents an important step in sustainably dealing with urban waste.

At the final stage of e-waste management, when discarded products reach a recycling facility for proper disassembly and handling, AI can significantly enhance the efficiency and safety of the entire process. Automated sorting powered by AI, using advanced sensors and cameras, can identify and categorize devices, such as laptops and phones, upon arrival, streamlining the initial sorting phase [82]. As products are disassembled, AI can further assist in separating materials, improving both efficiency and worker safety [83]. For example, precious metals, like gold or palladium, can be detected and isolated for specialized handling, while hazardous materials can be identified and removed to minimize health risks for workers [84]. AI can also optimize the entire recycling process by continuously monitoring plant operations. It can assess the efficiency of each processing stage, measure the percentage of recoverable materials successfully reclaimed, and identify potential material losses during separation [85]. Furthermore, AI systems can track the facility’s environmental impact, evaluating metrics such as energy consumption and emissions, ensuring the plant operates with minimal environmental harm. This data-driven approach not only enhances resource recovery but also supports safer, more sustainable recycling practices.

A case study in Malaysia discusses the need for proper management of household electronic waste. Collection and recycling efforts are unsuccessful, as the nation lacks a thorough set of regulations for household e-waste recycling efforts. The authors propose a smart e-waste collection system, completely integrated with IoT technology as well as all-embracing sensor-equipped collection boxes. These boxes carefully monitor waste levels in addition to notifying collectors when the bins reach capacity, much like the LPWAN system. However, a mobile application was developed to allow users to schedule waste disposal and locate collection points [86]. This enhancement points out that electronic waste has a lot of useful metals, such as gold and copper, making proper recycling economically beneficial while preventing toxic chemicals from polluting landfills. Household e-waste is largely unmanaged, unlike industrial e-waste, which is often regulated in Malaysia. Through IoT technology, the proposed system effectively optimizes several waste collection routes, considerably reduces multiple transportation costs, and greatly improves the quantity of material recovery [86]. This system works to improve e-waste collection and assist smart city projects in Malaysia by using sustainable waste management.

Furthermore, more implementation of AI is coming to rise in household waste management within Ukraine, in addition to highlighting its potential for improving waste classification, transparency, and sustainability. The suggested AI-driver k-means clustering method, coupled with a TIDL (multi-criteria taxonomic development level index), permits a generally more accurate evaluation of leftover waste production [87]. By identifying high-risk zones and optimizing resource allocation, this method addresses inefficiencies in waste management systems, particularly in regions where bureaucratic constraints, insufficient funding, and outdated infrastructure impede the process. The AI-based clustering model provides a systematic methodology for aligning Ukraine’s household waste management strategies with the European Union’s sustainability objectives. AI can act as a valuable, quantitative decision-making tool, easing the development of data-driven regulations and targeted investment strategies by reducing overall landfill dependency, improving wide-ranging recycling rates, and improving thorough ecological monitoring. These applications contribute toward a more transparent and efficient household waste supply chain. Additionally, in Ukraine, this implementation underscores the broader implications of AI-driven waste management, with a scalable framework for the European Union that could be adopted across the continent to promote waste processing that is ecologically responsible.

After exploring the vast potential of integrating artificial intelligence into the e-waste management industry, it becomes evident that such technologies could have significantly improved e-waste handling if adopted earlier. However, several substantial challenges continue to hinder widespread implementation. First and foremost, the high costs associated with AI technologies present a major barrier. Advanced components, like industrial robots, precision sensors, and high-performance computing systems, come with significant price tags, often deterring companies from making the investment [88]. While wealthier nations may have the resources to explore this technology, many developing countries lack the financial capacity to adopt such advanced systems. As previously mentioned, limited funding already restricts e-waste management capabilities in these regions, making the affordability gap even more apparent. Beyond cost, the complexity of implementing AI poses another challenge. Integrating AI into existing recycling infrastructure is not as simple as installing robots and expecting flawless results. Recycling facilities would require substantial upgrades, including expanded space, increased energy demands, and specialized personnel trained to operate and maintain these systems. Adapting AI technology is not just an expensive endeavor but a long-term investment that demands careful planning and restructuring of current systems [89]. Furthermore, since AI applications in e-waste management are still relatively new, there is no standardized framework for implementation. Each facility would require customized solutions tailored to its specific needs, further complicating the adoption process. These financial, technical, and logistical hurdles highlight the importance of strategic planning and global collaboration to ensure AI-driven advancements can be equitably adopted across all regions.

Privacy and security concerns represent significant challenges in the widespread adoption of artificial intelligence, particularly in the context of e-waste management. Like all digital technologies, AI systems are vulnerable to cyber threats if not properly secured. Insufficient safeguards could lead to data breaches, unauthorized access, and system compromises that disrupt operations or expose sensitive information [90]. The risks are even more pronounced with AI because it is still a rapidly evolving technology. Many of its vulnerabilities remain unaddressed, increasing the potential for privacy violations. For instance, if AI is embedded within smart electronic products, hackers could potentially access personal user data or manipulate system functions. Such risks emphasize the urgent need for comprehensive cybersecurity measures and regulatory frameworks to protect both users and infrastructure from malicious attacks. While the challenges associated with implementing AI in e-waste management—ranging from cost and complexity to security risks—are substantial, the long-term benefits could far outweigh these obstacles. With proper investment in secure, well-regulated systems, AI has the potential to revolutionize waste management, making it more efficient, sustainable, and effective in reducing global electronic waste.

8. Policy Reforms for Improved E-Waste Management

Governments, businesses, and organizations across the globe need to create regulations promoting sustainable waste handling due to the rapid increase of discarded electronics. As the demand for electronics rises, it is more vital than ever to advance proper recycling efforts, lessen harm to our world, and recover valuable materials. Several approaches have emerged for tackling the growing e-waste crisis. These approaches include EPR, regulatory frameworks, and public awareness campaigns, together with certain industry-led initiatives. International agreements attempt to regulate the transboundary movement of extremely hazardous waste, while regional policies enforce strict recycling targets. In addition to government involvement, many companies and people are also important in reducing electronic waste by reusing, repairing, and responsibly recycling it.

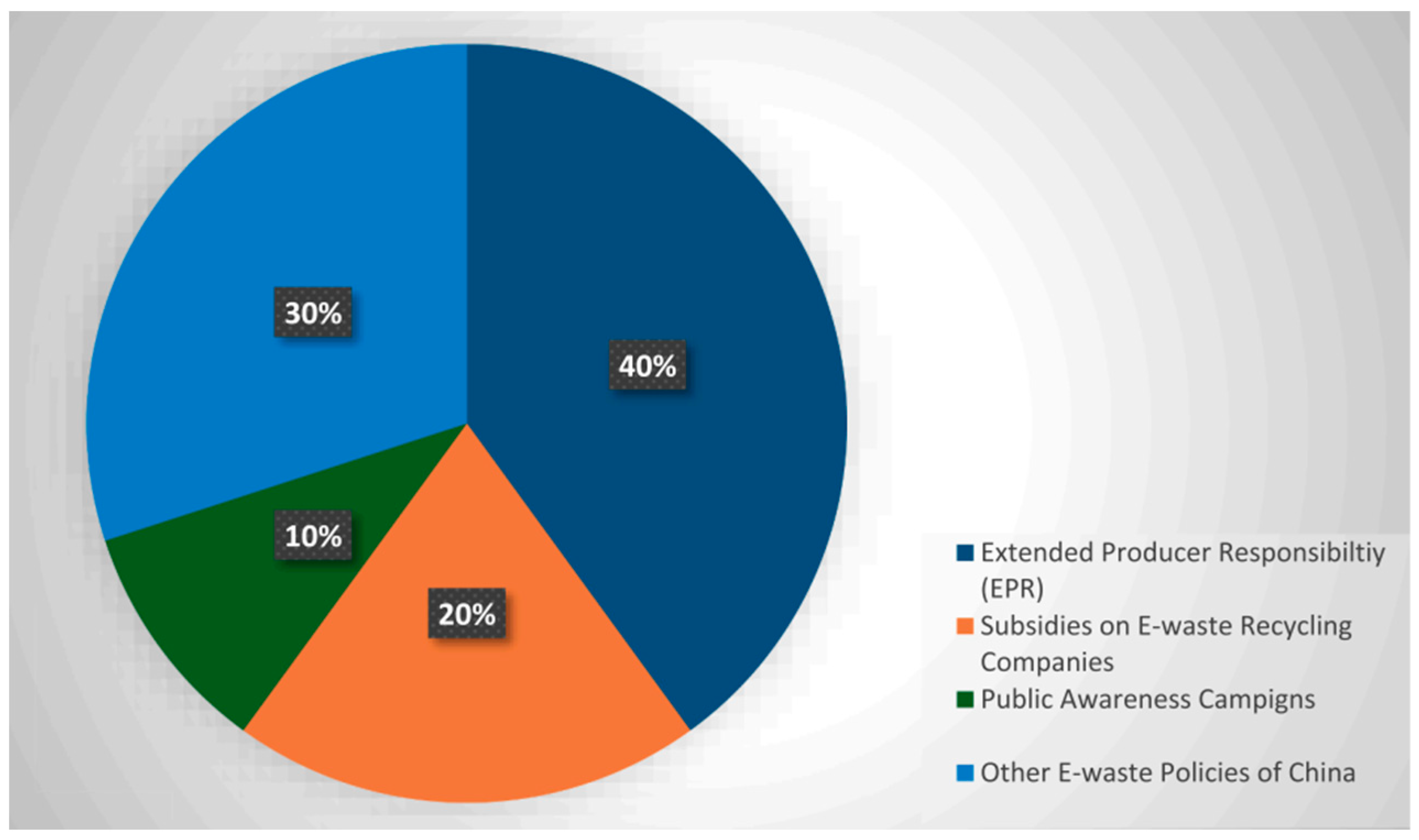

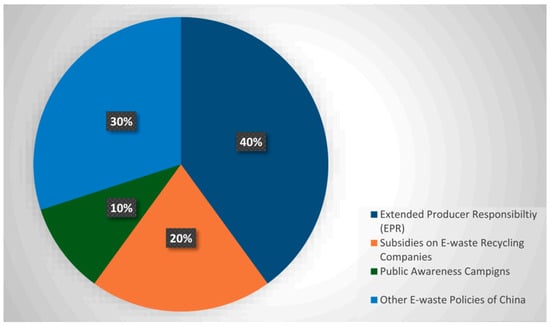

To illustrate global efforts, China, one of the largest producers of electronic waste, has implemented a multifaceted recycling strategy. This strategy breaks down expected recycling rates under various policies, highlighting that China does not rely on a single solution but rather a combination of complementary actions to address e-waste challenges effectively. Figure 4 shows the expected percentage of e-waste recycling based on the policies by China.

Figure 4.

Expected percentage of e-waste recycling by China’s e-waste policies [61].

Globally, numerous policies and industry recommendations have been implemented to address the growing challenge of e-waste pollution. The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal (BCCTMHWD), ratified by 189 countries, plays a critical role in curbing the export of hazardous waste to low- and middle-income nations, preventing unsafe disposal practices and the spread of harmful materials [61]. While the Basel Convention primarily focuses on restricting the global movement of hazardous waste, the WEEE Directives in the European Union provide a more detailed framework for e-waste management. These directives establish rigorous recycling targets for member states and mandate EPR, requiring manufacturers to oversee the entire lifecycle of their products, from production to end-of-life management. This approach ensures that both global and regional efforts work in tandem to reduce e-waste pollution through stringent accountability and sustainable practices.

The WEEE Directives have significantly reduced e-waste generation across the EU by enforcing strict penalties on non-compliant producers while establishing efficient collection and recycling systems. A key component of this success is the implementation of EPR, a policy approach that shifts the financial and operational responsibility of waste management from municipalities to manufacturers. Under EPR, manufacturers are accountable for the entire lifecycle of their products, from design and material selection to collection, processing, and recycling. This framework encourages eco-design practices, simplifies the recovery of valuable materials, and supports the transition toward a circular economy for electronics [61]. Additionally, the United Nations Environment Programme (UNEP) has played a significant role in global e-waste management by publishing comprehensive reports and guidelines on sustainable e-waste handling. UNEP’s Chemicals and Health Branch spearheads international collaboration for the environmentally sound management of chemicals and waste, ensuring global alignment with responsible recycling and disposal practices [33].

Retailers, manufacturers, and importers are obligated to accept used electrical and electronic equipment free of charge, even when consumers do not purchase a new device. Consumers, in turn, are required to return end-of-life equipment through proper channels, as disposing of such items through bulk waste collections or municipal solid waste is prohibited under the Ordinance on the Return, Taking Back, and Disposal of Electrical and Electronic Equipment (ORDEE) [33]. Effective e-waste management requires collaboration among governments, manufacturers, retailers, and consumers to develop comprehensive policies and programs. One such strategy is Extended Producer Responsibility (EPR), which holds producers accountable for the entire lifecycle of their products, from design and production to end-of-life disposal. By enforcing EPR policies, producers assume both financial and logistical responsibility for the collection and recycling of e-waste, driving the shift toward a circular economy while reducing environmental harm [91]. These programs not only encourage sustainable product design but also promote resource efficiency by recovering valuable materials and minimizing waste [92].

The Taiwanese government has implemented comprehensive legislation to regulate the responsible disposal and recycling of e-waste. These laws hold producers and importers accountable for the entire lifecycle of their products, requiring them to design goods with recyclability in mind, establish collection systems, and finance the recycling and safe disposal of e-waste [93]. The World Economic Forum’s Circular Transformation of Companies: Unlocking New Value in a Resource-Constrained World report emphasizes that achieving productivity, innovation, and sustainability improvements requires systemic change within industries. The rising global consumption of electronic devices, coupled with shorter product lifespans and limited repair options, has led to a surge in unwanted phones, laptops, and other gadgets. However, promoting e-waste reuse and recycling can support more responsible use of precious metals and minerals, aligning with the principles of a circular economy [93].