Abstract

Aggregates such as sand and gravel are the most mined resources on Earth and are the largest component in concrete. They are essential for construction but are becoming increasingly scarce. At the same time, large amounts of biomass ashes are produced in wood-fired power plants, offering potential as a partial substitute for decreasing sand resources. Due to the combustion technology of circulating fluidized bed boilers, their bottom ash offers high potential as a viable alternative to natural sand. This review examines previous research to assess the feasibility of replacing sand in concrete with bottom ash. Specific cementitious products are identified, where the substitution could realistically be performed in the concrete industry. Benefits and issues with partial substitution of bottom ash from wood combustion are discussed, and gaps in the research regarding sand replacements with bottom ash, notably the durability of the resulting concrete, are shown. Bottom ash has positive properties relevant for use in mortar and concrete, both regarding physical and chemical properties. Although limited research exists in the field, several researchers have demonstrated promising results when substituting sand for bottom ash in mortars. For lower substitution levels, little effect on the fresh and hardened properties is found.

1. Introduction

Although the environmental focus on concrete is usually a result of the heavy CO2 footprint of cement, there are also other sustainability issues related to concrete production. Sand only accounts for about 1% of the CO2 footprint of concrete [1], but constitutes a major issue in environmental protection, biodiversity, and depletion of natural resources [2].

Sand plays a key role in human civilization and is consequently one of the most exploited natural resources in the world, second only to water [3]. Approximately 50 billion tons of sand are produced each year, with the main user being the construction industry, with an estimated 30 billion tons of sand and gravel used as aggregates [4,5].

Concrete consists of cement, water, gravel, and sand, with sand constituting 25–40% of the concrete volume. As concrete is the most widely used human-made material with an annual resource demand of 30 Gt, sand for concrete is a driver of the depletion of global sand resources [6].

The issue is relevant globally, with illegal sand mining threatening vulnerable ecosystems in Asia, Africa, and Latin America [7], and resources being extracted faster than the replenishment rate [3]. Environmental effects of sand mining, when mining in rivers, point towards a reduction in fish populations, a decrease in biodiversity, and water quality [5].

The substantial research investigating alternative materials for concrete also implies a common understanding that sand resources are becoming scarce. Many alternative replacements to virgin sand are being suggested and researched [2,3,8,9,10,11,12].

Research in possible sand replacements are often based on whatever material is locally available, such as coal bottom ash in China [13], rice husk in India [14], sugarcane bagasse ash in Brazil [15,16], olive biomass ash in Spain [17]—along with globally available resources such as recycled concrete aggregates [18,19], municipal solid waste bottom ashes (MSWI) [20,21], and various industrial wastes [9].

This review will investigate woody biomass bottom ashes (BA), a regionally available resource in most of the world, and their suitability for use as a replacement for the natural, traditional sand in concrete.

1.1. Products with Potential for Sand Replacement with Wood Biomass Bottom Ash

The aim of this paper is to investigate whether wood bottom ash is suitable for use as sand in concrete, and which concrete products show the most potential for this objective. If specific, concrete products can be shown to be promising candidates for sand replacement, the likelihood of the utilization of BA will improve.

1.1.1. Suitability for Concrete Products

In Table 1, an overview of possible concrete products and their general characteristics is presented. A judgment of which concrete products are the most suitable is not made, since the current research does not cover this objective. See the forthcoming sections for a more detailed description of the concrete products and potential for sand substitution.

Table 1.

Overview of potential concrete products for sand substitution by wood bottom ash.

1.1.2. Dry-Cast Concrete (DCC)

Dry-cast concrete (DCC), also called zero slump concrete, is a technique where dry concrete is compacted to a degree where the formwork can be removed immediately after casting [22]. The method is used to make products like water and sewage pipes, paving stones, building blocks, and more.

Lessard et al. show that a DCC mix design with biomass BA is possible to develop, even if more compaction is needed to obtain the concrete to match the properties of the reference concrete without BA [23]. Their results showed a compressive strength reduction of 11.8% and 15.6% for replacement levels of 20% and 40%, respectively, at 91 days, which is higher than their stated requirement, but a noticeable difference from the reference with no BA.

1.1.3. Roller-Compacted Concrete (RCC)

Roller-compacted concrete (RCC) is a type of very dry concrete, like DCC, but compacted by vibratory rollers, similar or identical to asphalt rollers. RCC has a very low water and cement content, and a larger share of fine aggregate compared to regular concrete [24,25]. The use of BA in RCC has been demonstrated by Lessard et al., resulting in a loss of compressive strength of 18% at 50% replacement compared to their reference with no BA [26].

1.1.4. Pre-Cast Structural Elements

Concrete for pre-cast elements is generally in the high end with regard to quality, due to a high inherent production control. Elements such as walls, columns and slabs used internally in buildings are often not subjected to factors limiting the lifespan of concrete and are placed in lower exposure classes [27]. Their use as structural concrete still leads to high-quality requirements. Mix designs for pre-cast concrete are optimized for repetitive production, where workability and quick strength development for a fast demolding are desired properties.

For alternative materials to be utilized for structural elements, the raw material must be homogeneous. Experience with another alternative aggregate, recycled concrete aggregate (RCA), shows industrialization of alternative materials depends on managing the multiple varying parameters of the material. They ultimately influence the strength and durability of the final product [28], and for structural concrete, this means that strict quality control is necessary [29].

1.1.5. Tunnel Ballast Concrete

Ballast concrete is used in tunnels to counteract uplift forces from surrounding water by increasing the weight of a tunnel [30]. Another use is for leveling circular tunnels before the placement of rail tracks. It is usually placed as an unreinforced layer at the bottom of the bored or immersed tunnels [30,31]. A certain strength is required, but it is typically a low-strength concrete, and no further mechanical or durability properties are specified for ballast concrete.

These factors indicate a high potential for utilizing alternative aggregates to produce ballast concrete. Note that the use will be limited by the number of relevant tunnel projects in proximity to the ash production, which is likely low in most regions of the world.

No previous studies have analyzed ballast concrete and the effects of alternative aggregates on its properties, making a conclusive evaluation difficult.

1.1.6. Ready-Mix Concrete

Ready-mixed concrete is like pre-cast concrete but used for in situ castings at construction sites. It is delivered by concrete trucks, see the sketch Table 1 and poured into formwork on site. Requirements for this type of concrete vary greatly, since both reinforced and unreinforced concrete are used, high and lower strength, as well as for structural and non-structural applications.

The potential for incorporation of BA depends on the willingness of the concrete producers to incorporate alternative materials. This willingness will likely increase as sand resources decline and become more costly. As shown later in this study, the mechanical properties of the concrete might be affected by the incorporation of BA, but any negative effects can be reduced by reducing the substitution level.

1.1.7. Dry-Mix Concrete

Dry-mixed (or pre-mixed) concrete is a type of concrete consisting of various sub-groups. The common characteristic is that they are dry, pre-blended mixes with cement, aggregate, and admixtures delivered in bags. It is commonly designed for specific purposes, such as high-strength grouts, sprayed concrete (shotcrete), or mortars [32]. Admixtures in dry form can adjust the properties of the mix to be self-compacting, non-shrinkage, pumpable, or other specific needs [32].

As with pre-cast and ready-mix concrete, the high-end products have strict requirements for strength and durability. Lower-end products are likely simpler to incorporate alternative aggregates in, such as BA, as the demand for homogeneity of the materials will be lower. No previous studies have been found to have analyzed this specific type of concrete, making a conclusive evaluation problematic.

1.2. Production of Ash and Availability of Raw Material

Global biomass ash production is estimated at 95 million tons globally in 2018 [33]. The global concrete production in 2020 was 14 billion m3, roughly equivalent to 30 billion tons, which requires roughly 12 billion tons of sand. These assumptions lead to an amount of ash less than 1% of the sand used for concrete. Assuming a small amount of the ash produced is usable as sand, the case can be seen as a niche product in the concrete world.

However, as disposal and landfilling of ash is costly, and the cost of sand is increasing, there is economic potential for both concrete producers and ash producers to benefit from the utilization of ash as sand substitution. This creates a business case that can prove sustainable for both parties, as well as for the environment. In this way, the potential shown in this paper represents one of the many needed solutions to provide alternative aggregate materials for concrete, all of which are needed to reduce our strain on the environment.

1.3. Combustion of Biomass

The use of biomass, mainly in the form of wood, to produce heating and energy via combustion is expected to increase both within the European Union [34] and globally [35].

The EU considers sustainably produced biomass to be a renewable energy source [36], giving the member countries an incentive to utilize energy crops, forest wood, agricultural waste, etc., in their effort to reach their goals for CO2 emissions. As a result of the CO2-neutral status, as well as the domestically available resources in the member countries, the EU will rely on biomass as one of the main energy sources to achieve net-zero emissions by 2050 [34].

Since many types of biomass can be used in energy production [37,38], it increases the possibility for countries to diversify their energy system. The advantages are lower supply risks and higher self-sufficiency through lower fossil fuel imports, as 96% of biomass demand is supplied by biomass sourced within the respective countries in the EU [36].

Proponents of natural biomass argue that the loss of biodiversity due to the removal of old-growth forests damages the environment [39]. Research also suggests that biomass is only CO2-neutral in the best-case scenario of completely regrown forests, and that transient CO2 emissions are ignored [40]. However, due to the low cost and good synergy with other renewable energy sources, electricity and heating from biomass combustion remain a stable energy source in many countries and will be for many years to come [35]. The global production of biomass ashes was estimated to be 480 million tons in 2013 [37] and can be expected to continue due to the shift away from fossil fuel combustion [38].

1.4. Bottom Ash

A by-product of the combustion process is ash in the form of fly ash and bottom ash. Fly ashes are fine powders collected from the flue gas, while bottom ashes are the coarser fraction collected from the bottom of the boilers. The most prevalent type for smaller power plants is grate-fired boilers, where the fuel is piled onto a steel grid during combustion. Another common type is the Bubbling Fluidized Bed (BFB), where the bottom of the boiler is covered by a layer of sand, where air for the combustion is injected from below, causing to bed material to ‘bubble’.

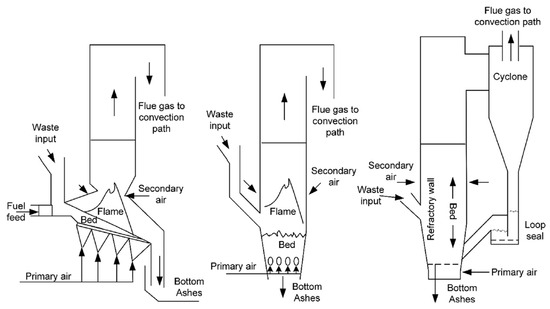

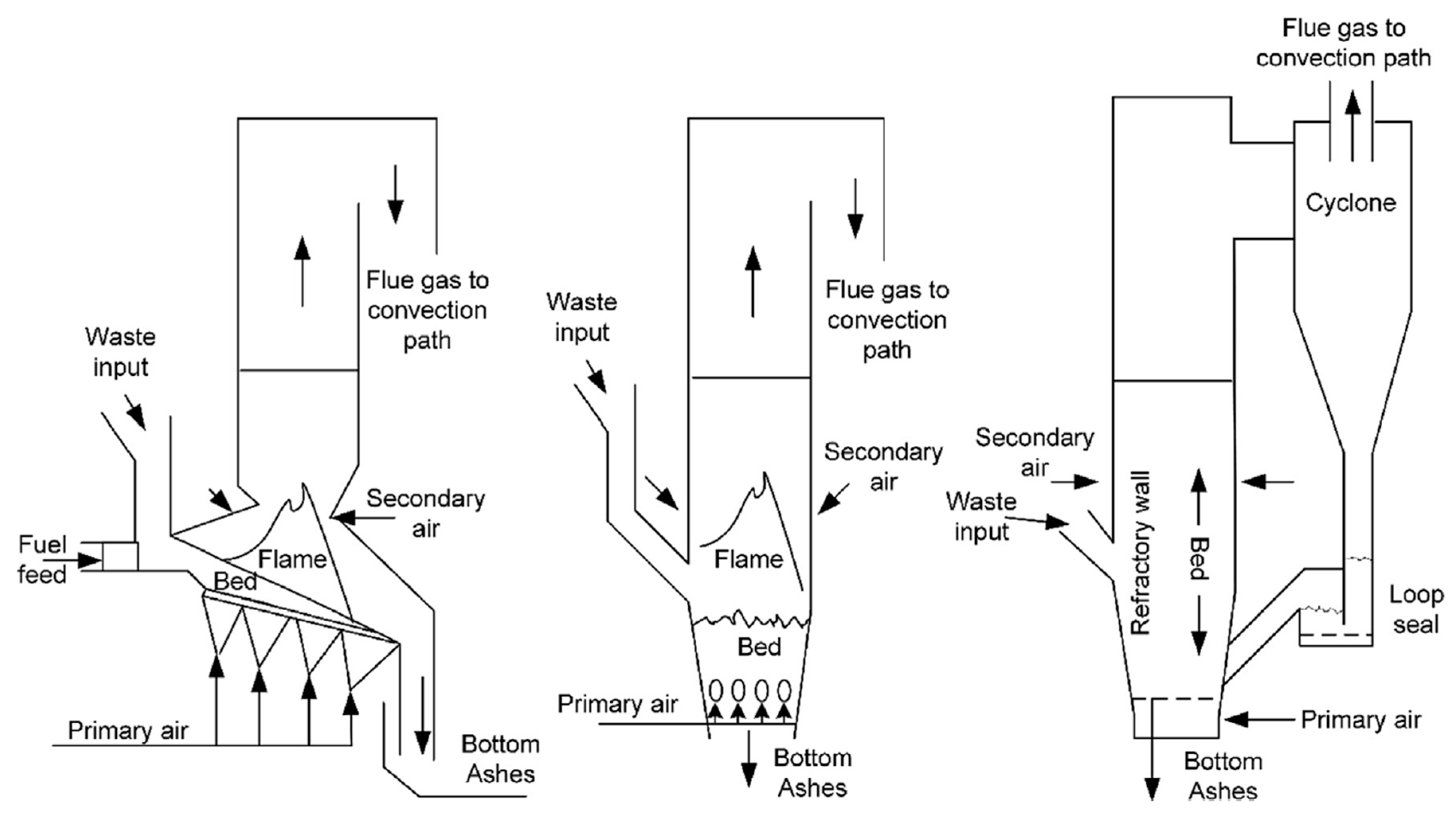

A common type of boiler for large, combined heat and power plants is the Circulating Fluidized Bed (CFB) boiler, where the feedstock requires a simultaneous feed-in of fine sand with the fuel to increase the efficiency of the boiler [41]. This sand is separated in a cyclone, and either fed back into the boiler or discarded as BA. See Figure 1 for illustrations of the combustion technologies.

This paper will analyze the prospect of utilizing ash from a circulating fluidized bed (CFB) boiler. It is a boiler chosen by energy companies due to its high fuel efficiency and flexibility regarding fuel quality and moisture content. Compared to the bubbling fluidized bed (BFB) boiler, CFB has a much higher internal air speed, creating a sandstorm within the boiler, which leads to a stable and even temperature in the entire boiler, and a very complete combustion [42,43,44].

Figure 1.

Illustration of a grate-fired boiler, a BFB, and a CFB. Source: [45].

Figure 1.

Illustration of a grate-fired boiler, a BFB, and a CFB. Source: [45].

Bottom ash is a waste product that is currently underutilized and poses an economic burden for the producers, and is a material that will increase in volume in the future [38]. Several opportunities for the utilization and valorization of BA have been researched, with BA suggested as a suitable replacement for aggregates in concrete, as seen in recent years [46,47,48,49].

Other areas of utilization have also been researched, e.g., as material in asphalt [50], cement replacement [51], soil improvement [52], bricks [53], and structural soil under roads [54]. Current usage is mainly as a low-grade fertilizer, but a large part is landfilled [52,55,56].

1.5. Combustion Technologies Compared

As explained in the previous section, combustion technologies have different technical characteristics, resulting in ashes of varying composition. Table 2 lists the characteristics of the three most common boiler types for wood combustion.

Table 2 shows the most common boiler types for wood combustion. Information in the sources is aggregated by the authors of this paper to provide a simplified overview of the characteristics of the three boiler types.

The BFB has a lower air inlet speed, and the bed material stays at the bottom of the boiler. The CFB boiler is developed from the BFB to have an advantage in the scalability of the plants, and sizes can reach up to 2000 MWth, compared to 10–100 MWth for BFBs.

The use of quartz sand or silica sand as bed material leads to high SiO2 levels in bottom ashes from both BFB and CFB boilers, making it potentially suitable for use in concrete [57,58,59,60].

The quartz sand used in CFB boilers is generally finer than in BFB boilers, commonly in the range 0.1 to 0.6 mm. This particle size distribution is smaller than the typical 0–2 mm or 0–4 mm of fine aggregate fraction in concrete, but is optimal for an efficient combustion and heat distribution within the boiler [43,61,62,63]. A change towards finer grading generally leads to lower workability and lower concrete strength [49,64]. It is thus a critical parameter of a given sand replacement and must be determined before use in concrete and mortar applications.

Some research shows abrasion of the bed material particles during combustion, due to their high velocity within the boiler, causing the particles to crack and become more rounded [65]. Studies analyzing bed material before and after combustion observe the particle size to be reduced [66], and SEM images reveal surface cracks and increased brittleness [67].

Table 2.

Characteristics of the boiler types chosen for comparison in this review.

Table 2.

Characteristics of the boiler types chosen for comparison in this review.

| Boiler Type | Circulating Fluidized Bed—CFB | Bubbling Fluidized Bed—BFB | Grate |

|---|---|---|---|

| Biomass fuel | Solids, powders | Solids, sludges | Solids |

| BA particle type | Bed material | Bed material | Agglomerates |

| Advantages | High efficiency Fuel flexibility Scalability | High efficiency Fuel flexibility for biomass fuels | Simple construction Low initial cost Low operating cost |

| Disadvantages | High initial cost High operating cost Agglomeration of bed material | High initial cost High operating cost Agglomeration of bed material | Low efficiency Slagging Emissions (NOx) |

| Production stability | High | High | Low |

| Initial cost | High | Medium-high | Low-medium |

| Operating cost | High | Medium-high | Medium |

| Size (thermal output) | Medium to large (30–1000 MW) | Medium (20–400 MW) | Small to medium (1–100 MW) |

| Operating temperature | 750–950 | 650–920 | <1100 |

| Sources | [41,43,68,69,70,71] | ||

A fraction of the BA is recycled as bed material after it has been discarded from the cyclone, and the other fraction is discarded to be disposed of by the plant owner. A drum sieve removes the largest fraction of particles from recirculation. The process of recirculating material reduces the consumption of virgin sand, and consequently also lowers the unburned carbon by recirculating unburned particles through the boiler. High-efficiency cyclones separate the coarser fly ash particles to be recirculated, further lowering the total organic carbon content (TOC) to the benefit of the boiler [61], but also improving the material for further use. Lower TOC leads to purer and more homogeneous material and improves feasibility for use in concrete [41].

For combustion of biomass, there is a tendency for agglomeration of the ash and particles in the bed material, which leads to the BA being partly composed of porous agglomerated particles with varying sizes [72,73]. This issue is prevalent for biomass fuels in general [74,75] but is less prevalent when wood chips are used as fuel [76].

The effect occurs when alkali metals from the fuel, mainly N and K, react with silica in the bed material to form alkali silicates—an effect seen at higher temperatures, and as low as 900–1000 °C [62]. Agglomeration is also an issue for fluidized bed boilers, but is reduced by the lower combustion temperatures—see Table 2.

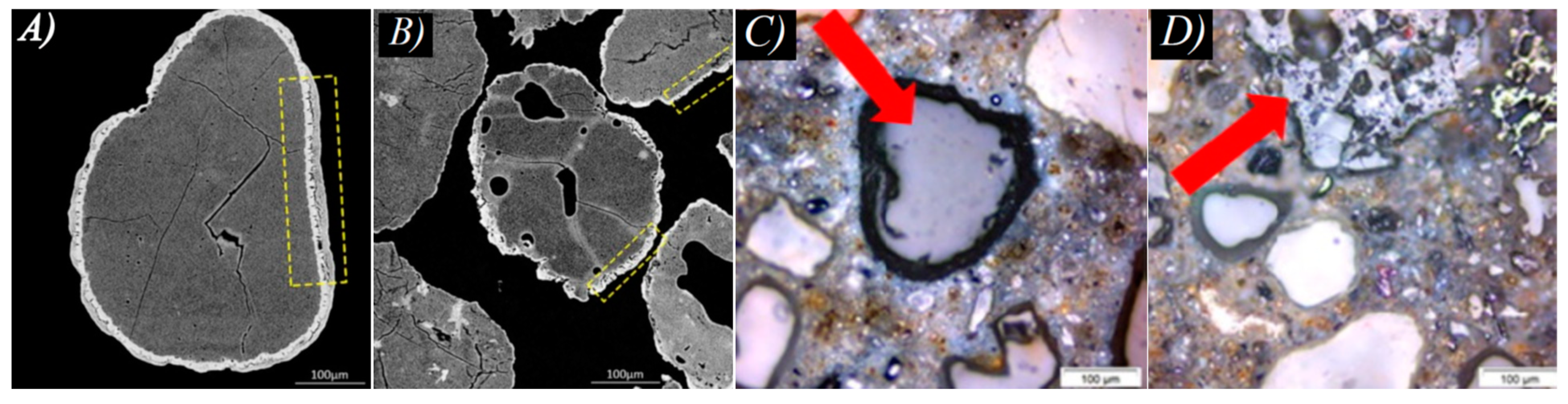

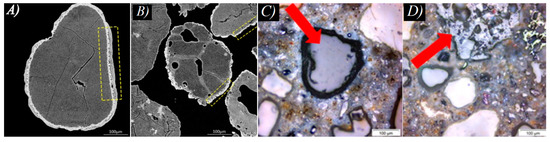

Figure 2A,B, the BA from a BFB and a CFB furnace can be seen. When comparing microscopy images of the particles, the agglomerated type can be seen in Figure 2C,D, which show the difference between BAs from fluidized bed boilers and grate-fired boilers. The CFB and BFB ash are fine sandy particles with some air pores and a shell-like layer on the surface. The sand particle is more homogenous, and lastly, the agglomerated particle from the grate furnace can be seen.

Figure 2.

(A) is BFB BA, (B) is CFB BA. Note the lighter colored surface layer on both particles and the internal cracks. (C) is a sand particle, and (D) is an agglomerated particle from a grate furnace. Sources: (A,B): [77], (C,D): [78]. The yellow markings on (A,B) can be ignored, as they stem from the original source. The red arrows on (C,D) point towards the sand particle and the grate BA particle, respectively.

The EU considers the BFB and CFB boilers “best available technology” for biomass combustion [43], and could thus be expected to become more widespread.

1.6. Environmental Potential and Issues

As mentioned in the previous sections, there is a combination of sand scarcity and a possible supply of replacement material. Every ton of ash can potentially replace a ton of natural sand, which presents a possible contribution to reducing the strain on natural resources. One study shows that the environmental potential of ash is greatest if used in building materials [79].

Heavy metals are well known to accumulate in biomass ashes, which creates a possibly polluted material not suitable for use in construction materials—see Section 3.3. The alternative use of the ashes as a low-grade fertilizer has the same issue, making a costly landfilling of the material the most common method of disposal [52].

Another issue is the rebound effect, where the positive environmental effects of utilizing the BA could be negated by an increased burning of biomass, since BA has become a valuable resource as sand replacement [80]. In this case, BA incurs a negligible cost in the overall economy of a power plant, and the rebound effect will not materialize as an increased combustion of biomass. The same conclusion is then logically reached when considering the possibility of an increase in the transport of biomass for fuel.

1.7. Aim of Current Review

The CFB BA is mainly discarded bed material, which is most commonly sand. This coincides with an increased shortage of locally available concrete sand in several regions of the world [81]. This presents the potential to save sand and increase the value of BA by partial replacement of sand with biomass BA.

This review focuses on works detailing the characteristics of biomass BAs from CFBs burning forest residue, wood chips, and other wood products, to investigate the potential in this promising segment. This will help mitigate the issue of BA’s varied composition caused by varying combustion and fuel types, as shown by previous reviews [48,49,82,83,84], by focusing on a more homogeneous material. CFB ashes are compared with the two main BA types, which are produced in BFB boilers and grate furnaces, respectively.

2. Requirements for Concrete Types and Exposure Classes

For alternative materials to be used in the concrete industry, they must fulfill the requirements given in the place of use. In a European context, the European standards, recognized by the EN prefix, provide the framework for the required properties of the concrete constituents. According to the EU, BA from wood combustion is considered non-hazardous waste [85]. Since ashes are not normally used as aggregates, the current standards do not have specific requirements suited for this application. However, in EN 450–1, a collection of requirements for fly ash is given [86]. Some of the requirements are directly related to its efficiency as a replacement for cement and are not relevant for a sand replacement. Other requirements seem relevant to use as a general guideline for determining suitability for using ashes in concrete. Since a negative impact from, e.g., high LoI or sulfate is expected for a cement replacement like fly ash, it would be relevant for a material replacing aggregate as well. ASTM C618–23 also provides limit values for fly ashes [87] and has a similar but less restrictive set of requirements—see Table 3 for an overview.

Table 3.

Properties of various ashes in comparison with EN 450–1 and ASTM C618-23 requirements.

Free CaO is formed at temperatures over 900 °C, and is thus, as expected, more prevalent in the grate ashes [57,93]. CaO and MgO are undesired for their ability to create a late expansion in concrete [64].

First, the standard for structural concrete EN 206 (Section 5.1.3 of the standard) determines that aggregate must comply with EN 12620 [94]. Per the definition in EN 12620, BA must be considered a manufactured aggregate, as it is “derived from an industrial process involving thermal modification” [95]. It is defined as fine aggr1egate, due to the aggregate size of less than 4 mm.

As the subject is a type of ash, it is also relevant to look at EN 450-1, a standard for fly ash from coal combustion used as a cement replacement [86]. According to these standards, it is possible to utilize BA as a fine aggregate. In the next sections, more detailed requirements regarding geometry, durability, and other properties will be explored.

Another option is to determine the equivalence of performance with a known satisfactory aggregate, where testing must be performed with the BA to show that durability, strength, and other properties are at a satisfactory level. This method can be costly and reduce the incentive of the industry to utilize the material, making direct approval via the standards the preferable option.

2.1. Geometrical Requirements (Grading)

Requirements for grading, such as the percentage passing different sieve sizes, are a critical parameter for concrete sand. However, the BA is produced in relatively limited quantities where substitution levels below 10% are likely—see Section 1.2. This means that the BA will have a negligible effect on the overall grading when blended with natural aggregates before use, given the specific material has a grading that is within a certain threshold, and is not too fine, e.g., dust. The total sand fraction must then comply with the grading requirements seen in Table 2 in EN 12620 (see also Section 3.4). EN 12620 does not give a specific requirement for the grading curve, but the American standard ASTM C33 does provide an interval for which fine aggregate must comply [96].

2.2. Fines, Physical, Durability, and Chemical Properties

Specific requirements in the European Norm EN 12620 are mainly for which properties that are relevant for fine aggregate, and how they must be tested to conform to the standard. Drying shrinkage must be equal to or less than 0.075%, and total sulfur must be equal to or less than 1%, but the remaining physical and chemical properties are stated as ‘shall be determined’. These requirements depend on Annex ZA in EN 12620 [95].

Annex ZA provides the EU member countries with flexibility to determine which requirements are relevant for constructions in their country. The requirements are thus dependent on the national specifications. An example of such national requirements is the DS 206:2024 in Denmark [97]. It states, using ASR as an example, which tests must be used, and what the specific requirements of the tests are, when assessing whether or not the aggregate is acceptable for use in Denmark.

The concrete producer must gain a CE mark for their product by following EN 12620 and the relevant national annexes.

3. Characteristics of Wood Bottom Ash

The composition of biomass BA depends mainly on the combination of fuel and combustion method. In this paper, the focus is on wood as fuel and combustion in BFB, CFB, and grate-fired boilers.

This section will present the physical and chemical properties of the ashes, along with other characteristics relevant to alternative sand materials in concrete.

3.1. Mineral Composition

In CFB and BFB boilers, the chemical composition of BA is mainly SiO2, with smaller amounts of CaO (Calcium oxide), Al2O3 (aluminum oxide), MgO (magnesium oxide), K2O (potassium oxide), and other oxides when analyzing the ash via XRF [56]. A significant amount of Fe2O3 (iron oxide) can also occur [51]. Note that the chemical composition is calculated as oxides in an XRF analysis, but the elements are not necessarily present in their oxide form. This is especially important for BFB and CFB ashes, where the silicate is mostly non-reactive bed material, and should not be confused with amorphous silicate such as silica fume (microsilica), which can act as a supplementary cementitious material, or in some cases cause ASR damage [98].

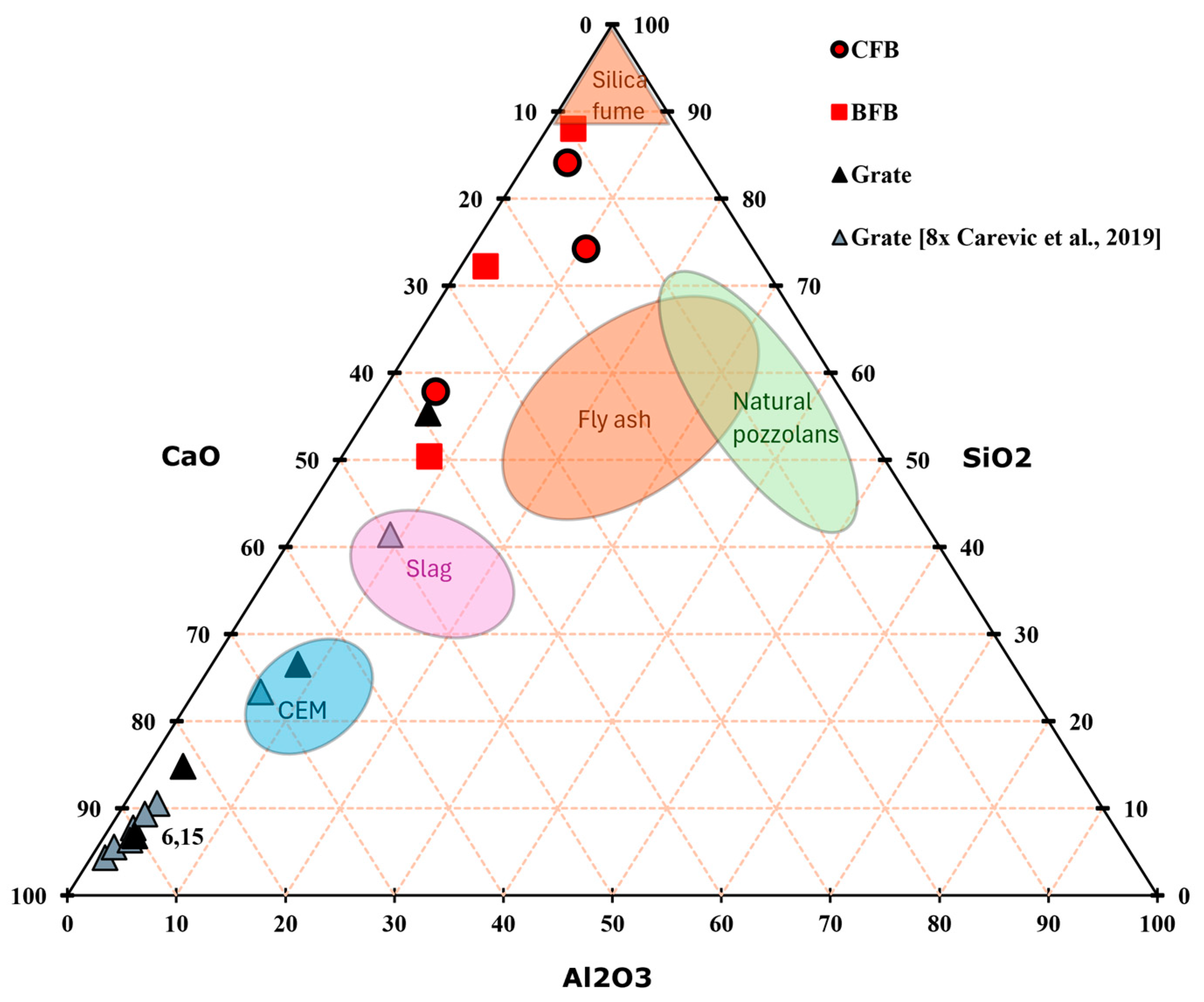

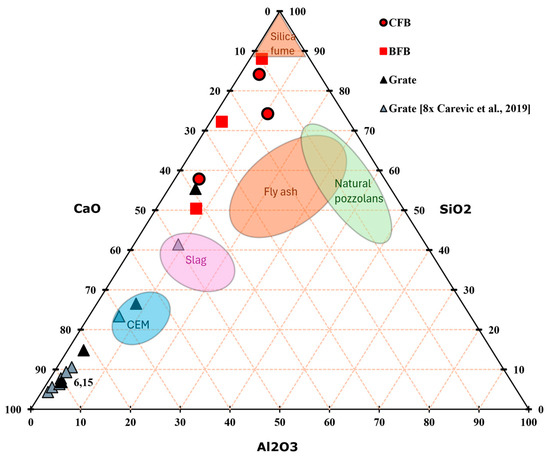

As shown in the SiO2-CaO-Al2O3 ternary diagram Figure 3 the composition of CFB tends to be grouped around the corner with high-silica contents. The ternary diagram is based on the characteristics of Supplementary Cementitious Materials (SCM) analyzed by Lothenbach, Scrivener et al. [99].

Figure 3.

Chemical composition of different ash types. Fuel is wood (whole trees, trimmings, waste wood, etc.). Sources: CFB [51,88,89], BFB [51,67,90], Grate [11,91,92], and 8 samples (B1-B8) from [51]. SCM-zones adapted via Lothenbach et al. [99].

As seen in Figure 3, there are tendencies in the ash composition when separating by combustion technology. For grate BAs, there is a clear trend towards a higher CaO content, making it more like Portland cement than CFB and BFB ashes, but not necessarily more suited as an SCM, as shown in the studies by Sigvardsen et al. [51,100]. The same ternary diagram is shown in the review by Schlupp et al., where the tendencies are similar when accounting for combustion type [49].

Zhai et al. also created a similar ternary diagram, but with a focus on the different types of fuel. In this figure, wood ashes are varied in composition, however, mostly based on their CaO content [38].

Pozzolanic Potential

In research regarding ash as a substitution for cement, a high level of pozzolanic activity is desired. However, when replacing sand, an inert chemical composition is needed. CFB BA from the combustion of wood chips has the highest content of primary oxides of the analyzed ashes in one paper [51]. This could indicate potential for pozzolanic activity, but as the inert sand in the bed material mainly consists of SiO2 in the form of sand, it is not expected to be reactive. A low amount of aluminosilicate particles indicates no expected pozzolanic activity. Regarding hydraulic activity, the same paper gives the CFB BA the lowest index score, indicating little ability to form cementitious products.

In another study of hydraulic activity, CFB BA showed less activity compared to grate furnaces and BFB boilers, providing conflicting and limited information on the matter [101].

3.2. Physical Properties

In Table 4, some of the most relevant properties when considering sand alternatives for concrete are presented. Absorption is higher than natural sand, which is commonly around <1%, in all cases. On the positive side, two sources show no loss on ignition, and the density of the ashes is relatively high.

Table 4.

Physical properties of different bottom ash types.

As implied by the lack of data in Table 4, the BA from CFB boilers requires further investigation. Information such as the absorption and density, two important factors for aggregates, is scarce in the literature. Table 4 indicates a density of the ashes that is lower than the sand, but, in general, around the density of regular concrete of 2000–2600 kg/m3 [94].

As seen in Table 4, grate bottom ashes have a higher LoI than the BFB and CFB ashes. Generally, as low a value as possible for LoI is desired. High LoI indicates a high content of carbon and/or organic matter, which affects concrete negatively by increasing water demand and reducing the stability of air entrainment agents [64,78]. LoI is low for ashes from fluidized beds, compared to other ashes [105], due to a more complete combustion of the feedstock. TGA analyses also show the same tendency, with the mass loss represented in several papers indicating a good burnout of the fuel, and a relatively pure ash [60,102]. The comparable properties of natural sand from different sources are also presented in Table 4, highlighting the differences and similarities between the materials. This table considers wood-fueled BFB/CFB/Grate boilers—a wider perspective can be found in other reviews [9,48,49,84,105,106,107].

3.3. Heavy Metals and Leaching

Some ashes are considered hazardous waste due to the heavy metal content, which makes it impossible to classify them as a component in construction materials [37]. For biomass BA, with code 10 01 01 in the European Waste Catalog [108], the EU considers biomass BA to be absolutely non-hazardous [109]. However, for the sake of analysis, the following analysis of leaching results with wood BA is compared with EU limit values.

Leaching values declared by the EU can be seen Table 5. Limit values are given in the council decision of 19 December 2002 [110].

Table 5.

Limit values for non-hazardous waste, expressed as mg/kg dry substance at L/S ratio of 10.

When comparing the concentration of heavy metals in eluates from grate furnace, BFB and CFB bottom ashes, these limits are not exceeded frequently—see the bold text-values in Table 6. Note that the same paper presents high Cr, Cu, Ni, Pb, and Zn values, which currently appear to be outliers compared to the remaining sources [101].

Table 6.

Concentration of elements in leaching eluates (EN 12457-2, L/S = 10 [111]) in percentages of the allowed limit for construction materials in the EU.

In general, the bottom ashes from all three types of boilers have relatively low heavy metal content compared to the relevant EU directive [110].

Compared to the fly ash fraction, BA differs by generally containing lower amounts of heavy metals [57,115,116,117,118]. This effect stems from the lower temperature of the flue gas where the fly ash is extracted (140–200 °C), compared to the temperature of the extracted BA (800–1000 °C) [119], meaning the volatile metals turn to vapor-phase and are extracted before they condense on the fly ash [70].

Highly volatile heavy metals such as Zn, Pb, Cd, and Hg show a distribution of 2.6 to 11.1% in the BA, with the fly ash containing the remaining majority fraction. For the least volatile heavy metals, Co, Ni, Cr, and V, the BA contained over half of the total content in the ashes.

Regarding Zn, some research concludes that it binds to the silica in the bed material and is expelled with the BA [62,120].

Apart from the low heavy metal content, research indicates that casting heavy metals into concrete reduces the leaching effect by binding them in the concrete [121,122], and that no additional leaching can be seen in biomass ash concretes compared to a reference concrete [123].

3.4. Morphology

Bottom ash is considered suitable for aggregate in concrete, as it has a similar granulometry to sand. It is finer and less well graded than optimal for use in concrete, enabling only partial substitution, as seen in the combined particle distribution graphs presented in the literature [49,84].

In Table 7, mean particle sizes of the three combustion technologies are presented, i.e., the size where 50% of the particles are smaller. There is no discernible difference between the combustion technologies for this parameter. For the BA samples with a finer grading, e.g., seen in Table 7 at 51–300 µm, the grading deviates significantly from regular sand, reducing the possible substitution level to a minimum. The grading of a given BA from a power plant is simple, and this aspect of the suitability for use in concrete can thus quickly be determined.

Table 7.

Mean particle size of wood bottom ashes, sorted by combustion technology. Values rounded to exclude decimals.

The shape of the BA particles, when analyzed by Scanning Electron Microscopes (SEM), generally shows sand-like particles with round edges, with a surface containing microfines or a generally rough texture, which could further reduce workability [56,60,89]. In some cases, the combustion process can cause wear and tear and reduce the particle size [66,102].

To increase the workability, it is possible to add plasticizers to the mix, which is performed with good results in several research projects, to keep the workability intact with increased substitution levels of ash [48].

4. Bottom Ash as Replacement of Fine Aggregates in Concrete and Mortars

This section will summarize research within the field of BBA used to replace natural fine aggregate. Much of the research is conducted using BBA from other types of furnaces than BFBs or CFBs. The BA particles in these cases are often melted and agglomerated particles, joined by the K2O content or by melting together in the combustion process. This results in a structurally weak aggregate with high water absorption and high alkali content [125]. Using these to replace natural sand leads to a poor performance of the concrete, worsening with increased replacement levels, seen in numerous studies [11,46,91,92,104]. As summarized in the sections below, there is potential to develop concrete with BA as a partial substitute for sand.

4.1. Strength

A relatively low amount of research has been carried out regarding CFB BA as an aggregate replacement. Research regarding bottom ashes in concrete mostly focuses on cement replacement, and the research that is made within aggregate replacement is often based on BA from grate combustors. In the review by Cabrera et al. [82], most sources use BA from grate-fired boilers, and fuel type is used as a sorting parameter. A recent review by Schlupp et al. [49] shows that combustion technology has a significant influence on the characteristics of BA, as also indicated by this paper. It could then be deduced that both fuel type and combustion technology should be used to give an early indication of the parameters of the BA.

Both studies show that in most cases, all hardened properties of concrete and mortar, including density, stiffness, flexural strength, and compressive strength, are reduced to some extent with the incorporation of BA as sand or filler. A review by Nascimento et al. also confirms the trend [48].

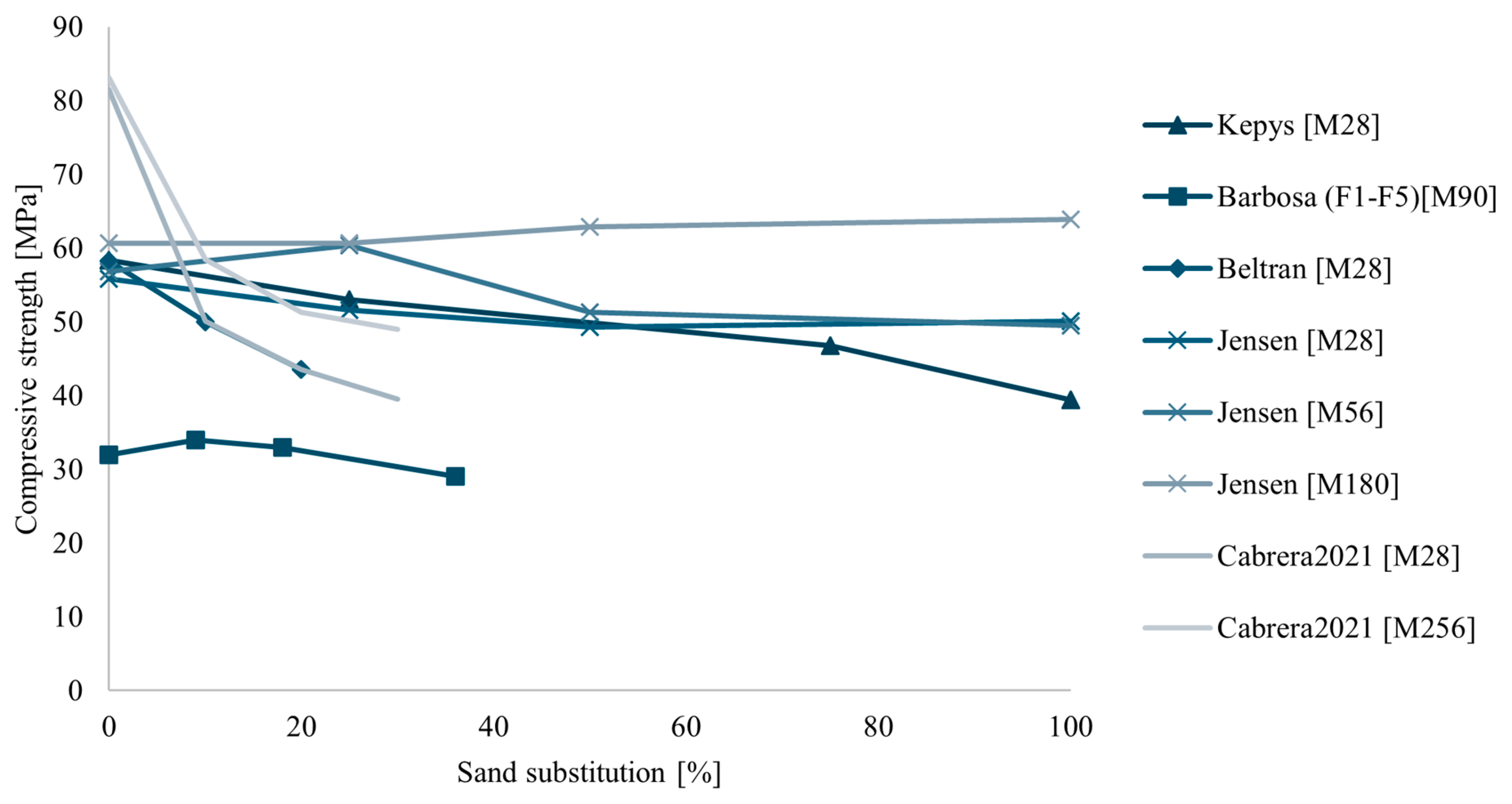

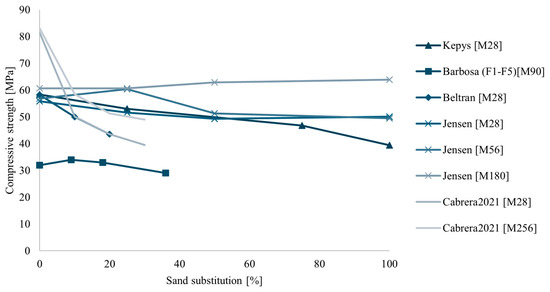

The limited literature can be compiled when wood bottom ashes, specifically, are researched as a substitution for sand in mortar or concrete. As such, Figure 4, showing the compressive strength as a function of the sand substitution rate, contains too few sources to make general conclusions. However, it is noticeable that most mixes—whether based on grate, BFB, or CFB bottom ashes—experience a reduction in strength with the inclusion of BA, as also anticipated based on the mentioned reviews.

Figure 4.

Compressive strength of mortars in the literature. Note that variations such as cement type, mix design, pre-treatments, etc., are not accounted for in this graph. All ashes are from the combustion of wood or forestry. Maturity shown in square brackets [MX]. Sources: [46,88,104,123,126].

Outliers can be seen, however. Barbosa et al. found a slight increase in strength at 9% and 18% replacement with BFB BA when tested at 90 maturity days [123]. The 28-day maturity strength also increased at 18% and 36% substitution, relative to the lower replacement levels. In the conference paper by Jensen et al., their mortar mix at 180 maturity days also shows a slight increase for 50% and 100% sand replacement for CFB BA [126].

Data are excluded when the method of substitution is based on ash volume. Due to the lower density of BA, the relative cement content by weight in the mix will increase. It is noted, however, that some results show an increase in strength with increasing substitution levels [68].

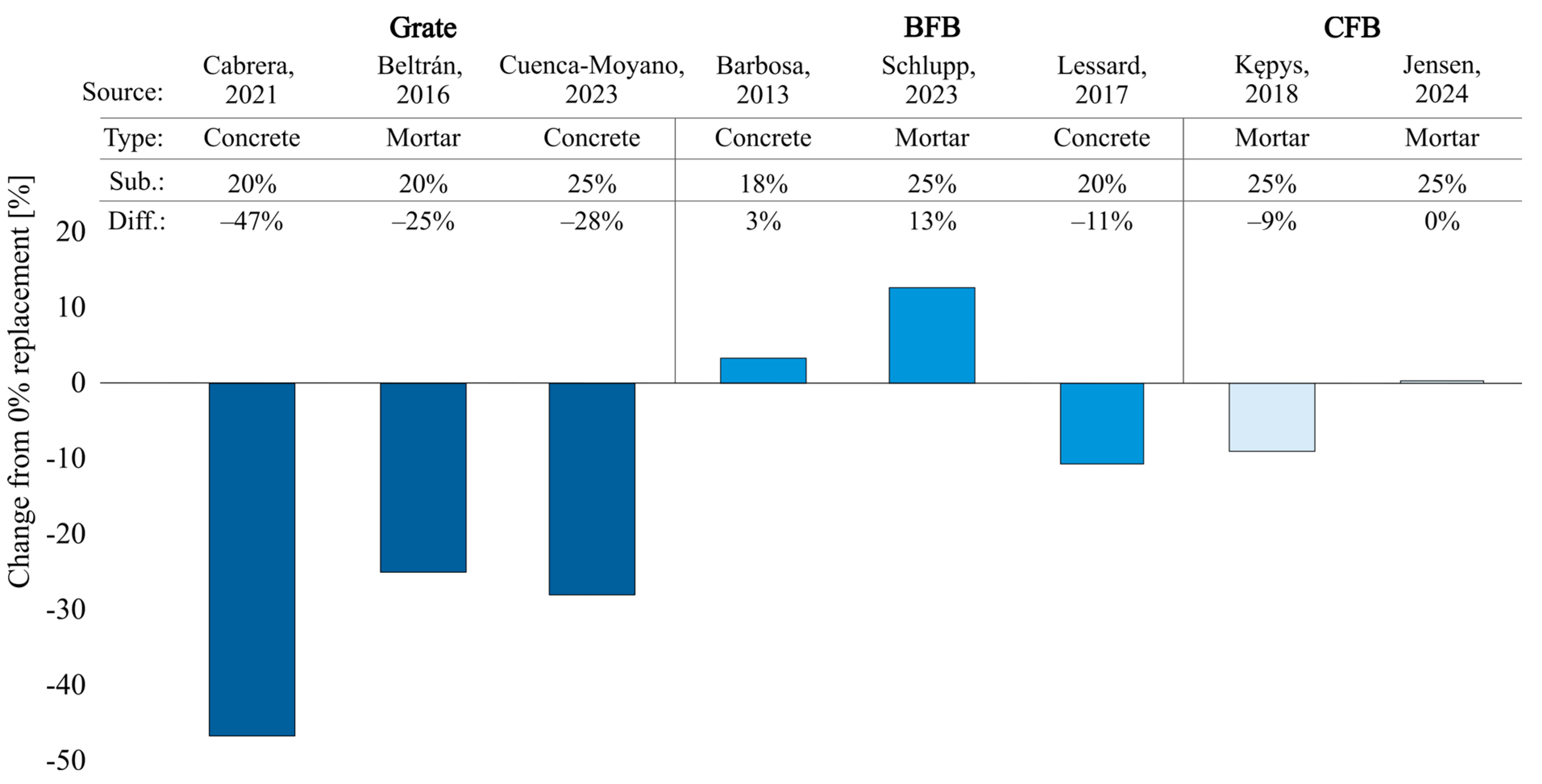

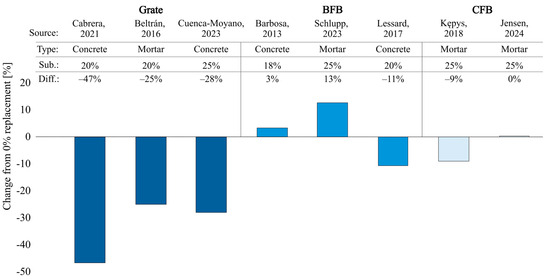

In Figure 5, the data are sorted by combustion type and analyzed as the relative change in compressive strength from the reference with 0% substitution to a substitution rate between 18 and 25%. Again, there is limited data about sand replacement with bottom ash, but the visualization in the figure is compelling. The data shows a tendency towards small variations from the reference sample at a relatively low substitution level. It is also shown that grate furnaces produce a bottom ash that is, as also evident by the previously presented physical properties, less suitable for use in concrete and mortar.

Figure 5.

Relative strength of mortars with a replacement ratio of 18–25% of wood BA, organized by combustion technology. Sources: [17,23,46,67,88,92,123,126].

4.2. Durability

The literature on the effect of BA substitution on concrete durability is limited. As mentioned in the review by Schlupp et al., there are dispersed results on chloride ingress, carbonation, and shrinkage, all showing a negative effect of BA. Many researchers have found that increased contents of BA will inevitably increase the porosity and water absorption, and lower the density of the mortar and concrete specimens—a clear indication that many durability parameters will also be reduced.

Durability of concrete is dependent on the environment in which it is placed, and in cold climates, the freeze–thaw resistance is critical. Again, there is no research on this subject, but also no indication from the previously mentioned properties that this durability aspect will be worsened using BA.

Alkali–Silica Reactions

Another regionally dependent durability aspect, in this case based on the raw materials used in the concrete, is the risk of alkali–silica reactions (ASR) or alkali aggregate reactions (AAR).

Alkali–silica reactions in concrete, shortened ASR, is a reaction between water, reactive aggregate, and alkalis that causes expansion and cracking within the hardened concrete. For ASR to occur, all three elements must be present, along with a high pH value.

Alkalis in concrete stem from sodium (Na) and potassium (K) in the cement, additives, and aggregate, with the total content expressed in Na2O equivalents. Total alkali content is calculated as in accordance with EN 196–2 [127].

The risk associated with bottom ashes replacing natural aggregates is the potential alkali content and reactive aggregate, such as porous opaline flint and other siliceous aggregates. The threshold of the total amount of alkalis in the concrete is 3 kg/m3.

Regarding the alkali content in biomass bottom ashes, several sources have investigated issues with K-content in the ash and bed material. The silica sand binds alkalis, which causes slagging and agglomeration of particles, increases corrosion in the boiler, and reduces the efficiency of the power plant [44,75,76,128]. Research shows that reactive alkali metals accumulate in the BA and bed material, with K-content increasing linearly as a function of operation time of the furnace, for various woody biomass fuels [74]. Vapor-phase K reacts with quartz sand to accumulate on the surface of the bed material particles, which are in the coarse ash fraction [62,129,130].

It is not known whether the K-content is chemically available to contribute to ASR (i.e., soluble), as the articles focus on the agglomeration of the ash particles. Acordi et al. see some expansion with their grate BA, where the expansion is very low, indicating no harmful reactions [78].

The producer of the material must ensure that the deleterious reaction does not occur in concrete, using tests such as ASTM C1260/C1293, RILEM AAR-2, or TI-B 51.

One paper shows expansion due to alkali aggregate reaction, but their ash is only partly composed of CFB BA [78].

4.3. Pre-Treatment of Ashes

As described in Section 3.4, the characteristics of the BA from CFB boilers with combustion of wood chips are distinguished by a relatively small particle size compared to regular concrete sand, but otherwise an inert and homogeneous material mainly composed of SiO2. This means that the processing required before using the BA as fine aggregate in a cementitious material is relatively small, but some of the possibilities are described in this section.

Sieving is the most applied pre-treatment, as it is a simple way to remove unwanted particles (charcoal, wood, etc.), and to improve the grading curve [41,66,78,79,90,102].

Another common processing is a simple water washing, which can remove salts, fines, alkalis, and pollutants [90,101,131,132].

Other processes, such as crushing, milling, and heating [11,58,92,133], are used to improve the reactivity of the ash and are thus not relevant when substituting sand.

5. Conclusions

Research regarding CFB ash in mortar or concrete is limited, but the available data are encouraging for a potential use of the ash as a replacement for virgin sand.

Several concrete types and products show promise for the potential utilization of wood BA as a sand substitution. Since research about the durability of concrete with BA is limited, the concrete types without reinforcement are likely to be the first products in the industry where BA will be utilized.

Properties of BA are shown to be dependent on combustion technology. Important material properties such as density, loss on ignition, and water absorption are similar to sand in many cases, and are generally better for BFB ashes than grate BA. Particle size distribution is a possibly limiting factor regarding the use of BA in concrete, as it is finer than regular concrete sand. There is limited information on the properties of CFB BA. For concrete and mortar with BFB and grate ashes, results indicate lower density and higher absorption, and a reduction in strength.

The heavy metal content and leaching of toxic materials are low, and the EU considers bottom ash from biomass combustion to be non-hazardous.

The literature indicates a possibility for pozzolanic activity of CFB BA, but results have not yet been produced to confidently confirm or debunk this.

Durability properties, such as ASR, freeze–thaw, and the effect on reinforcement corrosion, have yet to be investigated in depth and remain an aspect that must be considered in future research as a natural step towards implementation.

Regarding its use in a practical setting, there is potential in the concrete industry for the implementation of BA, as evidenced by the points mentioned above. Since sand scarcity is increasing, alternatives to sand will increase in value, and it will become more appealing to concrete producers.

Author Contributions

Conceptualization, A.H.J., C.K.E. and L.M.O.; methodology, A.H.J. and L.M.O.; formal analysis, A.H.J.; investigation, A.H.J.; data curation, A.H.J.; writing—original draft preparation, A.H.J.; writing—review and editing, A.H.J., C.K.E. and L.M.O.; visualization, A.H.J.; supervision, C.K.E. and L.M.O.; project administration, A.H.J., C.K.E. and L.M.O.; funding acquisition, A.H.J., C.K.E. and L.M.O. All authors have read and agreed to the published version of the manuscript.

Funding

Funding for this research was received from COWIfonden grant no. C-157.01, and Innovationsfonden grant no. 2108-00002B.

Data Availability Statement

No new data was created or analyzed in this study.

Acknowledgments

COWI A/S, COWIfonden, and Innovationsfonden are all greatly appreciated for providing the foundation for the project.

Conflicts of Interest

Authors A.H.J and C.K.E. were employed by the company COWI A/S. L.M.O declared that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AAR | Alkali aggregate reaction |

| ASR | Alkali–silica reaction |

| ASTM | American Society for Testing and Materials |

| BA | Bottom ash |

| BFB | Bubbling fluidized bed |

| CFB | Circulating fluidized bed |

| FA | Fly ash |

| DCC | Dry-cast concrete |

| EN | European norm (European standard) |

| EU | European Union |

| LoI | Loss on ignition |

| MSWI | Municipal solid waste incineration |

| RCA | Recycled concrete aggregate |

| RCC | Roller-compacted concrete |

| SEM | Scanning electron microscopy |

| TGA | Thermogravimetric analysis |

| XRF | X-ray fluorescence spectrometry |

References

- Andersen, C.E.; Rasmussen, F.N.; Zimmermann, R.K.; Kanafani, K.; Birgisdottir, H. Livscyklusvurdering for Cirkulaere Løsninger Med Fokus på Klimapåvirkning Forundersøgelse Polyteknisk Boghandel og Forlag. SBI Bind 2019:08, Copenhagen.

- Bendixen, M.; Best, J.; Hackney, C.; Iversen, L.L. Time Is Running Out for Sand. 2019. Available online: https://www.nature.com/articles/d41586-019-02042-4 (accessed on 12 March 2025).

- Peduzzi, P. Sand and Sustainability: 10 Strategic Recommendations to Avert a Crisis, UNEP. 2022. Available online: https://www.unep.org/resources/report/sand-and-sustainability-10-strategic-recommendations-avert-crisis (accessed on 12 March 2025).

- Peduzzi, P. Sand, rarer than one thinks. Environ. Dev. 2014, 11, 208–218. [Google Scholar] [CrossRef]

- Koehnken, L.; Rintoul, M.S.; Goichot, M.; Tickner, D.; Loftus, A.C.; Acreman, M.C. Impacts of riverine sand mining on freshwater ecosystems: A review of the scientific evidence and guidance for future research. River Res. Appl. 2020, 36, 362–370. [Google Scholar] [CrossRef]

- Miller, S.A.; Moore, F.C. Climate and health damages from global concrete production. Nat. Clim. Chang. 2020, 10, 439–443. [Google Scholar] [CrossRef]

- Han, Y.; Xu, W.; Liu, J.; Zhang, X.; Wang, K.; Wang, D.; Mei, Z. Ecological impacts of unsustainable sand mining: Urgent lessons learned from a critically endangered freshwater cetacean. Proc. R. Soc. B Biol. Sci. 2023, 290, 20221786. [Google Scholar] [CrossRef]

- Song, H.; Gu, G.; Cheng, Y. Experimental study on river sand replacement in concrete. In IOP Conference Series: Earth and Environmental Science, Volume 567, 2020 International Conference on Energy Saving and Environmental Protection and Civil Engineering, Shanghai, China, 7–9 August 2020; IOP Publishing Ltd.: Bristol, UK, 2020. [Google Scholar] [CrossRef]

- Mohanta, N.R.; Murmu, M. Alternative coarse aggregate for sustainable and eco-friendly concrete—A review. J. Build. Eng. 2022, 59, 105079. [Google Scholar] [CrossRef]

- Minane, J.R.; Becquart, F.; Abriak, N.E.; Deboffe, C. Upgraded Mineral Sand Fraction from MSWI Bottom Ash: An Alternative Solution for the Substitution of Natural Aggregates in Concrete Applications. Procedia Eng. 2017, 180, 1213–1220. [Google Scholar] [CrossRef]

- Rosales, J.; Cabrera, M.; Beltrán, M.G.; López, M.; Agrela, F. Effects of treatments on biomass bottom ash applied to the manufacture of cement mortars. J. Clean. Prod. 2017, 154, 424–435. [Google Scholar] [CrossRef]

- Torres, A.; Simoni, M.U.; Keiding, J.K.; Müller, D.B.; Ermgassen, S.O.S.E.Z.; Liu, J.; Jaeger, J.A.G.; Winter, M.; Lambin, E.F. Sustainability of the global sand system in the Anthropocene. One Earth 2021, 4, 639–650. [Google Scholar] [CrossRef]

- Zhou, H.; Bhattarai, R.; Li, Y.; Si, B.; Dong, X.; Wang, T.; Yao, Z. Towards sustainable coal industry: Turning coal bottom ash into wealth. Sci. Total Environ. 2022, 804, 149985. [Google Scholar] [CrossRef]

- Nair, D.G.; Jagadish, K.S.; Fraaij, A. Reactive pozzolanas from rice husk ash: An alternative to cement for rural housing. Cem. Concr. Res. 2006, 36, 1062–1071. [Google Scholar] [CrossRef]

- Filho, R.G.D.M.; Colpini, L.M.S.; Ferrer, M.M.; Nagano, M.F.; Rosso, J.M.; Volnistem, E.A.; Paraíso, P.R.; de Matos Jorge, L.M. Characterization of different sugarcane bagasse ashes generated for preparation and application as green products in civil construction. Clean. Technol. Env. Policy 2019, 21, 1687–1698. [Google Scholar] [CrossRef]

- de Sande, V.T.; Sadique, M.; Pineda, P.; Bras, A.; Atherton, W.; Riley, M. Potential use of sugar cane bagasse ash as sand replacement for durable concrete. J. Build. Eng. 2021, 39, 102277. [Google Scholar] [CrossRef]

- Beltrán, M.G.; Barbudo, A.; Agrela, F.; Jiménez, J.R.; De Brito, J. Mechanical performance of bedding mortars made with olive biomass bottom ash. Constr. Build. Mater. 2016, 112, 699–707. [Google Scholar] [CrossRef]

- Kirthika, S.K.; Singh, S.K. Durability studies on recycled fine aggregate concrete. Constr. Build. Mater. 2020, 250, 118850. [Google Scholar] [CrossRef]

- Nebiyu, W.M.; Nuramo, D.A.; Ketema, A.F. Experimental Study of Recycled Aggregate Concrete Produced from Recycled Fine Aggregate. Adv. Sci. Technol. 2021, 412, 49–67. [Google Scholar]

- Chimenos, J.M.; Segarra, M.; Fernandez, M.A.; Espiell, F. Characterization of the bottom ash in municipal solid waste incinerator. J. Hazard. Mater. 1999, 64, 211–222. [Google Scholar] [CrossRef]

- Jurič, B.; Hanžič, L.; Ilić, R.; Samec, N. Utilization of municipal solid waste bottom ash and recycled aggregate in concrete. Waste Manag. 2006, 26, 1436–1442. [Google Scholar] [CrossRef]

- Chidiac, S.E.; Zibara, H. Dry-cast concrete masonry products: Properties and durability. Can. J. Civ. Eng. 2007, 34, 1413–1423. [Google Scholar] [CrossRef]

- Lessard, J.M.; Omran, A.; Tagnit-Hamou, A.; Gagne, R. Feasibility of using biomass fly and bottom ashes in dry-cast concrete production. Constr. Build. Mater. 2017, 132, 565–577. [Google Scholar] [CrossRef]

- Kumar, B.A.V.R.; Ramakrishna, G. Performance evaluation of sustainable materials in roller compacted concrete pavements: A state of art review. J. Build. Pathol. Rehabil. 2022, 7, 78. [Google Scholar] [CrossRef]

- Wu, Z.; Libre, N.A.; Khayat, K.H. Factors affecting air-entrainment and performance of roller compacted concrete. Constr. Build. Mater. 2020, 259, 120413. [Google Scholar] [CrossRef]

- Lessard, J.-M.; Omran, A.; Tagnit-Hamou, A.; Gagne, R. Feasibility of Using Biomass Fly and Bottom Ashes to Produce RCC and PCC. J. Mater. Civ. Eng. 2017, 29, 04016267. [Google Scholar] [CrossRef]

- Elliott, K.S. Precast Concrete Structures, 1st ed.; Butterworth Heinemann: Oxford, UK, 2002. [Google Scholar]

- Wang, B.; Yan, L.; Fu, Q.; Kasal, B. A Comprehensive Review on Recycled Aggregate and Recycled Aggregate Concrete. Resour. Conserv. Recycl. 2021, 171, 105565. [Google Scholar] [CrossRef]

- Jin, R.; Chen, Q.; Soboyejo, A. Survey of the current status of sustainable concrete production in the U.S. Resour. Conserv. Recycl. 2015, 105, 148–159. [Google Scholar] [CrossRef]

- Lunniss, R.; Baber, J. Immersed Tunnels—Lunniss and Baber; Taylor & Francis Group: London, UK, 2013. [Google Scholar]

- Bickel, J.O.; Kuesel, T.R.; King, E.H. Tunnel Engineering Handbook, 2nd ed.; Kluwer Academic Publishers: Alphen aan den Rijn, The Netherlands, 1996. [Google Scholar] [CrossRef]

- Boulanger, P.; Goncalo, P. Industrial Mortars and Repairing Concrete Products. In Organic Materials for Sustainable Construction; John Wiley and Sons: Hoboken, NJ, USA, 2013; pp. 407–418. [Google Scholar] [CrossRef]

- Gabrijel, I.; Rukavina, M.J.; Štirmer, N. Influence of wood fly ash on concrete properties through filling effect mechanism. Materials 2021, 14, 7164. [Google Scholar] [CrossRef]

- Tsiropoulos, I.; Nijs, W.; Tarvydas, D.; Ruiz, P. Towards Net-Zero Emissions in the EU Energy System by 2050; Publications Office of the European Union: Luxembourg City, Luxembourg, 2020. [Google Scholar] [CrossRef]

- IEA. Renewables 2022. IEA. 2022. Available online: https://www.iea.org/reports/renewables-2022 (accessed on 4 October 2023).

- Energistyrelsen, Biomasseanalyse, Danish Energy Agency, Copenhagen. 2020. Available online: https://ens.dk/presse/energistyrelsen-offentliggoer-biomasseanalyse (accessed on 12 March 2025).

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the composition and application of biomass ash. Part 1. Phase-mineral and chemical composition and classification. Fuel 2013, 105, 40–76. [Google Scholar] [CrossRef]

- Zhai, J.; Burke, I.T.; Stewart, D.I. Beneficial management of biomass combustion ashes. Renew. Sustain. Energy Rev. 2021, 151, 111555. [Google Scholar] [CrossRef]

- Curran, M.; Hellweg, S.; Beck, J.; Beck, J. Is There Any Empirical Support for Biodiversity Offset Policy? Ecol. Appl. 2014, 24, 617–632. Available online: http://www.jstor.org/stable/24432178 (accessed on 12 March 2025). [CrossRef]

- Sterman, J.D.; Siegel, L.; Rooney-Varga, J.N. Does replacing coal with wood lower CO2 emissions? Dynamic lifecycle analysis of wood bioenergy. Environ. Res. Lett. 2018, 13, 015007. [Google Scholar] [CrossRef]

- James, A.K.; Thring, R.W.; Helle, S.; Ghuman, H.S. Ash management review-applications of biomass bottom ash. Energies 2012, 5, 3856–3873. [Google Scholar] [CrossRef]

- Karlsson, V.; Agernäs, T.; Svenstig, K.; Eskilsson, D. Miljötillståndsansökan Biokraftvärme Rya—03.B-Teknisk Beskrivning; Göteborg Energi: Göteborg, Sweden, 2021. [Google Scholar]

- Widell, H. Industrial-scale biomass combustion plants: Engineering issues and operation. Biomass Combust. Sci. Technol. Eng. 2013, 10, 225–277. [Google Scholar] [CrossRef]

- Belin, F.; James, D.E.; Walker, D.J.; Warrick, R.J. Waste Wood Combustion in Circulating Fluidized Bed Boilers. In Proceedings of the Second International Conference on Circulating Fluidized Beds, Compiégne, France, 14–18 March 1988; pp. 351–368. [Google Scholar] [CrossRef]

- Leckner, B.; Lind, F. Combustion of municipal solid waste in fluidized bed or on grate—A comparison. Waste Manag. 2020, 109, 94–108. [Google Scholar] [CrossRef] [PubMed]

- Cabrera, M.; Martinez-Echevarria, M.J.; López-Alonso, M.; Agrela, F.; Rosales, J. Self-compacting recycled concrete using biomass bottom ash. Materials 2021, 14, 6084. [Google Scholar] [CrossRef] [PubMed]

- Muthadhi, A.; Banupriya, S. Production of Self-Compacting Concrete with Fly Ash Using Bagasse Ash as Fine Aggregate. Iran. J. Sci. Technol.—Trans. Civ. Eng. 2022, 46, 2187–2200. [Google Scholar] [CrossRef]

- Nascimento, L.C.; Junior, G.B.; Xavier, G.d.C.; Monteiro, S.N.; Vieira, C.M.F.; de Azevedo, A.R.G.; Alexandre, J. Use of wood bottom ash in cementitious materials: A review. J. Mater. Res. Technol. 2023, 23, 4226–4243. [Google Scholar] [CrossRef]

- Schlupp, F.; Page, J.; Djelal, C.; Libessart, L. Use of Biomass Bottom Ash as an Alternative Solution to Natural Aggregates in Concrete Applications: A Review. Materials 2024, 17, 4504. [Google Scholar] [CrossRef]

- Tahami, S.A.; Arabani, M.; Mirhosseini, A.F. Usage of two biomass ashes as filler in hot mix asphalt. Constr. Build Mater. 2018, 170, 547–556. [Google Scholar] [CrossRef]

- Sigvardsen, N.M.; Kirkelund, G.M.; Jensen, P.E.; Geiker, M.R.; Ottosen, L.M. Impact of production parameters on physiochemical characteristics of wood ash for possible utilisation in cement-based materials. Resour. Conserv. Recycl. 2019, 145, 230–240. [Google Scholar] [CrossRef]

- Nurmesniemi, H.; Manskinen, K.; Pöykiö, R.; Dahl, O. Forest Fertilizer Properties of the Bottom Ash and Fly Ash from A Large-Sized (115 Mw) Industrial Power Plant Incinerating Wood-Based Biomass Residues. J. Univ. Chem. Technol. Metall. 2012, 47, 43–52. [Google Scholar]

- Eliche-Queseda, D.; Felipe-Sesé, M.A.; Fuentes-Sanchéz, M.J. Biomass bottom ash waste and by-products of the acetylene industry as raw materials for unfired bricks. J. Build. Eng. 2021, 38, 102191. [Google Scholar] [CrossRef]

- Cabrera, M.; Galvin, A.P.; Agrela, F.; Carvajal, M.D.; Ayuso, J. Characterisation and technical feasibility of using biomass bottom ash for civil infrastructures. Constr. Build Mater. 2014, 58, 234–244. [Google Scholar] [CrossRef]

- Milovanović, B.; Štirmer, N.; Carević, I.; Baričević, A. Wood biomass ash as a raw material in concrete industry. Gradjevinar 2019, 71, 505–514. [Google Scholar] [CrossRef]

- Li, L.; Yu, C.; Bai, J.; Wang, Q.; Luo, Z. Heavy metal characterization of circulating fluidized bed derived biomass ash. J. Hazard Mater. 2012, 233–234, 41–47. [Google Scholar] [CrossRef]

- Carević, I.; Serdar, M.; Štirmer, N.; Ukrainczyk, N. Preliminary screening of wood biomass ashes for partial resources replacements in cementitious materials. J. Clean. Prod. 2019, 229, 1045–1064. [Google Scholar] [CrossRef]

- Rissanen, J.; Ohenoja, K.; Kinnunen, P.; Romagnoli, M.; Illikainen, M. Milling of peat-wood fly ash: Effect on water demand of mortar and rheology of cement paste. Constr. Build Mater. 2018, 180, 143–153. [Google Scholar] [CrossRef]

- Dahl, O.; Nurmesniemi, H.; Pöykiö, R.; Watkins, G. Comparison of the characteristics of bottom ash and fly ash from a medium-size (32 MW) municipal district heating plant incinerating forest residues and peat in a fluidized-bed boiler. Fuel Process. Technol. 2009, 90, 871–878. [Google Scholar] [CrossRef]

- Modolo, R.C.E.; Silva, T.; Senff, L.; Tarelho, L.A.C.; Labrincha, J.A.; Ferreira, V.M.; Silva, L. Bottom ash from biomass combustion in BFB and its use in adhesive-mortars. Fuel Process. Technol. 2015, 129, 192–202. [Google Scholar] [CrossRef]

- Van Dijen, F.; Pels, J. Classification of Ashes and Identification of Possible Future Utilisations; Publications Office of the European Union: Luxembourg City, Luxembourg, 2019; Available online: https://ec.europa.eu/research/participants/documents/downloadPublic?documentIds=080166e5c4c6c430&appId=PPGMS (accessed on 12 March 2025). [CrossRef]

- Sandberg, J.; Karlsson, C.; Fdhila, R.B. A 7year long measurement period investigating the correlation of corrosion, deposit and fuel in a biomass fired circulated fluidized bed boiler. Appl. Energy 2011, 88, 99–110. [Google Scholar] [CrossRef]

- Wu, M.H.; Shih, K.; Lin, C.L. Impact of bed particle size distribution on the distribution of heavy metal during defluidization process in fluidized bed incinerator. Combust. Sci. Technol. 2012, 184, 811–828. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete, 5th ed.; Pearson: London, UK, 2011. [Google Scholar]

- Chourasia, S.; Alappat, B.J. Experimental study on the attrition and size distribution of bed material in a recirculating fluidized bed. Chem. Eng. Commun. 2017, 204, 1174–1186. [Google Scholar] [CrossRef]

- Schlupp, F.; Page, J.; Djelal, C.; Libessart, L. Use of biomass bottom ash as granular substitute in mortar. J. Build. Eng. 2023, 75, 106927. [Google Scholar] [CrossRef]

- Schlupp, F.; Page, J.; Djelal, C.; Libessart, L. Influence of recycled sand from biomass combustion on the mechanical, hydration and porous properties of mortar mixtures. Constr. Build Mater. 2023, 404, 133193. [Google Scholar] [CrossRef]

- Leckner, B. Hundred years of fluidization for the conversion of solid fuels. Powder. Technol. 2022, 411, 117935. [Google Scholar] [CrossRef]

- Khan, A.A.; de Jong, W.; Janses, P.J.; Spliethoff, H. Biomass combustion in fluidized bed boilers—Potential problems and remedies. Fuel Process. Technol. 2009, 90, 21–50. [Google Scholar] [CrossRef]

- Van Loo, S.; Koppejan, J. The Handbook of Biomass Combustion & Co-Firing, 1st ed.; Earthscan: London, UK, 2008. [Google Scholar]

- Valmet, Valmet BFB Boilers. 2025. Available online: https://www.valmet.com/energyproduction/bfb-boilers/ (accessed on 16 January 2025).

- Vamvuka, D.; Zografos, D.; Alevizos, G. Control methods for mitigating biomass ash-related problems in fluidized beds. Bioresour. Technol. 2008, 99, 3534–3544. [Google Scholar] [CrossRef]

- Kim, Y.H.; Kim, H.Y.; Yang, K.H.; Ha, J.S. Evaluation of workability and mechanical properties of bottom ash aggregate concrete. Appl. Sci. 2020, 10, 8016. [Google Scholar] [CrossRef]

- De Fusco, L.; Defoort, F.; Rajczyk, R.; Jeanmart, H.; Blondeau, J.; Contino, F. Ash Characterization of Four Residual Wood Fuels in a 100 kWth Circulating Fluidized Bed Reactor Including the Use of Kaolin and Halloysite Additives. Energy Fuels 2016, 30, 8304–8315. [Google Scholar] [CrossRef]

- Tranvik, A.E.; Sanati, M.; Zethraeus, B.; Lyberg, M. Influence of Ash Composition on Slagging and Defluidisation in a Biomass Fired Commercial CFB Boiler. Prog. Thermochem. Biomass Convers. 2008, 66, 824–830. [Google Scholar] [CrossRef]

- Sommersacher, P.; Brunner, T.; Obernberger, I. Fuel indexes: A novel method for the evaluation of relevant combustion properties of new biomass fuels. Energy Fuels 2012, 26, 380–390. [Google Scholar] [CrossRef]

- Valizadeh, A.; Skoglund, N.; Forsberg, F.; Lycksam, H.; Öhman, M. Role of surface morphology in bed particle layer formation on quartz bed particles in fluidized bed combustion of woody biomass. Fuel 2024, 357, 129702. [Google Scholar] [CrossRef]

- Acordi, J.; Luza, A.; Fabris, D.C.N.; Raupp-Pereira, F.; De Noni, A.; Montedo, O.R.K. New waste-based supplementary cementitious materials: Mortars and concrete formulations. Constr. Build Mater. 2020, 240, 117877. [Google Scholar] [CrossRef]

- da Costa, T.P.; Quinteiro, P.; Tarelho, L.A.C.; Arroja, L.; Dias, A.C. Environmental assessment of valorisation alternatives for woody biomass ash in construction materials. Resour. Conserv. Recycl. 2019, 148, 67–79. [Google Scholar] [CrossRef]

- Abdoli, S.; Kara, S.; Hauschild, M. System interaction, System of Systems, and environmental impact of products. CIRP Ann. 2019, 68, 17–20. [Google Scholar] [CrossRef]

- Larsen, G.; Greve, C.; Wismann, M. HVORNÅR ER DET SLUT MED GRUS I DANMARK? Aktuel Naturvidenskab 2019, 4, 12–15. [Google Scholar]

- Cabrera, M.; Díaz-lópez, J.L.; Agrela, F.; Rosales, J. Eco-efficient cement-based materials using biomass bottom ash: A review. Appl. Sci. 2020, 10, 8026. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the composition and application of biomass ash.: Part 2. Potential utilisation, technological and ecological advantages and challenges. Fuel 2013, 105, 19–39. [Google Scholar] [CrossRef]

- Agrela, F.; Cabrera, M.; Morales, M.M.; Zamorano, M.; Alshaaer, M. Biomass fly ash and biomass bottom ash. In New Trends in Eco-Efficient and Recycled Concrete; Elsevier: Amsterdam, The Netherlands, 2018; pp. 23–58. [Google Scholar] [CrossRef]

- Berra, M.; Mangialardi, T.; Paolini, A.E. Reuse of woody biomass fly ash in cement-based materials. Constr. Build Mater. 2015, 76, 286–296. [Google Scholar] [CrossRef]

- 450-1; Fly Ash for Concrete—Part 1: Definition, Specifications and Conformity Criteria. European Committee for Standardization: Brussels, Belgium, 2012.

- ASTM C618–23; Standard Specification for Coal Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2023. [CrossRef]

- Kȩpys, W. Bottom ash obtained from biomass burning in fluidised-bed boilers as a mortar component. In Proceedings of the E3S Web of Conferences, EDP Sciences, Villebon-sur-Yvette, France, 13 September 2018. [Google Scholar] [CrossRef]

- Tyni, S.K.; Karppinen, J.A.; Tiainen, M.S.; Laitinen, R.S. Preparation and characterization of amorphous aluminosilicate polymers from ash formed in combustion of peat and wood mixtures. J. Non-Cryst. Solids 2014, 387, 94–100. [Google Scholar] [CrossRef]

- Modolo, R.C.E.; Ferreira, V.M.; Tarelho, L.A.; Labrincha, J.A.; Senff, L.; Silva, L. Mortar formulations with bottom ash from biomass combustion. Constr. Build Mater. 2013, 45, 275–281. [Google Scholar] [CrossRef]

- Maschio, S.; Tonello, G.; Piani, L.; Furlani, E. Fly and bottom ashes from biomass combustion as cement replacing components in mortars production: Rheological behaviour of the pastes and materials compression strength. Chemosphere 2011, 85, 666–671. [Google Scholar] [CrossRef]

- Cuenca-Moyano, G.M.; Cabrera, M.; López-Alonso, M.; Martínez-Echevarría, M.J.; Agrela, F.; Rosales, J. Design of lightweight concrete with olive biomass bottom ash for use in buildings. J. Build. Eng. 2023, 69, 106289. [Google Scholar] [CrossRef]

- Steenari, B.M.; Karlsson, L.G.; Lindqvist, O. Evaluation of the leaching characteristics of wood ash and ash agglomeration. Biomass Bioenergy 1999, 16, 119–136. [Google Scholar] [CrossRef]

- EN 206:2013+A2:2021; Concrete—Specification, Performance, Production and Conformity. European Committee for Standardization: Brussels, Belgium, 2021.

- EN 12620:2002+A1; Aggregates for Concrete. European Committee for Standardization: Brussels, Belgium, 2008.

- ASTM C33/C33M; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2024. [CrossRef]

- DS 206:2024; Concrete—Rules for Application of EN 206 in Denmark; Danish Standards Association: Copenhagen, Denmark, 2024.

- Lindgård, J.; Andiç-Çakir, Ö.; Fernandes, I.; Rønning, T.F.; Thomas, M.D.A. Alkali-silica reactions (ASR): Literature review on parameters influencing laboratory performance testing. Cem. Concr. Res. 2012, 42, 223–243. [Google Scholar] [CrossRef]

- Lothenbach, B.; Scrivener, K.; Hooton, R.D. Supplementary cementitious materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Sigvardsen, N.M.; Geiker, M.R.; Ottosen, L.M. Reaction mechanisms of wood ash for use as a partial cement replacement. Constr. Build. Mater. 2021, 286, 122889. [Google Scholar] [CrossRef]

- Supancic, K.; Obernberger, I.; Kienzl, N.; Arich, A. Conversion and leaching characteristics of biomass ashes during outdoor storage—Results of laboratory tests. Biomass Bioenergy 2014, 61, 211–226. [Google Scholar] [CrossRef]

- Tarelho, L.A.C.; Teixeira, E.R.; Silva, D.F.R.; Modolo, R.C.E.; Labrincha, J.A.; Rocha, F. Characteristics of distinct ash flows in a biomass thermal power plant with bubbling fluidised bed combustor. Energy 2015, 90, 387–402. [Google Scholar] [CrossRef]

- Sklivaniti, V.; Tsakiridis, P.E.; Katsiotis, N.S.; Velissariou, D.; Pistofidis, N.; Papageorgiou, D.; Beazi, M. Valorisation of woody biomass bottom ash in Portland cement: A characterization and hydration study. J. Environ. Chem. Eng. 2017, 5, 205–213. [Google Scholar] [CrossRef]

- Beltrán, M.G.; Agrela, F.; Barbudo, A.; Ayuso, J.; Ramírez, A. Mechanical and durability properties of concretes manufactured with biomass bottom ash and recycled coarse aggregates. Constr Build Mater 2014, 72, 231–238. [Google Scholar] [CrossRef]

- Cruz, N.C.; Silva, F.C.; Tarelho, L.A.C.; Rodrigues, S.M. Critical review of key variables affecting potential recycling applications of ash produced at large-scale biomass combustion plants. Resour. Conserv. Recycl. 2019, 150, 104427. [Google Scholar] [CrossRef]

- Hinojosa, M.J.R.; Galvín, A.P.; Agrela, F.; Perianes, M.; Barbudo, A. Potential use of biomass bottom ash as alternative construction material: Conflictive chemical parameters according to technical regulations. Fuel 2014, 128, 248–259. [Google Scholar] [CrossRef]

- Nikbin, I.M.; Rahimi, R.S.; Allahyari, H.; Damadi, M. A comprehensive analytical study on the mechanical properties of concrete containing waste bottom ash as natural aggregate replacement. Constr. Build Mater. 2016, 121, 746–759. [Google Scholar] [CrossRef]

- European Commission, Commission Decision 2000/532/EC, Official Journal of the European Union, Brussels, Belgium. 2000. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32000D0532 (accessed on 12 March 2025).

- European Commission, Commission Notice 2018/C124/01 on Technical Guidance on the Classification of Waste. Official Journal of the European Union, Brussels, Belgium. 2018. Available online: https://www.hazwasteonline.com/2018/04/notice-2018-c-124/ (accessed on 12 March 2025).

- The Council of the European Union. Council Decision of 19 December 2002 Establishing Criteria and Procedures for the Acceptance of Waste at Landfills Pursuant to Article 16 of and Annex II to Directive 1999/32/EC; Official Journal of the European Union: Brussels, Belgium, 2003. [Google Scholar]

- EN 12457-2; Characterisation of Waste-Leaching-Compliance Test for Leaching of Granular Waste Part 2. European Committee for Standardization: Brussels, Belgium, 2002.

- Cabrera, M.; Galvin, A.P.; Agrela, F.; Beltran, M.G.; Ayuso, J. Reduction of leaching impacts by applying biomass bottom ash and recycled mixed aggregates in structural layers of roads. Materials 2016, 9, 228. [Google Scholar] [CrossRef] [PubMed]

- Freire, M.; Lopes, H.; Tarelho, L.A.C. Critical aspects of biomass ashes utilization in soils: Composition, leachability, PAH and PCDD/F. Waste Manag. 2015, 46, 304–315. [Google Scholar] [CrossRef]

- Barbosa, R.; Dias, D.; Lapa, N.; Lopes, H.; Mendes, B. Chemical and ecotoxicological properties of size fractionated biomass ashes. Fuel Process. Technol. 2013, 109, 124–132. [Google Scholar] [CrossRef]

- Rajamma, R.; Ball, R.J.; Tarelho, L.A.C.; Allen, G.C.; Labrincha, J.A.; Ferreira, V.M. Characterisation and use of biomass fly ash in cement-based materials. J. Hazard. Mater. 2009, 172, 1049–1060. [Google Scholar] [CrossRef]

- Steenari, B.-M.; Schelander, S.; Lindqvist, O. Chemical and leaching characteristics of ash from combustion of coal, peat and wood in a 12 MW CFB-a comparative study. Fuel 1999, 78, 249–258. [Google Scholar] [CrossRef]

- Pitman, R.M. Wood ash use in forestry—A review of the environmental impacts. Forestry 2006, 79, 563–588. [Google Scholar] [CrossRef]

- Ottosen, L.M.; Sigvardsen, N.M. Heavy Metal Leaching from Wood Ash Before and After Hydration and Carbonation. Environ. Sci. Pollut. Res. 2024. Available online: https://link.springer.com/article/10.1007/s11356-024-33221-0 (accessed on 12 March 2025). [CrossRef]

- Narodoslawsky, M.; Obernberger, I. From waste to raw material-the route from biomass to wood ash for cadmium and other heavy metals. J. Hazardous Mater. 1996, 50, 157–168. [Google Scholar] [CrossRef]

- Kauppinen, E.I.; Jokiniemi, J.K.; Lind, T.; Latva-Somppi, J. Ash Particle Formation and Metal Behaviour During Biomass Combustion in Fluidized Bed Boiler. In Characterization & Control of Interfaces for High Quality Advanced Materials; The American Ceramic Society: Westerville, OH, USA, 2005; pp. 347–354. [Google Scholar] [CrossRef]

- Drljača, D.M.; Vukić, L.M.; Dragić, D.M.; Borković, A.P.; Botić, T.T.; Dugić, P.T.; Papuga, S.V.; Šolić, M.D.; Maletić, S.P.; Gvero, P.M.; et al. Leaching of heavy metals from wood biomass ash, before and after binding in cement composite. J. Serbian Chem. Soc. 2022, 87, 1091–1108. [Google Scholar] [CrossRef]

- Bodker, J. Utilisation of Ash from Incineration of Wastewater Sludge (bio ash) in Concrete Production, Danish Technological Institute, Taastrup. 2007. Available online: https://webgate.ec.europa.eu/life/publicWebsite/project/LIFE05-ENV-DK-000153/utilisation-of-ash-from-incineration-of-wastewater-sludge-bio-ash-in-concrete-production (accessed on 12 March 2025).

- Barbosa, R.; Lapa, N.; Dias, D.; Mendes, B. Concretes containing biomass ashes: Mechanical, chemical, and ecotoxic performances. Constr. Build. Mater. 2013, 48, 457–463. [Google Scholar] [CrossRef]

- Dahl, O.; Nurmesniemi, H.; Pöykiö, R.; Watkins, G. Heavy metal concentrations in bottom ash and fly ash fractions from a large-sized (246 MW) fluidized bed boiler with respect to their Finnish forest fertilizer limit values. Fuel Process. Technol. 2010, 91, 1634–1639. [Google Scholar] [CrossRef]

- Li, D.; Ahn, S.; Kim, R.G.; Li, J.; Jung, S.; Jeon, C. Formation of agglomerates with core–shell structure in a large-scale CFB boiler. Fuel 2023, 332, 126197. [Google Scholar] [CrossRef]

- Jensen, A.H.; Ottosen, L.M.; Edvardsen, C.K. Mechanical properties of mortar substituting fine aggregate with wood bottom ash from fluidized bed boilers. In Proceedings of the 15th Fib International PhD Symposium in Civil Engineering, Fib, Fédération Internationale du béton, Budapest, Hungary, 28–30 August 2024; Balazs, G.L., Sólyom, S., Foster, S., Eds.; pp. 767–774. [Google Scholar]

- EN 196-2; Method of Testing Cement-Part 2: Chemical Analysis of Cement. European Committee for Standardization: Brussels, Belgium, 2013.

- Li, Q.H.; Zhang, Y.G.; Meng, A.H.; Li, L.; Li, G.X. Study on ash fusion temperature using original and simulated biomass ashes. Fuel Process. Technol. 2013, 107, 107–112. [Google Scholar] [CrossRef]

- Valmari, T.; Lind, T.M.; Kauppinen, E.I.; Sfiris, G.; Nilsson, K.; Maenhaut, W. Field study on ash behavior during circulating fluidized-bed combustion of biomass. 1. Ash formation. Energy Fuels 1999, 13, 379–389. [Google Scholar] [CrossRef]

- Tranvik, A.C.; Öhman, M.; Sanati, M. Bed material deposition in cyclones of wood fuel fired circulating fluidized beds (CFBs). Energy Fuels 2007, 21, 104–109. [Google Scholar] [CrossRef]

- Modolo, R.C.E.; Ascensão, G.; Senff, L.; Ribeiro, F.R.C.; Tarelho, L.A.D.C.; Ferreira, V.M.; Labrincha, J.A.; Silva, A.S.; Moraes, C.A.M. Recycling of ashes from biomass combustion as raw material for mortars. Mix Sustentável 2021, 7, 137–146. [Google Scholar] [CrossRef]

- Ottosen, L.M.; Hansen, E.Ø.; Jensen, P.E.; Kirkelund, G.M.; Golterman, P. Wood ash used as partly sand and/or cement replacement in mortar. Int. J. Sustain. Dev. Plan. 2016, 11, 781–791. [Google Scholar] [CrossRef]

- Skevi, L.; Baki, V.A.; Feng, Y.; Valderrabano, M.; Ke, X. Biomass Bottom Ash as Supplementary Cementitious Material: The Effect of Mechanochemical Pre-Treatment and Mineral Carbonation. Materials 2022, 15, 8357. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).