Abstract

Digital twins (DTs) represent an emerging technology that allows interaction between assets and their virtual replicas and enclose geometry from modeling procedures and dynamism from AI. DTs serve different purposes, e.g., testing how devices behave under diverse conditions or monitoring processes and supporting improvement. However, until now, the use of DTs for monitoring constructions has been limited, as they are frequently used only as a high-quality 3D digital representation without connecting to other systems, dynamic analysis, or simulation. This work proposes creating a DT for monitoring the construction of a wind farm. It draws a comparison between the as-designed models (from the design phase) and the as-built models (that represent the actual construction at different times). As a result, the DT can help to control deviations that may occur during construction. The authors propose using Unreal Engine to create an interface that includes as-designed models obtained from the building information modeling (BIM) and as-built models corresponding to different steps during the construction. The result is a video game-type interactive application with a timeline tool that allows going through the construction stages recorded in the as-built models and comparing them to the as-designed model.

1. Introduction

Monitoring the progress of a construction project is vital since it permits obtaining information that allows for making informed and timely decisions according to the project needs. Inadequate monitoring can lead to loss of control of the project, resulting in increased costs and time. The most used and long-established monitoring methods require manual data entry, which can be time-consuming and susceptible to human error; therefore, automation of these procedures would increase monitoring effectiveness [1].

Nowadays, the conception and management of building and civil works projects usually apply the building information modeling (BIM) methodology. The BIM methodology includes a digital model that centralizes all the information (e.g., geometrics, costs, maintenance, etc.); therefore, BIM models can represent the design phase (as-designed models) or the current state of the construction (as-built models). Thus, BIM models are the perfect starting point for construction monitoring as they include all the design information, allowing for comparing the as-designed model and the construction progress (as-built models) and obtaining any project deviation. The as-built models reflect the actual progress of a project at each moment, reflecting the reality and the evolution of construction through time.

On the other hand, digital twins (DTs) are an emerging technology that allow interaction between physical components, products, or systems in physical spaces and their corresponding virtual replicas in virtual spaces. DTs integrate multiple physics and scales and usually employ dynamic sensors and historical data, allowing a complex virtual model that is the counterpart of a physical one [2].

With the improvement of artificial intelligence (AI) in terms of software capabilities for 3D modeling and simulation in construction environments (BIM models) related to computer-aided design and engineering (CAD/CAE) and geographical information system (GIS) technologies, DTs now have a place in urban projects, land management, and public infrastructure. However, until now, the use of DTs in this area has been limited since they are usually just a high-quality 3D digital representation without any connection to other systems, dynamic analysis, or simulation.

Although some studies have focused on using as-built models for construction monitoring, they did not address the actual visualization of the construction progress. In addition, monitoring applications are usually complex, and generally, their usage requires experience.

This work proposes the creation of a DT for monitoring the construction of a wind farm. It compares a BIM model (from the design phase which contains the construction specifications) and as-built models representing the actual construction at different times. It also helps to control deviations regarding civil works that may occur during construction.

The authors propose using Unreal Engine to create an interface for user interaction that includes CAD/CAE models obtained from the BIM (resulting from the design phase) and as-built models corresponding to different steps during the construction.

The resulting application will constitute a simple and dynamic way of monitoring the construction while observing the actual changes and progress over time and the deviations that may have occurred according to the BIM model (original design) and the as-built models (representation of the actual construction progress at various stages).

2. Brief State of the Art

Monitoring the progress of construction can be achieved through its digitization, so diverse research works focus on this, such as that presented by Mannino et al. [3], centered on BIM models and IoT technologies integration. In addition, Rausch et al. [4] introduced computational algorithms applied to BIM software (Autodesk Revit, Maya, and others) to automate processes and computationally explore large decision space domains. On the other hand, Jiang [5] proposed combining the intelligent building construction process with DTs and the BIM methodology for construction monitoring and management. There are also studies based on scanners for the virtualization of constructions [6]. The combined use of BIM models with AI has great potential in architecture, engineering, and construction, as demonstrated in the review article by Pan et al. [7].

Existing research efforts deal with the automatization or semi-automatization of the monitoring of construction based on different approaches: computer vision techniques [2,8], updating as-built models [9,10,11], developing a BIM methodology to support dynamic asset management applications [12], etc. However, these approaches can become quite complex and do not cover the actual issue of visualizing the progress of the construction while comparing it to the initial design (BIM model).

There is also research on DTs applied to the construction industry, such as the ones presented in [13,14,15,16], and applied to the civil engineering sector, such as the studies introduced by Jiang et al. [17]. Likewise, Arkanmu et al. [18] highlighted the benefits of using cyber-physical systems and digital twins in the construction industry. Additionally, Moncada et al. [19] presented a DT of an electrical substation that implemented BIM tactics for 3D objects. Similarly, Zhang et al. [20] proposed a framework to utilize DTs and extend the level of detail (LoD) of BIM for construction site management. These studies focus on using BIM models as design models for creating digital twins; however, they do not go further, i.e., using as-built models of the construction progress for its monitoring.

In addition to monitoring construction progress, digital twins have been used to optimize and improve facilities [21,22,23,24]. There are even studies on so-called cognitive DTs, defined as digital twins capable of achieving cognitive elements such as memory, perception, and reasoning applied to the management of buildings and operations [25]. Likewise, some studies combine DTs with the BIM methodology to develop tools for renovating buildings [26,27,28] and designing, creating, and operating industrial facilities [29].

3. Materials and Methods

3.1. CAD Modeling

The use of digital twins and their visualization require three-dimensional models in which to introduce the different data for analysis. These models can be obtained from CAD software, which allows the creation and editing of both physical objects and environments that represent the virtual models to work with. In this study, the CAD modeling follows two approaches since two different models were used. On the one hand, the BIM models represent the project’s design phase and require the initial creation of these models. On the other hand, the as-built models correspond to the execution phases of the project and can be generated by modifying the BIM model or by incorporating data captured in the field, such as photogrammetric drone flights or LiDAR capture.

3.1.1. BIM Model

The BIM methodology allows the integration of all data and processes during the design phase of a project in a global and automated manner within the framework of a digital model. This model allows more efficient management of the interaction between all the project’s agents, so it is essential to have a three-dimensional model that fits as closely as possible to the initial conditions of the project and allows for defining the actions to be carried out.

In this work, the tasks associated with the BIM model were performed using Civil 3D software, which integrates efficient functions for designing primary civil engineering elements and supports BIM.

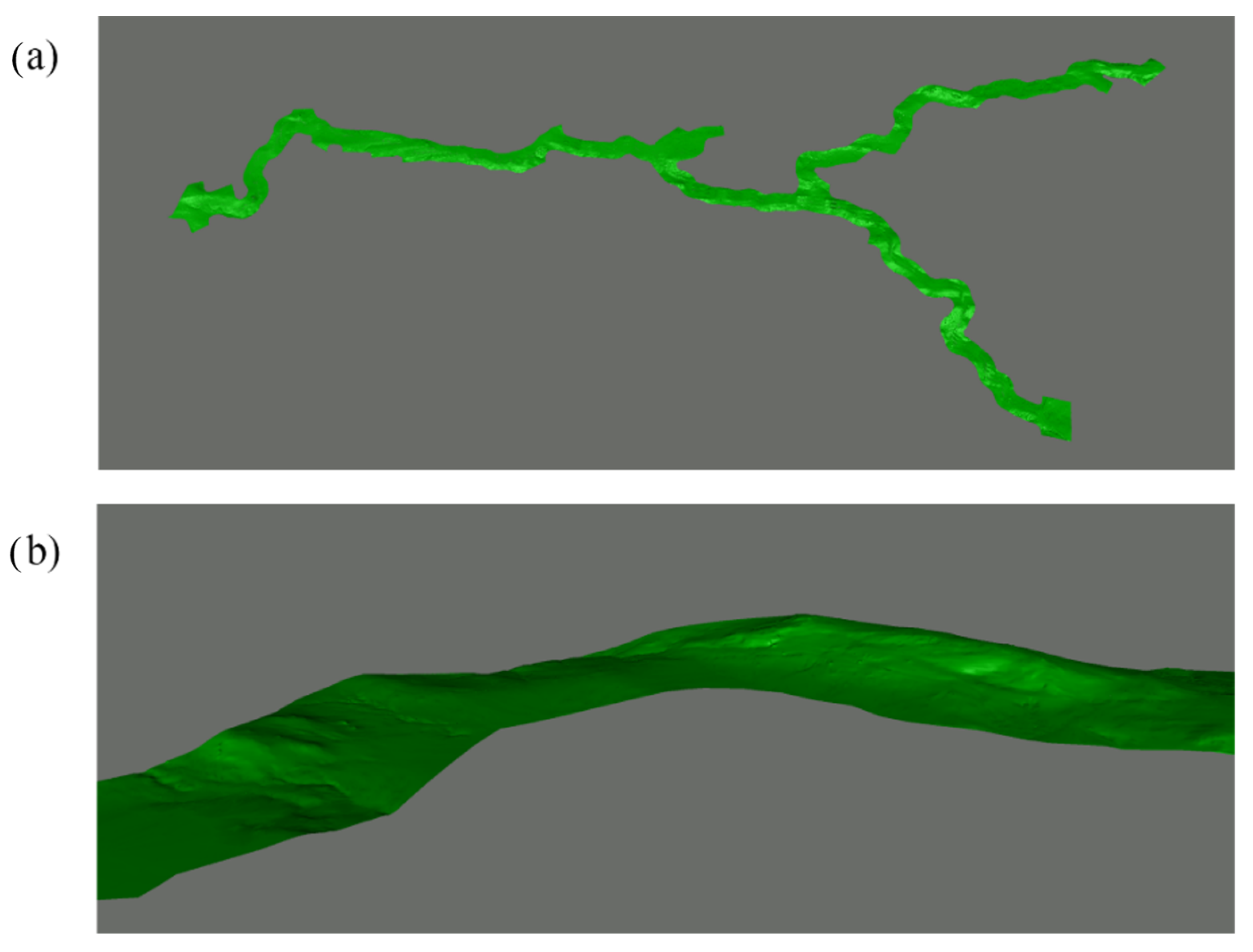

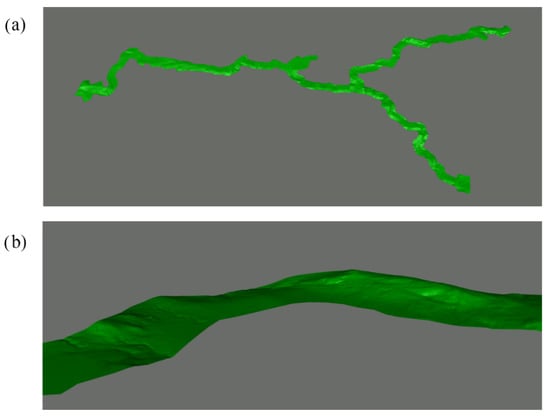

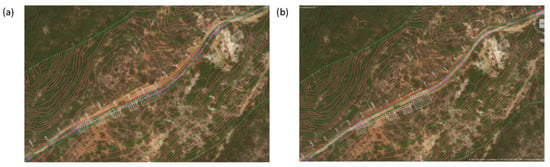

As mentioned above, it is essential that the modeling is as close as possible to the initial conditions. Therefore, a digital terrain model (DTM) obtained from photogrammetry by drone flight was used as a starting point (Figure 1) for the design of the model. The DTM covered the entire study area, intending to represent the surface on which the wind farm is located as accurately as possible.

Figure 1.

Digital terrain model (DTM). (a) DTM of the entire wind farm; (b) detail of the DTM in the study area.

Since the DTM was the starting point, all subsequent actions were carried out with this model as a reference. From here, the rest of the elements that make up the three-dimensional model were established, the main ones being those corresponding to the access roads to the wind farm, the platforms, and the wind turbines. The design was executed following the appropriate engineering criteria; however, this task is not described in this study as the focus is on the geometric and location aspects of the BIM model (from the design phase) for comparison with the as-built model.

3.1.2. As-Built Model

The project status during the different execution phases is represented by as-built models. These models represent what has actually been executed during the construction, so they can be compared with the initial BIM model to determine the differences or deviations that occurred during the construction phase.

Since the wind farm is still in the design phase and the work is a pilot investigation to determine the feasibility of its use, it was not possible to have actual as-built models obtained from field data. For this reason, a simulated as-built model was generated following execution criteria as close as possible to real conditions and generating deviations that can then be compared with the original BIM model (from the design phase).

Based on the BIM model, the geometry and location of the main elements were modified as specified below:

- Road layout: Modification of the layout in the plan of some roads, adjusting them to the existing roads to facilitate their construction. These adjustments involved slight deviations in the curvature and, therefore, a variation in the design of the alignment of the road.

- Road profile: In order to adjust the road base to the existing terrain, some modifications to the road profile and slope were proposed. In this case, these changes may lead to differences in the number of earthworks required.

Finally, to monitor the models and to be able to show the evolution of the progress during the execution of the construction, a work plan was considered in which the main tasks would be carried out in three months. Then, an as-built model was generated, which would simulate the construction progress at the end of these three months.

3.2. Unreal Engine Platform

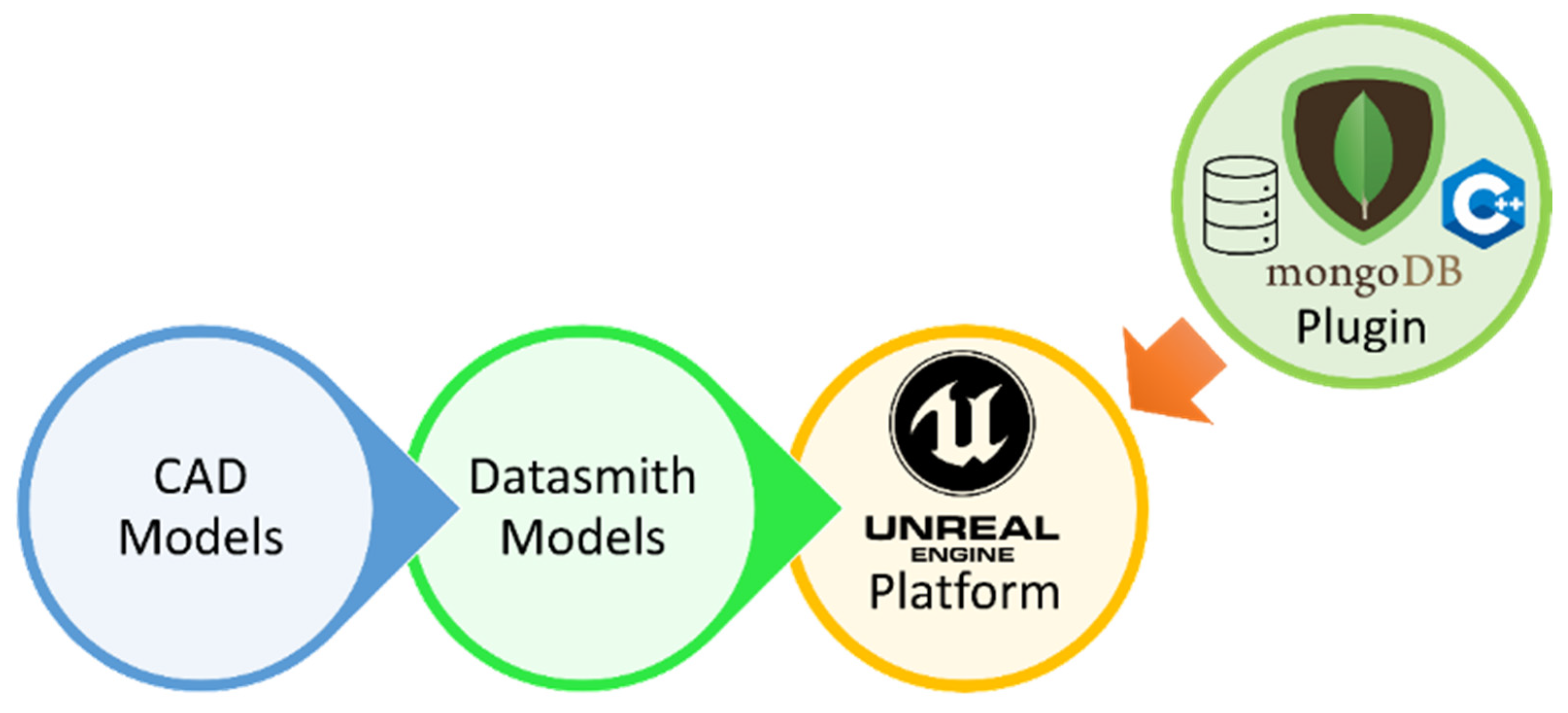

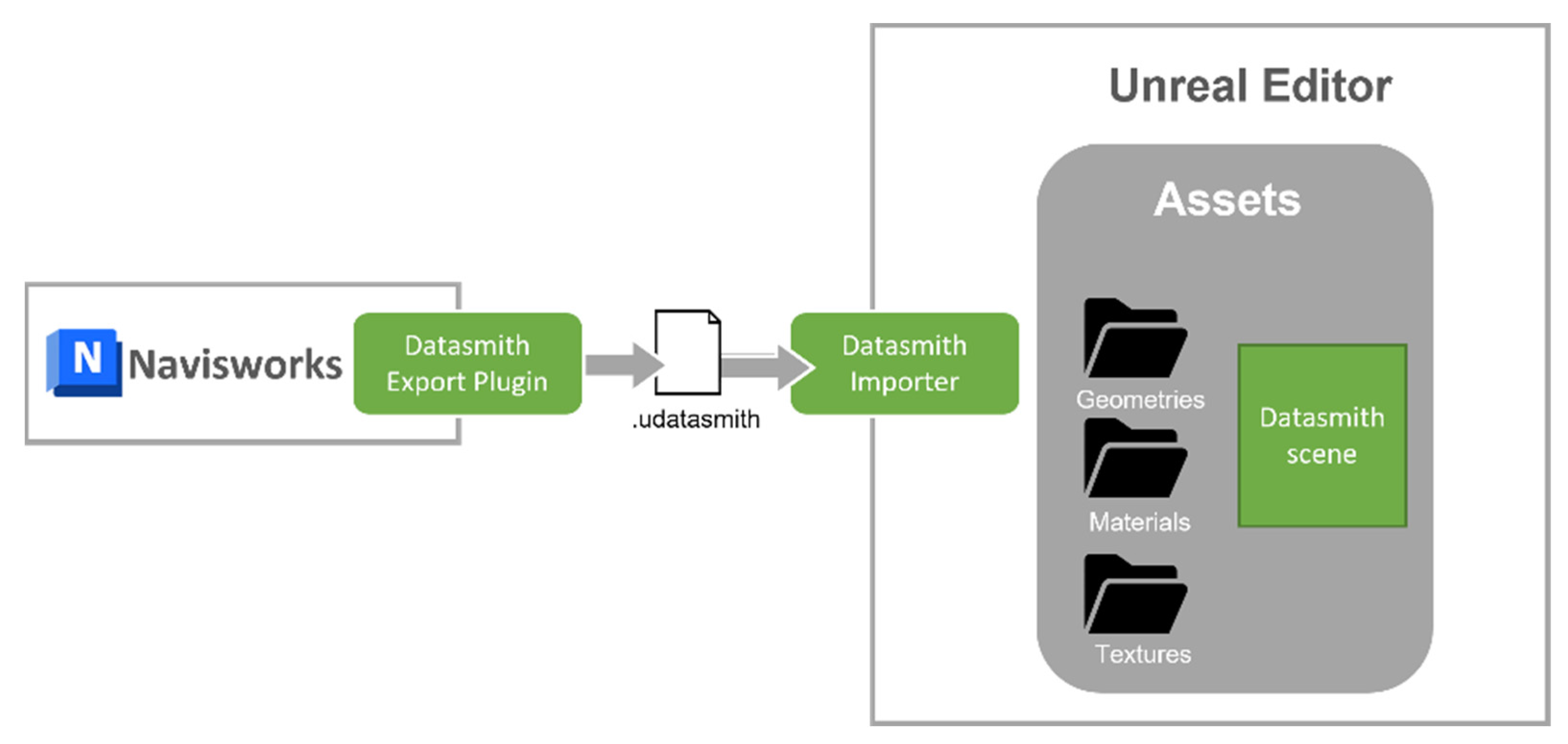

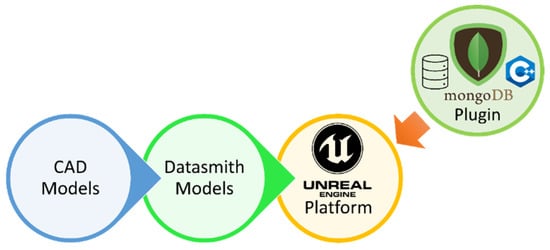

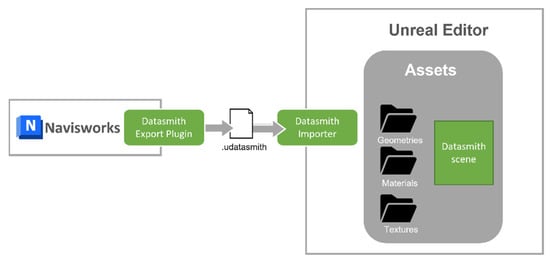

The authors propose developing a video game-type interface using Unreal Engine (UE) for user interaction. Then, once the CAD models are ready, the UE platform must include them. Thus, the authors used the Datasmith plugin to export the CAD models from the modeling application. Datasmith is a plugin that brings entire scenes and complex assets created in diverse design applications into Unreal Engine [30].

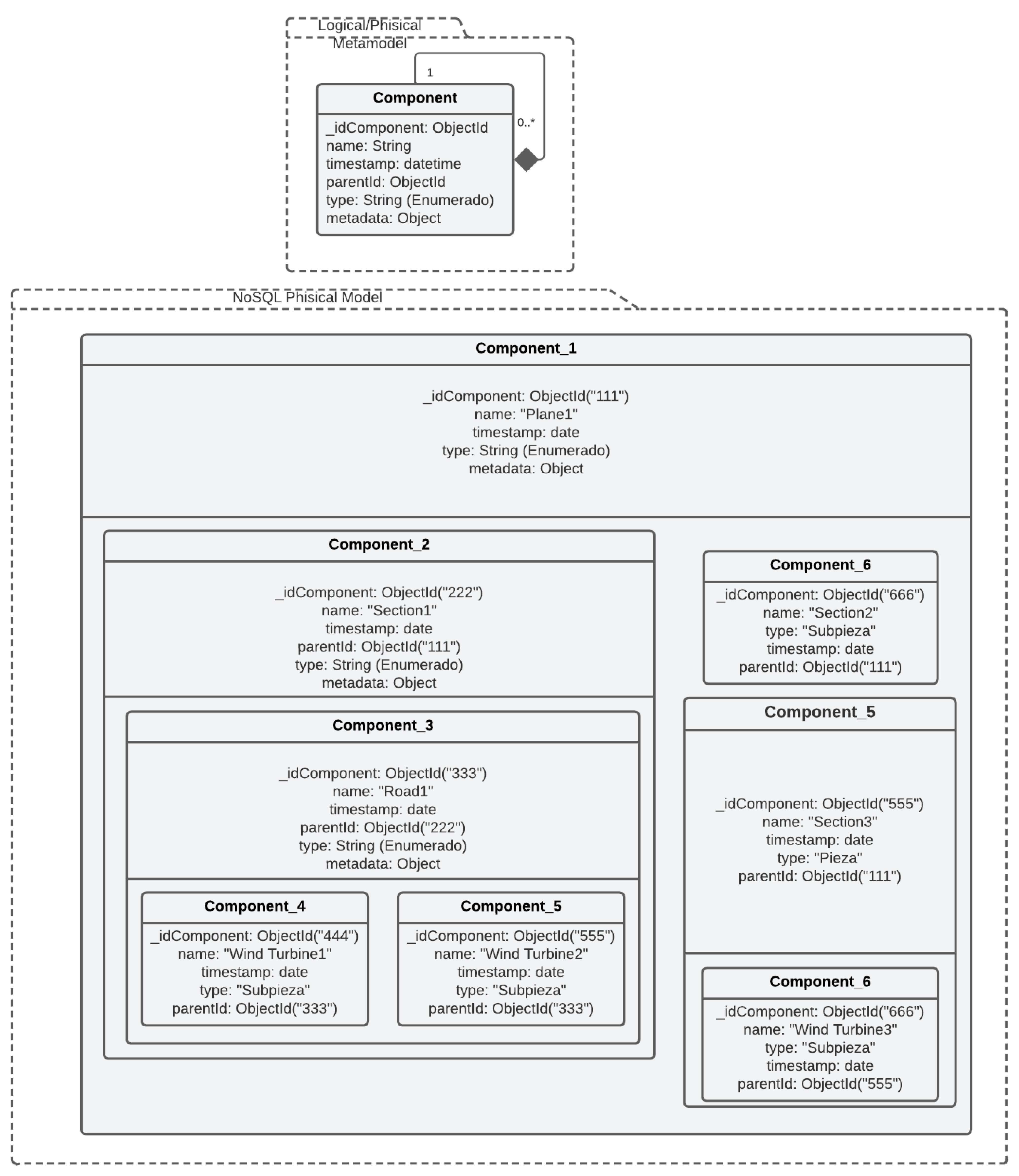

Once the Datasmith models were on the UE platform, some functionalities were developed to compare the BIM model (from the design phase) and the as-built models: (i) a timeline functionality that allows for changing the visualization between the BIM model, the as-built model, and the contrast of both through time; (ii) a non-relational model since the data to be stored are semi-structured (i.e., not all areas of a model will have the same parameters) and the project needs are unpredictable as they can change alongside progression. The authors propose use MongoDB, a non-relational database, due to its flexibility. Figure 2 shows a high-level scheme for the platform architecture.

Figure 2.

Platform architecture.

4. Results

4.1. BIM Model

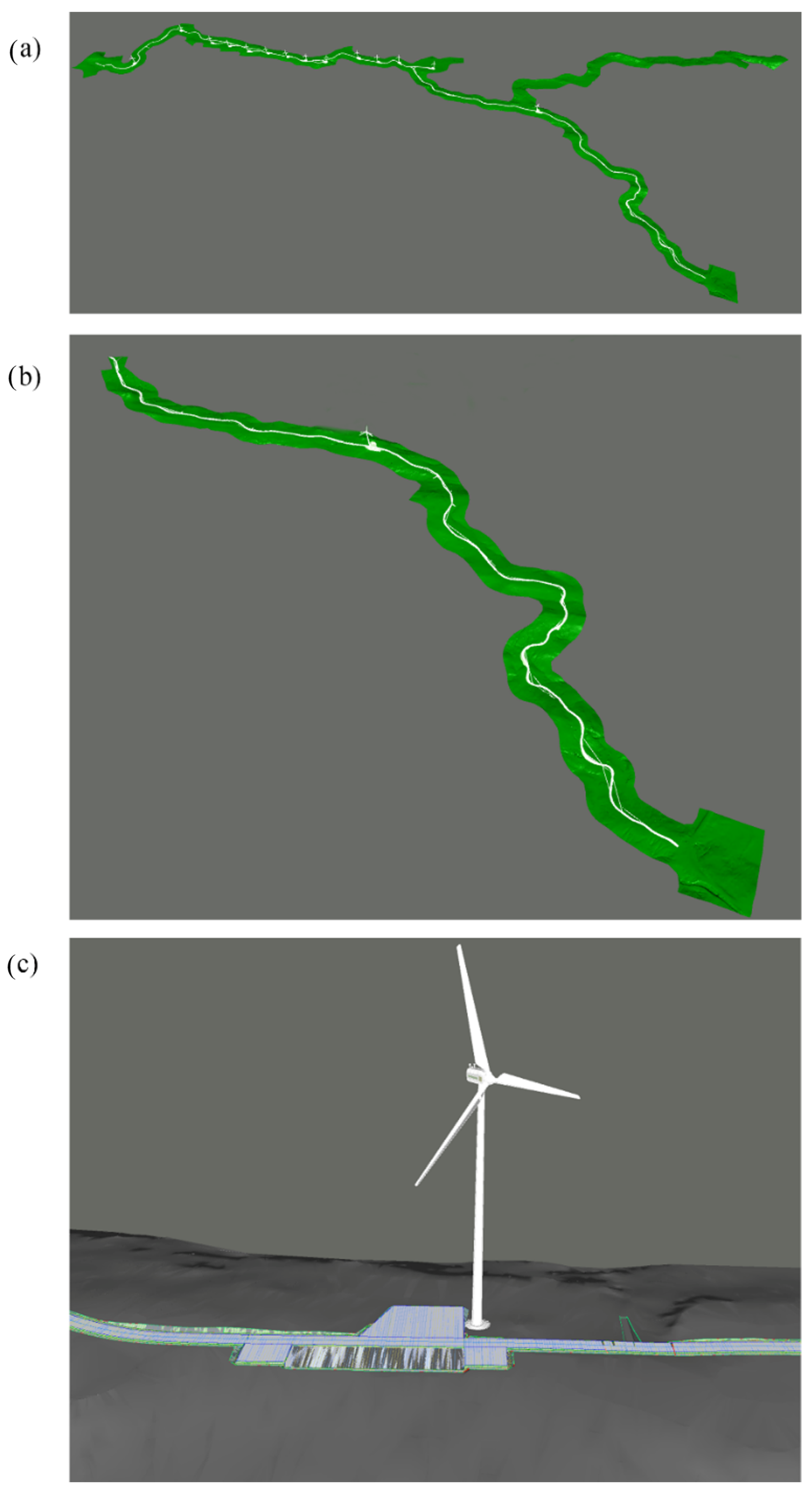

The CAD-generated BIM model of the wind farm is shown in Figure 3. This model includes the following elements and specifications:

Figure 3.

BIM model (from the design phase). (a) Entire wind farm; (b) case study area; (c) detail of the elements designed.

- Access roads with a total length of 6080 m and an average width of 6.5 m. Both the layout and the profile were adjusted to the existing orography using the DTM in Figure 1 as a reference.

- Platforms for the wind turbines, with space to facilitate access and unloading of bulky items with dimensions of 100 × 20 m and an area of 40 × 25 m to provide a flat area for the installation and maintenance of the wind turbines.

- Wind turbines, whose CAD modeling corresponds to the standard models for the design of projects offered by the installers, as it is not relevant in this case to model in detail each of their components. A total of 14 wind turbines were installed with a separation of approximately 350 m. However, the part analyzed in this study corresponds only to the first access section, where only one wind turbine is installed.

4.2. As-Built Model

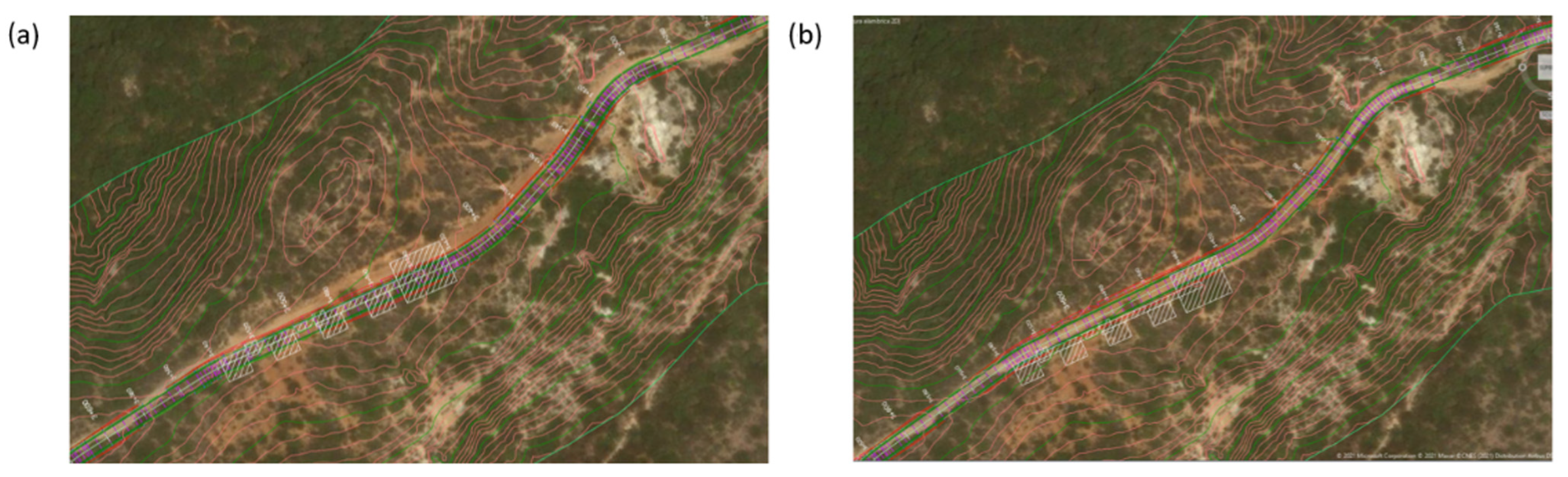

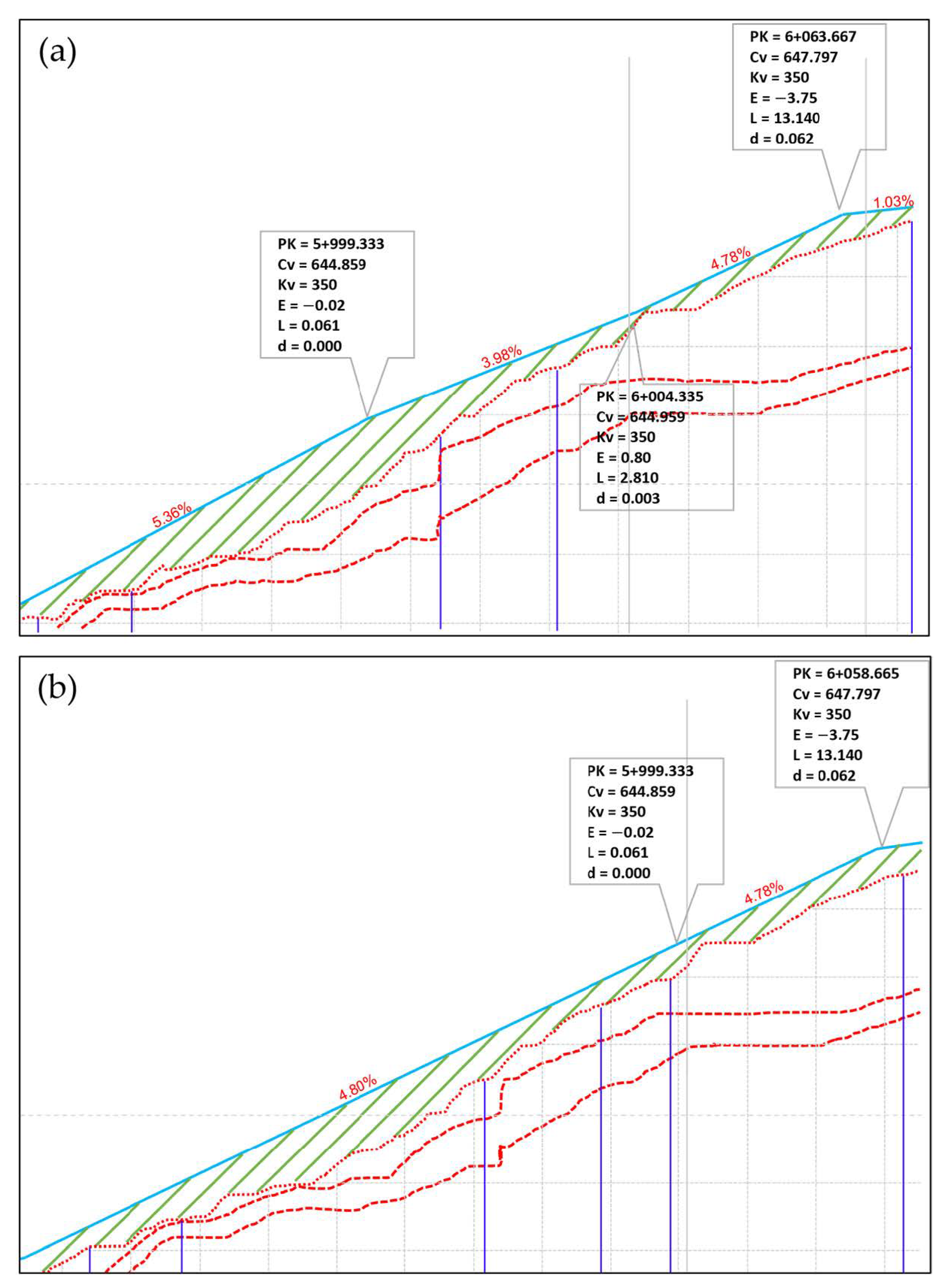

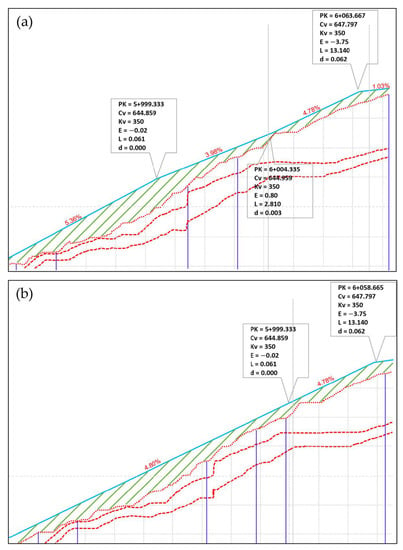

The as-built model was generated by modifying the BIM model (from the design phase). The different types of changes described in Section 3.1.2. were applied. Although all modifications can be visualized in the final result of the study with the tool developed, the results for each type of modification are described below in order to appreciate in detail the changes in geometry and design. The description and localization of the changes made to the road layout are shown in Table 1, while Figure 4 shows the detail of one of these modifications in the design phase. Table 2 describes the changes made to the road profile, and Figure 5 shows the change in the design of one of the actions with the difference between cuttings and embankments.

Table 1.

Changes made to the road layout to generate the as-built model.

Figure 4.

Changes to the access road layout plan view (K.P. 3 + 300 to 3 + 600): (a) initial design; (b) modified design.

Table 2.

Changes made to the road profile to generate the as-built model.

Figure 5.

Modifications to the access road layout profile view (K.P. 5 + 900): (a) initial design; (b) modified design.

Finally, with regard to the work plan, the progress corresponding to three months of construction was established; thus, in the next steps, the results will be shown once the following actions have been completed:

- Construction of the access road in its entirety (6080 m);

- Construction of the unloading zone and installation platform located at K.P. 3 + 700;

- Installation of the wind turbine corresponding to the aforementioned platform at K.P. 3 + 700.

4.3. Unreal Engine Application

Both generated CAD models, the BIM (from the design phase) and as-built models, were ported to the game engine UE, where different forms of interaction with the end user were introduced, generating a video game-type application.

These models were imported via the Unreal Engine Datasmith plugin as shown in Figure 6 [30]. This plugin allows for bringing complete pre-built scenes and complex assets created in different design applications [30].

Figure 6.

Datasmith workflow.

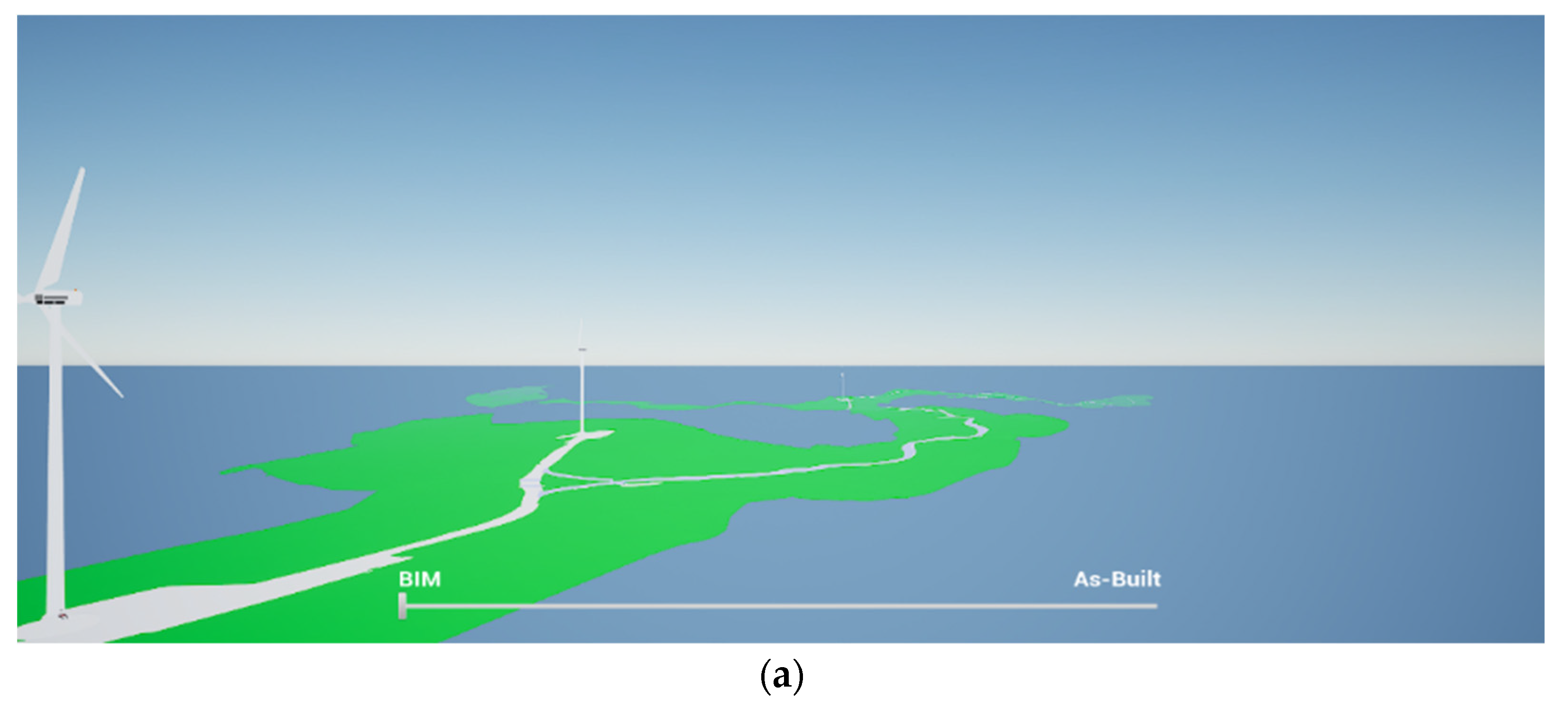

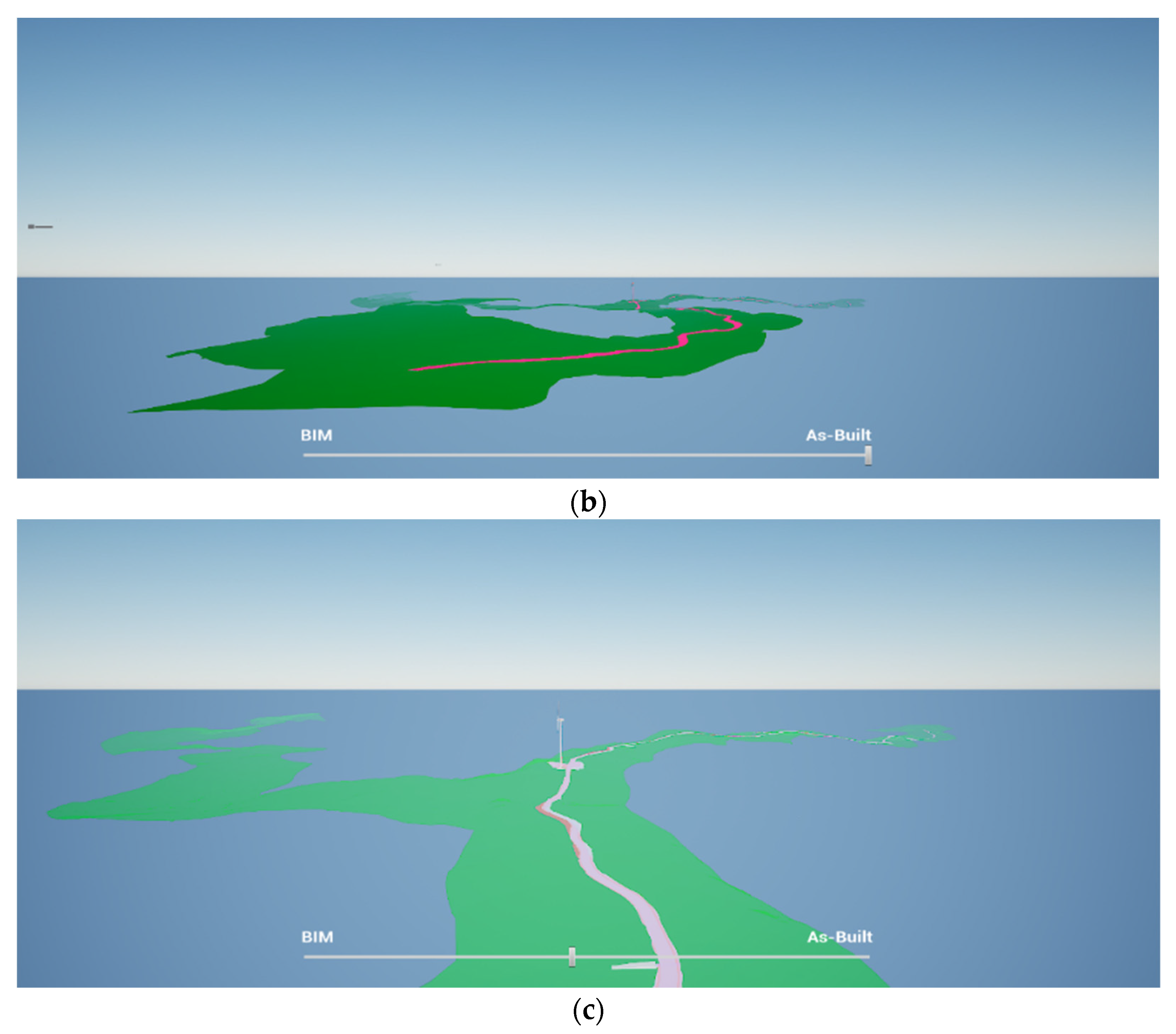

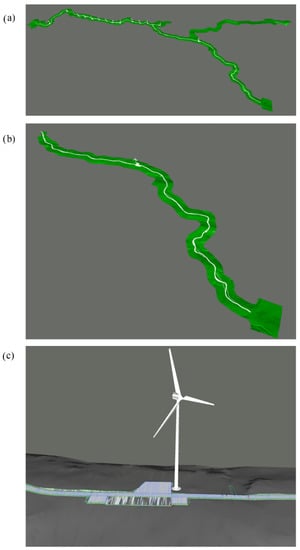

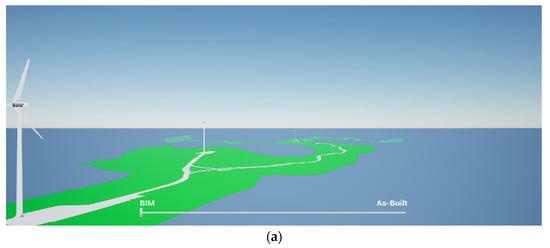

The result was an application prototype for monitoring the construction of a wind farm in a very didactic way based on the differences between the BIM model from the design phase and the as-built models of the construction progress.

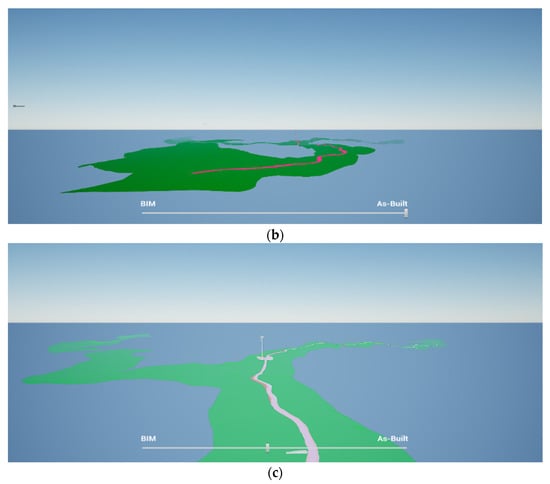

In the application, one model is superimposed on the other, and the asset materials’ visibility in the scene is modified to see the differences between the models, thus allowing supervision of the construction progress through time.

Different forms of interaction were created. The application allows users to fly over the entire wind farm—that is, fly over both models to capture the differences. Likewise, a slider was created to change the visualization from the BIM model to the as-built model, varying the materials visibility of both models, as seen in Figure 7.

Figure 7.

The application with the slider tool in different stages: (a) BIM model (from the design phase); (b) as-built model; (c) contrast of both.

The use of a video game-type interface (Figure 7), developed with Unreal Engine, is proposed. This interface is quite intuitive and allows a general view of the project, clearly showing the differences between the BIM model and the as-built model.

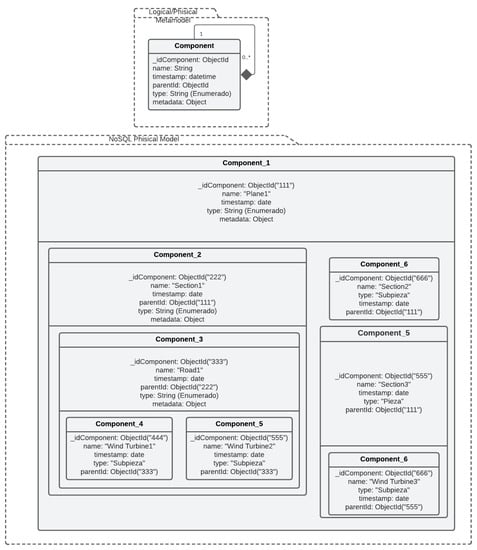

Data Model

In addition, a data model was created (Figure 8) to store the data obtained from this comparison, including the position of the wind turbines, the footing platform, the trace of the road, and the width and slope of the road, etc.

Figure 8.

Non-relational data model created for the monitoring of the wind farm (* being any positive number).

It was decided to use a non-relational data model due to the nature of the project and the data being quite variable. Non-relational databases allow greater flexibility and scalability. This decision led to the development of a MongoDB plugin for Unreal Engine for database management.

The non-relational data model shows the hierarchy between components, typical in a construction project and fundamental for its management. The usefulness of this hierarchy is in the easiness of monitoring the construction, letting users navigate through the planes to perform an exact comparison of the BIM (from the design phase) and as-built models, thus controlling deviations.

5. Discussion

This study has made it possible to find ways to apply the BIM methodology and as-built models to show deviations in construction and apply them to the field of digital twins.

This case study has made it possible to demonstrate that the use of the BIM methodology together with as-built models representing the real situation of the progress of construction allows the creation of a digital twin that shows the progress of the work.

On the one hand, the BIM model (from the design phase) was defined using Civil 3D software, representing the theoretical design of the wind farm. This BIM model contained both the original terrain and the proposed constructions for accesses, platforms, and wind turbines. When it comes to the construction process, this type of model is of great interest compared to traditional 2D design as it allows for a more detailed appreciation of all the elements and a more comprehensive understanding of the entire project.

On the other hand, the as-built model obtained allowed to generate changes in the geometry of the different elements with respect to the BIM model coming from the design phase. This new model allowed to represent possible deviations in the execution of the work with respect to the initial plan and to make a step-by-step comparison during the construction phase. Since an actual construction model is not available, the construction progress was simulated according to engineering criteria and the construction plan proposed in the project.

The DT developed in this project allows the integration and comparison of BIM and as-built models through time. Furthermore, this DT enables the application of simulations, which can be very useful in such construction works (e.g., flood simulation, structural analysis, etc.). This DT differs from the BIM or as-built models by themselves in that it can be used to see the difference between the models with smart visualization and it can even provide a predictive analysis of the construction.

Moreover, it has shown that creating digital twins with game engines allows intuitive and easy monitoring for anyone, thus overcoming the disadvantage of other techniques that require experts. Specifically, the use of Unreal Engine allowed the creation of powerful plugins such as the MongoDB plugin developed to provide models with semantics and achieve a useful digital twin.

6. Conclusions and Future Work

The authors have proposed a potent and novel tool for monitoring the progress of a construction project based on the concept of a digital twin and using a video game-type application developed with Unreal Engine.

For this, a case study of a wind farm under construction was established. First, CAD models of the BIM and as-built models of the wind farm were obtained, the latter being a simulation created from the BIM model due to limitations in obtaining new data on the construction progress.

Then, the generated CAD models were imported to Unreal Engine using the Datasmith plugin (which allows bringing complete pre-built scenes and complex assets created in different design applications to UE) for the development of the application. Using UE, different forms of interaction with users were programmed, such as (i) a timeline function, which allows to change the visualization between the BIM model coming from the design phase and the as-built model and also allows us to visualize them together to inspect the deviations in the construction, and (ii) a non-relational model that allows us to analyze and store these BIM vs. as-built model comparisons. Lastly, a way to fly over the entire wind farm based on the existing movements for video games was programmed, so the monitoring of the wind farm could be applied easily.

The main limitation of this study is the lack of automation in obtaining the CAD models. Going from the point cloud models obtained, for example, with a drone flight (to obtain the as-built models) to a CAD model was an arduous process in which manual work was essential. Furthermore, it is necessary to continue developing forms of user interaction that allow for visualizing the exact coordinates where deviations have occurred. Additionally, updating data to include new as-built models depends on the users, and it is a tedious process because of the difficulty of obtaining the CAD models and introducing them into the game. To solve this issue in future work, the authors propose using a plugin for UE called Datasmith Runtime, a collection of Datasmith features available at runtime. This plugin allows to import udatasmith files to UE applications at runtime and manipulate them, so the users can import to the application any model of the construction progress and compare it to the BIM model to detect deviations.

Author Contributions

Conceptualization, A.O.-B. and J.L.-R.; methodology, A.O.-B., J.L.-R. and P.M.-S.; software, A.O.-B., J.L.-R. and P.M.-S.; validation, A.O.-B., J.L.-R. and D.G.-A.; investigation, A.O.-B. and J.L.-R.; resources, A.O.-B.; writing—original draft preparation, A.O.-B. and J.L.-R.; writing—review and editing, A.O.-B., J.L.-R. and D.G.-A.; visualization, A.O.-B.; supervision, D.G.-A.; project administration, D.G.-A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data sharing is not applicable to this article.

Acknowledgments

This work was conducted with the collaboration of Ghenova Engineering in the framework of the CIEN project of CDTI, READY TWIN, Research in Emerging technologies to Achieve innovative solution for Digital TWINs.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Cumo, F. Digital Twin for Critical Infrastructures: The Ventotene Island Port Case, Italy. In Building Information Modelling (BIM) in Design, Construction and Operations IV; Casares, J., Mahdjoubi, L., Garrigós, A.G., Eds.; WIT Press: Southampton, UK, 2021; Volume 205, pp. 217–222. [Google Scholar]

- Reja, V.K.; Varghese, K.; Ha, Q.P. Computer vision-based construction progress monitoring. Autom. Constr. 2022, 138, 104245. [Google Scholar] [CrossRef]

- Mannino, A.; Dejaco, M.C.; Re Cecconi, F. Building Information Modelling and Internet of Things Integration for Facility Management—Literature Review and Future Needs. Appl. Sci. 2021, 11, 3062. [Google Scholar] [CrossRef]

- Rausch, C.; Sanchez, B.; Esfahani, M.E.; Haas, C. Computational Algorithms for Digital Twin Support in Construction; Construction Research Congress: Tempe, AZ, USA, 2020. [Google Scholar]

- Jiang, Y. Intelligent Building Construction Management Based on BIM Digital Twin. Comput. Intell. Neurosci. 2021, 2021, 4979249. [Google Scholar] [CrossRef]

- Ramonell, C.; Chacón, R. Open-source terrestrial laser scanner for the virtualization of geometrical entities in AEC classrooms. Comput. Appl. Eng. Educ. 2022, 30, 1009–1021. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. Integrating BIM and AI for Smart Construction Management: Current Status and Future Directions. Arch. Comput. Methods Eng. 2022, 122, 103517. [Google Scholar] [CrossRef]

- Nahangi, M.; Kim, M. Use cases for subcontractors and fabricators. In Infrastructure Computer Vision; Brilakis, I., Haas, C., Eds.; Elsevier: Oxford, UK, 2019; pp. 315–361. [Google Scholar]

- Rausch, C.; Haas, C. Automated shape and pose updating of building information model elements from 3D point clouds. Autom. Constr. 2021, 124, 103561. [Google Scholar] [CrossRef]

- Wang, B.; Wang, Q.; Cheng, J.C.; Yin, C. Object verification based on deep learning point feature comparison for scan-to-BIM. Autom. Constr. 2022, 142, 104515. [Google Scholar] [CrossRef]

- Tran, H.; Nguyen, T.N.; Christopher, P.; Bui, D.-K.; Khoshelham, K.; Ngo, T.D. A digital twin approach for geometric quality assessment of as-built prefabricated façades. J. Build. Eng. 2021, 41, 102377. [Google Scholar] [CrossRef]

- Moretti, N.; Xie, X.; Merino, J.; Brazauskas, J.; Parlikad, A.K. An openBIM Approach to IoT Integration with Incomplete As-Built Data. Appl. Sci. 2020, 10, 8287. [Google Scholar] [CrossRef]

- Almatared, M.; Liu, H.; Tang, S.; Sulaiman, M.; Lei, Z.; Li, H.X. Digital Twin in the Architecture, Engineering, and Construction Industry: A Bibliometric Review; Construction Research Congress: Arlington, VA, USA, 2022. [Google Scholar]

- Shishehgarkhaneh, M.B.; Keivani, A.; Moehler, R.C.; Jelodari, N.; Laleh, S.R. Internet of Things (IoT), Building Information Modeling (BIM), and Digital Twin (DT) in Construction Industry: A Review, Bibliometric, and Network Analysis. Buildings 2022, 12, 1503. [Google Scholar] [CrossRef]

- Li, M.; Li, M.; Liu, X.; Zhong, R.Y.; Pan, W. Digital twin-enabled real-time synchronization for planning, scheduling. Automotion Constr. 2022, 141, 104397. [Google Scholar]

- Opoku, D.-G.J.; Perera, S.; Osei-Kyei, R.; Rashidi, M. Digital twin application in the construction industry: A literature review. J. Build. Eng. 2021, 40, 102726. [Google Scholar] [CrossRef]

- Jiang, F.; Ma, L.; Broyd, T.; Chen, K. Digital twin and its implementations in the civil engineering sector. Autom. Constr. 2021, 130, 103838. [Google Scholar] [CrossRef]

- Akanmu, A.A.; Anumba, C.J.; Ogunseiju, O.O. Towards next generation cyber-physical systems and digital twins for construction. J. Inf. Technol. Constr. 2021, 26, 505–525. [Google Scholar] [CrossRef]

- Moncada, A.; Henao, E. Implementation of BIM aproach for the design of high and extra high voltage electrical substations. In Proceedings of the Conference—Living the Energy Transition, Medellín, Colombia, 4–6 December 2019. [Google Scholar]

- Zhang, J.; Cheng, J.C.; Chen, W.; Chen, K. Digital Twins for Construction Sites: Concepts, LoD Definition, and Applications. J. Manag. Eng. 2022, 38, 04021094. [Google Scholar] [CrossRef]

- Hosamo, H.; Hosamo, M.H.; Nielsen, H.K.; Svennevig, P.R.; Svidt, K. Digital Twin of HVAC system (HVACDT) for multiobjective optimization of energy consumption and thermal comfort based on BIM framework with ANN-MOGA. Adv. Build. Energy Res. 2022, 16, 1–49. [Google Scholar] [CrossRef]

- Corrado, C.R.; DeLong, S.M.; Holt, E.G.; Hua, E.Y.; Tolk, A. Combining Green Metrics and Digital Twins for Sustainability Planning and Governance of Smart Buildings and Cities. Sustainability 2022, 14, 12988. [Google Scholar] [CrossRef]

- Gourlis, G.; Kovacic, I. A holistic digital twin simulation framework for industrial facilities: BIM-based data acquisition for building energy modeling. Front. Built Environ. 2022, 8, 918821. [Google Scholar] [CrossRef]

- Yu, D.; He, Z. Digital twin-driven intelligence disaster prevention and mitigation for infrastructure: Advances, challenges, and opportunities. Nat. Hazards 2022, 112, 1–36. [Google Scholar] [CrossRef]

- El Mokhtari, K.; Panushev, I.; McArthur, J.J. Development of a Cognitive Digital Twin for Building Management and Operations. Front. Built Environ. 2022, 8, 856873. [Google Scholar] [CrossRef]

- Daniotti, B.; Masera, G.; Bolognesi, C.M.; Spagnolo, S.L.; Pavan, A.; Iannaccone, G.; Signorini, M.; Ciuffreda, S.; Mirarchi, C.; Lucky, M.; et al. The Development of a BIM-Based Interoperable Toolkit for Efficient Renovation in Buildings: From BIM to Digital Twin. Buildings 2022, 12, 231. [Google Scholar] [CrossRef]

- Levine, N.M.; Spencer, B.F. Post-Earthquake Building Evaluation Using UAVs: A BIM-Based Digital Twin Framework. Sensors 2022, 22, 873. [Google Scholar] [CrossRef] [PubMed]

- Kaewmoracharoen, M.; Suwan, T.; Nusen, P.; Champrasert, P. Fitness-for-Use of As-Built Building Information Modeling for Digital Twin. In Proceedings of the 37th International Technical Conference on Circuits/Systems, Computers and Communications (ITC-CSCC), Phuket, Thailland, 5–8 July 2022. [Google Scholar]

- Badenko, V.; Bolshakov, N.; Tishchenko, E.; Fedotov, A.; Celani, A.; Yadykin, V. Integration of Digital Twin and BIM Technologies within Factories of the Future. Mag. Civ. Eng. 2020, 101, 10114. [Google Scholar]

- Epic Games, Inc. Unreal Engine. Epic Games. Available online: https://docs.unrealengine.com/5.0/en-US/datasmith-plugins-for-unreal-engine/ (accessed on 2 November 2022).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).