1. Introduction

Interior permanent magnet synchronous motors (IPMSMs) have a wide range of applications in the field of electric drives due to their high torque density, high efficiency, good mechanical characteristics, and wide range of constant power operation [

1,

2,

3]. Compared with surface-mounted PMSMs (SPMSMs), due to the particular arrangement of permanent magnets in IPMSMs, their inductance convex polarity is significant, so in order to take full advantage of the reluctance torque generated by their convex polarity, IPMSMs usually do not impose a null

current but instead use the maximum torque per ampere (MTPA) control [

4]. At the same time, electric vehicles (EVs), at the forefront of the emerging new energy vehicle industry, are currently being widely promoted and adopted globally [

5]. For the battery and motor, this control technique plays a vital role in the energy-efficient operation of EVs [

6].

For IPMSM, due to the magnetic saturation of the rotor core, the cross-coupling between winding currents, and the uncertainty and nonlinearity of the machine parameters as well as the dependence of the parameters on temperature, the realization of accurate MTPA operation became one of the significant challenges facing the control technology of IPMSM. Therefore, many scholars have conducted a great deal of research on the MTPA control strategy of IPMSM [

7,

8]. The current MTPA control schemes can generally be divided into two categories: offline control strategies based on the mathematical model of the motor and online control strategies based on online search.

The most basic control strategy based on the mathematical model of the motor is the analytical solution approach [

9], where the MTPA formula about the

and

currents is derived through theoretical and mathematical operations. However, these formulas depend on the motor parameters. In contrast, for real IPMSMs, the parameters vary according to the operating conditions, such as temperature, magnetic saturation, etc., resulting in bias in the MTPA strategy of the analytical solution method. In order to eliminate the deviation caused by parameter variations, the look-up tables (LUTs) method [

10], the motor parameters calculation method [

11], the maximum torque control (MTC) reference frame method [

12], the scalar control (SC) method [

13], etc., are used in MTPA control to obtain MTPA operating points through off-line experiments. However, such methods require prior knowledge of machine parameters such as stator resistance, inductance, etc., which requires much time for off-line experiments and cannot be directly applied to different motors due to different materials and manufacturing tolerances. In addition, one of the drawbacks of this method is the need for more robustness and the impossibility of off-line tracking any parameter variations or other differences between the mathematical model used for off-line computation and the actual electrodynamics.

One solution to overcome the poor robustness problem is to search online for MTPA operating conditions without relying on any pre-computed information or mathematical modeling of the machine. The on-line optimization strategy control of MTPA based on the principle of extremum seeking control (ESC) [

14] can surmount the limitations of off-line MTPA control. ESC is an algorithm that adjusts the tracking MTPA operating point in a closed-loop manner without direct reference to the analysis of the motor model and related parameters and is highly adaptable to other motors. Currently, there are the following main types of realizations: high-frequency (HF) injection [

15], low-frequency (LF) injection [

16], virtual signal injection control (VSIC) [

17], perturb and observe (P&O) technique [

18], etc., the principles of which can be seen as an application of the ESC principle [

19]. For instance, the work presented in [

20] proposes an enhanced signal injection strategy responsible for correcting the MTPA reference deviation caused by motor parameter variations. It derives a parameter independent

with

MTPA control law responsible for generating MTPA current references based on a constant parameter model to improve the dynamic performance of MTPA operation. Furthermore, a new virtual signal injection method was proposed in the literature [

21], which compensates for the error caused by ignoring the higher-order bias terms in the traditional virtual signal injection strategy by fitting the

and

currents with higher order and superimposing them into the MTPA control law to obtain a more accurate MTPA operating point. An intriguing work in [

22] was proposed, where a gradient descent-based algorithm is designed to introduce a small

harmonic voltage into the machine to induce a small harmonic component in the motor speed. Velocity harmonic amplitude for MTPA angle detection is not dependent on the motor parameters and can reduce the error due to parameter variations. In literature [

23], an ESC strategy was employed to determine the optimal reference flux in real-time based on the relationship between the stator magnetic chain and the stator current, resulting in an MTPA-like approach that improves the efficiency of direct torque control.

Fractional calculus is a 300-year-old topic extending the conventional integer-order calculus to any arbitrary order. The idea of fractional calculus has been known since the development of regular calculus, with the first reference probably being the letter between Leibniz and L’Hospital in 1695 [

24]. But for a long time, it has been considered a singular mathematical problem. In recent years, since the introduction of fractional calculus into the field of engineering, the study of modeling physical phenomena using fractional-order calculus and fractional-order controllers has been widely conducted among researchers and scientists in the field [

25,

26]. There are some successful engineering applications reported in the literature for the PMSM control approach using fractional-order calculus. For example, the LUT-based fractional order composite controller was developed for the PMSM speed servo systems in [

27]. The researcher represented the skin effect in a solid rotor by means of resistance and inductance with fixed values and fractional-order inductance, depending on the frequency of induced eddy currents. Furthermore, to solve parameter fluctuations and disturbances, a novel fractional order model reference adaptive speed observer was proposed in [

28] that estimates the rotor position and the angular velocity from the stator currents for sensorless control of PMSM. The authors of [

29] have compared the design of a fractional-order proportional integral (FOPI) controller and an integer-order proportional integral controller for the PMSM speed regulation system, manipulating the current control scheme with a Xilinx FPGA chip to increase the system loop’s bandwidth, and the accuracy of the numerical implementation of the fractional-order operator is investigated. In [

30], a novel dead-time compensation method is introduced, which utilizes a FOPI controller to mitigate voltage errors. To address the dead-time effects, an enhanced particle swarm optimization algorithm is utilized for parameter design in the FOPI controller, resulting in accelerated convergence speed compared to other optimization algorithms.

With this motivation, the mathematical theoretical support of MTPA control is investigated, which is based on the traditional ESC strategy. An on-line search MTPA method based on fractional-order ESC (FO-ESC) is proposed. The fractional-order calculus in the extremum seeking optimization scheme is used to improve the convergence speed, robustness, and performance of the ESC method without increasing the complexity of the algorithm. A high-frequency sinusoidal excitation signal is superimposed on the stator current vector angle. A fractional-order filter is used to extract the gradient information of the current vector angle carried by the sinusoidal excitation signal. Then, a fractional-order integral optimizer determines the optimal current vector angle, thus realizing a more flexible and accurate MTPA control compared to existing work [

31].

The remainder of this article is arranged as follows:

Section 2 describes the mathematical model of IPMSM and the traditional model-based analytical solution method for the MTPA control strategy.

Section 3 introduces the extremum seeking control algorithm and the regular ESC optimization theory. In

Section 4, the mathematical model of FO-ESC under the Oustaloup algorithm is established.

Section 5 illustrates the superiority and effectiveness of the proposed control method through simulation.

Section 6 draws the conclusion of this article.

3. Principles of Extremum Seeking Control

In order to reduce the error of the analytical solution method MTPA control due to the variation of motor parameters, an MTPA control strategy based on the principle of extremum seeking search is proposed. The extremum seeking search algorithm is a kind of adaptive control, while the model-independent real-time optimization method treats the model as a whole as a black box and achieves the optimality of the target output only through the feedback of certain states.

As shown in Equation (5), when the load torque is certain,

is an extreme value (minimum) function of

. The online MTPA strategy is to continuously search for and update this extreme value point when operating conditions change. More notably, Antonello, R. et al. provide a theoretical analysis of the MTPA control strategy based on the operating principle of extremum seeking control, which provides valuable insights into the system design procedure, investigates the convergence of the optimal operating point, and experimentally tests the strategy on an IPMSM [

31].

The control block diagram of the traditional extremum seeking control is shown in

Figure 2.

Where is the input of the iterative search and is the coefficient of the optimization integrator, is the frequency and amplitude of the excitation signals, is the excitation signals (modulation and demodulation), is the output of the objective function of the system to be optimized, is the high-pass filter (HPF) and low-pass filter (LPF) cutoff frequencies of the gradient estimator.

According to

Figure 2, the iterative steps of the ESC are summarized as follows:

In the first step, a small high-frequency modulation signal

is injected into the estimated current angle

of the motor stator current to obtain the phase angle of the motor stator current:

Through the Taylor expansion, partial derivative terms above the second order are ignored because the value of the modulation signal amplitude

is very small and so it was sorted out:

In the second step, the DC term of

is filtered out by a HPF to obtain the following:

In the third step, by multiplying

with

to gets:

In the fourth step, the LPF can be passed again to obtain information about the gradient between the stator current and the current angle:

The fifth step, as shown in

Figure 3,

is satisfied only at the MTPA operating point

, while

is satisfied when

and

is satisfied when

. Thus, continuous excitation of current

constantly yields

. Then, by integrating, the current angle

for optimal MTPA operation can be updated in real-time.

4. Fractional-Order Extremum Seeking MTPA Strategy

The fractional-order extremum seeking algorithm is proposed in this work, in which fractional-order calculus operators are used in the extremum optimization process. Fractional-order calculus refers to fractional-order differentiation and integration, whose special form is integer-order calculus. The fractional-order model more realistically describes the behaviors of dynamic systems and takes into account non-local features [

33], unlimited memory [

34], etc. Compared to the traditional ESC, FO-ESC provides additional degrees of freedom with fractional-order factors, which provide more factors and possibilities for optimizing the controller parameters to fit the system characteristics and make the control system more flexible.

The fractional-order calculus operator is approximated using the Oustaloup algorithm in MATLAB and Simulink [

35], which uses multiple integer-order filters to approximate the fractional-order calculus. When the fitted frequency is

, the transfer function approximated by the Oustaloup method can be expressed as:

where

and

are constant factors, Equation (13) can be rewritten by the first-order Taylor expansion:

Thus, the fractional-order calculus operator

is expressed by:

More details regarding the Oustaloup algorithm can be found in [

36,

37].

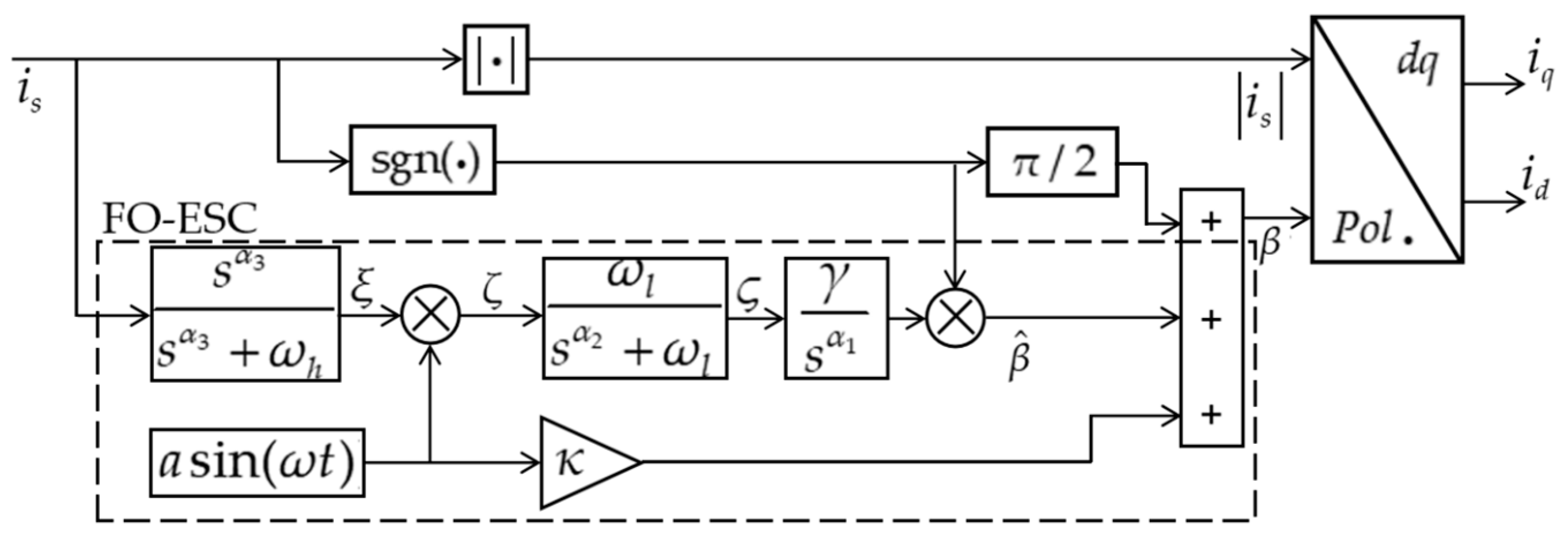

Based on the introduction of the FO operator, fractional-order extremum seeking MTPA control can be achieved by using fractional-order filters in the gradient estimator and optimizer of the ESC, as in

Figure 4, “

” will be replaced by “

” in gradient estimator and optimizer, where

,

is the initial value of the current angle,

is the excitation signal gain, and

is:

The mathematical equations based on the FO-ESC method can be introduced according to

Figure 4:

Unlike previous improved ESC methods that use complex mathematical operations (e.g., Hessian matrix calculations) or additional feed-forward and feedback control loops, as shown in Equation (17), this method uses fractional-order calculus without increasing the complexity of the algorithm, which is capable of searching for the optimal operating current angle of the MTPA much faster and achieves faster convergence and higher robustness.

Based on the previous analysis, in order to obtain a better control performance of the FO-ESC, the parameter tuning includes frequency and amplitude of the excitation signals, optimization integrator gain , the cutoff frequency of LPF and HPF , and fractional-order factors . The design procedure of the FO-ESC could be summarized as follows:

- A.

Select the excitation signal , and the optimization integrator gain :

The excitation signal frequency should be set as slow as possible compared to the plant. The large values of amplitude and optimization integrator gain represent a larger range of extreme seeking and thus lead to faster convergence rates. However, the ESC sensitivity and oscillation amplitude are increased due to large values of and . Thus, the selection of and should consider the trade-off between system stability and convergence speed.

- B.

Design the HPF and LPF according to the frequency of the excitation signal:

Generally speaking, the HPF frequency should be slower than the excitation frequency , and the LPF frequency should be slower than the HPF frequency .

- C.

Fractional-order factors :

As mentioned before, the fractional-order factors provide additional degrees of freedom with fractional-order factors for tuning the best controller performance.

In order to give an insight into the influences of fractional-order factors on the convergence performance of the FO-ESC and compare the performance of integer-order and FO-ESC numerically, these two algorithms are both applied to the double-integrator system [

38]:

with

and the output

.

reaches its maximum

at

.

,

. The control system is explained in

Figure 5, and the ESC and FO-ESC scheme are illustrated in

Figure 2 and

Figure 4, respectively. The sensitivity analysis of

is shown in

Figure 6.

From the sensitivity analysis results, it can be seen that FO-ESC has faster tracking performance and higher accuracy than integer order. Therefore, the convergence speed of ESC is improved by using fractional order factors. In addition, it is observed that the fractional-order factor of LPF has the strongest influence on the convergence performance. This sensitivity analysis provides a handy guide for tuning the parameters of the fractional order factor in the ESC.

5. Simulation Verification

In order to verify the accuracy and speed of the MTPA control, the whole drive system has been simulated in the MATLAB/Simulink environment. The overall schematic of the IPMSM control system is based on the proposed control scheme, as shown in

Figure 7. The

and

currents

are generated by the FO-ESC MTPA control law scheme illustrated in

Figure 4.

The

and

currents will be compared with the measured

and

currents in PI current controllers to generate the reference

and

voltages after decoupling. The decoupling scheme illustrated in

Figure 8.

The motor specifications of the IPMSM and the proposed FO-ESC tracking controller parameters are given in

Table 1 and

Table 2, respectively.

In IPMSM drives, the purpose of replacing conventional

strategy with the MTPA strategy is to reduce the current magnitude. Therefore, the current magnitude of the

method is compared with the traditional ESC and the proposed MTPA scheme at a speed of

and a load torque of

. For all the simulation results, the ESC is activated at

and the FO-ESC is activated at

. The current state based on different control methods results are shown in

Figure 9a–c.

As shown in

Figure 9a, the

current reduced to

from

and

current reduced to

from

when the control algorithm was switched from the

method to the traditional ESC scheme; the

current reduced to

from

and

current reduced to

from

when the control algorithm was switched from the traditional ESC method to the FO-ESC scheme.

As shown in

Figure 9b, the stator current magnitude was reduced accordingly to

from

when the control algorithm was switched from the

method to the conventional ESC scheme and reduced to

from

when the control algorithm was switched from the traditional ESC method to the FO-ESC scheme.

As shown in

Figure 9c, the current angle was increased accordingly to

from

when the control algorithm was switched from the

method to the traditional ESC scheme and to

from

when the control algorithm was switched from the conventional ESC method to the FO-ESC scheme.

In other words, the proposed MTPA scheme exhibits a lower current magnitude than the method under the given load torque, verifies the effectiveness of the algorithm, and compares with the conventional ESC control without increasing the complexity of the algorithm. The FO-ESC control does not affect the accuracy of MTPA.

The transient response of the proposed MTPA scheme was simulated at

under a step load torque of

, and the simulation results of increasing and decreasing load torque are depicted in

Figure 10a–c.

As shown in

Figure 10a the load torque changed to

from

at

and to

from

at

.

Figure 10b shows that the stator current magnitude was changed accordingly to

from

at

and to

from

at

.

Figure 10c shows that the current angle changed to

from

at

and to

from

at

.

It can be observed that the motor is able to arrive at the new steady state within of the load sudden load addition and subtraction, which shows a fast MTPA tracking response.

The dynamic response of the proposed MTPA scheme was simulated at

under a step reference speed of

, and the simulation results of increasing and decreasing speed are depicted in

Figure 11a–c.

In

Figure 11a, the sudden speed change between the traditional ESC and FO-ESC control strategies under the same controller parameters was compared. When the speed command is run at

, compared with the traditional ESC strategy, it is obvious to find that the FO-ESC control strategy reference speed changes from its initial value to the command speed at

with fewer oscillations; for the speed command to suddenly increase or decrease, e.g., when it is reduced to

from

, the overshoot of the traditional ESC strategy is 22%. The overshoot of the FO-ESC strategy is 11%.

Figure 11b,c show the stator’s current magnitude and the angle’s dynamic graphs. It can be seen that the change in speed under the command of load torque

does not affect the magnitude of the stator current or current angle, which indicates the correctness of the control strategy. Thus, a comparison of the results shows that, under the same circumstances, the dynamic control effect is more flexible when the motor is suddenly accelerated or decelerated under FO-ESC control. It also shows that the proposed scheme can achieve a satisfactory dynamic response.

In addition, to further validate the robustness of motor parameter variations under the FO-ESC control strategy. By changing some parameters in the motor model. For example,

is changed to

from

and

is changed to

from

, the stator current variation of the proposed MTPA scheme was simulated at

under a step load torque of

, and the simulation results are depicted in

Figure 12a,b.

Figure 12a,b shows the response of the motor stator current amplitude to a step change in torque. It can be seen that the current amplitude is initially large and then decreases rapidly until it reaches a minimum value for the MTPA condition. Moreover, when the load torque changed abruptly, the

and

currents were adjusted automatically until a new MTPA operation was reached. Therefore, it is verified that the scheme proposed in this paper can obtain a satisfactory dynamic response, and it is also shown that the control effect is not affected by the variation of motor parameters, which illustrates the robustness of the FO-ESC control scheme to torque disturbances.

In addition, based on the previous analysis, the algorithm execution time does not exceed 0.03 s. In other words, once the FO-ESC algorithm is enabled, the MTPA operation reaches its optimum within 0.03 s.

6. Conclusions

Aiming at the problem that the MTPA control strategy is based on the motor’s mathematical model, it is impossible to off-line track any parameter variations or other differences between the mathematical model used for off-line computation and the actual electrodynamics. A fractional-order extremum seeking control (FO-ESC) online MTPA method that is not model-based is proposed. In this work, we have studied and analyzed the traditional extremum seeking algorithm maximum torque-current ratio control strategy and proposed a new fractional-order extremum seeking algorithm control. Compared with the traditional extremum seeking algorithm, by introducing the fractional-order differential integral operator, the degree of freedom of the control strategy is improved without increasing the algorithm’s complexity, which makes its control of the system more flexible. The simulation results verify the control accuracy of the fractional-order extremum seeking MTPA strategy, the correct validity of the MTPA angle search under different speeds and load conditions, and the good dynamic and static tracking performance and flexibility of the strategy, which achieves the expected results.

The simulation results demonstrate that the proposed MTPA scheme has a faster convergence speed and a smoother tracking response without prior knowledge of motor parameters and is robust concerning torque and parameter variations. However, the MTPA control can only minimize the copper loss of the machine, which is a typical current control strategy below the base speed (i.e., in the constant-torque region), so this study focuses on the region below the base speed. Iron losses will increase significantly when the machine operates above the base speed (i.e., in the constant-power region). In this case, maximum efficiency control will be more appropriate for reducing motor loss. Investigations on extending the proposed approach to maximum efficiency control will be conducted in our future work.