Neural Fractional Order PID Controllers Design for 2-Link Rigid Robot Manipulator

Abstract

:1. Introduction

- Six controller structures are suggested by combining the proportional, integral, and derivate operations and neural networks.

- Suggest a new objective function to make the tuning process produces a controller that has a minimum chattering in the control signal.

- Applying a strong competition between the proposed controllers, especially for robustness, among the proposed controllers that integrate the specifications of the PID controller and neural networks.

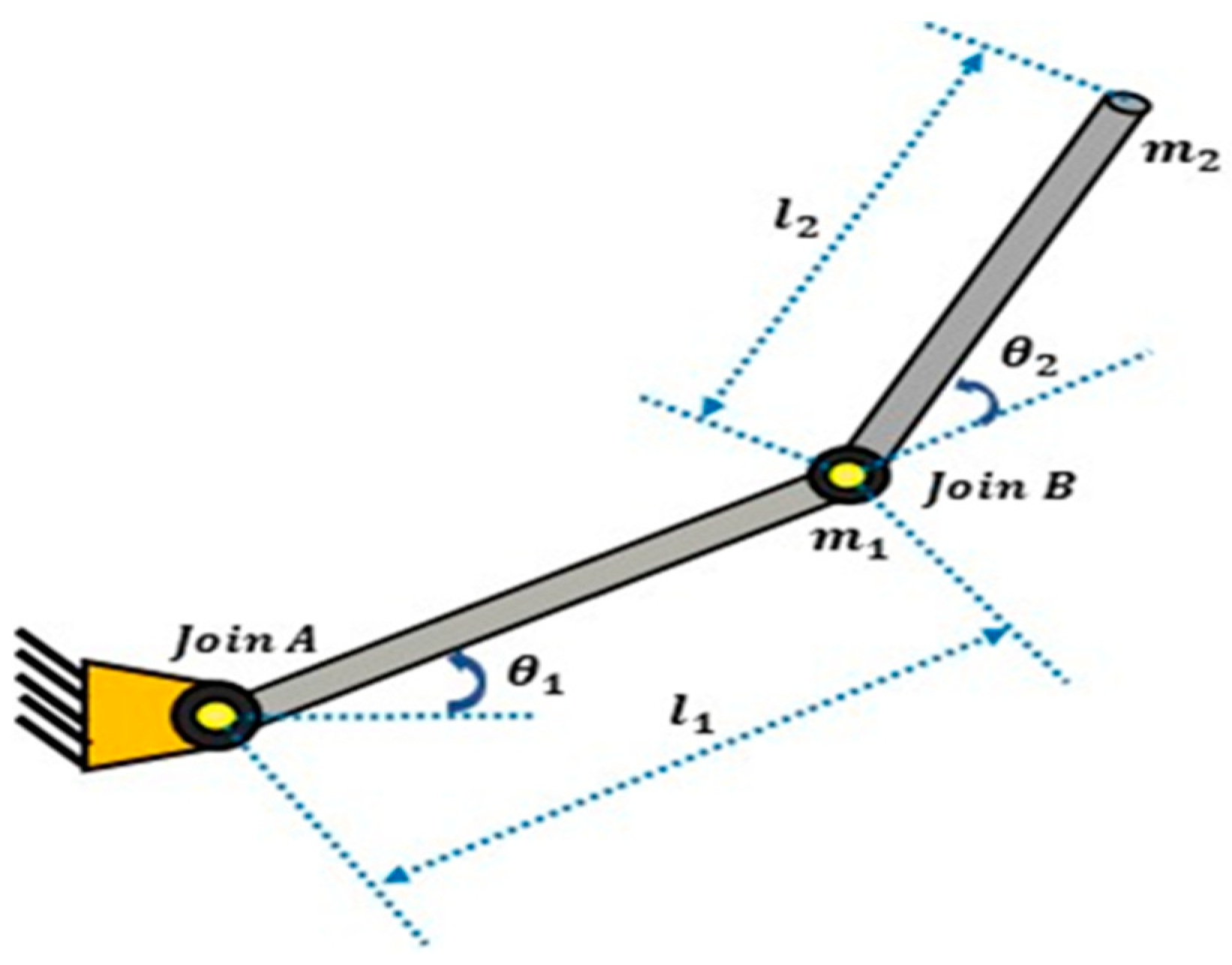

2. Dynamic Model of 2-LRRM

3. Artificial Gorilla Troops Optimizer (GTO)

3.1. Exploration Phase

3.2. Exploitation Phase

3.2.1. Following the Adult Silverback Leader

3.2.2. Competition for Adult Females

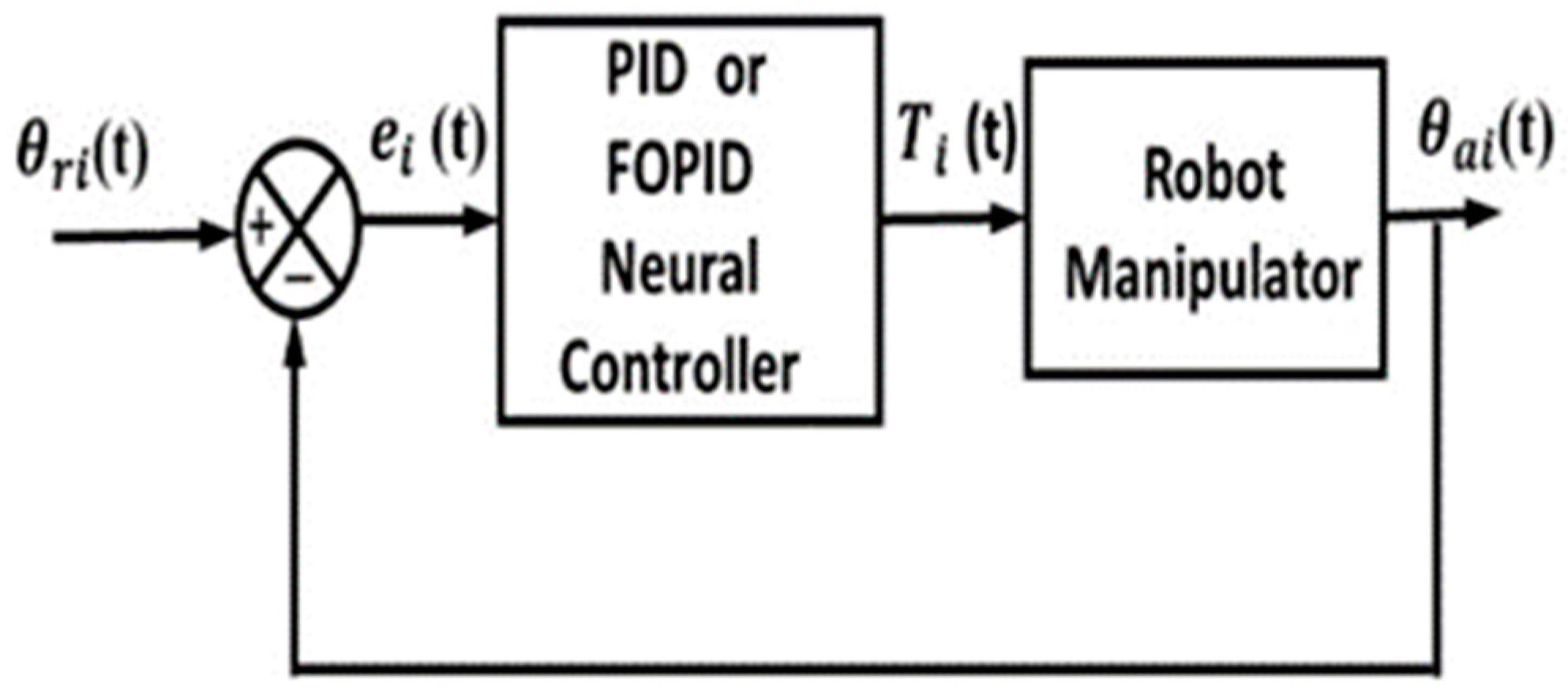

4. The Structures of the Proposed Controllers

4.1. Conventional PID Controller (Con-PID)

4.2. Conventional Fractional Order PID Controller (Con-FOPID)

4.3. Self-Tuning Neural Network PID Controller (STNN-PID)

4.4. Self-Tuning Neural Network FOPID Controller (STNN-FOPID)

4.5. Neural Network PID Controller (NN-PID)

4.6. Neural Network FOPID controller (NN-FOPID)

5. Simulation Results

5.1. Robustness Tests

5.1.1. Change Initial Position

5.1.2. Disturbance Addition

5.1.3. Parameters Variations

5.1.4. All Previous Tests Together

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Raj, R.; Kos, A. A Comprehensive Study of Mobile Robot: History, Developments, Applications, and Future Research Perspectives. Appl. Sci. 2022, 12, 6951. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, T.; Dian, S.; Zeng, X.; Wang, H. Balance Adjustment of Power-Line Inspection Robot Using General Type-2 Fractional Order Fuzzy PID Controller. Symmetry 2020, 12, 479. [Google Scholar] [CrossRef]

- Yang, C.; Huang, D.; He, W.; Cheng, L. Neural control of robot Manipulators with trajectory tracking constraints and input saturation. IEEE Trans. Neural Netw. Learn. Syst. 2021, 32, 4231–4242. [Google Scholar] [CrossRef] [PubMed]

- Rishag, H.T.; Hameed, S.M. Improvement the DFIG active power with variable speed wind using particle swarm optimization. Diyala J. Eng. Sci. 2016, 9, 12–22. [Google Scholar] [CrossRef]

- Elsisi, M.; Mahmud, K.; Lehtonen, M.; Darwish, M.M.F. An Improved Neural Network Algorithm to Efficiently Track Various Trajectories of Robot Manipulator Arms. IEEE Access 2021, 9, 11911–11920. [Google Scholar] [CrossRef]

- Manjeet, M.; Sathans, S. Fuzzy based Control of Two Link Robotic Manipulator and Comparative Analysis. In Proceedings of the 2013 International Conference on Communication Systems and Network Technologies, Washington, DC, USA, 6–8 April 2013; IEEE: Piscataway Township, NJ, USA, 2013; pp. 562–567. [Google Scholar]

- Dachang, Z.; Baolin, D.; Puchen, Z.; Shouyan, C. Constant Force PID Control for Robotic Manipulator Based on Fuzzy Neural Network Algorithm. Complexity 2020, 2020, 3491845. [Google Scholar] [CrossRef]

- Rahali, H.; Zeghlache, S.; Benyettou, L. Fault-Tolerant Control of Robot Manipulators Based on Adaptive Fuzzy Type-2 Backstepping in Attendance of Payload Variation. Int. J. Intell. Eng. Syst. 2021, 14, 312–325. [Google Scholar] [CrossRef]

- Mohan, V.; Chhabra, H.; Rani, A.; Singh, V. An expert 2DOF fractional order fuzzy PID controller for nonlinear systems. Neural Comput. Appl. 2018, 31, 4253–4270. [Google Scholar] [CrossRef]

- Bingi, K.; Rajanarayan Prusty, B.; Pal Singh, A. A Review on Fractional-Order Modelling and Control of Robotic Manipulators. Fractal Fract. 2023, 7, 77. [Google Scholar] [CrossRef]

- Sareena, A.; Rikesh, P. Application of PID Controller and Nonlinear Sliding Mode Control on Two Link Robotic Manipulator. Int. J. Eng. Res. Technol. 2019, 8, 504–508. [Google Scholar]

- Elkhateeb, N.; Badr, R.I. Novel PID Tracking Controller for 2DOF Robotic Manipulator System based on Artificial Bee Colony Algorithm. Electr. Control. Commun. Eng. 2017, 13, 55–62. [Google Scholar] [CrossRef]

- Ghamari, S.M.; Narm, H.G.; Mollaee, H. Fractional-order fuzzy PID controller design on buck converter with antlion optimization algorithm. IET Control. Theory Appl. 2022, 16, 340–352. [Google Scholar] [CrossRef]

- Suid, M.H.; Ahmad, M.A. Optimal tuning of sigmoid PID controller using Nonlinear Sine Cosine Algorithm for the Automatic Voltage Regulator system. ISA Trans. 2022, 128, 265–286. [Google Scholar] [CrossRef]

- Noordin, A.; Mohd Basri, M.A.; Mohamed, Z. Position and Attitude Tracking of MAV Quadrotor Using SMC-Based Adaptive PID Controller. Drones 2022, 6, 263. [Google Scholar] [CrossRef]

- Cao, G.; Zhao, X.; Ye, C.; Yu, S.; Li, B.; Jiang, C. Fuzzy adaptive PID control method for multi-mecanum-wheeled mobile robot. J. Mech. Sci. Technol. 2022, 36, 2019–2029. [Google Scholar] [CrossRef]

- Ghazali, M.R.B.; Ahmad, M.A.B.; Raja Ismail, R.M.T.B. Adaptive safe experimentation dynamics for data-driven neuroendocrine-PID control of MIMO systems. IETE J. Res. 2022, 68, 1611–1624. [Google Scholar] [CrossRef]

- Bandyopadhyay, B.; Kamal, S. Stabilization and Control of Fractional Order Systems: A Sliding Mode Approach; Springer International Publishing: Cham, Switzerland, 2015; Volume 317. [Google Scholar] [CrossRef]

- Almasri, E.; Uyguroglu, M.K. Modeling and Trajectory Planning Optimization for the Symmetrical Multiwheeled Omnidirectional Mobile Robot. Symmetry 2021, 13, 1033. [Google Scholar] [CrossRef]

- Jothi, G.; Inbarani, H.H.; Azar, A.T.; Devi, K.R. Rough set theory with Jaya optimization for acute lymphoblastic leukemia classification. Neural Comput. Appl. 2019, 31, 5175–5194. [Google Scholar] [CrossRef]

- Inbarani, H.H.; Banu, P.K.N.; Azar, A.T. Feature selection using swarm-based relative reduct technique for fetal heart rate. Neural Comput. Appl. 2014, 25, 793–806. [Google Scholar] [CrossRef]

- Meghni, B.; Dib, D.; Azar, A.T.; Saadoun, A. Effective Supervisory Controller to Extend Optimal Energy Management in Hybrid Wind Turbine under Energy and Reliability Constraints. Int. J. Dyn. Control. 2018, 6, 369–383. [Google Scholar] [CrossRef]

- Abdollahzadeh, B.; Soleimanian Gharehchopogh, F.; Mirjalili, S. Artificial gorilla troops optimizer: A new nature-inspired metaheuristic algorithm for global optimization problems. Int. J. Intell. Syst. 2021, 36, 5887–5958. [Google Scholar] [CrossRef]

- Ginidi, A.; Ghoneim, S.M.; Elsayed, A.; El-Sehiemy, R.; Shaheen, A.; El-Fergany, A. Gorilla Troops Optimizer for Electrically Based Single and Double-Diode Models of Solar Photovoltaic Systems. Sustainability 2021, 13, 9459. [Google Scholar] [CrossRef]

- Vázquez-Aveledo, S.; Romero, R.J.; Montiel-González, M.; Cerezo, J. Control Strategy Based on Artificial Intelligence for a Double-Stage Absorption Heat Transformer. Processes 2023, 11, 1632. [Google Scholar] [CrossRef]

- Mosaad, A.M.; Attia, M.A.; Abdelaziz, A.Y. Whale optimization algorithm to tune PID and PIDA controllers on AVR system. Ain Shams Eng. J. 2019, 10, 755–767. [Google Scholar] [CrossRef]

- Abdulameer, H.I.; Mohamed, M.J. Fractional Order Fuzzy PID Controller Design for 2-Link Rigid Robot Manipulator. Int. J. Intell. Eng. Syst. 2022, 15, 103–117. [Google Scholar]

- Delavari, H.; Ghaderi, R.; Ranjbar, N.A.; HosseinNia, S.H.; Momani, S. Adaptive Fractional PID Controller for Robot Manipulator. arXiv 2010, arXiv:1206.20272010. [Google Scholar]

- Meghni, B.; Dib, D.; Azar, A.T.; Ghoudelbourk, S.; Saadoun, A. Robust Adaptive Supervisory Fractional order Controller For optimal Energy Management in Wind Turbine with Battery Storage. Stud. Comput. Intell. 2017, 688, 165–202. [Google Scholar]

- Micev, M.; Calasan, M.; Oliva, D. Fractional Order PID Controller Design for an AVR System Using Chaotic Yellow Saddle Goatfish Algorithm. Mathematics 2020, 8, 1182. [Google Scholar] [CrossRef]

- Alzabut, J.; Tyagi, S.; Abbas, S. Discrete Fractional? Order BAM Neural Networks with Leakage Delay: Existence and Stability Results. Asian J. Control. 2022, 22, 143–155. [Google Scholar] [CrossRef]

- Thaiprayoon, C.; Sudsutad, W.; Alzabut, J.; Etemad, S.; Rezapour, S. On the qualitative analysis of the fractional boundary value problem describing thermostat control model via ψ-Hilfer fractional operator. Adv. Differ. Equ. 2021, 2021, 201. [Google Scholar] [CrossRef]

- Alzabut, J.; Abdeljawad, T. On existence of a globally attractive periodic solution of impulsive delay logarithmic population model. Appl. Math. Comput. 2008, 198, 463–469. [Google Scholar] [CrossRef]

- Wiora, J.; Wiora, A. Influence of Methods Approximating Fractional-Order Differentiation on the Output Signal Illustrated by Three Variants of Oustaloup Filter. Symmetry 2020, 12, 1898. [Google Scholar] [CrossRef]

- Patel, R.; Kumar, V. Multilayer Neuro PID Controller based on back propagation algorithm. Procedia Comput. Sci. 2015, 54, 207–214. [Google Scholar] [CrossRef]

- Chertovskikh, P.A.; Seredkin, A.V.; Gobyzov, O.A.; Styuf, A.S.; Pashkevich, M.G.; Tokarev, M.P. An Adaptive PID Controller with an Online Auto-Tuning by a Pretrained Neural Network. J. Phys. Conf. Ser. 2019, 1359, 012090. [Google Scholar] [CrossRef]

- Roy, R.; Tu, Y.-P.; Sheu, L.-J.; Chieng, W.-H.; Tang, L.-C.; Ismail, H. Path Planning and Motion Control of Indoor Mobile Robot under Exploration-Based SLAM (e-SLAM). Sensors 2023, 23, 3606. [Google Scholar] [CrossRef] [PubMed]

- Ali, O.A.M.; El-Zoghby, H.M.; Ghany, A.G.M.A. Maximizing the Generated Power from Hybrid Wind-Solar System Based on Fuzzy Self Tuning Single Neuron PID Controller. In Proceedings of the 2018 Twentieth International Middle East Power Systems Conference (MEPCON), Cairo, Egypt, 18–20 December 2018; IEEE: Piscataway Township, NJ, USA, 2018; pp. 748–753. [Google Scholar] [CrossRef]

| Parameters | Nominal Value |

|---|---|

| m1 | 0.1 kg |

| m2 | 0.1 kg |

| l1 | 0.8 m |

| l2 | 0.4 m |

| g | 9.81 m/s2 |

| Controller | Total Number of Controller Parameters | Range of PID Gains Kp, Ki, Kd | Corner Frequency of Derivative Filter N | Range of Fractional Parameters | All Other Parameters Range |

|---|---|---|---|---|---|

| Con-PID | 8 | −150 to 150 | 10 to 100 | μ ≡ 1 λ ≡ 1 | -------- |

| Con-FOPID | 12 | −150 to 150 | 10 to 100 | μ ≡ 0 to 2 λ ≡ 0 to 2 | -------- |

| STNN-PID | 122 | −150 to 150 | 10 to 100 | μ ≡ 1 λ ≡ 1 | V ≡ −5 to 5 W≡ −1 to 1 |

| STNN-FOPID | 162 | −150 to 150 | 10 to 100 | μ ≡ 0 to 2 λ ≡ 0 to 2 | V ≡ −5 to 5 W≡ −1 to 1 |

| NNPID | 66 | −150 to 150 | ------ | μ ≡ 1 λ ≡ 1 | −1 to 1 |

| NNFOPID | 70 | −150 to 150 | ------ | μ ≡ 0 to 2 λ ≡ 0 to 2 | −1 to 1 |

| Controller | ITSE | No. of Slop Sign Change in All Control Signals |

|---|---|---|

| Con-PID | 3.729543 × 10−4 | 93 |

| Con-FOPID | 2.227023 × 10−4 | 47 |

| STNN-PID | 3.075515 × 10−4 | 91 |

| STNN-FOPID | 3.883774 × 10−4 | 45 |

| NNPID | 0.954084 × 10−4 | 85 |

| NNFOPID | 0.748071 × 10−4 | 94 |

| Controller Type | Link No. | Rise Time | Over Shoot % | Settling Time | ITSE ×10−4 |

|---|---|---|---|---|---|

| Con-PID | L1 | 0.070 | 6.6 | 0.684 | 1.47752 |

| L2 | 0.012 | 5.95 | 0.188 | 0.64646 | |

| Con-FOPID | L1 | 0.074 | 3.27 | 0.584 | 1.30261 |

| L2 | 0.054 | 1.40 | 0.131 | 0.10037 | |

| STNN-PID | L1 | 0.069 | 6.14 | 0.594 | 1.12337 |

| L2 | 0.012 | 7.41 | 0.394 | 0.83790 | |

| STNN-FOPID | L1 | 0.081 | 4.40 | 6.430 | 1.25247 |

| L2 | 0.026 | 1.05 | 0.166 | 1.00217 | |

| NN-PID | L1 | 0.081 | 1.60 | 0.134 | 0.34509 |

| L2 | 0.042 | 2.84 | 0.103 | 0.07345 | |

| NN-FOPID | L1 | 0.076 | 1.80 | 0.123 | 0.31060 |

| L2 | 0.043 | 0.47 | 0.043 | 0.03249 |

| Controller | ITSE |

|---|---|

| Con-PID | 1.82669 × 10−4 |

| Con-FOPID | 1.17614 × 10−4 |

| STNN-PID | 1.61995 × 10−4 |

| STNN-FOPID | 27.3328 × 10−4 |

| NN-PID | 1.05251 × 10−4 |

| NN-FOPID | 0.24644 × 10−4 |

| Controller | ITSE |

|---|---|

| Con-PID | 5.54533 × 10−4 |

| Con-FOPID | 1.43023 × 10−4 |

| STNN-PID | 191.4245 × 10−4 |

| STNN-FOPID | Unstable |

| NN-PID | 2.1375 × 10−4 |

| NN-FOPID | 0.092827 × 10−4 |

| Controller | ITSE |

|---|---|

| Con-PID | 1.183509 × 10−4 |

| Con-FOPID | 0.691371 × 10−4 |

| STNN-PID | 0.743505 × 10−4 |

| STNN-FOPID | Unstable |

| NN-PID | 0.196180 × 10−4 |

| NN-FOPID | 0.005068 × 10−4 |

| Controller | ITSE |

|---|---|

| Con-PID | 6.54278 × 10−4 |

| Con-FOPID | 2.09812 × 10−4 |

| STNN-PID | Unstable |

| STNN-FOPID | Unstable |

| NN-PID | 4.26462 × 10−4 |

| NN-FOPID | 0.447529 × 10−4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohamed, M.J.; Oleiwi, B.K.; Abood, L.H.; Azar, A.T.; Hameed, I.A. Neural Fractional Order PID Controllers Design for 2-Link Rigid Robot Manipulator. Fractal Fract. 2023, 7, 693. https://doi.org/10.3390/fractalfract7090693

Mohamed MJ, Oleiwi BK, Abood LH, Azar AT, Hameed IA. Neural Fractional Order PID Controllers Design for 2-Link Rigid Robot Manipulator. Fractal and Fractional. 2023; 7(9):693. https://doi.org/10.3390/fractalfract7090693

Chicago/Turabian StyleMohamed, Mohamed Jasim, Bashra Kadhim Oleiwi, Layla H. Abood, Ahmad Taher Azar, and Ibrahim A. Hameed. 2023. "Neural Fractional Order PID Controllers Design for 2-Link Rigid Robot Manipulator" Fractal and Fractional 7, no. 9: 693. https://doi.org/10.3390/fractalfract7090693