Enhanced Impedance Control of Cable-Driven Unmanned Aerial Manipulators Using Fractional-Order Nonsingular Terminal Sliding Mode Control with Disturbance Observer Integration

Abstract

:1. Introduction

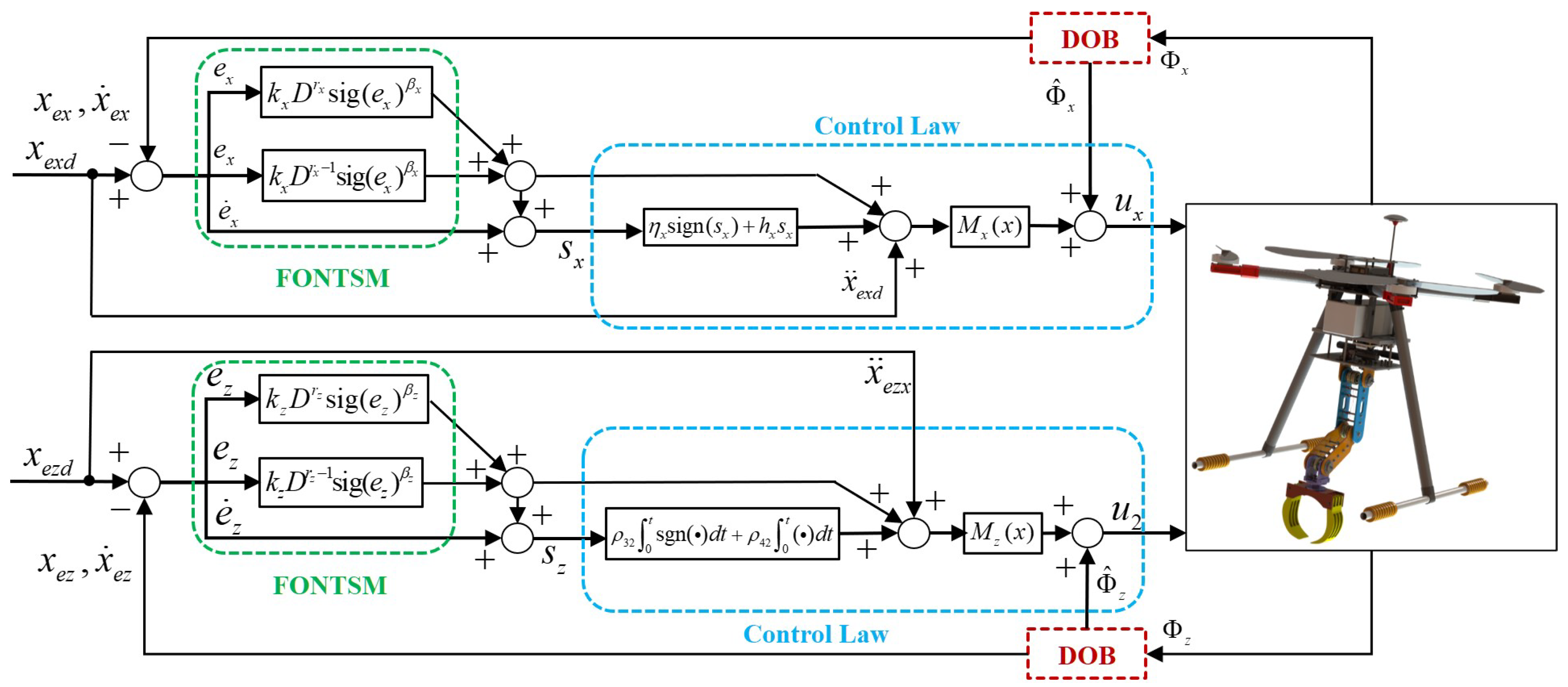

- A FONTSM-DOB control strategy is developed to achieve impedance control for UAMs during contact operations with the external environment under lumped disturbances. This strategy integrates the strengths of fractional-order (FO) calculus, nonsingular terminal sliding mode (NTSM), and disturbance observer (DOB) techniques, significantly enhancing UAM control performance while ensuring smooth and compliant contact interactions. This approach effectively addresses the challenges of operating in uncertain environments, providing both robustness and precision in aerial manipulation tasks.

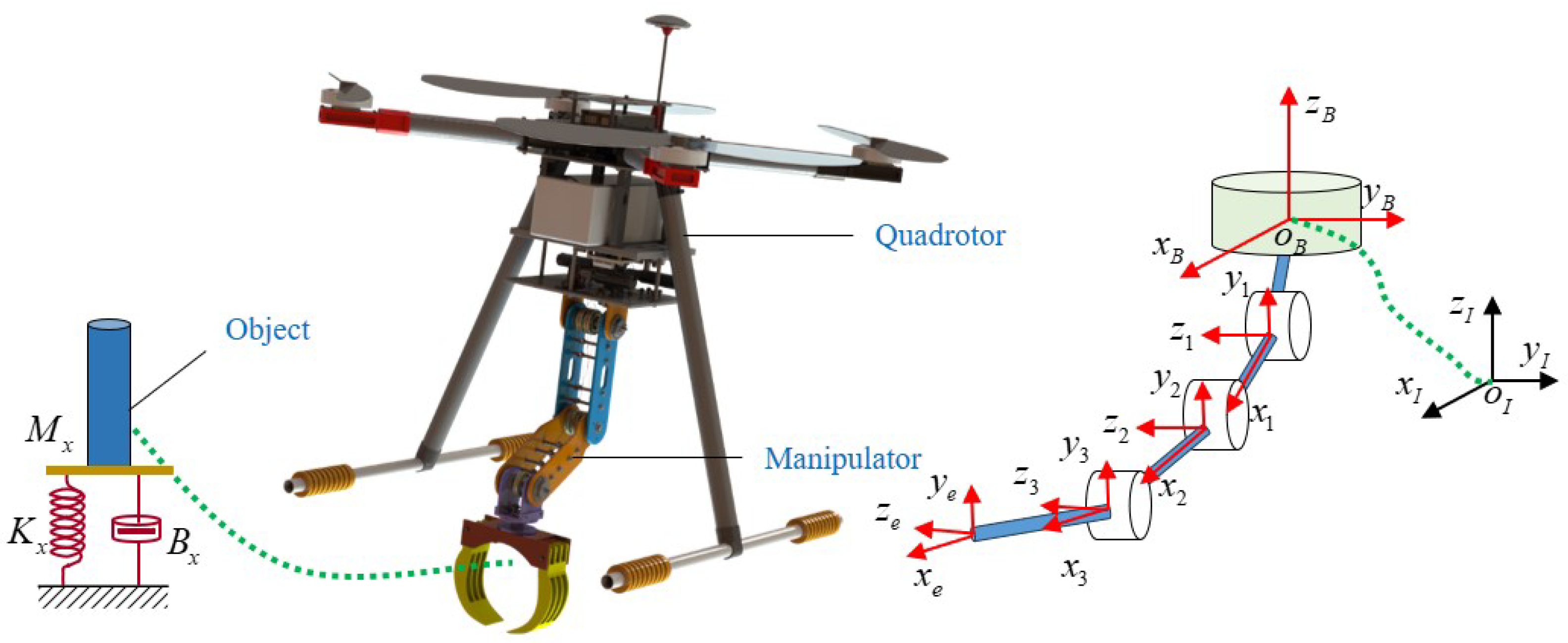

- Given the redundancy of the designed UAM, the inverse kinematics problem is addressed using the Jacobian matrix. Additionally, the flexibility of the links and cables is modeled as joint flexibility, allowing for the establishment of a rigid-flexible coupling dynamic model. This approach more accurately captures the dynamic characteristics of the aerial manipulator, providing a realistic representation of its behavior during operation.

- The UAM designed in this paper incorporates a cable-driven mechanism, where the drive units (e.g., motors, reducers) are mounted at the manipulator’s base. This design remotely transmits force and torque to the robotic arm’s joints via flexible cables, significantly reducing the manipulator’s inertia and achieving a lightweight overall structure. This approach not only enhances the manipulator’s dynamic performance but also optimizes the system’s structural efficiency, making it more suitable for complex aerial manipulation tasks.

2. UAM Mathematical Model

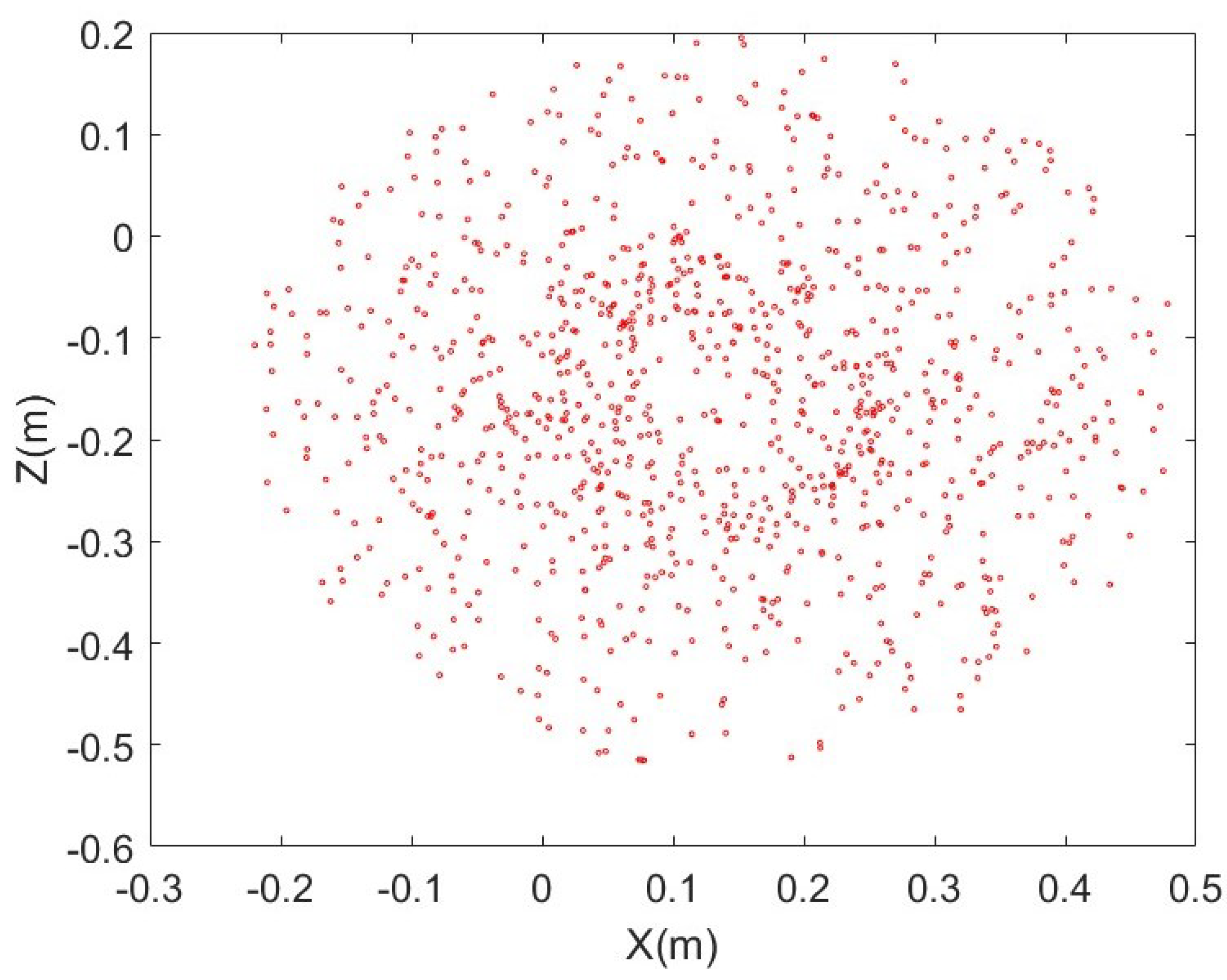

2.1. Manipulator Kinematics

2.2. Manipulator Dynamics

3. Controller Design

3.1. Disturbance Observer Design

3.2. FONTSMC Design

3.3. Stability Analysis

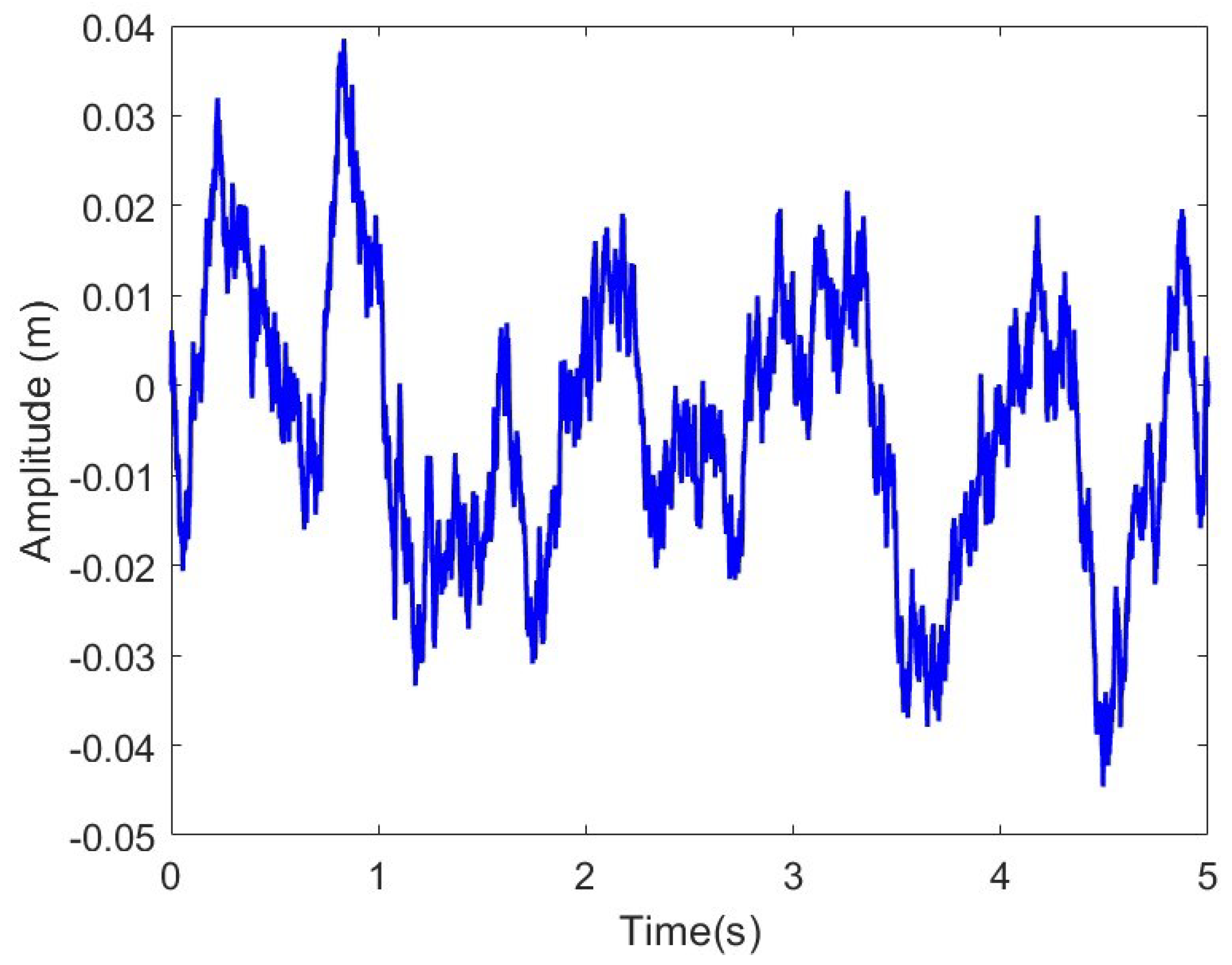

4. Simulation and Results

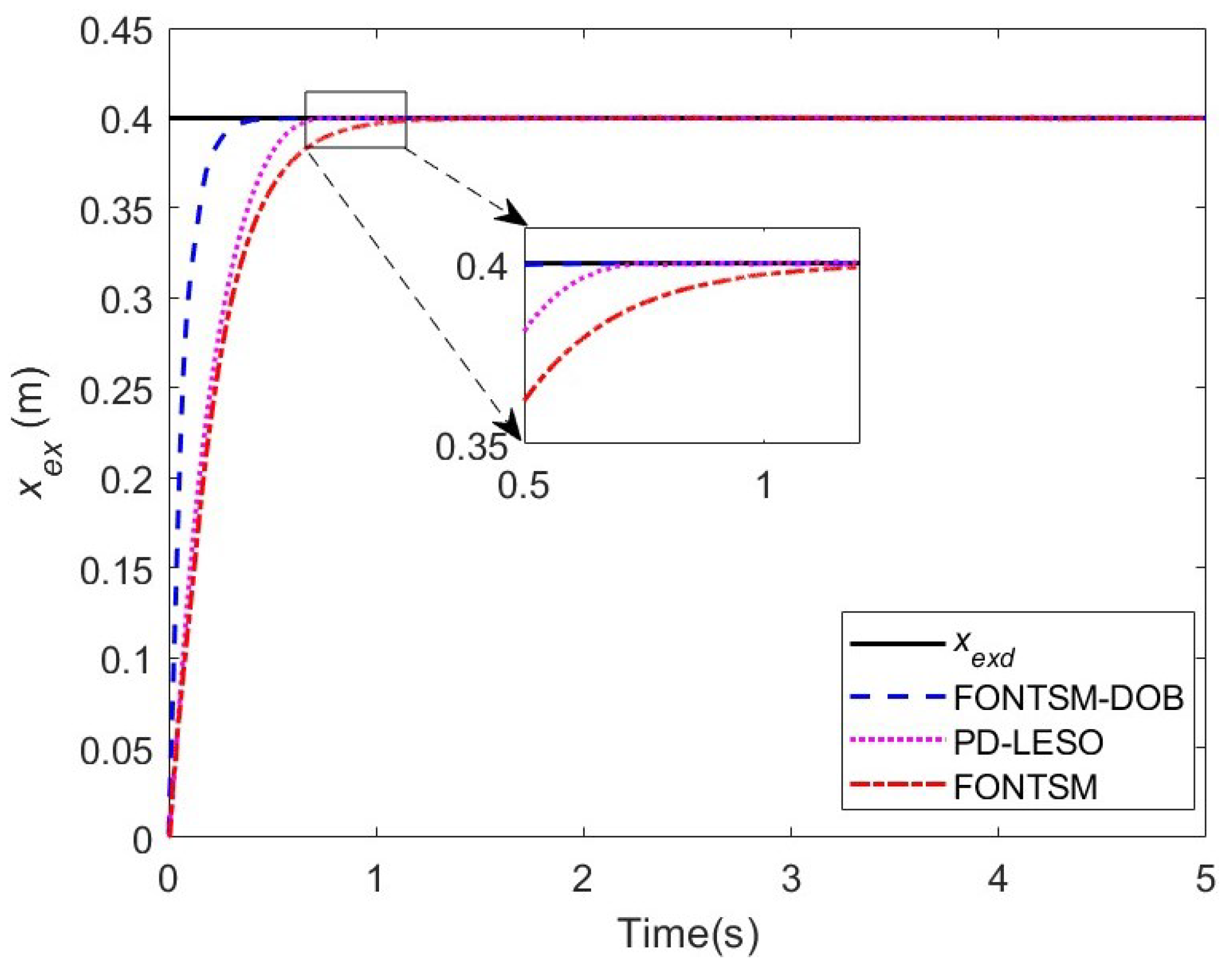

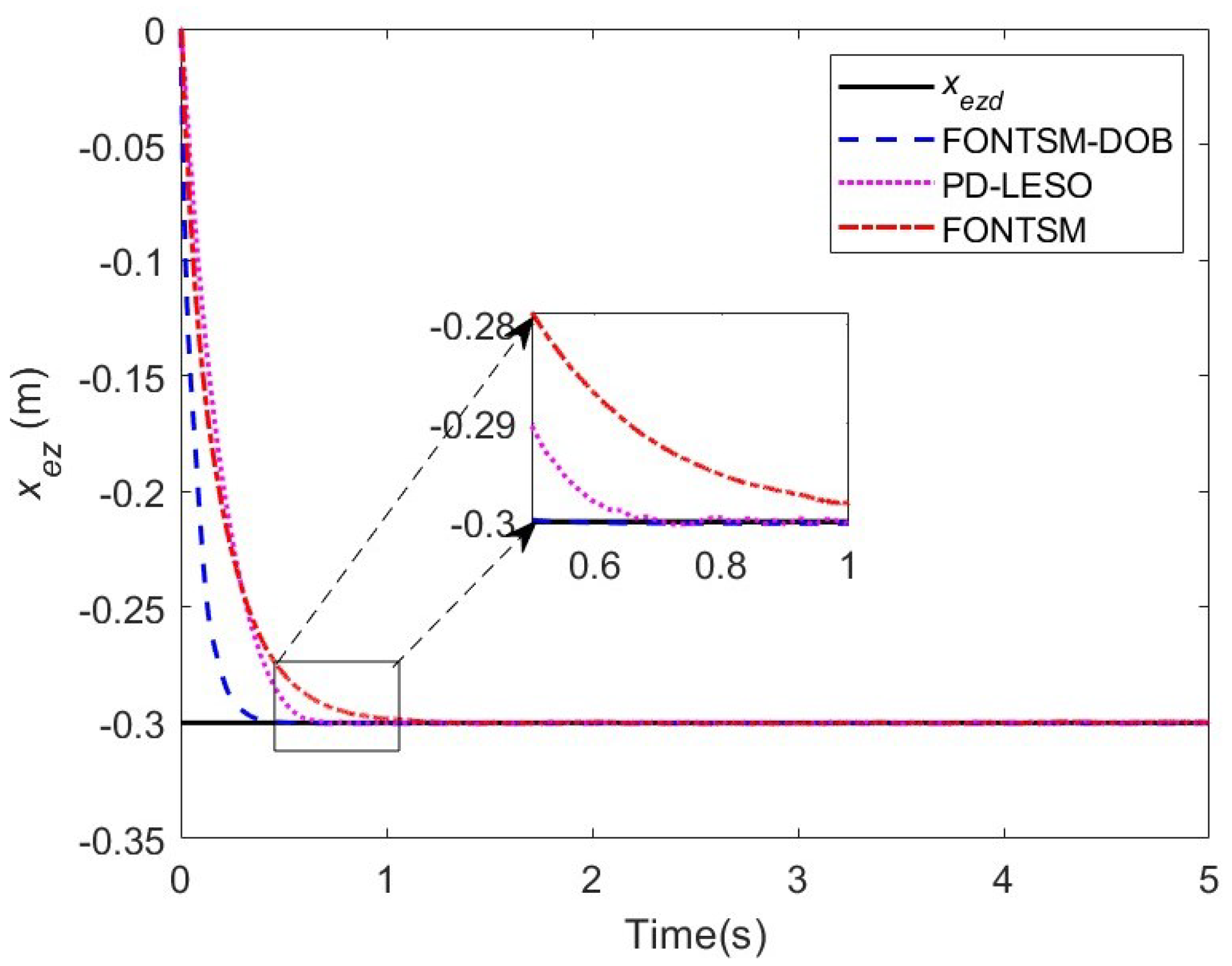

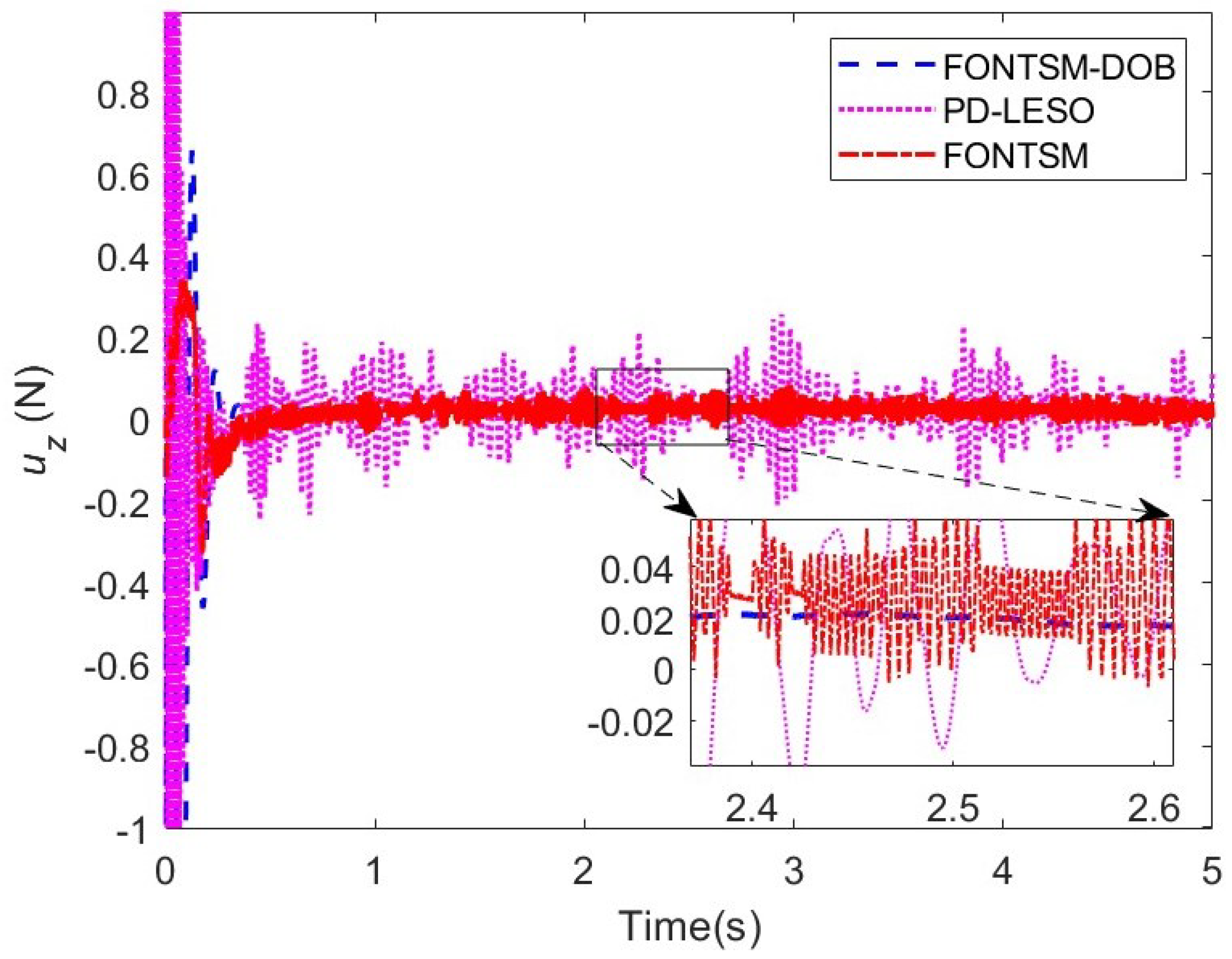

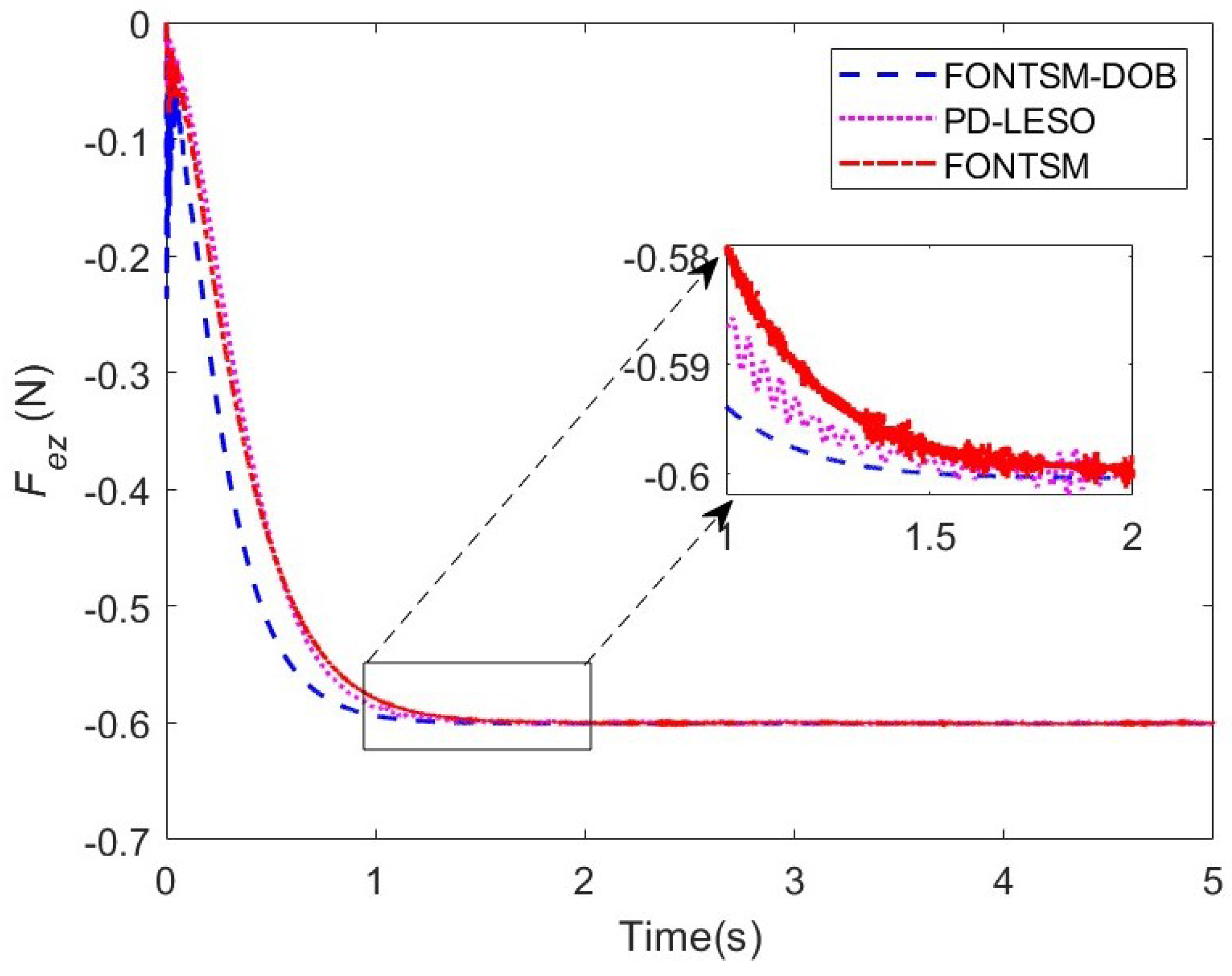

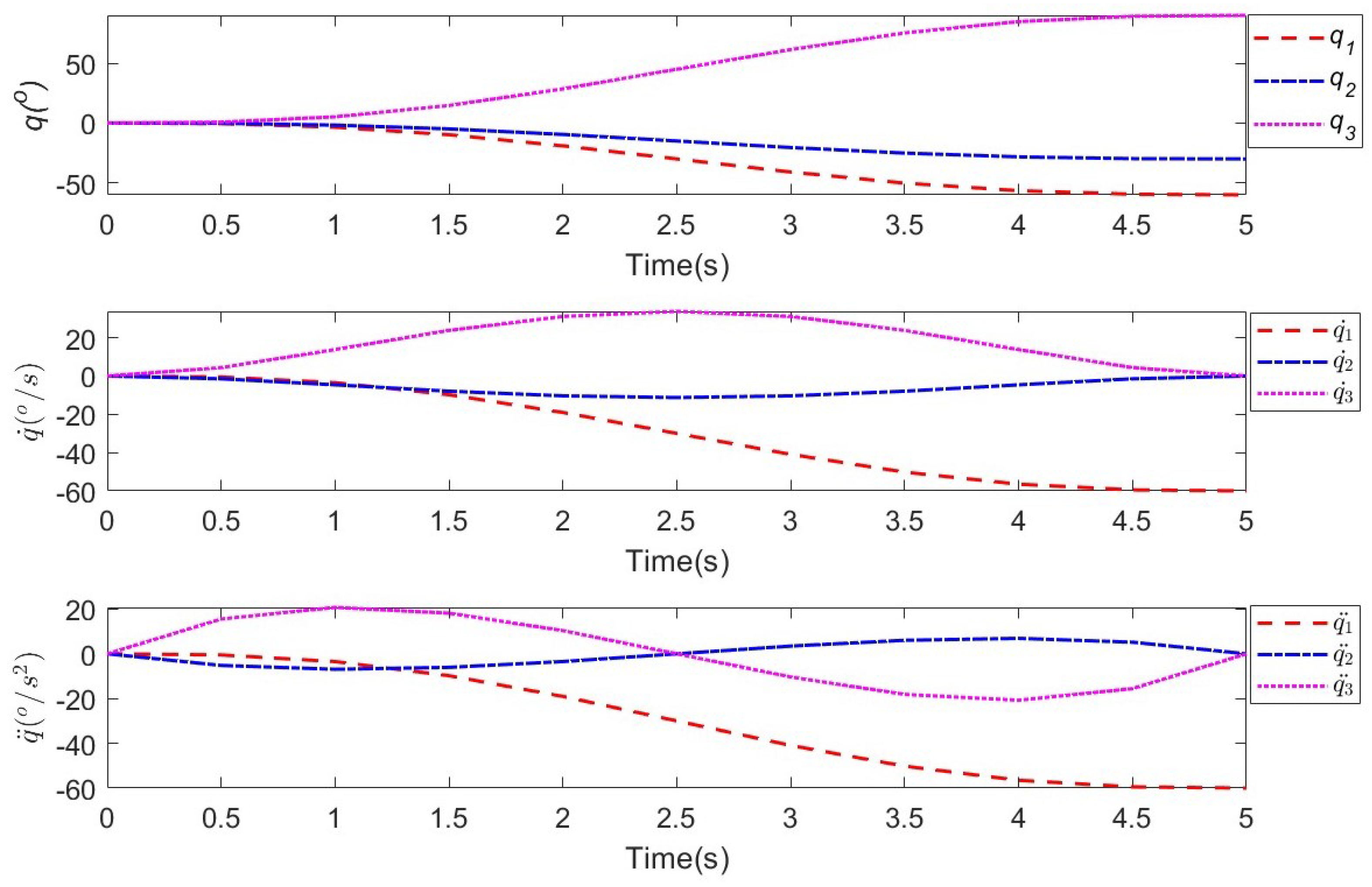

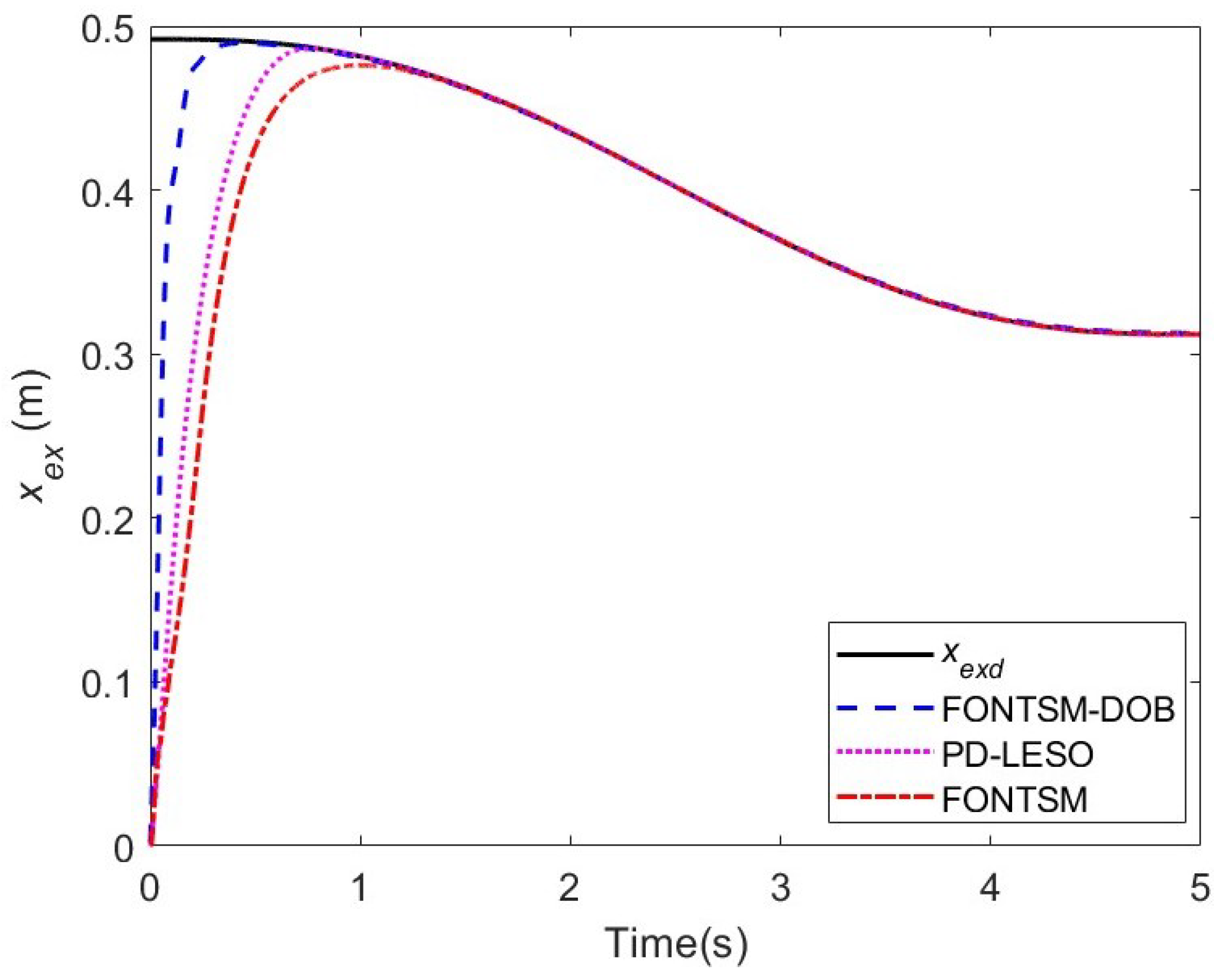

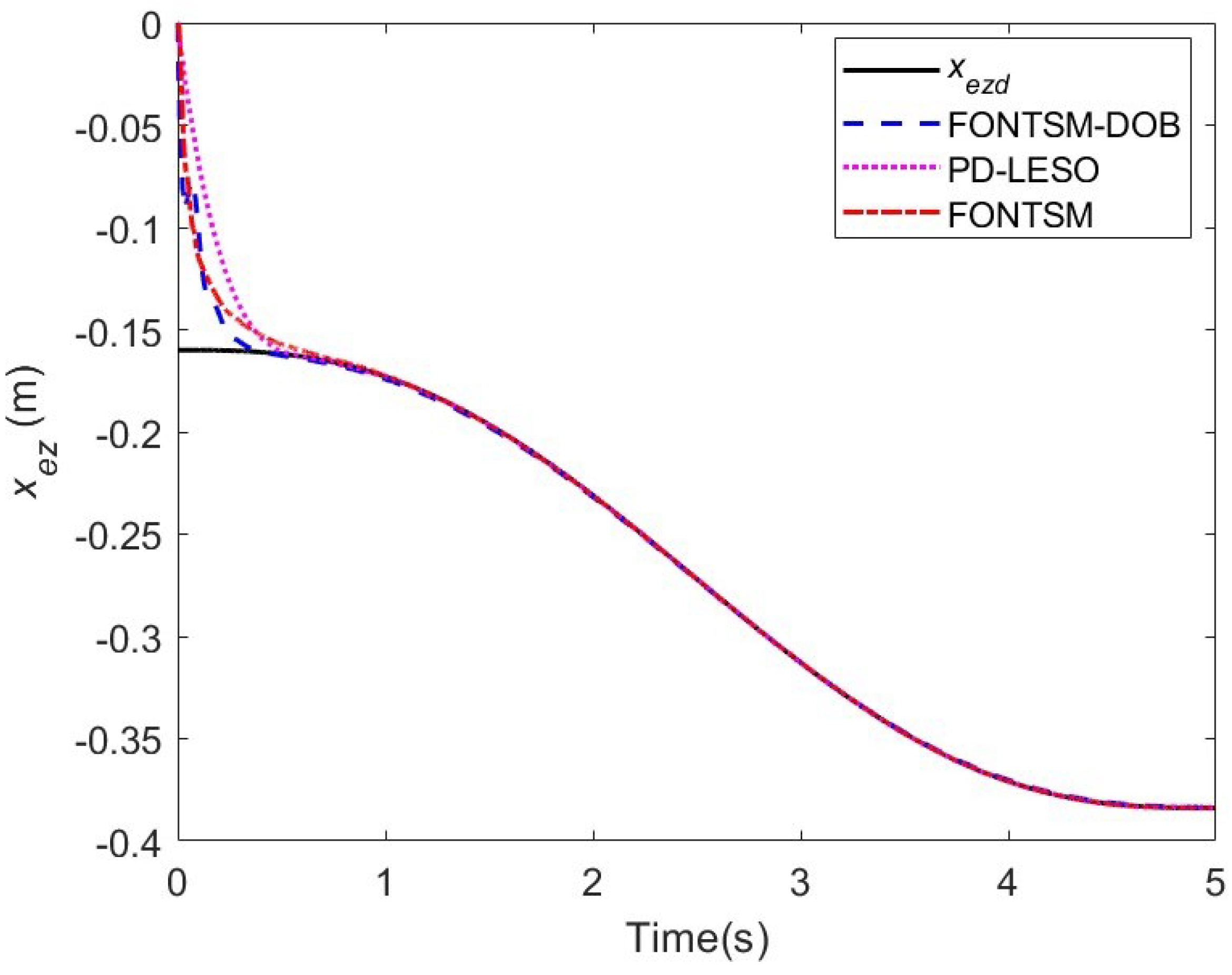

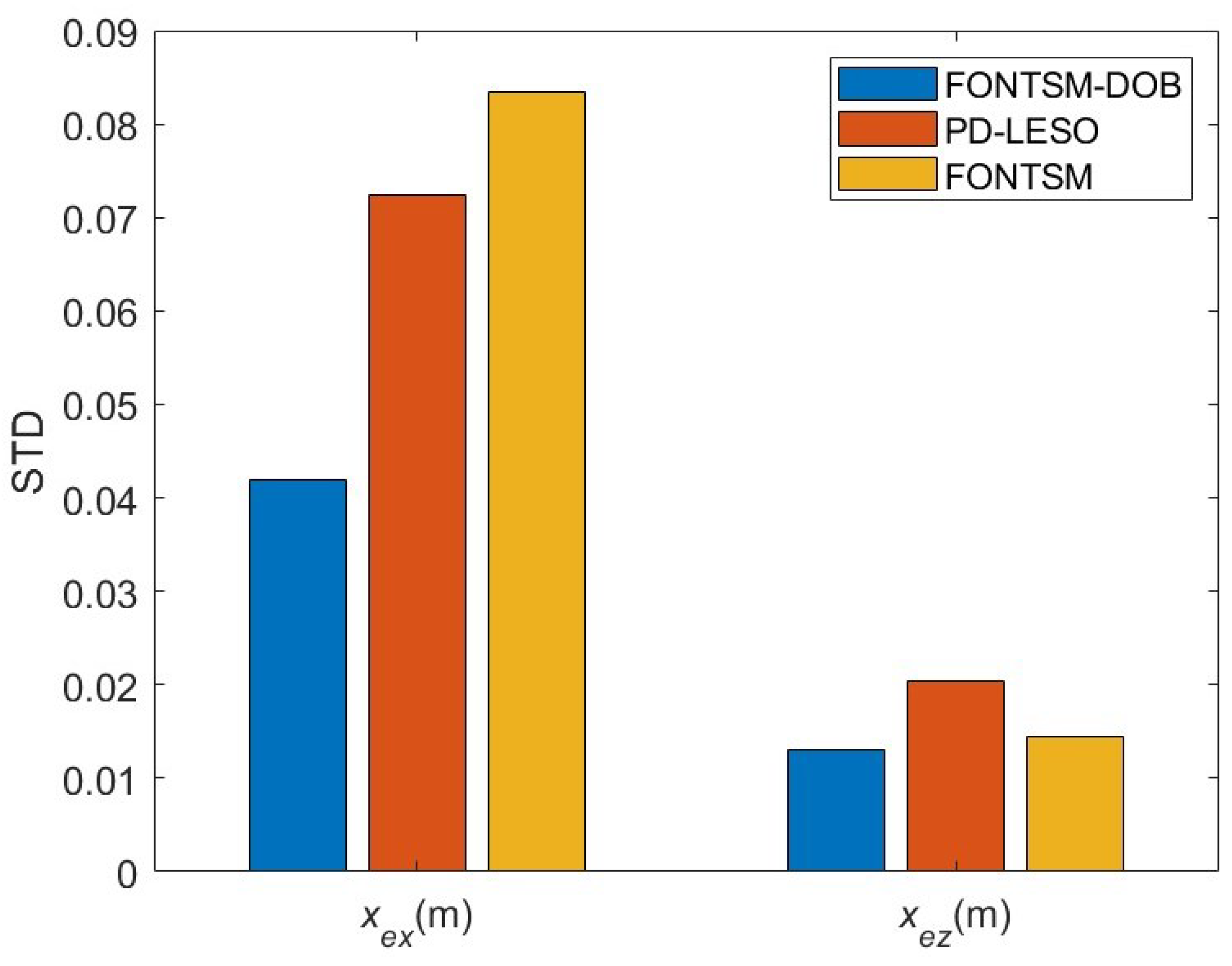

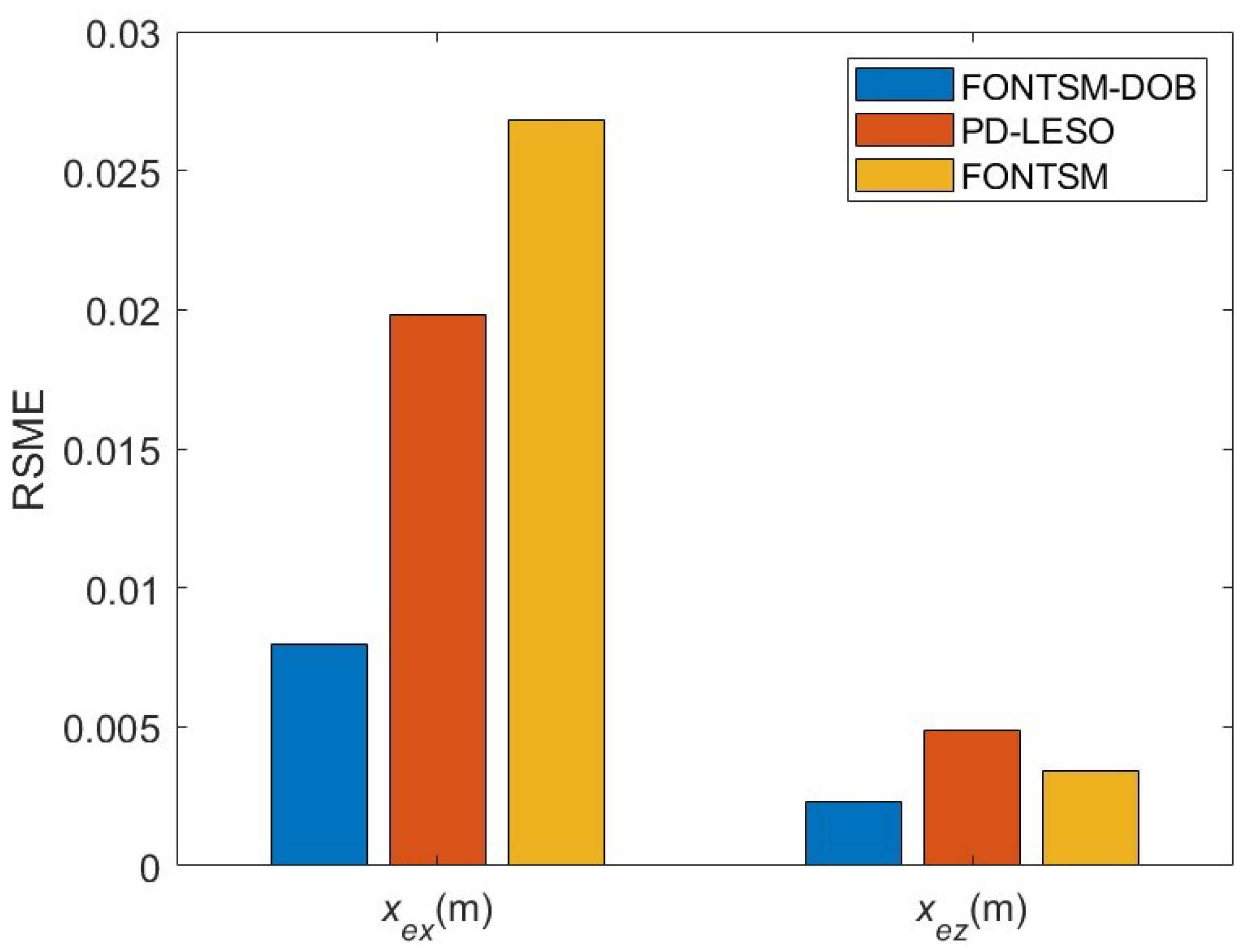

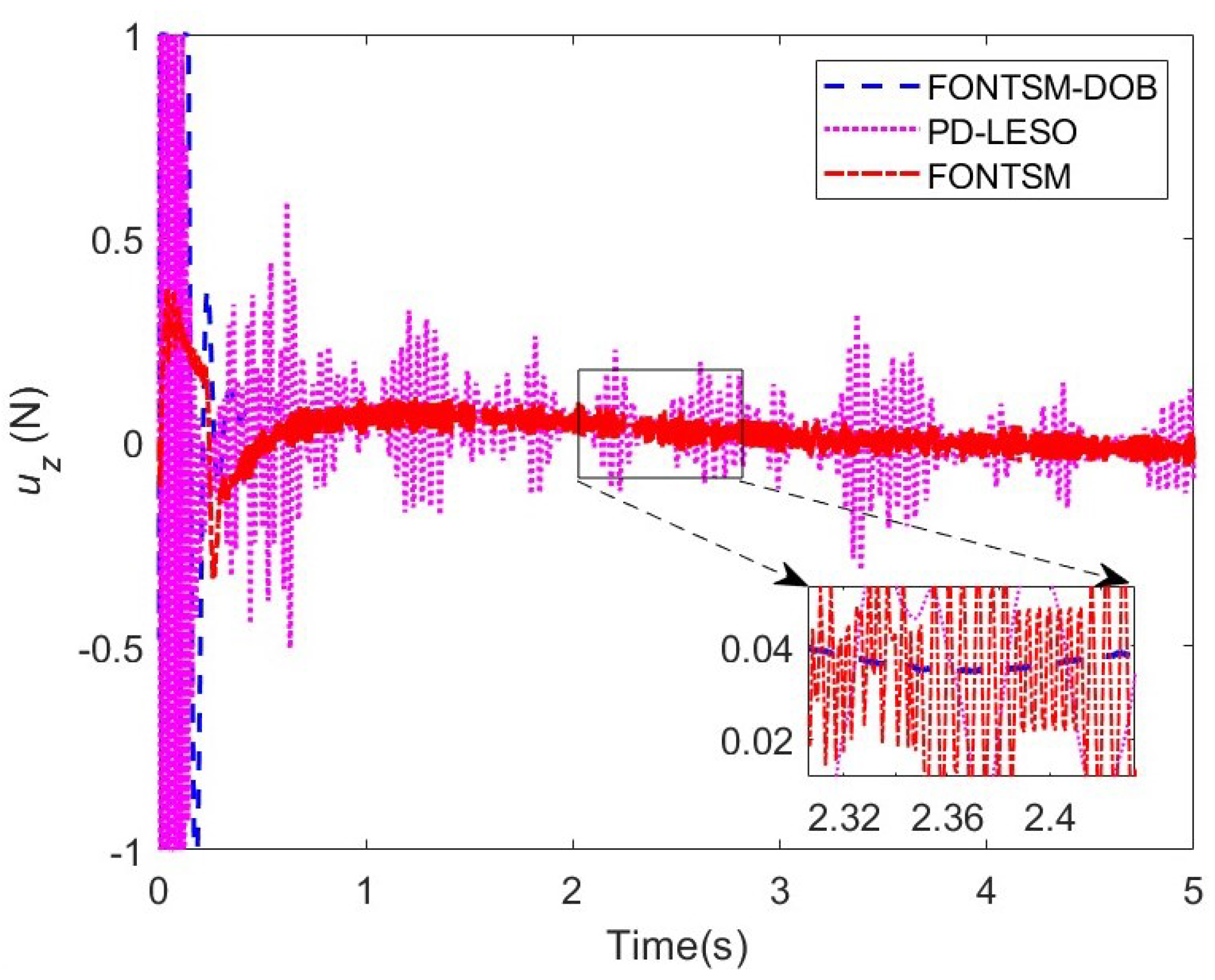

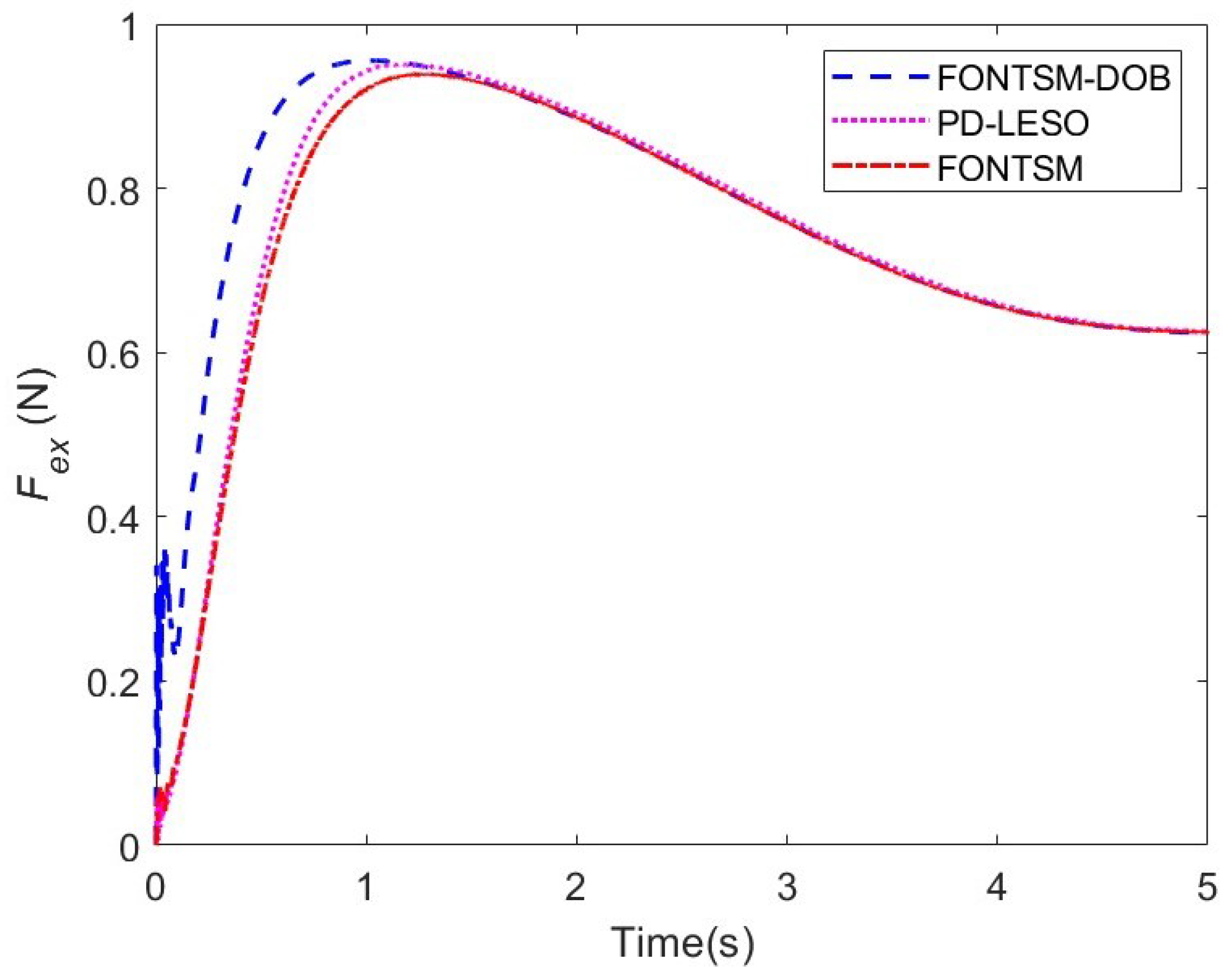

4.1. Case 1: Tracking a Step Signal

4.2. Case 2: Tracks a Harmonic Signal

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| UAV | Unmanned aerial vehicles |

| UAM | Unmanned aerial manipulator |

| DOF | Degree-of-freedom |

| SMC | Sliding mode control |

| TSM | Terminal sliding mode |

| FTSM | Fast terminal sliding mode |

| NFTSM | Nonsingular fast terminal sliding mode |

| DOB | Disturbance observer |

| IO | Integer-order |

| FO | Fractional order |

| FONTSM-DOB | Fractional order nonsingular terminal sliding mode based on DOB |

| DH | Denavit–Hartenberg |

References

- Uthayasooriyan, A.; Vanegas, F.; Jalali, A.; Digumarti, K.M.; Janabi-Sharifi, F.; Gonzalez, F. Tendon-Driven Continuum Robots for Aerial Manipulation—A Survey of Fabrication Methods. Drones 2024, 8, 269. [Google Scholar] [CrossRef]

- Ramon-Soria, P.; Arrue, B.C.; Ollero, A. Grasp planning and visual servoing for an outdoors aerial dual manipulator. Engineering 2020, 6, 77–88. [Google Scholar] [CrossRef]

- Tognon, M.; Chávez, H.A.T.; Gasparin, E.; Sablé, Q.; Bicego, D.; Mallet, A.; Lany, M.; Santi, G.; Revaz, B.; Cortés, J.; et al. A truly-redundant aerial manipulator system with application to push-and-slide inspection in industrial plants. IEEE Robot. Autom. Lett. 2019, 4, 1846–1851. [Google Scholar] [CrossRef]

- Phillips-Grafflin, C.; Suay, H.B.; Mainprice, J.; Alunni, N.; Lofaro, D.; Berenson, D.; Chernova, S.; Lindeman, R.W.; Oh, P. From autonomy to cooperative traded control of humanoid manipulation tasks with unreliable communication: Applications to the valve-turning task of the darpa robotics challenge and lessons learned. J. Intell. Robot. Syst. 2016, 82, 341–361. [Google Scholar] [CrossRef]

- Ding, L.; Zhu, G.; Li, Y.; Wang, Y. Cable-Driven Unmanned Aerial Manipulator Systems for Water Sampling: Design, Modeling, and Control. Drones 2023, 7, 450. [Google Scholar] [CrossRef]

- Kutia, J.R.; Stol, K.A.; Xu, W. Aerial manipulator interactions with trees for canopy sampling. IEEE/ASME Trans. Mechatronics 2018, 23, 1740–1749. [Google Scholar] [CrossRef]

- Meng, X.; He, Y.; Han, J. Survey on aerial manipulator: System, modeling, and control. Robotica 2020, 38, 1288–1317. [Google Scholar] [CrossRef]

- Xu, W.; Cao, L.; Zhong, C. Review of aerial manipulator and its control. Int. J. Robot. Control Syst. 2021, 1, 308–325. [Google Scholar] [CrossRef]

- Zeng, J.; Zhong, H.; Wang, Y.; Fan, S.; Zhang, H. Autonomous control design of an unmanned aerial manipulator for contact inspection. Robotica 2023, 41, 1145–1158. [Google Scholar] [CrossRef]

- Liu, J.; Li, Z.; Tian, Y.; Zheng, W. Dynamic modeling and active disturbance rejection control of parallel aerial manipulator system. In Proceedings of the Advances in Guidance, Navigation and Control: Proceedings of 2020 International Conference on Guidance, Navigation and Control, ICGNC 2020, Tianjin, China, 23–25 October 2020; Springer: Berlin/Heidelberg, Germany, 2022; pp. 3281–3293. [Google Scholar]

- Ding, L.; Wu, H. Dynamical Modelling and Robust Control for an Unmanned Aerial Robot Using Hexarotor with 2-DOF Manipulator. Int. J. Aerosp. Eng. 2019, 2019, 5483073. [Google Scholar] [CrossRef]

- Li, H.; Li, Z.; Liu, J.; Zheng, X.; Yu, X.; Kaynak, O. Adaptive neural network backstepping control method for aerial manipulator based on coupling disturbance compensation. J. Frankl. Inst. 2024, 361, 106733. [Google Scholar] [CrossRef]

- Xu, W.; Cao, L.; Peng, B.; Wang, L.; Gen, C.; Liu, Y. Adaptive nonsingular fast terminal sliding mode control of aerial manipulation based on nonlinear disturbance observer. Drones 2023, 7, 88. [Google Scholar] [CrossRef]

- Huang, Q.; Dong, C.; Yu, Z.; Chen, X.; Li, Q.; Chen, H.; Liu, H. Resistant compliance control for biped robot inspired by humanlike behavior. IEEE/ASME Trans. Mechatronics 2022, 27, 3463–3473. [Google Scholar] [CrossRef]

- Xu, M.; Hu, A.; Wang, H. Image-based visual impedance force control for contact aerial manipulation. IEEE Trans. Autom. Sci. Eng. 2022, 20, 518–527. [Google Scholar] [CrossRef]

- Byun, J.; Kim, J.; Eom, D.; Lee, D.; Kim, C.; Kim, H.J. Image-Based Time-Varying Contact Force Control of Aerial Manipulator using Robust Impedance Filter. IEEE Robot. Autom. Lett. 2024, 9, 4854–4861. [Google Scholar] [CrossRef]

- Bonilla, I.; Mendoza, M.; Campos-Delgado, D.U.; Hernández-Alfaro, D.E. Adaptive impedance control of robot manipulators with parametric uncertainty for constrained path–tracking. Int. J. Appl. Math. Comput. Sci. 2018, 28, 363–374. [Google Scholar] [CrossRef]

- Jin, Z.; Qin, D.; Liu, A.; Zhang, W.a.; Yu, L. Model predictive variable impedance control of manipulators for adaptive precision-compliance tradeoff. IEEE/ASME Trans. Mechatronics 2022, 28, 1174–1186. [Google Scholar] [CrossRef]

- Kong, D.; Huang, Q. Impedance force control of manipulator based on variable universe fuzzy control. Actuators 2023, 12, 305. [Google Scholar] [CrossRef]

- Sai, H.; Xu, Z.; Li, Y.; Wang, K. Adaptive nonsingular fast terminal sliding mode impedance control for uncertainty robotic manipulators. Int. J. Precis. Eng. Manuf. 2021, 22, 1947–1961. [Google Scholar] [CrossRef]

- Lee, J.; Chang, P.H.; Jin, M. Adaptive integral sliding mode control with time-delay estimation for robot manipulators. IEEE Trans. Ind. Electron. 2017, 64, 6796–6804. [Google Scholar] [CrossRef]

- Nicolis, D.; Allevi, F.; Rocco, P. Operational space model predictive sliding mode control for redundant manipulators. IEEE Trans. Robot. 2020, 36, 1348–1355. [Google Scholar] [CrossRef]

- Zhai, J.; Xu, G. A novel non-singular terminal sliding mode trajectory tracking control for robotic manipulators. IEEE Trans. Circuits Syst. II Express Briefs 2020, 68, 391–395. [Google Scholar] [CrossRef]

- Van, M.; Mavrovouniotis, M.; Ge, S.S. An adaptive backstepping nonsingular fast terminal sliding mode control for robust fault tolerant control of robot manipulators. IEEE Trans. Syst. Man, Cybern. Syst. 2018, 49, 1448–1458. [Google Scholar] [CrossRef]

- Yi, S.; Zhai, J. Adaptive second-order fast nonsingular terminal sliding mode control for robotic manipulators. ISA Trans. 2019, 90, 41–51. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, L.; Fang, X. High-order fast nonsingular terminal sliding mode control of permanent magnet linear motor based on double disturbance observer. IEEE Trans. Ind. Appl. 2022, 58, 3696–3705. [Google Scholar] [CrossRef]

- Luo, W.; Liu, S. Disturbance observer based nonsingular fast terminal sliding mode control of underactuated AUV. Ocean. Eng. 2023, 279, 114553. [Google Scholar] [CrossRef]

- Wang, Y.; Li, B.; Yan, F.; Chen, B. Practical adaptive fractional-order nonsingular terminal sliding mode control for a cable-driven manipulator. Int. J. Robust Nonlinear Control 2019, 29, 1396–1417. [Google Scholar] [CrossRef]

- Mathiyalagan, K.; Sangeetha, G. Second-order sliding mode control for nonlinear fractional-order systems. Appl. Math. Comput. 2020, 383, 125264. [Google Scholar] [CrossRef]

- Fei, J.; Wang, H.; Fang, Y. Novel neural network fractional-order sliding-mode control with application to active power filter. IEEE Trans. Syst. Man, Cybern. Syst. 2021, 52, 3508–3518. [Google Scholar] [CrossRef]

- Fei, J.; Wang, Z.; Pan, Q. Self-constructing fuzzy neural fractional-order sliding mode control of active power filter. IEEE Trans. Neural Netw. Learn. Syst. 2022, 34, 10600–10611. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, X.; Cheng, Y. Adaptive finite-time disturbance observer-based recursive fractional-order sliding mode control of redundantly actuated cable driving parallel robots under disturbances and input saturation. J. Vib. Control 2023, 29, 675–688. [Google Scholar] [CrossRef]

- Dou, B.; Yue, X. Disturbance observer-based fractional-order sliding mode control for free-floating space manipulator with disturbance. Aerosp. Sci. Technol. 2023, 132, 108061. [Google Scholar] [CrossRef]

- Song, T.; Fang, L.; Zhang, Y.; Shen, H. Recursive terminal sliding mode based control of robot manipulators with a novel sliding mode disturbance observer. Nonlinear Dyn. 2024, 112, 1105–1121. [Google Scholar] [CrossRef]

- Suarez, A.; Heredia, G.; Ollero, A. Physical-virtual impedance control in ultralightweight and compliant dual-arm aerial manipulators. IEEE Robot. Autom. Lett. 2018, 3, 2553–2560. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, Y.; Wang, D.; Ju, F.; Chen, B.; Wu, H. Practical continuous nonsingular terminal sliding mode control of a cable-driven manipulator developed for aerial robots. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2020, 234, 1011–1023. [Google Scholar] [CrossRef]

- Ding, Y.; Wang, Y.; Chen, B. A practical time-delay control scheme for aerial manipulators. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2021, 235, 371–388. [Google Scholar] [CrossRef]

- Li, B.; Liu, H.; Ahn, C.K.; Gong, W. Optimized intelligent tracking control for a quadrotor unmanned aerial vehicle with actuator failures. Aerosp. Sci. Technol. 2024, 144, 108803. [Google Scholar] [CrossRef]

- Belalia, A.; Schouraqui, S. Trajectory tracking of a robot arm using images sequences. Int. J. Comput. Digit. Syst. 2024, 16, 1067–1081. [Google Scholar] [CrossRef]

- Cardou, P.; Bouchard, S.; Gosselin, C. Kinematic-sensitivity indices for dimensionally nonhomogeneous jacobian matrices. IEEE Trans. Robot. 2010, 26, 166–173. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, R.; Ju, F.; Zhao, J.; Chen, B.; Wu, H. A light cable-driven manipulator developed for aerial robots: Structure design and control research. Int. J. Adv. Robot. Syst. 2020, 17, 1729881420926425. [Google Scholar] [CrossRef]

- Ding, L.; Liu, K.; Zhu, G.; Wang, Y.; Li, Y. Adaptive robust control via a nonlinear disturbance observer for cable-driven aerial manipulators. Int. J. Control. Autom. Syst. 2023, 21, 604–615. [Google Scholar] [CrossRef]

- Ding, L.; Ma, R.; Wu, Z.; Qi, R.; Ruan, W. Optimal Joint Space Control of a Cable-Driven Aerial Manipulator. CMES-Comput. Model. Eng. Sci. 2023, 135, 441–464. [Google Scholar] [CrossRef]

- Naceri, A.; Schumacher, T.; Li, Q.; Calinon, S.; Ritter, H. Learning optimal impedance control during complex 3D arm movements. IEEE Robot. Autom. Lett. 2021, 6, 1248–1255. [Google Scholar] [CrossRef]

- Yang, C.; Huang, D.; He, W.; Cheng, L. Neural control of robot manipulators with trajectory tracking constraints and input saturation. IEEE Trans. Neural Netw. Learn. Syst. 2020, 32, 4231–4242. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Chen, X.; Yu, J.; Liu, J. Adaptive neural network-based finite-time impedance control of constrained robotic manipulators with disturbance observer. IEEE Trans. Circuits Syst. II Express Briefs 2021, 69, 1412–1416. [Google Scholar] [CrossRef]

- He, T.; Wu, Z. Neural network disturbance observer with extended weight matrix for spacecraft disturbance attenuation. Aerosp. Sci. Technol. 2022, 126, 107572. [Google Scholar] [CrossRef]

- Van, M.; Ge, S.S. Adaptive fuzzy integral sliding-mode control for robust fault-tolerant control of robot manipulators with disturbance observer. IEEE Trans. Fuzzy Syst. 2020, 29, 1284–1296. [Google Scholar] [CrossRef]

- Della Santina, C.; Truby, R.L.; Rus, D. Data–driven disturbance observers for estimating external forces on soft robots. IEEE Robot. Autom. Lett. 2020, 5, 5717–5724. [Google Scholar] [CrossRef]

- Li, S.; Yang, J.; Chen, W.H.; Chen, X. Disturbance Observer-Based Control: Methods and Applications; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Yao, Y.; Ding, L.; Wang, Y. Fractional-Order Nonsingular Terminal Sliding Mode Control of a Cable-Driven Aerial Manipulator Based on RBF Neural Network. Int. J. Aeronaut. Space Sci. 2024, 25, 759–771. [Google Scholar] [CrossRef]

- Guo, Y.; Ma, B.; Chen, L.; Wu, R. Adaptive sliding mode control for a class of Caputo type fractional-order interval systems with perturbation. IET Control Theory Appl. 2017, 11, 57–65. [Google Scholar] [CrossRef]

- Karami-Mollaee, A.; Tirandaz, H.; Barambones, O. On dynamic sliding mode control of nonlinear fractional-order systems using sliding observer. Nonlinear Dyn. 2018, 92, 1379–1393. [Google Scholar] [CrossRef]

- Gao, J.; Liang, X.; Chen, Y.; Zhang, L.; Jia, S. Hierarchical image-based visual serving of underwater vehicle manipulator systems based on model predictive control and active disturbance rejection control. Ocean. Eng. 2021, 229, 108814. [Google Scholar] [CrossRef]

- Raoufi, M.; Delavari, H. Experimental implementation of a novel model-free adaptive fractional-order sliding mode controller for a flexible-link manipulator. Int. J. Adapt. Control Signal Process. 2021, 35, 1990–2006. [Google Scholar] [CrossRef]

- Chaudhury, A.N.; Ghosal, A. Optimum design of multi-degree-of-freedom closed-loop mechanisms and parallel manipulators for a prescribed workspace using Monte Carlo method. Mech. Mach. Theory 2017, 118, 115–138. [Google Scholar] [CrossRef]

| Link | Link Length | Link Twist | Joint Offset | Joint Angle |

|---|---|---|---|---|

| 1 | 0.12 | 0 | 0 | |

| 2 | 0.12 | 0 | 0 | |

| 3 | 0.12 | 0 | 0 |

| Controller | Parameters |

|---|---|

| PD-LESO | , |

| FONTSM | , , , , |

| FONTSM-DOB | , , , , , |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, L.; Xia, T.; Ma, R.; Liang, D.; Lu, M.; Wu, H. Enhanced Impedance Control of Cable-Driven Unmanned Aerial Manipulators Using Fractional-Order Nonsingular Terminal Sliding Mode Control with Disturbance Observer Integration. Fractal Fract. 2024, 8, 579. https://doi.org/10.3390/fractalfract8100579

Ding L, Xia T, Ma R, Liang D, Lu M, Wu H. Enhanced Impedance Control of Cable-Driven Unmanned Aerial Manipulators Using Fractional-Order Nonsingular Terminal Sliding Mode Control with Disturbance Observer Integration. Fractal and Fractional. 2024; 8(10):579. https://doi.org/10.3390/fractalfract8100579

Chicago/Turabian StyleDing, Li, Tian Xia, Rui Ma, Dong Liang, Mingyue Lu, and Hongtao Wu. 2024. "Enhanced Impedance Control of Cable-Driven Unmanned Aerial Manipulators Using Fractional-Order Nonsingular Terminal Sliding Mode Control with Disturbance Observer Integration" Fractal and Fractional 8, no. 10: 579. https://doi.org/10.3390/fractalfract8100579