Mechanical Response of Mudstone Based on Acoustic Emission Fractal Features

Abstract

:1. Introduction

2. Methods

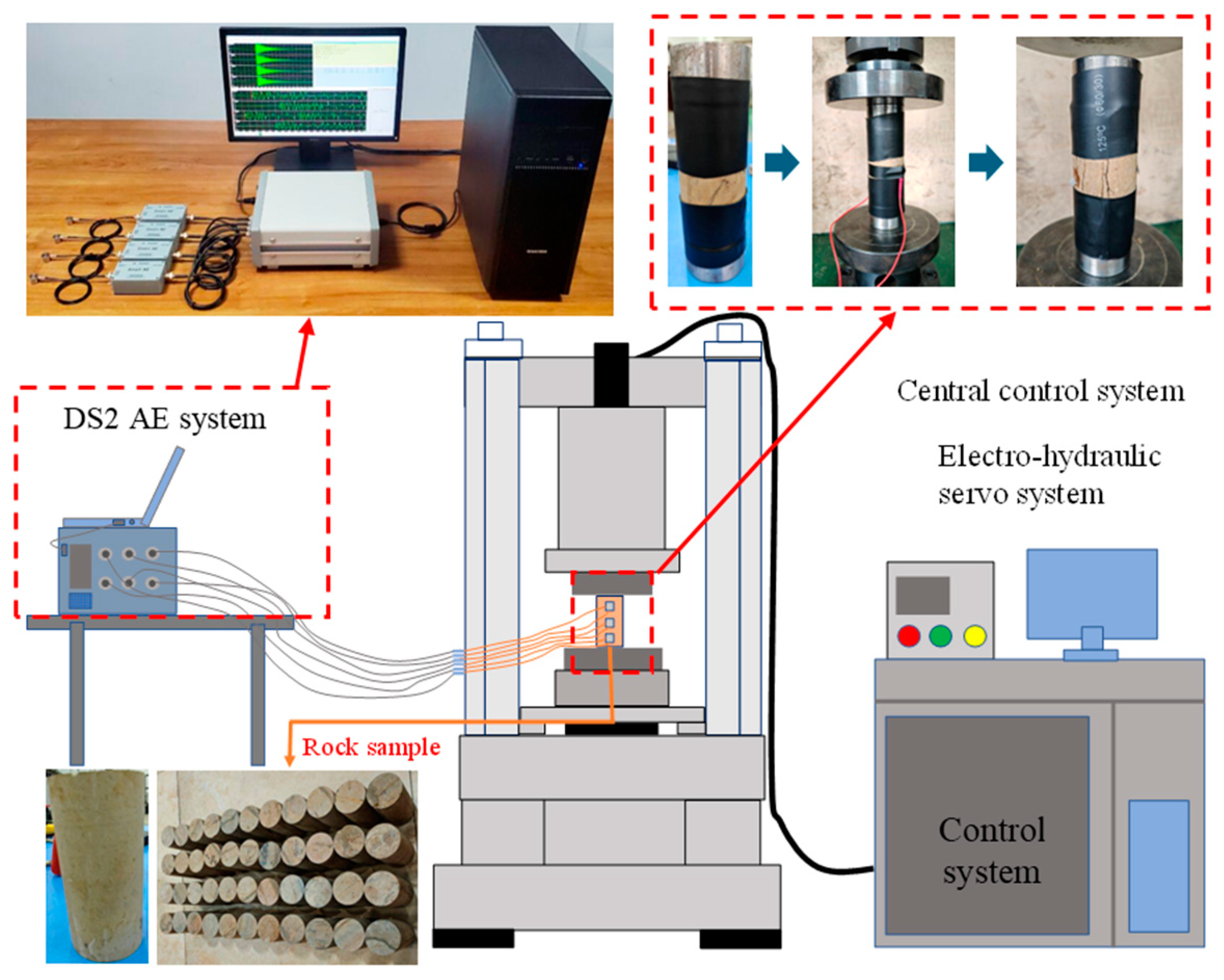

2.1. Specimens and Experimental System

2.2. Experimental Methods

3. Results and Discussion

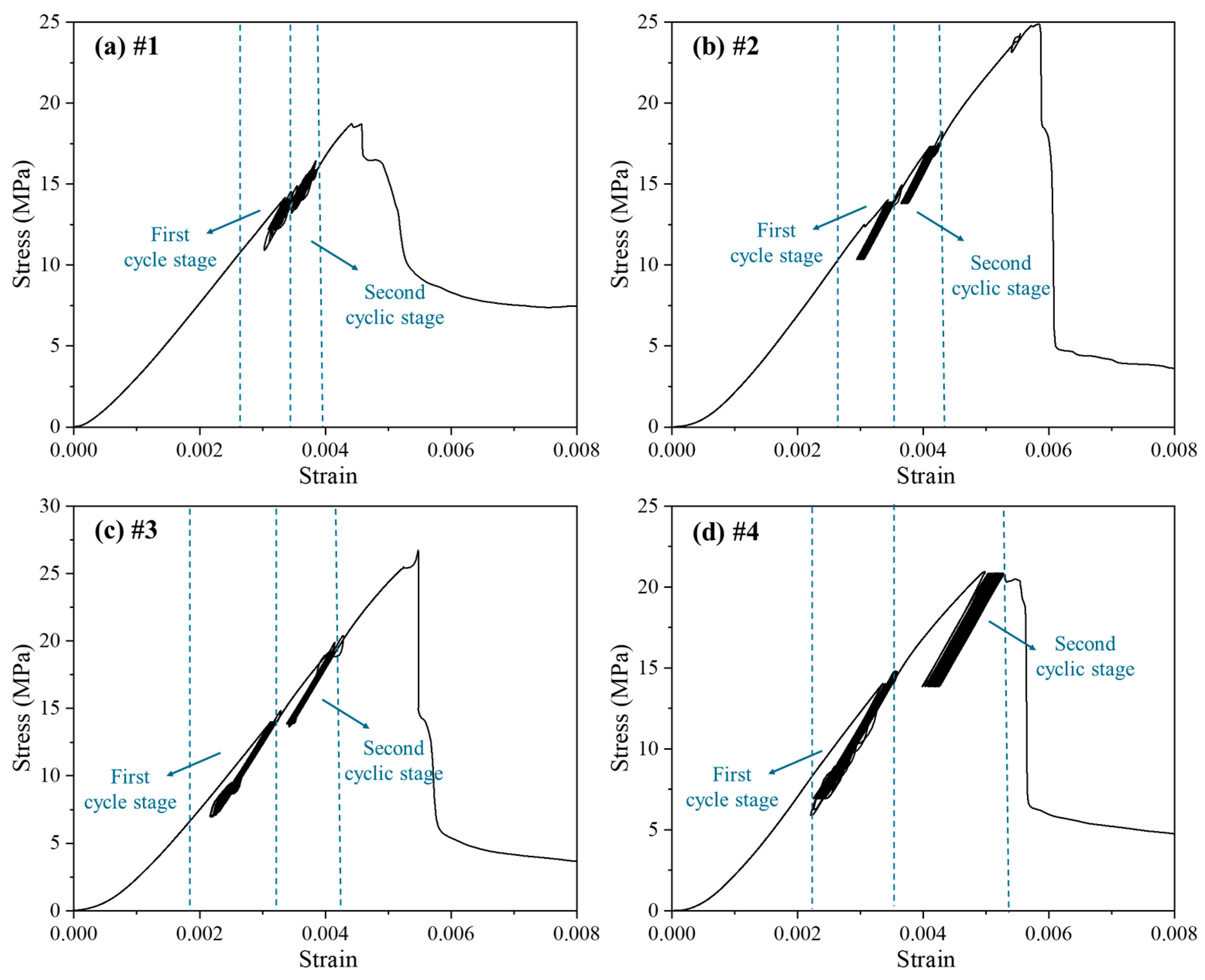

3.1. Stress–Strain Characteristics

3.2. Deformation Evolution

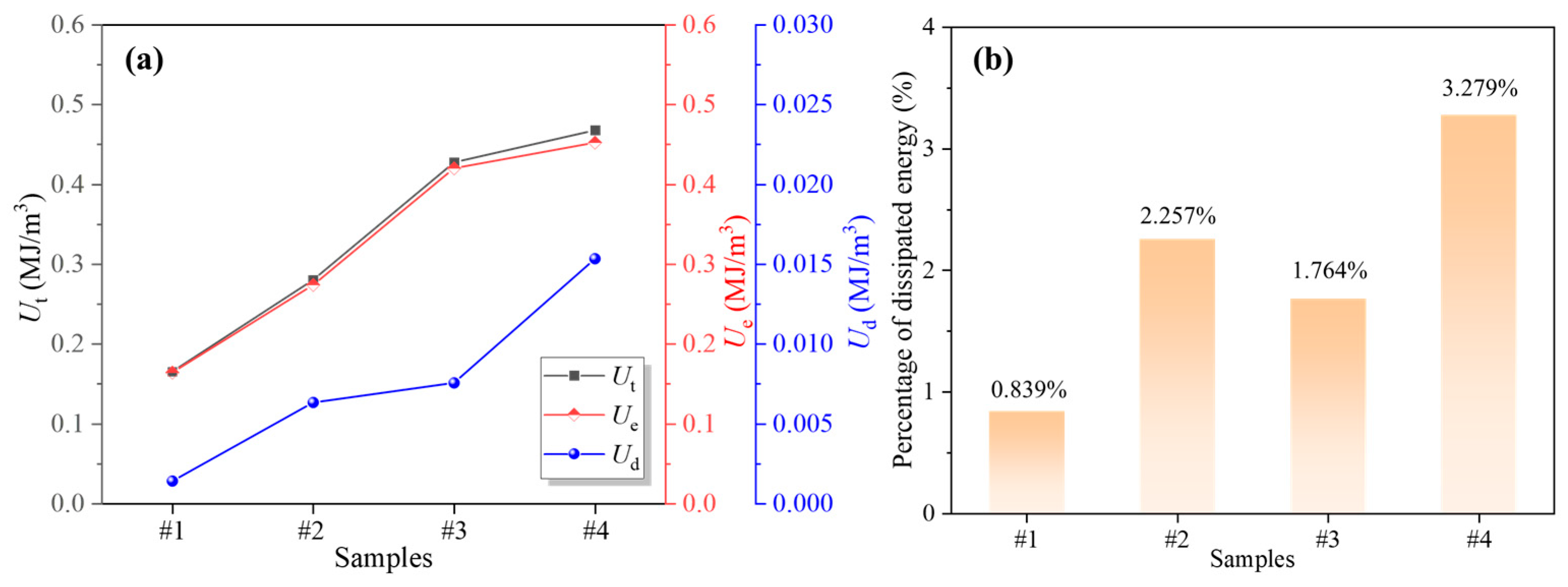

3.3. Energy Characteristics

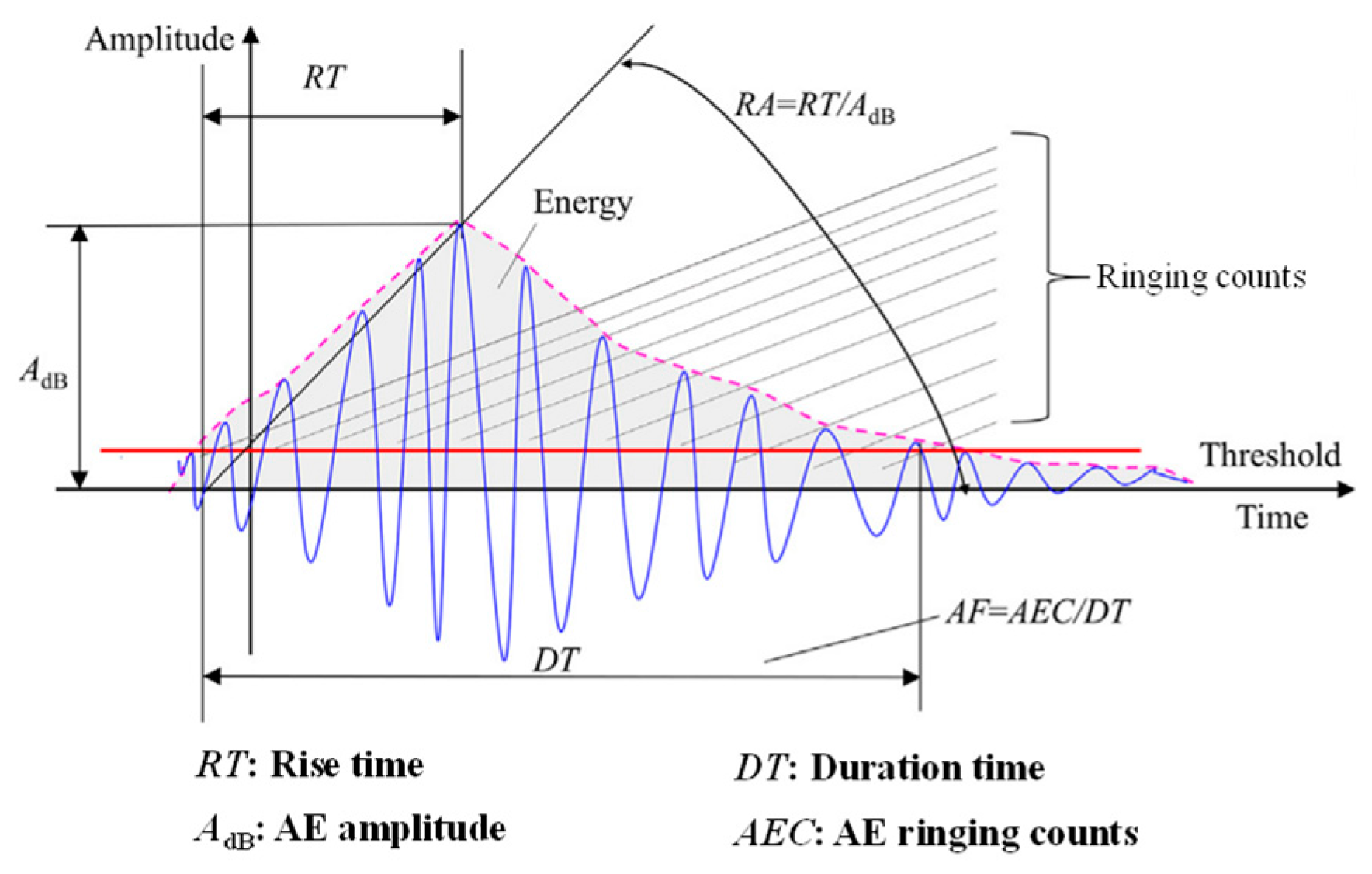

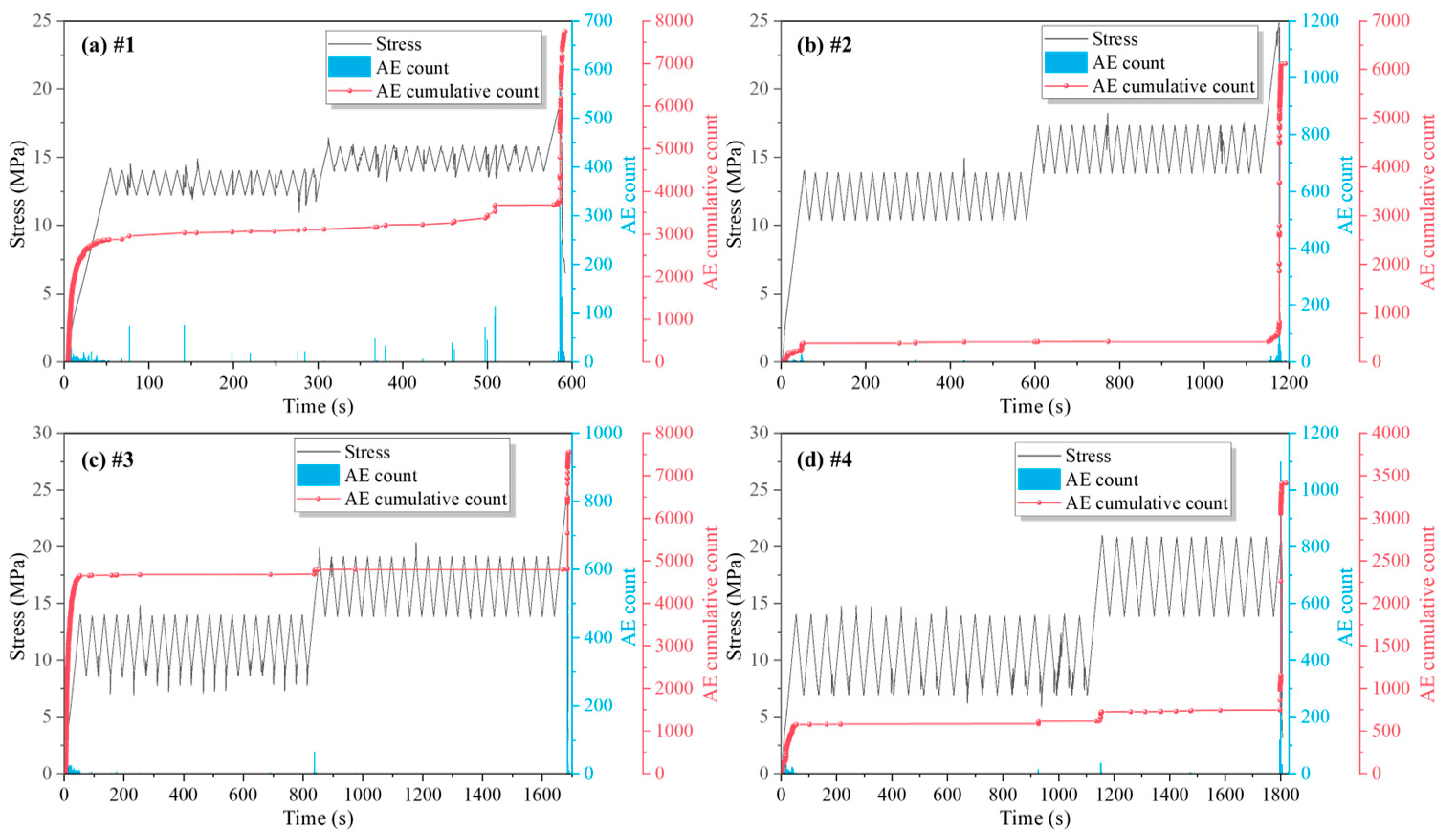

3.4. AE Count Characteristics

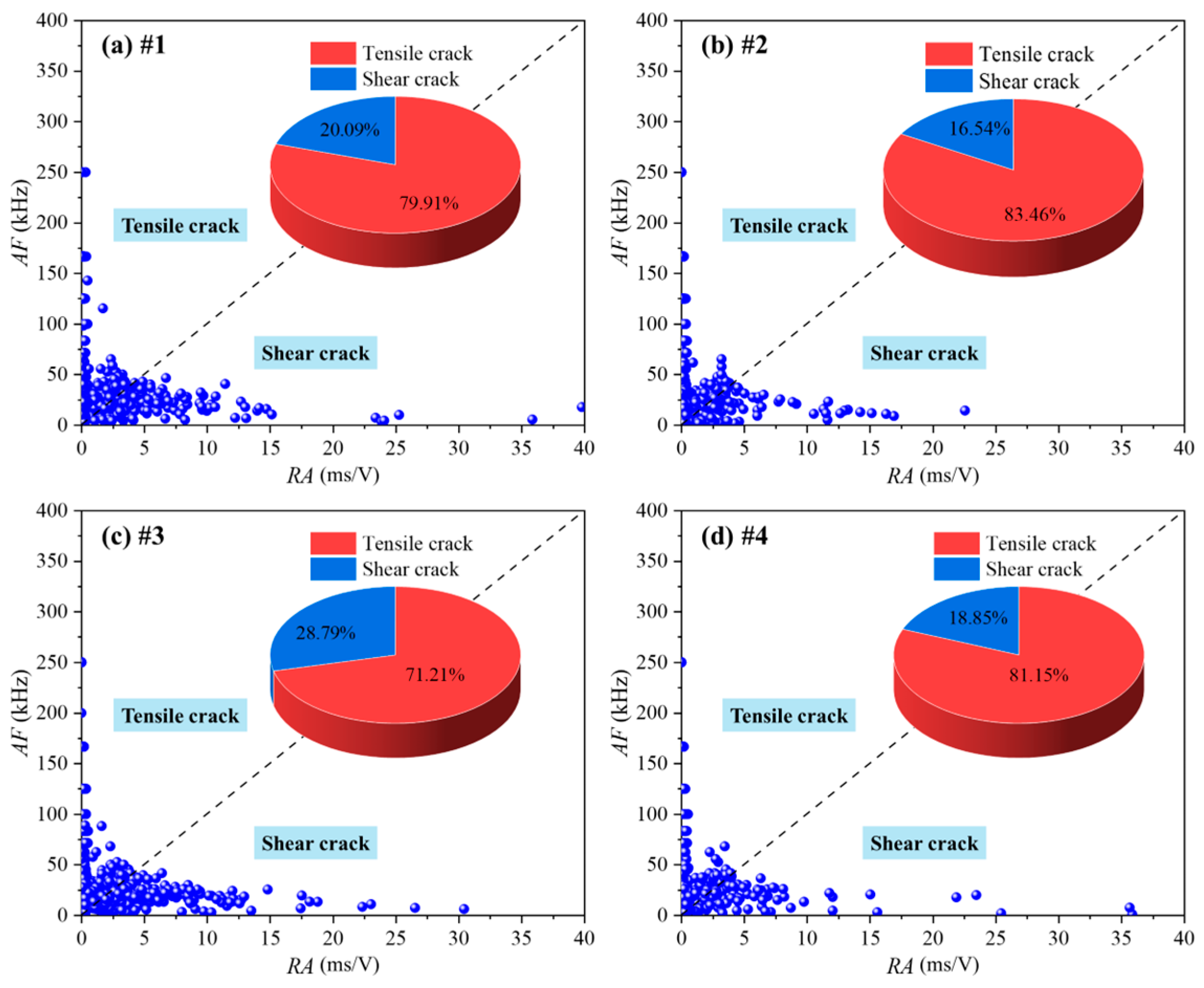

3.5. Failure Modes of Mudstone at Different Stress Amplitudes

3.6. Relationship Between Multifractal Features and Fracture Extension

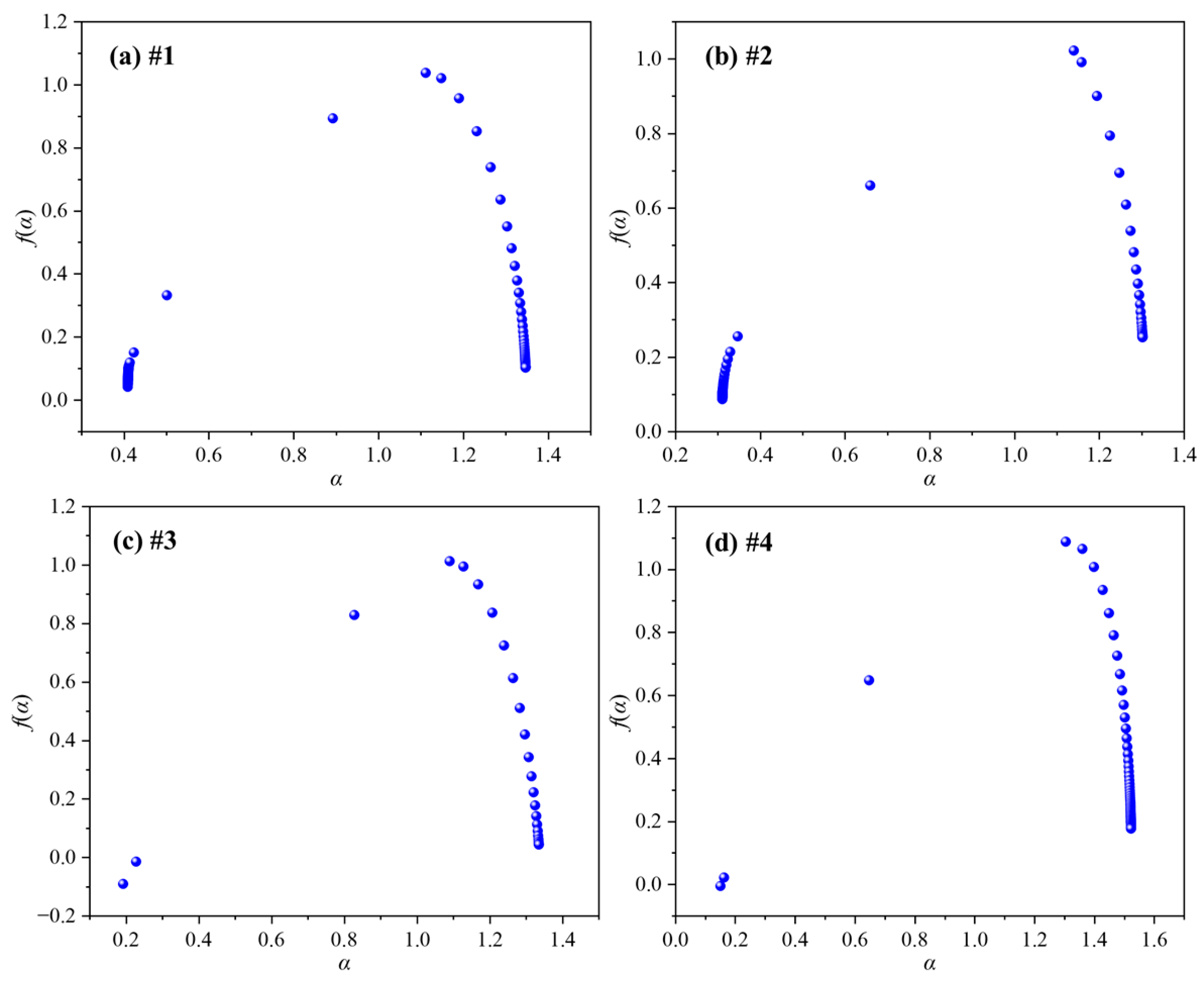

3.6.1. Multifractal Calculations

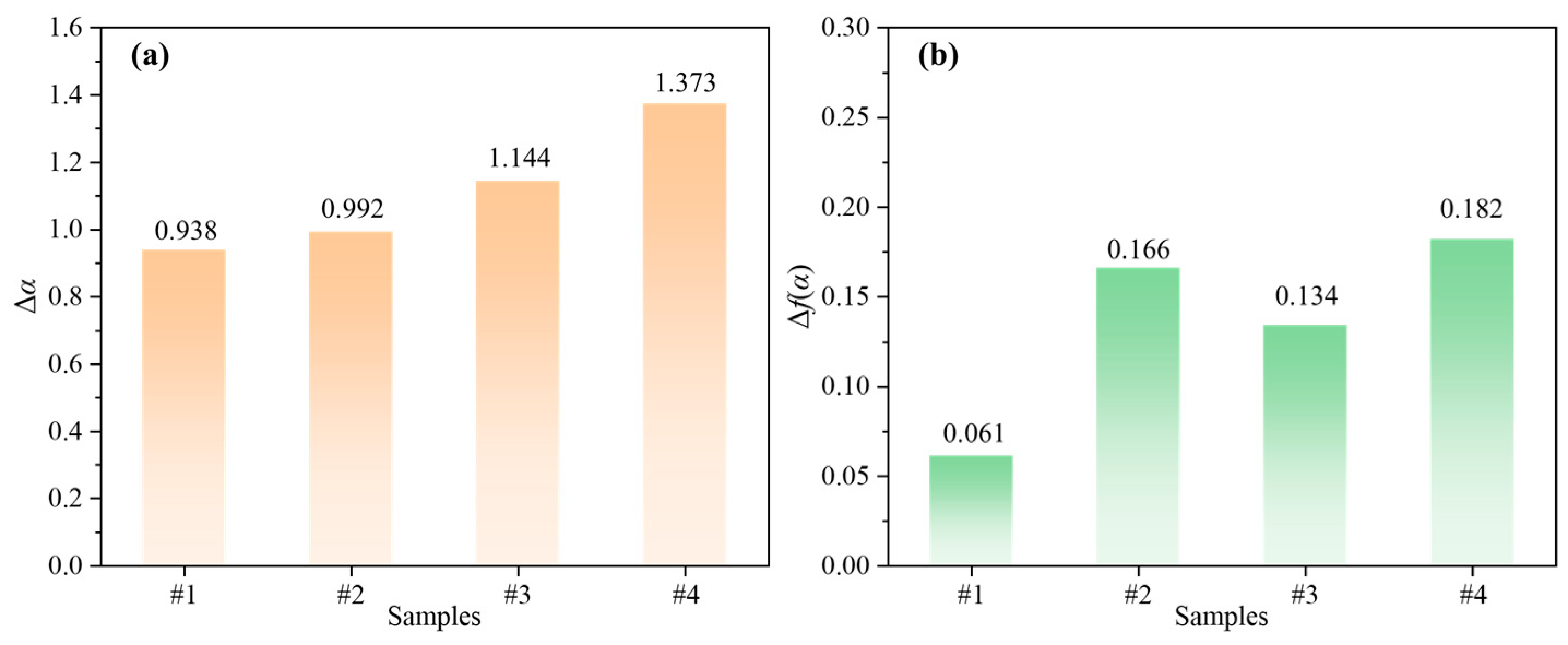

3.6.2. AE Counts Multifractal Features

3.6.3. Fracture Expansion Mechanism Based on AE Multifractal Features

4. Conclusions

- (1)

- Under low-stress amplitudes, mudstone shows better elastic recovery ability and less damage accumulation, and each deformation parameter is kept at a relatively stable level, indicating that the stability of the specimen is better. Under high-stress amplitudes and cyclic loadings, the LURR fluctuation of mudstone increases, the CIS rises rapidly, and the loading and unloading elastic modulus decreases significantly, indicating that the internal fracture of the specimen gradually expands and penetrates through, the plastic deformation accumulates, the stiffness decreases and the stability of the structure is gradually lost;

- (2)

- Different stress amplitudes significantly affect the energy evolution characteristics of mudstone specimens during cyclic loading. At low-stress amplitudes, the mudstone mainly experiences elastic deformation, and most of the energy can be recovered with less damage. At high-stress amplitudes, the mudstone experiences significant irreversible damage and shows a high percentage of dissipated energy;

- (3)

- With an increase in the stress amplitude, the accumulated AE counts show an accelerated growth trend. This rapid increase in cumulative AE reflects the irreversible damage accumulation characteristic of mudstone under high-stress amplitudes and indicates that the risk of material destabilization under high-stress conditions increases significantly. Tensile failure dominates at all stress amplitudes, where the failure mechanism within mudstone is mainly characterized by the extension of tensile-type fractures;

- (4)

- As the stress amplitude increased, Δα and Δf show an increasing trend. This indicates that the fracture extension process shifts from a relatively uniform and simple pattern to a more heterogeneous and complex pattern. This transformation reflects the nonlinear and multiscale fracture characteristics of mudstone under high-stress conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zou, Q.L.; Chen, Z.H.; Cheng, Z.H.; Liang, Y.P.; Xu, W.J.; Wen, P.R.; Zhang, B.C.; Liu, H.; Kong, F.J. Evaluation and intelligent deployment of coal and coalbed methane coupling coordinated exploitation based on Bayesian network and cuckoo search. Int. J. Min. Sci. Technol. 2022, 32, 1315–1328. [Google Scholar] [CrossRef]

- Liang, Y.P.; Yang, K.; Yang, Z.L.; Li, Q.G.; Chen, Q.; Sun, W.J. Hydro-mechanical-damage coupling effect of hydraulic fracturing in fractured dual-medium coal masses. Comput. Geotech. 2025, 178, 106909. [Google Scholar] [CrossRef]

- Zang, Z.S.; Li, Z.H.; Gu, Z.J.; Niu, Y.; Yin, S.; Kong, X.G.; Zhang, X. The multi-dimensional joint response of the electric potential time–frequency-field in the fracture process of flawed coal under dynamic load. Theor. Appl. Fract. Mech. 2024, 131, 104415. [Google Scholar] [CrossRef]

- Dai, J.H.; Gong, F.Q.; Huang, D.; Zhang, Q.H. Quantitative evaluation method of rockburst prevention effect for anchoring rock masses around deep-buried tunnels. Tunn. Undergr. Space Technol. 2024, 156, 106268. [Google Scholar] [CrossRef]

- Zhao, J.J.; Tian, S.X.; Jiang, Z.B.; Li, P.; Li, Z.Q.; Gou, R.T.; Ma, T.F. Study on the mechanism of SiO2-H2O nanofluid enhanced water injection in coal seam. Appl. Surf. Sci. 2024, 658, 159843. [Google Scholar] [CrossRef]

- Su, E.L.; Wei, J.Q.; Chen, H.D.; Chen, X.J.; Liang, Y.P.; Zou, Q.L.; Zhu, X.Y. Effect of CO2 injection on coalbed permeability based on a thermal-hydraulic-mechanical coupling model. Energy Fuels 2024, 38, 11078–11092. [Google Scholar] [CrossRef]

- Dai, J.H.; Gong, F.Q.; Xu, L. Rockburst criterion and evaluation method for potential rockburst pit depth considering excavation damage effect. J. Rock Mech. Geotech. Eng. 2024, 16, 1649–1666. [Google Scholar] [CrossRef]

- Ran, Q.C.; Liang, Y.P.; Zou, Q.L.; Zhang, B.C. Asymmetric characteristics of “three-field” in overburden of inclined coal seam groups and target extraction mechanism. Coal Sci. Technol. 2024, 52, 177–192. [Google Scholar] [CrossRef]

- Fu, Q.; Yang, J.; Gao, Y.B.; Li, C.J.; Song, H.X.; Liu, Y.X.; Wu, X. Combined blasting for protection of gob-side roadway with thick and hard roof. J. Rock Mech. Geotech. Eng. 2024, 16, 3165–3180. [Google Scholar] [CrossRef]

- Li, G.C.; Yang, S.; Sun, Y.T.; Xu, J.H.; Li, J.H. Research progress of roadway surrounding strata rock control technologies under complex conditions. Coal Sci. Technol. 2022, 50, 29–45. [Google Scholar] [CrossRef]

- Liu, H.D.; Liu, C.Y.; Yue, X.; Wang, J. Study on mechanical properties and acoustic emission characteristics of mudstone-clay composites under uniaxial compression. Eng. Geol. 2024, 332, 107478. [Google Scholar] [CrossRef]

- Lu, Y.L.; Pu, H.; Wang, L.G.; Li, Z.L.; Meng, X.Y.; Wang, B.; Zhang, K.W. Fracture evolution in mudstone specimens containing a pre-existing flaw under true triaxial compression. Int. J. Rock Mech. Min. Sci. 2021, 138, 104594. [Google Scholar] [CrossRef]

- Yu, M.Y.; Liu, B.G.; Liu, K.Y.; Sun, J.L.; Deng, T.B.; Wang, Q. Creep behavior of carbonaceous mudstone under triaxial hydraulic coupling condition and constitutive modelling. Int. J. Rock Mech. Min. Sci. 2023, 164, 105357. [Google Scholar] [CrossRef]

- Chu, P.; Xie, H.P.; Hu, J.J.; Li, M.H.; Li, R.; Li, C.B. Anisotropic fracture behavior and corresponding fracture process zone of laminated shale through three-point bending tests. J. Rock Mech. Geotech. Eng. 2024, in press. [CrossRef]

- Chen, J.R.; Yin, X.H.; Zhou, C.T.; Pan, M.Y.; Han, Z.Y.; Zhou, T. Interaction between flaws and failure characteristics of red sandstone containing double flaws under compressive-shear loading. Eng. Fract. Mech. 2023, 292, 109664. [Google Scholar] [CrossRef]

- Xu, L.; Gong, F.Q.; Liu, Z.X. Experiments on rockburst proneness of pre-heated granite at different temperatures: Insights from energy storage, dissipation and surplus. J. Rock Mech. Geotech. Eng. 2022, 14, 1343–1355. [Google Scholar] [CrossRef]

- He, Q.C.; Liu, J.F.; Wu, F.; Li, C.B.; Gao, R.B.; Ye, C.F.; Zhu, S.J. Fatigue properties and constitutive model of Jintan salt rock subjected to complex cyclic loading. Int. J. Min. Sci. Technol. 2025, in press. [CrossRef]

- Pan, D.G.; Wang, K.; Lu, P.; Chen, F. Experimental study of nonlinear dynamic parameters of mudstone with different vibration frequencies. J. China Univ. Min. Technol. 2019, 48, 1188–1196. [Google Scholar] [CrossRef]

- Liu, Y.D.; Kang, H.P. Study on mechanical behavior and failure mode of water-bearing mudstone under loading and unloading path. J. Min. Saf. Eng. 2022, 39, 1011–1020. [Google Scholar] [CrossRef]

- Li, K.; Yu, W.J.; Liao, Z.; Guo, H.X.; Pan, B.; Khamphouvanh, V.; Yang, J. A laboratory-testing-based study on mechanical properties and dilatancy characteristics of deeply buried mudstone under different stress loading rates. J. China Coal Soc. 2023, 48, 3360–3371. [Google Scholar] [CrossRef]

- Zhang, L.; Li, B.; Zhu, B.L.; Luo, B. Loading and Unloading Mechanical Properties and Energy Evolution Mechanism of Red-Bed Mudstone. J. Southwest Jiaotong Univ. 2023, 58, 592–602. [Google Scholar] [CrossRef]

- Wang, K.; Pan, D.G.; Lu, W.Y.; Chen, F. Experimental study on damping characteristics of mudstone and sandstone under graded cyclic loading. J. Cent. S. Univ. 2019, 50, 3046–3054. [Google Scholar]

- Xu, Y.; Li, C.J.; Zheng, Q.Q.; Ni, X.; Wang, Q.Q. Analysis of energy evolution and damage characteristics of mudstone under cyclic loading and unloading. Chin. J. Rock Mech. Eng. 2019, 38, 2084–2091. [Google Scholar] [CrossRef]

- Li, X.B.; Liu, X.S.; Tan, Y.L.; Chen, A.; Wang, H.L.; Wang, X.; Yang, S.L. Rheological mechanical properties and its constitutive relation of soft rock considering influence of clay mineral composition and content. Int. J. Coal Sci. Technol. 2023, 10, 48. [Google Scholar] [CrossRef]

- Cheng, C.H.; Hu, Q.T.; Luo, Y.J.; Wang, B.C.; Tao, R.; Sun, Y.L. Experimental study of deformation evolution around the gas extraction borehole in a composite stratum. Fuel 2024, 381, 133296. [Google Scholar] [CrossRef]

- Ma, T.F.; Zou, Q.L.; Ran, Q.C.; Kong, F.J. Compaction and re-crushing characteristics of sandstone granules with different gradations under cyclic loading. Adv. Powder Technol. 2024, 35, 104611. [Google Scholar] [CrossRef]

- Li, W.X.; Li, Q.G.; Qian, Y.N.; Ling, F.P.; Liu, R.H. Structural properties and failure characteristics of granite after thermal treatment and water cooling. Geomech. Geophys. Geo-Energy Geo-Resour. 2023, 9, 171. [Google Scholar] [CrossRef]

- Saffari, P.R.; Thongchom, C.; Jearsiripongkul, T.; Saffari, P.R.; Keawsawasvong, S.; Kongwat, S. Thermo-vibro-acoustic analysis of pavement under a harmonically rectangular moving load. Int. J. Thermofluids 2023, 20, 100409. [Google Scholar] [CrossRef]

- Ye, C.F.; Xie, H.P.; Wu, F.; Li, C.B. Study on the nonlinear time-dependent deformation characteristics and viscoelastic-plastic model of shale under direct shear loading path. Bull. Eng. Geol. Environ. 2023, 82, 189. [Google Scholar] [CrossRef]

- Yu, T.Y.; Jiang, G.L.; Rao, Q.Z.; Chen, H.Y.; Wu, L.; Liu, X.F. Investigation of Damage and Deformation Characteristics of Soft Red Mudstone Using Acoustic Emission Parameter Analysis under High-Cycle Cyclic Loading Conditions. China Railw. Sci. 2024, 45, 12–25. [Google Scholar]

- Li, G.C.; Yang, S.; Sun, Y.T.; Li, J.H.; Hao, H.R.; Shao, Z.Y. Study on mechanical response characteristics and damage mechanism of water-containing muddy rock under low strain rate dynamic loading. J. China Coal Soc. 2024, 49, 4768–4784. [Google Scholar] [CrossRef]

- Kong, X.G.; Wang, E.Y.; Li, S.G.; Lin, H.F.; Xiao, P.; Zhang, K.Z. Fractals and chaos characteristics of acoustic emission energy about gas-bearing coal during loaded failure. Fractals-Complex Geom. Patterns Scaling Nat. Soc. 2019, 27, 1950072. [Google Scholar] [CrossRef]

- Liu, Y.B.; Meng, X.X. Dynamic multifractal characteristics of acoustic emission about composite samples with different stress loading and unloading conditions. Sci. Rep. 2024, 14, 7533. [Google Scholar] [CrossRef] [PubMed]

- Zang, Z.S.; Li, Z.H.; Yin, S.; Kong, X.G.; Niu, Y.; Liu, B.L.; Li, H.H. Study on the propagation and multifractal characteristics of stress waves in coal based on electric potential and DIC characterization. Chaos Solitons Fractals 2024, 184, 115059. [Google Scholar] [CrossRef]

- Kong, X.G.; Wang, E.Y.; He, X.Q.; Li, D.X.; Liu, Q.L. Time-varying multifractal of acoustic emission about coal samples subjected to uniaxial compression. Chaos Solitons Fractals 2017, 103, 571–577. [Google Scholar] [CrossRef]

- Qiu, L.M.; Zhu, Y.; Song, D.Z.; He, X.Q.; Wang, W.X.; Liu, Y.; Xiao, Y.Z.; Wei, M.H.; Yin, S.; Liu, Q. Study on the Nonlinear Characteristics of EMR and AE during Coal Splitting Tests. Minerals 2022, 12, 108. [Google Scholar] [CrossRef]

- Zhang, H.R.; Guo, W.H. Acoustic Emission Waveform Characteristics of Red Sandstone Failure under Uniaxial Compression after Thermal Damage. Sustainability 2022, 14, 13285. [Google Scholar] [CrossRef]

- Kong, X.G.; Wang, E.Y.; He, X.Q.; Li, Z.H.; Li, D.X.; Liu, Q.L. Multifractal characteristics and acoustic emission of coal with joints under uniaxial loading. Fractals-Complex Geom. Patterns Scaling Nat. Soc. 2017, 25, 1750045. [Google Scholar] [CrossRef]

- Dong, L.J.; Yan, M.C.; Chen, Y.C.; Yang, L.B.; Sun, D.Y. Study on Mechanical and Acoustic Emission Characteristics of Backfill-Rock Instability under Different Stress Conditions. Sensors 2024, 24, 4112. [Google Scholar] [CrossRef] [PubMed]

- Xie, X.B.; Li, S.Q.; Guo, J. Study on Multiple Fractal Analysis and Response Characteristics of Acoustic Emission Signals from Goaf Rock Bodies. Sensors 2022, 22, 2746. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, X.F.; Wang, X.R.; Liu, Y.B.; Xie, H.; Du, P.F. Acoustic Emission Characteristics of Coal Failure Under Triaxial Loading and Unloading Disturbance. Rock Mech. Rock Eng. 2023, 56, 1043–1061. [Google Scholar] [CrossRef]

- Zhang, B.C.; Liang, Y.P.; Zou, Q.L.; Ning, Y.H.; Kong, F.J. Damage and hardening evolution characteristics of sandstone under multilevel creep–fatigue loading. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 43. [Google Scholar] [CrossRef]

- Zou, Q.L.; Hu, Y.L.; Zhou, X.L. Performance of metal circular tube under different loading amplitudes and dynamic resistance-yielding mechanism. Mater. Today Commun. 2024, 39, 108913. [Google Scholar] [CrossRef]

- Xu, L.; Gong, F.Q.; Dai, J.H.; He, Z.C. Effects of bedding angles on rockburst proneness of layered anisotropic phyllites. J. Rock Mech. Geotech. Eng. 2024, in press. [CrossRef]

- Zou, Q.L.; Chen, Z.H.; Zhan, J.F.; Chen, C.M.; Gao, S.K.; Kong, F.J.; Xia, X.F. Morphological evolution and flow conduction characteristics of fracture channels in fractured sandstone under cyclic loading and unloading. Int. J. Min. Sci. Technol. 2023, 33, 1527–1540. [Google Scholar] [CrossRef]

- Yang, C.; Hassani, F.; Zhou, K.P.; Xiong, X.; Wang, F.M.; Shao, Y. Effect of microwave treatment on the thermal properties and dynamic splitting behavior of red sandstone. Can. Geotech. J. 2022, 59, 1231–1242. [Google Scholar] [CrossRef]

- Si, X.F.; Luo, Y.; Gong, F.Q.; Huang, J.C.; Han, K.F. Temperature effect of rockburst in granite caverns: Insights from reduced-scale model true-triaxial test. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 26. [Google Scholar] [CrossRef]

- Guo, Y.D.; Li, X.B.; Huang, L.Q.; Dyskin, A.; Pasternak, E. Insight into the dynamic tensile behavior of deep anisotropic shale reservoir after water-based working fluid cooling. Int. J. Rock Mech. Min. Sci. 2024, 182, 105875. [Google Scholar] [CrossRef]

- Yang, S.Q.; Li, H.; Yang, Z.; Wang, S.S.; Sun, B.W.; Hu, Y.J. Three-dimensional peridynamic simulation on triaxial compression failure mechanical behavior of cylindrical marble specimen containing pre-existing fissures. Eng. Fract. Mech. 2024, 312, 110600. [Google Scholar] [CrossRef]

- Li, H.; Yang, S.Q.; Yang, Z.; Zhou, X.P.; Tian, W.L.; Wang, S.S. Experimental and numerical study on the mechanical behaviors and crack propagation of sandstone containing two parallel fissures. Theor. Appl. Fract. Mech. 2023, 126, 103965. [Google Scholar] [CrossRef]

- Li, F.; Gao, M.Z.; Ye, S.Q.; Xie, J.; Deng, H.C.; Yang, B.G.; Liu, J.J.; Yang, Z.D.; Tang, R.F. Formation mechanism of core discing during drilling under deep in-situ stress environment: Numerical simulation and laboratory testing. J. Cent. S. Univ. 2023, 30, 3303–3321. [Google Scholar] [CrossRef]

- Ma, Q.; Liu, X.L.; Tan, Y.L.; Wang, R.S.; Xie, W.Q.; Wang, E.Z.; Liu, X.S.; Shang, J.L. Experimental study of loading system stiffness effects on mechanical characteristics and kinetic energy calculation of coal specimens. Rock Mech. Rock Eng. 2024, 57, 9941–9957. [Google Scholar] [CrossRef]

- Ran, Q.C.; Chen, P.; Liang, Y.P.; Ye, C.F.; Zhang, B.C.; Wu, Z.P.; Ma, T.F.; Chen, Z.H. Hardening-damage evolutionary mechanism of sandstone under multi-level cyclic loading. Eng. Fract. Mech. 2024, 307, 110291. [Google Scholar] [CrossRef]

- Ma, T.F.; Zou, Q.L.; Chen, J.L.; Kong, F.J.; Ran, Q.C.; Wang, P.T. Multi-stage evolution characteristics and particle size effect of sandstone granules subjected to cyclic loads. Eng. Fract. Mech. 2024, 312, 110614. [Google Scholar] [CrossRef]

- Li, C.B.; Tu, J.H.; Xie, H.P.; Hu, J.J. Tensile behavior and damage mechanisms of hot dry rock under thermal shock fatigue and seawater dissolution. Adv. Geo-Energy Res. 2024, 13, 132–145. [Google Scholar] [CrossRef]

- Wu, F.; Liu, Y.; Gao, R.; Li, C.; Chen, J.; Ye, C. Study on the influence mechanism of interfacial inclination angle on the mechanical behavior of coal and concrete specimens. Constr. Build. Mater. 2024, 443, 137787. [Google Scholar] [CrossRef]

- Li, K.S.; Yang, S.Q.; Liu, C.X.; Chen, Y.; Zhang, G.L.; Ma, Q. Mechanical response and microscopic damage mechanism of pre-flawed sandstone subjected to monotonic and multilevel cyclic loading: A laboratory-scale investigation. Int. J. Min. Sci. Technol. 2023, 33, 1487–1510. [Google Scholar] [CrossRef]

- Chen, Z.W.; Liu, Z.X.; Chen, J.Z.; Li, X.B.; Huang, L.Q. Intelligent identification of acoustic emission Kaiser effect points and its application in efficiently acquiring in-situ stress. Int. J. Miner. Metall. Mater. 2024, in press.

- Guo, Y.D.; Huang, L.Q.; Li, X.B. Experimental and numerical investigation on the fracture behavior of deep anisotropic shale reservoir under in-situ temperature. Energy 2023, 282, 128969. [Google Scholar] [CrossRef]

- Wang, H.J.; Liu, D.; Cui, Z.D.; Cheng, C.; Jian, Z. Investigation of the fracture modes of red sandstone using XFEM and acoustic emissions. Theor. Appl. Fract. Mech. 2016, 85, 283–293. [Google Scholar] [CrossRef]

- Du, K.; Luo, X.Y.; Liu, M.H.; Liu, X.L.; Zhou, J. Understanding the evolution mechanism and classification criteria of tensile -shear cracks in rock failure process from acoustic emission (AE) characteristics. Eng. Fract. Mech. 2024, 296, 109864. [Google Scholar] [CrossRef]

- Chen, J.; Ye, Y.B.; Pu, Y.Y.; Xu, W.H.; Mengli, D. Experimental study on uniaxial compression failure modes and acoustic emission characteristics of fissured sandstone under water saturation. Theor. Appl. Fract. Mech. 2022, 119, 103359. [Google Scholar] [CrossRef]

- Li, S.G.; He, D.; Kong, X.G.; Lin, H.F.; Ma, Y.K.; Li, X.L.; Zhan, M.Z.; Ji, P.F.; Yang, S.R. Relationship between micro-pores fractal characteristics about NMR T2 spectra and macro cracks fractal laws based on box dimension method of coal under impact load from energy dissipation theory. Chaos Solitons Fractals 2024, 189, 115685. [Google Scholar] [CrossRef]

- Wu, Z.P.; Liang, Y.P.; Miao, K.J.; Li, Q.G.; Liu, S.C.; Ran, Q.C.; Sun, W.J.; Yin, H.L.; Ma, Y. Damage law and reasonable width of coal pillar under gully area: Linking fractal characteristics of coal pillar fractures to their stability. Fractal Fract. 2024, 8, 407. [Google Scholar] [CrossRef]

- Ran, Q.C.; Liang, Y.P.; Zou, Q.L.; Zhang, B.C.; Li, R.F.; Chen, Z.H.; Ma, T.F.; Kong, F.J.; Liu, H. Characteristics of mining-induced fractures under inclined coal seam group multiple mining and implications for gas migration. Nat. Resour. Res. 2023, 32, 1481–1501. [Google Scholar] [CrossRef]

- Ye, C.F.; Xie, H.P.; Wu, F.; Hu, J.J.; Ren, L.; Li, C.B. Asymmetric failure mechanisms of anisotropic shale under direct shear. Int. J. Rock Mech. Min. Sci. 2024, 183, 105941. [Google Scholar] [CrossRef]

- Ran, Q.C.; Liang, Y.P.; Yang, Z.L.; Zou, Q.L.; Ye, C.F.; Tian, C.L.; Wu, Z.P.; Zhang, B.C.; Wang, W.Z. Deterioration mechanisms of coal mechanical properties under uniaxial multi-level cyclic loading considering initial damage effects. Int. J. Rock Mech. Min. Sci. 2025, 186, 106006. [Google Scholar] [CrossRef]

- Xie, Y.C.; Hou, M.Z.; Li, C.B. Anisotropic characteristics of acoustic emission and the corresponding multifractal spectrum during progressive failure of shale under cyclic loading. Int. J. Rock Mech. Min. Sci. 2023, 165, 105364. [Google Scholar] [CrossRef]

- He, Q.C.; Wu, F.; Zhou, X.H.; Ye, C.F.; Chen, J.; Gao, R.B. Compressive failure patterns and acoustic emission characteristics of reservoir rocks subjected to chemical corrosion for underground energy storage. J. Energy Storage 2025, 170, 114950. [Google Scholar] [CrossRef]

- Lei, R.D.; Tan, Y.L.; Berto, F.; Hu, C.; Qi, X. Temporal-frequency distribution and multi-fractal characterization of acoustic emission of rock materials containing two parallel pre-existing flaws. Fatigue Fract. Eng. Mater. Struct. 2023, 46, 2139–2155. [Google Scholar] [CrossRef]

| Number | Diameter (mm) | Height (mm) |

|---|---|---|

| #1 | 49.37 | 100.71 |

| #2 | 49.62 | 100.79 |

| #3 | 49.57 | 100.79 |

| #4 | 49.55 | 100.62 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, X.; Liang, Y.; Ran, Q. Mechanical Response of Mudstone Based on Acoustic Emission Fractal Features. Fractal Fract. 2025, 9, 83. https://doi.org/10.3390/fractalfract9020083

Chang X, Liang Y, Ran Q. Mechanical Response of Mudstone Based on Acoustic Emission Fractal Features. Fractal and Fractional. 2025; 9(2):83. https://doi.org/10.3390/fractalfract9020083

Chicago/Turabian StyleChang, Xianyin, Yunpei Liang, and Qican Ran. 2025. "Mechanical Response of Mudstone Based on Acoustic Emission Fractal Features" Fractal and Fractional 9, no. 2: 83. https://doi.org/10.3390/fractalfract9020083

APA StyleChang, X., Liang, Y., & Ran, Q. (2025). Mechanical Response of Mudstone Based on Acoustic Emission Fractal Features. Fractal and Fractional, 9(2), 83. https://doi.org/10.3390/fractalfract9020083