Abstract

A silicon mechanical-photonic wavelength converter, not based on absorption, has been recently proposed to address the need for all-silicon photodetectors in the infrared spectrum. Its implementation requires high-frequency modulation, from hundreds of kHz to 1 MHz, of a light beam over an area of a few hundred microns. Since the displacement amplitudes of tens of microns at these frequencies are unfeasible, a moving grate is proposed to locally modulate the light. The MEMS actuator, an array of 1 µm-wide 1 µm-spaced beams (100 × 100 µm2 area), achieved displacements of 70 nm at atmospheric pressure and 350 nm under low vacuum, with 10 Vpp actuation at 290 kHz (FOM displacement × frequency2 above previously reported works).

1. Introduction

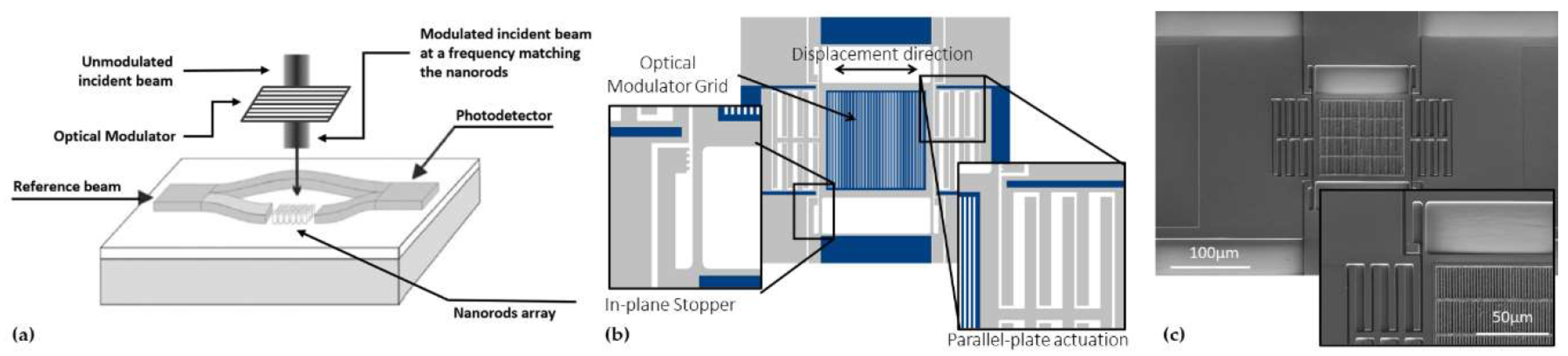

Several silicon-based photonic detectors have been proposed but are unsuitable for wavelengths larger than 1 µm. A silicon mechanical-photonic wavelength converter (MPWC) was proposed [1] for an all-silicon infrared detector, not based on absorption, consisting of a Mach–Zehnder interferometer (Figure 1) in which the incident input light is modulated at a temporal frequency matched to the mechanic resonance of nanorods in the reference beam waveguide, and relying on the resonance of the nanorods due to optical gradient force. The challenge is to fabricate MEMS shutters/actuators with high-enough operation frequencies (and enough displacement amplitude) and silicon nanorod arrays with matching resonant frequencies, resulting in a 1–2 MHz feasible range. High-frequency MEMS resonators exist but with displacements limited to the picometer range [2,3].

Figure 1.

(a) Schematic representation of MPWC device with MEMS optical modulator, (b) MEMS optical modulator devices layout, and (c) SEM images of the fabricated devices.

2. MEMS Optical Modulator

A MEMS optical modulator with a grate-shape or beam array is proposed to decrease the required displacement amplitude. For an array of 1µm-wide beams at a 2 µm pitch, a displacement of ±500 nm at a frequency of 0.5 kHz would be effective in locally modulating light at 1 MHz. The challenge lies in having micrometer displacements at such a high frequency with a movable structure with an area of 100 × 100 µm2 (given the trade-off between the resonance frequency and displacement amplitude typical of MEMS optical shutters). The design includes a 2 µm pitch grating, four springs, and parallel-plate actuation electrodes on a 3 µm SOI (Figure 1b, Table 1). The main micromachining steps are (a) device layer thinning from 5 μm to 2 μm; (b) FS metal deposition; (c) FS and BS SiO2 deposition; (d) metal grid patterning; (e) BS hard-mask patterning; (f) FS device lithography; (g) FS lithography and Si etching; (h) BS Si etch; and (i) HF vapor etching.

Table 1.

Microstructure’s main parameters.

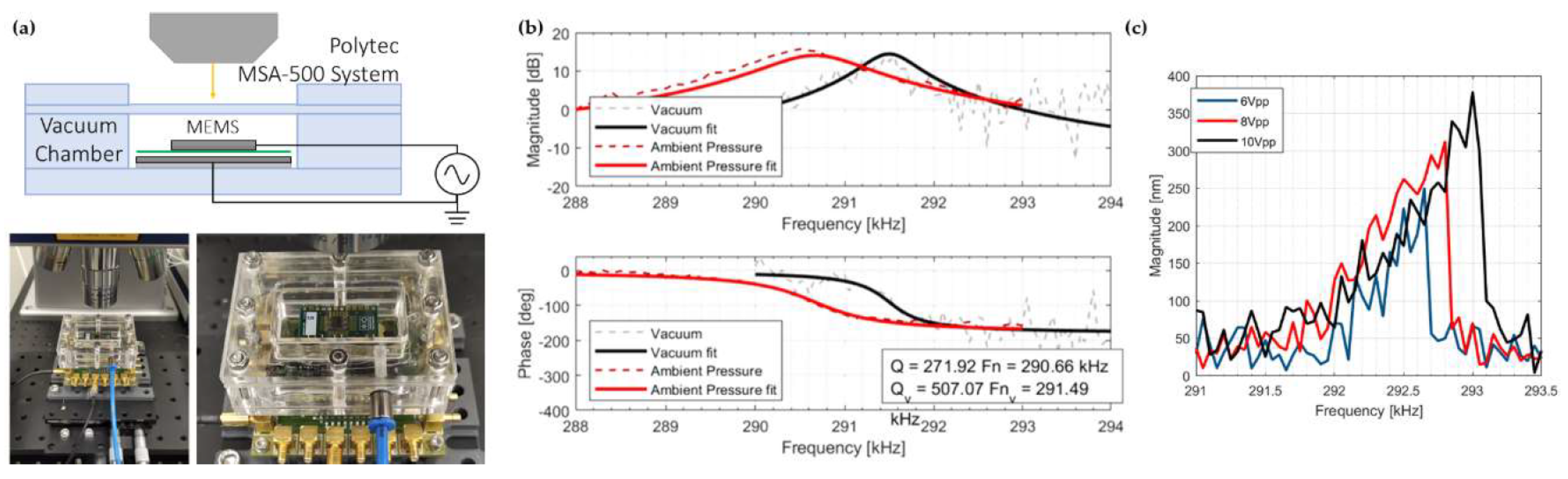

3. Experimental Results and Discussion

The in-plane motion of the fabricated devices (Figure 1c) was measured on a Polytec MSA-500 at atmospheric pressure and in low vacuum (above −0.9 bar) using an acrylic vacuum chamber (Figure 2a). A natural frequency (Fn) near 290 kHz (lower than expected due to over-etch) and quality factors (Q) of 271 (atm) and 507 (in vacuum) were extracted from measurements (Figure 2b). At a higher vacuum (~10 mbar), maximum displacement amplitudes of 378 nm at 293 kHz were achieved (Figure 2c), with positive Fn shifts (from nonlinear spring softening). Further work focuses on the redesign to meet the 0.5 MHz target and optical modulation validation.

Figure 2.

(a) Experimental setup, (b) bode plots at different pressures, and (c) magnitude displacement in low-pressure conditions for different amplitude actuation signals.

Author Contributions

Conceptualization, R.A.D. and Z.Z.; methodology, F.S.A., C.C., R.A.D. and I.S.G.; investigation, R.A.D., I.P. and I.S.G.; writing, I.P. and I.S.G.; experimental characterization, J.V., I.P. and I.S.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Raw data is available by request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Rudnitsky, A.; Agdarov, S.; Gulitsky, K.; Zalevsky, Z. Silicon based mechanic-photonic wavelength converter for infrared photo-detection. Opt. Commun. 2017, 392, 114–118. [Google Scholar] [CrossRef]

- Singh, P.; Gupta, P.; Srivastava, P.; Goswami, M.; Singh, B.R. Design and analysis of high resonant frequency (1 MHz) MEMS accelerometer. In Proceedings of the 2013 Students Conference on Engineering and Systems (SCES), Allahabad, India, 12–14 April 2013. [Google Scholar]

- Eltagoury, Y.M.; Soliman, M.; Sabry, Y.M.; Alotaibi, M.J.; Khalil, D. Electrostatic comb-drive actuator with high in-plane translational velocity. Micromachines 2016, 7, 188. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).