Effect of Lattice Structure on Mechanical Properties of Ti-6Al-4V-Ta Alloy for Improved Antibacterial Properties

Abstract

1. Introduction

2. Materials, Methodology, and Equipment

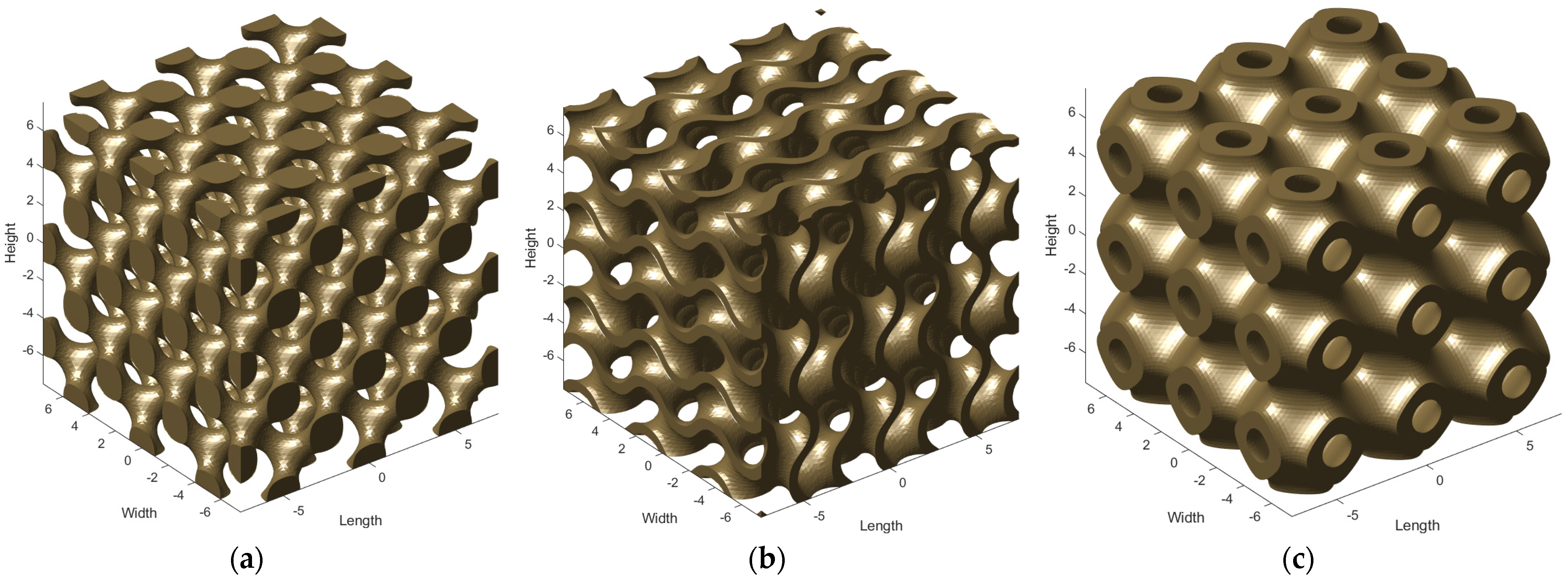

2.1. Lattice Structures’ Design

2.2. LPBF Process Parameters and Manufacturing

2.3. Lattice Structure Characterization

2.4. Antibacterial Tests

3. Results and Discussion

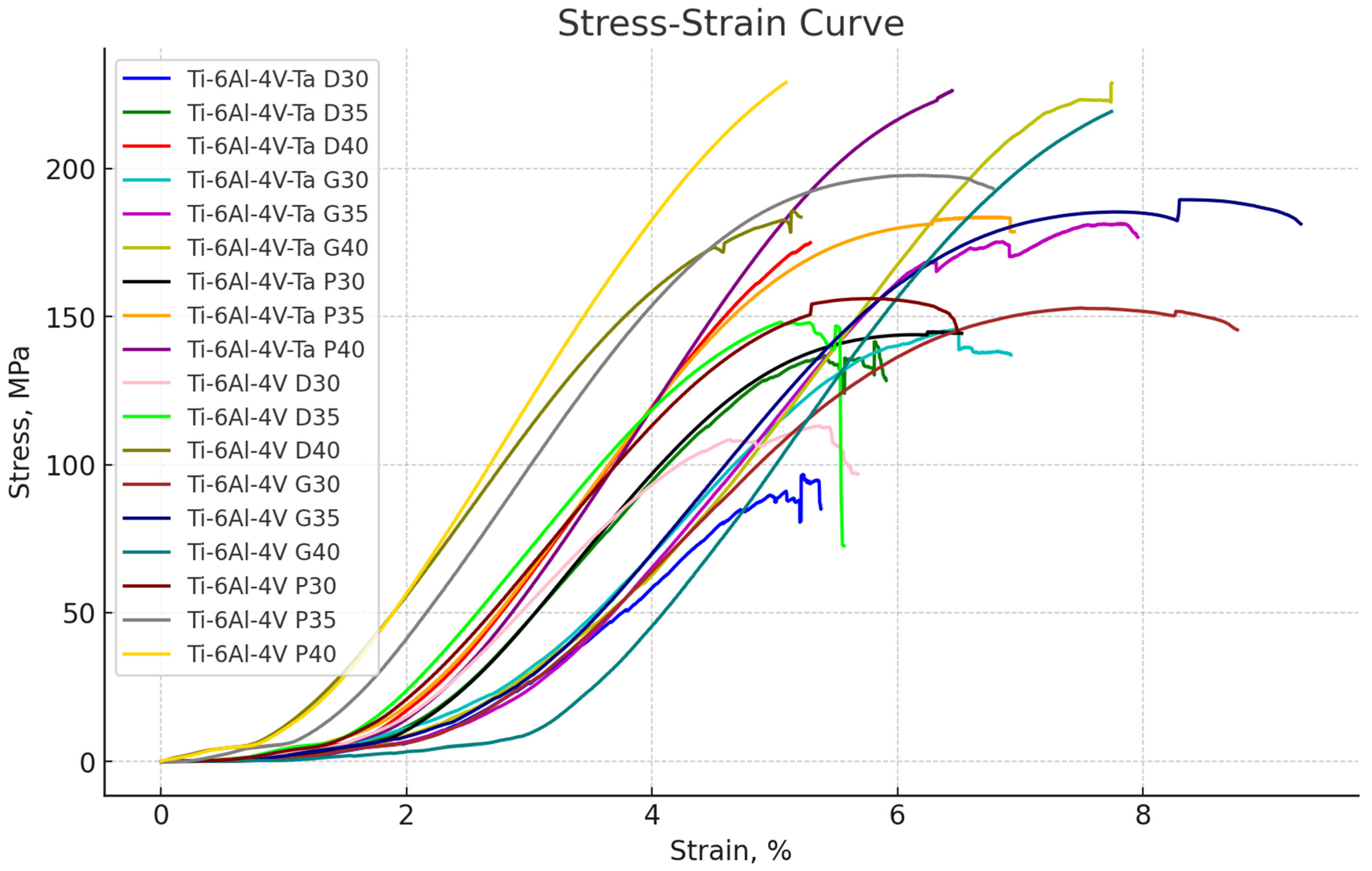

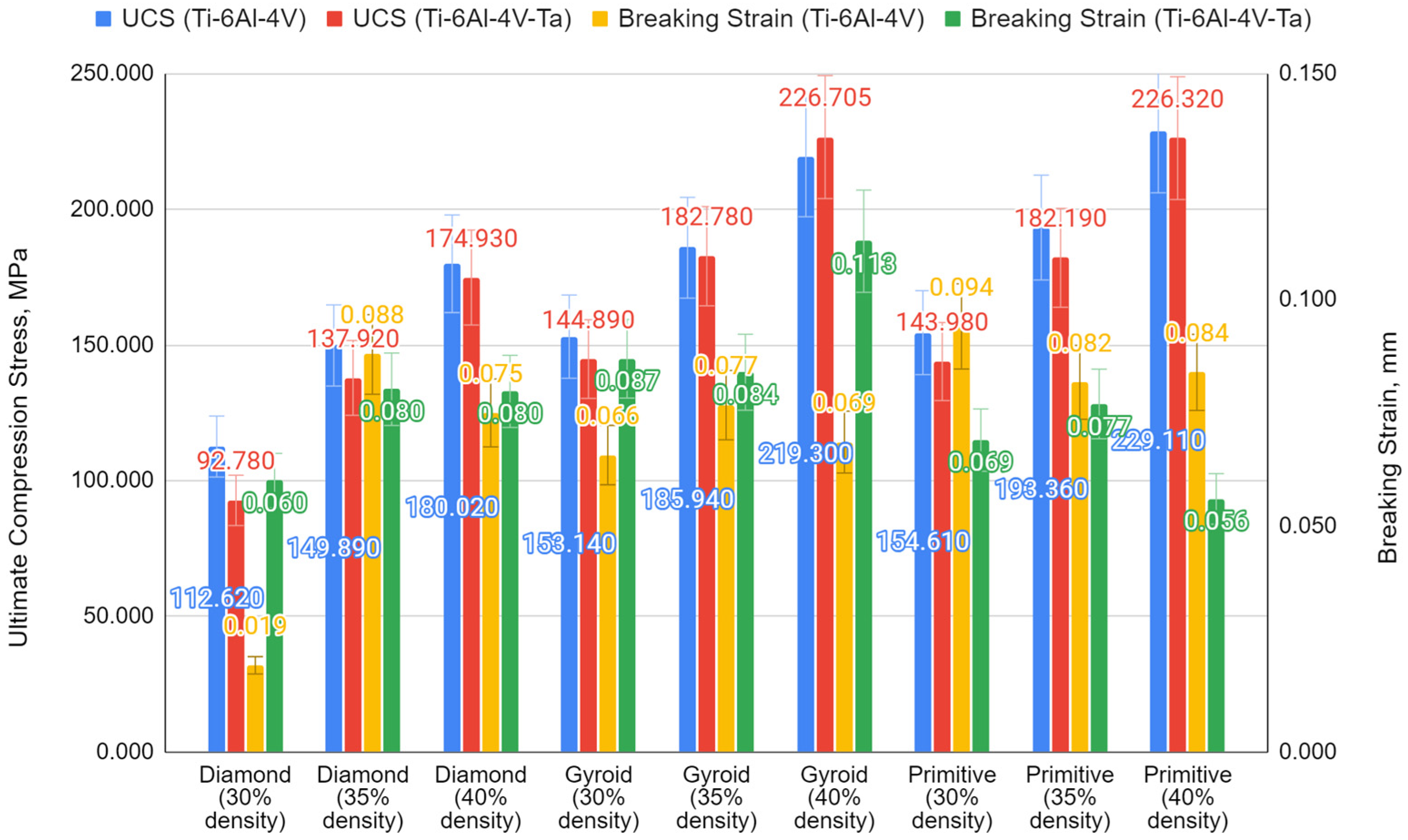

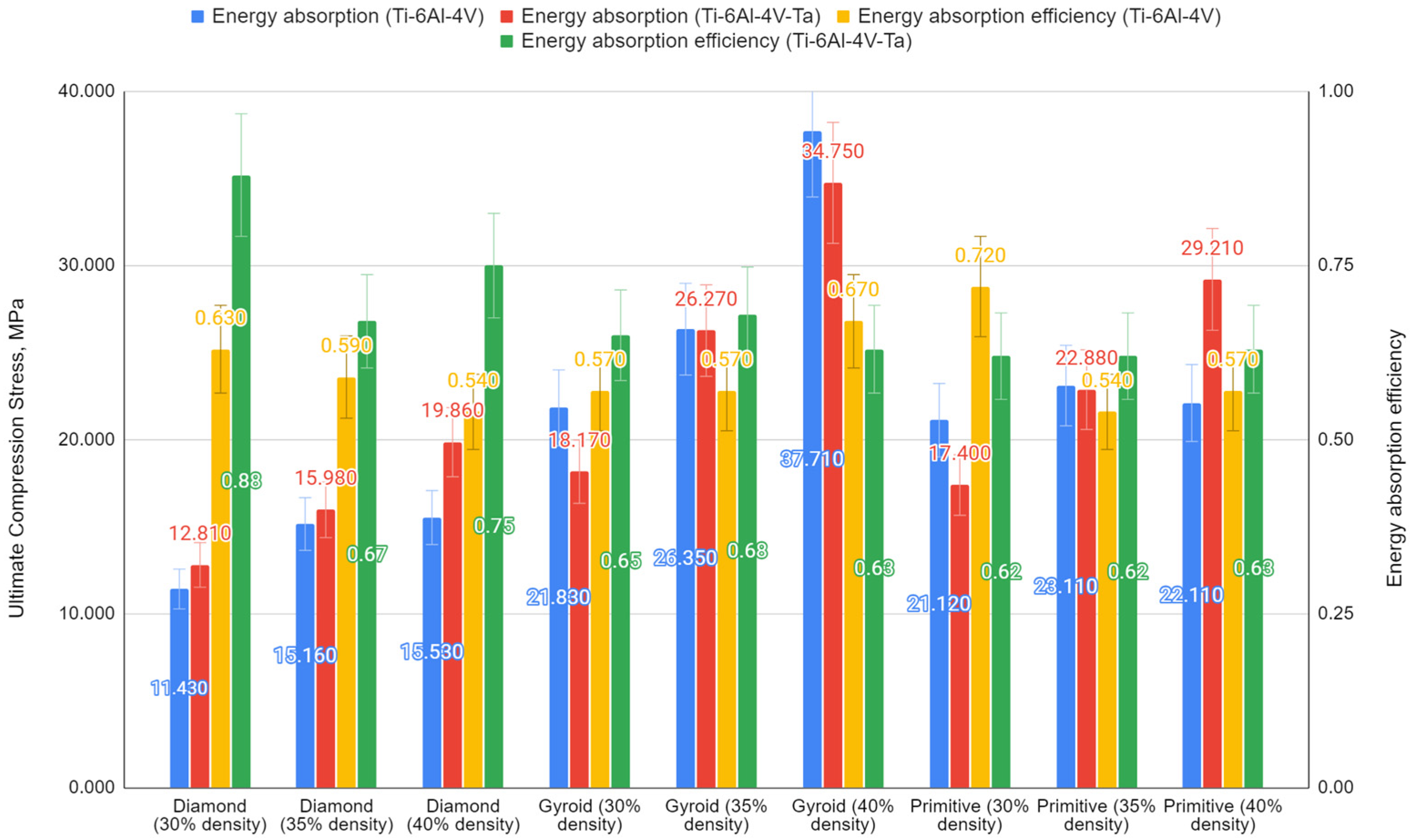

3.1. Effect of Lattice Structures on Mechanical Properties

3.1.1. Effect of Ti-6Al-4V Lattice Structures on Mechanical Properties

3.1.2. Effect of Ti-6Al-4V-Ta Lattice Structures on Mechanical Properties

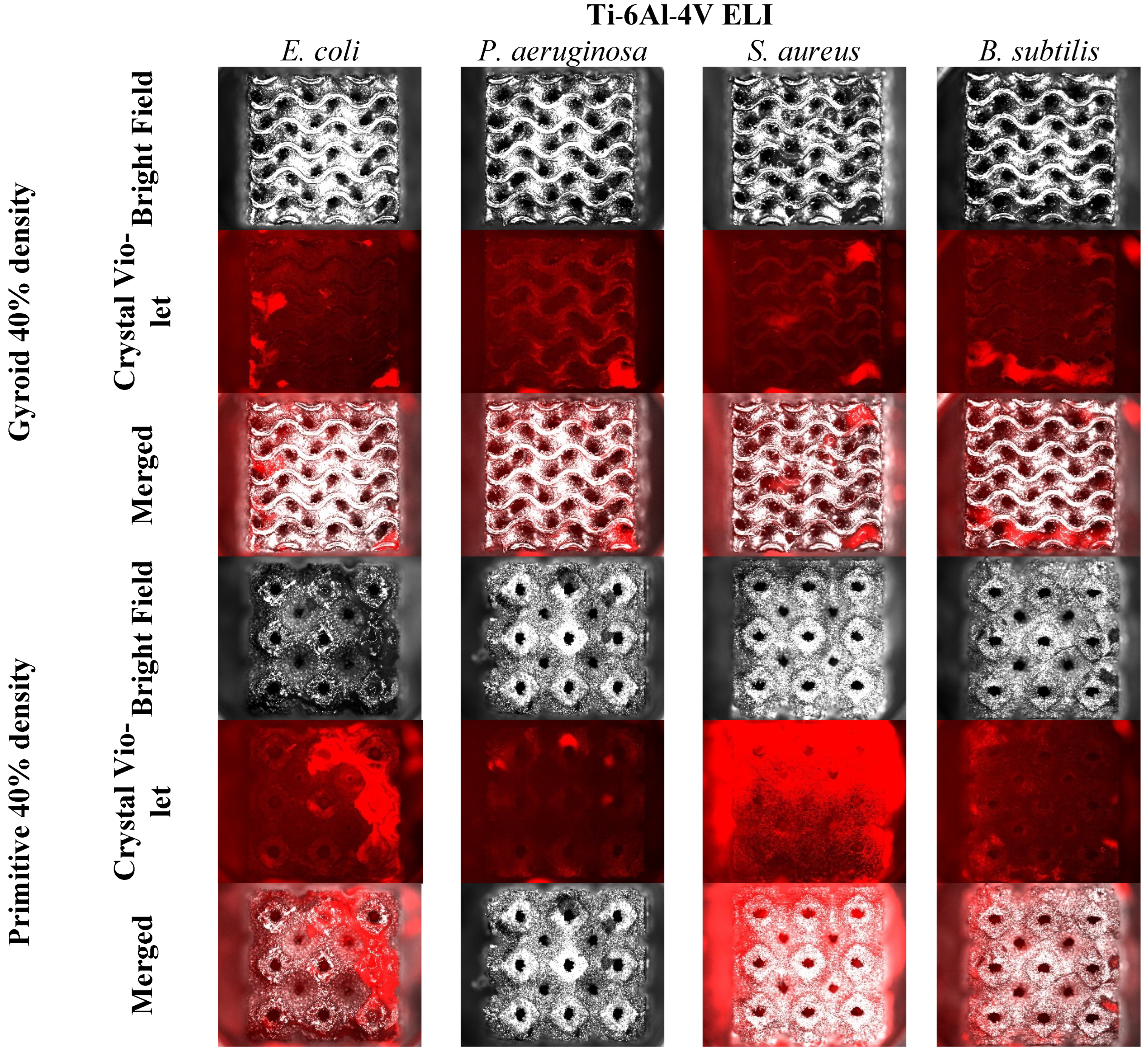

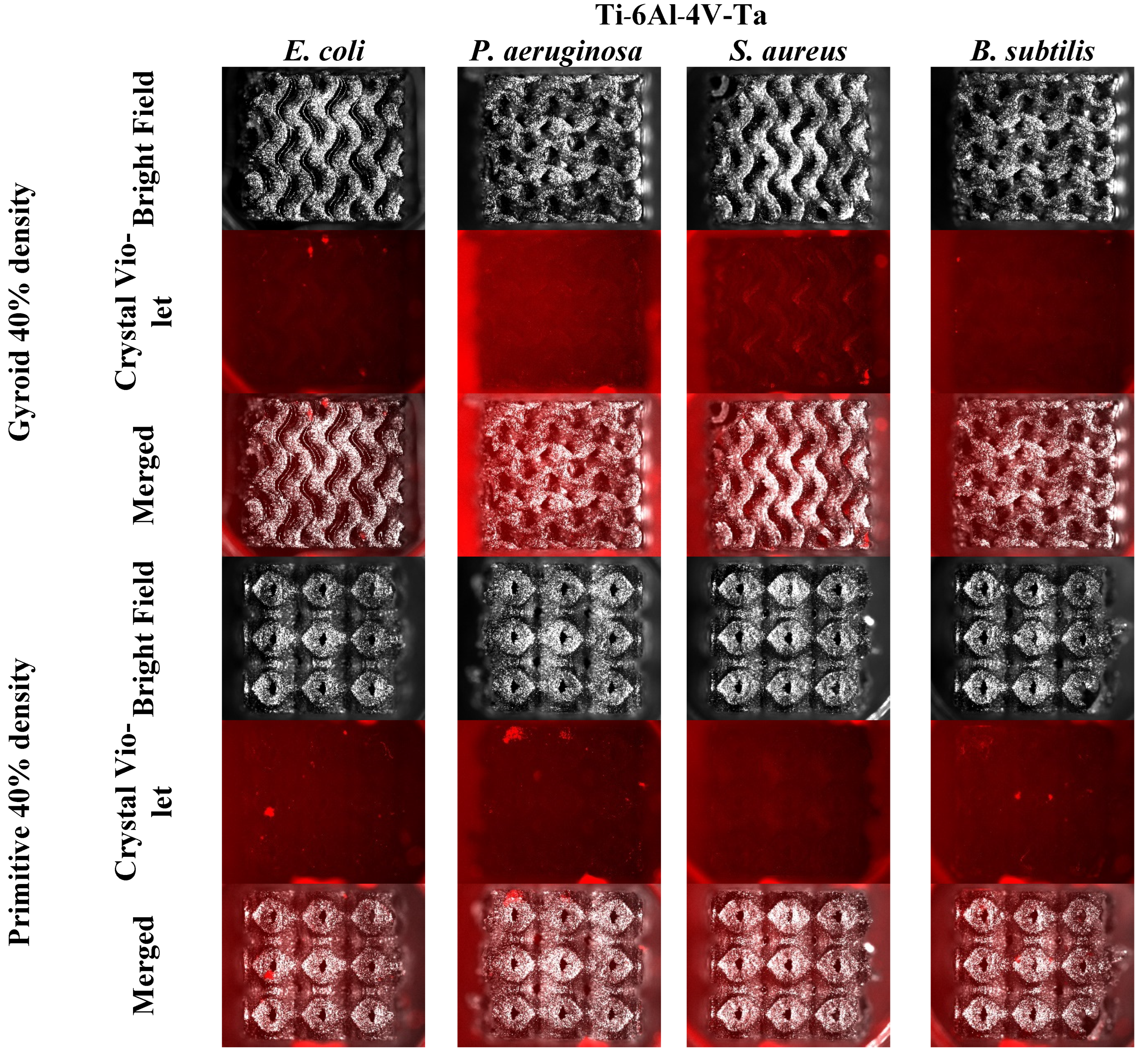

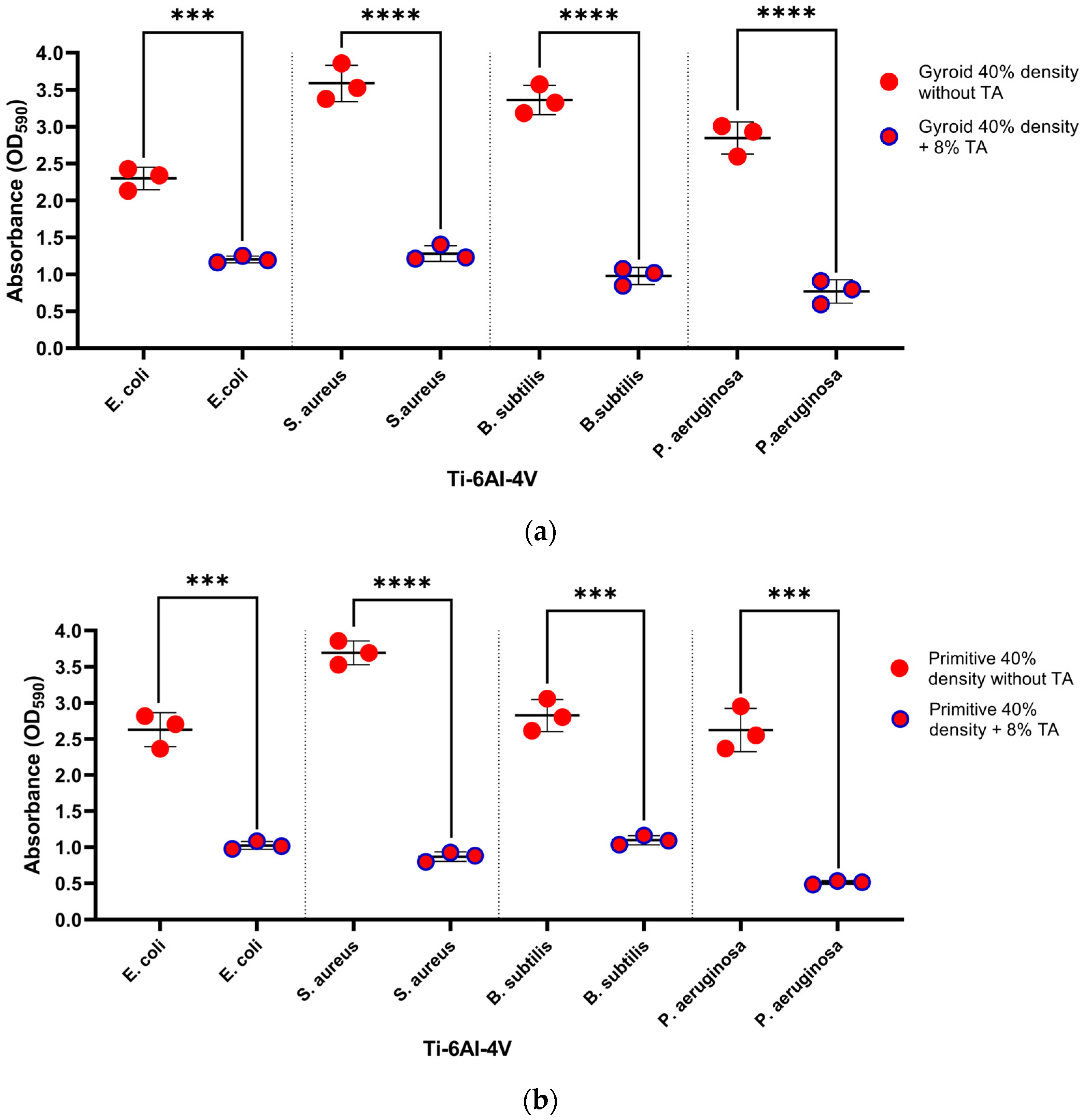

3.2. Antibacterial Response of Different Lattice Structures

4. Conclusions

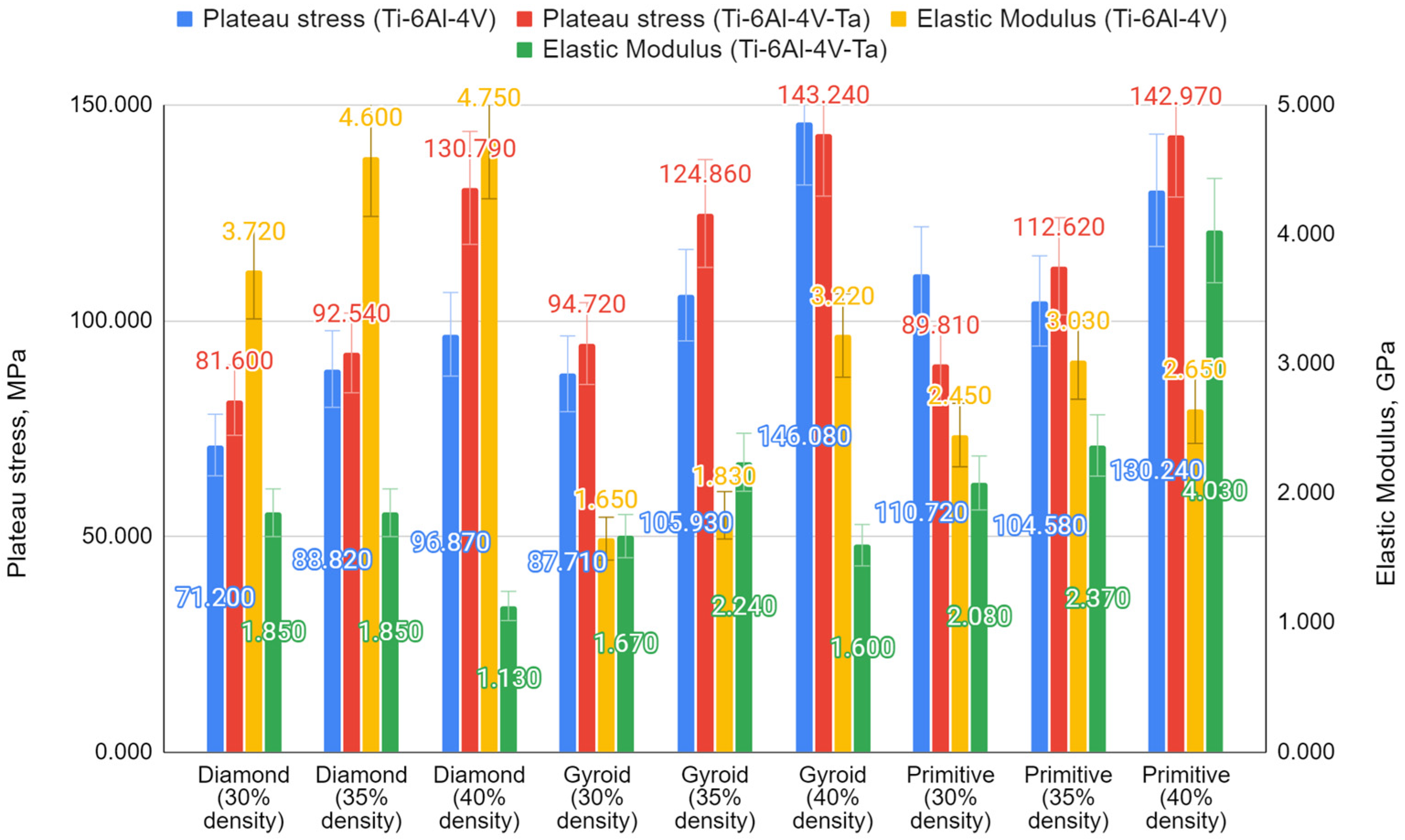

- A foray into the mechanical realm revealed that the Gyroid and Primitive lattice structures, at a judicious 40% density, stand out with their superior ultimate compressive strength, marking a significant stride towards emulating the biomechanical harmony of bone. The elastic modulus of the Ti-6Al-4V + 8% Ta structures fluctuates across a more extensive range. For example, compared to its pure Ti-6Al-4V cousin, the elastic modulus (4.03 GPa) of the Primitive arrangement at 40% density with a Ta addition is much greater. This implies a stiffer material, which, given the potential for stress shielding, would be less appropriate for use in some particular implant applications. For instance, the Gyroid arrangement at 40% density notably improves its energy absorption (34.75 MJ/m3) compared to its pure Ti-6Al-4V equivalents. Therefore, it implies that the Ta alloying enhances the material’s energy dissipation capacity, a desirable quality for implants that tolerate dynamic loads. In addition, Ti-6Al-4V-Ta has raised plateau stress, a measurement of the stress at which a material deforms plastically under continuous load. For example, the Gyroid structure with 40% density with Ta shows more significant plateau stress (143.24 MPa) than the pure Ti-6Al-4V structures. Therefore, the alloyed material may tolerate higher stresses before permanent deformation occurs.

- According to biomedical response research, Ta treatments and surface topology play a significant role in the production of biofilms. The Gyroid 40% density surfaces’ more significant surface area and intricacy may allow them to withstand higher levels of bacterial adherence than the Primitive 40% surfaces. On Ti-6Al-4V implants, however, the addition of 8% Ta seems to reduce this impact, providing a potential way of preventing biofilm formation. More investigation is necessary to determine the biological significance of these findings in the context of infection management and to investigate the molecular foundations of these discoveries.

- Overall, this study offers critical new insights into developing next-generation implant materials, making a substantial contribution to the rapidly expanding field of additive manufacturing for medical purposes. The results open up new directions for research and development in materials science and biomedical engineering and better patient outcomes through improved implant designs. This study represents a significant advancement in the ongoing effort to revolutionize implant technology.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Cui, Y.-W.; Wang, L.; Zhang, L.-C. Towards load-bearing biomedical titanium-based alloys: From essential requirements to future developments. Prog. Mater. Sci. 2024, 144, 101277. [Google Scholar] [CrossRef]

- Chen, X.; Qiu, C. Development of a novel metastable beta titanium alloy with ultrahigh yield strength and good ductility based on laser power bed fusion. Addit. Manuf. 2022, 49, 102501. [Google Scholar] [CrossRef]

- Majdi, H.S.; Saud, A.N.; Koç, E.; Juboori, A. Investigation of the Effect of Adding Tantalum on the Microstructure and Mechanical Properties of Biomedical Ti-15Mo Alloy. IFMBE Proc. 2022, 87, 637–646. [Google Scholar] [CrossRef]

- Li, X.; Ye, S.; Yuan, X.; Yu, P. Fabrication of biomedical Ti-24Nb-4Zr-8Sn alloy with high strength and low elastic modulus by powder metallurgy. J. Alloys Compd. 2019, 772, 968–977. [Google Scholar] [CrossRef]

- Lei, S.; Zhang, J.; An, X.; Guo, Y.; Xu, X.; Ma, Z.; Yao, W.; Kong, Q. Mechanical and corrosion properties of Ti–29Nb–13Ta-4.6Zr alloy prepared by cryomilling and spark plasma sintering. Vacuum 2023, 215, 112316. [Google Scholar] [CrossRef]

- Zhang, Y.; Cui, J.; Chen, K.-Y.; Kuo, S.H.; Sharma, J.; Bhatta, R.; Liu, Z.; Ellis-Mohr, A.; An, F.; Li, J.; et al. A smart coating with integrated physical antimicrobial and strain-mapping functionalities for orthopedic implants. Sci. Adv. 2023, 9, 18. [Google Scholar] [CrossRef]

- Sirdeshmukh, N.; Dongre, G. Achieving controlled topography and wettability through laser surface texturing of Ti6Al4V for bioengineering applications. Results Eng. 2023, 17, 100898. [Google Scholar] [CrossRef]

- Orrù, R.; Licheri, R.; Maccioni, A.; Cao, G. Densification behavior, microstructure evolution, and mechanical properties of spark plasma sintered Ti–Ta alloys. Mater. Sci. Eng. A 2021, 803, 140676. [Google Scholar]

- Katti, D.S. Biomaterials in total joint replacement surgery: Applications of additive manufacturing. Mater. Today 2018, 21, 404–416. [Google Scholar]

- Zhang, X.; Jiang, Y.; Wang, S.; Wang, S.; Wang, Z.; Yu, Z.; Zhang, Z.; Ren, L. Compression Behavior and Failure Mechanisms of Bionic Porous NiTi Structures Built via Selective Laser Melting. Acta Metall. Sin. (Engl. Lett.) 2023, 36, 926–936. [Google Scholar] [CrossRef]

- Han, X.; Ma, J.; Tian, A.; Wang, Y.; Li, Y.; Dong, B.; Tong, X.; Ma, X. Surface modification techniques of titanium and titanium alloys for biomedical orthopaedics applications: A review. Colloids Surf. B Biointerfaces 2023, 227, 113339. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.-Y.; Liang, S.-X.; Liu, Y.; Zhang, L.C. Additive manufacturing of metallic lattice structures: Unconstrained design, accurate fabrication, fascinated performances, and challenges. Mater. Sci. Eng. R 2021, 146, 100648. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Shaikhnag, A. Formnext 2023: Spearheading Lattice Manufacturing Advancements with Farsoon Technologies, Hyperganic, and BASF Forward AM; 3D Printing Industry: London, UK, 2023. [Google Scholar]

- Pérez-Ruiz, J.M.; Marin, F.; Martínez, S.A.; Lamikiz, A.; Urbikain, G.; de Lacalle, L.N.L. Stiffening near-net-shape functional parts of Inconel 718 LPBF considering material anisotropy and subsequent machining issues. Mech. Syst. Signal Process. 2022, 168, 108675. [Google Scholar] [CrossRef]

- Pérez-Ruiz, J.; González-Barrio, H.; Sanz-Calle, M.; Gómez-Escudero, G.; Munoa, J.; de Lacalle, L.L. Machining stability improvement in LPBF printed components through stiffening by crystallographic texture control. CIRP Ann. 2023, 72, 141–144. [Google Scholar] [CrossRef]

- Pérez-Ruiz, J.D.; Galbusera, F.; Caprio, L.; Previtali, B.; de Lacalle, L.N.L.; Lamikiz, A.; Demir, A.G. Laser beam shaping facilitates tailoring the mechanical properties of IN718 during powder bed fusion. J. Mater. Process. Technol. 2024, 328, 118393. [Google Scholar] [CrossRef]

- Singh, M.; Gusain, S.; Mishra, S.K.; Ramkumar, J.; Escudero, G.G.; Barrio, H.G.; Ochoa, A.C.; de Nacalle, L.N.L. Near-circular EDM hole drilling for deterministic cellular lattice structures of LPBF IN718. Mater. Lett. 2023, 350, 134886. [Google Scholar] [CrossRef]

- City University of Hong Kong. CityU Researchers Devise Method to Enhance Strength of 3D Printed Polymeric Lattice Components. 7 September 2022. Available online: https://www.cityu.edu.hk/research/stories/2022/09/07/cityu-invents-method-convert-3d-printed-polymer-100-times-stronger-ductile-hybrid-carbon-microlattice-material (accessed on 23 June 2024).

- Koslow, T. 3D Cocooner: Creating Bionic Lattice Structures with a Robotic Spinneret; 3D Printing Industry: London, UK, 2024. [Google Scholar]

- Suresh, S.; Sun, C.-N.; Tekumalla, S.; Rosa, V.; Nai, S.M.L.; Wong, R.C.W. Mechanical properties and in vitro cytocompatibility of dense and porous Ti–6Al–4V ELI manufactured by selective laser melting technology for biomedical applications. J. Mech. Behav. Biomed. Mater. 2021, 123, 104712. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Li, Y.; Luo, X.; Ding, Y. Enhancing antibacterial property of porous titanium surfaces with silver nanoparticles coatings via electron-beam evaporation. J. Mater. Sci. Mater. Med. 2022, 33, 57. [Google Scholar] [CrossRef]

- Challa, V.S.A.; Mali, S.; Misra, R.D.K. Reduced toxicity and superior cellular response of preosteoblasts to Ti-6Al-7Nb alloy and comparison with Ti-6Al-4V. J. Biomed. Mater. Res. Part A 2013, 101A, 2083–2089. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiu, P.; Jia, Z.; Zhang, Z.; Zhang, T.; Yin, C.; Chen, Y.; Cheng, Y.; Cai, H.; Zhang, K.; et al. Effect of vanadium released from micro-arc oxidized porous Ti6Al4V on biocompatibility in orthopedic applications. Colloids Surf. B Biointerfaces 2018, 169, 366–374. [Google Scholar] [CrossRef] [PubMed]

- Chlebus, E.; Kuźnicka, B.; Kurzynowski, T.; Dybała, B. Microstructure and mechanical behaviour of Ti―6Al―7Nb alloy produced by selective laser melting. Mater. Charact. 2011, 62, 488–495. [Google Scholar] [CrossRef]

- Li, Y.; Yang, C.; Zhao, H.; Qu, S.; Li, X.; Li, Y. New Developments of Ti-Based Alloys for Biomedical Applications. Materials 2014, 7, 1709–1800. [Google Scholar] [CrossRef] [PubMed]

- Lúcia, A.; Hammer, P.; Vaz, L.G.; Rocha, L.A. Are new TiNbZr alloys potential substitutes of the Ti6Al4V alloy for dental applications? An electrochemical corrosion study. Biomed. Mater. 2013, 8, 065005. [Google Scholar] [CrossRef]

- Sing, S.L.; Wiria, F.E.; Yeong, W.Y. Selective laser melting of titanium alloy with 50 wt% tantalum: Effect of laser process parameters on part quality. Int. J. Refract. Met. Hard Mater. 2018, 77, 120–127. [Google Scholar] [CrossRef]

- Ureña, J.; Tejado, E.; Pastor, J.Y.; Velascos, F.; Tsipas, S.; Jimenez-Morales, A.; Gordo, E. Role of beta-stabilizing elements on the microstructure and mechanical properties evolution of modified PM Ti surfaces designed for biomedical applications. Powder Metall. 2018, 61, 90–99. [Google Scholar] [CrossRef]

- Shang, C.; Hou, X.; Lu, Y.; Zhang, R.; Lu, X.; Yuan, C. Simultaneous improvement of strength and ductility of laser additively produced Ti6Al4V by adding tantalum. J. Alloys Compd. 2024, 976, 173171. [Google Scholar] [CrossRef]

- Wu, W.-H.; Yang, Y.-Q.; Xiao, D.-M.; Chen, C.-Y.; Mao, G.-S. Pore forming results of controllable ultra-light structured parts by selective laser melting. Opt. Precis. Eng. 2017, 25, 1547–1556. [Google Scholar] [CrossRef]

- Nauryz, N.; Omarov, S.; Kenessova, A.; Pham, T.T.; Talamona, D.; Perveen, A. Powder-Mixed Micro-Electro-Discharge Machining-Induced Surface Modification of Titanium Alloy for Antibacterial Properties. J. Manuf. Mater. Process. 2023, 7, 214. [Google Scholar] [CrossRef]

- Smith, J.; Wang, L.; Brown, P. Mechanical Properties of Ti-6Al-4V-Ta Alloys. J. Mater. Sci. Eng. 2023, 45, 567–578. [Google Scholar]

- Johnson, R.; Lee, K.; Hernandez, M. Enhancements in Titanium Alloys with Tantalum Additions. Int. J. Adv. Mater. 2022, 34, 289–301. [Google Scholar]

- Cutolo, A.; Engelen, B.; Desmet, W.; Van Hooreweder, B. Mechanical properties of diamond lattice Ti–6Al–4V structures produced by laser powder bed fusion: On the effect of the load direction. J. Mech. Behav. Biomed. Mater. 2020, 104, 103656. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Sun, W.; Li, X.; Liu, J.; Wang, T. Impact of density on the mechanical performance of Ti-6Al-4V lattices fabricated by additive manufacturing. Mater. Lett. 2022, 306, 130–134. [Google Scholar]

- Zhang, L.; Wu, Q.; Feng, H.; Chen, S. Influence of lattice design on the elastic properties of Ti-6Al-4V structures. Int. J. Mech. Sci. 2023, 185, 105819. [Google Scholar]

- Wang, K.; Zhou, Y.; Gao, M.; Yang, F. Recent advancements in additive manufacturing of bio-medical implants: Focus on lattice structures. J. Biomed. Mater. Res. 2023, 111, 456–470. [Google Scholar]

- Zhang, Y.; Guo, D.; Baorui, M. Numerical Analysis of Eccentric Compression Performance of CFRP-Confined Concrete-Filled Steel Tube (CFST) Columns. J. Inst. Eng. Ser. A 2022, 103, 543–555. [Google Scholar] [CrossRef]

- Eskandari, H.; Lashgari, H.R.; Zangeneh, S.; Kong, C.; Ye, L.; Eizadjou, M.; Wang, H. Microstructural characterization and mechanical properties of SLM-printed Ti–6Al–4V alloy: Effect of build orientation. J. Mater. Res. 2022, 37, 2645–2660. [Google Scholar] [CrossRef]

- Brown, J.R.; Smith, A.M.; Williams, B.D.; Martin, H.L. Energy absorption properties of additively manufactured Ti-6Al-4V lattice structures for biomedical applications. Mater. Sci. Eng. C 2021, 119, 111568. [Google Scholar]

- Lee, S.H.; Park, J.K.; Kim, M.H.; Choi, D.Y. Optimization of lattice structures for improved mechanical performance in biomedical implants. J. Biomed. Mater. Res. Part B Appl. Biomater. 2022, 110, 134–145. [Google Scholar]

- Chen, Y.; Zhang, L.F.; Li, X.Q.; Huang, P.T. Dynamic loading behavior of Ti-6Al-4V lattice structures: Implications for implant design. J. Mech. Behav. Biomed. Mater. 2023, 136, 105530. [Google Scholar]

- Park, H.S.; Lee, J.W.; Jung, S.K.; Kim, M.S. Stress distribution and energy absorption in Ti-6Al-4V lattice structures fabricated by additive manufacturing. Addit. Manuf. 2023, 48, 102045. [Google Scholar]

- Patel, R.; Smith, L.; Johnson, T.; Brown, M. Enhancement of mechanical properties in Ti-6Al-4V alloys with Tantalum additions. J. Alloys Compd. 2021, 862, 158202. [Google Scholar]

- Zhang, Y.; Li, W.; Wang, X.; Zhao, J.; Chen, Q. Tantalum alloying effects on the mechanical performance of titanium lattice structures. Mater. Sci. Eng. A 2022, 832, 142405. [Google Scholar]

- Kim, S.H.; Lee, M.J.; Park, T.H.; Choi, Y.S. Comparative study on the mechanical properties of Ti-6Al-4V and Ti-6Al-4V-Ta alloys. J. Mech. Sci. Technol. 2023, 37, 685–693. [Google Scholar]

- Li, J.; Wang, K.; Zhou, L.; Zhang, M.X. Mechanical behavior of Ti-6Al-4V alloys with Tantalum: Implications for biomedical applications. Mater. Today Commun. 2023, 36, 104789. [Google Scholar]

| Models | Density, % | UCS, mm | Height, mm | Width, mm |

|---|---|---|---|---|

| Diamond | 30, 35, 40 | 3 | 15 | 15 |

| Gyroid | 30, 35, 40 | 3 | 15 | 15 |

| Primitive | 30, 35, 40 | 3 | 15 | 15 |

| Experiment Number | Yield Strength, MPa | Ultimate Tensile Strength, MPa | Elastic Modulus, GPa |

|---|---|---|---|

| 1 | 1213.59 ± 5.95 | 1220.11 ± 6 | 209.95 ± 1.48 |

| 2 | 1064.01 ± 4.59 | 1213.56 ± 5.32 | 183.45 ± 1.29 |

| 3 | 885.09 ± 4.34 | 1212.36 ± 5.13 | 177.02 ± 1.25 |

| average | 1054.23 ± 4.96 | 1215.34 ± 5.48 | 190.14 ± 1.34 |

| Tested Lattice Structures | Yield Strength, MPa | Ultimate Compression Stress, MPa | Elastic Modulus, GPa |

|---|---|---|---|

| Diamond (30% density) | 107.89 ± 1.61 | 112.62 ± 1.7 | 6.17 ± 0.12 |

| Diamond (35% density) | 139.76 ± 2.05 | 149.89 ± 2.18 | 1.93 ± 0.05 |

| Diamond (40% density) | 168.2 ± 2.52 | 180.02 ± 2.63 | 3.4 ± 0.29 |

| Gyroid (30% density) | 137.81 ± 1.76 | 153.14 ± 1.96 | 2.38 ± 0.27 |

| Gyroid (35% density) | 174.73 ± 2.16 | 185.94 ± 2.34 | 2.47 ± 0.37 |

| Gyroid (40% density) | 209.33 ± 2.45 | 219.3 ± 2.57 | 3.2 ± 0.14 |

| Primitive (30% density) | 144.7 ± 2.08 | 154.61 ± 2.23 | 2.2 ± 0.14 |

| Primitive (35% density) | 176.98 ± 2.43 | 193.36 ± 2.63 | 2.41 ± 0.29 |

| Primitive (40% density) | 220.55 ± 3.11 | 229.11 ± 3.19 | 2.73 ± 0.19 |

| Tested Lattice Structures | Energy Absorption, MJ/m3 | Energy Absorption Efficiency | Plateau Stress, MPa |

|---|---|---|---|

| Diamond (30% density) | 11.43 ± 0.31 | 0.63 ± 0.26 | 71.2 ± 0.14 |

| Diamond (35% density) | 15.16 ± 0.11 | 0.59 ± 0.29 | 88.82 ± 0.13 |

| Diamond (40% density) | 15.53 ± 0.33 | 0.54 ± 0.33 | 96.87 ± 0.09 |

| Gyroid (30% density) | 21.83 ± 0.12 | 0.57 ± 0.3 | 87.71 ± 0.2 |

| Gyroid (35% density) | 26.35 ± 0.25 | 0.57 ± 0.3 | 105.93 ± 0.05 |

| Gyroid (40% density) | 37.71 ± 0.21 | 0.67 ± 0.24 | 146.08 ± 0.06 |

| Primitive (30% density) | 21.12 ± 0.08 | 0.72 ± 0.2 | 110.72 ± 0.2 |

| Primitive (35% density) | 23.11 ± 0.08 | 0.54 ± 0.33 | 104.58 ± 0.3 |

| Primitive (40% density) | 22.11 ± 0.08 | 0.57 ± 0.31 | 130.24 ± 0.17 |

| Tested Lattice Structures | Yield Strength, MPa | Ultimate Compression Stress, MPa | Elastic Modulus, GPa |

|---|---|---|---|

| Diamond (30% density) | 37.15 ± 0.28 | 92.78 ± 0.55 | 1.55 ± 0.32 |

| Diamond (35% density) | 132.213 ± 0.83 | 137.92 ± 0.87 | 1.85 ± 0.11 |

| Diamond (40% density) | 162.65 ± 1.11 | 174.93 ± 1.09 | 1.13 ± 0.1 |

| Gyroid (30% density) | 113.28 ± 0.5 | 144.89 ± 0.84 | 1.67 ± 0.24 |

| Gyroid (35% density) | 145.44 ± 0.98 | 182.78 ± 1.01 | 2.24 ± 0.17 |

| Gyroid (40% density) | 162.26 ± 0.88 | 226.705 ± 1.08 | 1.6 ± 0.29 |

| Primitive (30% density) | 132.63 ± 0.84 | 143.98 ± 0.93 | 2.08 ± 0.06 |

| Primitive (35% density) | 166.54 ± 1.04 | 182.19 ± 1.13 | 2.37 ± 0.26 |

| Primitive (40% density) | 214.27 ± 1.26 | 226.32 ± 1.33 | 4.03 ± 0.02 |

| Tested Lattice Structures | Energy Absorption, MJ/ m3 | Energy Absorption Efficiency | Plateau Stress, MPa |

|---|---|---|---|

| Diamond (30% density) | 12.81 ± 0.14 | 0.88 ± 0.09 | 81.60 ± 0.28 |

| Diamond (35% density) | 15.98 ± 0.1 | 0.67 ± 0.23 | 92.54 ± 0.32 |

| Diamond (40% density) | 19.86 ± 0.61 | 0.75 ± 0.18 | 130.79 ± 0.56 |

| Gyroid (30% density) | 18.17 ± 012 | 0.65 ± 0.24 | 94.72 ± 0.51 |

| Gyroid (35% density) | 26.27 ± 0.19 | 0.68 ± 0.22 | 124.86 ± 0.1 |

| Gyroid (40% density) | 34.75 ± 0.53 | 0.63 ± 0.26 | 143.24 ± 0.17 |

| Primitive (30% density) | 17.4 ± 0.28 | 0.62 ± 0.27 | 89.81 ± 0.13 |

| Primitive (35% density) | 22.88 ± 0.08 | 0.62 ± 0.27 | 112.62 ± 0.27 |

| Primitive (40% density) | 29.21 ± 0.15 | 0.63 ± 0.26 | 142.97 ± 0.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhumabekova, A.; Toleubekova, M.; Pham, T.T.; Talamona, D.; Perveen, A. Effect of Lattice Structure on Mechanical Properties of Ti-6Al-4V-Ta Alloy for Improved Antibacterial Properties. J. Manuf. Mater. Process. 2024, 8, 133. https://doi.org/10.3390/jmmp8040133

Zhumabekova A, Toleubekova M, Pham TT, Talamona D, Perveen A. Effect of Lattice Structure on Mechanical Properties of Ti-6Al-4V-Ta Alloy for Improved Antibacterial Properties. Journal of Manufacturing and Materials Processing. 2024; 8(4):133. https://doi.org/10.3390/jmmp8040133

Chicago/Turabian StyleZhumabekova, Anel, Malika Toleubekova, Tri Thanh Pham, Didier Talamona, and Asma Perveen. 2024. "Effect of Lattice Structure on Mechanical Properties of Ti-6Al-4V-Ta Alloy for Improved Antibacterial Properties" Journal of Manufacturing and Materials Processing 8, no. 4: 133. https://doi.org/10.3390/jmmp8040133

APA StyleZhumabekova, A., Toleubekova, M., Pham, T. T., Talamona, D., & Perveen, A. (2024). Effect of Lattice Structure on Mechanical Properties of Ti-6Al-4V-Ta Alloy for Improved Antibacterial Properties. Journal of Manufacturing and Materials Processing, 8(4), 133. https://doi.org/10.3390/jmmp8040133