Microstructure Refinement of Bulk Inconel 718 Parts During Fabrication with EB-PBF Using Scanning Strategies: Transition from Bidirectional-Raster to Stochastic Point-Based Melting

Abstract

1. Introduction

2. Materials and Methods

2.1. Powder Characteristics

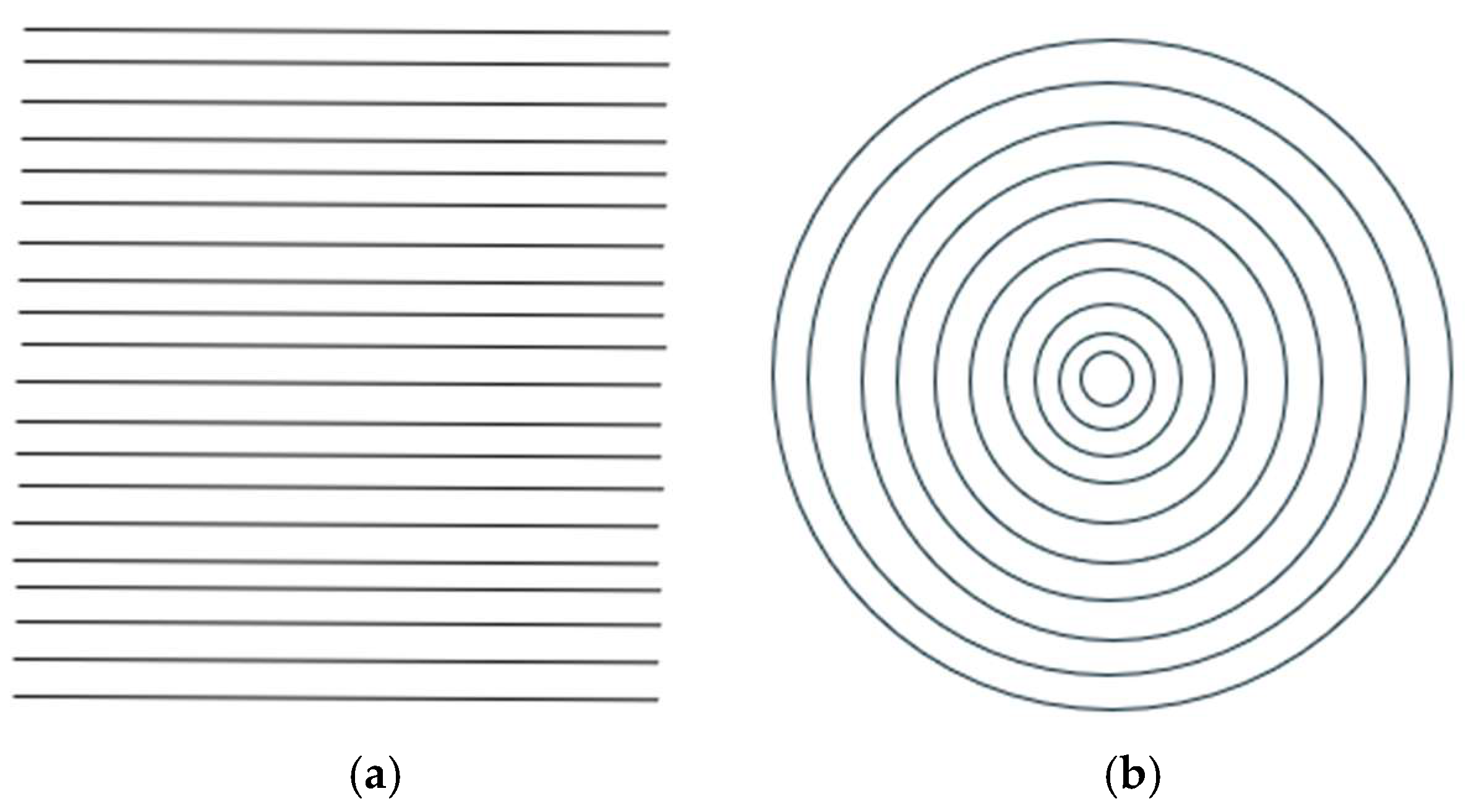

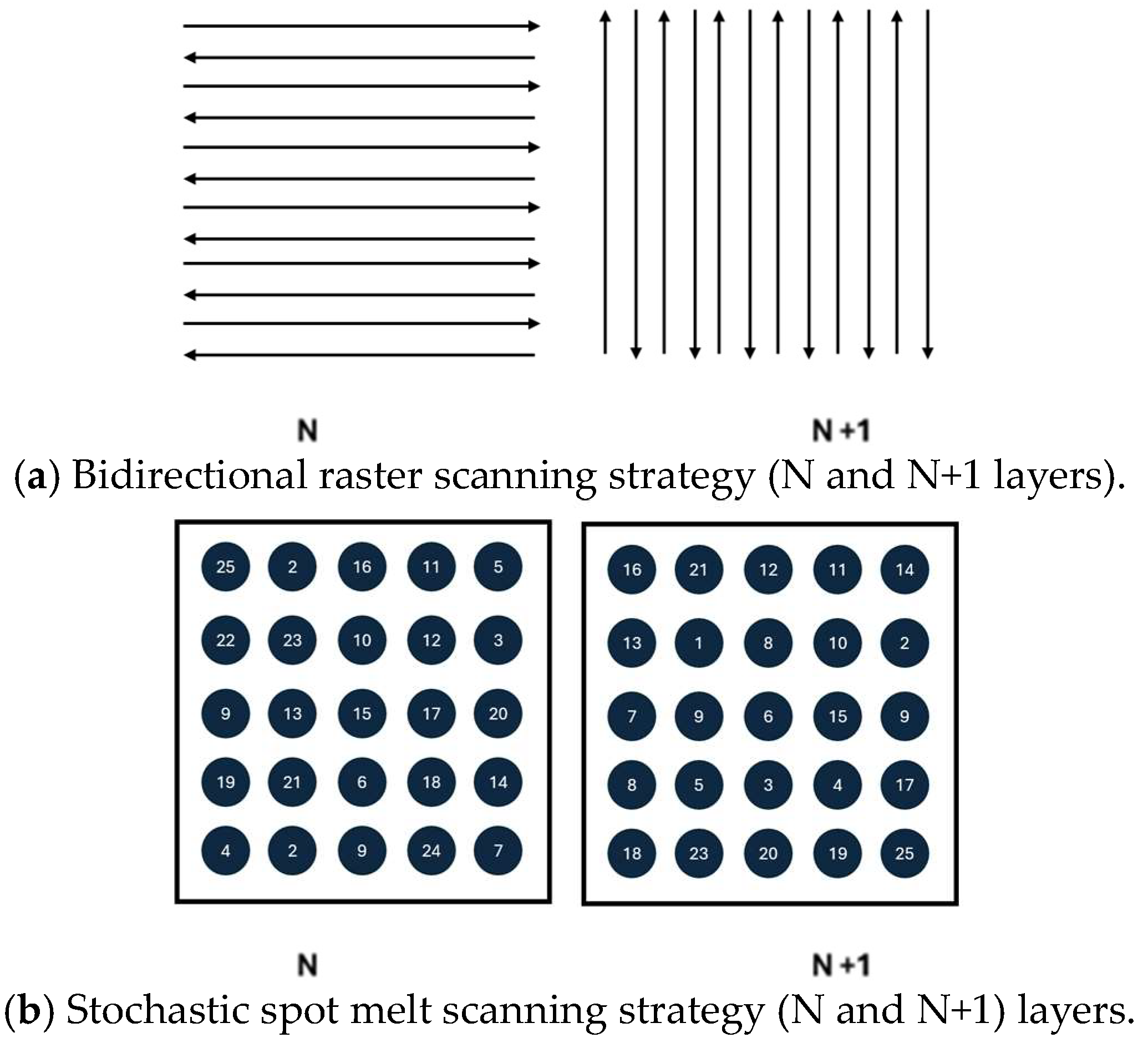

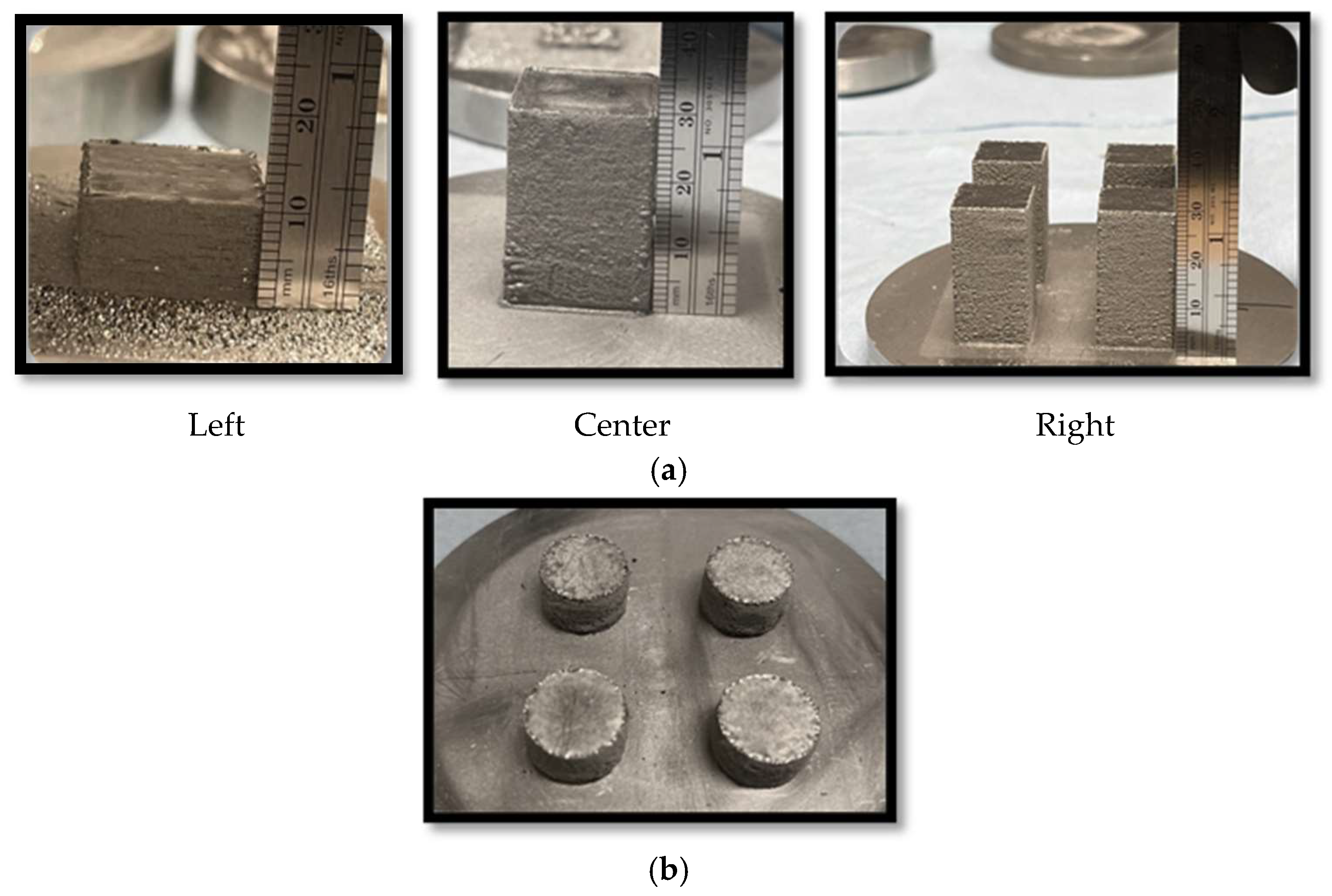

2.2. Fabrication Process

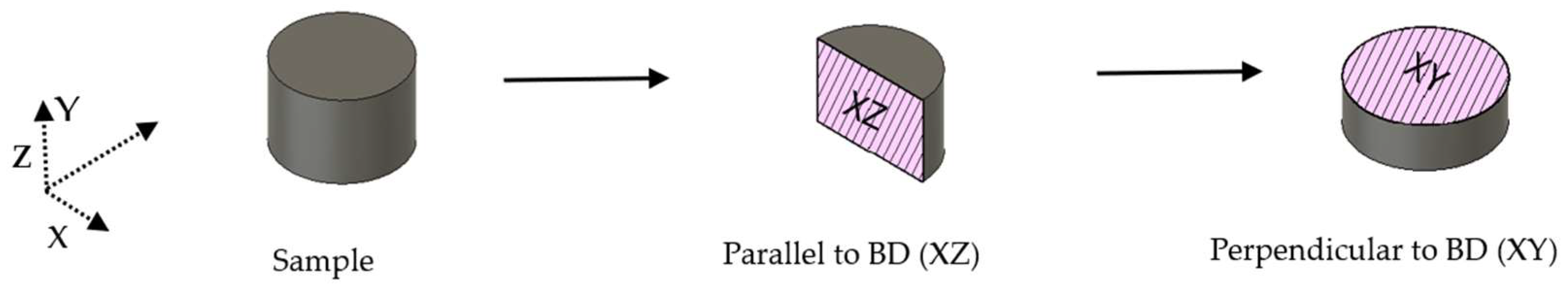

2.3. Microstructure and Hardness Characterization

3. Results and Discussion

3.1. Parameter Development

3.2. Microstructure Characterization

3.2.1. Raster Scan Build

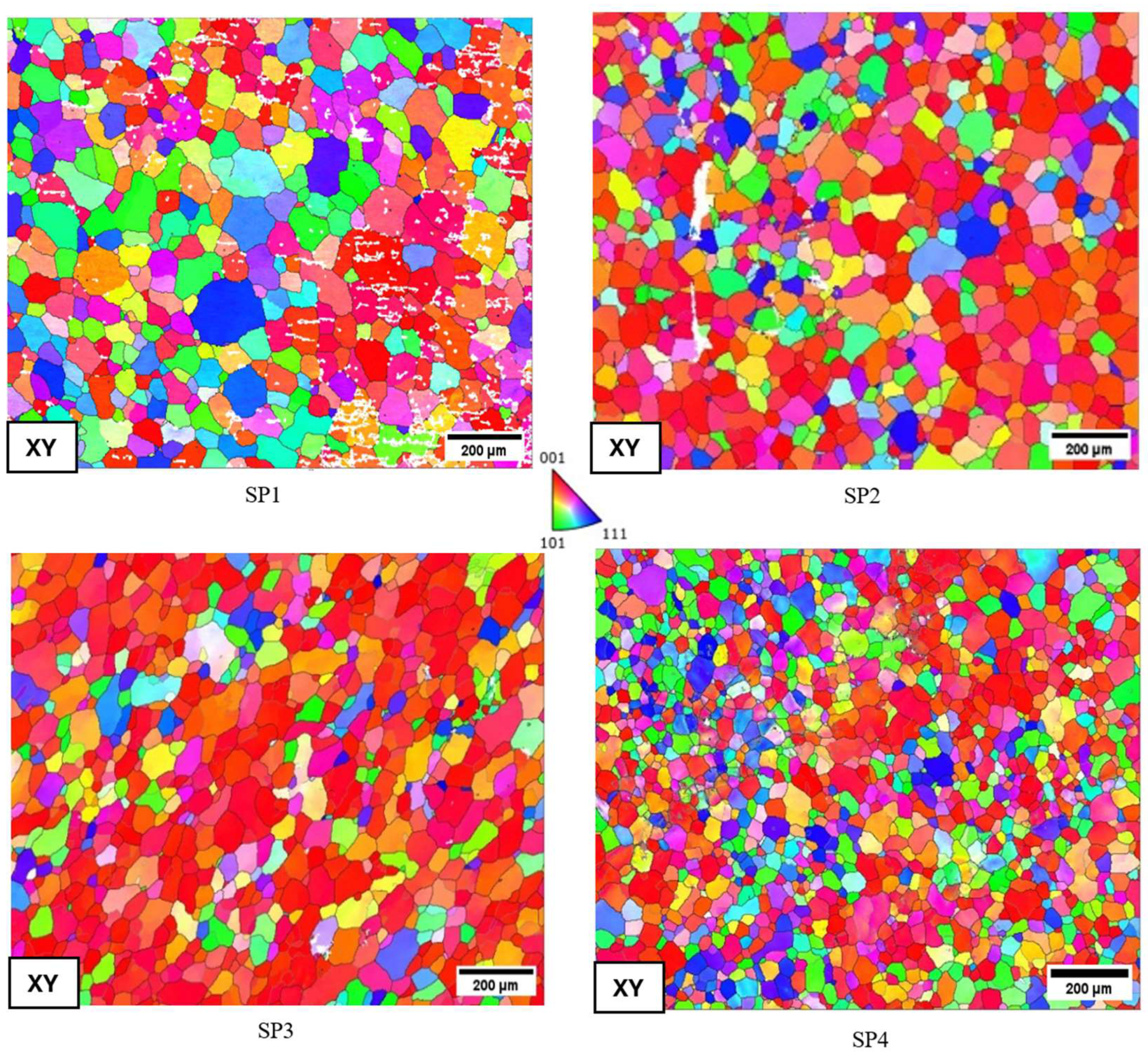

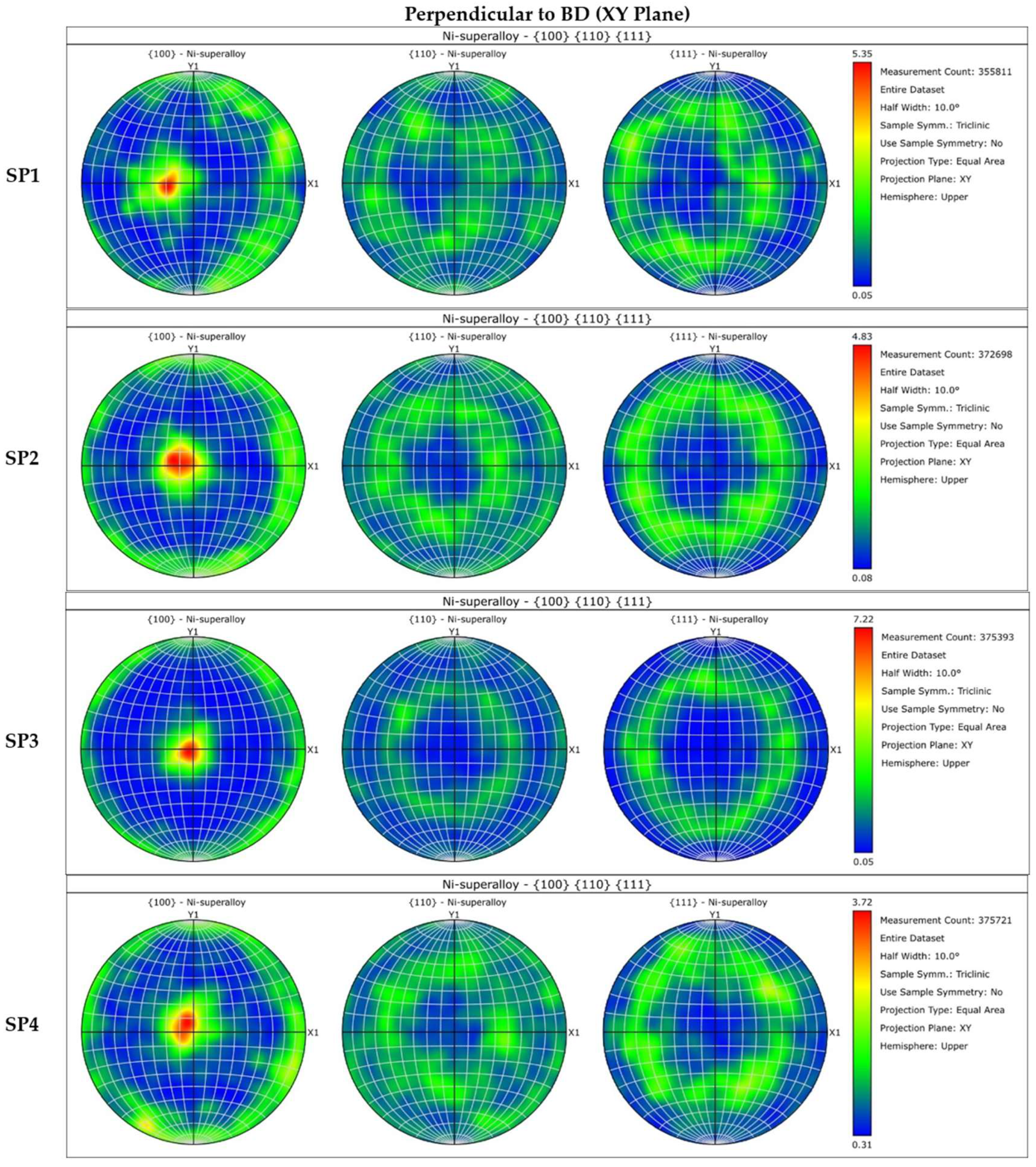

3.2.2. Stochastic Spot Scan Build

3.2.3. Comparison Between Raster and Stochastic Spot Melt EBSD Results

3.3. Microhardness Value in HV1 Scale

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal Additive Manufacturing in Aerospace: A Review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Ghosh, A.; Naiyer, I.; Gogoi, B.; Goswami, K.M.; Sharma, D.; Kumar, H.; Panda, A.; Kumar, R.; Sahoo, A.K. Implementation of the Additive Manufacturing Technology towards Producing High-Performance Aerospace Components—A Review. AIP Conf. Proc. 2024, 3007, 100043. [Google Scholar] [CrossRef]

- Pradeep, P.V.; Paul, A.; Paul, L.; Davim, J.P. Chapter 8—Application of Micro Machining and Additive Manufacturing Processes for Difficult-to-Cut Materials in Aerospace Industry—A Review. In Modern Manufacturing Processes for Aircraft Materials; Gürgen, S., Pruncu, C.I., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 227–262. ISBN 978-0-323-95318-4. [Google Scholar]

- Nabil, S.T.; Arrieta, E.; Wicker, R.B.; Benedict, M.; Medina, F. Effect of Thermal Aging in the Fatigue Life of Hot Isostatic Pressed AlSi10Mg Fabricated by Laser Powder Bed Fusion. In Proceedings of the 33th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 25–27 July 2022. [Google Scholar]

- Diaz, J.C.; Watanabe, K.; Rubio, A.; De La Cruz, A.; Godinez, D.; Nabil, S.T.; Murr, L.E.; Wicker, R.B.; Arrieta, E.; Medina, F. Effect of Layer Thickness and Heat Treatment on Microstructure and Mechanical Properties of Alloy 625 Manufactured by Electron Beam Powder Bed Fusion. Materials 2022, 15, 7767. [Google Scholar] [CrossRef]

- Babu, S.S.; Raghavan, N.; Raplee, J.; Foster, S.J.; Frederick, C.; Haines, M.; Dinwiddie, R.; Kirka, M.K.; Plotkowski, A.; Lee, Y.; et al. Additive Manufacturing of Nickel Superalloys: Opportunities for Innovation and Challenges Related to Qualification. Metall. Mater. Trans. A 2018, 49, 3764–3780. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive Manufacturing of Metallic Components—Process, Structure and Properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Zaman, S.; Favela, S.; Herrera, N.E.; Gandara, A.; Molina, L.; Hassan, M.S.; Gomez, S.G.; Ramirez, J.E.M.; Mahmud, M.S.; Martinez, A.C.; et al. 3D Printing of Cyanate Ester Resins with Interpenetration Networks for Enhanced Thermal and Mechanical Properties. J. Appl. Polym. Sci. 2024, 141, e55423. [Google Scholar] [CrossRef]

- Hassan, M.S.; Delgadillo, A.; Mahmud, M.S.; Munoz, J.; Zaman, S.; Gomez, S.G.; Marquez, C.; Ho, J.C.; Lin, Y. Additive Manufacturing of Carbon Fiber Reinforced Epoxy Thermoset with Improved Thermomechanical Properties. J. Compos. Sci. 2023, 7, 171. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, Y.; Zhang, J.; Yue, X.; Zhou, H.; Sun, Y. Inconel 718 Alloy Strengthening Mechanism and Fatigue Life of Microtexture-Induced Microjet Coupled with Cavifying Water Jet. Vacuum 2024, 222, 113060. [Google Scholar] [CrossRef]

- Nabil, S.T.; Banuelos, C.; Ramirez, B.; Cruz, A.; Watanabe, K.I.; Arrieta, E.; Wicker, R.B.; Medina, F. Exploring IN718 Alloy Production with Bi-Directional Raster and Stochastic Spot Melting Techniques Using an Open-Source Electron Beam Melting System. In Proceedings of the 34th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 14–16 August 2023. [Google Scholar]

- Pollock, T.M.; Tin, S. Nickel-Based Superalloys for Advanced Turbine Engines: Chemistry, Microstructure and Properties. J. Propuls. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

- Das, N. Advances in Nickel-Based Cast Superalloys. Trans. Indian Inst. Met. 2010, 63, 265–274. [Google Scholar] [CrossRef]

- Gessinger, G.H.; Bomford, M.J. Powder Metallurgy of Superalloys. Int. Metall. Rev. 1974, 19, 51–76. [Google Scholar] [CrossRef]

- Frech, T.; Scholzen, P.; Schäflein, P.; Löpenhaus, C.; Kauffmann, P.; Klocke, F. Design for PM Challenges and Opportunities for Powder Metal Components in Transmission Technology. Procedia CIRP 2018, 70, 186–191. [Google Scholar] [CrossRef]

- Mostafaei, A.; Ghiaasiaan, R.; Ho, I.-T.; Strayer, S.; Chang, K.-C.; Shamsaei, N.; Shao, S.; Paul, S.; Yeh, A.-C.; Tin, S.; et al. Additive Manufacturing of Nickel-Based Superalloys: A State-of-the-Art Review on Process-Structure-Defect-Property Relationship. Prog. Mater. Sci. 2023, 136, 101108. [Google Scholar] [CrossRef]

- Kumaran, M.; Senthilkumar, V.; Sathies, T.; Justus Panicker, C.T. 6—Design and Topology Optimization for Additive Manufacturing of Multilayer (SS316L and AlSi10Mg) Piston. In Advances in Metal Additive Manufacturing; Salunkhe, S., Amancio-Filho, S.T., Davim, J.P., Eds.; Woodhead Publishing Reviews: Mechanical Engineering Series; Woodhead Publishing: Cambridge, UK, 2023; pp. 203–217. ISBN 978-0-323-91230-3. [Google Scholar]

- Xiong, Y.; Tang, Y.; Zhou, Q.; Ma, Y.; Rosen, D.W. Intelligent Additive Manufacturing and Design: State of the Art and Future Perspectives. Addit. Manuf. 2022, 59, 103139. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Ramirez, D.A.; Martinez, E.; Hernandez, J.; Amato, K.N.; Shindo, P.W.; Medina, F.R.; Wicker, R.B. Metal Fabrication by Additive Manufacturing Using Laser and Electron Beam Melting Technologies. J. Mater. Sci. Technol. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Li, Q.; Li, X.-R.; Dong, B.-X.; Zhang, X.-L.; Shu, S.-L.; Qiu, F.; Zhang, L.-C.; Zhang, Z.-H. Metallurgy and Solidification Microstructure Control of Fusion-Based Additive Manufacturing Fabricated Metallic Alloys: A Review. Acta Metall. Sin. Engl. Lett. 2024, 37, 29–53. [Google Scholar] [CrossRef]

- Lee, D.; Park, S.; Lee, C.-H.; Hong, H.-U.; Oh, J.; So, T.-Y.; Kim, W.-S.; Seo, D.; Han, J.; Ko, S.-H.; et al. Correlation between Microstructure and Mechanical Properties in Additively Manufactured Inconel 718 Superalloys with Low and High Electron Beam Currents. J. Mater. Res. Technol. 2024, 28, 2410–2419. [Google Scholar] [CrossRef]

- Zinovieva, O.; Zinoviev, A.; Ploshikhin, V. Three-Dimensional Modeling of the Microstructure Evolution during Metal Additive Manufacturing. Comput. Mater. Sci. 2018, 141, 207–220. [Google Scholar] [CrossRef]

- Song, B.; Zhao, X.; Li, S.; Han, C.; Wei, Q.; Wen, S.; Liu, J.; Shi, Y. Differences in Microstructure and Properties between Selective Laser Melting and Traditional Manufacturing for Fabrication of Metal Parts: A Review. Front. Mech. Eng. 2015, 10, 111–125. [Google Scholar] [CrossRef]

- Carroll, B.E.; Palmer, T.A.; Beese, A.M. Anisotropic Tensile Behavior of Ti–6Al–4V Components Fabricated with Directed Energy Deposition Additive Manufacturing. Acta Mater. 2015, 87, 309–320. [Google Scholar] [CrossRef]

- Brandt, M. Laser Additive Manufacturing: Materials, Design, Technologies, and Applications; Woodhead Publishing: Cambridge, UK, 2016; ISBN 978-0-08-100434-0. [Google Scholar]

- Boban, J.; Puthanveettil Madathil, A.; Ahmed, A.; Rahman, A. An Overview on Post-Processing of Metal Additive Manufactured Components. In Materials Science and Materials Engineering; University of Strathclyde, Glasgow: Glasgow, UK, 2024; Available online: https://www.sciencedirect.com/science/article/abs/pii/B9780323960205002417 (accessed on 14 April 2024).

- Basha, S.M.; Venkaiah, N.; Srivatsan, T.S.; Sankar, M.R. Post-Processing Techniques for Metal Additive Manufactured Products: Role and Contribution of Abrasive Media Assisted Finishing. Mater. Manuf. Process. 2024, 39, 737–760. [Google Scholar] [CrossRef]

- Actual State-of-the-Art of Electron Beam Powder Bed Fusion. Available online: https://www.tandfonline.com/doi/epdf/10.1080/26889277.2022.2040342?needAccess=true (accessed on 14 April 2024).

- Körner, C. Additive Manufacturing of Metallic Components by Selective Electron Beam Melting—A Review. Int. Mater. Rev. 2016, 61, 361–377. [Google Scholar] [CrossRef]

- Zhang, L.-C.; Liu, Y.; Li, S.; Hao, Y. Additive Manufacturing of Titanium Alloys by Electron Beam Melting: A Review. Adv. Eng. Mater. 2018, 20, 1700842. [Google Scholar] [CrossRef]

- Galati, M. Chapter 8—Electron Beam Melting Process: A General Overview. In Additive Manufacturing; Pou, J., Riveiro, A., Davim, J.P., Eds.; Handbooks in Advanced Manufacturing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 277–301. ISBN 978-0-12-818411-0. [Google Scholar]

- Raghavan, N.; Simunovic, S.; Dehoff, R.; Plotkowski, A.; Turner, J.; Kirka, M.; Babu, S. Localized Melt-Scan Strategy for Site Specific Control of Grain Size and Primary Dendrite Arm Spacing in Electron Beam Additive Manufacturing. Acta Mater. 2017, 140, 375–387. [Google Scholar] [CrossRef]

- Sames, W.J.; Unocic, K.A.; Dehoff, R.R.; Lolla, T.; Babu, S.S. Thermal Effects on Microstructural Heterogeneity of Inconel 718 Materials Fabricated by Electron Beam Melting. J. Mater. Res. 2014, 29, 1920–1930. [Google Scholar] [CrossRef]

- Dehoff, R.R.; Kirka, M.M.; List, F.A.; Unocic, K.A.; Sames, W.J. Crystallographic Texture Engineering through Novel Melt Strategies via Electron Beam Melting: Inconel 718. Mater. Sci. Technol. 2015, 31, 939–944. [Google Scholar] [CrossRef]

- Sun, S.-H.; Koizumi, Y.; Saito, T.; Yamanaka, K.; Li, Y.-P.; Cui, Y.; Chiba, A. Electron Beam Additive Manufacturing of Inconel 718 Alloy Rods: Impact of Build Direction on Microstructure and High-Temperature Tensile Properties. Addit. Manuf. 2018, 23, 457–470. [Google Scholar] [CrossRef]

- Kirka, M.M.; Medina, F.; Dehoff, R.; Okello, A. Mechanical Behavior of Post-Processed Inconel 718 Manufactured through the Electron Beam Melting Process. Mater. Sci. Eng. A 2017, 680, 338–346. [Google Scholar] [CrossRef]

- Strondl, A.; Palm, M.; Gnauk, J.; Frommeyer, G. Microstructure and Mechanical Properties of Nickel Based Superalloy IN718 Produced by Rapid Prototyping with Electron Beam Melting (EBM). Mater. Sci. Technol. 2011, 27, 876–883. [Google Scholar] [CrossRef]

- Helmer, H.E.; Körner, C.; Singer, R.F. Additive Manufacturing of Nickel-Based Superalloy Inconel 718 by Selective Electron Beam Melting: Processing Window and Microstructure. J. Mater. Res. 2014, 29, 1987–1996. [Google Scholar] [CrossRef]

- Karimi, P.; Sadeghi, E.; Ålgårdh, J.; Olsson, J.; Colliander, M.H.; Harlin, P.; Toyserkani, E.; Andersson, J. Tailored Grain Morphology via a Unique Melting Strategy in Electron Beam-Powder Bed Fusion. Mater. Sci. Eng. A 2021, 824, 141820. [Google Scholar] [CrossRef]

- Helmer, H.; Bauereiß, A.; Singer, R.F.; Körner, C. Grain Structure Evolution in Inconel 718 during Selective Electron Beam Melting. Mater. Sci. Eng. A 2016, 668, 180–187. [Google Scholar] [CrossRef]

- Ding, X.; Koizumi, Y.; Aoyagi, K.; Kii, T.; Sasaki, N.; Hayasaka, Y.; Yamanaka, K.; Chiba, A. Microstructural Control of Alloy 718 Fabricated by Electron Beam Melting with Expanded Processing Window by Adaptive Offset Method. Mater. Sci. Eng. A 2019, 764, 138058. [Google Scholar] [CrossRef]

- Dehoff, R.R.; Kirka, M.M.; Sames, W.J.; Bilheux, H.; Tremsin, A.S.; Lowe, L.E.; Babu, S.S. Site Specific Control of Crystallographic Grain Orientation through Electron Beam Additive Manufacturing. Mater. Sci. Technol. 2015, 31, 931–938. [Google Scholar] [CrossRef]

- Polonsky, A.T.; Raghavan, N.; Echlin, M.P.; Kirka, M.M.; Dehoff, R.R.; Pollock, T.M. Scan Strategies in EBM-Printed IN718 and the Physics of Bulk 3D Microstructure Development. Mater. Charact. 2022, 190, 112043. [Google Scholar] [CrossRef]

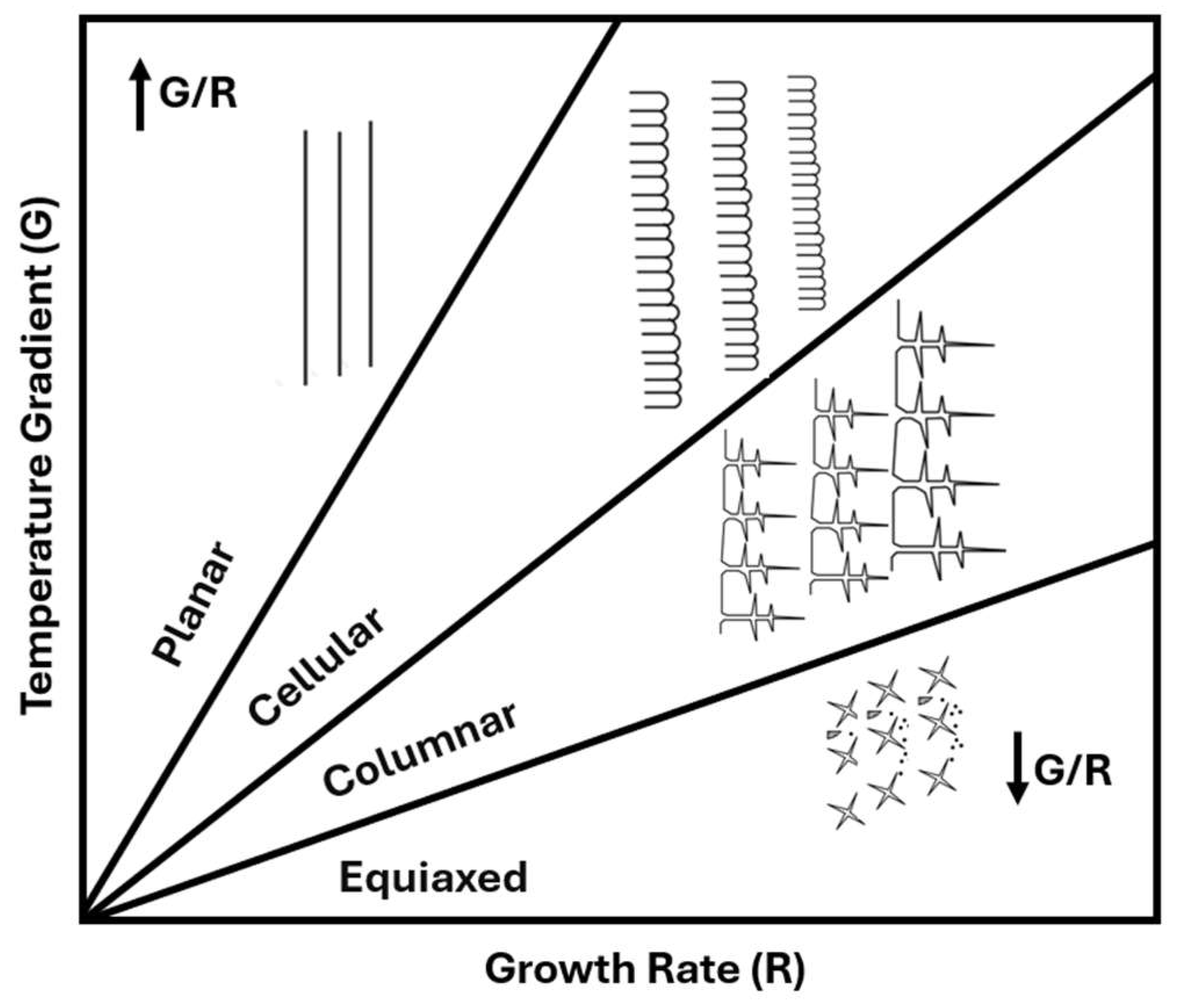

- Boettinger, W.J.; Coriell, S.R.; Greer, A.L.; Karma, A.; Kurz, W.; Rappaz, M.; Trivedi, R. Solidification Microstructures: Recent Developments, Future Directions. Acta Mater. 2000, 48, 43–70. [Google Scholar] [CrossRef]

- Lee, Y.S.; Kirka, M.M.; Dinwiddie, R.B.; Raghavan, N.; Turner, J.; Dehoff, R.R.; Babu, S.S. Role of Scan Strategies on Thermal Gradient and Solidification Rate in Electron Beam Powder Bed Fusion. Addit. Manuf. 2018, 22, 516–527. [Google Scholar] [CrossRef]

- Knapp, G.L.; Raghavan, N.; Plotkowski, A.; DebRoy, T. Experiments and Simulations on Solidification Microstructure for Inconel 718 in Powder Bed Fusion Electron Beam Additive Manufacturing. Addit. Manuf. 2019, 25, 511–521. [Google Scholar] [CrossRef]

- Ramakrishnan, P. Welding Metallurgy. Indian Weld. J. 1972, 4, 89. [Google Scholar] [CrossRef]

| Power (W) | Speed (mm/s) | Ea (J/mm2) | Relative Optical Density (%) | Type |

|---|---|---|---|---|

| 720 | 2400 | 3 | 97.81 | Solid |

| 600 | 2400 | 2.5 | 95.7 | LOF |

| 300 | 1200 | 2.5 | 96.47 | LOF |

| 360 | 1200 | 3 | 98.38 | Solid |

| 300 | 800 | 3.75 | 99.87 | Solid |

| Specimen | SP1 | SP2 | SP3 | SP4 |

|---|---|---|---|---|

| Power (Watt) | 720 | 660 | 420 | 360 |

| Spot Dwell (microseconds) | 125 | 125 | 250 | 250 |

| Eas (J/mm2) | 9 | 8.25 | 10.25 | 9 |

| Melt Time (seconds) | 2.21 | 2.21 | 4.42 | 4.42 |

| Metric (Parallel to Build Direction) | Raster Build | Stochastic Spot Melt Build | ||||

|---|---|---|---|---|---|---|

| Top Section | Bottom Section | SP1 | SP2 | SP3 | SP4 | |

| Grain Count | 425 | 813 | 192 | 308 | 342 | 643 |

| Mean Aspect Ratio | 5.9 | 3.6 | 2.9 | 2.7 | 2.6 | 2.5 |

| Area-weighted Mean Aspect Ratio | 10.9 | 5.6 | 3.5 | 4.0 | 3.9 | 3.5 |

| Min Aspect Ratio | 1.1 | 1.0 | 1.0 | 1.1 | 1.0 | 1.0 |

| Max Aspect Ratio | 36.8 | 36.3 | 9.6 | 9.8 | 9.9 | 12.7 |

| Standard Deviation | 5.4 | 2.9 | 1.6 | 1.5 | 1.5 | 1.5 |

| Build | Test 1 | Test 2 | Test 3 | Test 4 | Test 5 | Mean | Standard Deviation |

|---|---|---|---|---|---|---|---|

| Raster | 451 | 437 | 431 | 418 | 432 | 434 | 11.9 |

| SP1 | 397 | 266 | 235 | 238 | 352 | 298 | 72.9 |

| SP2 | 395 | 306 | 288 | 304 | 359 | 330 | 44.9 |

| SP3 | 391 | 365 | 359 | 388 | 405 | 382 | 17.1 |

| SP4 | 401 | 412 | 408 | 406 | 412 | 408 | 4.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nabil, S.T.; Banuelos, C.; Madigan, M.E.; Tin, S.; Rodriguez, J.I.; Murr, L.E.; Wicker, R.B.; Medina, F. Microstructure Refinement of Bulk Inconel 718 Parts During Fabrication with EB-PBF Using Scanning Strategies: Transition from Bidirectional-Raster to Stochastic Point-Based Melting. J. Manuf. Mater. Process. 2024, 8, 241. https://doi.org/10.3390/jmmp8060241

Nabil ST, Banuelos C, Madigan ME, Tin S, Rodriguez JI, Murr LE, Wicker RB, Medina F. Microstructure Refinement of Bulk Inconel 718 Parts During Fabrication with EB-PBF Using Scanning Strategies: Transition from Bidirectional-Raster to Stochastic Point-Based Melting. Journal of Manufacturing and Materials Processing. 2024; 8(6):241. https://doi.org/10.3390/jmmp8060241

Chicago/Turabian StyleNabil, Shadman Tahsin, Cristian Banuelos, Michael E. Madigan, Sammy Tin, Jacob I. Rodriguez, Lawrence E. Murr, Ryan B. Wicker, and Francisco Medina. 2024. "Microstructure Refinement of Bulk Inconel 718 Parts During Fabrication with EB-PBF Using Scanning Strategies: Transition from Bidirectional-Raster to Stochastic Point-Based Melting" Journal of Manufacturing and Materials Processing 8, no. 6: 241. https://doi.org/10.3390/jmmp8060241

APA StyleNabil, S. T., Banuelos, C., Madigan, M. E., Tin, S., Rodriguez, J. I., Murr, L. E., Wicker, R. B., & Medina, F. (2024). Microstructure Refinement of Bulk Inconel 718 Parts During Fabrication with EB-PBF Using Scanning Strategies: Transition from Bidirectional-Raster to Stochastic Point-Based Melting. Journal of Manufacturing and Materials Processing, 8(6), 241. https://doi.org/10.3390/jmmp8060241