Processability and Material Behavior of NiTi Shape Memory Alloys Using Wire Laser-Directed Energy Deposition (WL-DED)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Additive Manufacturing of NiTi Parts

2.2.1. Single-Track Experiments

2.2.2. Fabrication of Bulk Samples

2.3. Material Characterization

3. Results and Discussion

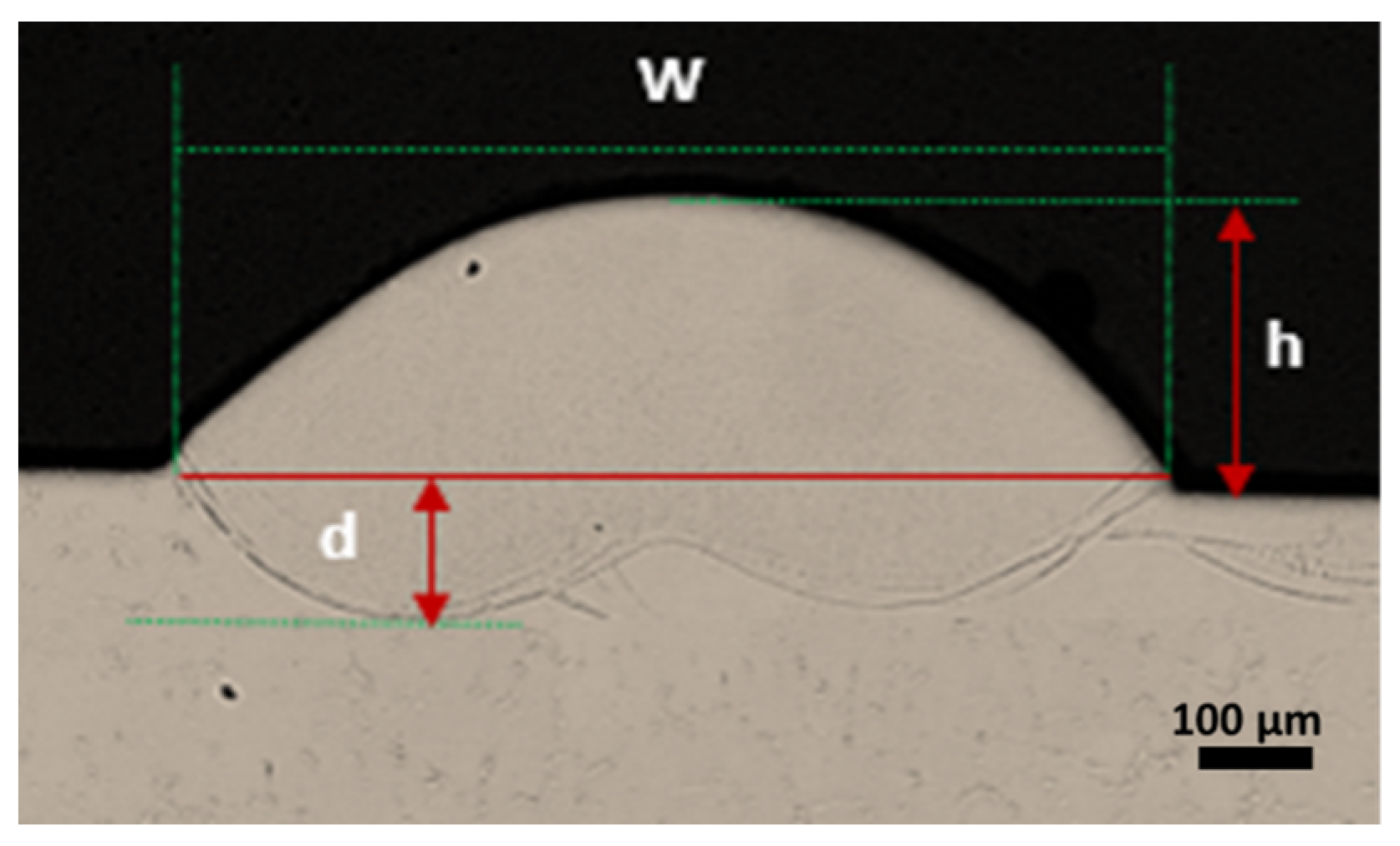

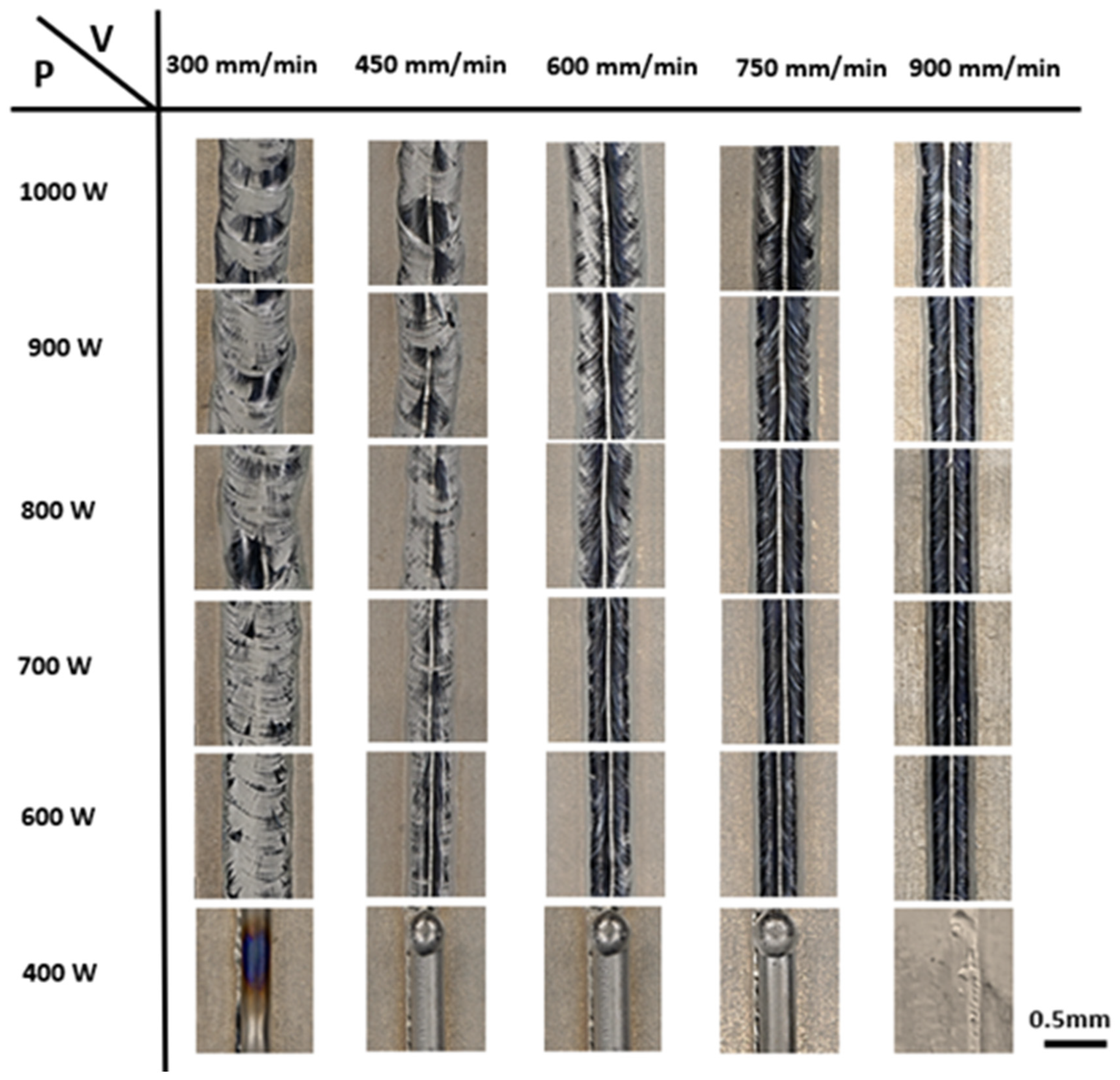

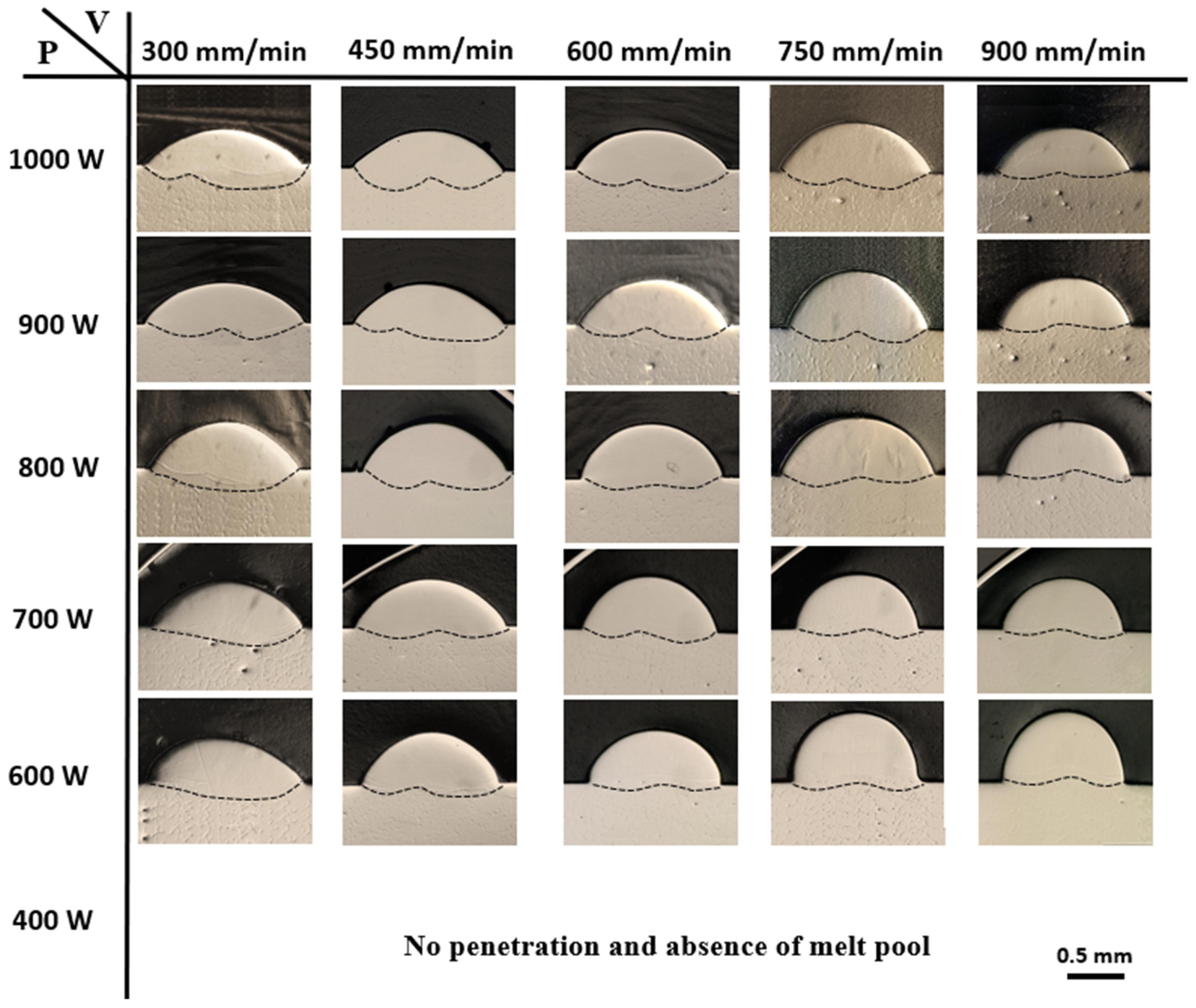

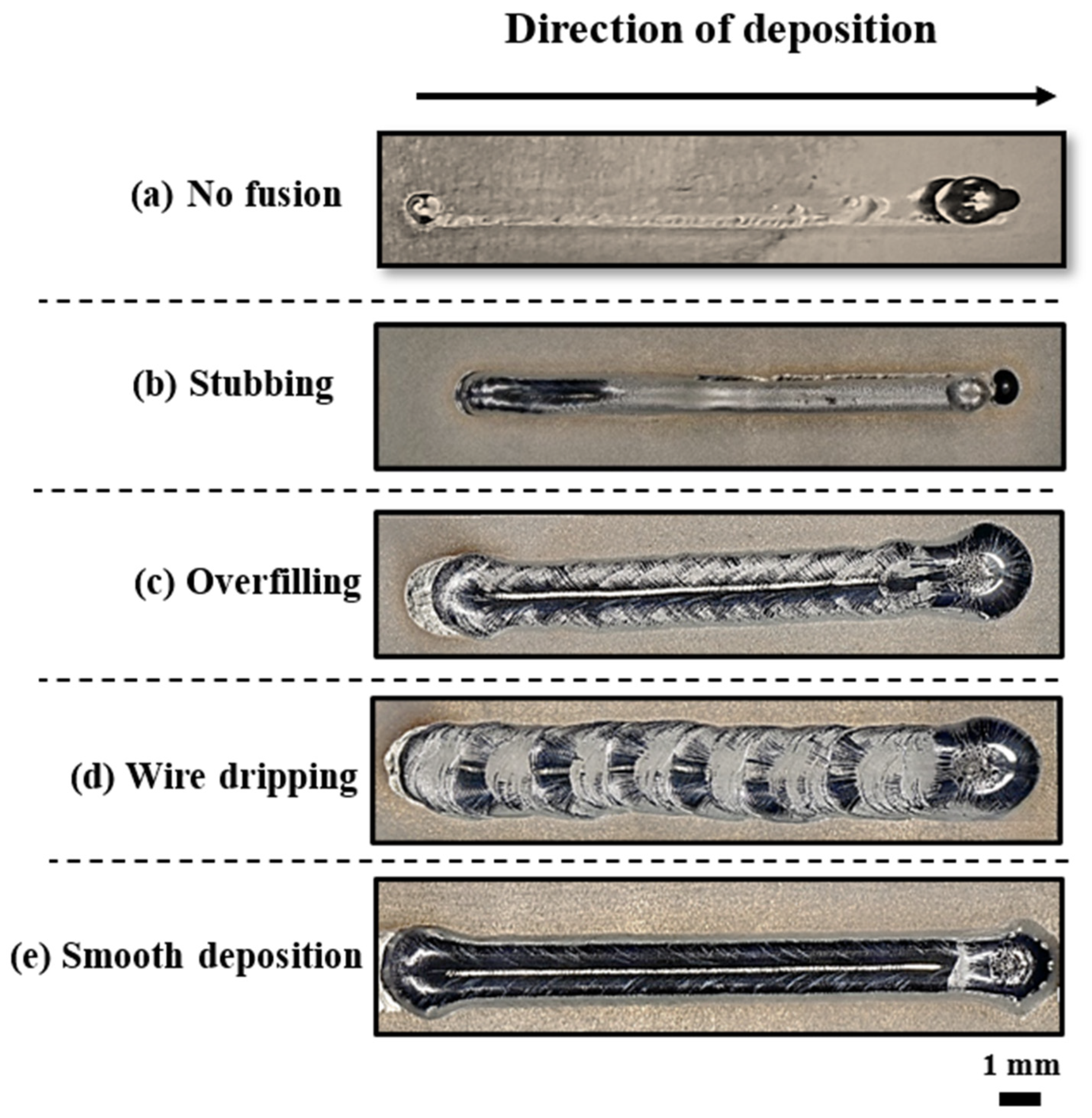

3.1. Single-Track Analysis from Top-View to Cross-Section

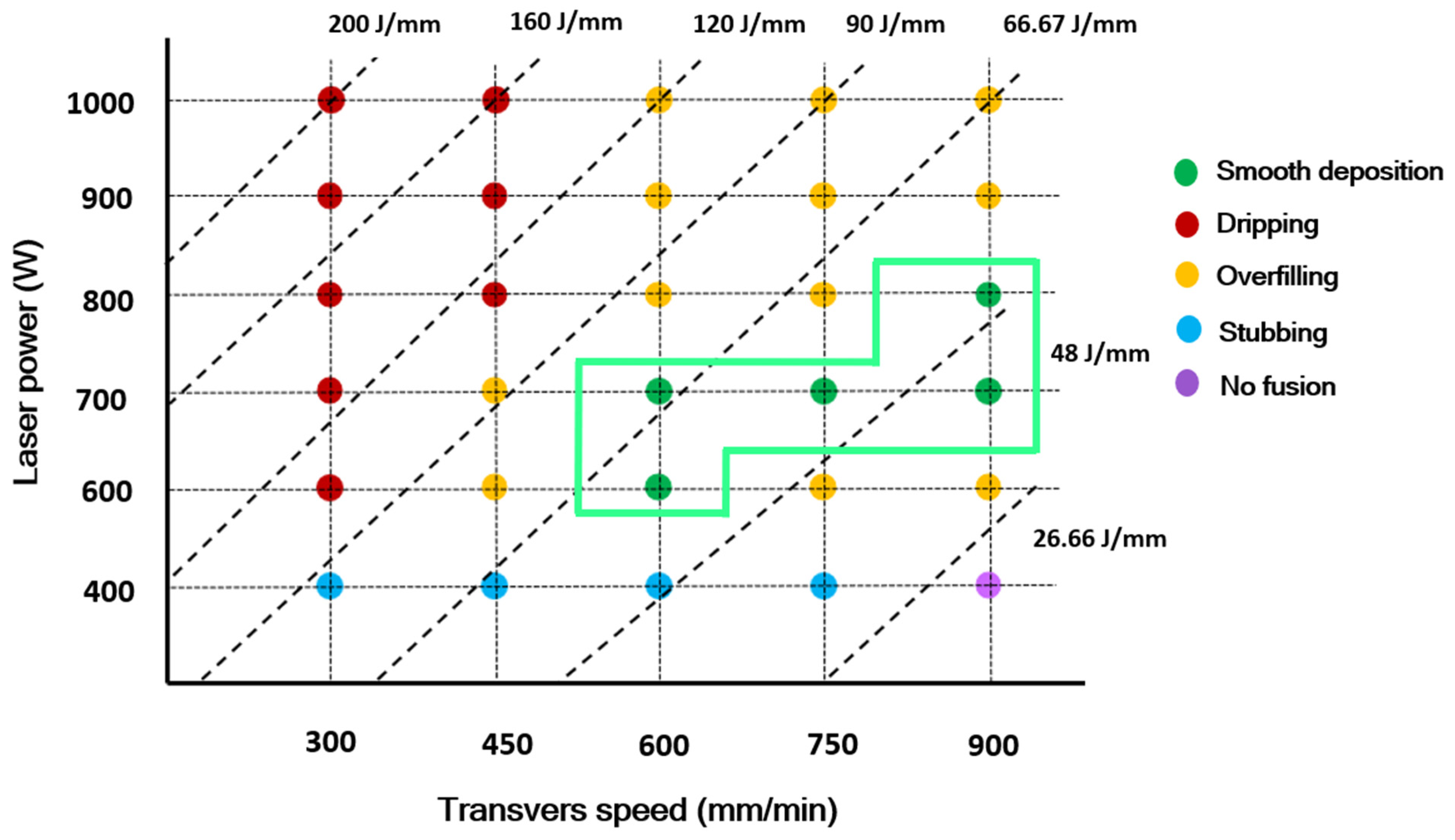

3.2. Printability Map

3.3. Analysis of Bulk Cubes

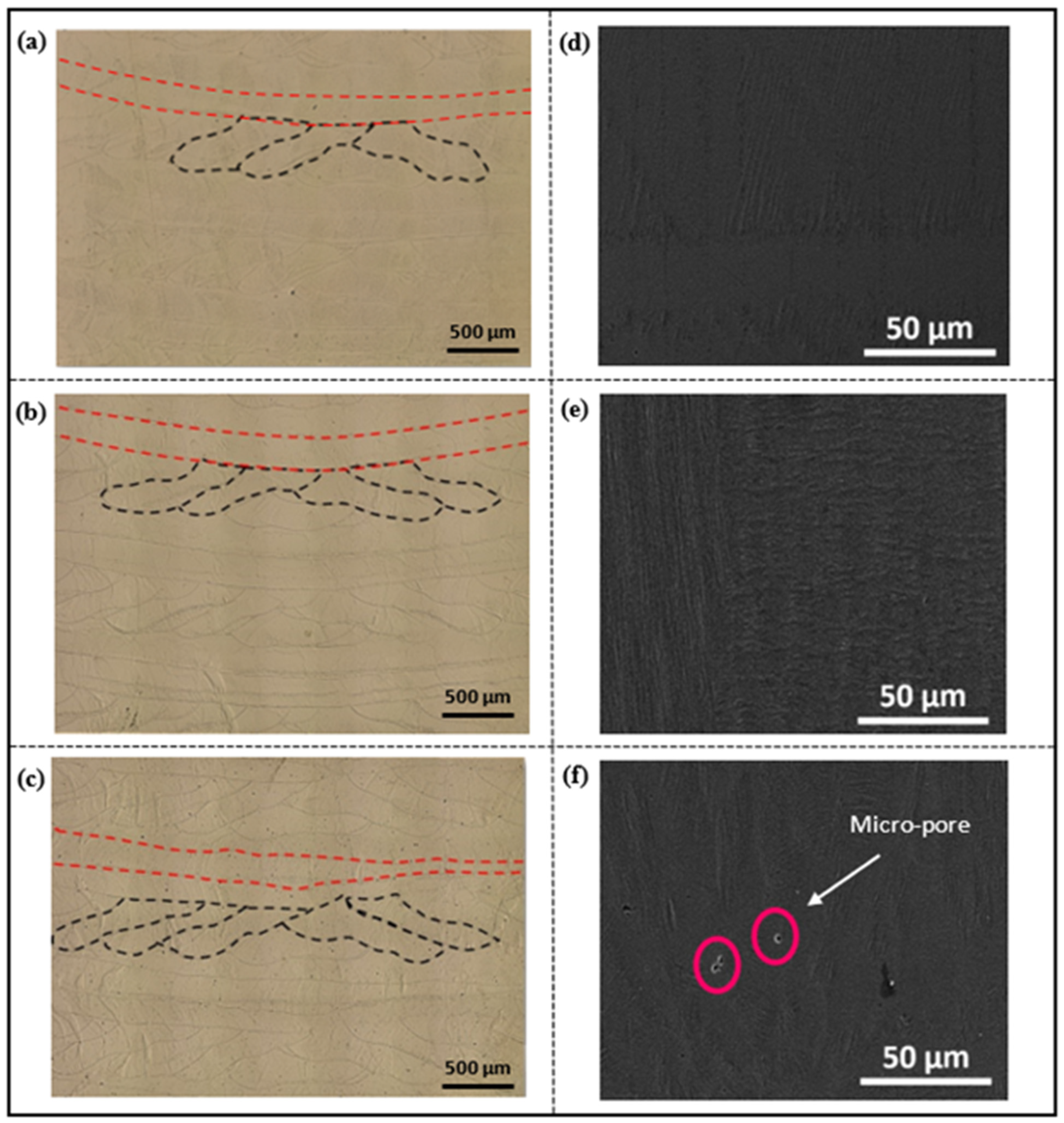

3.3.1. Cross-Sectional Analysis of NiTi Cubes

Effect of Energy Density on the Melt Pool Microstructure

3.3.2. Effect of Energy Input on Relative Density of NiTi Cubes

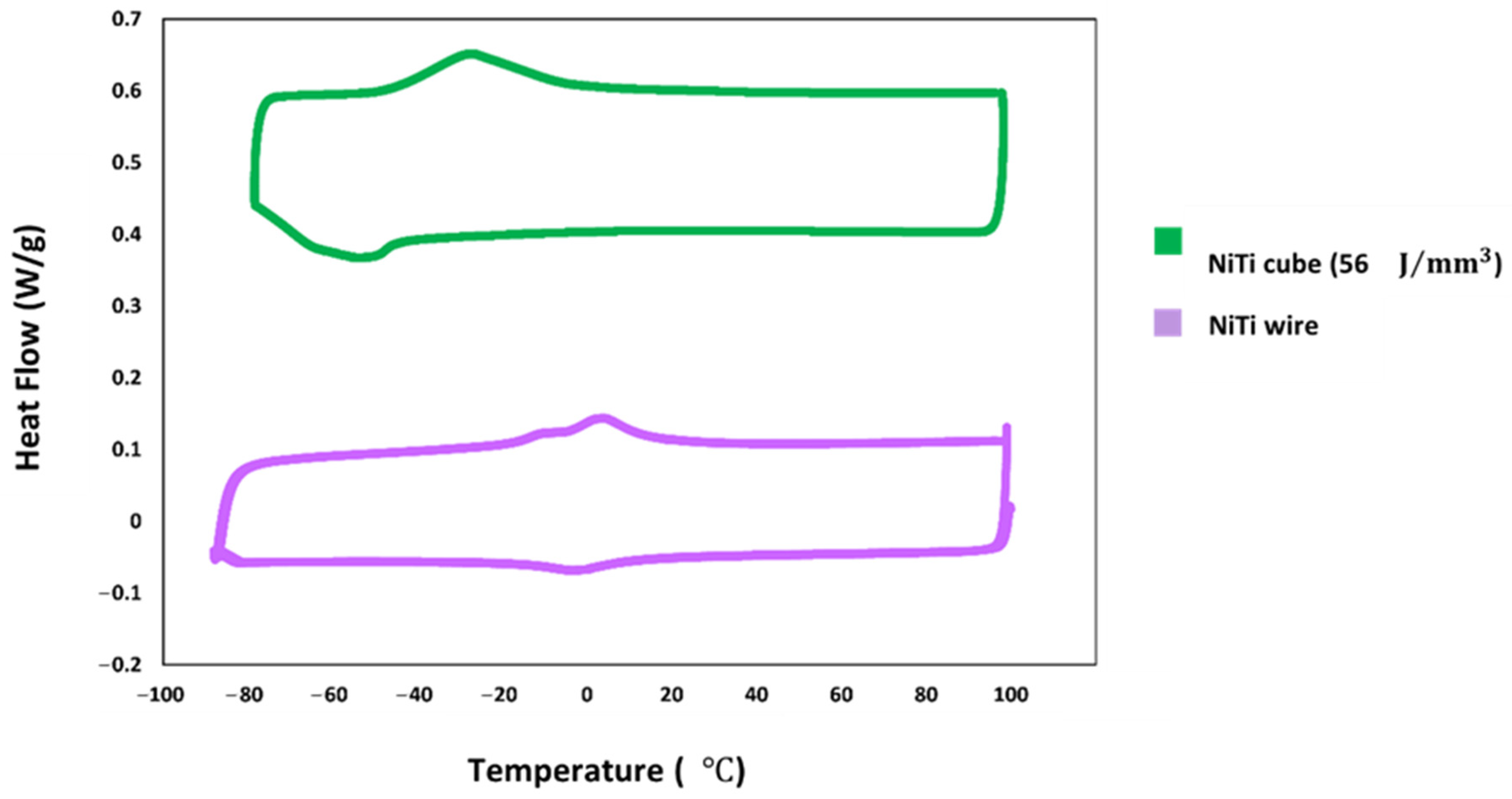

3.3.3. Phase Transformation Temperature Analysis

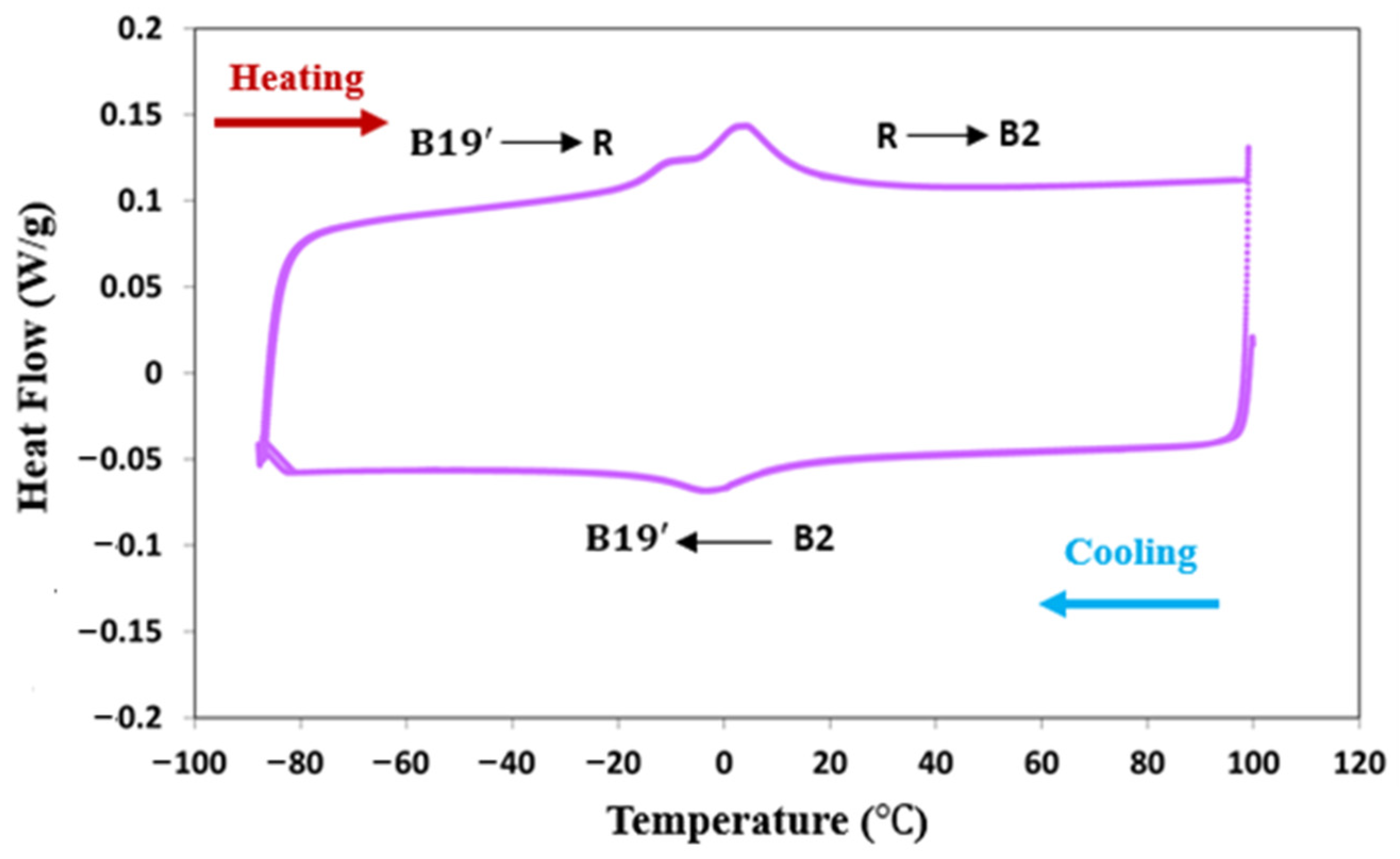

Transformation Temperature Transition from Wire to Cube

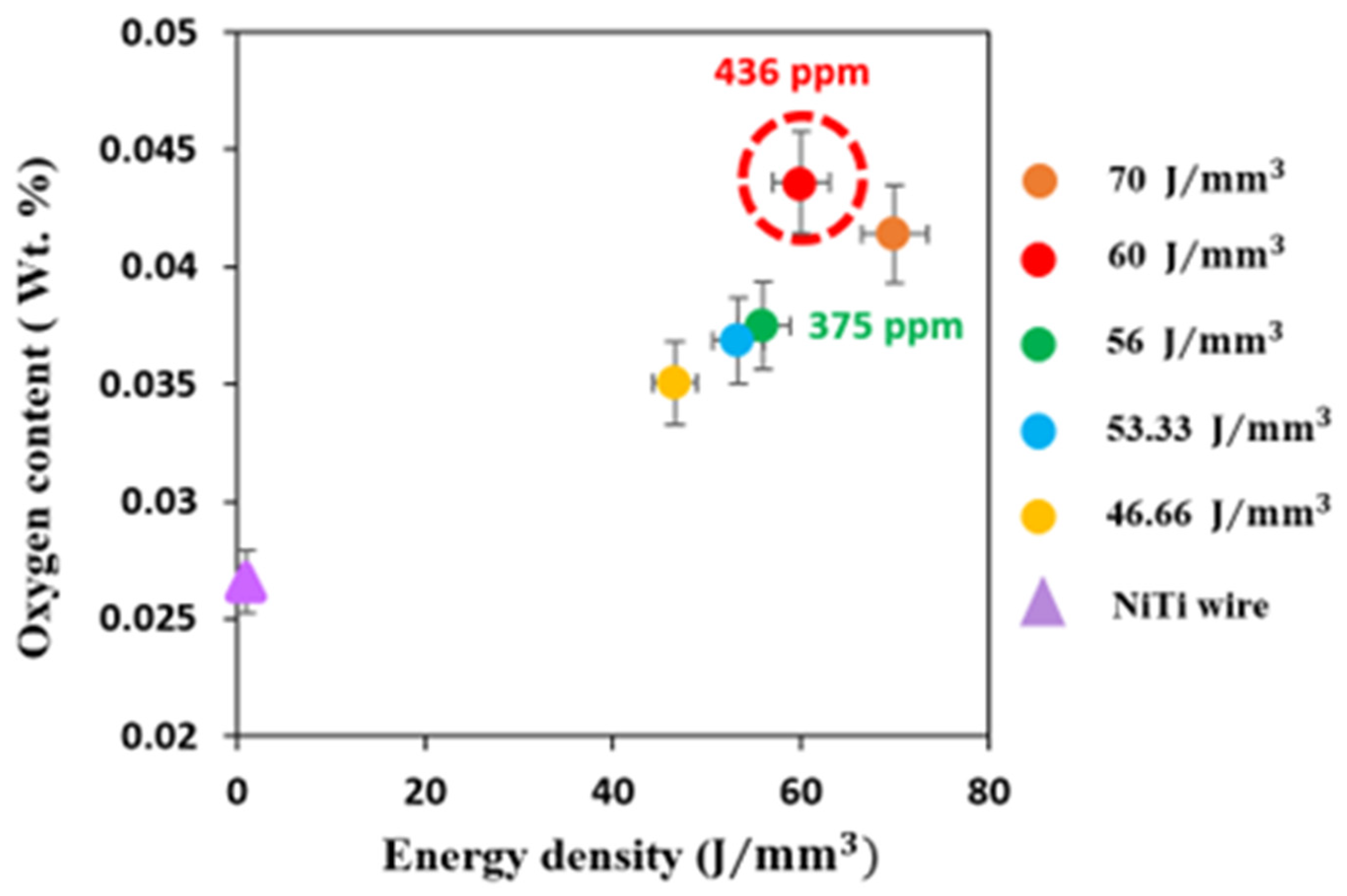

Effect of Energy Density on Transformation Temperature of Cubes

3.3.4. Hardness Evaluation of Fabricated NiTi Cubes

4. Conclusions

- The single-track study found that laser power between 600 W and 800 W, combined with transverse speeds ranging from 600 mm/min to 900 mm/min, produced the optimal results. These parameters corresponded to an energy density range of 46.66–70 J/mm3, offering a valuable guideline for future NiTi fabrication using WL-DED.

- The cube study demonstrated that lower to intermediate energy densities (46.66 to 56 J/mm3) produced superior results, achieving relative densities exceeding 98%, with some samples surpassing 99%, and favorable phase transformation temperatures for Nickel-Titanium (NiTi) components. In contrast, high energy densities resulted in uneven surfaces, while low energy densities caused discontinuous melts, both of which adversely affected the quality of the parts produced.

- A correlation between increasing energy density and hardness was observed, with higher energy densities leading to greater nickel evaporation and a relative increase in titanium content. The printed NiTi cubes exhibited a hardness of approximately 290 HV, lower than the 350 HV of cold-drawn NiTi wire, due to the absence of work hardening and the effects of localized heat treatment during laser processing.

- High-quality NiTi parts with minimal defects were successfully produced, addressing challenges in manufacturing large and complex components. This advancement shows great potential for industries such as biomedical, aerospace, and civil engineering, particularly for applications like seismic dampers for energy dissipation, which could enhance structural resilience in earthquake-prone areas.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Y.; Xie, Z.; Jan, V.H.; Luc, D. Deformation of shape memory alloys associated with twinned domain re-configurations. Mater. Sci. Eng. A 1999, 273, 679–684. [Google Scholar] [CrossRef]

- McNANEY, J.M.; Valentina, I.; Jung, Y.; Panayiotis, P.; Ritchie, R.O. An experimental study of the superelastic effect in a shape-memory Nitinol alloy under biaxial loading. Mech. Mater. 2003, 35, 969–986. [Google Scholar] [CrossRef]

- Bruneau, M.; Chang, S.E.; Eguchi, R.T.; Lee, G.C.; O’Rourke, T.D.; Reinhorn, A.M.; Shinozuka, M.; Tierney, K.; Wallace, W.A.; Von Winterfeldt, D. A framework to quantitatively assess and enhance the seismic resilience of communities. Earthq. Spectra 2003, 19, 733–752. [Google Scholar] [CrossRef]

- Saadat, S.; Salichs, J.; Mohammad, N.; Hou, Z.; Davoodi, H.; Isa, B.O.; Suzuki, Y.; Masuda, A. An overview of vibration and seismic applications of NiTi shape memory alloy. Smart Mater. Struct. 2002, 11, 218. [Google Scholar] [CrossRef]

- Elahinia, M.H.; Mahdi, H.; Majid, T.; Sarit, B.B. Manufacturing and processing of NiTi implants: A review. Prog. Mater. Sci. 2012, 57, 911–946. [Google Scholar] [CrossRef]

- Nematollahi, M.; Keyvan, S.; Parisa, B.; Mohammad, E. Functionally graded NiTi shape memory alloy: Selective laser melting fabrication and multi-scale characterization. Mater. Lett. 2021, 292, 129648. [Google Scholar] [CrossRef]

- Pelton, A.R.; Russell, S.M.; DiCello, J. The physical metallurgy of nitinol for medical applications. Jom 2003, 55, 33–37. [Google Scholar] [CrossRef]

- Haberland, C.; Mohammad, E.; Jason, W.; Horst, M. Visions, concepts and strategies for smart nitinol actuators and complex nitinol structures produced by additive manufacturing. In Smart Materials, Adaptive Structures and Intelligent Systems; American Society of Mechanical Engineers: New York City, NY, USA, 2013. [Google Scholar]

- Haberland, C.; Mohammad, E.; Jason, M.W.; Horst, M.; Jan, F. On the development of high quality NiTi shape memory and pseudoelastic parts by additive manufacturing. Smart Mater. Struct. 2014, 23, 104002. [Google Scholar] [CrossRef]

- Shayesteh Moghaddam, N.; Mohsen, T.A.; Amirhesam, A.; Christoph, H.; Scott, H.; Michael, M.; Mohammad, E.; David, D. Metals for bone implants: Safety, design, and efficacy. Biomanufacturing Rev. 2016, 1, 1. [Google Scholar] [CrossRef]

- Saedi, S.; Turabi, A.S.; Andani, M.T.; Moghaddam, N.S.; Elahinia, M.; Karaca, H.E. Texture, aging, and superelasticity of selective laser melting fabricated Ni-rich NiTi alloys. Mater. Sci. Eng. A 2017, 686, 1–10. [Google Scholar] [CrossRef]

- Hamilton, R.F.; Bimber, B.A.; Andani, M.T.; Elahinia, M. Multi-scale shape memory effect recovery in NiTi alloys additive manufactured by selective laser melting and laser directed energy deposition. J. Mater. Process. Technol. 2017, 250, 55–64. [Google Scholar] [CrossRef]

- Saedi, S.; Saghaian, S.E.; Jahadakbar, A.; Moghaddam, N.S.; Andani, M.T.; Saghaian, S.M.; Lu, Y.C.; Elahinia, M.; Karaca, H.E. Shape memory response of porous NiTi shape memory alloys fabricated by selective laser melting. J. Mater. Sci. Mater. Med. 2018, 29, 40. [Google Scholar] [CrossRef]

- Jahadakbar, A.; Nematollahi, M.; Safaei, K.; Bayati, P.; Giri, G.; Dabbaghi, H.; Dean, D.; Elahinia, M. Design, modeling, additive manufacturing, and polishing of stiffness-modulated porous nitinol bone fixation plates followed by thermomechanical and composition analysis. Metals 2020, 10, 151. [Google Scholar] [CrossRef]

- Bayati, P.; Safaei, K.; Nematollahi, M.; Jahadakbar, A.; Yadollahi, A.; Mahtabi, M.; Elahinia, M. Toward understanding the effect of remelting on the additively manufactured NiTi. Int. J. Adv. Manuf. Technol. 2021, 112, 347–360. [Google Scholar] [CrossRef]

- Nematollahi, M.; Saghaian, S.E.; Safaei, K.; Bayati, P.; Bassani, P.; Biffi, C.; Tuissi, A.; Karaca, H.; Elahinia, M. Building orientation-structure-property in laser powder bed fusion of NiTi shape memory alloy. J. Alloys Compd. 2021, 873, 159791. [Google Scholar] [CrossRef]

- Safaei, K.; Nematollahi, M.; Bayati, P.; Dabbaghi, H.; Benafan, O.; Elahinia, M. Torsional behavior and microstructure characterization of additively manufactured NiTi shape memory alloy tubes. Eng. Struct. 2021, 226, 111383. [Google Scholar] [CrossRef]

- Safaei, K.; Abedi, H.; Nematollahi, M.; Kordizadeh, F.; Dabbaghi, H.; Bayati, P.; Javanbakht, R.; Jahadakbar, A.; Elahinia, M.; Poorganji, B. Additive manufacturing of NiTi shape memory alloy for biomedical applications: Review of the LPBF process ecosystem. Jom 2021, 73, 3771–3786. [Google Scholar] [CrossRef]

- Walker, J.M.; Haberland, C.; Andani, M.T.; Karaca, H.E.; Dean, D.; Elahinia, M. Process development and characterization of additively manufactured nickel–titanium shape memory parts. J. Intell. Mater. Syst. Struct. 2016, 27, 2653–2660. [Google Scholar] [CrossRef]

- Ahn, D.-G. Directed energy deposition (DED) process: State of the art. Int. J. Precis. Eng. Manuf.-Green Technol. 2021, 8, 703–742. [Google Scholar] [CrossRef]

- Parvizi, S.; Hashemi, S.M.; Asgarinia, F.; Nematollahi, M.; Elahinia, M. Effective parameters on the final properties of NiTi-based alloys manufactured by powder metallurgy methods: A review. Prog. Mater. Sci. 2021, 117, 100739. [Google Scholar] [CrossRef]

- Bagheri, A.; Yadollahi, A.; Mahtabi, M.J.; Paudel, Y.; Vance, E.; Shamsaei, N.; Horstemeyer, M.F. Microstructure-based MultiStage fatigue modeling of NiTi alloy fabricated via direct energy deposition (DED). J. Mater. Eng. Perform. 2022, 31, 4761–4775. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, X.; Parvez, M.M.; Liou, F. A review on metallic alloys fabrication using elemental powder blends by laser powder directed energy deposition process. Materials 2020, 13, 3562. [Google Scholar] [CrossRef] [PubMed]

- Dass, A.; Moridi, A. State of the art in directed energy deposition: From additive manufacturing to materials design. Coatings 2019, 9, 418. [Google Scholar] [CrossRef]

- Hwang, T.; Woo, Y.Y.; Han, S.W.; Moon, Y.H. Functionally graded properties in directed-energy-deposition titanium parts. Opt. Laser Technol. 2018, 105, 80–88. [Google Scholar] [CrossRef]

- Feenstra, D.; Banerjee, R.; Fraser, H.L.; Huang, A.; Molotnikov, A.; Birbilis, N. Critical review of the state of the art in multi-material fabrication via directed energy deposition. Curr. Opin. Solid State Mater. Sci. 2021, 25, 100924. [Google Scholar] [CrossRef]

- Ansari, M.; Jabari, E.; Toyserkani, E. Opportunities and challenges in additive manufacturing of functionally graded metallic materials via powder-fed laser directed energy deposition: A review. J. Mater. Process. Technol. 2021, 294, 117117. [Google Scholar] [CrossRef]

- Kumar, S.; Marandi, L.; Balla, V.K.; Bysakh, S.; Piorunek, D.; Eggeler, G.; Das, M.; Sen, I. Microstructure–Property correlations for additively manufactured NiTi based shape memory alloys. Materialia 2019, 8, 100456. [Google Scholar] [CrossRef]

- Baran, A.; Polanski, M. Microstructure and properties of LENS (laser engineered net shaping) manufactured Ni-Ti shape memory alloy. J. Alloys Compd. 2018, 750, 863–870. [Google Scholar] [CrossRef]

- Zheng, D.; Li, R.-D.; Yuan, T.-C.; Xiong, Y.; Song, B.; Wang, J.-X.; Su, Y.-D. Microstructure and mechanical property of additively manufactured NiTi alloys: A comparison between selective laser melting and directed energy deposition. J. Cent. South Univ. 2021, 28, 1028–1042. [Google Scholar] [CrossRef]

- Derekar, K. A review of wire arc additive manufacturing and advances in wire arc additive manufacturing of aluminium. Mater. Sci. Technol. 2018, 34, 895–916. [Google Scholar] [CrossRef]

- Li, Z.; Sui, S.; Ma, X.; Tan, H.; Zhong, C.; Bi, G.; Clare, A.T.; Gasser, A.; Chen, J. High deposition rate powder-and wire-based laser directed energy deposition of metallic materials: A review. Int. J. Mach. Tools Manuf. 2022, 181, 103942. [Google Scholar] [CrossRef]

- Svetlizky, D.; Zheng, B.; Vyatskikh, A.; Das, M.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Laser-based directed energy deposition (DED-LB) of advanced materials. Mater. Sci. Eng. A 2022, 840, 142967. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, X.; Konovalov, S. Additive manufacturing based on welding arc: A low-cost method. J. Surf. Investig. X-Ray Synchrotron Neutron Tech. 2017, 11, 1317–1328. [Google Scholar] [CrossRef]

- Lu, T.; Liu, C.; Li, Z.; Wu, Q.; Wang, J.; Xu, T.; Liu, J.; Wang, H.; Ma, S. Hot-wire arc additive manufacturing Ti–6.5 Al–2Zr–1Mo–1V titanium alloy: Pore characterization, microstructural evolution, and mechanical properties. J. Alloys Compd. 2020, 817, 153334. [Google Scholar] [CrossRef]

- Chaturvedi, M.; Scutelnicu, E.; Rusu, C.C.; Mistodie, L.R.; Mihailescu, D.; Subbiah, A.V. Wire arc additive manufacturing: Review on recent findings and challenges in industrial applications and materials characterization. Metals 2021, 11, 939. [Google Scholar] [CrossRef]

- Yu, L.; Chen, K.; Zhang, Y.; Liu, J.; Yang, L.; Shi, Y. Microstructures and mechanical properties of NiTi shape memory alloys fabricated by wire arc additive manufacturing. J. Alloys Compd. 2022, 892, 162193. [Google Scholar] [CrossRef]

- Singh, S.; Resnina, N.; Belyaev, S.; Jinoop, A.N.; Shukla, A.; Palani, I.A.; Paul, C.P.; Bindra, K.S. Investigations on NiTi shape memory alloy thin wall structures through laser marking assisted wire arc based additive manufacturing. J. Manuf. Process. 2021, 66, 70–80. [Google Scholar] [CrossRef]

- Shen, C.; Reid, M.; Liss, K.-D.; Hua, X.; Pan, Z.; Mou, G.; Huang, Y.; Li, H. In-situ neutron diffraction study on the high temperature thermal phase evolution of wire-arc additively manufactured Ni53Ti47 binary alloy. J. Alloys Compd. 2020, 843, 156020. [Google Scholar] [CrossRef]

- Wang, J.; Pan, Z.; Wang, Y.; Wang, L.; Su, L.; Cuiuri, D.; Zhao, Y.; Li, H. Evolution of crystallographic orientation, precipitation, phase transformation and mechanical properties realized by enhancing deposition current for dual-wire arc additive manufactured Ni-rich NiTi alloy. Addit. Manuf. 2020, 34, 101240. [Google Scholar] [CrossRef]

- Liu, G.; Zhou, S.; Lin, P.; Zong, X.; Chen, Z.; Zhang, Z.; Ren, L. Analysis of microstructure, mechanical properties, and wear performance of NiTi alloy fabricated by cold metal transfer based wire arc additive manufacturing. J. Mater. Res. Technol. 2022, 20, 246–259. [Google Scholar] [CrossRef]

- Dhinakaran, V.; Ajith, J.; Fahmidha, A.F.Y.; Jagadeesha, T.; Sathish, T.; Stalin, B. Wire Arc Additive Manufacturing (WAAM) process of nickel based superalloys–A review. Mater. Today Proc. 2020, 21, 920–925. [Google Scholar] [CrossRef]

- Baufeld, B.; Widdison, R.; Dutilleul, T. Wire based electron beam additive manufacturing. In Proceedings of the 70th IIW Assembly and International Conference, Shanghai, China, 25–30 June 2017. [Google Scholar]

- Zapata, A.; Bernauer, C.; Stadter, C.; Kolb, C.G.; Zaeh, M.F. Investigation on the cause-effect relationships between the process parameters and the resulting geometric properties for wire-based coaxial laser metal deposition. Metals 2022, 12, 455. [Google Scholar] [CrossRef]

- Elmer, J.W.; Vaja, J.; Carpenter, J.S.; Coughlin, D.R.; Dvornak, M.J.; Hochanadel, P.; Gurung, P.; Johnson, A.; Gibbs, G. Wire-based additive manufacturing of stainless steel components. Weld. J. 2020, 99, 1618196. [Google Scholar] [CrossRef]

- Akbari, M.; Ding, Y.; Kovacevic, R. Process development for a robotized laser wire additive manufacturing. In Proceedings of the International Manufacturing Science and Engineering Conference, Vigo, Pontevedra, Spain, 28–30 June 2017. [Google Scholar]

- Wang, M.; Ventzke, V.; Kashaev, N. Wire-based laser directed energy deposition of AA7075: Effect of process parameters on microstructure and mechanical properties. J. Mater. Res. Technol. 2022, 21, 388–403. [Google Scholar] [CrossRef]

- Motta, M.; Demir, A.G.; Previtali, B. High-speed imaging and process characterization of coaxial laser metal wire deposition. Addit. Manuf. 2018, 22, 497–507. [Google Scholar] [CrossRef]

- Miller, D.A.; Lagoudas, D.C. Influence of cold work and heat treatment on the shape memory effect and plastic strain development of NiTi. Mater. Sci. Eng. A 2001, 308, 161–175. [Google Scholar] [CrossRef]

- Khelfaoui, F.; Guénin, G. Influence of the recovery and recrystallization processes on the martensitic transformation of cold worked equiatomic Ti–Ni alloy. Mater. Sci. Eng. A 2003, 355, 292–298. [Google Scholar] [CrossRef]

- Su, P.; Wu, S. The four-step multiple stage transformation in deformed and annealed Ti49Ni51 shape memory alloy. Acta Mater. 2004, 52, 1117–1122. [Google Scholar] [CrossRef]

- Chang, S.; Wu, S.; Chang, G. Transformation sequence in severely cold-rolled and annealed Ti50Ni50 alloy. Mater. Sci. Eng. A 2006, 438, 509–512. [Google Scholar] [CrossRef]

- Todoroki, T.; Tamura, H. Effect of heat treatment after cold working on the phase transformation in TiNi alloy. Trans. Jpn. Inst. Met. 1987, 28, 83–94. [Google Scholar] [CrossRef]

- Zhu, J.; Wu, H.-H.; Wu, Y.; Wang, H.; Zhang, T.; Xiao, H.; Wang, Y.; Shi, S.-Q. Influence of Ni4Ti3 precipitation on martensitic transformations in NiTi shape memory alloy: R phase transformation. Acta Mater. 2021, 207, 116665. [Google Scholar] [CrossRef]

- Yao, X. An Advanced TEM Study on Quantification of Precipitates in Low Temperature Aged Ni-Ti Shape Memory Alloy. Doctoral Thesis, University of Antwerp, Antwerp, Belgium, 2019. [Google Scholar]

- Xu, B.; Sun, Y.; Yu, C.; Hu, J.; Zhu, J.; Xiong, J.; Kan, Q.; Wang, C.; Wang, Q.; Kang, G. Effect of Ni4Ti3 precipitates on the functional properties of NiTi shape memory alloys: A phase field study. Int. J. Plast. 2024, 177, 103993. [Google Scholar] [CrossRef]

- Chang, S.-H.; Lin, K.-H.; Wu, S.-K. Effects of cold-rolling/aging treatments on the shape memory properties of Ti49.3Ni50.7 shape memory alloy. Materials 2017, 10, 704. [Google Scholar] [CrossRef] [PubMed]

- Chang, S.; Wu, S.; Chang, G. Grain size effect on multiple-stage transformations of a cold-rolled and annealed equiatomic TiNi alloy. Scr. Mater. 2005, 52, 1341–1346. [Google Scholar] [CrossRef]

- Cho, Y.H.; Khan, M.S.; Goodwin, F.E.; Zhou, Y.N. Effect of torch angle and position on bead geometry and joint strength during arc-brazing of DP600. Int. J. Adv. Manuf. Technol. 2022, 121, 543–557. [Google Scholar] [CrossRef]

- Sun, L.; Jiang, F.; Huang, R.; Yuan, D.; Su, Y.; Guo, C.; Wang, J. Investigation on the process window with liner energy density for single-layer parts fabricated by wire and arc additive manufacturing. J. Manuf. Process. 2020, 56, 898–907. [Google Scholar] [CrossRef]

- Bastola, N.; Jahan, M.P.; Rangasamy, N.; Rakurty, C.S. A review of the residual stress generation in metal additive manufacturing: Analysis of cause, measurement, effects, and prevention. Micromachines 2023, 14, 1480. [Google Scholar] [CrossRef] [PubMed]

- Rathor, S.; Kant, R.; Singla, E. Effect of laser energy density on bead characteristics in wire-DED. Sādhanā 2024, 49, 104. [Google Scholar] [CrossRef]

- Piazza, S.; Merrigan, B.; Dowling, D.P.; Celikin, M. The effects of geometry and laser power on the porosity and melt pool formation in additively manufactured 316L stainless steel. Int. J. Adv. Manuf. Technol. 2020, 111, 1457–1470. [Google Scholar] [CrossRef]

- Huang, W.; Chen, S.; Xiao, J.; Jiang, X.; Jia, Y. Laser wire-feed metal additive manufacturing of the Al alloy. Opt. Laser Technol. 2021, 134, 106627. [Google Scholar] [CrossRef]

- Li, B.; Wang, B.; Zhu, G.; Zhang, L.; Lu, B. Low-roughness-surface additive manufacturing of metal-wire feeding with small power. Materials 2021, 14, 4265. [Google Scholar] [CrossRef] [PubMed]

- Shao, J.; Yu, G.; He, X.; Li, S.; Li, Z.; Wang, X. Process maps and optimal processing windows based on three-dimensional morphological characteristics in laser directed energy deposition of Ni-based alloy. Opt. Laser Technol. 2021, 142, 107162. [Google Scholar] [CrossRef]

- Abioye, T.; Folkes, J.; Clare, A. A parametric study of Inconel 625 wire laser deposition. J. Mater. Process. Technol. 2013, 213, 2145–2151. [Google Scholar] [CrossRef]

- Bozeman, S.C.; Isgor, O.B.; Tucker, J.D. Effects of processing conditions on the solidification and heat-affected zone of 309L stainless steel claddings on carbon steel using wire-directed energy deposition. Surf. Coat. Technol. 2022, 444, 128698. [Google Scholar] [CrossRef]

- Kisielewicz, A.; Pandian, K.T.; Sthen, D.; Hagqvist, P.; Bermejo, M.A.V.; Sikström, F.; Ancona, A. Hot-wire laser-directed energy deposition: Process characteristics and benefits of resistive pre-heating of the feedstock wire. Metals 2021, 11, 634. [Google Scholar] [CrossRef]

- Jurić, I.; Garašić, I.; Bušić, M.; Kožuh, Z. Influence of shielding gas composition on structure and mechanical properties of wire and arc additive manufactured Inconel 625. Jom 2019, 71, 703–708. [Google Scholar] [CrossRef]

- Bieg, F.; Scheider, D.; Kledwig, C.; Maucher, C.; Möhring, H.-C.; Reisacher, M. Development of a laser preheating concept for directed energy deposition. J. Laser Appl. 2023, 35, 042052. [Google Scholar] [CrossRef]

- Akbari, M.; Kovacevic, R. An investigation on mechanical and microstructural properties of 316LSi parts fabricated by a robotized laser/wire direct metal deposition system. Addit. Manuf. 2018, 23, 487–497. [Google Scholar] [CrossRef]

- Abadi, S.N.R.; Mi, Y.; Kisielewicz, A.; Sikström, F.; Choquet, I. Influence of laser-wire interaction on heat and metal transfer in directed energy deposition. Int. J. Heat Mass Transf. 2023, 205, 123894. [Google Scholar] [CrossRef]

- Bassis, M.; Kotliar, A.; Koltiar, R.; Ron, T.; Leon, A.; Shirizly, A.; Aghion, E. The effect of a slow strain rate on the stress corrosion resistance of austenitic stainless steel produced by the wire laser additive manufacturing process. Metals 2021, 11, 1930. [Google Scholar] [CrossRef]

- Bassis, M.; Ron, T.; Leon, A.; Kotliar, A.; Kotliar, R.; Shirizly, A.; Aghion, E. The Influence of Intralayer Porosity and Phase Transition on Corrosion Fatigue of Additively Manufactured 316L Stainless Steel Obtained by Direct Energy Deposition Process. Materials 2022, 15, 5481. [Google Scholar] [CrossRef]

- Saedi, S.; Turabi, A.S.; Andani, M.T.; Haberland, C.; Karaca, H.; Elahinia, M. The influence of heat treatment on the thermomechanical response of Ni-rich NiTi alloys manufactured by selective laser melting. J. Alloys Compd. 2016, 677, 204–210. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, J.; Coddet, C. Microstructure and transformation behavior of in-situ shape memory alloys by selective laser melting Ti–Ni mixed powder. J. Mater. Sci. Technol. 2013, 29, 863–867. [Google Scholar] [CrossRef]

- Andani, M.T.; Haberland, C.; Walker, J.; Elahinia, M. An investigation of effective process parameters on phase transformation temperature of nitinol manufactured by selective laser melting. In Smart Materials, Adaptive Structures and Intelligent Systems; American Society of Mechanical Engineers: New York City, NY, USA, 2014. [Google Scholar]

- Bormann, T.; Schumacher, R.; Müller, B.; Mertmann, M.; De Wild, M. Tailoring selective laser melting process parameters for NiTi implants. J. Mater. Eng. Perform. 2012, 21, 2519–2524. [Google Scholar] [CrossRef]

- Wei, S.; Zhang, J.; Zhang, L.; Zhang, Y.; Song, B.; Wang, X.; Fan, J.; Liu, Q.; Shi, Y. Laser powder bed fusion additive manufacturing of NiTi shape memory alloys: A review. Int. J. Extrem. Manuf. 2023, 5, 032001. [Google Scholar] [CrossRef]

- Saedi, S.; Moghaddam, N.S.; Amerinatanzi, A.; Elahinia, M.; Karaca, H.E. On the effects of selective laser melting process parameters on microstructure and thermomechanical response of Ni-rich NiTi. Acta Mater. 2018, 144, 552–560. [Google Scholar] [CrossRef]

- Mahmud, A.S.; Wu, Z.; Yang, H.; Liu, Y. Effect of cold work and partial annealing on thermomechanical behaviour of Ti-50.5 at% Ni. Shape Mem. Superelasticity 2017, 3, 57–66. [Google Scholar] [CrossRef]

| Alloy | Ni | Ti | C | O | N | Co | Cu | Cr | Fe | Nb |

|---|---|---|---|---|---|---|---|---|---|---|

| NiTi Wire | 55.94 | Balance | 0.0317 | 0.0300 | 0.0006 | 0.0001 | 0.0008 | 0.0005 | 0.0085 | 0.0001 |

| NiTi Substrate | 55.90 | Balance | 0.0010 | 0.0290 | 0.0010 | 0.0030 | 0.0050 | 0.0030 | 0.0020 | 0.0030 |

| Ms (°C) | Mf (°C) | As (°C) | Af (°C) | |

|---|---|---|---|---|

| NiTi wire | 10.12 | −18.32 | −19.24 | 14.46 |

| Laser power, P (W) | 400, 600–1000 |

| Transverse speed, V (mm/min) | 300, 450, 600, 750, 900 |

| Linear energy density, (J/mm) | 26.66–200 |

| Parameter Set # | Laser Power (W) | Transverse Speed (mm/min) | Wire Feed Rate (mm/s) | Energy Density (J/mm3) |

|---|---|---|---|---|

| 1 | 600 | 600 | 9.8 | 60 |

| 2 | 700 | 600 | 9.8 | 70 |

| 3 | 700 | 750 | 12.25 | 56 |

| 4 | 700 | 900 | 14.75 | 46.66 |

| 5 | 800 | 900 | 14.75 | 53.33 |

| Alloy | Ms (°C) | Mf (°C) | As (°C) | Af (°C) |

|---|---|---|---|---|

| NiTi wire | 10.12 | −18.32 | −19.24 | 14.46 |

| NiTi cube (Ev = 56 J/mm3) | −44.2 | −73.84 | −40.75 | −4.53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dabbaghi, H.; Taheri Andani, N.; Pourshams, M.; Sojoodi, M.; Poorganji, B.; Elahinia, M. Processability and Material Behavior of NiTi Shape Memory Alloys Using Wire Laser-Directed Energy Deposition (WL-DED). J. Manuf. Mater. Process. 2025, 9, 15. https://doi.org/10.3390/jmmp9010015

Dabbaghi H, Taheri Andani N, Pourshams M, Sojoodi M, Poorganji B, Elahinia M. Processability and Material Behavior of NiTi Shape Memory Alloys Using Wire Laser-Directed Energy Deposition (WL-DED). Journal of Manufacturing and Materials Processing. 2025; 9(1):15. https://doi.org/10.3390/jmmp9010015

Chicago/Turabian StyleDabbaghi, Hediyeh, Nasrin Taheri Andani, Mohammad Pourshams, Mahyar Sojoodi, Behrang Poorganji, and Mohammad Elahinia. 2025. "Processability and Material Behavior of NiTi Shape Memory Alloys Using Wire Laser-Directed Energy Deposition (WL-DED)" Journal of Manufacturing and Materials Processing 9, no. 1: 15. https://doi.org/10.3390/jmmp9010015

APA StyleDabbaghi, H., Taheri Andani, N., Pourshams, M., Sojoodi, M., Poorganji, B., & Elahinia, M. (2025). Processability and Material Behavior of NiTi Shape Memory Alloys Using Wire Laser-Directed Energy Deposition (WL-DED). Journal of Manufacturing and Materials Processing, 9(1), 15. https://doi.org/10.3390/jmmp9010015