Abstract

This study investigates the impact of different filler wires (ER5356, ER4043, and ER4047) on the microstructural and mechanical properties of EN AW-6082 Al alloy joints produced by tungsten inert gas (TIG) welding. Butt-welded samples with a single V-groove joint configuration were prepared using optimized welding parameters. The welded samples were subjected to visual inspection, microstructural analysis, hardness testing, tensile testing, and impact toughness evaluation. The results showed that all the welds were free of visible defects. Microstructural examination revealed that the ER5356 filler produced the finest grain structure of 18.03 ± 3 μm, while ER4047 resulted in the coarsest grains of 36.07 ± 5 μm. Correspondingly, the joints made with ER5356 exhibited the highest tensile stress of 278 ± 6 MPa, yield stress of 219 ± 5.4 MPa, hardness values of 72.7 ± 5 HV, and welding efficiency of 86.07%, whereas those made with ER4047 produced the lowest values. The hardness in the weld region was lower than that in the parent metal and heat-affected zone for all samples. However, ER4047 welds demonstrated superior impact toughness and strain-hardening capacity. The findings underscore the importance of filler metal selection in tailoring mechanical properties for high-performance applications.

1. Introduction

Aluminum alloys play a pivotal role across industries due to their excellent strength-to-weight ratio, corrosion resistance, and versatility in fabrication [1,2,3]. Among these, AA6082, a medium-strength alloy belonging to the 6xxx series, is widely recognized for its superior mechanical properties and weldability. Its advantages include being lightweight and having a higher tensile strength-to-weight ratio, high toughness, good weldability, good formability, recyclability, high corrosion resistance, high thermal conductivity, and low cost [4,5,6]. The most popular medium-strength aluminum alloy, AA6082 (an Al–Mg–Mn alloy), has gained widespread recognition for the creation of lightweight structures [7,8]. Welding heat-treatable aluminum alloys poses significant challenges due to the inherent alterations in microstructure during the welding process. These alloys, including those in the 6xxx series, are highly sensitive to thermal cycles, which can lead to the dissolution or coarsening of strengthening precipitates in the weld zone (WZ) and heat-affected zone (HAZ). This results in a localized reduction in mechanical properties, such as tensile strength and hardness, compromising the overall structural integrity of the joint [9,10]. Addressing these challenges requires optimized welding techniques to restore strength and minimize adverse effects on performance. Tungsten inert gas (TIG) welding is widely regarded as a preferred method for joining aluminum alloys due to its precision and versatility [11,12]. This technique uses a non-consumable tungsten electrode and an inert shielding gas, typically argon, to create high-quality welds. TIG welding is particularly advantageous for both thin and thick aluminum plates, as it provides excellent control over heat input, reducing the risk of warping in thinner materials while ensuring deep penetration and strong joints in thicker sections [12,13,14]. Therefore, many different metals, including aluminum, have been subjected to welding [15,16,17]. Ishak et al. [18] conducted a detailed examination of the effect of ER5356, ER4043, and ER4047 filler metals on AA6061 alloy TIG-welded joints. Their study revealed that specimens welded using ER5356 filler metal exhibited higher macrohardness and tensile stress values than those welded using ER4043 and ER4047. Specifically, they found that the tensile stress for joints welded with ER5356 was 223 MPa, compared to 214 MPa for ER4043 and 209 MPa for ER4047. The macrohardness values in the weld zone (WZ) followed a similar trend, with ER5356 exhibiting the highest hardness. Verma et al. [19] investigated the effects of ER4043 and ER5356 filler wires on dissimilar AA5083-O and AA6061-T6 joints welded by MIG welding. They observed a reduction in the tensile strength of MIG joints compared to the both AA5083-O and AA6061-T6 base materials. In addition, they concluded that the joints welded with ER5356 demonstrated superior tensile strength (221 MPa) and elongation (8.2%) compared with those welded with ER4043 (207 MPa and 6.5%, respectively). They attributed this to the formation of finer structures and more regular distribution of Mg2Si precipitates in ER5356 welds. Cao et al. [20] provided a comprehensive review of the metallurgical aspects of laser welding aluminum alloys, including the effects of filler metals on microstructure and defect formation. They noted that the filler metal composition significantly influenced the grain structure, precipitation behavior, and susceptibility to hot cracking in the weld zone. For instance, they found that Si-containing fillers (such as ER4043) tended to promote columnar grain growth, whereas Mg-containing fillers (such as ER5356) encouraged equiaxed grain formation. Kah et al. [21] specifically investigated hot cracking in AA6005 and AA6082 welds. They discovered that proper filler metal selection could mitigate cracking tendencies by altering solidification behavior and intermetallic compound formation. Their study showed that the ER5356 filler metal was more effective in reducing hot cracking susceptibility than ER4043 because of its higher Mg content, which promotes a more favorable solidification sequence. Gadallah et al. [22] studied the influences of filler metals on the corrosion behavior and microstructure of similar and dissimilar aluminum alloy GTA welded joints. They found that the filler metal composition influenced the morphology and distribution of intermetallic precipitates, which in turn affected the corrosion behavior. Their research showed that the ER5356 filler metal produced welds with better corrosion resistance than ER4043, which was attributed to the formation of a more protective oxide layer. Although previous research has explored the impact of filler metals on various aluminum alloys, there is a gap in understanding their specific effects on AA6082. This study correlates the microstructural changes induced by different filling rods with the mechanical characteristics and fracture morphology of EN AW-6082 joints. By comprehensively examining the effects of ER5356, ER4043, and ER4047 filler metals on AA6082 TIG-welded joints, this study provides an understanding of the optimization of welding parameters for this widely used aluminum alloy.

2. Materials and Methods

2.1. Materials Used and Welding Operation

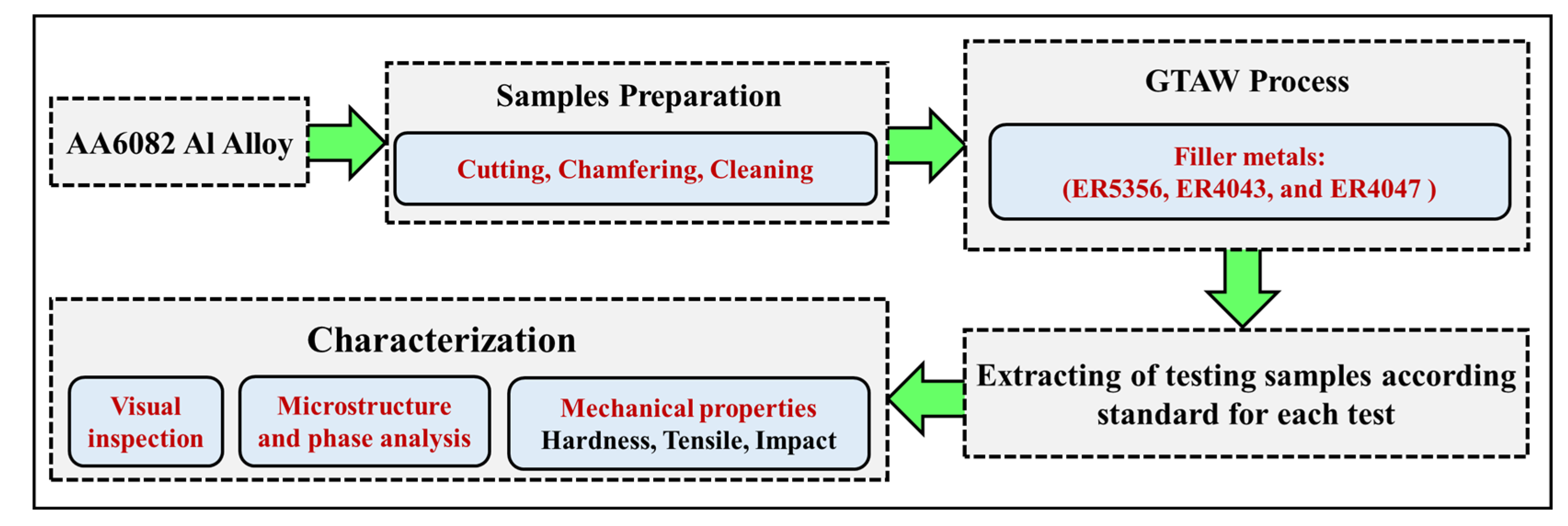

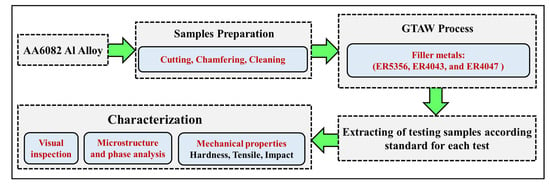

The materials used in this study were an Al–Mg–Mn Al alloy with a 6 mm thickness (supplied by the Aluminum Company Egyptalum in Egypt) and various welding filler alloys, including ER5356 (Al—4.9%Mg), ER4043 (Al—5.3%Si), and ER4047 (Al—13%Si), with a diameter of 3.2 mm. The chemical compositions and mechanical characteristics of the base material (BM) and welding wires are presented in Table 1 and Table 2, respectively. The methodological steps followed in this study are outlined in the flowchart shown in Figure 1.

Table 1.

Chemical compositions of the Al–Mg–Mn alloy and welding fillers, wt.%.

Table 2.

Mechanical characteristics of the Al–Mg–Mn alloy and welding fillers.

Figure 1.

Flowchart of experimental steps conducted before and after welding.

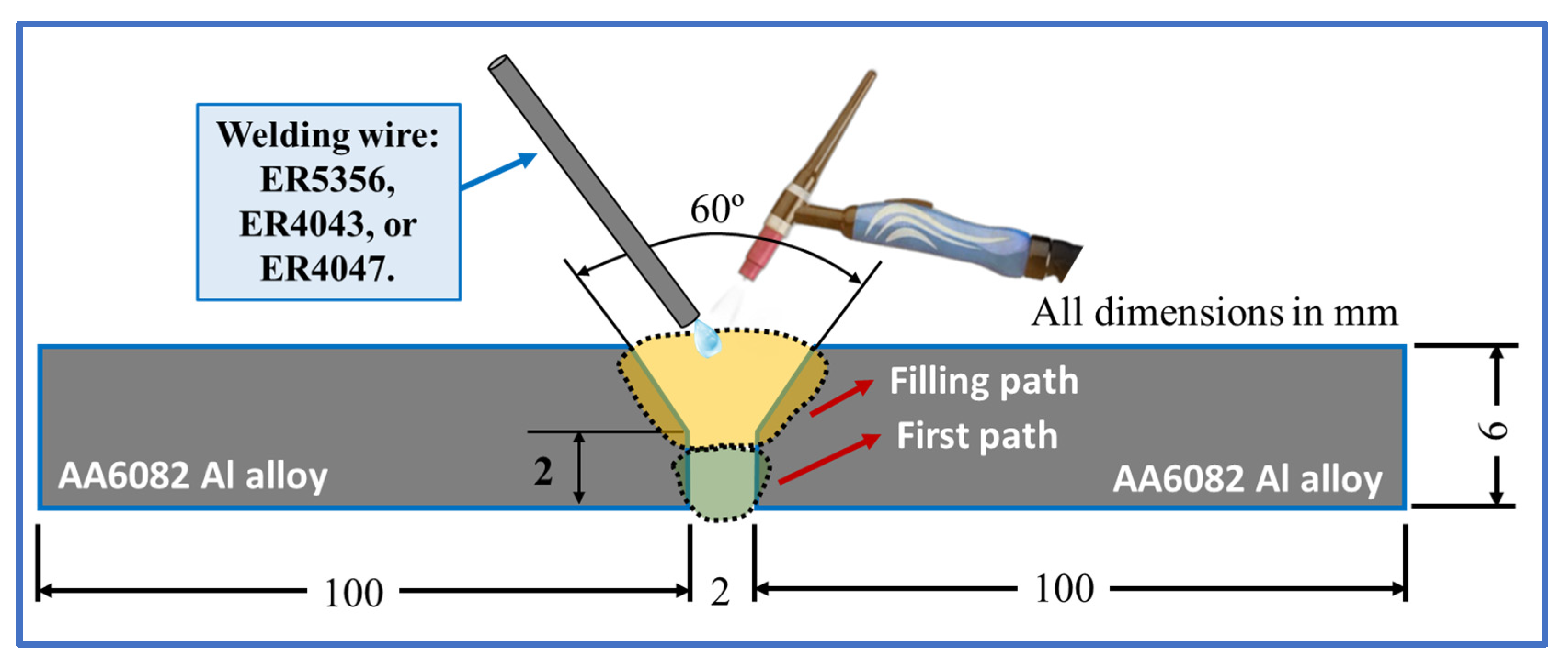

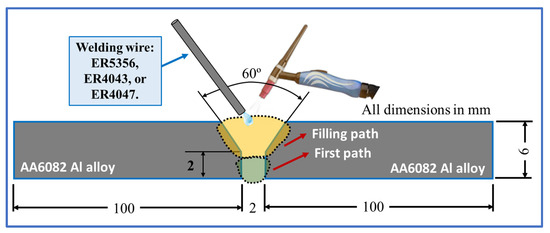

The BM was fabricated for GTAW with dimensions of 150 mm in length and 100 mm in width using vertical milling machining. Butt welding featured a single V-groove with a root gap of 2 mm, root face of 2 mm, and unilateral bevel angle of 30°, according to American Welding Society (AWS) code D1.2/D1.2M [18,23], as depicted in Figure 2. Before welding, the joints were cleaned using a wire brush and acetone to remove rust, oil, and other contaminants from the welding surfaces. Pure Ar, with a purity of 99.99%, was employed as the shielding gas. In this study, an AWS EWTH-2 non-consumable tungsten electrode with a 2.4 mm diameter was utilized. Table 3 provides an overview of the welding parameters for all the welding samples. The welding parameters used in this study, as detailed in Table 3, were selected based on standard practices employed at Petrojet Co., Suez, Egypt, where all welding parameters were conducted in the company’s laboratories.

Figure 2.

Schematic of the GTAW joints filled with ER5356, ER404, and ER4047 filler metals.

Table 3.

TIG welding parameters for Al–Mg–Mn alloy.

2.2. Microstructure Characterization

The microstructures of the manufactured butt welds were investigated by analyzing metallographic samples prepared from transverse weld line cross sections. Subsequently, the welded specimens were ground and polished with sandpaper of various grit sizes (1000, 1200, 1500, and 2400 grit) according to the metallographic practice standard ASTM E3-11 [24]. In addition, the microstructures of the different welding areas, including the weld zone, HAZ, and base metal, were analyzed using a modified Keller reagent (3 mL HCl, 5 mL HNO3, 2 mL HF, and 190 mL distilled H2O) [25] and an optical microscope (OM; Nikon Instruments Inc., Tokyo, Japan) coupled with a scanning electron microscope (SEM; JEOL, Tokyo, Japan). The grain sizes of all the solder joints prepared were measured using the ImageJ program (1.54d version, National Institutes of Health, North Bethesda, MD, USA) from photomicrographs taken under polarized light using an optical microscope.

2.3. Mechanical Property Tests

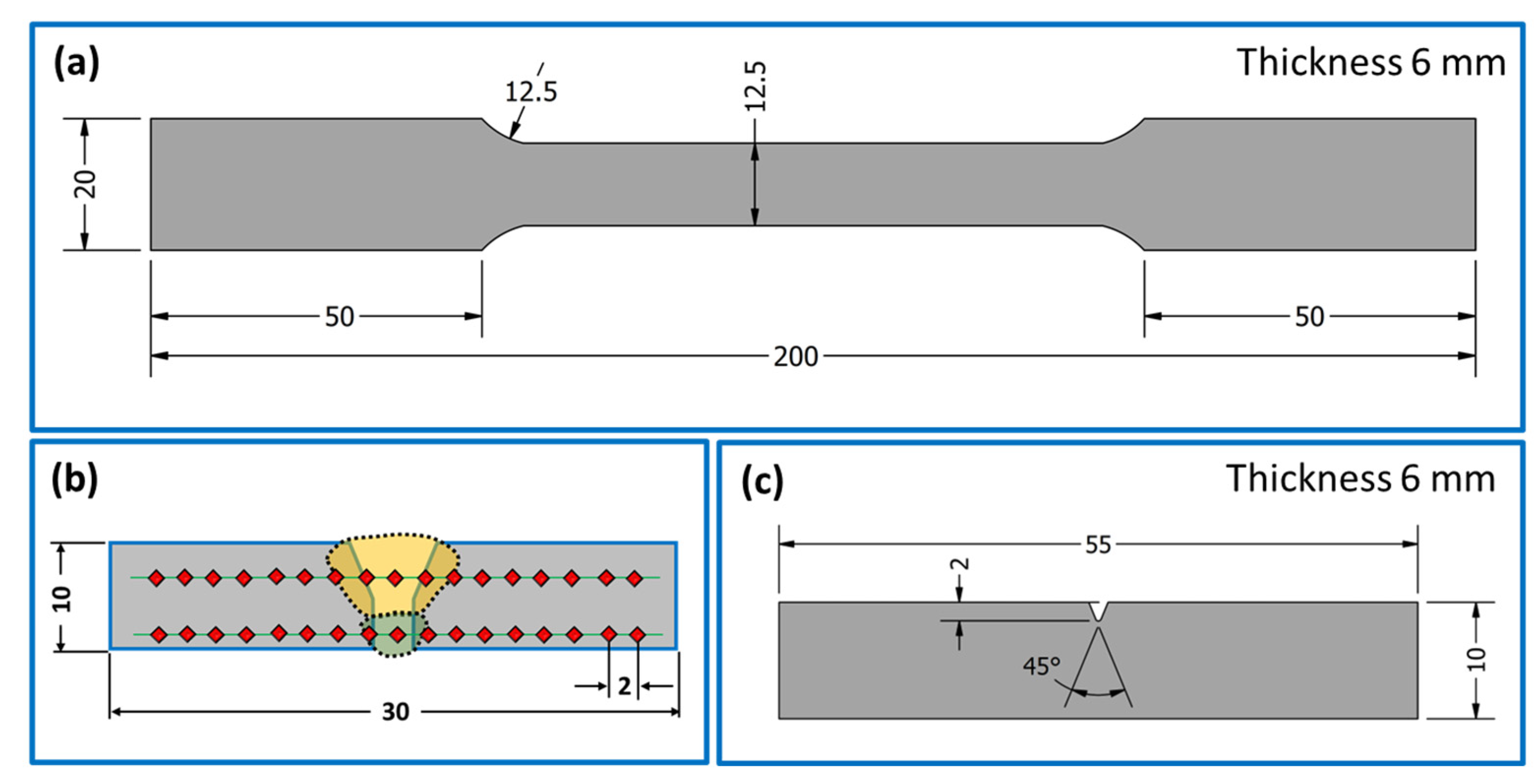

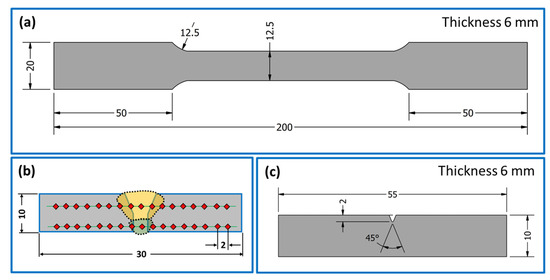

Hardness measurements along the traverse weld line section were taken in two lines (Figure 3b) using a Vickers hardness tester (HWDV-75, TTS Unlimited, Osaka, Japan) with a load of 500 g and a 15 s residence time; the distance between the two points was 1 mm. Hardness samples were cut and prepared according to the ASTM E384-09 [26]. Tensile tests were conducted using a tensile testing machine (WDW-300D Testing Machine, 30-ton, Dongguan, China) to determine the tensile strength of all weld specimens. Tensile samples were prepared according to ASTM E-8M-04 (Figure 3a) [27]. The strain rate was set to 5 mm/min, and the ultimate tensile stress (UTS), yield stress (YS), and elongation (El%) were recorded based on the parameters of different welding wires. Finally, a Charpy impact test was performed at room temperature using a JB-300B Charpy pendulum impact-testing machine. Impact test specimens were prepared according to ASTM E23-01 with a thickness of 6 mm (Figure 3c).

Figure 3.

Schematic depiction of the testing samples: (a) tensile, (b) hardness, and (c) Charpy impact tests.

3. Results and Discussion

3.1. Visual Inspection

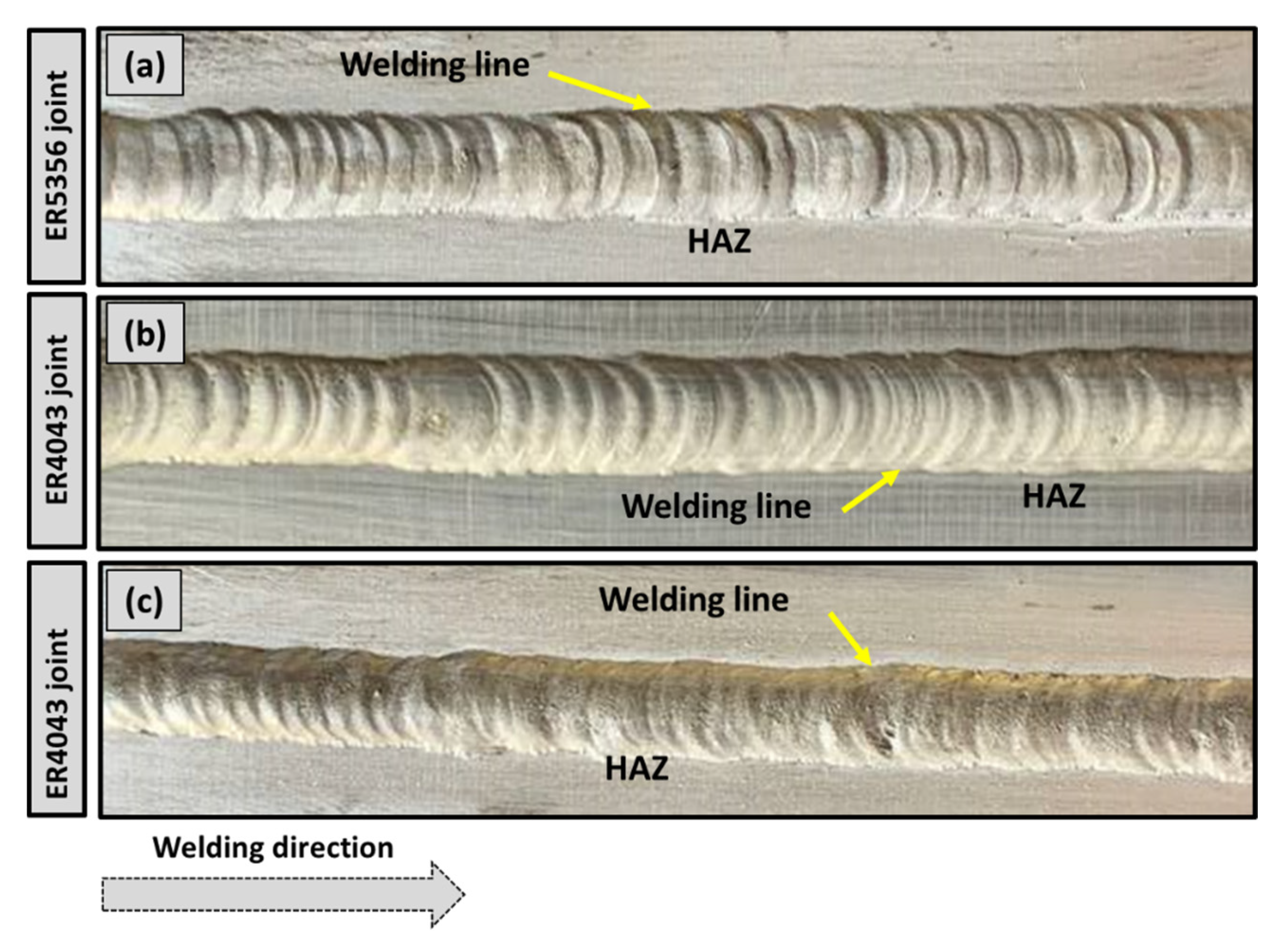

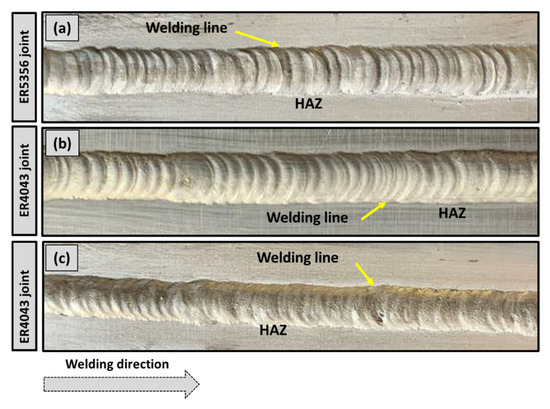

The surface morphologies of the TIG-welded joints of the AA6082 Al alloy filled with ER5356, ER4043, and ER4047 filler rods are illustrated in Figure 4. Additionally, visual inspection emphasized the significance of the welding procedure, welding parameters, welder qualifications, and, ultimately, the weldability of aluminum alloys. First, the filler metals, which sometimes fluctuated slightly during welding, were consistently melted owing to the uniform energy distribution of the TIG. As a result, the TIG welding procedure enhanced the welding arc stability. Second, the V-shaped groove of the BM improved the ability of the filler to spread. Consequently, this technique can provide a well-welded double-faced appearance. Based on the visual examination test results, all welded joints exhibited an acceptable welding appearance with smooth, consistent semicircular traces. However, the width of the joint welded with ER5356 was greater than that of the joints welded with the ER4043 and ER4047 filling rods. Specifically, ER5356, ER4043, and ER4047 welding wires exhibited average weld bead widths of 9.44, 9.1, and 8.79 mm, respectively, as shown in Figure 4a–c. These results can be attributed to the high welding temperature and low welding speed (welder hand speed) during welding. Nonetheless, neither cracks nor porosity were observed on the top surface of the samples after welding, as depicted in Figure 4. Despite this, the welded joint images shown in Figure 4a,b display irregularities in the welding line owing to unstable hand movements of the welders during the welding process.

Figure 4.

Visual inspection of welded samples using various filling rods: (a) ER5356, (b) ER4043, and (c) ER4047.

3.2. Microstructure Investigation

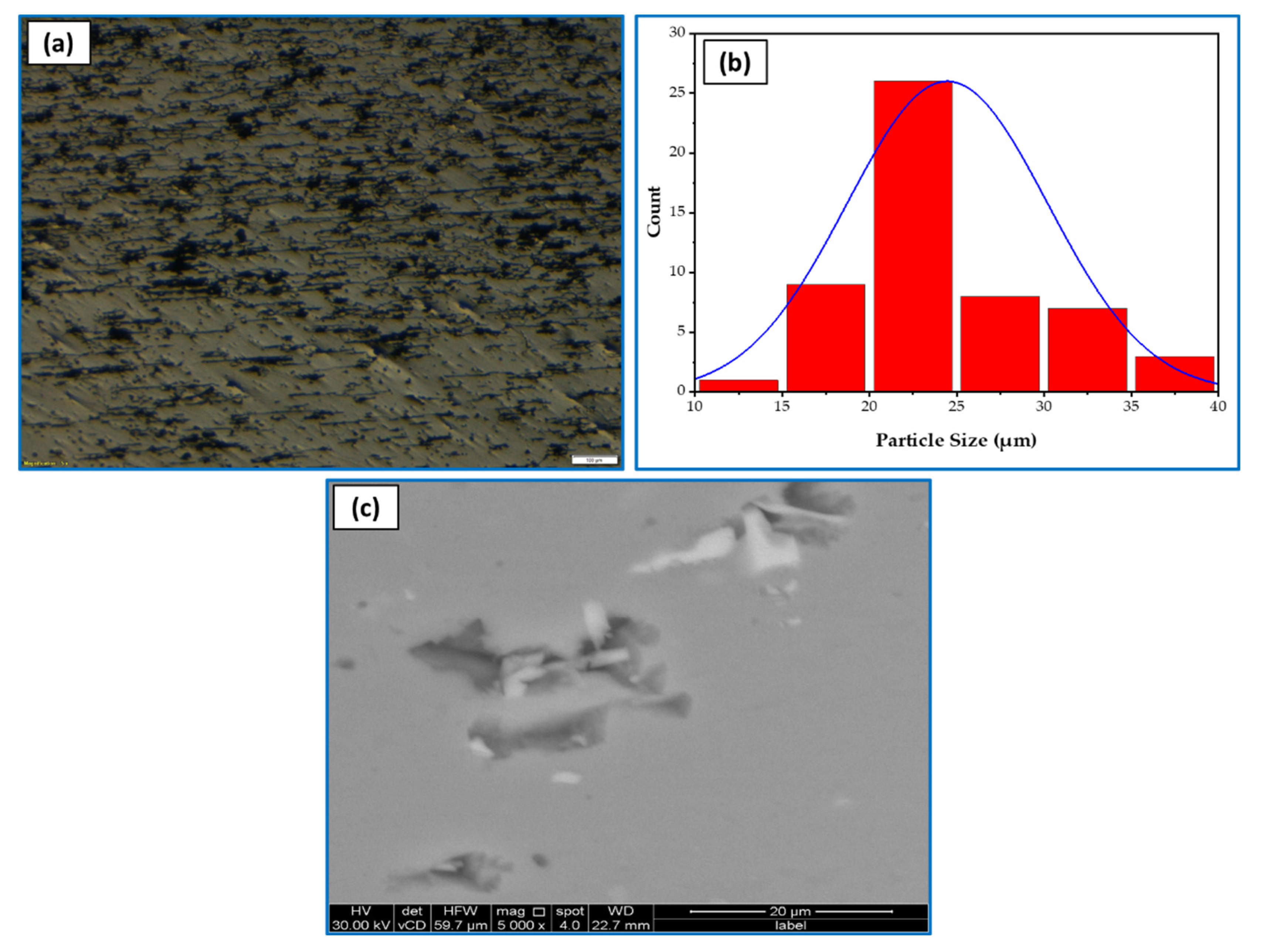

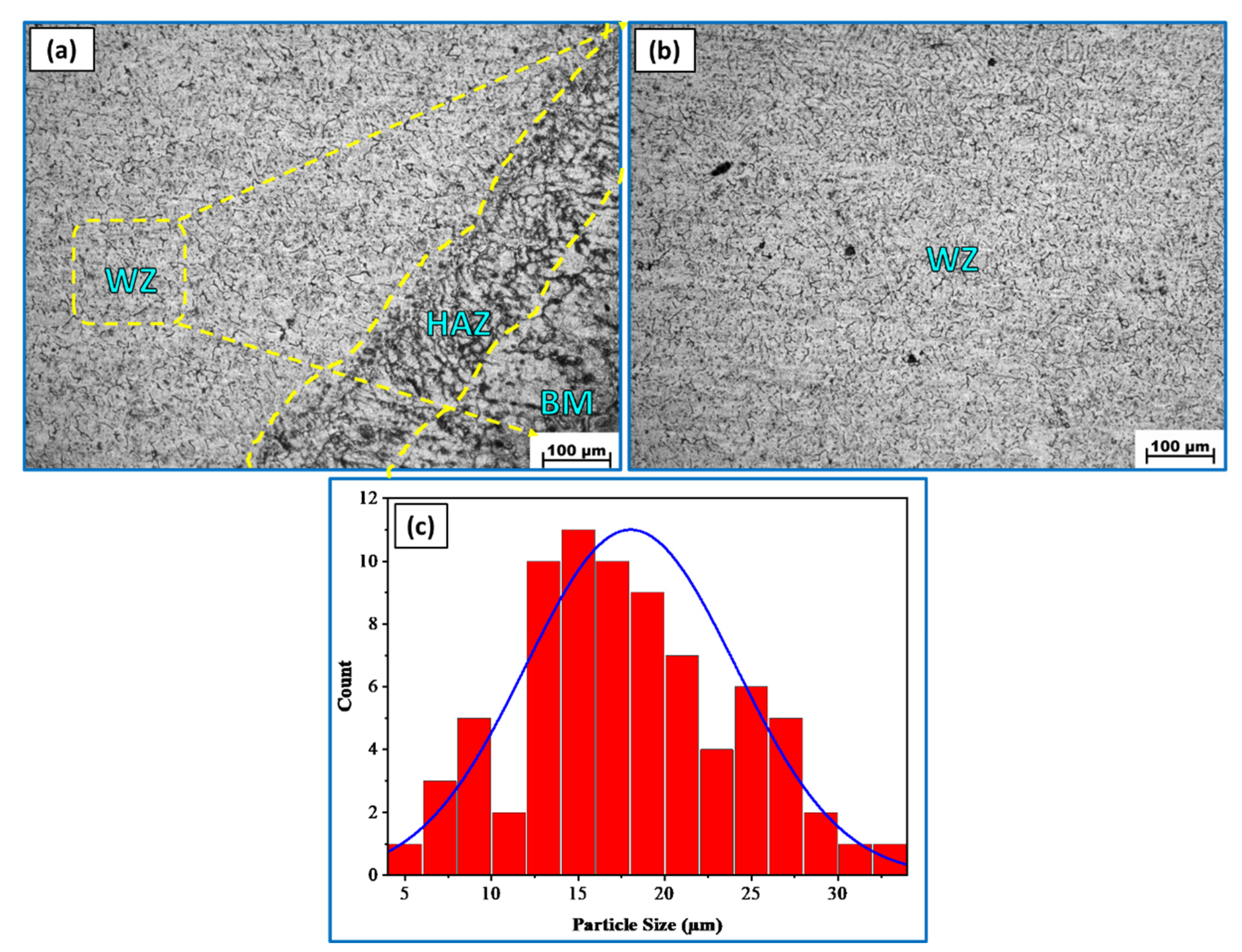

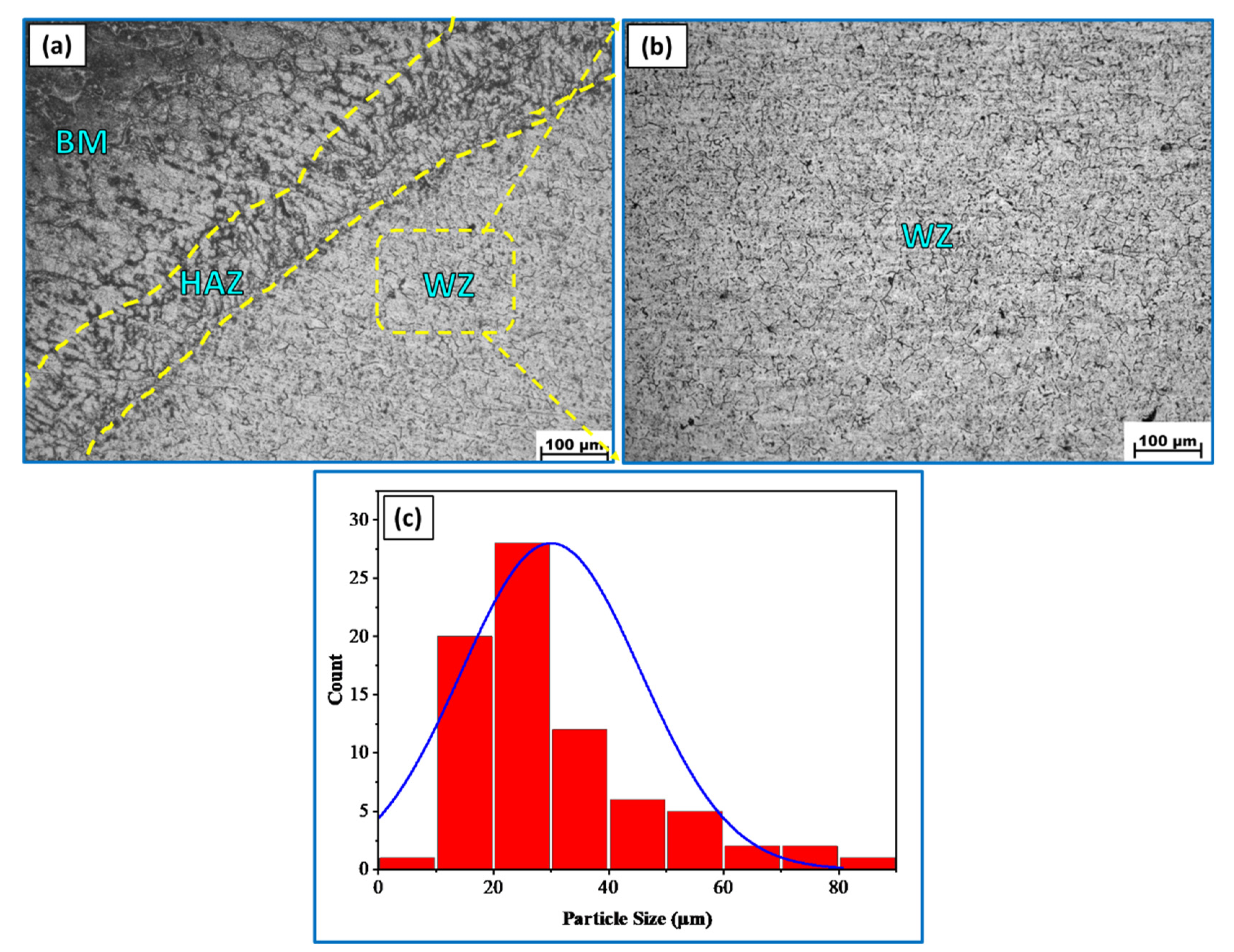

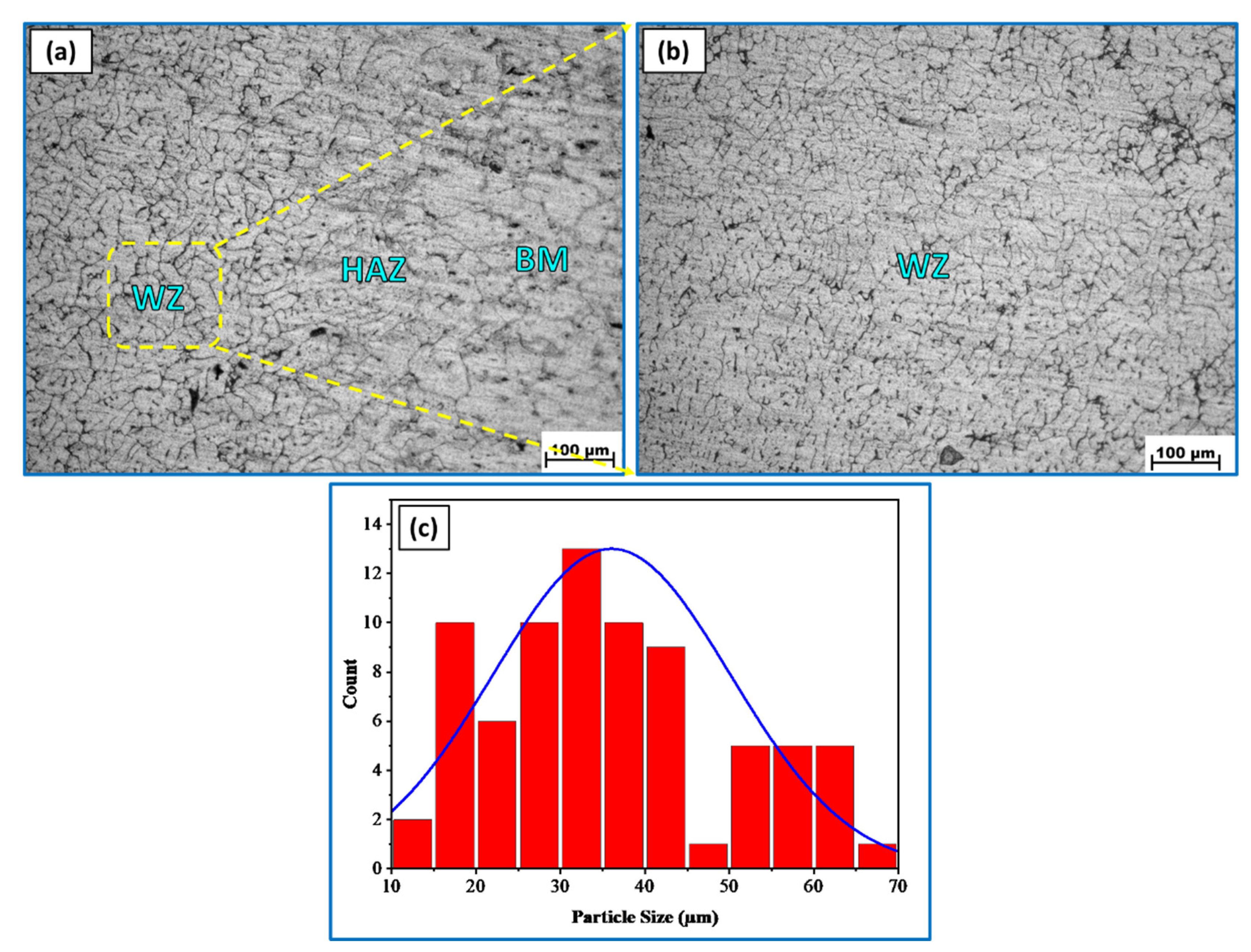

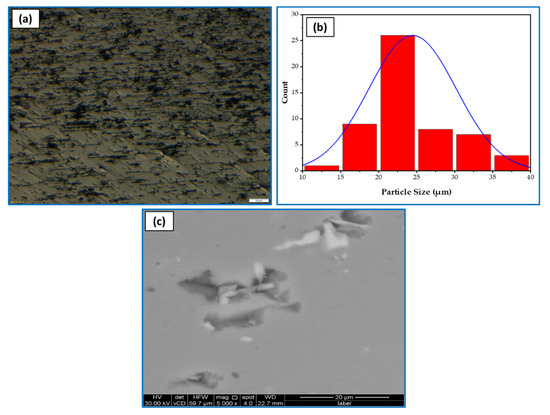

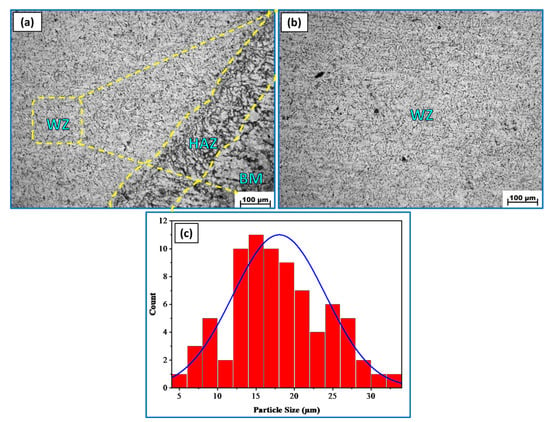

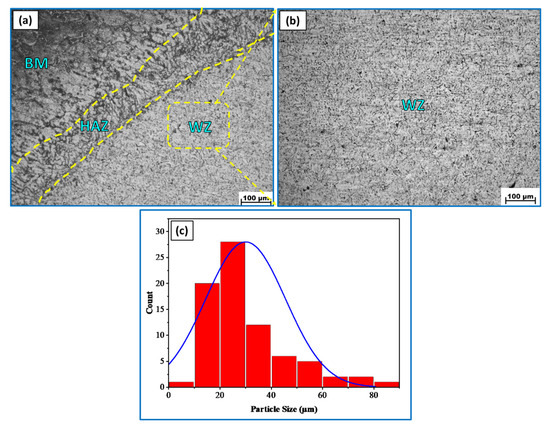

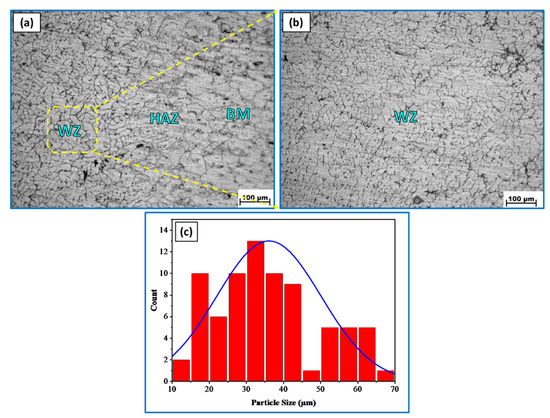

Figure 5 illustrates the microstructural morphology of the base material made from the AA6082 Al alloy. Furthermore, the BM region exhibited grains that were evenly distributed along the rolling direction together with a matrix phase (Figure 5a). The white region depicts the α-Al solid solution in the diagram, whereas the black dots denote the reinforced phase. Furthermore, it is important to observe that adjacent to the dendritic limits there is a complex network of aluminum precipitates intertwined with a significant proportion of Mg2Si eutectic, which is visually represented as black [28]. The grain size results of BM after estimation and analysis by the linear intercept method and ImageJ program showed that the average grain size was 24.46 ± 4 µm [29], as depicted in Figure 5b. Figure 5c depicts the intermetallic precipitate of the Mg2Si phase in the BM. The filler metal used in the weld significantly affects the microstructural morphology of the Al alloy. The different areas within the welded specimen, which were formed using different welding wires, are labeled HAZ, WZ, and BM in Figure 6a, Figure 7a and Figure 8a. Within the HAZ, the BM that has not undergone fusion and is exposed to the thermal cycle of welding, the development of characteristics, and the morphology of the microstructure differ from those of both the BM and WZ. The microstructure mostly depends on the heat cycle, which causes disintegration and deposition of the second phase. The heat-affected zone experienced significant thermal cycling owing to intense welding, resulting in recrystallization. The fibrous arrangement vanished, resulting in the formation of coarse and irregular dendritic structures. Small diffuse phases were formed in the spaces between the grains, and the reinforcing phase was dispersed evenly [30]. As shown in Figure 6b, Figure 7b and Figure 8b, the appearance of a locally dense distribution causes distinct black spots for the welding operation to be broken oxide in the state flow in a nonhomogeneous apportionment. Because ER4043 and ER4047 filler metals contain less Mg than ER5356 filler metals, the precipitation of Mg2Si increases with increasing Mg content in welding wires [31]. Gadallah et al. [22] showed that the potential cause of cracking during the solidification of joints filled by ER4043 and ER4047 welding rods at the WZ may be an increase in Si concentration as a result of segregation in the mushy zones, resulting in a longer solidification range. The presence of elements such as silicon and magnesium in the weldment had opposing effects on solidification cracking. While a higher Si concentration increases the probability of cracking during solidification, a higher Mg concentration in the filler metal of ER5356 decreases this probability [20]. The filler wire point of fusion and crystallization with the substrate is known as the WZ. In the aluminum alloy WZ, the α-Al solid solution dominated the phase composition, as shown in Figure 6b, Figure 7b and Figure 8b. In addition, The ER5356 filler consistently produced the finest grain structure with an average size of 18.03 ± 3 μm. In comparison, ER4043 resulted in notably larger grains averaging 30.01 ± 2 μm, while ER4047 produced the coarsest microstructure with grains averaging 36.07 ± 5 μm, as shown in Figure 6c, Figure 7c and Figure 8c. Different filler metals had a significant effect on both the microstructure and the Mg2Si phase distribution. The growth of dendritic crystals in ER5356 filler metals was reduced when the Mg concentration exceeded 4.5% [32]. This caused the WZ crystals to disperse uniformly and adopt a cell-like appearance. Under these welding variables, an excessive concentration of Si in the welded joints filled with the filler metals ER4043 and ER4047 negatively affected the deposition of the Mg2Si strengthening phase and decreased the mechanical characteristics of the joint. Thus, because Si and Mg were the primary elements added to AA6082 Al alloys via welding wires, Mg2Si was the primary strengthening phase [21].

Figure 5.

(a) Microstructural morphology of the AA6082 Al alloy, (b) grain analysis, and (c) SEM image of intermetallic precipitates.

Figure 6.

(a) Interface of microstructural morphology for a welded joint with ER5356 filler metal, (b) weld region, and (c) grain size analysis of the weld region.

Figure 7.

(a) Interface of microstructural morphology for a welded joint with ER4043 filler metal, (b) weld region, and (c) grain size analysis of the weld region.

Figure 8.

(a) Interface of the microstructure morphology for a welded sample using an ER4047 welding rod, (b) weld region, and (c) grain size analysis of the weld region.

3.3. Mechanical Characteristics

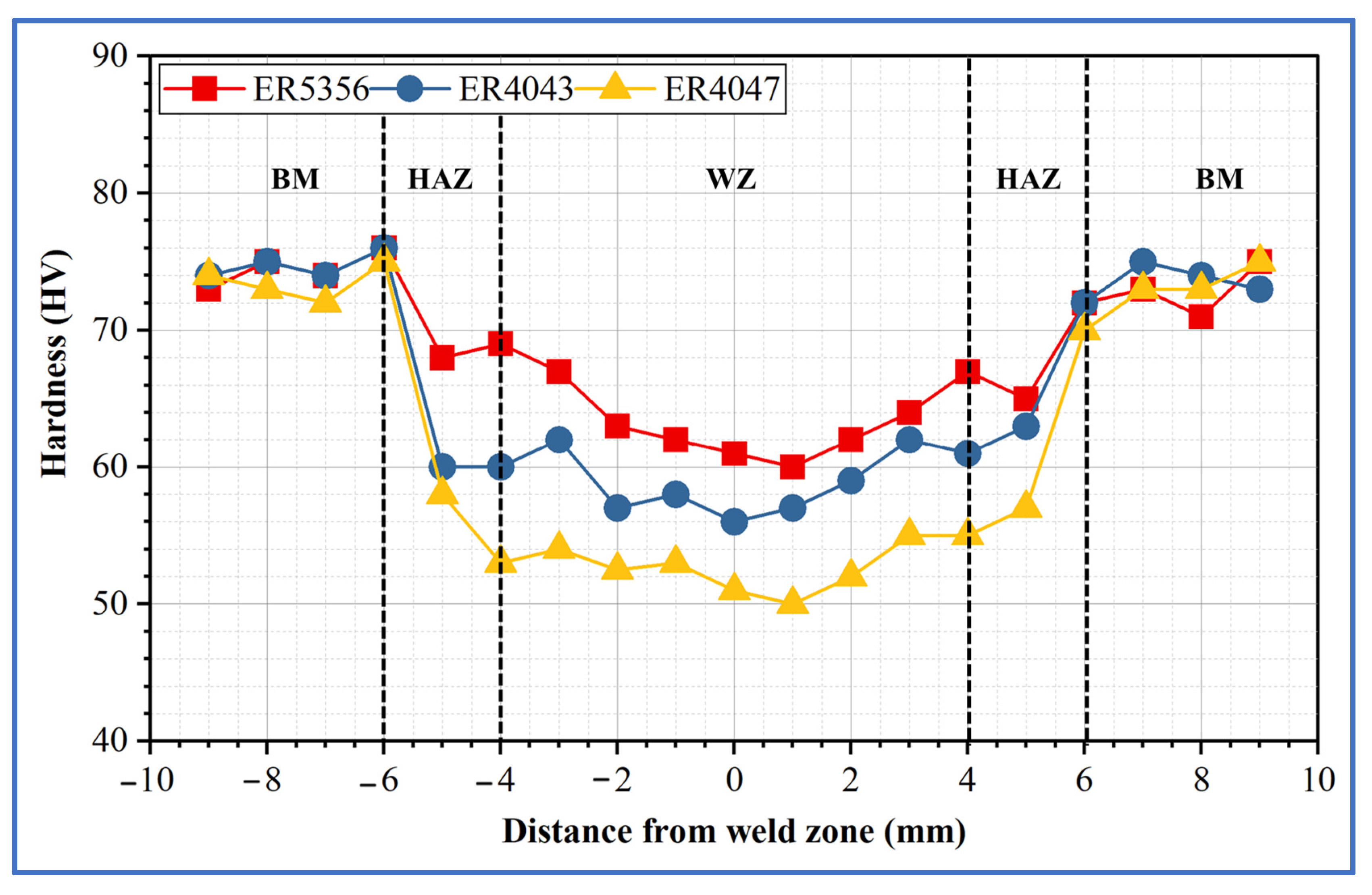

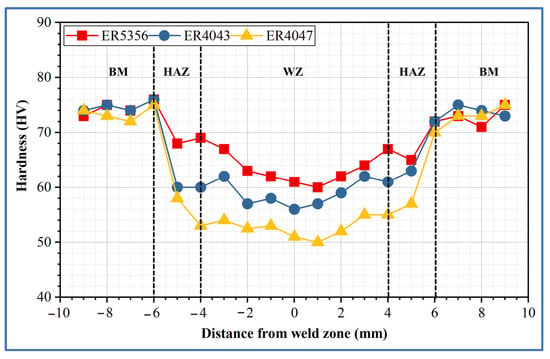

Figure 9 illustrates the hardness distribution across the welded joints of AA6082 aluminum alloy produced using different filler metals (ER5356, ER4043, and ER4047) in TIG welding. The hardness results depict the Vickers hardness values measured along the transverse cross-section of the welded samples encompassing the BM, HAZ, and WZ. The results reveal a consistent pattern across all samples, with the WZ exhibiting a lower hardness than the BM and HAZ. Specifically, the average hardness values in the WZ for joints welded with ER5356, ER4043, and ER4047 filler metals were 72.7 ± 5 HV, 63.4 ± 2 HV, and 52.8 ± 4 HV, respectively. The HAZ demonstrated slightly higher hardness values of 78.7 ± 4 HV, 67.5 ± 7 HV, and 58.5 ± 3 HV for the respective filler metals. This hardness distribution can be attributed to the microstructural changes induced by the welding process, particularly the formation and distribution of strengthening precipitates, such as Mg2Si. The superior hardness observed in samples welded with ER5356 filler metal aligns with the findings of Ishak et al. [18], who reported higher macrohardness values in AA6061 alloy joints welded with ER5356 compared to those welded with ER4043 and ER4047. During the TIG welding process, thermal cycling and the composition of the filler metal significantly influenced the precipitation of strengthening phases, such as Mg₂Si. Variations in the distribution of these precipitates across the welded joint contributed to the differences in the hardness values. Specifically, the WZ showed localized decreases in hardness due to lower concentrations of Mg₂Si precipitates, as suggested by Manti et al. [2] in their study on Al–Mg–Si weldments, as evident in the middle region of Figure 9 (x-axis range: −4 to 4 mm). In contrast, the HAZ experienced localized hardening owing to thermal gradients, which can induce partial dissolution and subsequent re-precipitation of secondary phases, as observed by Kostrivas and Lippold [33] in their investigation of aluminum alloy weld fusion boundary microstructures. It can be concluded that the samples welded with the ER5356 filler metal exhibited the highest hardness values in the weld zone, surpassing those welded with ER4043 by 14.7% and ER4047 by 37.7%.

Figure 9.

Hardness values of welded joints using various welding wires.

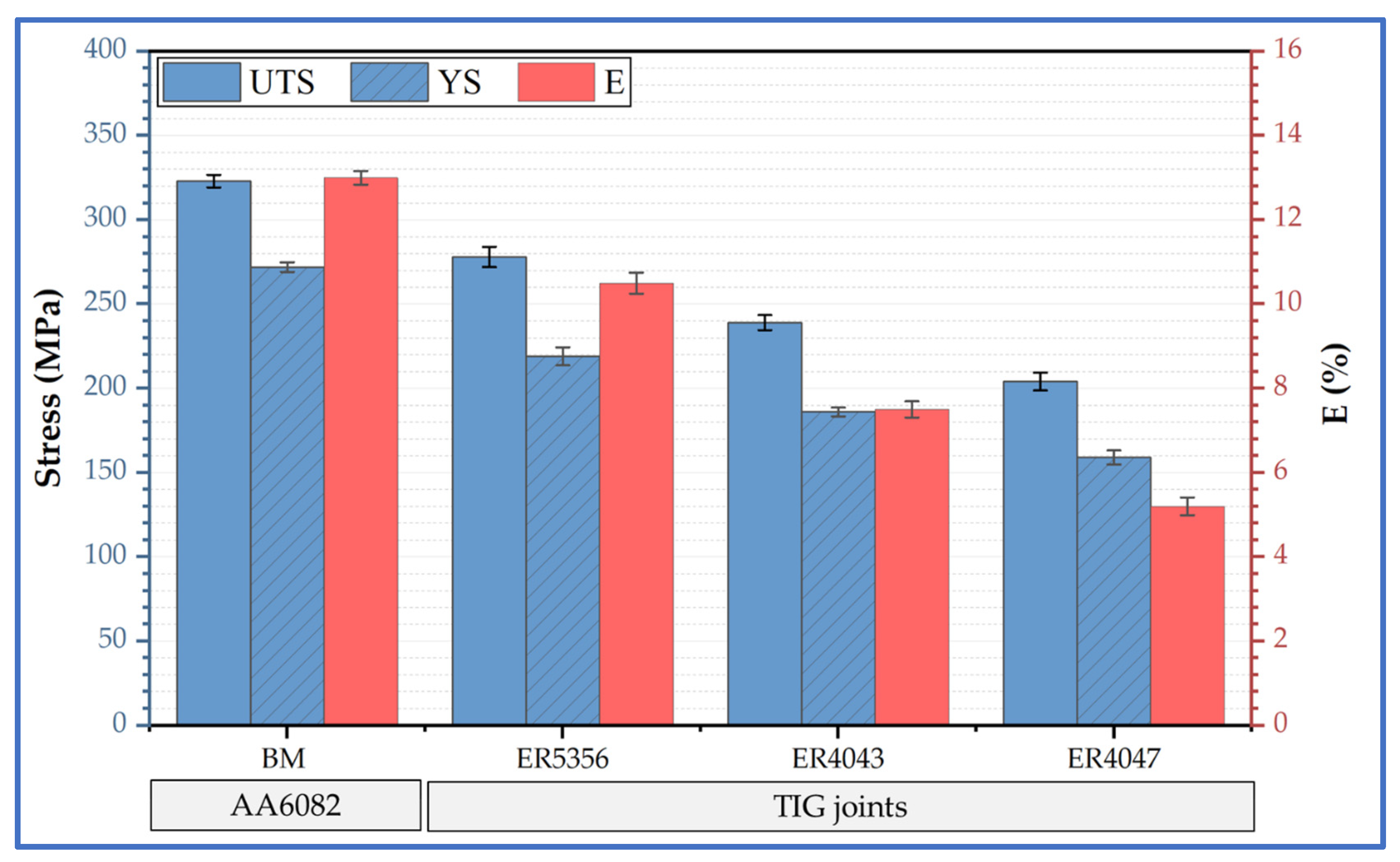

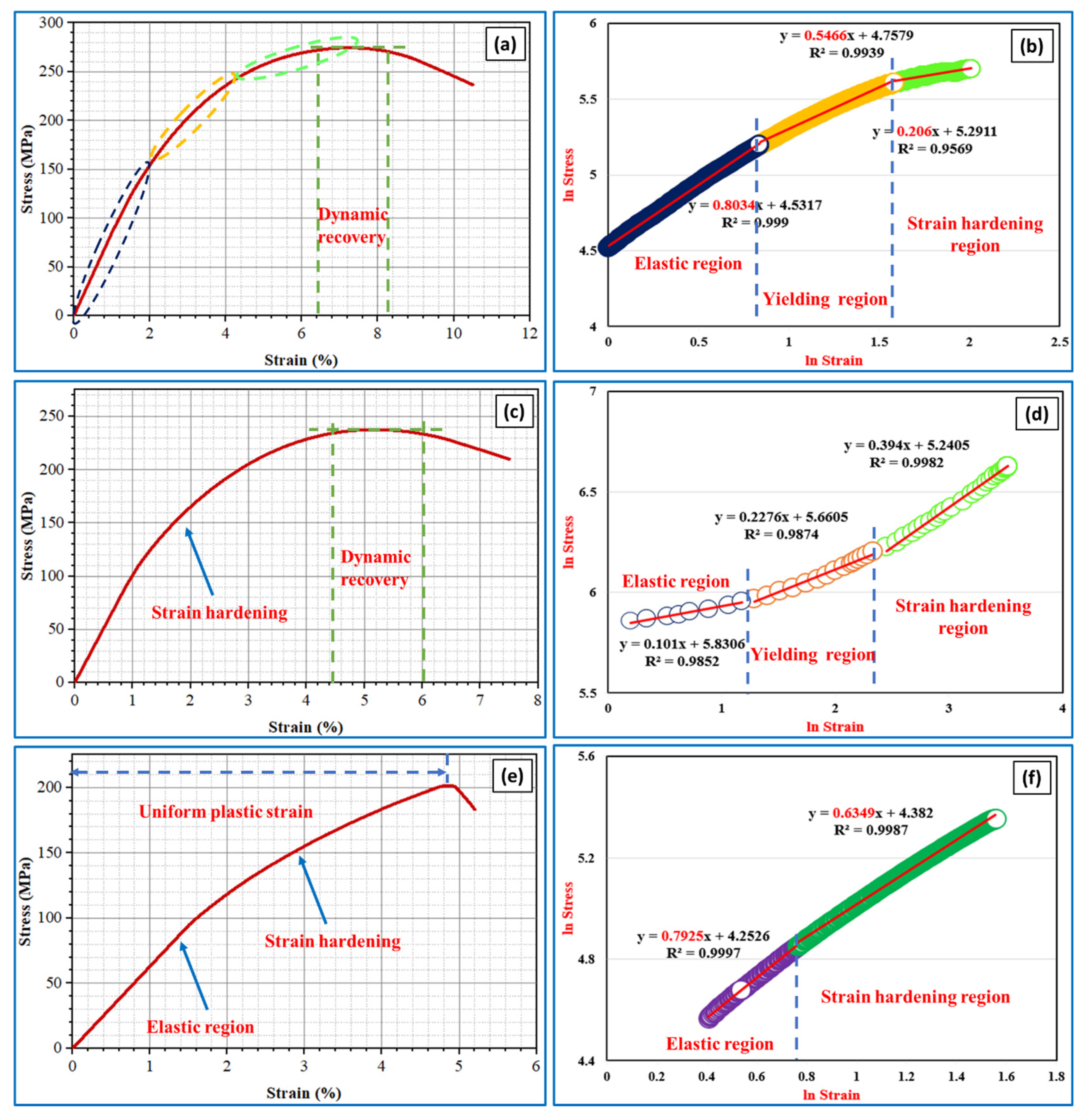

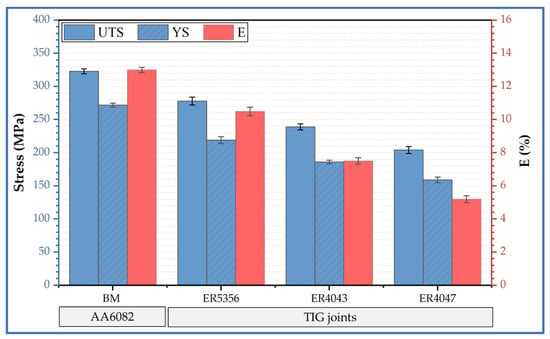

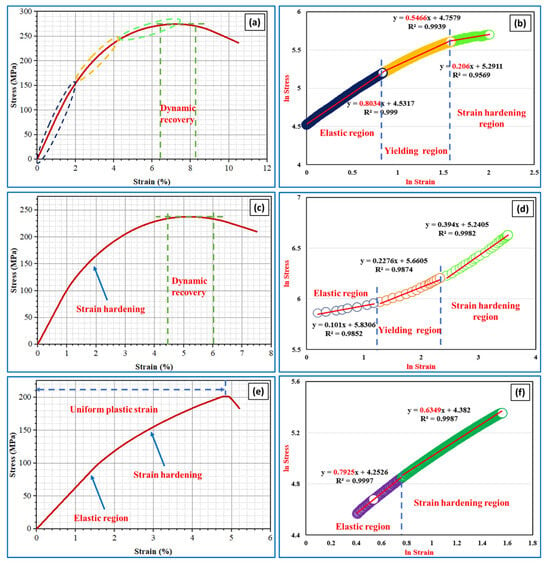

Figure 10 shows the mechanical characteristics of the BM and the welded samples. The BM had a tensile stress of 323 ± 4 MPa, YS of 272 ± 3 MPa, and elongation of 13 ± 0.16 %. Nonetheless, the UTS of the BM was higher than those of the welded samples fabricated using ER5356, ER4043, and ER4047 filler metals, which were 278 ± 6, 239 ± 4.5, and 204 ± 5.3 MPa, respectively. Similarly, the yield stress of the welded joints was 219 ± 5.4 MPa, 186 ± 2.6 MPa, and 159 ± 4.2 MPa, respectively, which were lower than those of the BM. According to Lakshminarayanan et al. [4], alloying elements, such as Si and Mg, are primarily responsible for the improved mechanical properties of BMs. In addition, the combination of these two elements results in a precipitation reaction and the formation of a stronger Mg2Si precipitate. Thus, higher strength is provided to these alloys by the fine and homogeneous dispersion of these precipitates throughout the Al matrix. In general, more Si is considered advantageous for improving the ductility of welded structures [34]. Consequently, the welded joints produced with different filling rods (ER5053, ER4043, and ER4047) had welding efficiency values of 86.07%, 74%, and 63.16%, respectively, which were 13.93%, 26%, and 36.84 less than those of the BM, as shown in Table 4. The joints welded using the ER5356 filler rod achieved the highest yield and ultimate tensile stress values compared with the other welded samples produced using ER4043 and ER4047 filler metals. The BM elongation percentage was 13 ± 0.16%, whereas the filler rods ER5356, ER4043, and ER4047 elongated the welded joints by 10.5 ± 0.25%, 7.5 ± 0.19%, and 5.2 ± 0.21%, respectively. Among the three varieties of welded samples, the samples produced by filler rods ER4043 and ER4047 exhibited lower ductility values than those produced by ER5356. The presence of Mg₂Si enhances the ductility by preventing stress concentration points and ensuring even strain distribution under load. This effect is particularly evident in joints welded with ER5356, where the higher Mg content promotes the formation of fine Mg2Si precipitates [19,28]. Figure 11 shows the tensile stress–strain responses of the joints welded with different filler metals. A comprehensive examination of the stress–strain diagram was performed to evaluate the failure point, deformation characteristics under tensile strength, and failure modes of the welded joints produced using various filling rods (ER5356, ER4043, and ER4047).The specimens welded with ER5356 and ER4043 filling rods showed that dynamic recovery occurred in the stress–strain curve, which improved the HV, UTS, YS, and welding efficiency, whereas ER4047 did not show any dynamic recovery in the stress–strain curve, as shown in Figure 11a,c,e. In addition, the stress–strain curve was divided into three regions, except for the weld samples with the ER4047 filling rod, which were divided into two regions to analyze and determine the work hardening (n value) for each region. The first region was defined as the elastic region, where the area of the joint welded by the ER5356 filling rod showed the highest strain hardening compared with the other filling rods, as shown in Figure 11b. This can be attributed to the influence of the Mg content in the filling rod ER5356 being higher than that of the Si content in the ER4043 and ER4047 filling rods on the mechanical behavior and dynamic recovery during Al alloy welding. In addition, the increased Mg content in the ER5356 filler metals led to a fine grain size and increased the intermetallic precipitation of the Mg2Si phase in the weld region. However, the second regime was defined as the yielding region, which showed convergence in the n values for the welded samples with the ER5356 and ER4043 filling rods (Figure 11b,d). Finally, the third region of the curve was defined as the strain-hardening regime, where the increasing n value caused the increased tensile stress. The welded samples with ER5356 and ER4047 showed convergences in the n values of 0.5466 and 0.6349, respectively, as shown in Figure 11b,f, but the sample welded with ER4043 showed the lowest n value of 0.394, as depicted in Figure 11d. Before the ultimate tensile point, the tensile load suddenly decreased for every sample of the welded specimens, indicating brittle fracture of the welded joints by ER5356 and ER4043 owing to improper bond formation in the WZ. The failure of the welded specimen manufactured using the ER4047 filler rod occurred in the WZ, whereas the welded specimens manufactured using ER5356 and ER4043 failed in the HAZ. Consequently, the elongation of the weld joint produced by the ER4047 filler metal was higher before the ultimate stress point. ER4043 and ER5356 showed no discernible decrease in the tensile stress, indicating that there was no segregation or formation of brittle zones in these welds. However, compared to the welded joint manufactured with ER4047 filler metal, the welded joints manufactured with ER5356 and ER4043 filler metals exhibited higher stress and elongation. Thus, it can be deduced that changing the chemical composition of the filling rod is highly beneficial for welding the AA6082 Al alloy. Moreover, research has demonstrated that the metal-hardening capacity can be represented as the ratio of ultimate tensile stress (σUTS) to yield stress (σYS) [35,36]. The hardening capacity was remodeled as an established variable by Afrin et al. [35] as follows:

Figure 10.

Mechanical behavior of welded joints with different filling rods.

Table 4.

Welding efficiency, metal-hardening capacity, and toughness of AA6082 Al alloy BM and TIG-welded samples.

Figure 11.

Stress–strain curves and n values for welded samples with different filling rods: (a,b) specimens welded with filling rod ER5356, (c,d) specimens welded with filling rod ER4043, and (e,f) specimens welded with filling rod ER4047.

Table 4 lists the percentage of the hardening capacity (Hc%) calculated for the BM and welded joints using various filler metals. For each manufactured specimen, Hc% improved with the use of different filling rods, ER5356, ER4043, and ER4047, whereas the base metal exhibited a decrease in the hardening capacity percentage. As depicted in Table 4, the Hc% of the welded samples by ER4043 filler metals (0.28495) was greater than that of the BM (0.1875) and the welded joints by ER5356 (0.26941) and ER4047 (0.28302). The metal-hardening capacity is inversely correlated with the yield stress, which in turn is correlated with the grain structure, according to the Hall–Petch relationship (Equation (1)) [37,38,39]. When the grain structure of the welded samples increased, the UTS and YS decreased, and the hardening capacity increased. This explains the reason for the elevated levels of hardening capacity exhibited by the welded joints utilizing ER4043 and ER5356 in contrast to the BM and welded joints utilizing ER4047. Meanwhile, as the UTS decreased, the difference in the flow resistance between the interior and grain boundaries decreased, ultimately lowering the metal-hardening capacity. Based on an extensive study of the mechanical behavior of AA6082 containing the eutectic Mg2Si phase, these alloys should be used to fabricate high-strength lightweight industrial sectors, such as the automotive and aerospace industries, to reduce weight and power consumption [40]. Table 4 lists the results of the Charpy impact toughness tests. The BM has an impact toughness of 97.5 J at room temperature. Additionally, the welded joints made with the filler metals ER5356, ER4043, and ER4047 were 112, 126.5, and 139 J, respectively, which were 14.87%, 29.74%, and 42.56% greater than that of the BM, respectively. Compared with the ER5356 and ER4043 welded joints, the joint filled with ER4047 exhibited a maximum toughness of 139 J owing to the low distribution of the area fraction of the Mg2Si eutectic phase in the WZ [41]. Coarser grains may be associated with the evolution of microstructure morphology during welding, as shown in Figure 8.

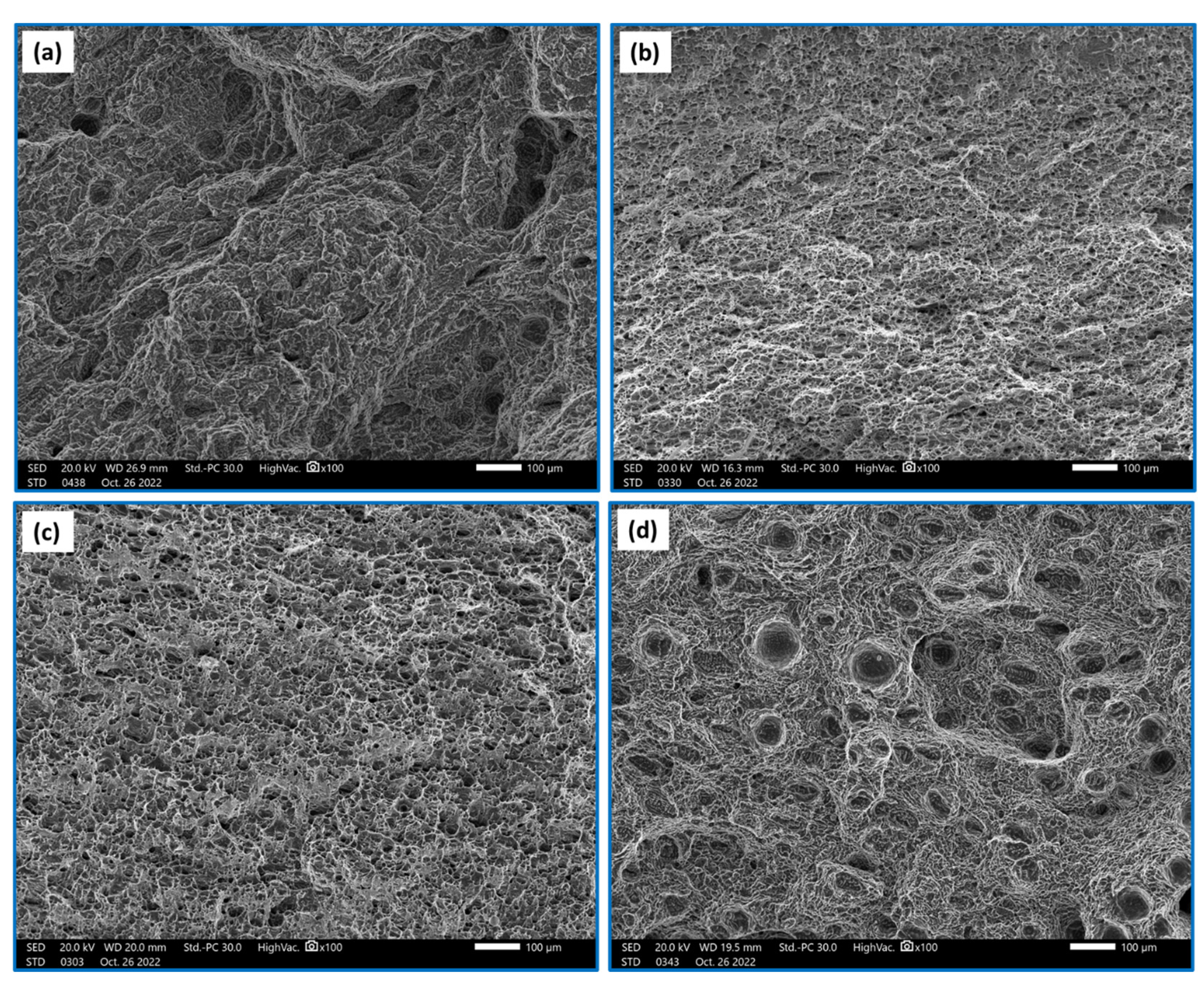

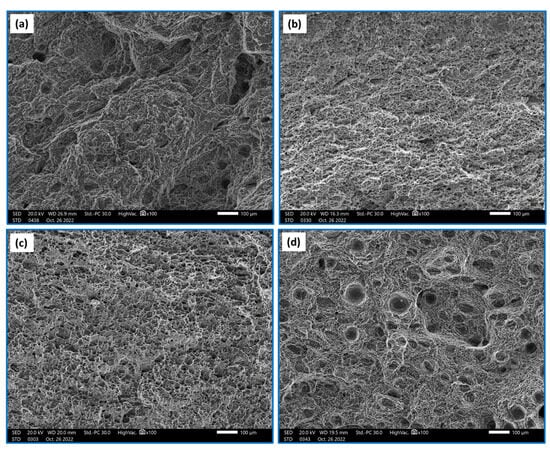

Figure 12a–d shows the morphologies of the fracture surfaces of the BM and welded joints with different filler metals. The properties of the welded samples and the BMs were comparable. As demonstrated in Figure 12a–d, all the samples primarily exhibited ductile fractures. Generally, fractures were found in the HAZ of the welded joints welded with ER5356 and ER4043, whereas fractures in the welded joint welded with ER4047 were found in the WZ. Additionally, the fracture surface dimple sizes of the BM and welded samples with ER4047 filler metals (Figure 12a,d) were larger and shallower, respectively, than those of the welded samples with ER5356 and ER4043 filler metals (Figure 12b,c) after an in-depth study of the SEM images. This is because the joints welded with ER4047 and ER4043 are more deformable than those welded with ER5356, which means that the area fraction of the Mg2Si eutectic phase is lower than that of joints welded with ER5356 filler metals [19]. Consequently, although the AA6082 Al alloy was deformed at room temperature, the fractured BM and weld samples exhibited a ductile fracture mode, including plastic deformation, void formation, and void growth, resulting from the material flow of the matrix during plastic deformation. Additionally, the microvoids gathered because of the joining of neighboring voids, which eventually caused necking and fracture.

Figure 12.

Fracture surface morphologies of BM and welded joints using various welding wires: (a) BM, (b) ER5356, (c) ER4043, and (d) ER4047.

4. Conclusions

This study investigated the effects of three different filler metals (ER5356, ER4043, and ER4047) on the microstructure and mechanical properties of EN AW-6082 aluminum alloy joints welded using TIG welding. The key findings are as follows.

- Microstructure: the ER5356 filler produced the finest grain structure in the weld zone of 18.03 ± 3 μm, followed by ER4043 of 30.01 ± 2 μm, while ER4047 resulted in the coarsest grains of 36.07 ± 5 μm.

- Tensile properties: Joints welded with ER5356 exhibited the highest ultimate tensile strength of 278 ± 6 MPa and yield strength of 219 ± 5.4 MPa, corresponding to the highest weld efficiency of 86.07%. The ER5356 filler produced the hardest weld zone of 72.7 ± 5 HV, compared to ER4043 of 63.4 ± 2 HV and ER4047 of 52.8 ± 4 HV.

- The ER4047 filler resulted in the highest impact toughness of 139 J, followed by ER4043 (126.5 J) and ER5356 (112 J). ER4043 exhibited the highest strain hardening capacity (0.285), closely followed by ER4047 (0.283) and ER5356 (0.269).

- Welds made with ER5356 and ER4043 fractured in the heat-affected zone, while ER4047 welds failed in the weld zone, indicating the influence of filler composition on fracture location and characteristics.

5. Future Recommendations

- Investigate the effects of various post-weld heat treatment regimens on the microstructure and mechanical properties of the welded joints to potentially enhance their performance.

- Conduct detailed corrosion and fatigue behavior to evaluate the impact of different filler metals on the corrosion and fatigue behavior of the welded joints in various environments.

- Compare the results of this study with other welding techniques, such as friction stir welding or laser welding, to identify the most suitable joining method for the EN AW-6082 aluminum alloy.

Author Contributions

Conceptualization, M.M.Z.A., M.I.A.H., R.A.F., Y.G.Y.E. and E.A.G.; methodology, M.M.Z.A., M.I.A.H., R.A.F., Y.G.Y.E. and E.A.G.; software, M.M.Z.A., M.I.A.H., R.A.F., Y.G.Y.E. and E.A.G.; validation, M.M.Z.A., B.A., M.I.A.H., R.A.F., Y.G.Y.E. and E.A.G.; formal analysis, M.M.Z.A., M.I.A.H., R.A.F., Y.G.Y.E. and E.A.G.; investigation, M.M.Z.A., M.I.A.H., R.A.F., Y.G.Y.E. and E.A.G.; resources, M.M.Z.A., M.I.A.H., R.A.F., Y.G.Y.E. and E.A.G.; data curation, M.M.Z.A., M.I.A.H., R.A.F., Y.G.Y.E. and E.A.G.; writing—original draft preparation, M.M.Z.A., M.I.A.H., R.A.F., Y.G.Y.E. and E.A.G.; writing—review and editing, M.M.Z.A., M.I.A.H., R.A.F., Y.G.Y.E. and E.A.G.; visualization, M.M.Z.A., M.I.A.H., R.A.F., Y.G.Y.E. and E.A.G.; supervision, M.M.Z.A. and B.A.; project administration, M.M.Z.A. and B.A.; funding acquisition, M.M.Z.A. and B.A. All authors have read and agreed to the published version of the manuscript.

Funding

The authors extend their appreciation to Prince Sattam bin Abdulaziz University for funding this research work through the project number (PSAU/2024/01/827616).

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Li, H.; Zou, J.; Yao, J.; Peng, H. The Effect of TIG Welding Techniques on Microstructure, Properties and Porosity of the Welded Joint of 2219 Aluminum Alloy. J. Alloys Compd. 2017, 727, 531–539. [Google Scholar] [CrossRef]

- Manti, R.; Dwivedi, D.K.; Agarwal, A. Microstructure and Hardness of Al-Mg-Si Weldments Produced by Pulse GTA Welding. Int. J. Adv. Manuf. Technol. 2008, 36, 263–269. [Google Scholar] [CrossRef]

- Baskoro, A.S.; Amat, M.A.; Pratama, A.I.; Kiswanto, G.; Winarto, W. Effects of Tungsten Inert Gas (TIG) Welding Parameters on Macrostructure, Microstructure, and Mechanical Properties of AA6063-T5 Using the Controlled Intermittent Wire Feeding Method. Int. J. Adv. Manuf. Technol. 2019, 105, 2237–2251. [Google Scholar] [CrossRef]

- Lakshminarayanan, A.K.; Balasubramanian, V.; Elangovan, K. Effect of Welding Processes on Tensile Properties of AA6061 Aluminium Alloy Joints. Int. J. Adv. Manuf. Technol. 2009, 40, 286–296. [Google Scholar] [CrossRef]

- Trdan, U.; Žagar, S.; Grum, J.; Luis Ocaña, J. Surface Modification of Laser- and Shot-Peened 6082 Aluminium Alloy: Laser Peening Effect to Pitting Corrosion. Int. J. Struct. Integr. 2011, 2, 9–21. [Google Scholar] [CrossRef]

- Dhakal, B.; Swaroop, S. Effect of Laser Shock Peening on Mechanical and Microstructural Aspects of 6061-T6 Aluminum Alloy. J. Mater. Process. Technol. 2020, 282, 116640. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Seleman, M.M.E.S.; Ahmed, E.; Reyad, H.A.; Touileb, K.; Albaijan, I. Friction Stir Spot Welding of Different Thickness Sheets of Aluminum Alloy AA6082-T6. Materials 2022, 15, 2971. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Ahmed, E.; Reyad, H.A.; Alsaleh, N.A.; Albaijan, I. A Novel Friction Stir Deposition Technique to Refill Keyhole of Friction Stir Spot Welded AA6082-T6 Dissimilar Joints of Different Sheet Thicknesses. Materials 2022, 15, 6799. [Google Scholar] [CrossRef]

- Rahaman Hazari, H.; Balubai, M.; Suresh Kumar, D.; Ul Haq, A. Experimental Investigation of TIG Welding on AA 6082 and AA 8011. Mater. Today Proc. 2019, 19, 818–822. [Google Scholar] [CrossRef]

- Zhang, X.; Lv, Y.; Hashimoto, T.; Nilsson, J.O.; Zhou, X. Intergranular Corrosion of AA6082 Al–Mg–Si Alloy Extrusion: The Influence of Trace Cu and Grain Boundary Misorientation. J. Alloys Compd. 2021, 853, 157228. [Google Scholar] [CrossRef]

- Kumar, G.S.; Ramesh, M.; Dinesh, S.; Paramasivam, P.; Parthipan, N. Investigation of the TIG Welding Process for Joining AA6082 Alloy Using Grey Relational Analysis. Adv. Mater. Sci. Eng. 2022, 2022, 5670172. [Google Scholar] [CrossRef]

- Ramarajan, A.; Jayakumar, K. Influence of Pulsed TIG Welding Process Parameters on the Mechanical Characteristics of AA5083 with AA6082 Weldments. Mater. Res. Express 2023, 10, 026504. [Google Scholar] [CrossRef]

- Ji, H.; Hu, Y.; Yu, R.; Liu, S.; Pei, W.; Wang, B. Experimental Study on TIG Full Welding and Single Pass Welding Quality of 6061-T6 Aluminum Alloy Sheet. J. Mater. Res. Technol. 2023, 27, 5965–5976. [Google Scholar] [CrossRef]

- Wang, H.; Chang, S.; Zhou, Z.; Wang, W. Effect of TIG Remelting on the Microstructure, Mechanical Properties, and Corrosion Behavior of 5052 Aluminum Alloy Joints in MIG Welding. J. Mater. Res. Technol. 2024, 32, 2255–2267. [Google Scholar] [CrossRef]

- Baskoro, A.S.; Amat, M.A.; Simatupang, S.P.D.; Abrara, Y.; Widyianto, A. Weld Geometry, Mechanical Properties, Microstructure and Chemical Composition of Aa6063 in Tungsten Inert Gas Welding with Intermittent Controlled Wire Feeding Method. Metals 2021, 11, 316. [Google Scholar] [CrossRef]

- Baskoro, A.S.; Amat, M.A.; Putra, R.D.; Widyianto, A.; Abrara, Y. Investigation of Temperature History, Porosity and Fracture Mode on Aa1100 Using the Controlled Intermittent Wire Feeder Method. Evergreen 2020, 7, 86–91. [Google Scholar] [CrossRef]

- Mannapovich, S.R.; Touileb, K. Improving the Formation and Quality of Weld Joints on Aluminium Alloys during TIG Welding Using Flux Backing Tape. Metals 2024, 14, 321. [Google Scholar] [CrossRef]

- Ishak, M.; Noordin, N.F.M.; Razali, A.S.K.; Shah, L.H.A.; Romlay, F.R.M. Effect of Filler on Weld Metal Structure of AA6061 Aluminum Alloy by Tungsten Inert Gas Welding. Int. J. Automot. Mech. Eng. 2015, 11, 2438–2446. [Google Scholar] [CrossRef]

- Verma, R.P.; Pandey, K.N.; Sharma, Y. Effect of ER4043 and ER5356 Filler Wire on Mechanical Properties and Microstructure of Dissimilar Aluminium Alloys, 5083-O and 6061-T6 Joint, Welded by the Metal Inert Gas Welding. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 229, 1021–1028. [Google Scholar] [CrossRef]

- Cao, X.; Wallace, W.; Immarigeon, J.P.; Poon, C. Research and Progress in Laser Welding of Wrought Aluminum Alloys. II. Metallurgical Microstructures, Defects, and Mechanical Properties. Mater. Manuf. Process. 2003, 18, 23–49. [Google Scholar] [CrossRef]

- Kah, P.; Hiltunen, E.; Martikainen, J. Investigation of Hot Cracking in the Welding of Aluminium Alloys (6005 & 6082). In Proceedings of the 63rd Annual Assembly & International Conference of the International Institute of Welding, Istanbul, Turkey, 11–17 July 2010; pp. 373–380. [Google Scholar] [CrossRef]

- Gadallah, E.A.; El Aal, M.I.A.; Mohamed, A.Y.; El-Fahhar, H.H. Effects of Filler on the Microstructure and Corrosion of Similar and Dissimilar Gas Inert Tungsten Arc Welding Aluminum Alloys Joints. Sci. Rep. 2023, 13, 19011. [Google Scholar] [CrossRef]

- Mehdi, H.; Singh, B.; Salah, A.N.; Dubey, M.K.; Mishra, S.; Kumar, S. Effect of PWHT on Metallurgical and Mechanical Characterization of Dissimilar Welded Joint of P91 and P92 Steels. J. Adhes. Sci. Technol. 2024, 38, 1395–1412. [Google Scholar] [CrossRef]

- Kaufman, J.G. Introduction to Aluminum Alloys and Tempers; ASM International: Metals Park, OH, USA, 2000; Volume 28. [Google Scholar]

- Davis, J.R. Alloying Understanding Basics; ASM International: Metals Park, OH, USA, 2001; ISBN 0-87170-744-6. [Google Scholar]

- Fouad, R.A.; Habba, M.I.A.; Elshaghoul, Y.G.Y.; El, M.M.; Seleman, S.; Hafez, K.M.; Hamid, F.S.; Barakat, W.S. The Influence of Various Welding Wires on Microstructure, and Mechanical Characteristics of AA7075 Al-Alloy Welded by TIG Process. Sci. Rep. 2024, 14, 19023. [Google Scholar] [CrossRef] [PubMed]

- Sudheesh, N.; Thirunavukkarasu, K. The Effect of Adding Magnesium to the Filler Material on the Hardness of Tig Welded Aluminium Alloy-Aa 6082. Int. J. Mech. Prod. Eng. Res. Dev. 2020, 10, 837–858. [Google Scholar] [CrossRef]

- Bayat, N.; Carlberg, T.; Cieslar, M. In-Situ Study of Phase Transformations during Homogenization of 6005 and 6082 Al Alloys. J. Alloys Compd. 2017, 725, 504–509. [Google Scholar] [CrossRef]

- Hemdan, H.; Fahhar, E.; Gadallah, E.A.; Habba, M.I.A.; El, M.M.; Seleman, S.; Ahmed, M.M.Z.; Mohamed, A.Y.; Fouad, R.A. Effect of Post-Weld Heat-Treatment and Solid-State Thermomechanical Treatment on the Properties of the AA6082 MIG Welded Joints. Sci. Rep. 2024, 14, 4380. [Google Scholar] [CrossRef]

- Cui, S.; Tian, F.; Ma, R.; Yu, Y.; Xu, L. Study on the Morphology, Microstructure, and Properties of 6082-T6 Aluminum Alloy Joints in MIG Welding. Metals 2023, 13, 1245. [Google Scholar] [CrossRef]

- Seth, P.P.; Parkash, O.; Kumar, D. Structure and Mechanical Behavior Ofin Situdeveloped Mg2Si Phase in Magnesium and Aluminum Alloys—A Review. RSC Adv. 2020, 10, 37327–37345. [Google Scholar] [CrossRef]

- Yan, S.; Ma, C.; Chen, H. Modifying Microstructures and Mechanical Properties of Laser-Arc Welded Joints of Dissimilar Advanced Aluminum Alloys. Mater. Charact. 2020, 164, 110331. [Google Scholar] [CrossRef]

- Kostrivas, A.; Lippold, J.C. Fusion Boundary Microstructure Evolution in Aluminium Alloys. Weld. World 2006, 50, 24–34. [Google Scholar] [CrossRef]

- Aziz, A.A.A.; Ibrahim, M.F.A.; Jalar, A.; Junaidi, S.; Abdullah, S.; Rashdi, N.; Kornain, Z. Effects of Different Fillers on Microstructure and Tensile Properties of Welded AA6061-T6. Key Eng. Mater. 2011, 462–463, 1189–1193. [Google Scholar] [CrossRef]

- Afrin, N.; Chen, D.L.; Cao, X.; Jahazi, M. Strain Hardening Behavior of a Friction Stir Welded Magnesium Alloy. Scr. Mater. 2007, 57, 1004–1007. [Google Scholar] [CrossRef]

- Luo, J.; Mei, Z.; Tian, W.; Wang, Z. Diminishing of Work Hardening in Electroformed Polycrystalline Copper with Nano-Sized and Uf-Sized Twins. Mater. Sci. Eng. A 2006, 441, 282–290. [Google Scholar] [CrossRef]

- Sudha, G.T.; Stalin, B.; Ravichandran, M.; Balasubramanian, M. Mechanical Properties, Characterization and Wear Behavior of Powder Metallurgy Composites - A Review. Mater. Today Proc. 2020, 22, 2582–2596. [Google Scholar] [CrossRef]

- Ligda, J.P. Effects of Grain Size on the Quasi-Static Mechanical Properties of Ultrafine-Grained and Nanocrystalline Tantalum. Ph.D. Dissertation, The University of North Carolina at Charlotte, Charlotte, NC, USA, 2013. [Google Scholar]

- Aderibigbe, I.; Popoola, P.; Sadiku, E.; Biro, E. Low-Temperature Deformation Mechanism and Strain-Hardening Behaviour of Laser Welded Dual-Phase Steels. Metals 2022, 12, 1317. [Google Scholar] [CrossRef]

- Kulekci, M.K. Magnesium and Its Alloys Applications in Automotive Industry. Int. J. Adv. Manuf. Technol. 2008, 39, 851–865. [Google Scholar] [CrossRef]

- Ahmed, M.; Javidani, M.; Maltais, A.; Chen, X.-G. Comparison of Mechanical, Fatigue, and Corrosion Properties of Fusion-Welded High-Strength AA6011 Alloy Using Three Filler Wires. Processes 2024, 12, 1172. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).