Innovative and Sustainable Advances in Polymer Composites for Additive Manufacturing: Processing, Microstructure, and Mechanical Properties

Abstract

:1. Introduction

2. Advantages of Additive Manufacturing (AM)

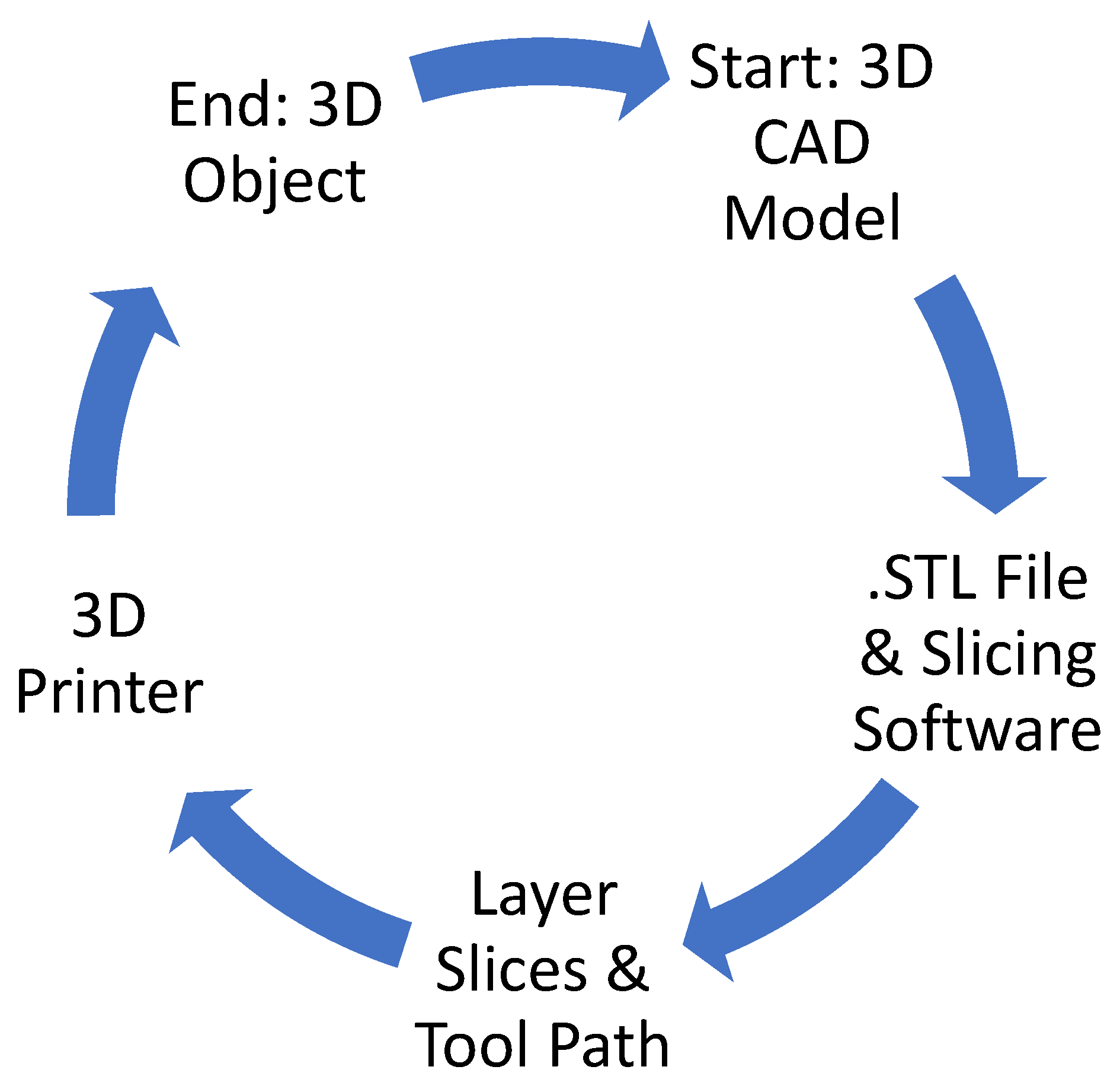

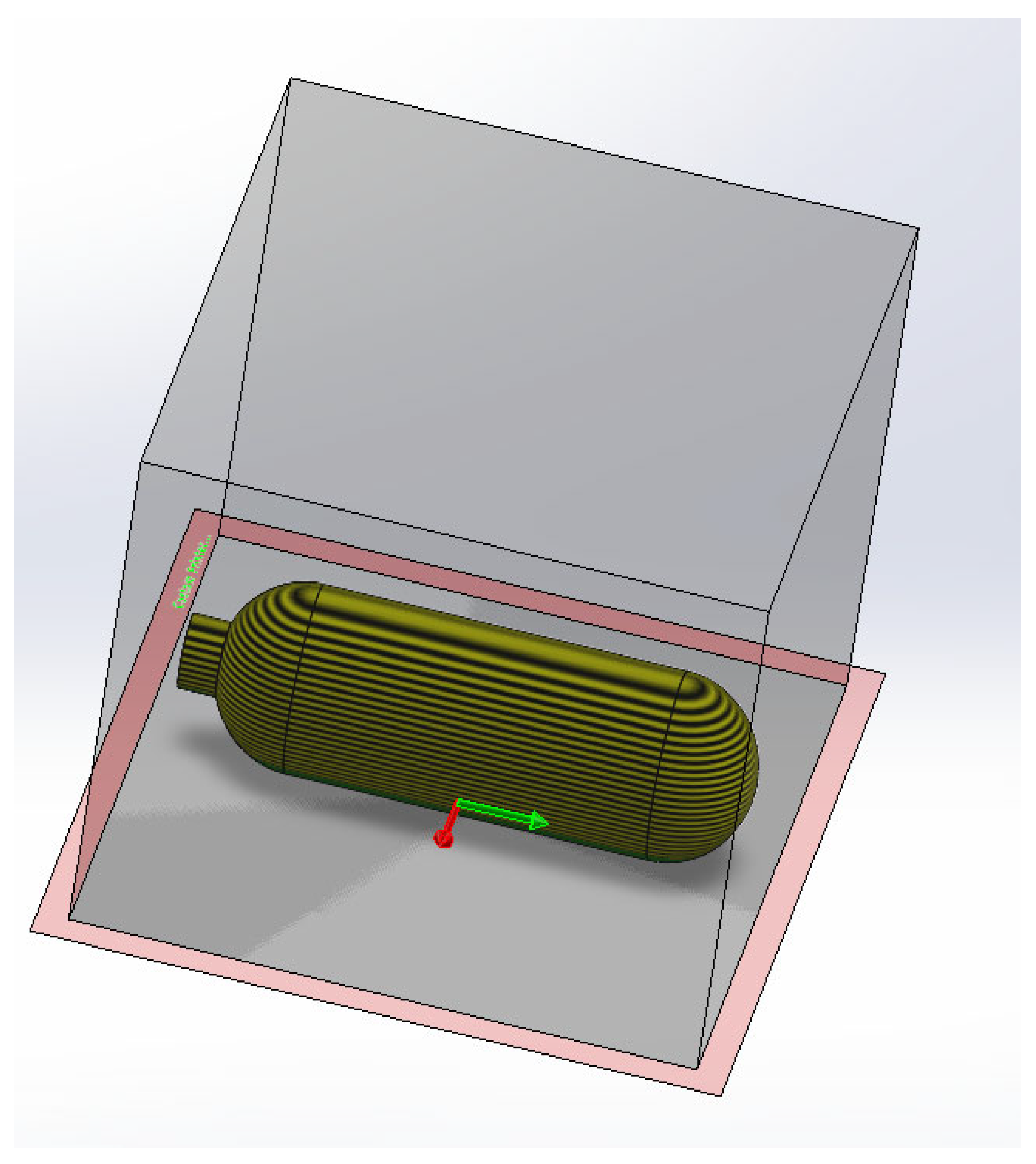

3. Additive Manufacturing (AM) Techniques

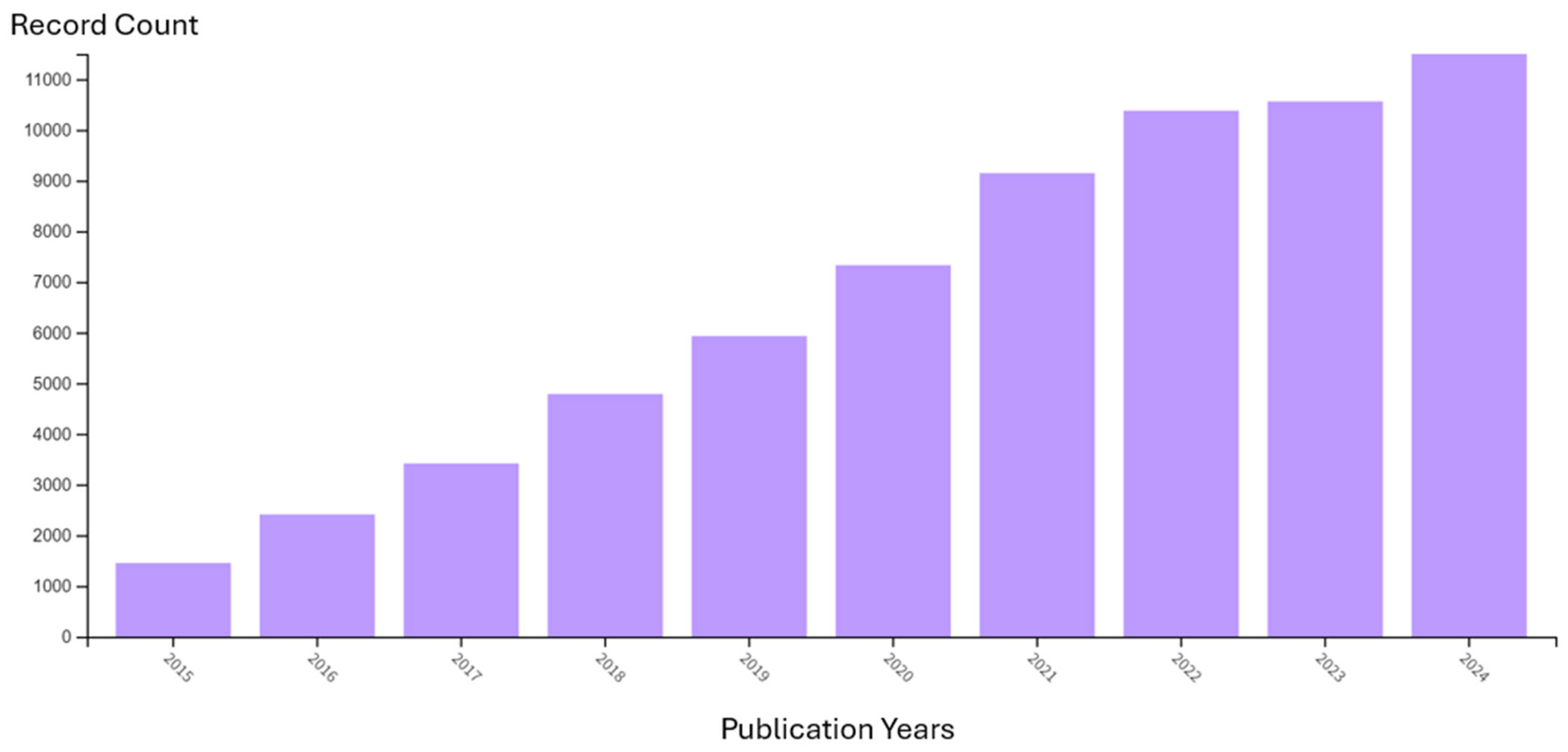

4. Evolution and Current Status of AM Technology

5. Sustainability of AM Polymers

6. Challenges and Future Directions

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cann, C.; Saharudin, M.S. Design and Fabrication of a Wrist Splint for Burn Patient Rehabilitation Using 3D Printing Technologies. Proc. J. Phys. Conf. Ser. 2023, 2643, 012003. [Google Scholar] [CrossRef]

- Srivastava, P.; Sahlot, P. Additive Manufacturing in Industry 4.0: A Review. In Proceedings of the Lecture Notes in Mechanical Engineering; Springer: Singapore, 2023. [Google Scholar]

- De, A.; Ramasubramian, B.; Ramakrishna, S.; Chellappan, V. Advances in Additive Manufacturing Techniques for Electrochemical Energy Storage. Adv. Mater. Technol. 2024, 9, 2301439. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, Z.; Li, J.; Li, X.; Cheng, L. From Materials to Devices Using Fused Deposition Modeling: A State-of-Art Review. Nanotechnol. Rev. 2020, 9, 1594–1609. [Google Scholar] [CrossRef]

- Luo, X.; Cheng, H.; Wu, X. Nanomaterials Reinforced Polymer Filament for Fused Deposition Modeling: A State-of-the-Art Review. Polymers 2023, 15, 2980. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.; Islam, K.S.; Dip, T.M.; Chowdhury, M.F.M.; Debnath, S.R.; Hasan, S.M.M.; Sakib, M.S.; Saha, T.; Padhye, R.; Houshyar, S. A Review on Nanomaterial-Based Additive Manufacturing: Dynamics in Properties, Prospects, and Challenges. Prog. Addit. Manuf. 2024, 9, 1197–1224. [Google Scholar] [CrossRef]

- Yousefi Kanani, A.; Kennedy, A. Experimental and Numerical Analysis of Additively Manufactured Foamed Sandwich Beams. Compos. Struct. 2023, 312, 116866. [Google Scholar] [CrossRef]

- Alam, F.; Varadarajan, K.M.; Koo, J.H.; Wardle, B.L.; Kumar, S. Additively Manufactured Polyetheretherketone (PEEK) with Carbon Nanostructure Reinforcement for Biomedical Structural Applications. Adv. Eng. Mater. 2020, 22, 2000483. [Google Scholar] [CrossRef]

- Fidan, I.; Naikwadi, V.; Alkunte, S.; Mishra, R.; Tantawi, K. Energy Efficiency in Additive Manufacturing: Condensed Review. Technologies 2024, 12, 21. [Google Scholar] [CrossRef]

- Islam, M.A.; Mobarak, M.H.; Rimon, M.I.H.; Al Mahmud, M.Z.; Ghosh, J.; Ahmed, M.M.S.; Hossain, N. Additive Manufacturing in Polymer Research: Advances, Synthesis, and Applications. Polym. Test. 2024, 132, 108364. [Google Scholar] [CrossRef]

- Azman, A.H.; Vignat, F.; Villeneuve, F. Cad Tools and File Format Performance Evaluation in Designing Lattice Structures for Additive Manufacturing. J. Teknol. 2018, 80. [Google Scholar] [CrossRef]

- Ali Nahran, S.; Saharudin, M.S.; Mohd Jani, J.; Wan Muhammad, W.M. The Degradation of Mechanical Properties Caused by Acetone Chemical Treatment on 3D-Printed PLA-Carbon Fibre Composites. In Advanced Structured Materials; Springer International Publishing: Cham, Switzerland, 2022; Volume 167. [Google Scholar]

- Ahn, D.; Kweon, J.H.; Choi, J.; Lee, S. Quantification of Surface Roughness of Parts Processed by Laminated Object Manufacturing. J. Mater. Process Technol. 2012, 212, 339–346. [Google Scholar] [CrossRef]

- Dermeik, B.; Travitzky, N. Laminated Object Manufacturing of Ceramic-Based Materials. Adv. Eng. Mater. 2020, 22, 2000256. [Google Scholar] [CrossRef]

- Aravind, D.; Krishnasamy, S.; Rajini, N.; Siengchin, S.; Kumar, T.S.M.; Chandrasekar, M.; Yorseng, K. Thermal and Tensile Properties of 3D Printed ABS-Glass Fibre, ABS-Glass Fibre-Carbon Fibre Hybrid Composites Made by Novel Hybrid Manufacturing Technique. J. Thermoplast. Compos. Mater. 2024, 37, 206–225. [Google Scholar] [CrossRef]

- Kreider, M.C.; Sefa, M.; Fedchak, J.A.; Scherschligt, J.; Bible, M.; Natarajan, B.; Klimov, N.N.; Miller, A.E.; Ahmed, Z.; Hartings, M.R. Toward 3D Printed Hydrogen Storage Materials Made with ABS-MOF Composites. Polym. Adv. Technol. 2018, 29, 867–873. [Google Scholar] [CrossRef] [PubMed]

- Getachew, M.T.; Shiferaw, M.Z.; Ayele, B.S. The Current State of the Art and Advancements, Challenges, and Future of Additive Manufacturing in Aerospace Applications. Adv. Mater. Sci. Eng. 2023, 2023, 8817006. [Google Scholar] [CrossRef]

- Radhika, C.; Shanmugam, R.; Ramoni, M.; Bk, G. A Review on Additive Manufacturing for Aerospace Application. Mater. Res. Express 2024, 11, 022001. [Google Scholar]

- Isasi-Sanchez, L.; Morcillo-Bellido, J.; Ortiz-Gonzalez, J.I.; Duran-Heras, A. Synergic Sustainability Implications of Additive Manufacturing in Automotive Spare Parts: A Case Analysis. Sustainability 2020, 12, 8461. [Google Scholar] [CrossRef]

- Arunkumar, D.T.; Basavakumar, K.G.; Sharath, P.C.; Pattanaik, A. Additive Manufacturing in Automotive Industries. In Materials Horizons: From Nature to Nanomaterials; Elsevier: Amsterdam, The Netherlands, 2024; Volume Part F1488. [Google Scholar]

- Muhammad, M.S.; Kerbache, L.; Elomri, A. Potential of Additive Manufacturing for Upstream Automotive Supply Chains. Supply Chain Forum 2022, 23, 1–19. [Google Scholar] [CrossRef]

- Suthithanakom, S.; Sithiwichankit, C.; Chaiprabha, K.; Chancharoen, R. Flexible Actuation with Intrinsic Sensing for Ram Extrusion 3D Printing. Int. J. Adv. Manuf. Technol. 2024, 131, 5787–5799. [Google Scholar] [CrossRef]

- Krkobabić, M.; Medarević, D.; Pešić, N.; Vasiljević, D.; Ivković, B.; Ibrić, S. Digital Light Processing (DLP) 3D Printing of Atomoxetine Hydrochloride Tablets Using Photoreactive Suspensions. Pharmaceutics 2020, 12, 833. [Google Scholar] [CrossRef]

- Nigam, A.; Tai, B.L. Surface Characterization of Three-Dimensional Printed Fiber-Reinforced Polymer Following an In-Process Mechanical–Chemical Finishing Method. J. Manuf. Sci. Eng. 2023, 145, 081002. [Google Scholar] [CrossRef]

- Raspall, F.; Velu, R.; Vaheed, N.M. Fabrication of Complex 3D Composites by Fusing Automated Fiber Placement (AFP) and Additive Manufacturing (AM) Technologies. Adv. Manuf. Polym. Compos. Sci. 2019, 5, 6–16. [Google Scholar] [CrossRef]

- Frketic, J.; Dickens, T.; Ramakrishnan, S. Automated Manufacturing and Processing of Fiber-Reinforced Polymer (FRP) Composites: An Additive Review of Contemporary and Modern Techniques for Advanced Materials Manufacturing. Addit. Manuf. 2017, 14, 69–86. [Google Scholar] [CrossRef]

- Gerdes, S.; Gaikwad, A.; Ramesh, S.; Rivero, I.V.; Tamayol, A.; Rao, P. Monitoring and Control of Biological Additive Manufacturing Using Machine Learning. J. Intell. Manuf. 2024, 35, 1055–1077. [Google Scholar] [CrossRef]

- Headley, C.V.; Herrera del Valle, R.J.; Ma, J.; Balachandran, P.; Ponnambalam, V.; LeBlanc, S.; Kirsch, D.; Martin, J.B. The Development of an Augmented Machine Learning Approach for the Additive Manufacturing of Thermoelectric Materials. J. Manuf. Process. 2024, 116, 165–175. [Google Scholar] [CrossRef]

- Wu, C.; Wan, B.; Entezari, A.; Fang, J.; Xu, Y.; Li, Q. Machine Learning-Based Design for Additive Manufacturing in Biomedical Engineering. Int. J. Mech. Sci. 2024, 266, 108828. [Google Scholar] [CrossRef]

- Zhou, H.R.; Yang, H.; Li, H.Q.; Ma, Y.C.; Yu, S.; Shi, J.; Cheng, J.C.; Gao, P.; Yu, B.; Miao, Z.Q.; et al. Advancements in Machine Learning for Material Design and Process Optimization in the Field of Additive Manufacturing. China Foundry 2024, 21, 101–115. [Google Scholar] [CrossRef]

- Zacharov, I.; Arslanov, R.; Gunin, M.; Stefonishin, D.; Bykov, A.; Pavlov, S.; Panarin, O.; Maliutin, A.; Rykovanov, S.; Fedorov, M. “Zhores”—Petaflops Supercomputer for Data-Driven Modeling, Machine Learning and Artificial Intelligence Installed in Skolkovo Institute of Science and Technology. Open Eng. 2019, 9, 512–520. [Google Scholar] [CrossRef]

- Fu, Z.; Liu, W.; Huang, C.; Mei, T. A Review of Performance Prediction Based on Machine Learning in Materials Science. Nanomaterials 2022, 12, 2957. [Google Scholar] [CrossRef] [PubMed]

- Ng, W.L.; Goh, G.L.; Goh, G.D.; Ten, J.S.J.; Yeong, W.Y. Progress and Opportunities for Machine Learning in Materials and Processes of Additive Manufacturing. Adv. Mater. 2024, 36, 2310006. [Google Scholar] [CrossRef]

- Nakajima, H.; Dijkstra, P.; Loos, K. The Recent Developments in Biobased Polymers toward General and Engineering Applications: Polymers That Are Upgraded from Biodegradable Polymers, Analogous to Petroleum-Derived Polymers, and Newly Developed. Polymers 2017, 9, 523. [Google Scholar] [CrossRef] [PubMed]

- Chawla, K.; Singh, R.; Singh, J. On Recyclability of Thermoplastic ABS Polymer as Fused Filament for FDM Technique of Additive Manufacturing. World J. Eng. 2022, 19, 352–360. [Google Scholar] [CrossRef]

- Ramezani Dana, H.; Barbe, F.; Delbreilh, L.; Azzouna, M.B.; Guillet, A.; Breteau, T. Polymer Additive Manufacturing of ABS Structure: Influence of Printing Direction on Mechanical Properties. J. Manuf. Process 2019, 44, 288–298. [Google Scholar] [CrossRef]

- Bamiduro, O.; Owolabi, G.; Haile, M.A.; Riddick, J.C. The Influence of Load Direction, Microstructure, Raster Orientation on the Quasi-Static Response of Fused Deposition Modeling ABS. Rapid Prototyp. J. 2019, 25, 462–472. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; De Carolis, V.; Montagna, F.; Palumbo, E.; Corcione, C.E. Development and Characterization of Sustainable PLA/Olive Wood Waste Composites for Rehabilitation Applications Using Fused Filament Fabrication (FFF). J. Build. Eng. 2022, 56, 104673. [Google Scholar] [CrossRef]

- Colorado, H.A.; Velásquez, E.I.G.; Monteiro, S.N. Sustainability of Additive Manufacturing: The Circular Economy of Materials and Environmental Perspectives. J. Mater. Res. Technol. 2020, 9, 8221–8234. [Google Scholar] [CrossRef]

- Al Rashid, A.; Koç, M. Additive Manufacturing for Sustainability and Circular Economy: Needs, Challenges, and Opportunities for 3D Printing of Recycled Polymeric Waste. Mater. Today Sustain. 2023, 24, 100529. [Google Scholar] [CrossRef]

- Osswald, T.A.; Jack, D.A.; Thompson, M.S. Polymer Composites–Special Issue Review for Additive Manufacturing of Composites. Polym. Compos. 2023, 44, 8195–8199. [Google Scholar] [CrossRef]

- Karnik, S.R.; Gaitonde, V.N.; Mata, F.; Davim, J.P. Investigative Study on Machinability Aspects of Unreinforced and Reinforced PEEK Composite Machining Using ANN Model. J. Reinf. Plast. Compos. 2008, 27, 751–768. [Google Scholar] [CrossRef]

- Wada, T.; Churei, H.; Yokose, M.; Iwasaki, N.; Takahashi, H.; Uo, M. Application of Glass Fiber and Carbon Fiber-Reinforced Thermoplastics in Face Guards. Polymers 2021, 23, 18. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Lin, Y.; Yang, L.; Wu, S.; Tang, D.Y.; Yan, C.; Shi, Y. Additive Manufacturing of Carbon Fiber-Reinforced Composites: A Review. Appl. Compos. Mater. 2024, 31, 353–398. [Google Scholar] [CrossRef]

- Mishra, V.; Negi, S.; Kar, S. FDM-Based Additive Manufacturing of Recycled Thermoplastics and Associated Composites. J. Mater. Cycles Waste Manag. 2023, 25, 758–784. [Google Scholar] [CrossRef] [PubMed]

- Mirzaali, M.J.; Cruz Saldívar, M.; Herranz de la Nava, A.; Gunashekar, D.; Nouri-Goushki, M.; Doubrovski, E.L.; Zadpoor, A.A. Multi-Material 3D Printing of Functionally Graded Hierarchical Soft–Hard Composites. Adv. Eng. Mater. 2020, 22, 1901142. [Google Scholar] [CrossRef]

- Ciccone, F.; Bacciaglia, A.; Ceruti, A. Optimization with Artificial Intelligence in Additive Manufacturing: A Systematic Review. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 303. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saharudin, M.S.; Ullah, A.; Younas, M. Innovative and Sustainable Advances in Polymer Composites for Additive Manufacturing: Processing, Microstructure, and Mechanical Properties. J. Manuf. Mater. Process. 2025, 9, 51. https://doi.org/10.3390/jmmp9020051

Saharudin MS, Ullah A, Younas M. Innovative and Sustainable Advances in Polymer Composites for Additive Manufacturing: Processing, Microstructure, and Mechanical Properties. Journal of Manufacturing and Materials Processing. 2025; 9(2):51. https://doi.org/10.3390/jmmp9020051

Chicago/Turabian StyleSaharudin, Mohd Shahneel, Asif Ullah, and Muhammad Younas. 2025. "Innovative and Sustainable Advances in Polymer Composites for Additive Manufacturing: Processing, Microstructure, and Mechanical Properties" Journal of Manufacturing and Materials Processing 9, no. 2: 51. https://doi.org/10.3390/jmmp9020051

APA StyleSaharudin, M. S., Ullah, A., & Younas, M. (2025). Innovative and Sustainable Advances in Polymer Composites for Additive Manufacturing: Processing, Microstructure, and Mechanical Properties. Journal of Manufacturing and Materials Processing, 9(2), 51. https://doi.org/10.3390/jmmp9020051