Deposition and Characterization of Fluoropolymer–Ceramic (ECTFE/Al2O3) Coatings via Atmospheric Plasma Spraying

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

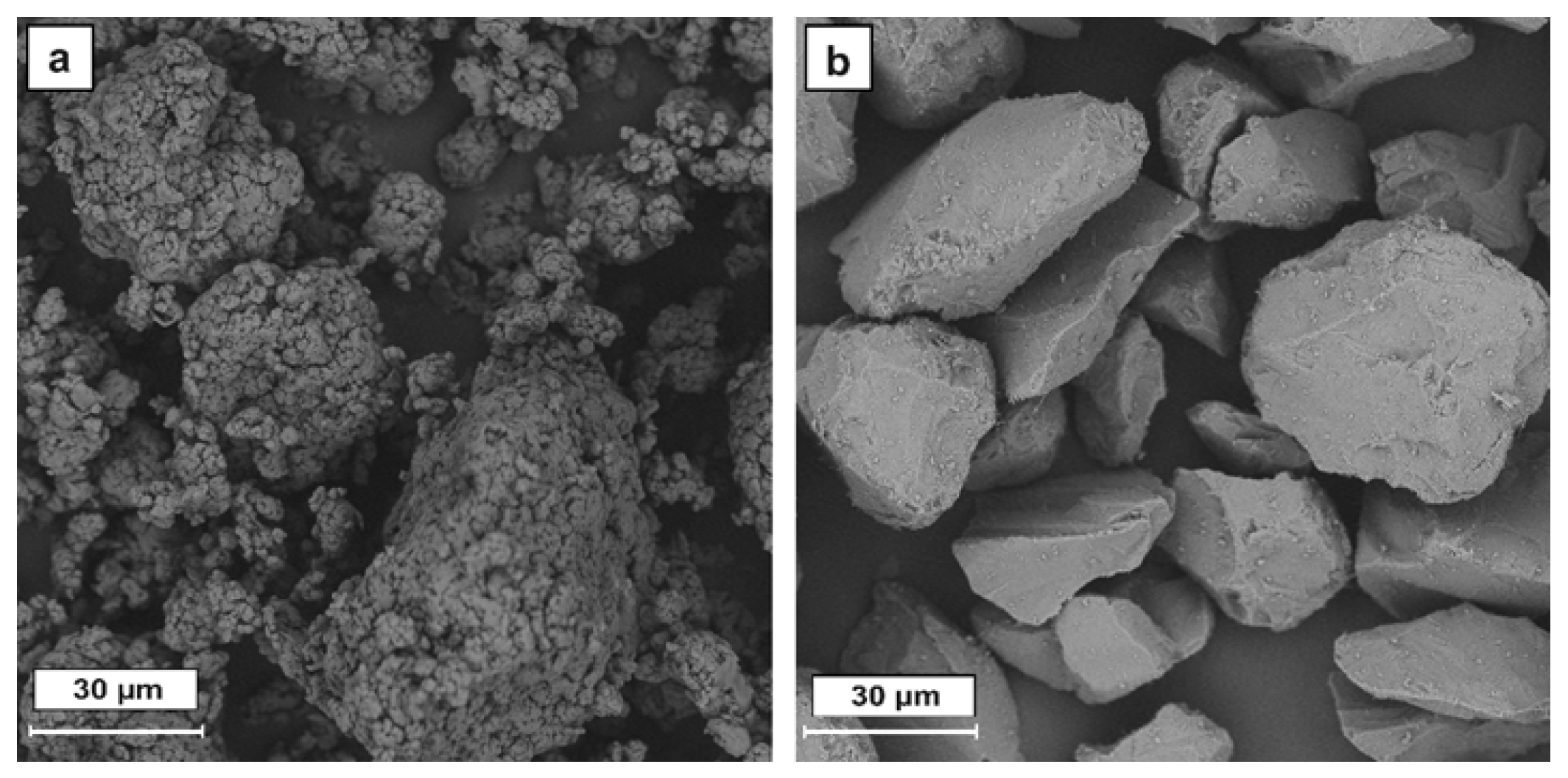

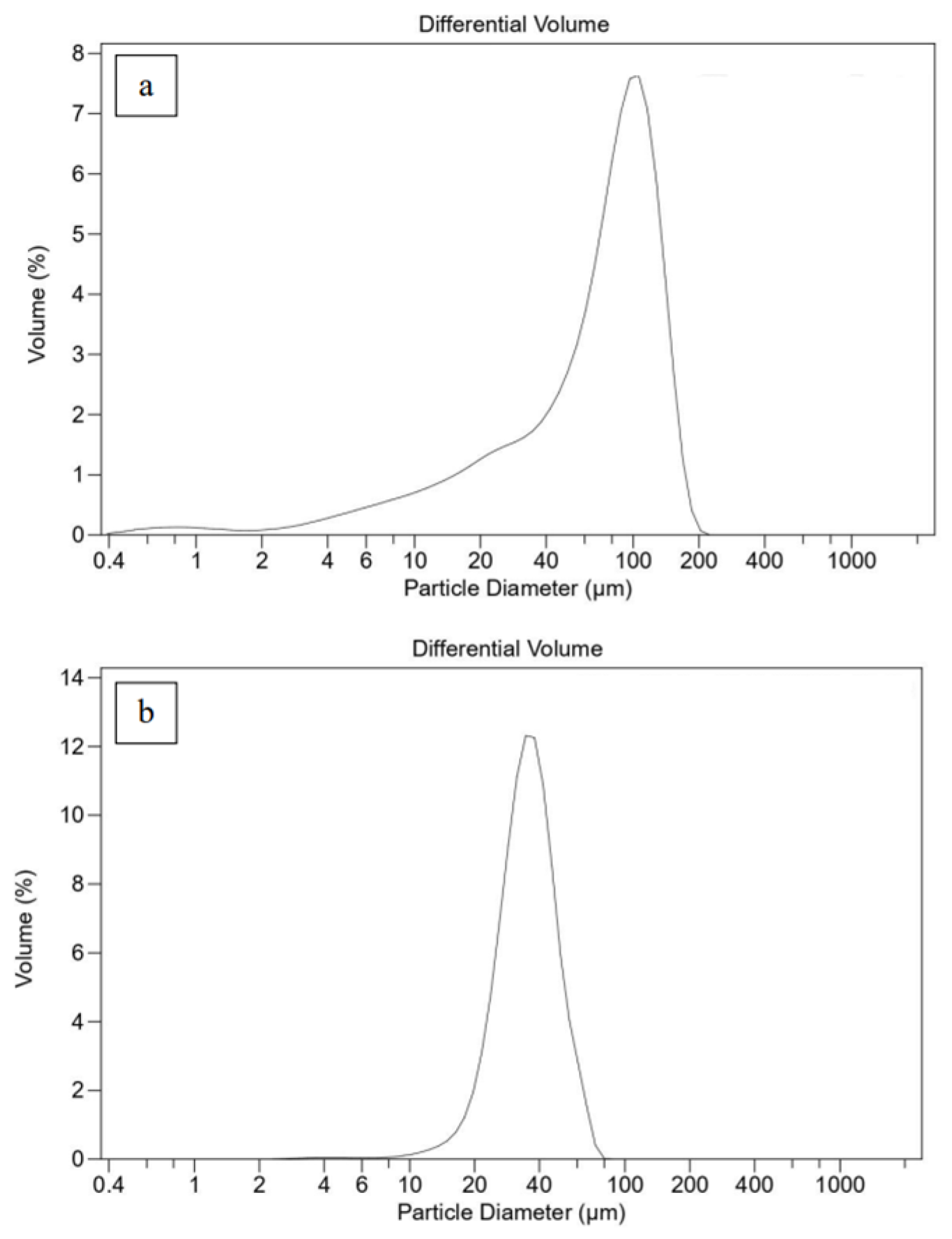

2.2. Powder Characterization

2.3. Coating Deposition

2.4. Coating Characterization

3. Results and Discussion

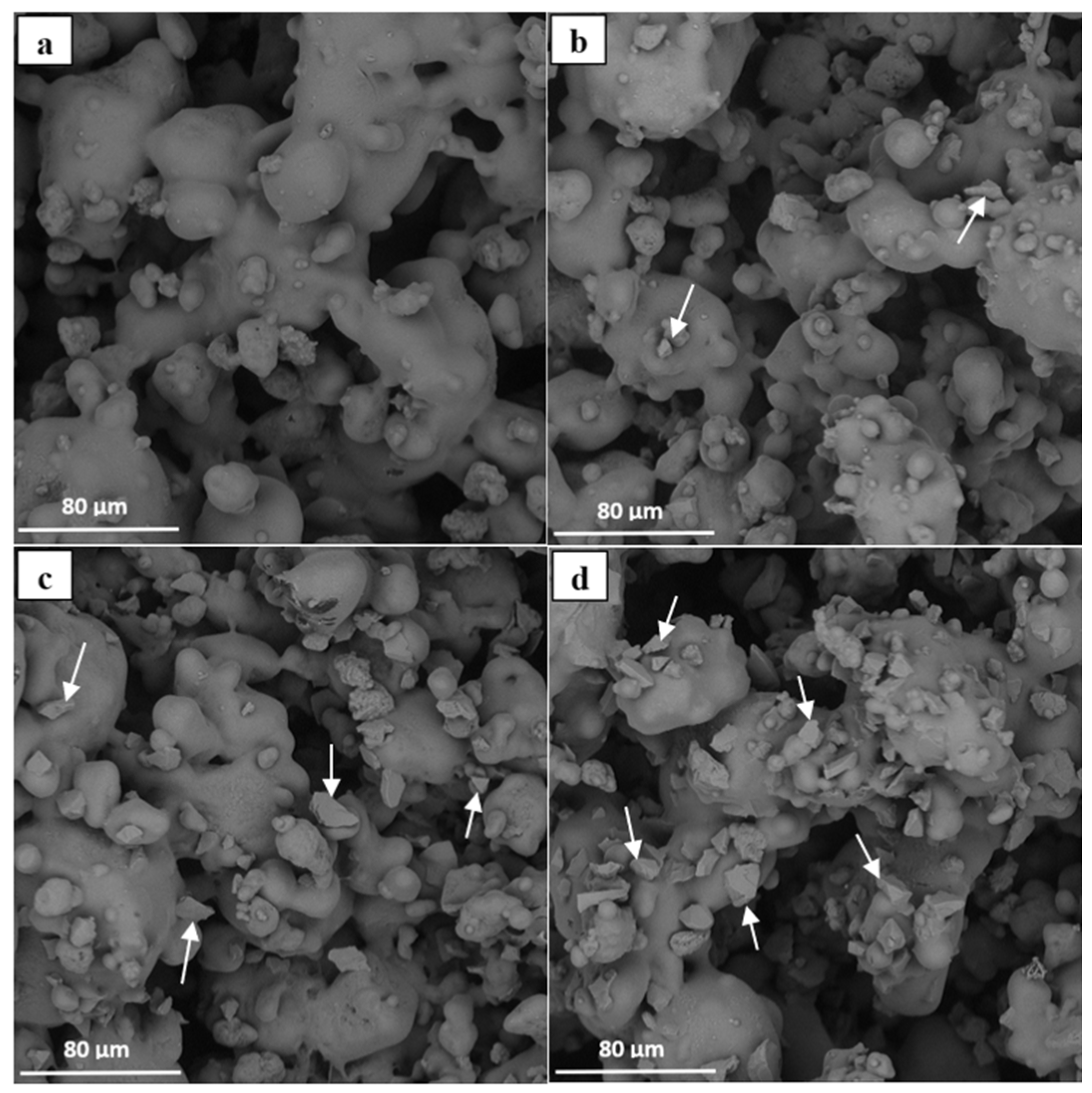

3.1. Powder Characterization

3.2. Coatings Characterization

3.3. Coatings Adhesion Properties

3.4. Coating Tribology

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- McKeen, L.W. Fluorinated Coatings. In Introduction to Fluoropolymers; Elsevier: Amsterdam, The Netherlands, 2013; pp. 231–276. ISBN 978-1-4557-7442-5. [Google Scholar]

- Ameduri, B. Fluoropolymers: The Right Material for the Right Applications. Chem.—Eur. J. 2018, 24, 18830–18841. [Google Scholar] [CrossRef] [PubMed]

- Améduri, B. The Promising Future of Fluoropolymers. Macromol. Chem. Phys. 2020, 221, 1900573. [Google Scholar] [CrossRef]

- Deng, H.; Dong, Y.; Zhang, C.; Xie, Y.; Zhang, C.; Lin, J. An Instant Responsive Polymer Driven by Anisotropy of Crystal Phases. Mater. Horiz. 2018, 5, 99–107. [Google Scholar] [CrossRef]

- Zouari, S.; Ghorbel, H.; Langlade, C.; Liao, H.; Elleuch, R. Painting Process Design and Characterization of Polymer Coatings on Brass. J. Mater. Eng. Perform. 2022, 31, 180–190. [Google Scholar] [CrossRef]

- Briscoe, B.J. Wear of Poly (Tetrafluoroethylene) Polymer and Its Control; American Chemical Society: Washington, DC, USA, 1985; pp. 151–170. [Google Scholar]

- Petrovicova, E.; Knight, R.; Schadler, L.S.; Twardowski, T.E. Nylon 11/Silica Nanocomposite Coatings Applied by the HVOF Process. I. Microstructure and Morphology. J. Appl. Polym. Sci. 2000, 77, 1684–1699. [Google Scholar] [CrossRef]

- Petrovicova, E.; Knight, R.; Schadler, L.S.; Twardowski, T.E. Nylon 11/Silica Nanocomposite Coatings Applied by the HVOF Process. II. Mechanical and Barrier Properties. J. Appl. Polym. Sci. 2000, 78, 2272–2289. [Google Scholar] [CrossRef]

- Sawyer, W.G.; Freudenberg, K.D.; Bhimaraj, P.; Schadler, L.S. A Study on the Friction and Wear Behavior of PTFE Filled with Alumina Nanoparticles. Wear 2003, 254, 573–580. [Google Scholar] [CrossRef]

- Tomala, A.M.; Słota, D.; Florkiewicz, W.; Piętak, K.; Dyląg, M.; Sobczak-Kupiec, A. Tribological Properties and Physiochemical Analysis of Polymer-Ceramic Composite Coatings for Bone Regeneration. Lubricants 2022, 10, 58. [Google Scholar] [CrossRef]

- Chen, R.; Zhang, Y.; Xie, Q.; Chen, Z.; Ma, C.; Zhang, G. Transparent Polymer-Ceramic Hybrid Antifouling Coating with Superior Mechanical Properties. Adv. Funct. Mater. 2021, 31, 2011145. [Google Scholar] [CrossRef]

- Sagar, A.; Hemant, P. A Review on Thermal Spray Coating Processes. Int. J. Curr. Trends Eng. Res. 2016, 2, 556–563. [Google Scholar]

- Sampath, S. Thermal Spray Applications in Electronics and Sensors: Past, Present, and Future. J. Therm. Spray Technol. 2010, 19, 921–949. [Google Scholar] [CrossRef]

- Lima, R.S.; Marple, B.R. Thermal Spray Coatings Engineered from Nanostructured Ceramic Agglomerated Powders for Structural, Thermal Barrier and Biomedical Applications: A Review. J. Therm. Spray Technol. 2007, 16, 40–63. [Google Scholar] [CrossRef]

- Petrovicova, E.; Schadler, L.S. Thermal Spraying of Polymers. Int. Mater. Rev. 2002, 47, 169–190. [Google Scholar] [CrossRef]

- Zouari, S.; Ghorbel, H.; Danlos, Y.; Liao, H.; Elleuch, R. Comparative Study of HVOF-Sprayed NiCrBSi Alloy and 316L Stainless Steel Coatings on a Brass Substrate. J. Therm. Spray Technol. 2019, 28, 1284–1294. [Google Scholar] [CrossRef]

- Garrido, B.; Albaladejo-Fuentes, V.; Dosta, S.; Garcia-Giralt, N.; Garcia-Cano, I. 45S5/PEEK Coatings by Cold Gas Spray with In Vitro Bioactivity, Degradation, and Cellular Proliferation. J. Therm. Spray Technol. 2024, 895–911. [Google Scholar] [CrossRef]

- Costil, S.; Mateus, C.; Coddet, C. Ceramic/Fluoropolymer Composite Coatings by Plasma Spraying. Surf. Coat. Technol. 2006, 201, 2020–2027. [Google Scholar] [CrossRef]

- Leivo, E.; Wilenius, T.; Kinos, T.; Vuoristo, P.; Mäntylä, T. Properties of Thermally Sprayed Fluoropolymer PVDF, ECTFE, PFA and FEP Coatings. Prog. Org. Coat. 2004, 49, 69–73. [Google Scholar] [CrossRef]

- Geldart, D.; Abdullah, E.C.; Hassanpour, A.; Nwoke, L.C.; Wouters, I. Characterization of Powder Flowability Using Measurement of Angle of Repose. China Particuology 2006, 4, 104–107. [Google Scholar] [CrossRef]

- ISO 4624:2023; Paints and Varnishes—Pull-Off Test for Adhesion. International Organization for Standardization: Geneva, Switzerland, 2023.

- ASTM G99-95; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 1995.

- Pawlowski, L. The Science and Engineering of Thermal Spray Coatings; John Wiley & Sons: Hoboken, NJ, USA, 2008; ISBN 0-470-75407-9. [Google Scholar]

- Perumal, G.; Geetha, M.; Asokamani, R.; Alagumurthi, N. A Comparative Study on the Wear Behavior of Al2O3 and SiC Coated Ti-6Al-4V Alloy Developed Using Plasma Spraying Technique. Trans. Indian Inst. Met. 2013, 66, 109–115. [Google Scholar] [CrossRef]

- Cañas, E.; Vicent, M.; Bannier, E.; Carpio, P.; Orts, M.J.; Sánchez, E. Effect of Particle Size on Processing of Bioactive Glass Powder for Atmospheric Plasma Spraying. J. Eur. Ceram. Soc. 2016, 36, 837–845. [Google Scholar] [CrossRef]

- Lv, S.; Zhang, J.; Ni, H.; Wang, X.; Zhu, Y.; Gu, T. Study on Preparation of Aluminum Ash Coating Based on Plasma Spray. Appl. Sci. 2019, 9, 4980. [Google Scholar] [CrossRef]

- Bosh, N.; Deggelmann, L.; Blattert, C.; Mozaffari, H.; Müller, C. Synthesis and Characterization of Halar® Polymer Coating Deposited on Titanium Substrate by Electrophoretic Deposition Process. Surf. Coat. Technol. 2018, 347, 369–378. [Google Scholar] [CrossRef]

- Robotti, M.; Dosta, S.; Fernández-Rodríguez, C.; Hernández-Rodríguez, M.J.; Cano, I.G.; Melián, E.P.; Guilemany, J.M. Photocatalytic Abatement of NOx by C-TiO2/Polymer Composite Coatings Obtained by Low Pressure Cold Gas Spraying. Appl. Surf. Sci. 2016, 362, 274–280. [Google Scholar] [CrossRef]

- Li, C.-J.; Luo, X.-T.; Yao, S.-W.; Li, G.-R.; Li, C.-X.; Yang, G.-J. The Bonding Formation during Thermal Spraying of Ceramic Coatings: A Review. J. Therm. Spray Technol. 2022, 31, 780–817. [Google Scholar] [CrossRef]

- Sobolev, V.V.; Guilemany, J.M.; Nutting, J.; Miquel, J.R. Development of Substrate-Coating Adhesion in Thermal Spraying. Int. Mater. Rev. 1997, 42, 117–136. [Google Scholar] [CrossRef]

- Wetzel, B.; Haupert, F.; Zhang, M.Q. Epoxy Nanocomposites with High Mechanical and Tribological Performance. Compos. Sci. Technol. 2003, 63, 2055–2067. [Google Scholar] [CrossRef]

| Density (g/cm3) | Tensile Stress at Break (MPa) | Flexural Strength (MPa) | Hardness, Shore D |

|---|---|---|---|

| 1.68 | 40–57 | 45–55 | 70–75 |

| Spraying Parameters | |

|---|---|

| Primary gas (Ar) flow rate (slpm) | 95 |

| Secondary gas (H2) flow rate (slpm) | 1 |

| Carrier gas (Ar) flow rate (slpm) | 7 |

| Voltage (V) | 55.5 |

| Arc current (A) | 300 |

| Traverse gun speed (mm/s) | 500 |

| Stand-off distance (mm) | 100 |

| Spraying cycles | 3 |

| Coating | Semi-Quantification of Al2O3 (%) | Thickness (µm) |

|---|---|---|

| ECTFE | 0.0 ± 0.0 | 205 ± 12 |

| ECTFE + 5 wt.% Al2O3 | 1.5 ± 0.3 | 198 ± 17 |

| ECTFE + 10 wt.% Al2O3 | 3.5 ± 0.5 | 213 ± 13 |

| ECTFE + 15 wt.% Al2O3 | 4.2 ± 0.2 | 194 ± 10 |

| Coating | ECTFE | ECTFE + 5 wt.% Al2O3 | ECTFE + 10 wt.% Al2O3 | ECTFE + 15 wt.% Al2O3 |

|---|---|---|---|---|

| Bond strength (MPa) | 7.5 ± 0.9 | 10.1 ± 0.9 | 10.1 ± 0.8 | 9.3 ± 1.3 |

| Coating | ECTFE | ECTFE + 5 wt.% Al2O3 | ECTFE + 10 wt.% Al2O3 | ECTFE + 15 wt.% Al2O3 |

|---|---|---|---|---|

| Friction. Co | 0.68 ± 0.01 | 0.71 ± 0.01 | 0.72 ± 0.01 | 0.66 ± 0.01 |

| Coating | ECTFE | ECTFE + 5 wt.% Al2O3 | ECTFE + 10 wt.% Al2O3 | ECTFE + 15 wt.% Al2O3 |

|---|---|---|---|---|

| Weight loss (mg/1000 rev) | 73.8 ± 2.2 | 72.6 ± 2.5 | 74.6 ± 1.7 | 70.7 ± 3.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdennadher, M.; Garrido, B.; Albaladejo-Fuentes, V.; Garcia-Cano, I.; Bouguecha, A.; Elleuch, R. Deposition and Characterization of Fluoropolymer–Ceramic (ECTFE/Al2O3) Coatings via Atmospheric Plasma Spraying. J. Manuf. Mater. Process. 2025, 9, 50. https://doi.org/10.3390/jmmp9020050

Abdennadher M, Garrido B, Albaladejo-Fuentes V, Garcia-Cano I, Bouguecha A, Elleuch R. Deposition and Characterization of Fluoropolymer–Ceramic (ECTFE/Al2O3) Coatings via Atmospheric Plasma Spraying. Journal of Manufacturing and Materials Processing. 2025; 9(2):50. https://doi.org/10.3390/jmmp9020050

Chicago/Turabian StyleAbdennadher, Mariem, Beatriz Garrido, Vicente Albaladejo-Fuentes, Irene Garcia-Cano, Anas Bouguecha, and Riadh Elleuch. 2025. "Deposition and Characterization of Fluoropolymer–Ceramic (ECTFE/Al2O3) Coatings via Atmospheric Plasma Spraying" Journal of Manufacturing and Materials Processing 9, no. 2: 50. https://doi.org/10.3390/jmmp9020050

APA StyleAbdennadher, M., Garrido, B., Albaladejo-Fuentes, V., Garcia-Cano, I., Bouguecha, A., & Elleuch, R. (2025). Deposition and Characterization of Fluoropolymer–Ceramic (ECTFE/Al2O3) Coatings via Atmospheric Plasma Spraying. Journal of Manufacturing and Materials Processing, 9(2), 50. https://doi.org/10.3390/jmmp9020050