Influence of Natural Fiber Content on the Frictional Material of Brake Pads—A Review

Abstract

:1. Introduction

2. Asbestos Material and Natural Fiber Life-Cycle Assessment

2.1. Asbestos Material Life Cycle Assessment

2.2. Natural Fiber Life-Cycle Assessment

3. Formulation and Manufacturing Process

4. Influence of Natural Fiber on the Mechanical and Tribological Properties

5. Conclusions

- 1-

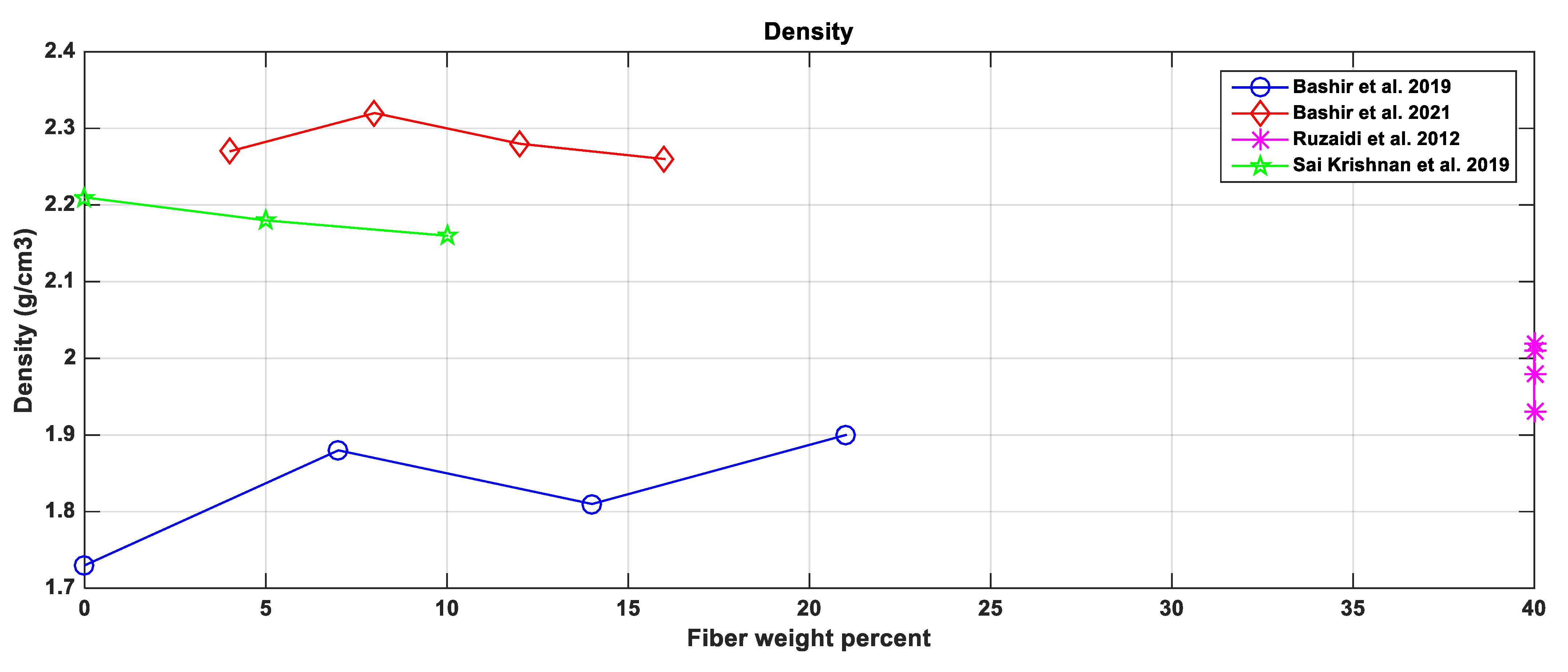

- The density of banana peels increases when the weight percentage of natural fibers is below 10%, then decreases before rising again at a weight percentage of 20%.

- 2-

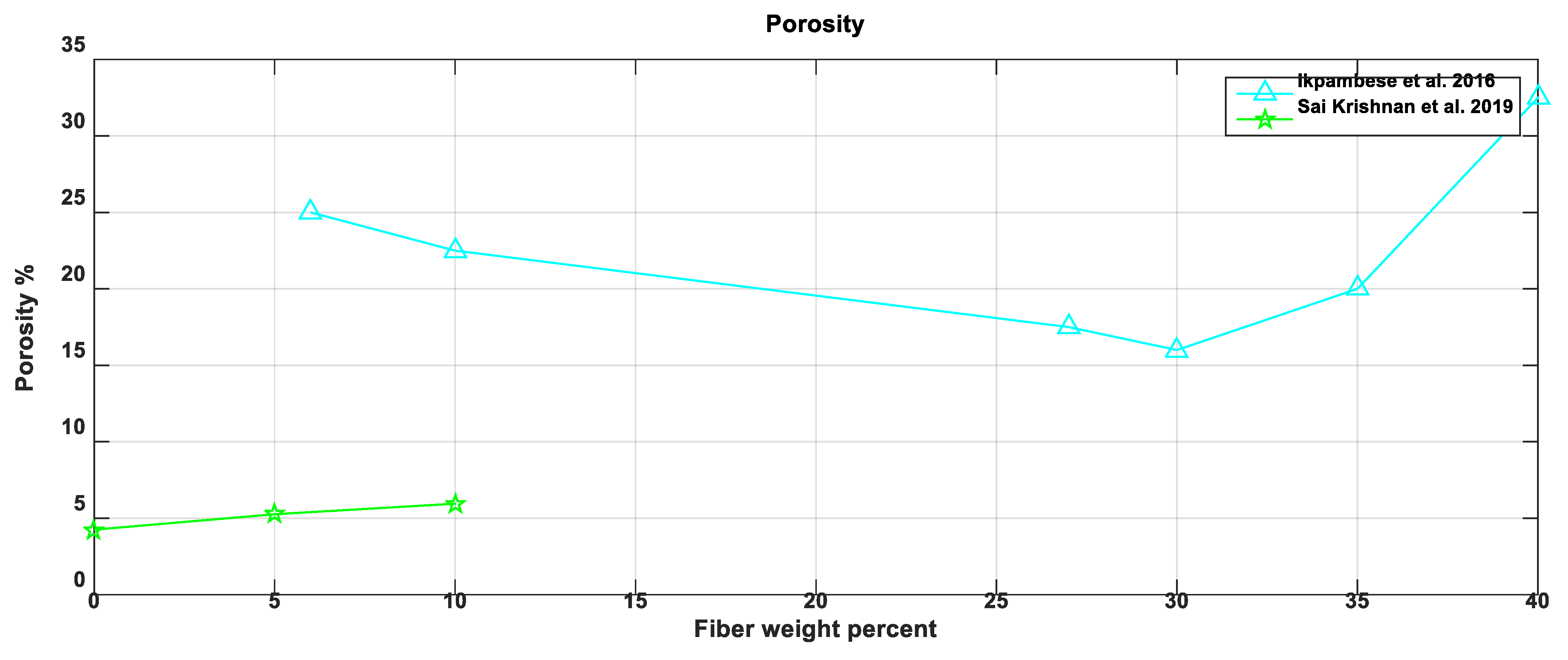

- The porosity generally decreases as the content of the natural fiber in the composite’s formulation increases.

- 3-

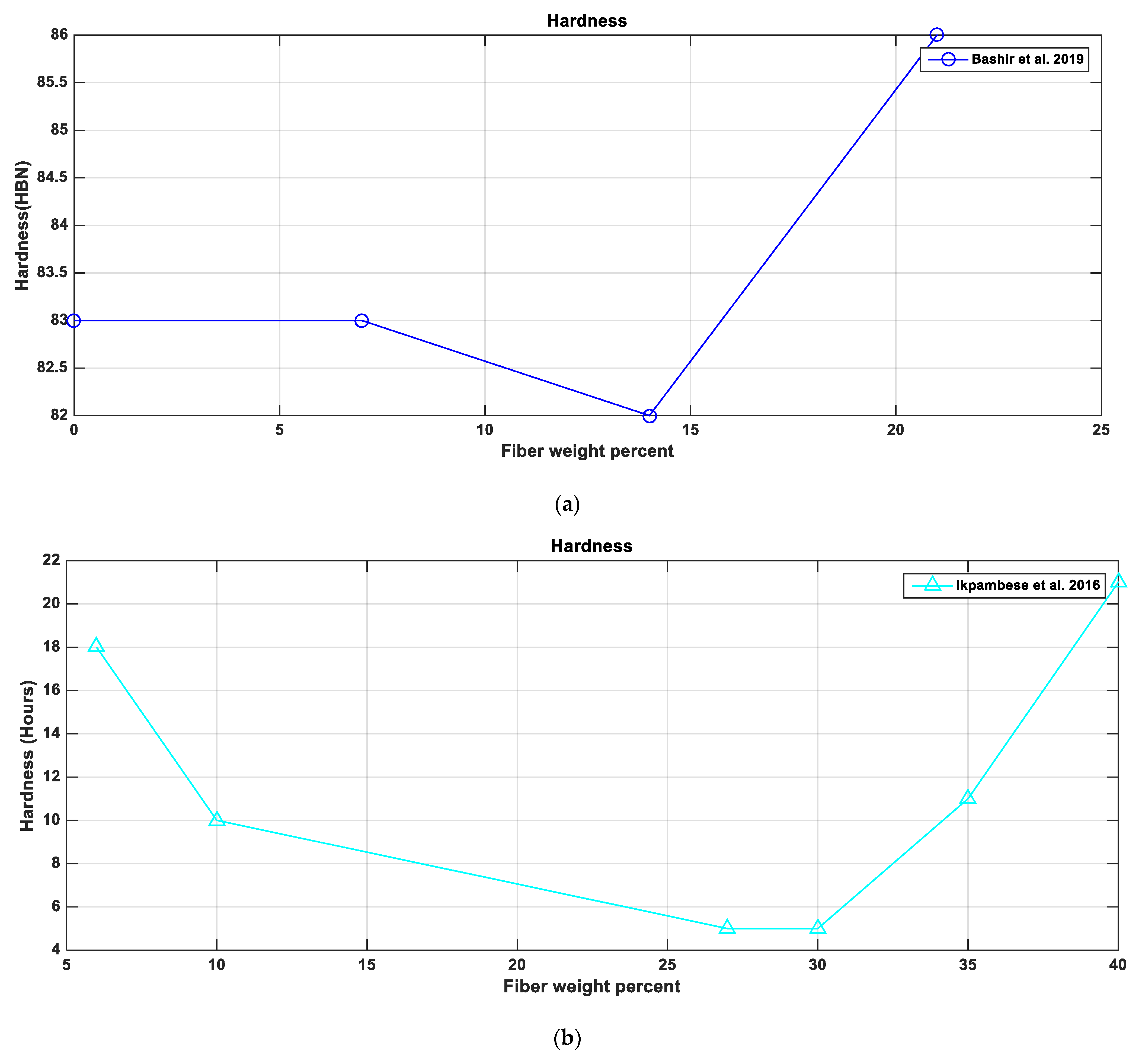

- The hardness of the composites increases for both banana peels and palm kernels, except for the 46% parent matrix and palm kernel as a fiber.

- 4-

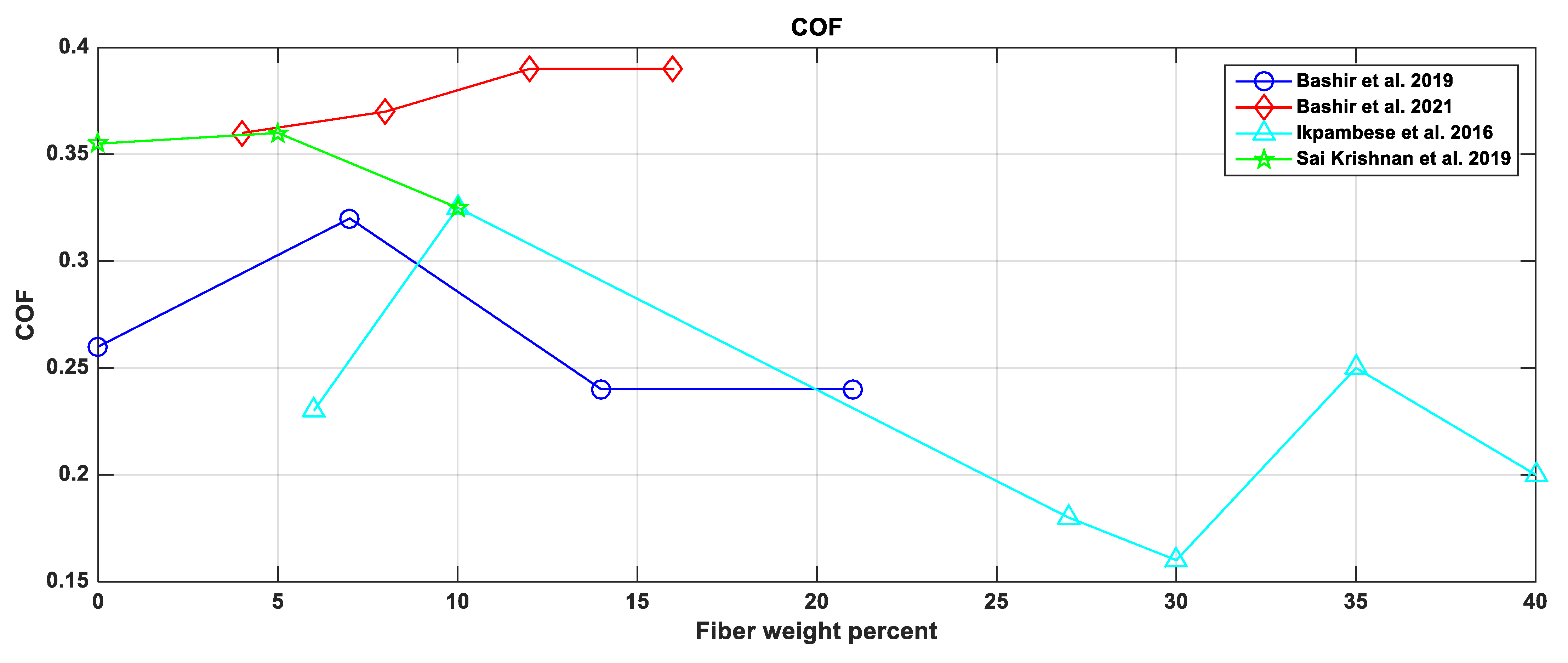

- The COF increases initially, then decreases and become stable as the weight percentage of natural increases.

- 5-

- Only the 46% parent matrix and palm kernels as fiber show a decrease, followed by an increase, as the percentage of other ingredients change, not just the fiber and resin.

- 6-

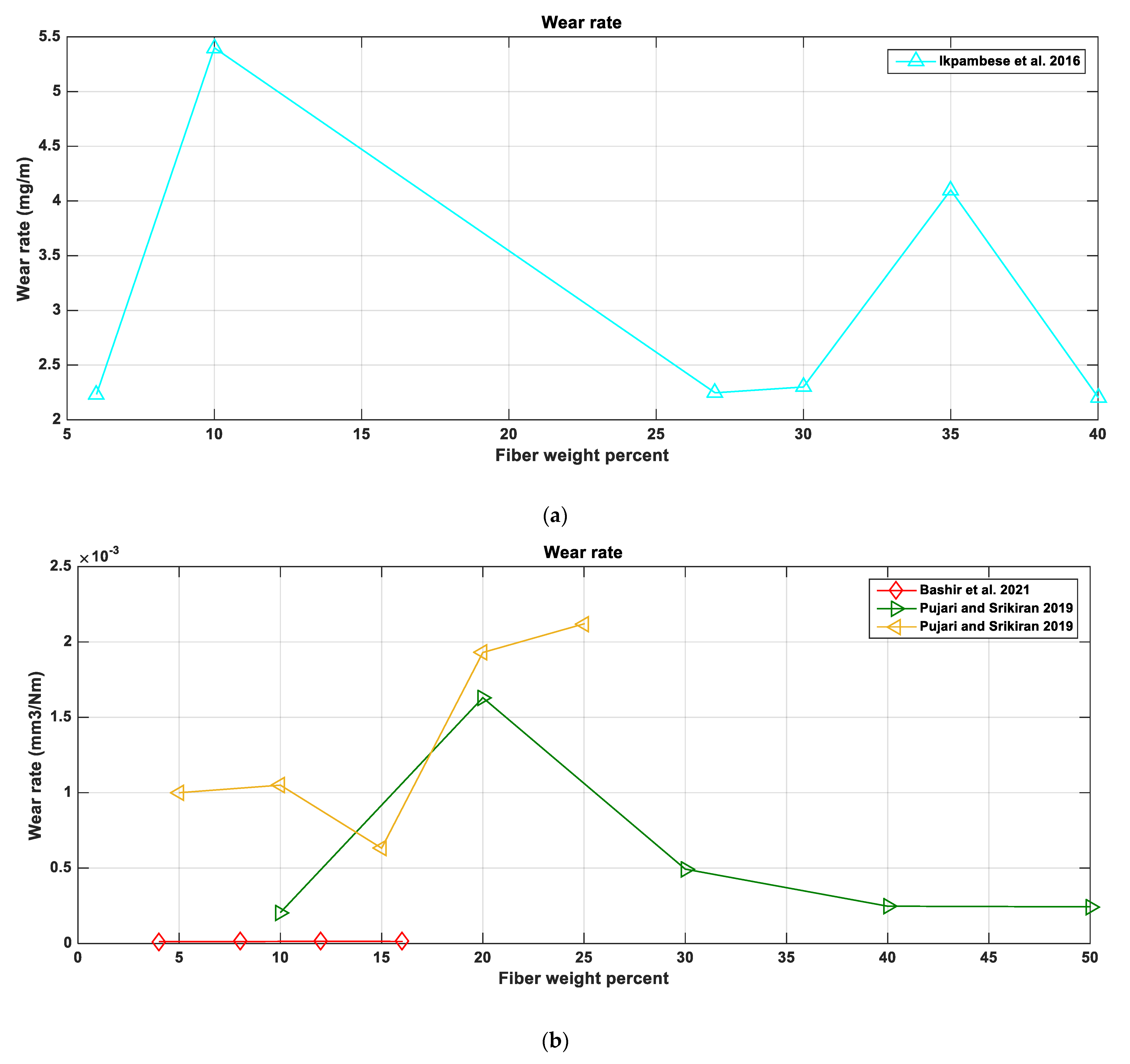

- The wear rate increases as the weight percentage of natural fiber increases, except for palm kernels (10–50%) and 35% phenolic resin.

- 7-

- The compression load during processing has an impact on the mechanical and tribological properties.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tarr, W.; Rhee, S. Static friction of automotive friction materials. Wear 1975, 33, 373–375. [Google Scholar] [CrossRef]

- Bijwe, J. Composites as friction materials: Recent developments in non-asbestos fiber reinforced friction materials? A review. Polym. Compos. 1997, 18, 378–396. [Google Scholar] [CrossRef]

- Tsang, P.; Jacko, M.; Rhee, S. Comparison of Chase and inertial brake Dynamometer testing of automotive friction materials. Wear 1985, 103, 217–232. [Google Scholar] [CrossRef]

- Kumar, V.V.; Kumaran, S.S. Friction material composite: Types of brake friction material formulations and effects of various ingredients on brake performance—A review. Mater. Res. Express 2019, 6, 082005. [Google Scholar] [CrossRef]

- Ibhadode, A.O.A.; Dagwa, I.M. Development of asbestos-free friction lining material from palm kernel shell. J. Braz. Soc. Mech. Sci. Eng. 2008, 30, 166–173. [Google Scholar] [CrossRef]

- Smales, H. Friction Materials—Black Art or Science? Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 1995, 209, 151–157. [Google Scholar] [CrossRef]

- Cruz, J.; Fangueiro, R. Surface Modification of Natural Fibers: A Review. Procedia Eng. 2016, 155, 285–288. [Google Scholar] [CrossRef]

- Thiyagarajan, V.; Kalaichelvan, K.; Vijay, R.; Singaravelu, D.L. Influence of thermal conductivity and thermal stability on the fade and recovery characteristics of non-asbestos semi-metallic disc brake pad. J. Braz. Soc. Mech. Sci. Eng. 2015, 38, 1207–1219. [Google Scholar] [CrossRef]

- Vijay, R.; Singaravelu, D.L.; Filip, P. Influence of molybdenum disulfide particle size on friction and wear characteristics of non-asbestos-based copper-free brake friction composites. Surf. Rev. Lett. 2019, 27, 1950085. [Google Scholar] [CrossRef]

- Mahale, V.; Bijwe, J.; Sinha, S. Influence of nano-potassium titanate particles on the performance of NAO brake-pads. Wear 2017, 376–377, 727–737. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Sustainable Bio-Composites from Renewable Resources: Opportunities and Challenges in the Green Materials World. J. Polym. Environ. 2002, 10, 19–26. [Google Scholar] [CrossRef]

- Balaji, A.; Karthikeyan, B.; Raj, C.S. Bagasse Fiber-The Future Biocomposite Material: A Review. Int. J. Cemtech Res. 2014, 7, 223–233. Available online: https://www.researchgate.net/publication/270453697 (accessed on 5 August 2022).

- Kumar, R.; Singh, S.; Singh, O.V. Bioconversion of lignocellulosic biomass: Biochemical and molecular perspectives. J. Ind. Microbiol. Biotechnol. 2008, 35, 377–391. [Google Scholar] [CrossRef]

- Mehanny, S.; Magd, E.E.A.-E.; Ibrahim, M.; Farag, M.; Gil-San-Millan, R.; Navarro, J.; Habbak, A.E.H.E.; El-Kashif, E. Extraction and characterization of nanocellulose from three types of palm residues. J. Mater. Res. Technol. 2020, 10, 526–537. [Google Scholar] [CrossRef]

- El-Moayed, M.H.; Kühn, J.; Lee, S.-H.; Farag, M.; Mehanny, S. Potential of Lignin Valorization with Emphasis on Bioepoxy Production. In Lignin-Chemistry, Structure, and Application; Sand, A., Tuteja, J., Eds.; IntechOpen: Rijeka, Croatia, 2022. [Google Scholar] [CrossRef]

- Väisänen, T.; Haapala, A.; Lappalainen, R.; Tomppo, L. Utilization of agricultural and forest industry waste and residues in natural fiber-polymer composites: A review. Waste Manag. 2016, 54, 62–73. [Google Scholar] [CrossRef]

- Ashori, A. Municipal Solid Waste as a Source of Lignocellulosic Fiber and Plastic for Composite Industries. Polym. Technol. Eng. 2008, 47, 741–744. [Google Scholar] [CrossRef]

- Mehanny, S.; Farag, M.; Rashad, R.M.; Elsayed, H. Fabrication and characterization of starch based bagasse fiber composite. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE), Houston, TX, USA, 9–15 November 2012; Volume 3, no. PARTS A, B, and C. pp. 1345–1353. [Google Scholar] [CrossRef]

- Ibrahim, M.; Moustafa, H.; EL Rahman, E.N.A.; Mehanny, S.; Hemida, M.H.; El-Kashif, E. Reinforcement of Starch Based Biodegradable Composite Using Nile Rose Residues. J. Mater. Res. Technol. 2020, 9, 6160–6171. [Google Scholar] [CrossRef]

- Mehanny, S.; Darwish, L.; El Haleem, A.; El Habbak, M.; El-Kashif, E.; Farag, M.; Ibrahim, H. Effect of Glue and Temperatures on Mechanical Properties of Starch-Based Biodegradable Composites Reinforced with Bagasse Fibers. Int. J. Biotechnol. Biomater. Eng. 2019, 1, 2. [Google Scholar]

- Zoghlami, A.; Paës, G. Lignocellulosic Biomass: Understanding Recalcitrance and Predicting Hydrolysis. Front. Chem. 2019, 7, 874. [Google Scholar] [CrossRef]

- Anderson, E.M.; Stone, M.L.; Katahira, R.; Reed, M.; Muchero, W.; Ramirez, K.J.; Beckham, G.T.; Román-Leshkov, Y. Differences in S/G ratio in natural poplar variants do not predict catalytic depolymerization monomer yields. Nat. Commun. 2019, 10, 2033. [Google Scholar] [CrossRef] [Green Version]

- Hassan, S.S.; Williams, G.A.; Jaiswal, A.K. Moving towards the second generation of lignocellulosic biorefineries in the EU: Drivers, challenges, and opportunities. Renew. Sustain. Energy Rev. 2019, 101, 590–599. [Google Scholar] [CrossRef]

- Mehanny, S.; Ibrahim, H.; Darwish, L.; Farag, M.; El-Habbak, A.-H.M.; El-Kashif, E. Effect of Environmental Conditions on Date Palm Fiber Composites. In Date Palm Fiber Composites; Springer: Singapore, 2020; pp. 287–320. [Google Scholar] [CrossRef]

- Ibrahim, H.; Mehanny, S.; Darwish, L.; Farag, M. A Comparative Study on the Mechanical and Biodegradation Characteristics of Starch-Based Composites Reinforced with Different Lignocellulosic Fibers. J. Polym. Environ. 2017, 26, 2434–2447. [Google Scholar] [CrossRef]

- Mehanny, S.; Darwish, L.; Ibrahim, H.; El-Wakad, M.T.; Farag, M. High-Content Lignocellulosic Fibers Reinforcing Starch-Based Biodegradable Composites: Properties and Applications. In Composites from Renewable and Sustainable Materials; InTech: London, UK, 2016. [Google Scholar] [CrossRef]

- Mehanny, S.; Magd, E.; Sorbara, S.; Navarro, J.; Gil-San-Millan, R. Spanish Poplar Biomass as a Precursor for Nanocellulose Extraction. Appl. Sci. 2021, 11, 6863. [Google Scholar] [CrossRef]

- Elsayed, H.; Farag, M.; Megahed, H.; Mehanny, S. Influence of flax fibers on properties of starch-based composites. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE), Houston, TX, USA, 9–15 November 2012; Volume 3, no. PARTS A, B, and C. pp. 1397–1408. [Google Scholar] [CrossRef]

- Delgado, C.O.; Fleuri, L.F. Orange and mango by-products: Agro-industrial waste as source of bioactive compounds and botanical versus commercial description—A review. Food Rev. Int. 2015, 32, 1–14. [Google Scholar] [CrossRef]

- Spasiano, D.; Pirozzi, F. Treatments of asbestos containing wastes. J. Environ. Manag. 2017, 204, 82–91. [Google Scholar] [CrossRef]

- Pini, M.; Scarpellini, S.; Rosa, R.; Neri, P.; Gualtieri, A.F.; Ferrari, A.M. Management of Asbestos Containing Materials: A Detailed LCA Comparison of Different Scenarios Comprising First Time Asbestos Characterization Factor Proposal. Environ. Sci. Technol. 2021, 55, 12672–12682. [Google Scholar] [CrossRef]

- Tukker, A. Peer Reviewed: Life-cycle assessment and the precautionary principle. Environ. Sci. Technol. 2002, 36, 70A–75A. [Google Scholar] [CrossRef] [Green Version]

- Guinée, J.B.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Ekvall, T.; Rydberg, T. Life Cycle Assessment: Past, Present, and Future. Environ. Sci. Technol. 2010, 45, 90–96. [Google Scholar] [CrossRef]

- Muralikrishna, I.V.; Manickam, V. (Eds.) Chapter Five—Life Cycle Assessment. In Environmental Management; Butterworth-Heinemann: Oxford, UK, 2017; pp. 57–75. [Google Scholar] [CrossRef]

- Terazono, A.; Moriguchi, Y.; Sakai, S.; Takatsuki, H. Environmental impact assessment of sprayed-on asbestos in buildings. J. Mater. Cycles Waste Manag. 2000, 2, 80–88. [Google Scholar] [CrossRef]

- Loss, A.; Toniolo, S.; Mazzi, A.; Manzardo, A.; Scipioni, A. LCA comparison of traditional open cut and pipe bursting systems for relining water pipelines. Resour. Conserv. Recycl. 2018, 128, 458–469. [Google Scholar] [CrossRef]

- Ramesh, M.; Deepa, C.; Kumar, L.R.; Sanjay, M.R.; Siengchin, S. Life-cycle and environmental impact as-sessments on processing of plant fibres and its bio-composites: A critical review. J. Ind. Tex. 2020, 51, 5518S–5542S. [Google Scholar] [CrossRef]

- Sial, T.A.; Khan, M.N.; Lan, Z.; Kumbhar, F.; Ying, Z.; Zhang, J.; Sun, D.; Li, X. Contrasting effects of banana peels waste and its biochar on greenhouse gas emissions and soil biochemical properties. Process. Saf. Environ. Prot. 2018, 122, 366–377. [Google Scholar] [CrossRef]

- Parfitt, J.; Barthel, M.; Macnaughton, S. Food waste within food supply chains: Quantification and potential for change to 2050. Philos. Trans. R. Soc. B Biol. Sci. 2010, 365, 3065–3081. [Google Scholar] [CrossRef]

- Kimbrough, R.D. Halogenated Biphenyls, Terphenyls, Naphthalenes, Dibenzodioxins and Related Products. Food Chem. Toxicol. 1982, 20, 232–233. [Google Scholar] [CrossRef]

- Lam, S.S.; Liew, R.K.; Cheng, C.K.; Rasit, N.; Ooi, C.K.; Ma, N.L.; Ng, J.-H.; Lam, W.H.; Chong, C.T.; Chase, H.A. Pyrolysis production of fruit peel biochar for potential use in treatment of palm oil mill effluent. J. Environ. Manag. 2018, 213, 400–408. [Google Scholar] [CrossRef]

- Eriksson, M.; Spångberg, J. Carbon footprint and energy use of food waste management options for fresh fruit and vegetables from supermarkets. Waste Manag. 2017, 60, 786–799. [Google Scholar] [CrossRef]

- Bashir, M.; Qayoum, A.; Saleem, S.S. Influence of lignocellulosic banana fiber on the thermal stability of brake pad material. Mater. Res. Express 2019, 6, 115551. [Google Scholar] [CrossRef]

- Bashir, M.; Qayoum, A.; Saleem, S.S. Experimental Investigation of Thermal and Tribological Characteristics of Brake Pad Developed from Eco-Friendly Materials. J. Bio- Tribo-Corrosion 2021, 7, 66. [Google Scholar] [CrossRef]

- Kholil, A.; Dwiyati, S.T.; Wirawan, R.; Elvin, M. Brake Pad Characteristics of Natural Fiber Composites from Coconut Fibre and Wood Powder. J. Phys. Conf. Ser. 2021, 2019, 012068. [Google Scholar] [CrossRef]

- Sutikno; Pramujati, B.; Safitri, S.D.; Razitania, A. Characteristics of natural fiber reinforced composite for brake pads material. AIP Conf. Proc. 2018, 1983, 050009. [Google Scholar] [CrossRef]

- Kholil, A.; Dwiyati, S.T.; Sugiharto, A.; Sugita, I.W. Characteristics composite of wood powder, coconut fiber and green mussel shell for electric motorcycle brake pads. J. Phys. Conf. Ser. 2019, 1402, 055095. [Google Scholar] [CrossRef]

- Singh, T.; Pruncu, C.I.; Gangil, B.; Singh, V.; Fekete, G. Comparative performance assessment of pineapple and Kevlar fibers based friction composites. J. Mater. Res. Technol. 2020, 9, 1491–1499. [Google Scholar] [CrossRef]

- Craciun, A.L.; Pinca-Bretotean, C.; Utu, I.-D.; Josan, A. Tribological properties of nonasbestos brake pad material by using coconut fiber. IOP Conf. Ser. Mater. Sci. Eng. 2017, 163, 12014. [Google Scholar] [CrossRef]

- Maleque, M.A.; Atiqah, A. Development and Characterization of Coir Fibre Reinforced Composite Brake Friction Materials. Arab. J. Sci. Eng. 2013, 38, 3191–3199. [Google Scholar] [CrossRef]

- Fu, Z.; Suo, B.; Yun, R.; Lu, Y.; Wang, H.; Qi, S.; Jiang, S.; Lu, Y.; Matejka, V. Development of eco-friendly brake friction composites containing flax fibers. J. Reinf. Plast. Compos. 2012, 31, 681–689. [Google Scholar] [CrossRef]

- Idris, U.; Aigbodion, V.; Abubakar, I.; Nwoye, C. Eco-friendly asbestos free brake-pad: Using banana peels. J. King Saud Univ.-Eng. Sci. 2015, 27, 185–192. [Google Scholar] [CrossRef] [Green Version]

- Ma, Y.; Shen, S.; Tong, J.; Ye, W.; Yang, Y.; Zhou, J. Effects of bamboo fibers on friction performance of friction materials. J. Thermoplast. Compos. Mater. 2012, 26, 845–859. [Google Scholar] [CrossRef]

- Sukrawan, Y.; Hamdani, A.; Mardani, S.A. Effect of bamboo weight faction on mechanical properties in non-asbestos composite of motorcycle brake pad. Mater. Phys. Mech. 2019, 42, 367–372. [Google Scholar] [CrossRef]

- Balaji, M.A.S.; Kalaichelvan, K.; Mohanamurugan, S.; Balaji, M.A.S. Effect of varying cashew dust and resin on friction material formulation: Stability and sensitivity of μ to pressure, speed and temperature. Int. J. Surf. Sci. Eng. 2014, 8, 327–344. [Google Scholar] [CrossRef]

- Ikpambese, K.; Gundu, D.; Tuleun, L. Evaluation of palm kernel fibers (PKFs) for production of asbestos-free automotive brake pads. J. King Saud Univ.-Eng. Sci. 2016, 28, 110–118. [Google Scholar] [CrossRef]

- Pujari, S.; Srikiran, S. Experimental investigations on wear properties of Palm kernel reinforced composites for brake pad applications. Def. Technol. 2018, 15, 295–299. [Google Scholar] [CrossRef]

- Kumar, N.; Singh, T.; Grewal, J.S.; Patnaik, A.; Fekete, G. Experimental investigation on the physical, mechanical and tribological properties of hemp fiber-based non-asbestos organic brake friction composites. Mater. Res. Express 2019, 6, 085710. [Google Scholar] [CrossRef]

- Afolabi, M.; Abubakre, O.; Lawal, S.; Raji, A. Experimental Investigation of Palm Kernel Shell and Cow Bone Reinforced Polymer Composites for Brake Pad Production. Int. J. Chem. Mater. Res. 2015, 3, 27–40. [Google Scholar] [CrossRef]

- Swamidoss, V.F.; Prasanth. Fabrication and characterization of brake pad using pineapple leaf fiber (palf). Int. J. Res. Comput. Appl. Nrobotics 2015, 3, 107–111. Available online: https://www.ijrcar.com (accessed on 6 June 2022).

- Crăciun, A.L.; Heput, T.; Bretotean, C.P. Formulation of materials with natural fiber for brake system components. Ann. Fac. Eng. Hunedoara-Int. J. Eng. 2016, 14, 17–20. [Google Scholar]

- Ghazali, C.M.R.; Kamarudin, H.; Shamsul, J.B.; Abdullah, M.M.A.; Rafiza, A. Mechanical Properties and Wear Behavior of Brake Pads Produced from Palm Slag. Adv. Mater. Res. 2011, 341–342, 26–30. [Google Scholar] [CrossRef]

- Rajan, R.; Tyagi, Y.K.; Singh, S. Waste and natural fiber based automotive brake composite materials: Influence of slag and coir on tribological performance. Polym. Compos. 2021, 43, 1508–1517. [Google Scholar] [CrossRef]

- Gawande, S.H.; Raibhole, V.N.; Banait, A.S. Study on Tribological Investigations of Alternative Automotive Brake Pad Materials. J. Bio-Tribo-Corros. 2020, 6, 93. [Google Scholar] [CrossRef]

- Kussuma, F.; Sutikno. Testing of mechanical characteristics of coconut fiber reinforced for composite brake pads for two-wheeled vehicles. IOP Conf. Ser. Mater. Sci. Eng. 2019, 546, 042018. [Google Scholar] [CrossRef]

- Ma, Y.; Liu, Y.; Shang, W.; Gao, Z.; Wang, H.; Guo, L.; Tong, J. Tribological and mechanical properties of pine needle fiber reinforced friction composites under dry sliding conditions. RSC Adv. 2014, 4, 36777–36783. [Google Scholar] [CrossRef]

- Krishnan, G.S.; Babu, L.G.; Pradhan, R.; Kumar, S. Study on tribological properties of palm kernel fiber for brake pad applications. Mater. Res. Express 2019, 7, 015102. [Google Scholar] [CrossRef]

- Naveen, E.; Venkatachalam, N.; Maheswaran, N. Alkalichemical Treatment on the Surface of Natural Fiber. 2007. Available online: www.saeindiaskcet.org (accessed on 1 April 2022).

- Liu, W.; Mohanty, A.K.; Drzal, L.T.; Askel, P.; Misra, M. Effects of alkali treatment on the structure, morphology and thermal properties of native grass fibers as reinforcements for polymer matrix composites. J. Mater. Sci. 2004, 39, 1051–1054. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Hassan, S.B.; Asuke, F.; Agunsoye, J.O. Experimental Investigation of the Chemo-Mechanical Properties of Electroless Ni-Zn-P/Cow Horn Particle Composite Coating on Mild Steel View Project Development of Asbestos-Free Brake Pad Using Bagasse. 2010. Available online: https://www.researchgate.net/publication/287501538 (accessed on 9 June 2022).

- Hwang, S.Y.; Lee, N.R.; Kim, N. Experiment and Numerical Study of Wear in Cross Roller Thrust Bearings. Lubricants 2015, 3, 447–458. [Google Scholar] [CrossRef]

- Sawczuk, W.; Ulbrich, D.; Kowalczyk, J.; Merkisz-Guranowska, A. Evaluation of Wear of Disc Brake Friction Linings and the Variability of the Friction Coefficient on the Basis of Vibroacoustic Signals. Sensors 2021, 21, 5927. [Google Scholar] [CrossRef]

- Jang, H.; Ko, K.; Kim, S.; Basch, R.; Fash, J. The effect of metal fibers on the friction performance of automotive brake friction materials. Wear 2004, 256, 406–414. [Google Scholar] [CrossRef]

- El-Tayeb, N.; Liew, K. On the dry and wet sliding performance of potentially new frictional brake pad materials for automotive industry. Wear 2009, 266, 275–287. [Google Scholar] [CrossRef]

| Impact Category | Unit | Residual Material Landfill | Thermal Inertisation Treatment (Allocated) | Thermal Inertisation Treatment (Not Allocated) |

|---|---|---|---|---|

| Human toxicity, cancer | Cases | 2.18 × 10−1 | 3.33 × 10−3 | 5.83 × 10−3 |

| Human toxicity, noncancer | Cases | 1.34 × 10−2 | 4.48 × 10−3 | 7.85 × 10−3 |

| Freshwater ecotoxicity | PAF·m3·day | 1.58 × 1010 | 1.96 × 109 | 3.43 × 109 |

| Friction Composite | Other Ingredients | Fiber Content Variation | Optimum Fiber Content | Fiber Treatment | Manufacturing Process | Ref. |

|---|---|---|---|---|---|---|

| Banana fiber/ PR | Parent matrix (63%) [C, Ca (OH)2, CaCO3, Al2O3, MoS2, Sb2S3, MgO, SiC, SW, PAN fiber, PR] [10, 6, 10, 2, 2.6, 2, 3, 3.4, 12, 12%, balance] | 0, 7, 14, 21 (Wt.%) | 7 Wt.% | - | 15 MPa, 150 °C, 10 min. | [43] |

| Parent matrix (82%) [(CaCO3 and BaSO4), (PAN fiber, CaSiO3, SF), (C, MoS2, Al2O3, SiC, MgO), PR], [30, 29, 23, balance] | 4, 8, 12, 16% (Wt.%) | 12 Wt.% | - | 15 MPa, 150 °C, 10 min. | [44] | |

| [PR, ((BUNCp), (BCp))] [(5, 10, 15, 20, 25, 30%), balance] | BUNCp, BCp | BCp 30% PR, BUNCp 25% PR | - | - | [52] | |

| palm kernel fibers/ER | [ER, Al2O3, C, CaCO3] [(15, 19,23,25,30,40), (5, 0, 10, 5, 5, 6), (5, 5, 10, 5, 5, 29), (40, 70, 30, 35, 20, 15%)] | 35, 6, 27, 30, 40, 10% (Wt.%) | 10 Wt.% | NaOH soaking for 24 h | 100 KN, 25 °C, 2 min | [56] |

| Palm kernel fibers/PR | [PR, C, Al2O3] [35, (35, 30, 25, 20,10), (20, 15, 10, 5, 5%)] | 10, 20, 30, 40, 50% (Wt.%) | 50 Wt.% | NaOH soaking for 24 h | - | [57] |

| [PR, C, Al2O3, wheat, Nile rose] [35, (35, 30, 25, 20,10), (20, 15, 10, 5, 5), (3, 5, 5, 10, 10), (2, 5, 10, 10, 15%) | 5, 10, 15, 20, 25% (Wt.%) | - | - | |||

| Palm slag/PR | [PR, C, SF, Al2O3] [20, 10, 20, 10%] | 40% (Wt.%) | - | - | Hot pressing process | [62] |

| Palm kernel fibers/PR | Parent matrix (46%) [Acrylic fiber, RwF, SF, Ca(OH)₂, PR, NBR, CR, CaO, SiC, artificial C, MoS2, BaSO4] [4, 6, 5, 3, 9, 3, 2, 2, 3, 9, (14, 14, 6), (40, 35, 38%)] | 0, 5, 10% (Wt.%) | 5 Wt.% | NaOH soaking for 24 h | - | [67] |

| Friction Composite | T-M/St | COF | Wear Rate (WR) | WR Unit | T-M/St | Hardness | T-M/St | Porosity (P%) | T-M/St | Compressive Strength/Compressibility | Thermal Conductivity (TC) | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Banana fiber/ PR | Pin-on-disc- (Figure 1) | - | FWt↑ → WR↑ | g | HBN | FWt↑ → HBN↑ | - | - | - | - | - | [43] |

| Disc brake SAE J661 (Figure 2) | FWt↑ → COF↑ RPM↑ → COF↑ | FWt↑ → WR↑ RPM↑→ WR↑, up to certain point then ↓ | cm3/Nm | HRC. ASTM-E18 | FWt↑ → HRC↑ | - | - | - | - | FWt↑ → TC↑ | [44] | |

| Pin-on-disc- ASTM: G99-05 | FWt↓ → COF↓ | FWt↓→ WR↓ | mg/m | HBN ‘‘B’’ scale | FWt↓→ HBN↑ | - | - | Honsfield Tensometer | FWt↓→ σ↑ | - | [52] | |

| palm kernel fibers/ER | Inertia dynamotor | FWt↑ → COF↓ up to certain point then↑ | FWt↑ → WR↓, up to certain point then↑ | mg/m | Inertia dynamometer | FWt↑ → Hardness↑ | - | FWt↑→ P%↑. | - | - | No trend | [56] |

| Palm kernel fibers/PR | Pin on the disc/ ASTM G-99 | - | FWt↑ → WR↑, up to certain point then↓ | mm3/N.m | HRC ASTM D-785 | FWt↑ → HRC↑ | - | - | - | - | - | [57] |

| FWt↑ → WR↑ | FWt↑ → HRC↑. | - | - | - | - | - | ||||||

| Palm slag/PR | Pin-on-disc | - | Pressure↑ → WR↓ | m3/m | HRC type E. | Pressure↑→HRC↑ | - | - | UTM | Pressure↑ → σ↑ | - | [62] |

| Palm kernel fibers/PR | Chase Test IS2741 | FWt↑ → COF↓ | - | - | HRC K scale. IS 2742 | FWt↓→ HRC↑ | JIS D 4418 | FWt↑→ P%↑. | - | No trend | - | [67] |

| Properties | Commercial Pad (Asbestos Base) | Banana Peels Optimum Formulations | Palm Kernels | Palm Slag | |||||

|---|---|---|---|---|---|---|---|---|---|

| 7 Wt.% & 63% Parent Matrix | 12 Wt.% & 82% Parent Matrix | BCp at 30% Phenolic Resin | BUNCp at 25% Phenolic Resin | 10 Wt.% & 40% Resin | 50 Wt.% & 35% Resin | 5 Wt.% & 46% Parent Matrix | 40 Wt.% at 60 Ton | ||

| Density (g/cm3) | 1.89 | 1.88 | 2.28 | 1.2 | 1.26 | - | - | - | |

| Porosity | 18% | - | - | - | - | 22% | - | 5.26% | |

| Wear rate | 3.8 mg/m /0.72 × 10−6 mm3/mm | 0.006 g | 1.38 × 10−5 mm3/Nm | 4.67 mg/m | 4.15 mg/m | 3.98 | 2.4 × 10−4 mm3/Nm | - | 0.89 × 10−6 mm3/mm |

| COF | 0.3–0.4 | 0.325 | - | 0.35 | 0.4 | 0.33 | - | 0.36 | |

| Hardness | 101 (Brinell)/9.83 (h) | 83 (Brinell) | 86 (Rockwell) | 71.6 (Brinell) | 98.8 (Brinell) | 10 (h) | 2.98 (Rockwell) | 97 (Rockwell) | 61 (Rockwell) |

| Compressive strength (MPa) | 110 | 61.2 | 95.6 | - | 57.7 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ammar, Z.; Ibrahim, H.; Adly, M.; Sarris, I.; Mehanny, S. Influence of Natural Fiber Content on the Frictional Material of Brake Pads—A Review. J. Compos. Sci. 2023, 7, 72. https://doi.org/10.3390/jcs7020072

Ammar Z, Ibrahim H, Adly M, Sarris I, Mehanny S. Influence of Natural Fiber Content on the Frictional Material of Brake Pads—A Review. Journal of Composites Science. 2023; 7(2):72. https://doi.org/10.3390/jcs7020072

Chicago/Turabian StyleAmmar, Zeina, Hamdy Ibrahim, Mahmoud Adly, Ioannis Sarris, and Sherif Mehanny. 2023. "Influence of Natural Fiber Content on the Frictional Material of Brake Pads—A Review" Journal of Composites Science 7, no. 2: 72. https://doi.org/10.3390/jcs7020072

APA StyleAmmar, Z., Ibrahim, H., Adly, M., Sarris, I., & Mehanny, S. (2023). Influence of Natural Fiber Content on the Frictional Material of Brake Pads—A Review. Journal of Composites Science, 7(2), 72. https://doi.org/10.3390/jcs7020072