Fracture Mechanisms and Toughness in Polymer Nanocomposites: A Brief Review

Abstract

:1. Introduction

2. Fracture Mechanics and Toughness of Polymer Nanocomposites

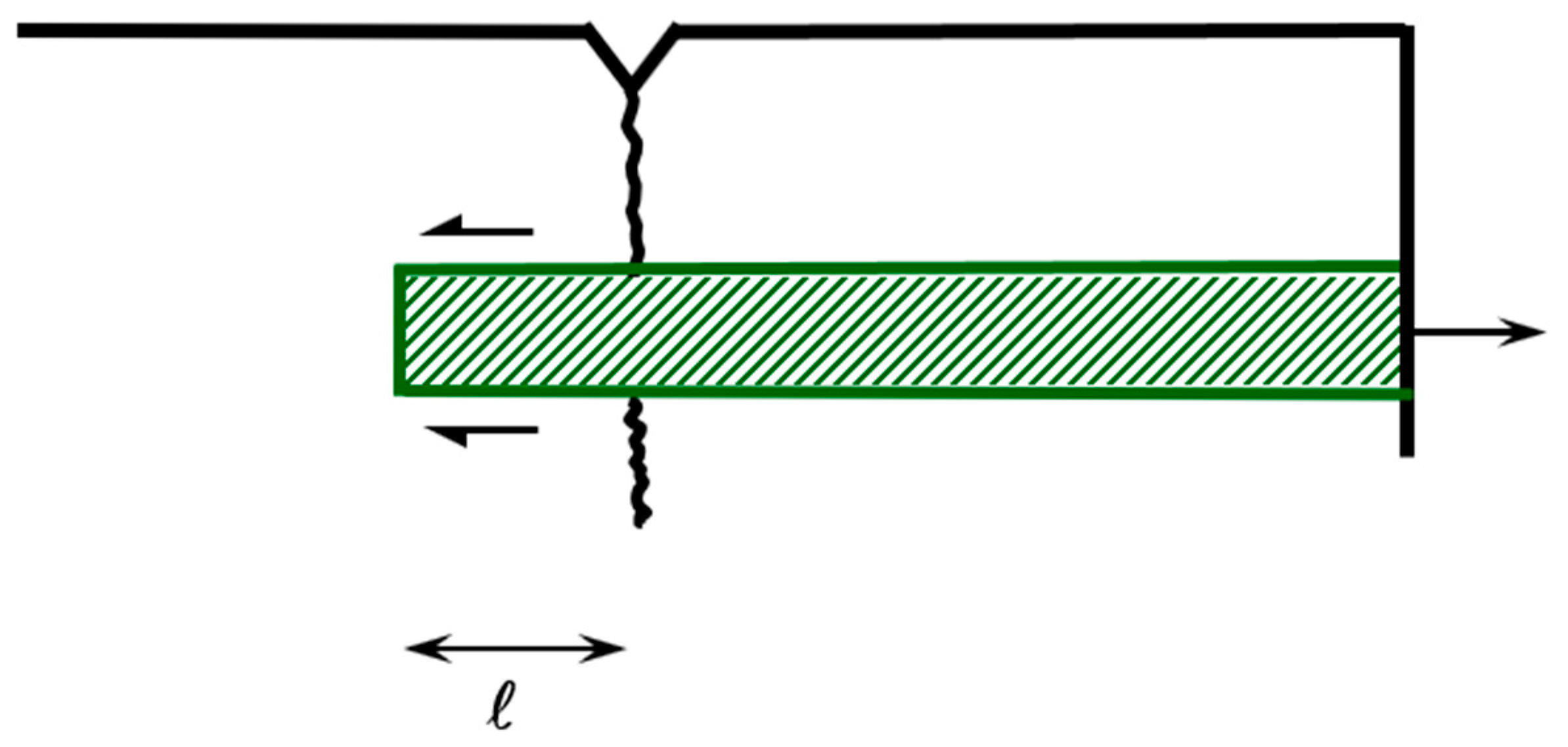

2.1. Nanofiber Pull-Out

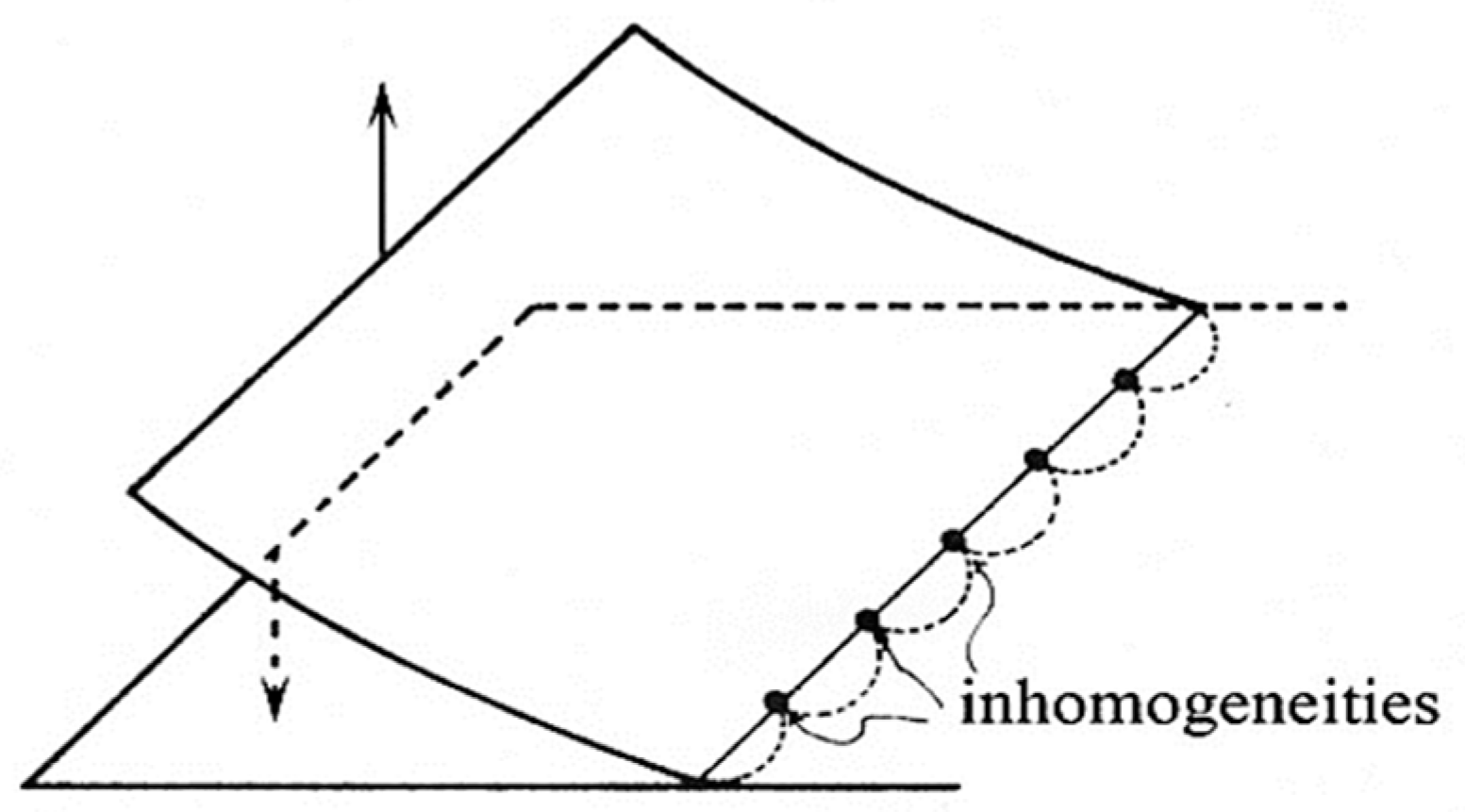

2.2. Crack Front Bowing

3. Examples of Fracture in Nanocomposites

- Nanocomposite films of pullulan reinforced by starch nanoplatelets (biomimicking a leaf vein network structure) exhibited enhanced mechanical properties: specifically, toughness values of pullulan with 1% w/w nanoplatelets reached up to 69.65 MJ m−3, being 223% higher than that of the neat pullulan film [8].

- Nanocomposites of an epoxy matrix, reinforced by a hybrid nanofiller consisting of exfoliated montmorillonite clay layers inside a fibrous network of cellulose nanofibers (CNF), were developed by using a sustainable green hybrid nanofiller. The inclusion of 0.5 phr of only CNF (1.085 MPa m1/2) enhanced the fracture toughness value by 25% compared to neat epoxy (from 0.866 MPa m½ to 1.085 MPa m½). Although the addition of nanoclay alone did not exhibit a significant improvement, the addition of 0.5 phr of the hybrid nanofiller resulted in a drastic increase of 32.3% in the KIC value (1.176 MPa m1/2) [9].

- Efficient balance between hardness/toughness and transparency was obtained in PMMA-based nanocomposites, by the simultaneous addition of controlled amounts of poly (vinyl butyral) (PVB) and titania (TiO2) nanofibers.Accordingly, PMMA/PVB/TiO2 composites containing 3 wt% and 5 wt% nanoparticles exhibited a significantly higher fracture toughness compared with the neat polymer: 2.73 (0.128) MPa m1/2, 4.24 (0.154) MPa m1/2, and 3.16 (0.495) MPa m1/2, respectively. Also, the fracture toughness of the PMMA nanocomposite was increased by 55% by the addition of 3 wt% titania nanoparticles, while maintaining a high transmittance above 75–80% in the visible domain [10].

- Thermo-conductive and healable nanocomposites, exhibiting a nacre-like hierarchical architecture, produced by incorporating boron nitride nanosheets (BNNSs) into a polyurethane matrix through a bottom-up assembly process and lamination technology, resulted in a simultaneous enhancement in stiffness of 5.3 times, in strength of 20.1 times, and in fracture toughness of 16.4 times in the nacre-mimetic nanocomposite compared to those of the polyurethane matrix [11].

- Multiwall carbon nanotube (MWCNT)-MXene hybrid nanofillers-based epoxy nanocomposites exhibited a fracture toughness of 1.79 MPa·m1/2 with the addition of 1 wt% MWCNT/MXene hybrid, as compared to only 0.97 MPa·m1/2 of the neat epoxy measured, primarily attributed to crack deflection and filler debonding mechanisms [12].

- A nacre-inspired lightweight and thermally conductive boron nitride nanosheet/epoxy layered (BNNEL) nanocomposite, exhibited a high fracture toughness of 4.22 MPa·m1/2 at a boron nitride nanosheet loading of 2.08 vol.%, being seven-fold higher than the fracture toughness of the pure epoxy matrix [13].

- Poly(arylene ether ketone)-based nanocomposites, containing 0.1% of cellulose nanofibers (CNF), preliminarily dispersed in the monomer prior to polymerization, increased both tensile strength and elongation and improved the tensile fracture toughness to approximately two-fold, to 44.1 MJ m−3, as compared to 21.3 MJ m−3 in the pure matrix. An amount of 0.1% was found to be the maximum CNF amount, which did not reduce the molecular weight of the poly(arylene ether ketone) matrix. At 0.1 wt% CNF, both tensile strength and elongation increased about 30% and 83%, respectively, and the tensile toughness was increased by 207%, through the interaction between the matrix and the nanofiber filler [14].

- A silicone rubber-based stretchable piezoresistive strain sensor nanocomposite was synergistically toughened, using multiwalled carbon nanotubes (MWCNTs) and molybdenum disulfide (MoS2). A toughness of 8.46 kJ/m3 was obtained at 5 phr MWCNT-MoS2 hybrids, being 125% higher than the unfilled rubber, indicating a significant synergistic effect of the hybrid filler [15].

- The effect of random Graphene Nanoplatelets (GNP) versus aligned Fe3O4-GNP nanoplatelets on the fracture resistance of epoxy nanocomposites was investigated, attempting at optimizing fracture properties like the crack growth resistance (KIC), critical stress in tensity factor (GIC), and critical crack tip opening displacement (CTODc). The results indicated a significant increase in fracture toughness of 27.39% and 58.64% for the respective aligned Fe3O4-GNP and GNP loadings, at 0.600 wt%, (1.2 MPa m1/2 and 1.49 MPa m1/2, respectively, as compared to 0.94 MPa m1/2, for pure epoxy) [16].

- Nanocomposites of PMMA-ZrO2 were investigated for biomedical and denture implant applications. The fracture toughness consistently increased with increasing nanofiller content, reaching a maximum value of 6.58 MPa m½, obtained at a 5% nanofiller content (as compared to about 5 MPa m½ for the neat PMMA), and drastically decreased with higher nanofiller contents [17].

- A “bottom-up” manufacturing method of montmorillonite-based nanocomposite material was investigated with the purpose of mimicking the freshwater mussel Cristaria plicata’s nacre architecture and properties by the self-assembly of montmorillonite/chitosan/polyvinyl alcohol and low-temperature lamination process—thus resembling the mussel’s shell consisting of a combination of aragonite and organic matter arranged in an oriented “Brick-and-Mortar” pattern. A fracture toughness of ~2.2 MPa m1/2 was obtained for the artificial nacre, which is only slightly lower than that of natural C. plicata nacre (~2.4 MPa m1/2) [18].

- Epoxy-based nanocomposites reinforced by carbon nanotubes (CNT) sponge were prepared in order to solve the difficulties associated with the dispersion and re-agglomeration of the CNTs. The KIC value of the nanocomposites reached 1.86 MPa m1/2, being 104% higher compared with that of the matrix (KIC(Epoxy) = 0.91 MPa m1/2). The improved fracture properties of nanocomposites were mainly attributed to crack deflection and bifurcation [19].

- The effect of nanofillers dimensions on the mechanical and toughness properties of epoxy resin was investigated using two-dimensional boron nitride (BN) and zero-dimensional silica (SiO2). At 3.0 wt%, KIC values of 1.020 MPa m0.5 and 1.135 MPa m0.5, were obtained for epoxy/BN and epoxy/SiO2, respectively, as compared to 0.597 MPa m0.5 for the neat epoxy [20].

- Nanocomposites consisting of epoxy/carbon fabric (CF) laminate composites with inclusions of 0.5 to 2 wt% multiwalled carbon nanotubes (MWCNT) were analyzed. The volume fraction of carbon fabric was 0.65 for all the laminates. The tensile and fracture properties of the composites improved significantly with MWCNT content, but declined beyond 1 wt%, due to agglomeration. The fracture toughness properties of epoxy nano and multiscale composites were 3.0 MPa m1/2 and 19.1 MPa m1/2, respectively, as compared to 1.8 MPa m1/2 for the neat epoxy [21].

- Carboxyl-functionalized multiwalled carbon nanotubes (COOH-MWCNTs) and a thermoplastic polyetherimide (TP), were combined with each of the two types of epoxy resins, namely, diglycidyl ether of bisphenol A (DGEBA) and tetraglycidyl-4,4′-diaminodiphenylmethane (TGDDM). The Mode-I fracture toughness (GIC), of the epoxy blends exhibited a synergistic enhancement in the fracture toughness of the resin. The highest obtained values for DGEBA were with 0.3% CNT and 10% TP: 182.6 J m−2, as compared to 96 J m−2 for the pure matrix, and for TGDDM with 0.3% CNT and 10% TP: 130.7 J m−2, as compared to 61.3 J m−2 for the pure matrix [22].

- Epoxy nanocomposites, with two-dimensional (2H polytype) molybdenum disulfide (MoS2) nanoplatelets as a filler, functionalized by simultaneous in situ exfoliation in the presence of cetyltrimethylammonium bromide (CTAB), were fabricated via sonication, ranging in content from 0.1 wt% up to 1 wt%.The maximum fracture properties were obtained with an f-MoS2 nanoplatelets loading of 0.25 wt% as it shows KIC value of 1.52 MPa m1/2, corresponding to an improvement of 81% when compared to neat epoxy (0.84 MPa m1/2), which declined for higher nanoplatelet loads [23].

- Carbon black-filled epoxy nanocomposites were produced with 1%, 3%, 5%, and 10% filler loading. The fracture toughness value of all nanocomposites showed an increasing trend with the increase in the CNBFs loading up to 5%, beyond which a pronounced decline was observed—the highest fracture toughness obtained reached 2.3 MPa m1/2, compared to 0.22 MPa m1/2 for the pure epoxy matrix [24].

- Epoxy nanocomposites with ozone and tetraethylenepentamine (TEPA)-functionalized nanodiamonds (ozone/TEPA ND) were produced to improve thermal conductivity and fracture resistance by enhancing interfacial interactions. The highest fracture toughness was achieved with 0.5 wt% ozone/TEPA ND composites (16.1 MPa m1/2), which was 121% higher than with the pristine non-functionalized ND nanocomposite [25].

- Poly(butylene terephthalate) (PBT) nanocomposites were reinforced with montmorillonite (MMT) and nano precipitated calcium carbonate (NPCC). The highest fracture toughness values were obtained at 6% nanofiller content for each of the two nanocomposite types, i.e., 2.01 MPa m1/2 and 1.86 MPa m1/2 for the PBT-MMT and PBT-NPCC nanocomposites, respectively, being 57% and 45% higher than the fracture toughness of the neat matrix (1.28 MPa m1/2), respectively [26].

- A green and efficient method was used to prepare epoxy/GO nanocomposites by in situ polymerization for synthesizing nanocomposites, eliminating the need for organic solvents and surfactants. EP/GO nanocomposites with 0.6 wt% of GO exhibited a fracture toughness of 1.62 MJ m−3 compared to the fracture toughness of the pure epoxy of 0.66 MJ m−3 [27].

- Hybrid ternary systems of thermoplastic/Cloisite clay/thermoset polyester, containing a thermoplastic additive (copolymer of methyl methacrylate and styrene, were prepared and analyzed. While a consistent decrease in the tensile stress was observed for all tested nanocomposites formulations, as compared to the pristine matrix—all tested samples exhibited significant fracture toughness enhancement. Depending on the nanocomposite formulation type, a maximum fracture toughness enhancement of 66% was obtained [28].

- Epoxy nanocomposites were prepared with aramid nanofibers (ANFs), which were surface-functionalized with chlorinated cellulose nanocrystals and 3-glycidoxypropyltrimethoxysilane, intended at improving compatibility with the epoxy matrix. At 1.5 wt% nanofiber content, the Young’s modulus and tensile strength were increased by 15.1% and 10.1%, respectively, and the fracture toughness exhibited a 250% increase, as compared to the neat epoxy resin [29].

- Nature-derived nanocellulose (NC) reinforcement was used to fabricate shape memory epoxy-based nanocomposites (SMEPNs). NC acetylation modification was performed to improve the compatibility between NCs and the epoxy matrix. SMEPNs with 0.06 wt% of the nanofibers resulted in a fracture toughness improvement of over 42%, along with the enhancement of only several % in the elastic modulus, and ultimate strength [30].

- Epoxy nanocomposites with aramid nanofibers (ANFs) functionalized with glycidyl ether silane exhibited a Young’s modulus and tensile strength increase of 16.8% and 14.0%, respectively, at 1 wt% ANFs, and a fracture toughness increase by 440% at 1.5 wt% ANFs [31].

4. Effects of Agglomeration

5. Aspects of Polymer Chain Behavior and Interphase Formation

5.1. Chain Configuration

5.2. Interphases in Polymer Nanocomposites

6. Nano-Geometrical and Atomic-Scale Effects

7. Theoretical Investigations of Fracture Toughness

8. Interlayer Nanoreinforcements of Polymer Composites

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Stern, N.; Marom, G.; Zhang, L.; Hu, X. Micromechanics of Nanocomposites. In Comprehensive Composite Materials II; Beaumont, P.W.R., Zweben, C.H., Eds.; Academic Press: Oxford, UK, 2018; Volume 6, pp. 1–27. [Google Scholar]

- Marom, G.; Wagner, H.D. Should polymer nanocomposites be regarded as molecular composites? J. Mater. Sci. 2017, 52, 8357–8361. [Google Scholar] [CrossRef]

- Marom, G.; Wagner, H.D. A perspective on the structure and properties of nanocomposites. Polym. Compos. 2020, 41, 2986–2989. [Google Scholar] [CrossRef]

- Lyashenko-Miller, T.; Fitoussi, J.; Marom, G. The loading rate effect on Mode II fracture toughness of composites interleaved with CNT nanocomposites. Nanocomposites 2016, 2, 1–7. [Google Scholar] [CrossRef]

- Lange, F. The interaction of a crack front with a second-phase dispersion. Philos. Mag. 1970, 22, 0983–0992. [Google Scholar] [CrossRef]

- Day, R.J.; Lovell, P.A.; Wazzan, A.A. Toughened carbon/epoxy composites made by using core/shell particles. Compos. Sci. Tech. 2001, 61, 41–56. [Google Scholar] [CrossRef]

- Domun, N.; Hadavinia, H.; Zhang, T.; Sainsbury, T.; Liaghata, G.H.; Vahid, S. Improving the fracture toughness and the strength of epoxy using nanomaterials—A review of the current status. Nanoscale 2015, 7, 10294–10329. [Google Scholar] [CrossRef]

- Xiao, Q.; Dai, M.; Huang, M.; Lim, L.T. Bioinspired pullulan-starch nanoplatelets nanocomposite films with enhanced mechanical properties. Carbohydr. Polym. 2024, 329, 121769. [Google Scholar] [CrossRef]

- George, J.S.; Vahabi, H.; Maria, H.J.; Anju, C.S.; Thomas, S. Sustainable hybrid green nanofiller based on cellulose nanofiber for enhancing the properties of epoxy resin. Colloids Surf. A Physicochem. Eng. Asp. 2024, 694, 134082. [Google Scholar] [CrossRef]

- Stojanović, D.B.; Brajović, L.; Obradović, V.; Mijailović, D.; Dramlić, D.; Kojović, A.; Uskoković, P.S. Hybrid acrylic nanocomposites with excellent transparency and hardness/toughness balance. Prog. Org. Coat. 2020, 139, 105437. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, J.; Zhou, S.; Jing, J.; Fu, J. A nacre-inspired thermo conductive and healable nanocomposite captures extremely enhanced stiffness and toughness. Compos. Part B Eng. 2024, 272, 111228. [Google Scholar] [CrossRef]

- Dong, M.; Tomes, O.; Soul, A.; Hu, Y.; Bilotti, E.; Zhang, H.; Papageorgiou, D.G. Hybrid Ti3C2T x MXene and Carbon Nanotube Reinforced Epoxy Nanocomposites for Self-Sensing and Structural Health Monitoring. ACS Appl. Nano Mater. 2024, 7, 3314–3325. [Google Scholar] [CrossRef]

- Wang, H.; Lu, R.; Li, L.; Liang, C.; Yan, J.; Liang, R.; Sun, G.; Jiang, L.; Cheng, Q. Strong, tough, and thermally conductive nacre-inspired boron nitride nanosheet/epoxy layered nanocomposites. Nano Res. 2024, 17, 820–828. [Google Scholar] [CrossRef]

- Chung, S.; Park, S.A.; Park, S.B.; Kwak, H.; Oh, D.X.; Hwang, D.S.; Jeon, H.; Koo, J.M.; Park, J. Biobased super engineering plastic nanocomposite of cellulose nanofibers and isosorbide. Polym. Degrad. Stab. 2023, 215, 110445. [Google Scholar] [CrossRef]

- Alam, M.N.; Kumar, V.; Lee, D.J.; Choi, J. Synergistically toughened silicone rubber nanocomposites using carbon nanotubes and molybdenum disulfide for stretchable strain sensors. Compos. Part B Eng. 2023, 259, 110759. [Google Scholar] [CrossRef]

- Tiwari, A. Nanocomposite fracture analysis: Aligned Fe3O4-GNP nanoplatelets’ effects on KIC, GIC, CTODc, and fracture mechanisms in epoxy matrices. Compos. Struct. 2024, 341, 118208. [Google Scholar] [CrossRef]

- Kumari, S.; Hussain, A.; Rao, J.; Singh, K.; Avinashi, S.K.; Gautam, C. Structural, mechanical and biological properties of PMMA-ZrO2 nanocomposites for denture applications. Mater. Chem. Phys. 2023, 295, 127089. [Google Scholar] [CrossRef]

- Kexuan, S.; Xu, W.; Wu, N.; Ouyang, S. Mussel-Inspired Renewable and High-Performance Montmorillonite-Based Composites with a “Brick-and-Mortar” Structure. J. Polym. Environ. 2023, 31, 3081–3093. [Google Scholar] [CrossRef]

- Ma, Q.; Hao, B.; Ma, P.C. In-situ characterization on the fracture behavior of three-dimensional polymer nanocomposites reinforced by CNT sponge. Compos. Sci. Technol. 2022, 217, 109132. [Google Scholar] [CrossRef]

- Li, X.; Wang, Q.; Cui, X.; Feng, X.; Teng, F.; Xu, M.; Su, W.; He, J. Study on the mechanical and toughness behavior of epoxy nano-composites with zero-dimensional and two-dimensional nano-fillers. Polymers 2022, 14, 3618. [Google Scholar] [CrossRef]

- Sarath Kumar, P.; Jayanarayanan, K.; Deeraj, B.D.S.; Joseph, K.; Balachandran, M. Synergistic effect of carbon fabric and multiwalled carbon nanotubes on the fracture, wear and dynamic load response of epoxy-based multiscale composites. Polym. Bull. 2022, 79, 5063–5084. [Google Scholar] [CrossRef]

- Ma, H.; Aravand, M.A.; Falzon, B.G. Synergistic enhancement of fracture toughness in multiphase epoxy matrices modified by thermoplastic and carbon nanotubes. Compos. Sci. Technol. 2021, 201, 108523. [Google Scholar] [CrossRef]

- Sahu, M.; Narasimhan, L.; Raichur, A.M.; Sover, A.; Ciobanu, R.C.; Lucanu, N.; Aradoaei, M. Improving fracture toughness of tetrafunctional epoxy with functionalized 2D molybdenum disulfide nanosheets. Polymers 2021, 13, 4440. [Google Scholar] [CrossRef] [PubMed]

- Dungani, R.; Sumardi, I.; Alamsyah, E.M.; Aditiawati, P.; Karliati, T.; Malik, J.; Sulistyono. A study on fracture toughness of nano-structured carbon black-filled epoxy composites. Polym. Bull. 2021, 78, 6867–6885. [Google Scholar] [CrossRef]

- Kim, S.H.; Rhee, K.Y.; Park, S.J. Amine-terminated chain-grafted nanodiamond/epoxy nanocomposites as interfacial materials: Thermal conductivity and fracture resistance. Compos. Part B Eng. 2020, 192, 107983. [Google Scholar] [CrossRef]

- Soudmand, B.H.; Shelesh-Nezhad, K.; Hassanifard, S. Toughness evaluation of poly (butylene terephthalate) nanocomposites. Theor. Appl. Fract. Mech. 2020, 108, 102662. [Google Scholar] [CrossRef]

- Mirzapour, M.; Robert, M.; Benmokrane, B. In Situ Processing to Achieve High-Performance Epoxy Nanocomposites with Low Graphene Oxide Loading. C 2024, 10, 52. [Google Scholar] [CrossRef]

- Chaeichian, S.; Wood-Adams, P.M.; Hoa, S.V. Effect of morphology on fracture toughness of unsaturated polyester-based hybrid nanocomposites. Polymer 2015, 72, 154–164. [Google Scholar] [CrossRef]

- Jung, J.; Sodano, H.A. Cellulose nanocrystal functionalized aramid nanofiber reinforced epoxy nanocomposites with high strength and toughness. Nanotechnology 2023, 34, 245703. [Google Scholar] [CrossRef]

- Yu, T.; Zhu, F.; Peng, X.; Chen, Z. Acetylated Nanocelluloses Reinforced Shape Memory Epoxy with Enhanced Mechanical Properties and Outstanding Shape Memory Effect. Nanomaterials 2022, 12, 4129. [Google Scholar] [CrossRef]

- Jung, J.; Sodano, H.A. High strength epoxy nanocomposites reinforced by epoxy functionalized aramid nanofibers. Polymer 2020, 195, 122438. [Google Scholar] [CrossRef]

- Santos, P.; Silva, A.P.; Reis, P.N. The Effect of Carbon Nanofibers on the Mechanical Performance of Epoxy-Based Composites: A Review. Polymers 2024, 16, 2152. [Google Scholar] [CrossRef]

- Matthews, F.L.; Rawlings, R.D. Composite Materials: Engineering and Science; CRC Press: Boca Raton, FL, USA; Woodhead Publishing Limited: Cambridge, UK, 2006. [Google Scholar]

- Horniak, G.L.; Tibbals, H.F.; Dutta, J.; Moore, J.J. Introduction to Nanoscience & Nanotechnology; CRC Press: New York, NY, USA; Taylor & Francis Group: Abingdon, UK, 2009. [Google Scholar]

- Ozin, G.A.; Arsenault, A.C.; Cademartiri, L. Nanochemistry, A Chemical Approach to Nanomaterials; RSC Publishing: Cambridge, UK, 2009. [Google Scholar]

- Van Olphen, H. An Introduction to Clay Colloid Chemistry; Interscience Publishers: New York, NY, USA, 1964. [Google Scholar]

- Zare, Y. Study of nanoparticles aggregation/agglomeration in polymer particulate nanocomposites by mechanical properties. Compos. Part A Appl. Sci. Manuf. 2016, 84, 158–164. [Google Scholar] [CrossRef]

- Kumar, S. Investigating effect of CNT agglomeration in CNT/polymer nanocomposites using multiscale finite element method. Mech. Mater. 2023, 183, 104706. [Google Scholar] [CrossRef]

- Ma, X.; Zare, Y.; Rhee, K.Y. A two-step methodology to study the influence of aggregation/agglomeration of nanoparticles on Young’s modulus of polymer nanocomposites. Nanoscale Res. Lett. 2017, 12, 621. [Google Scholar] [CrossRef] [PubMed]

- Abhiram, B.R.; Ghosh, D. Influence of nanofiller agglomeration on fracture properties of polymer nanocomposite: Insights from atomistic simulation. Eng. Fract. Mech. 2023, 290, 109503. [Google Scholar]

- Du, H.; Zhang, J.; Fang, C.; Weng, G.J. Modeling the evolution of graphene agglomeration and the electrical and mechanical properties of graphene/polypropylene nanocomposites. J. Appl. Polym. Sci. 2023, 140, 53292. [Google Scholar] [CrossRef]

- Hsieh, T.H.; Kinloch, A.J.; Taylor, A.C.; Kinloch, I.A. The effect of carbon nanotubes on the fracture toughness and fatigue performance of a thermosetting epoxy polymer. J. Mater. Sci. 2011, 46, 7525–7535. [Google Scholar] [CrossRef]

- Bower, D.I. Introduction to Polymer Physics; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- Sommer, J.U.; Reiter, G. (Eds.) Polymer Crystallization—Observations, Concepts and Interpretations; Lecture Notes in Physics; Springer: Berlin, Germany, 2003. [Google Scholar]

- Liu, Q.; Sun, X.; Li, H.; Yan, S. Orientation-induced crystallization of isotactic polypropylene. Polymer 2013, 54, 4404–4421. [Google Scholar] [CrossRef]

- Hu, W. Personal perspective on strain-induced polymer crystallization. J. Phys. Chem. B 2023, 127, 822–827. [Google Scholar] [CrossRef]

- Stern, T. Single-Step Synthesis and Characterization of Non-Linear Tough and Strong Segmented Polyurethane Elastomer Consisting of Very Short Hard and Soft Segments and Hierarchical Side-Reacted Networks and Single-Step Synthesis of Hierarchical Hyper-Branched Polyurethane. Molecules 2024, 29, 1420. [Google Scholar] [CrossRef]

- Stern, T.; Wachtel, E.; Marom, G. Origin, Morphology and Crystallography of Transcrystallinity in Polyethylene-Based Single Polymer Composites. Compos. Part A Appl. Sci. Manuf. 1997, 28, 437–444. [Google Scholar] [CrossRef]

- Quan, H.; Li, Z.-M.; Yang, M.-B.; Huang, R. On transcrystallinity in semi-crystalline polymer composites. Compos. Sci. Technol. 2005, 65, 999–1021. [Google Scholar] [CrossRef]

- Liang, Y.; Zheng, G.; Liu, S.; Dai, K.; Liu, C.; Chen, J.; Shen, C. β-Crystal in the iPP melt encapsulated by transcrystallinity and spherulites: Effect of molecular weight. J. Mater. Sci. 2013, 48, 2326–2333. [Google Scholar] [CrossRef]

- Billon, N.; Magnet, C.; Haudin, J.M.; Lefebvre, D. Transcrystallinity effects in thin polymer films. Experimental and theoretical approach. Colloid Polym. Sci. 1994, 272, 633–654. [Google Scholar] [CrossRef]

- Li, C.; Gao, Y.; Wang, L.; Li, J.; Guo, S. Fabrication, structure, and properties of Poly-(Lactide) multilayers with ultrahigh content, ordered, and continuous transcrystallinity. Polymer 2021, 228, 123933. [Google Scholar] [CrossRef]

- Stern, T.; Teishev, A.; Marom, G.; Varelidis, P.C.; Papaspyrides, C.D. Processing of Composites of Chopped PE Fiber-Reinforced PE Matrix. Adv. Compos. Lett. 1996, 5, 103–106. [Google Scholar]

- Stern, T.; Teishev, A.; Marom, G. Composites of Polyethylene Reinforced with Chopped Polyethylene Fibers: Effect of Transcrystalline Interphase. Compos. Sci. Technol. 1997, 57, 1009–1015. [Google Scholar] [CrossRef]

- Stern, T.; Wachtel, E.; Marom, G. Epitaxy and Lamellar Twisting in Transcrystalline Polyethylene. J. Polym. Sci. Part B Polym. Phys. 1997, 35, 2429–2433. [Google Scholar] [CrossRef]

- Zafeiropoulos, N.E.; Papaspyrides, C.D.; Varelidis, P.C.; Stern, T.; Marom, G. Characterization of Coatings of LDPE Residual Matrix Deposited on Glass Fibers by a Dissolution/Reprecipitation Recycling Process. Compos. Part A Appl. Sci. Manuf. 1999, 30, 831–838. [Google Scholar] [CrossRef]

- Zhang, S.; Minus, M.L.; Zhu, L.; Wong, C.P.; Kumar, S. Polymer transcrystallinity induced by carbon nanotubes. Polymer 2008, 49, 1356–1364. [Google Scholar] [CrossRef]

- Lenes, M.; Gregersen, Ø.W. Effect of surface chemistry and topography of sulphite fibres on the transcrystallinity of polypropylene. Cellulose 2006, 13, 345–355. [Google Scholar] [CrossRef]

- Karger-Kocsis, J. Interphase with Lamellar Interlocking and Amorphous Adherent—A Model to Explain Effects of Transcrystallinity. Adv. Compos. Lett. 2000, 9, 96369350000900. [Google Scholar] [CrossRef]

- Abdou, J.P.; Reynolds, K.J.; Pfau, M.R.; van Staden, J.; Braggin, G.A.; Tajaddod, N.; Minus, M.; Reguero, V.; Vilatela, J.J.; Zhang, S. Interfacial crystallization of isotactic polypropylene surrounding macroscopic carbon nanotube and graphene fibers. Polymer 2016, 91, 136–145. [Google Scholar] [CrossRef]

- Liang, Y.; Liu, S.; Dai, K.; Wang, B.; Shao, C.; Zhang, Q.; Wang, S.; Zheng, G.; Liu, C.; Chen, J.; et al. Transcrystallization in nanofiber bundle/isotactic polypropylene composites: Effect of matrix molecular weight. Colloid Polym. Sci. 2012, 290, 1157–1164. [Google Scholar] [CrossRef]

- Cho, B.G.; Lee, J.E.; Hwang, S.H.; Han, J.H.; Chae, H.G.; Park, Y.B. Enhancement in mechanical properties of polyamide 66-carbon fiber composites containing graphene oxide-carbon nanotube hybrid nanofillers synthesized through in situ interfacial polymerization. Compos. Part A Appl. Sci. Manuf. 2020, 135, 105938. [Google Scholar] [CrossRef]

- Karevan, M.; Kalaitzidou, K. Formation of a complex constrained region at the graphite nanoplatelets-polyamide 12 interface. Polymer 2013, 54, 3691–3698. [Google Scholar] [CrossRef]

- Zare, Y.; Rhee, K.Y. A simple technique for calculation of an interphase parameter and interphase modulus for multilayered interphase region in polymer nanocomposites via modeling of young’s modulus. Phys. Mesomech. 2020, 23, 332–339. [Google Scholar] [CrossRef]

- Zare, Y.; Rhee, K.Y. Dependence of Z parameter for tensile strength of multi-layered interphase in polymer nanocomposites to material and interphase properties. Nanoscale Res. Lett. 2017, 12, 42. [Google Scholar] [CrossRef]

- Huang, J.; Zhou, J.; Liu, M. Interphase in polymer nanocomposites. JACS Au 2022, 2, 280–291. [Google Scholar] [CrossRef]

- Brent Strong, A. Plastics—Materials and Processing; Prentice Hall: Upper Saddle River, NJ, USA, 1996. [Google Scholar]

- Stern, T. Transcrystalline Mechanism of Banded Spherulites Development in Melt-Crystallized Semicrystalline Polymers. Polymers 2024, 16, 2411. [Google Scholar] [CrossRef]

- Stern, T. Polymeric Micro-Sequential Concentric Transcrystalline Morphology Self-Assembly, with Intermittent Self-Shear-Oriented Amorphous Layers. Polym. Adv. Technol. 2017, 28, 1670–1675. [Google Scholar] [CrossRef]

- Su, F.; Ji, Y.; Meng, L.; Chang, J.; Chen, L.; Li, L. Shear-induced precursors in polyethylene: An in-situ synchrotron radiation scanning X-ray microdiffraction study. Polymer 2018, 135, 61–68. [Google Scholar] [CrossRef]

- Yao, X.; Gao, X.; Jiang, J.; Xu, C.; Deng, C.; Wang, J. Comparison of carbon nanotubes and graphene oxide coated carbon fiber for improving the interfacial properties of carbon fiber/epoxy composites. Compos. Part B Eng. 2018, 132, 170–177. [Google Scholar] [CrossRef]

- Vijayan, R.; Ghazinezami, A.; Taklimi, S.R.; Khan, M.Y.; Askari, D. The geometrical advantages of helical carbon nanotubes for high-performance multifunctional polymeric nanocomposites. Compos. Part B Eng. 2019, 156, 28–42. [Google Scholar] [CrossRef]

- Yousefi, E.; Sheidaei, A.; Mahdavi, M.; Baniassadi, M.; Baghani, M.; Faraji, G. Effect of nanofiller geometry on the energy absorption capability of coiled carbon nanotube composite material. Compos. Sci. Technol. 2017, 153, 222–231. [Google Scholar] [CrossRef]

- Nardelli, M.B.; Yakobson, B.I.; Bernholc, J. Mechanism of strain release in carbon nanotubes. Phys. Rev. B 1998, 57, R4277. [Google Scholar] [CrossRef]

- Harik, V.M. Mechanics of carbon nanotubes: Applicability of the continuum-beam models. Comput. Mater. Sci. 2002, 24, 328–342. [Google Scholar] [CrossRef]

- Ru, C.Q. Effect of van der Waals forces on axial buckling of a double-walled carbon nanotube. J. Appl. Phys. 2000, 87, 7227–7231. [Google Scholar] [CrossRef]

- Ru, C.Q. Axially compressed buckling of a doublewalled carbon nanotube embedded in an elastic medium. J. Mech. Phys. Solids 2001, 49, 1265–1279. [Google Scholar] [CrossRef]

- Namilae, S.; Chandra, N. Role of atomic scale interfaces in the compressive behavior of carbon nanotubes in composites. Compos. Sci. Technol. 2006, 66, 2030–2038. [Google Scholar] [CrossRef]

- Lee, J.; Wang, H.; Kim, J.H.; Shin, H. Recent studies on the multiscale modeling and simulation of polymer nanocomposites. JMST Adv. 2023, 5, 85–91. [Google Scholar] [CrossRef]

- Wang, H.; Shin, H. Recent studies on the multiscale models for predicting fracture toughness of polymer nanocomposites. Multiscale Sci. Eng. 2022, 4, 1–9. [Google Scholar] [CrossRef]

- Lachman, N.; Wagner, H.D. Correlation between interfacial molecular structure and mechanics in CNT/epoxy nano-composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1093–1098. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Zeinedini, A. Effect of CNTs debonding on mode I fracture toughness of polymeric nanocomposites. Mater. Des. 2016, 101, 56–65. [Google Scholar] [CrossRef]

- Shin, H. Multiscale model to predict fracture toughness of CNT/epoxy nanocomposites. Compos. Struct. 2021, 272, 114236. [Google Scholar] [CrossRef]

- Mirjalili, V.; Hubert, P. Modelling of the carbon nanotube bridging effect on the toughening of polymers and experimental verification. Compos. Sci. Technol. 2010, 70, 1537–1543. [Google Scholar] [CrossRef]

- Wang, H.; Lee, J.; Kim, J.H.; Shin, H. Multiscale strategy to predict the fracture toughness and crack extension behavior of ozone-functionalized carbon nanotube/epoxy nanocomposites. Chem. Eng. J. 2023, 465, 142985. [Google Scholar] [CrossRef]

- Hollaway, L.C. A review of the present and future utilization of FRP composites in the civil infrastructure with reference to their important in-service properties. Constr. Build. Mater. 2010, 24, 2419–2445. [Google Scholar] [CrossRef]

- Chen, D.; Luo, Q.; Meng, M.; Li, Q.; Sun, G. Low velocity impact behavior of interlayer hybrid composite laminates with carbon/glass/basalt fibres. Compos. Part B Eng. 2019, 176, 107191. [Google Scholar] [CrossRef]

- Mirjalili, V.; Ramachandramoorthy, R.; Hubert, P. Enhancement of fracture toughness of carbon fiber laminated composites using multi wall carbon nanotubes. Carbon 2014, 79, 413–423. [Google Scholar] [CrossRef]

- Waqas, M.; Robert, C.; Arif, U.; Radacsi, N.; Ray, D.; Koutsos, V. Improving the through-thickness electrical conductivity of carbon fiber reinforced polymer composites using interleaving conducting veils. J. Appl. Polym. Sci. 2022, 139, e53060. [Google Scholar] [CrossRef]

- Ozdemir, N.G. Toughening of carbon fibre reinforced polymer composites with rubber nanoparticles for advanced industrial applications. Express Polym. Lett. 2016, 10, 394–407. [Google Scholar] [CrossRef]

- Towsyfyan, H.; Biguri, A.; Boardman, R.; Blumensath, T. Successes and challenges in non-destructive testing of aircraft composite structures. Chin. J. Aeronaut. 2020, 33, 771–791. [Google Scholar] [CrossRef]

- Pingkarawat, K.; Mouritz, A.P. Comparative study of metal and composite z-pins for delamination fracture and fatigue strengthening of composites. Eng. Fract. Mech. 2016, 154, 180–190. [Google Scholar] [CrossRef]

- Dransfield, K.A.; Jain, L.K.; Mai, Y.W. On the effects of stitching in CFRPs—I. Mode I delamination toughness. Compos. Sci. Technol. 1998, 58, 815–827. [Google Scholar] [CrossRef]

- Mouritz, A.P.; Cox, B.N. A mechanistic interpretation of the comparative in-plane mechanical properties of 3D woven, stitched and pinned composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 709–728. [Google Scholar] [CrossRef]

- Gojny, F.H.; Wichmann, M.H.G.; Köpke, U.; Fiedler, B.; Schulte, K. Carbon nanotube-reinforced epoxy-composites: Enhanced stiffness and fracture toughness at low nanotube content. Compos. Sci. Technol. 2004, 64, 2363–2371. [Google Scholar] [CrossRef]

- Li, Y.; Hori, N.; Arai, M.; Hu, N.; Liu, Y.; Fukunaga, H. Improvement of interlaminar mechanical properties of CFRP laminates using VGCF. Compos. Part A Appl. Sci. Manuf. 2009, 40, 2004–2012. [Google Scholar] [CrossRef]

- Yuan, B.; Tan, B.; Hu, Y.; Shaw, J.; Hu, X. Improving impact resistance and residual compressive strength of carbon fibre composites using un-bonded non-woven short aramid fibre veil. Compos. Part A Appl. Sci. Manuf. 2019, 121, 439–448. [Google Scholar] [CrossRef]

- Ou, Y.; González, C.; Vilatela, J.J. Understanding interlaminar toughening of unidirectional CFRP laminates with carbon nanotube veils. Compos. Part B Eng. 2020, 201, 108372. [Google Scholar] [CrossRef]

- Ou, Y.; González, C.; Vilatela, J.J. Interlaminar toughening in structural carbon fiber/epoxy composites interleaved with carbon nanotube veils. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105477. [Google Scholar] [CrossRef]

- He, Y.; Zhang, J.; Yao, L.; Tang, J.; Che, B.; Ju, S.; Jiang, D. A multi-layer resin film infusion process to control CNTs distribution and alignment for improving CFRP interlaminar fracture toughness. Compos. Struct. 2021, 260, 113510. [Google Scholar] [CrossRef]

- Körbelin, J.; Kötter, B.; Voormann, H.; Brandenburg, L.; Selz, S.; Fiedler, B. Damage tolerance of few-layer graphene modified CFRP: From thin-to thick-ply laminates. Compos. Sci. Technol. 2021, 209, 108765. [Google Scholar] [CrossRef]

- Hu, Y.; Wei, Y.; Han, G.; Zhang, J.; Sun, G.; Hu, X.; Cheng, F. Comparison of impact resistance of carbon fibre composites with multiple ultra-thin CNT, aramid pulp, PBO and graphene interlayers. Compos. Part A Appl. Sci. Manuf. 2022, 155, 106815. [Google Scholar] [CrossRef]

- Zhang, J.; Lin, T.; Wang, X. Electrospun nanofibre toughened carbon/epoxy composites: Effects of polyetherketone cardo (PEK-C) nanofibre diameter and interlayer thickness. Compos. Sci. Technol. 2010, 70, 1660–1666. [Google Scholar] [CrossRef]

- García-Rodríguez, S.M.; Costa, J.; Rankin, K.E.; Boardman, R.P.; Singery, V.; Mayugo, J.A. Interleaving light veils to minimise the trade-off between mode-I interlaminar fracture toughness and in-plane properties. Compos. Part A Appl. Sci. Manuf. 2020, 128, 105659. [Google Scholar] [CrossRef]

- Fulmali, A.O.; Patnaik, S.; Rathore, D.K.; Bhattacharjee, D.; Gwalani, B.; Ray, B.C.; Prusty, R.K. Enhanced extreme temperature bending and delamination resistance of GFRP composites through z-directional aligned nano-reinforcement: Emphasizing the effects of CNT functionalization. Compos. Sci. Technol. 2023, 244, 110272. [Google Scholar] [CrossRef]

- Lyashenko-Miller, T.; Marom, G. Delamination fracture toughness of UHMWPE fibers/polyurethane laminates interleaved with carbon nanotube-reinforced polyurethane films. Polym. Adv. Technol. 2017, 28, 606–612. [Google Scholar] [CrossRef]

- Lyashenko, T.; Lerman, N.; Wolf, A.; Harel, H.; Marom, G. Improved Mode II delamination fracture toughness of composite materials by selective placement of protein-surface treated CNT. Compos. Sci. Technol. 2013, 85, 29–35. [Google Scholar] [CrossRef]

- Ravishankar, B.; Nayak, S.K.; Kader, M.A. Hybrid composites for automotive applications—A review. J. Reinf. Plast. Compos. 2019, 38, 835–845. [Google Scholar] [CrossRef]

- Blythe, A.; Fox, B.; Nikzad, M.; Eisenbart, B.; Chai, B.X.; Blanchard, P.; Dahl, J. Evaluation of the failure mechanism in polyamide nanofibre veil toughened hybrid carbon/glass fibre composites. Materials 2022, 15, 8877. [Google Scholar] [CrossRef]

- Blythe, A.; Fox, B.; Nikzad, M.; Eisenbart, B.; Chai, B.X. Stiffness Degradation under Cyclic Loading Using Three-Point Bending of Hybridised Carbon/Glass Fibres with a Polyamide 6, 6 Nanofibre Interlayer. J. Compos. Sci. 2022, 6, 270. [Google Scholar] [CrossRef]

- Beckermann, G.W. Nanofiber interleaving veils for improving the performance of composite laminates. Reinf. Plast. 2017, 61, 289–293. [Google Scholar] [CrossRef]

- Mohammadi, R.; Najafabadi, M.A.; Saghafi, H.; Saeedifar, M.; Zarouchas, D. A quantitative assessment of the damage mechanisms of CFRP laminates interleaved by PA66 electrospun nanofibers using acoustic emission. Compos. Struct. 2021, 258, 113395. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stern, T.; Marom, G. Fracture Mechanisms and Toughness in Polymer Nanocomposites: A Brief Review. J. Compos. Sci. 2024, 8, 395. https://doi.org/10.3390/jcs8100395

Stern T, Marom G. Fracture Mechanisms and Toughness in Polymer Nanocomposites: A Brief Review. Journal of Composites Science. 2024; 8(10):395. https://doi.org/10.3390/jcs8100395

Chicago/Turabian StyleStern, Theodor, and Gad Marom. 2024. "Fracture Mechanisms and Toughness in Polymer Nanocomposites: A Brief Review" Journal of Composites Science 8, no. 10: 395. https://doi.org/10.3390/jcs8100395