Characterisation of the Mechanical Properties of Natural Fibre Polypropylene Composites Manufactured with Automated Tape Placement

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

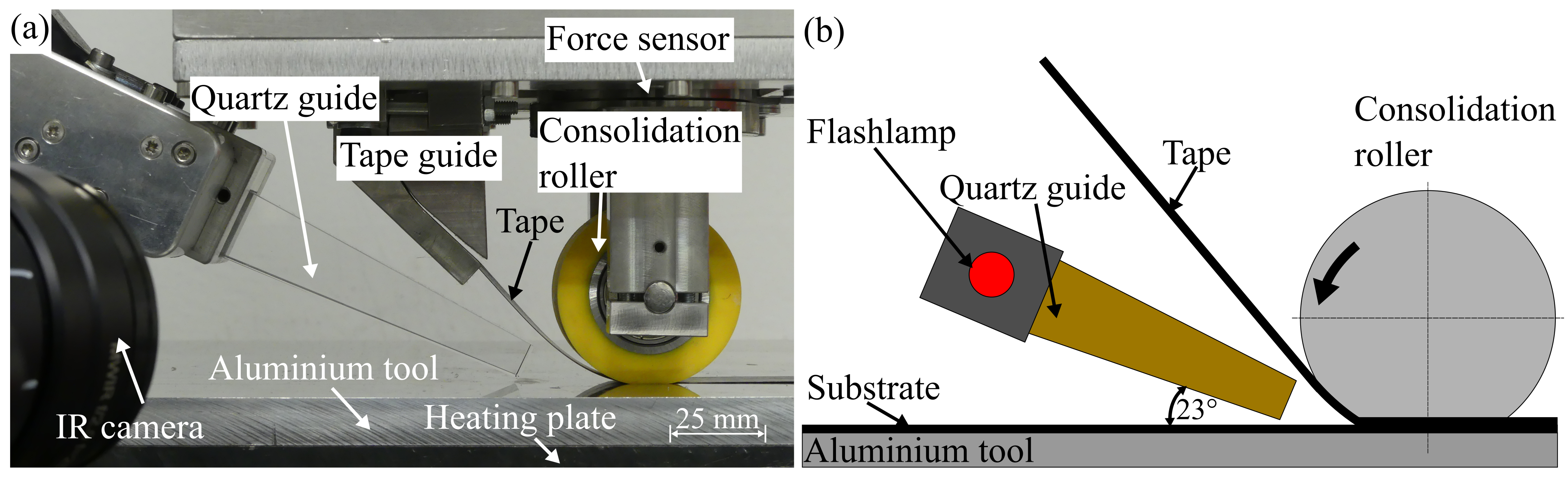

2.2. ATP System and Placement Trials

2.3. Temperature and Pressure Measurement

2.4. Thermogravimetric Analysis

2.5. Differential Scanning Calorimetry

2.6. Mechanical Tests

2.6.1. Tensile Test Setup

2.6.2. Compression Test Setup

2.6.3. Three-Point Bending Test Setup

2.6.4. Double Cantilever Beam Setup

3. Results and Discussion

3.1. Temperature Evaluation

3.2. Pressure Measurement

3.3. Thermophysical Analysis

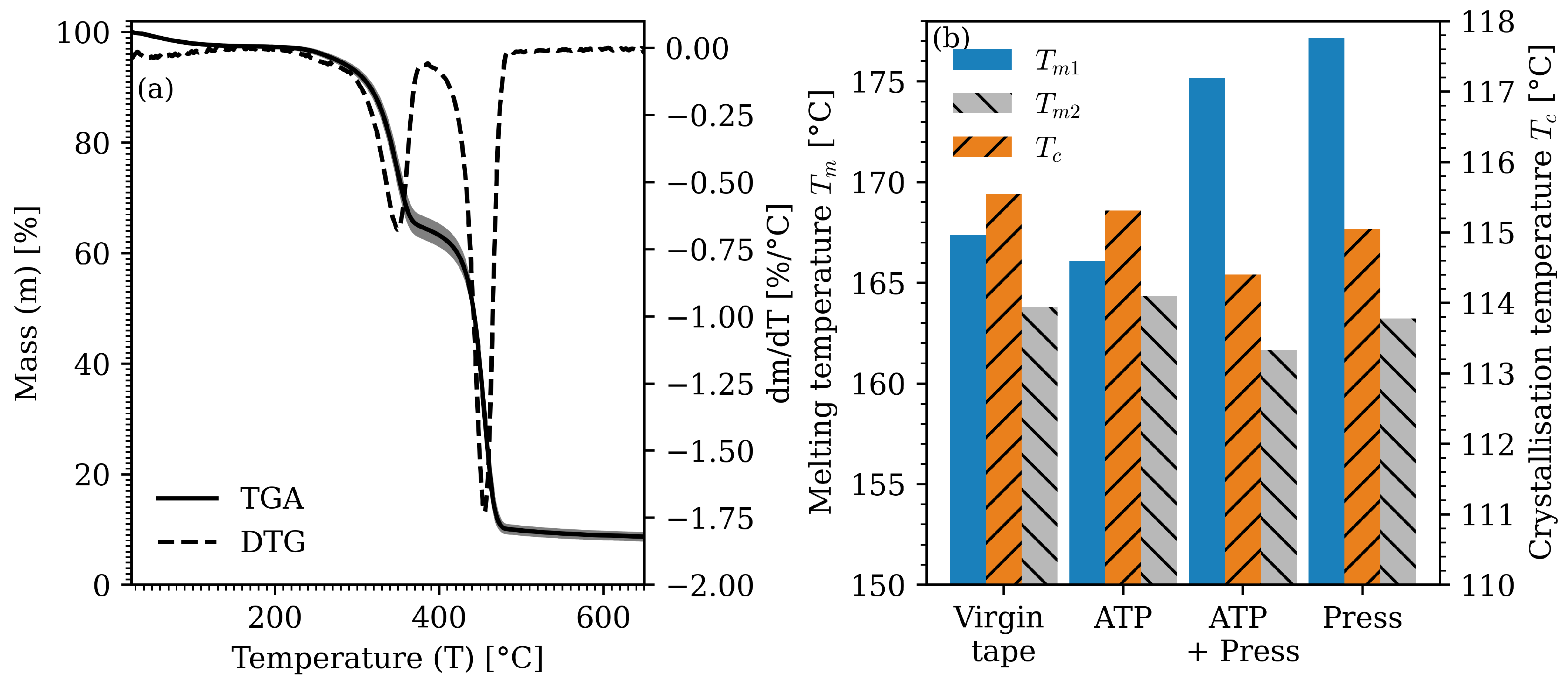

3.3.1. TGA Measurements

3.3.2. DSC Measurements

3.4. Mechanical Tests

3.4.1. Tensile Tests

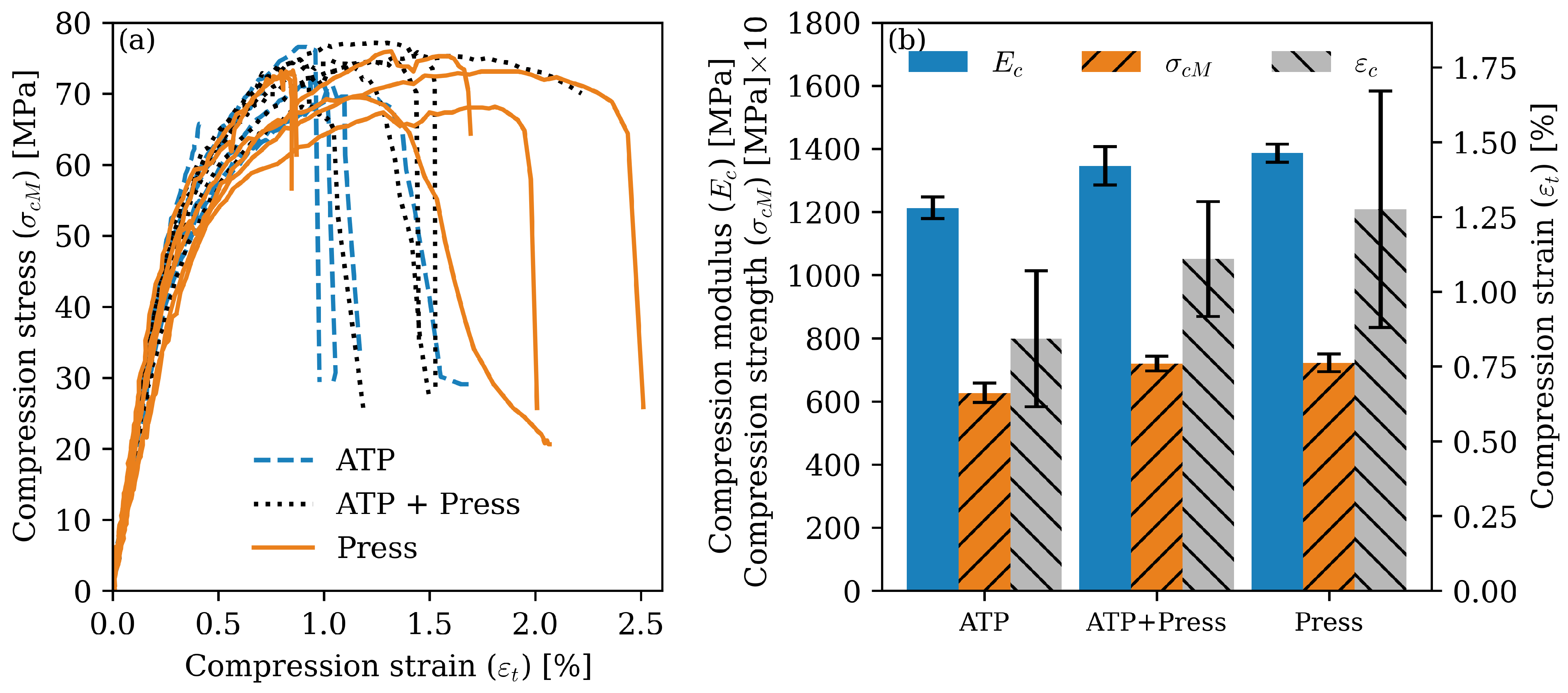

3.4.2. Compression Tests

3.4.3. Three-Point Bending Tests

3.4.4. Double Cantilever Beam Tests

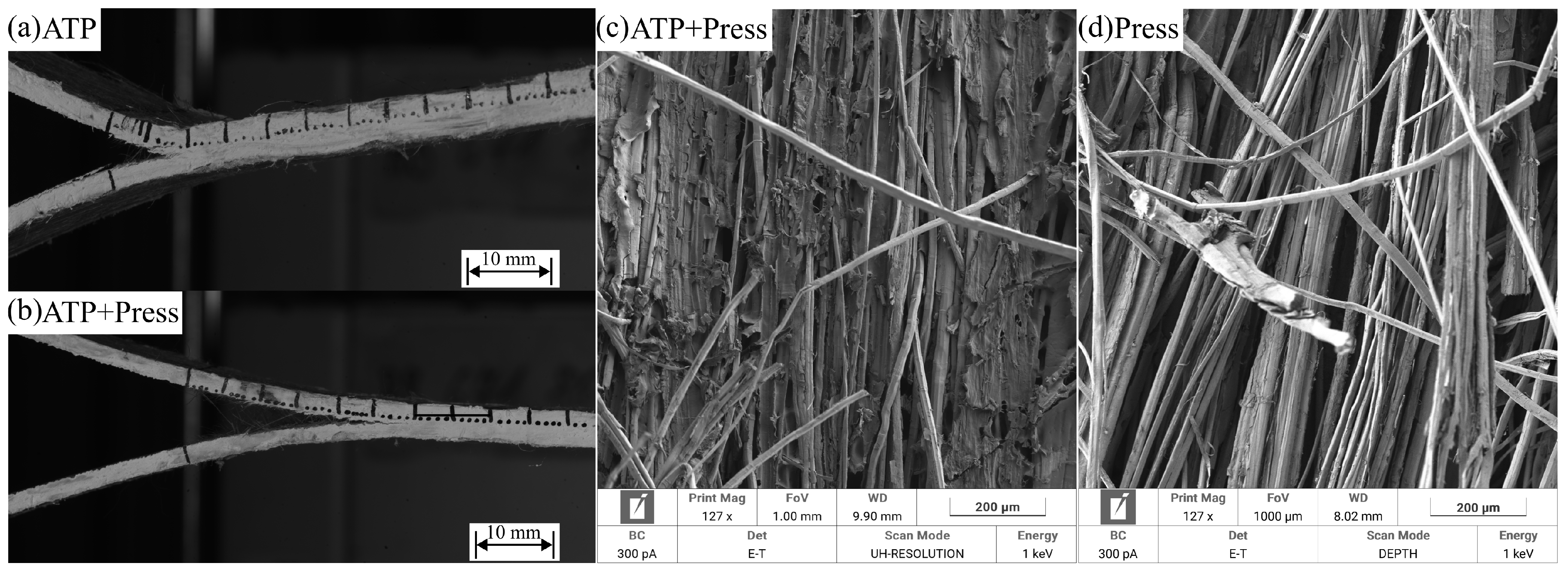

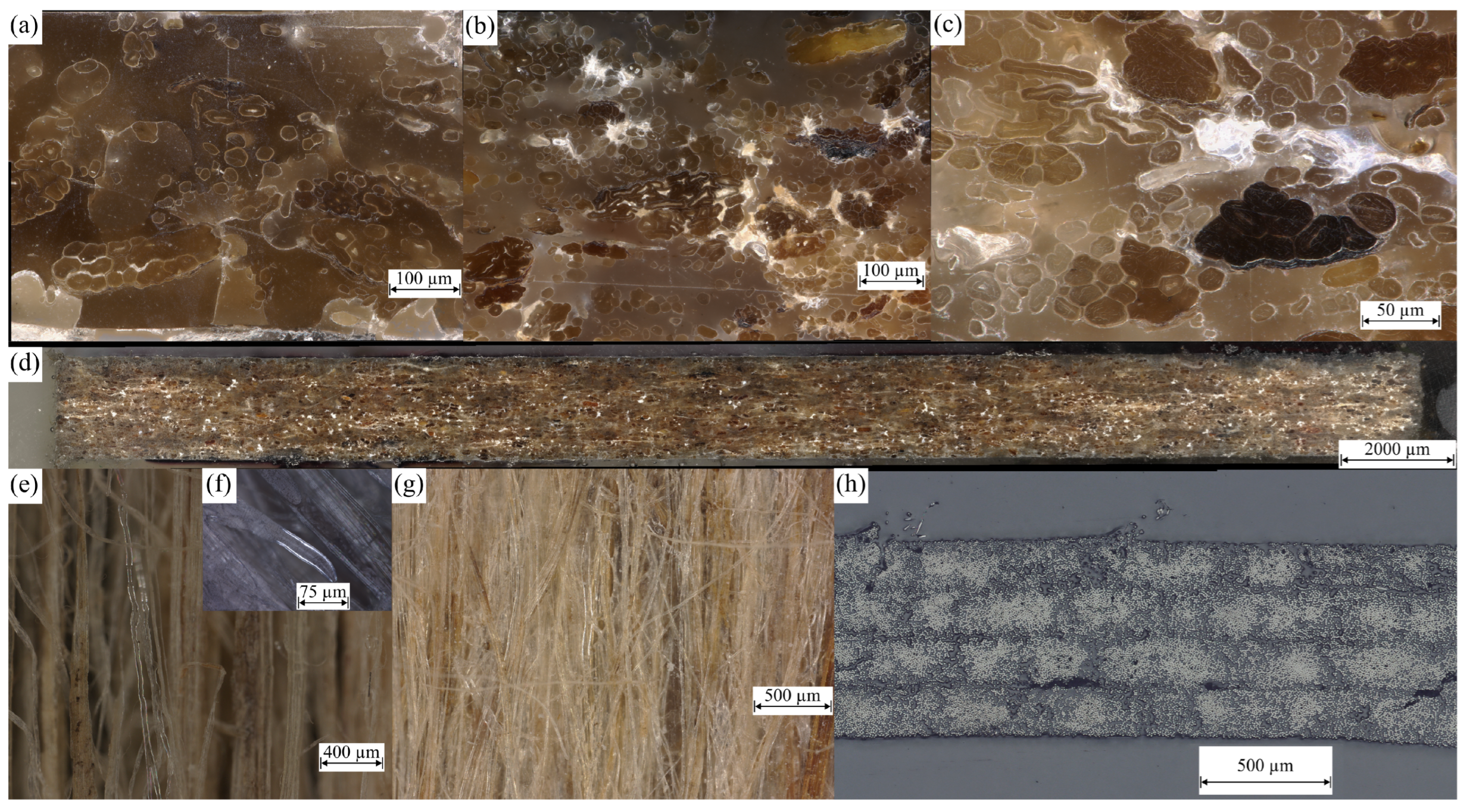

3.5. Micrographs

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Asim, M.; Paridah, M.T.; Chandrasekar, M.; Shahroze, R.M.; Jawaid, M.; Nasir, M.; Siakeng, R. Thermal stability of natural fibers and their polymer composites. Iran. Polym. J. 2020, 29, 625–648. [Google Scholar] [CrossRef]

- Alves, C.; Ferrão, P.; Silva, A.J.; Reis, L.G.; Freitas, M.; Rodrigues, L.B.; Alves, D.E. Ecodesign of automotive components making use of natural jute fiber composites. J. Clean. Prod. 2010, 18, 313–327. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Arpitha, G.R.; Naik, L.L.; Gopalakrishna, K.; Yogesha, B. Applications of Natural Fibers and Its Composites: An Overview. Nat. Resour. 2016, 7, 108–114. [Google Scholar] [CrossRef]

- Baley, C. Analysis of the flax fibres tensile behaviour and analysis of the tensile stiffness increase. Compos. Part A Appl. Sci. Manuf. 2002, 33, 939–948. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites—A review. Compos. Part B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Wazeer, A.; Das, A.; Abeykoon, C.; Sinha, A.; Karmakar, A. Composites for electric vehicles and automotive sector: A review. Green Energy Intell. Transp. 2023, 2, 100043. [Google Scholar] [CrossRef]

- Nishida, H.; Carvelli, V.; Fujii, T.; Okubo, K. Thermoplastic vs. thermoset epoxy carbon textile composites. IOP Conf. Ser. Mater. Sci. Eng. 2018, 406, 012043. [Google Scholar] [CrossRef]

- Baley, C.; Kervoëlen, A.; Lan, M.; Cartié, D.; Le Duigou, A.; Bourmaud, A.; Davies, P. Flax/PP manufacture by automated fibre placement (AFP). Mater. Des. 2016, 94, 207–213. [Google Scholar] [CrossRef]

- Gourier, C.; Le Duigou, A.; Bourmaud, A.; Baley, C. Mechanical analysis of elementary flax fibre tensile properties after different thermal cycles. Compos. Part A Appl. Sci. Manuf. 2014, 64, 159–166. [Google Scholar] [CrossRef]

- Shubhra, Q.T.H.; Alam, A.; Quaiyyum, M.A. Mechanical properties of polypropylene composites. J. Thermoplast. Compos. Mater. 2013, 26, 362–391. [Google Scholar] [CrossRef]

- Neitzel, M.; Mitschang, P.; Breuer, U. (Eds.) Handbuch Verbundwerkstoffe: Werkstoffe, Verarbeitung, Anwendung, 2nd ed.; Carl Hanser Verlag GmbH Co KG: Munich, Germany, 2014. [Google Scholar]

- Jiang, W.; Chen, C.; Chen, Z.; Huang, Z.; Zhou, H. Effect of crystallinity on optical properties of PEEK prepreg tapes for laser-assisted automated fiber placement. Compos. Commun. 2023, 38, 101490. [Google Scholar] [CrossRef]

- Zhang, B.; Kim, B.C. Experimental characterisation of large in-plane shear behaviour of unidirectional carbon fibre/epoxy prepreg tapes for continuous tow shearing (CTS) process. Compos. Part A Appl. Sci. Manuf. 2022, 162, 107168. [Google Scholar] [CrossRef]

- Çelik, O.; Bussink, T.; Peeters, D.; Teuwen, J.; Dransfeld, C. The effect of Laser-Induced deconsolidation on the compaction behavior of thermoplastic composite tapes. Compos. Part A Appl. Sci. Manuf. 2021, 151, 106670. [Google Scholar] [CrossRef]

- Chanteli, A.; Bandaru, A.K.; Peeters, D.; O’Higgins, R.M.; Weaver, P.M. Influence of repass treatment on carbon fibre-reinforced PEEK composites manufactured using laser-assisted automatic tape placement. Compos. Struct. 2020, 248, 112539. [Google Scholar] [CrossRef]

- Clancy, G.; Peeters, D.; Oliveri, V.; Jones, D.; O’Higgins, R.M.; Weaver, P.M. A study of the influence of processing parameters on steering of carbon Fibre/PEEK tapes using laser-assisted tape placement. Compos. Part B Eng. 2019, 163, 243–251. [Google Scholar] [CrossRef]

- Shafaq; Donough, M.J.; Farnsworth, A.L.; Phillips, A.W.; St John, N.A.; Gangadhara Prusty, B. Influence of deposition rates on the mode I fracture toughness of in-situ consolidated thermoplastic composites. Compos. Part B Eng. 2023, 251, 110474. [Google Scholar] [CrossRef]

- Moghadamazad, M.; Hoa, S.V. Models for heat transfer in thermoplastic composites made by automated fiber placement using hot gas torch. Compos. Part C Open Access 2022, 7, 100214. [Google Scholar] [CrossRef]

- Khodaei, A.; Shadmehri, F. Intimate contact development for automated fiber placement of thermoplastic composites. Compos. Part C Open Access 2022, 8, 100290. [Google Scholar] [CrossRef]

- Gain, A.K.; Oromiehie, E.; Prusty, B.G. Nanomechanical characterisation of CF-PEEK composites manufactured using automated fibre placement (AFP). Compos. Commun. 2022, 31, 101109. [Google Scholar] [CrossRef]

- Oromiehie, E.; Gain, A.K.; Donough, M.J.; Prusty, B.G. Fracture toughness assessment of CF-PEEK composites consolidated using hot gas torch assisted automated fibre placement. Compos. Struct. 2022, 279, 114762. [Google Scholar] [CrossRef]

- Satheesh, B.; Tonejc, M.; Potakowskyj, L.; Pletz, M.; Fauster, E.; Kaynak, B.; Schledjewski, R. Peel strength characterisation on ply/ply interface using wedge and T-peel/pull-type tests. Polym. Polym. Compos. 2018, 26, 431–445. [Google Scholar] [CrossRef]

- Rajasekaran, A.; Shadmehri, F. Steering of carbon fiber/PEEK tapes using Hot Gas Torch-assisted automated fiber placement. J. Thermoplast. Compos. Mater. 2022, 36, 1651–1679. [Google Scholar] [CrossRef] [PubMed]

- Grouve, W. Weld Strength of Laser-Assisted Tape-Placed Thermoplastic Composites. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 2012. [Google Scholar]

- Danezis, A.; Williams, D.; Edwards, M.; Skordos, A.A. Heat transfer modelling of flashlamp heating for automated tape placement of thermoplastic composites. Compos. Part A Appl. Sci. Manuf. 2021, 145, 106381. [Google Scholar] [CrossRef]

- Di Boon, Y.; Joshi, S.C.; Bhudolia, S.K. Review: Filament Winding and Automated Fiber Placement with In Situ Consolidation for Fiber Reinforced Thermoplastic Polymer Composites. Polymers 2021, 13, 1951. [Google Scholar] [CrossRef] [PubMed]

- McGregor, O.; Duhovic, M.; Somashekar, A.A.; Bhattacharyya, D. Pre-impregnated natural fibre-thermoplastic composite tape manufacture using a novel process. Compos. Part A Appl. Sci. Manuf. 2017, 101, 59–71. [Google Scholar] [CrossRef]

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Nasri, M.; Garnier, C. A comprehensive review of natural fibers and their composites: An eco-friendly alternative to conventional materials. Results Eng. 2023, 19, 101271. [Google Scholar] [CrossRef]

- Legenstein, A.; Füssel, L.; Heider, D.; Gillespie, J.W., Jr.; Cender, T.A. Stretch-Steering of Highly Aligned Discontinuous Fiber Tape with Automated Fiber Placement. Compos. Part B Eng. 2024, 287, 111801. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Sperber, V.E.; Faruk, O. Natural and Wood Fibre Reinforcement in Polymers, 13th ed.; Smithers Rapra Publishing: Shawbury, UK, 2002. [Google Scholar]

- Charlet, K.; Baley, C.; Morvan, C.; Jernot, J.P.; Gomina, M.; Bréard, J. Characteristics of Hermès flax fibres as a function of their location in the stem and properties of the derived unidirectional composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1912–1921. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Mamun, A.A.; Lucka-Gabor, M.; Gutowski, V.S. The effects of acetylation on properties of flax fibre and its polypropylene composites. Express Polym. Lett. 2008, 2, 413–422. [Google Scholar] [CrossRef]

- Komuraiah, A.; Kumar, N.S.; Prasad, B.D. Chemical Composition of Natural Fibers and its Influence on their Mechanical Properties. Mech. Compos. Mater. 2014, 50, 359–376. [Google Scholar] [CrossRef]

- Mohammed, M.; Rasidi, M.S.; Mohammed, A.; Rahman, R.; Osman, A.; Adam, T.; Betar, B.; Dahham, O. Interfacial bonding mechanisms of natural fibre-matrix composites: An overview. BioResources 2022, 17, 7031–7090. [Google Scholar] [CrossRef]

- Drzal, L.T.; Rich, M.J.; Lloyd, P.F. Adhesion of Graphite Fibers to Epoxy Matrices: I. The Role of Fiber Surface Treatment. J. Adhes. 1983, 16, 1–30. [Google Scholar] [CrossRef]

- Messiry, M.E. Theoretical analysis of natural fiber volume fraction of reinforced composites. Alex. Eng. J. 2013, 52, 301–306. [Google Scholar] [CrossRef]

- Le Gall, M.; Davies, P.; Martin, N.; Baley, C. Recommended flax fibre density values for composite property predictions. Ind. Crop. Prod. 2018, 114, 52–58. [Google Scholar] [CrossRef]

- Maddah A., H. Polypropylene as a Promising Plastic: A Review. Am. J. Polym. Sci. 2016, 6, 1–11. [Google Scholar] [CrossRef]

- Stokes-Griffin, C.M.; Compston, P. A combined optical-thermal model for near-infrared laser heating of thermoplastic composites in an automated tape placement process. Compos. Part A Appl. Sci. Manuf. 2015, 75, 104–115. [Google Scholar] [CrossRef]

- Lafranche, E.; Oliveira, V.M.; Martins, C.I.; Krawczak, P. Prediction of injection-moulded flax fibre reinforced polypropylene tensile properties through a micro-morphology analysis. J. Compos. Mater. 2015, 49, 113–128. [Google Scholar] [CrossRef]

- Ahmed, A.K.; Atiqullah, M.; Pradhan, D.R.; Al-Harthi, M.A. Crystallization and melting behavior of i-PP: A perspective from Flory’s thermodynamic equilibrium theory and DSC experiment. RSC Adv. 2017, 7, 42491–42504. [Google Scholar] [CrossRef]

- DIN EN ISO 527-4:2023-07; Plastics—Determination of Tensile Properties—Part 4: Test Conditions for Isotropic and Orthotropic Fibre-Reinforced Plastic Composites. International Organization for Standardization: Geneva, Switzerland, 2023. [CrossRef]

- ISO 14126:2023; Fibre-Reinforced Plastic Composites—Determination of Compressive Properties in the In-Plane Direction. International Organization for Standardization: Geneva, Switzerland, 2023.

- ISO 14125:1998; Fibre-Reinforced Plastic Composites: Determination of Flexural Properties. International Organization for Standardization: Geneva, Switzerland, 1998.

- ISO 15024:2023; Fibre-Reinforced Plastic Composites: Determination of Mode I Interlaminar Fracture Toughness, GIC, for Unidirectionally Reinforced Materials. International Organization for Standardization: Geneva, Switzerland, 2023.

- Legenstein, A.; Fauster, E. Effect of Flashlamp Heating System Parameters on the Wedge Peel Strength of Thermoplastic Carbon Fiber Tape in the Automated Tape Placement Process. J. Manuf. Mater. Process. 2024, 8, 91. [Google Scholar] [CrossRef]

- Bourmaud, A.; Morvan, C.; Baley, C. Importance of fiber preparation to optimize the surface and mechanical properties of unitary flax fiber. Ind. Crop. Prod. 2010, 32, 662–667. [Google Scholar] [CrossRef]

- Tordjeman, P.; Robert, C.; Marin, G.; Gerard, P. The effect of α, β crystalline structure on the mechanical properties of polypropylene. Eur. Phys. J. E 2001, 4, 459–465. [Google Scholar] [CrossRef]

- Hu, Y.; Liao, Y.; Zheng, Y.; Ikeda, K.; Okabe, R.; Wu, R.; Ozaki, R.; Xu, J.; Xu, Q. Influence of Cooling Rate on Crystallization Behavior of Semi-Crystalline Polypropylene: Experiments and Mathematical Modeling. Polymers 2022, 14, 3646. [Google Scholar] [CrossRef] [PubMed]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef]

- Baley, C.; Gomina, M.; Breard, J.; Bourmaud, A.; Davies, P. Variability of mechanical properties of flax fibres for composite reinforcement. A review. Ind. Crop. Prod. 2020, 145, 111984. [Google Scholar] [CrossRef]

- Bos, H.L.; van den Oever, M.J.A.; Peters, O.C.J.J. Tensile and compressive properties of flax fibres for natural fibre reinforced composites. J. Mater. Sci. 2002, 37, 1683–1692. [Google Scholar] [CrossRef]

- Baley, C.; Goudenhooft, C.; Perré, P.; Lu, P.; Pierre, F.; Bourmaud, A. Compressive strength of flax fibre bundles within the stem and comparison with unidirectional flax/epoxy composites. Ind. Crops Prod. 2019, 130, 25–33. [Google Scholar] [CrossRef]

- Prapavesis, A.; Tojaga, V.; Östlund, S.; van Willem Vuure, A. Back calculated compressive properties of flax fibers utilizing the Impregnated Fiber Bundle Test (IFBT). Compos. Part A Appl. Sci. Manuf. 2020, 135, 105930. [Google Scholar] [CrossRef]

- Jerabek, M.; Major, Z.; Lang, R.W. Uniaxial compression testing of polymeric materials. Polym. Test. 2010, 29, 302–309. [Google Scholar] [CrossRef]

- International Polymer Solutions Inc. Irvine, USA. Polypropylene—Datasheet, 2024. Available online: https://www.ipolymer.com/pdf/Polypropylene.pdf (accessed on 9 September 2024).

- Wu, C.M.; Lai, W.Y.; Wang, C.Y. Effects of Surface Modification on the Mechanical Properties of Flax/β-Polypropylene Composites. Materials 2016, 9, 314. [Google Scholar] [CrossRef]

- Karian, H.G. Handbook of Polypropylene and Polypropylene Composites; Plastics Engineering; Marcel Dekker: New York, NY, USA, 2003; Volume 51. [Google Scholar]

| Cellulose | Hemicellulose | Pectin | Lignin | Wax | Moisture |

|---|---|---|---|---|---|

| 64.1–75% | 11–20.6% | 1.8–2.3% | 2–2.9% | 1.5–1.7% | 7.9–10 w% |

| Material | Processing Method | Young’s Modulus () [GPa] | Tensile Strength () [MPa] | Elongation at Break () [%] |

|---|---|---|---|---|

| FLX/PP | ATP | 14.9 ± 0.3 | 134.4 ± 2.5 | 1.4 ± 0.03 |

| FLX/PP | ATP + Press | 17.4 ± 1.0 | 143.9 ± 6.2 | 1.3 ± 0.03 |

| FLX/PP | Press | 15.5 ± 0.9 | 133.7 ± 5.6 | 1.4 ± 0.07 |

| Material | Processing Method | Compression Modulus () [MPa] | Compression Strength () [MPa] | Compression Strain () [%] |

|---|---|---|---|---|

| FLX/PP | ATP | 1213.0 ± 37.1 | 62.7 ± 3.4 | 0.84 ± 0.25 |

| FLX/PP | ATP + Press | 1346.2 ± 66.4 | 72.0 ± 2.6 | 1.11 ± 0.21 |

| FLX/PP | Press | 1386.2 ± 31.5 | 72.2 ± 3.1 | 1.28 ± 0.43 |

| Material | Processing Method | Flexural Modulus () [GPa] | Flexural Strength () [MPa] | Flexural Strain () [%] |

|---|---|---|---|---|

| FLX/PP | ATP | 11.7 ± 1.0 | 137.7 ± 6.5 | 2.5 ± 0.1 |

| FLX/PP | ATP + Press | 16.4 ± 0.6 | 156.2 ± 8.0 | 2.0 ± 0.1 |

| FLX/PP | Press | 17.9 ± 0.5 | 172.8 ± 5.5 | 2.1 ± 0.07 |

| Material | Processing Method | BT [J/m2] | CBT [J/m2] | MCC [J/m2] |

|---|---|---|---|---|

| FLX/PP | ATP | - | - | - |

| FLX/PP | ATP + Press | 393.70 ± 223.00 | 390.02 ± 220.58 | 413.13 ± 170.28 |

| FLX/PP | Press | 32.95 ± 20.66 | 23.18 ± 14.14 | 72.70 ± 57.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Legenstein, A.; Haiden, L.; Feuchter, M.; Fauster, E. Characterisation of the Mechanical Properties of Natural Fibre Polypropylene Composites Manufactured with Automated Tape Placement. J. Compos. Sci. 2024, 8, 396. https://doi.org/10.3390/jcs8100396

Legenstein A, Haiden L, Feuchter M, Fauster E. Characterisation of the Mechanical Properties of Natural Fibre Polypropylene Composites Manufactured with Automated Tape Placement. Journal of Composites Science. 2024; 8(10):396. https://doi.org/10.3390/jcs8100396

Chicago/Turabian StyleLegenstein, Alexander, Lukas Haiden, Michael Feuchter, and Ewald Fauster. 2024. "Characterisation of the Mechanical Properties of Natural Fibre Polypropylene Composites Manufactured with Automated Tape Placement" Journal of Composites Science 8, no. 10: 396. https://doi.org/10.3390/jcs8100396

APA StyleLegenstein, A., Haiden, L., Feuchter, M., & Fauster, E. (2024). Characterisation of the Mechanical Properties of Natural Fibre Polypropylene Composites Manufactured with Automated Tape Placement. Journal of Composites Science, 8(10), 396. https://doi.org/10.3390/jcs8100396