Damage Model of Carbon-Fiber-Reinforced Concrete Based on Energy Conversion Principle

Abstract

:1. Introduction

2. Test Materials and Methods

2.1. Materials

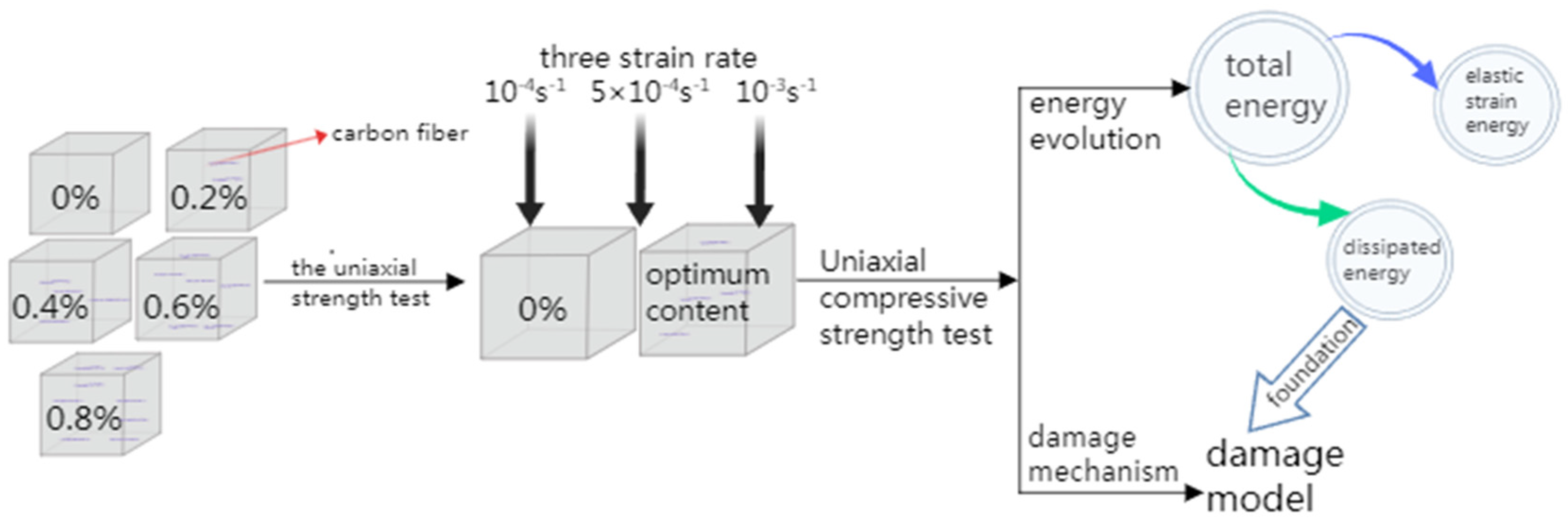

2.2. Experimental Design

2.3. Specimen Making

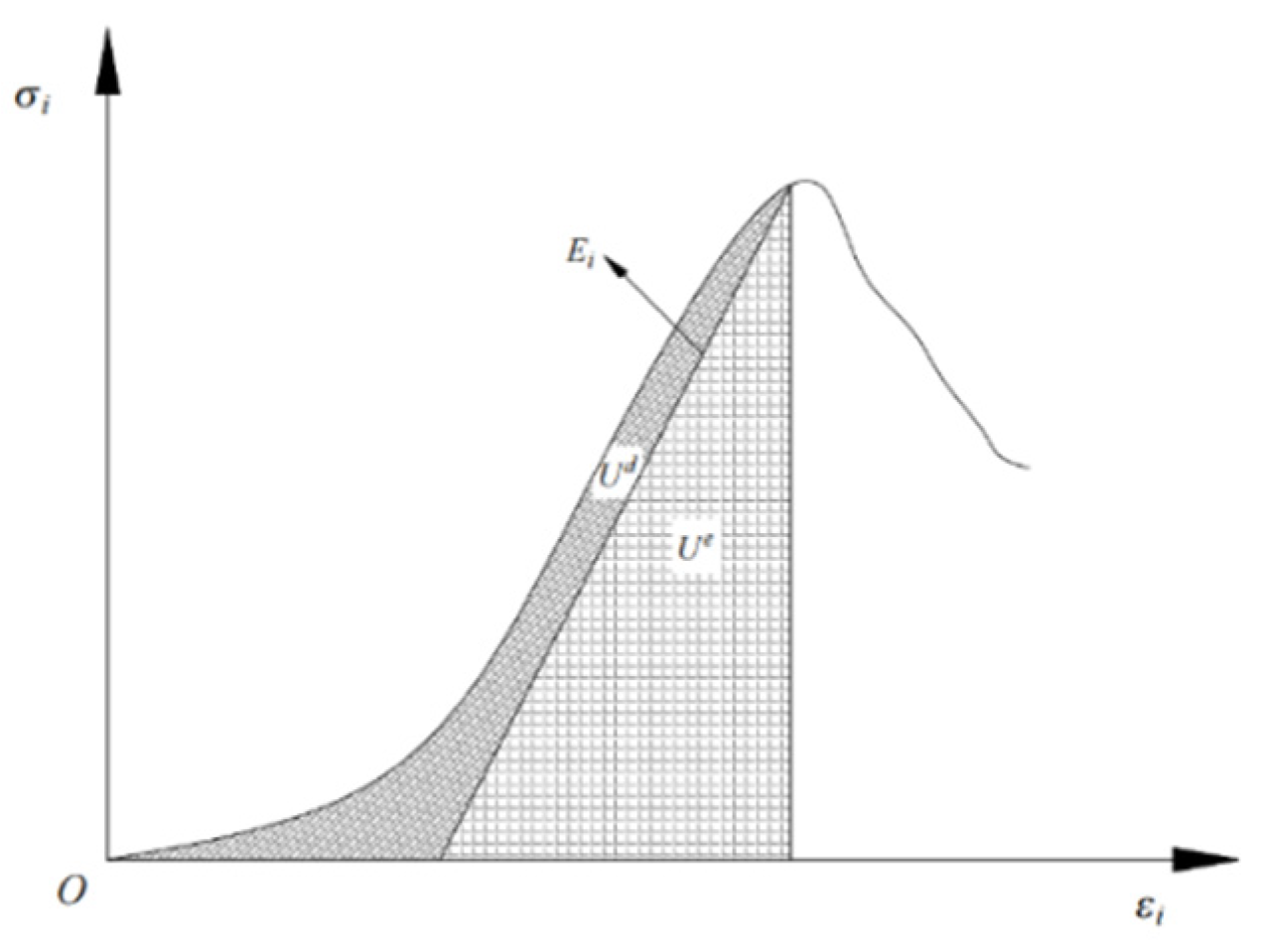

2.4. Energy Calculation Method

3. Compressive Test Results with Different CF Contents

3.1. Uniaxial Compressive Strength, Splitting Tensile Strength

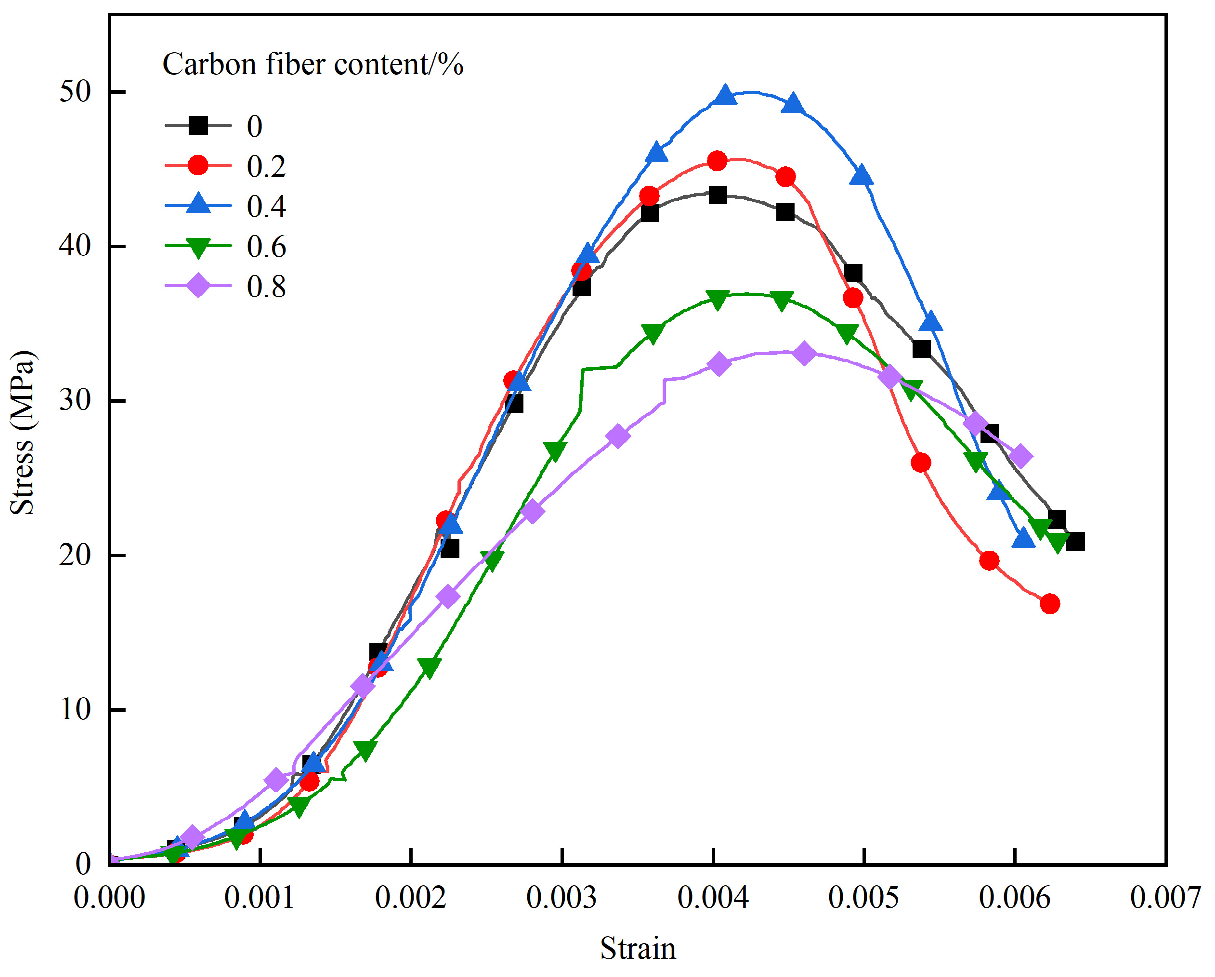

3.2. Stress–Strain Relationship

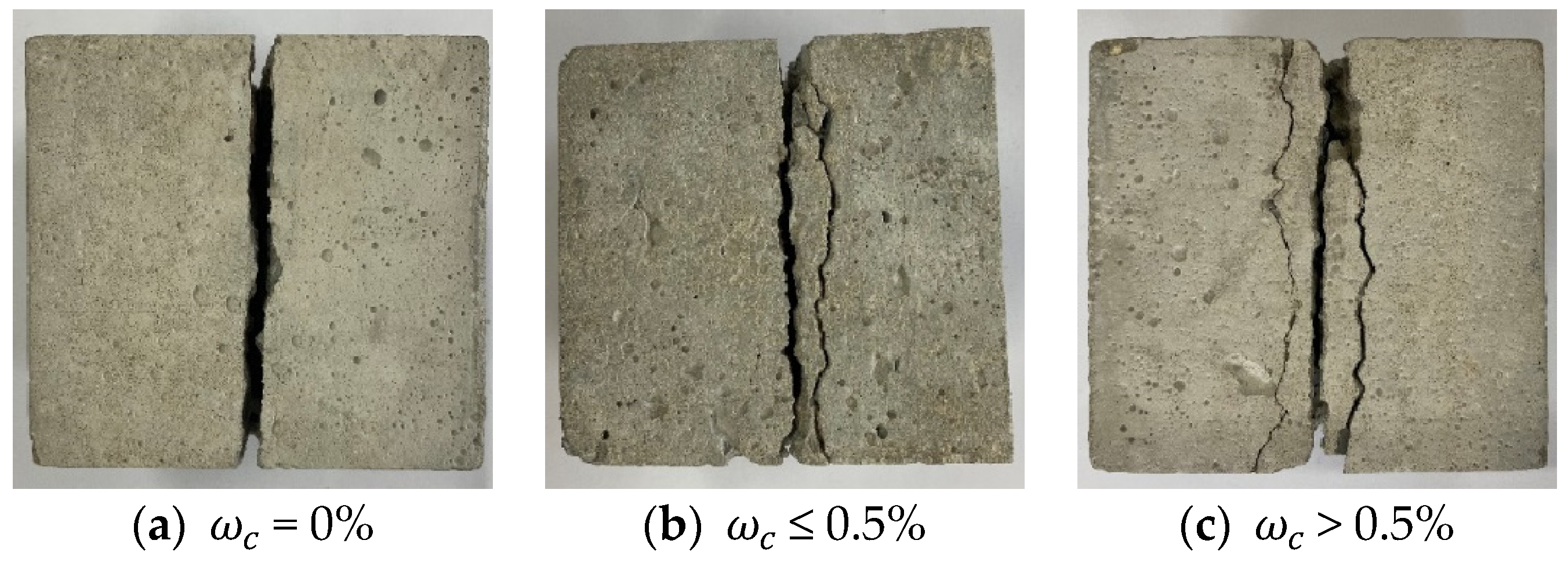

3.3. Normal Strain Rate Failure Mode

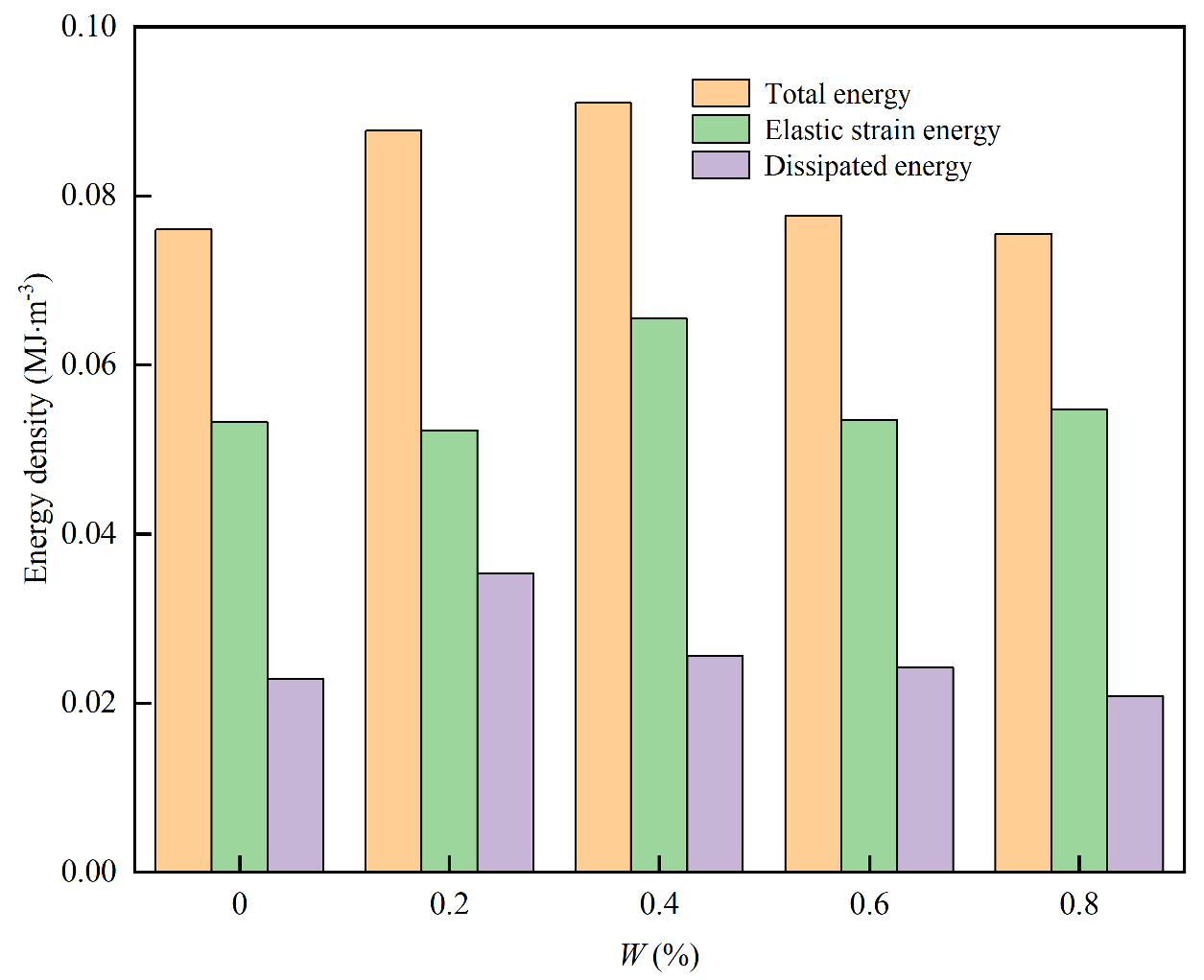

3.4. Energy Characteristics at Peak Load

4. Compressive Test Results at Multiple Strain Rates

4.1. Uniaxial Compressive Strength

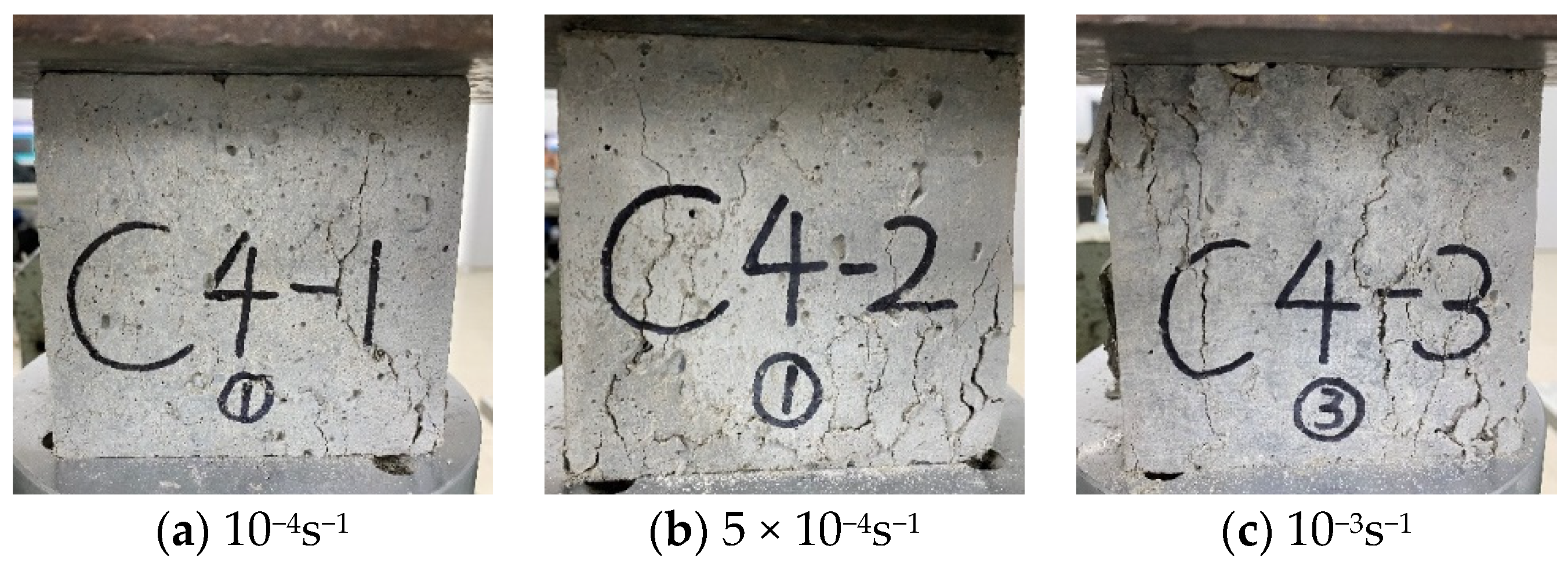

4.2. Multi-Strain Rate Failure Modes

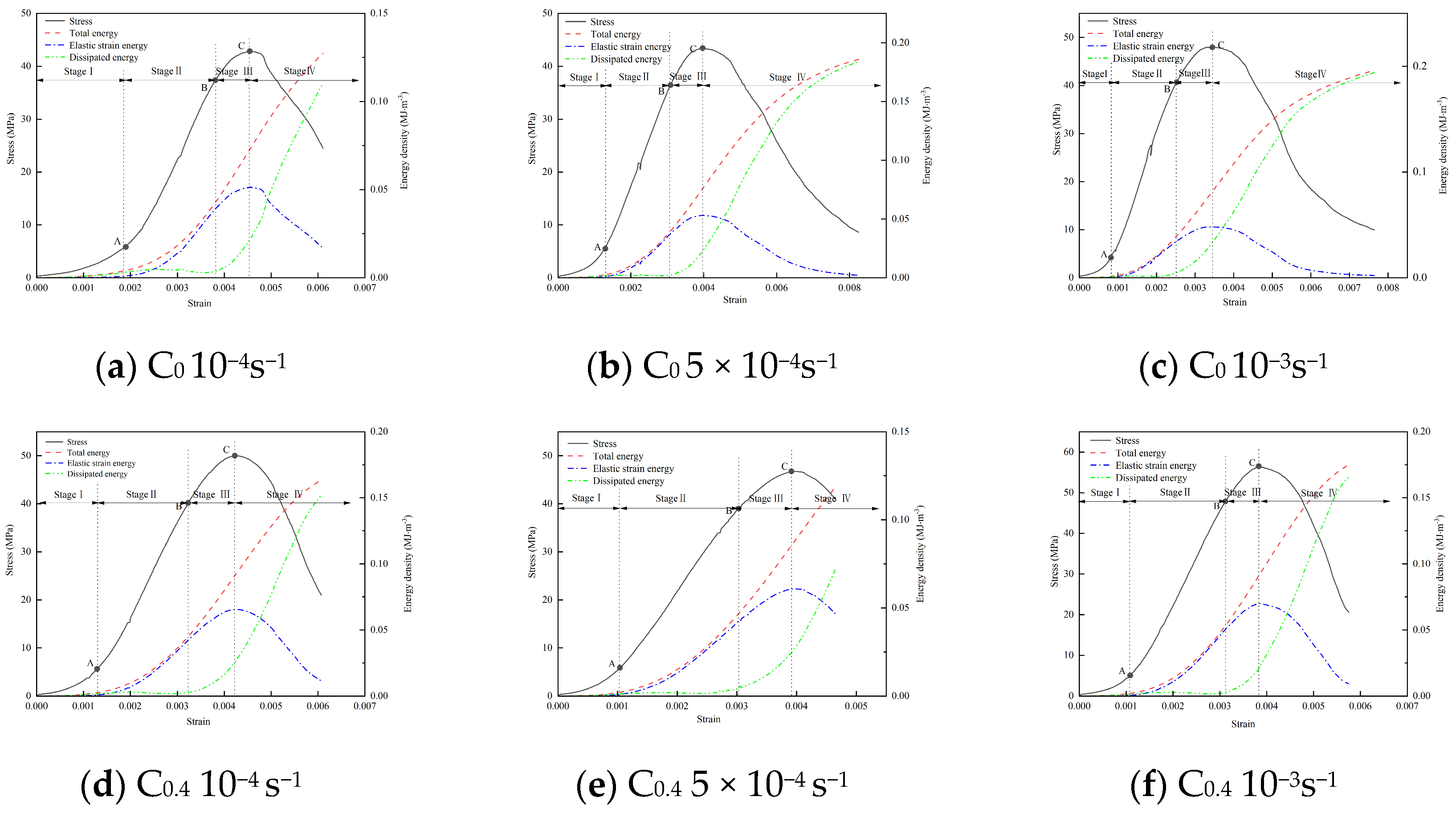

4.3. Energy Development Laws and Transformation Properties

- (1)

- Compression stage (I). Due to the presence of pores and microcracks in the carbon fiber concrete specimen, at this stage, the energy absorbed from the outside of the concrete specimen is essentially used to close the internal pores and microcracks of the specimen, and there is almost no input energy at this time that the elastic strain energy is converted. It can be seen from Figure 10 that the conversion rate of the elastic deformation energy gradually increases and the conversion rate of the dissipation energy gradually decreases during the densification phase.

- (2)

- Elastic deformation stage (II). When the elastic deformation energy conversion-rate curve intersects with the dissipation energy conversion-rate curve for the first time, i.e., α = β, the specimen enters the phase of elastic deformation. At this stage, the concrete specimen can be regarded as an ideal linear elastic body, and the concrete mainly undergoes reversible elastic deformation. In the elastic deformation phase, the energy conversion rate of elastic deformation gradually increases, and the conversion rate of dissipated energy gradually decreases. Comparing Figure 9a–c, the energy dissipation at the elastic deformation stage can be seen more clearly at a small strain rate. This is because at a low strain rate, the load is applied over a longer period of time, and crack sliding occurs within the specimen.

- (3)

- Plastic deformation stage (III). With increasing strain, the energy conversion rate of elastic strain reaches the maximum value, and the conversion rate of the dissipation energy reaches the minimum value. At this point, the specimen enters the plastic deformation phase. At this stage, the concrete specimen gradually loses elasticity under the action of axial tension. The microcracks inside the specimen expand rapidly, the elastic strain energy conversion rate decreases rapidly, and the dissipative energy conversion rate increases sharply. The specimen gradually reaches the limit of its load-bearing capacity and plastic deformation occurs. As can be seen from Figure 9, with the increasing strain rate of the 0.4% carbon fiber concrete specimen, the strain corresponding to the sudden turning point of the dissipated energy is larger than that of the plain concrete. This is because the carbon fiber consumes the deformation energy through its own compression deformation before the dissipation energy reaches the abrupt inflection point, so as to retard the deformation of the specimen. When the strain rate is small, the energy dissipation phenomenon is serious. As the strain rate increases, the proportion of dissipated energy gradually decreases.

- (4)

- Destruction stage (IV). With the gradual increase in the axial load, the specimen reaches the peak stress and begins to damage. Numerous cracks appear on the surface of the specimen, and the input strain energy is mainly dissipated in the form of the surface energy and kinetic energy of the cracks. During the destruction phase of the specimen, as α continues to decrease and β gradually increases, a second point occurs where α = β occurs and the critical point of permanent concrete damage is reached. After that, the energy conversion rate of the elastic strain continues to decrease and the dissipation energy conversion rate continues to increase, α < β; the level of elastic strain energy is low; and the specimen is unable to store the elastic strain energy, causing damage to occur.

5. Ontological Modeling Based on Energy Dissipation

5.1. Establishment of the Ontological Model

5.2. Calculation of Damage Sizes

5.3. Determination of Parameters

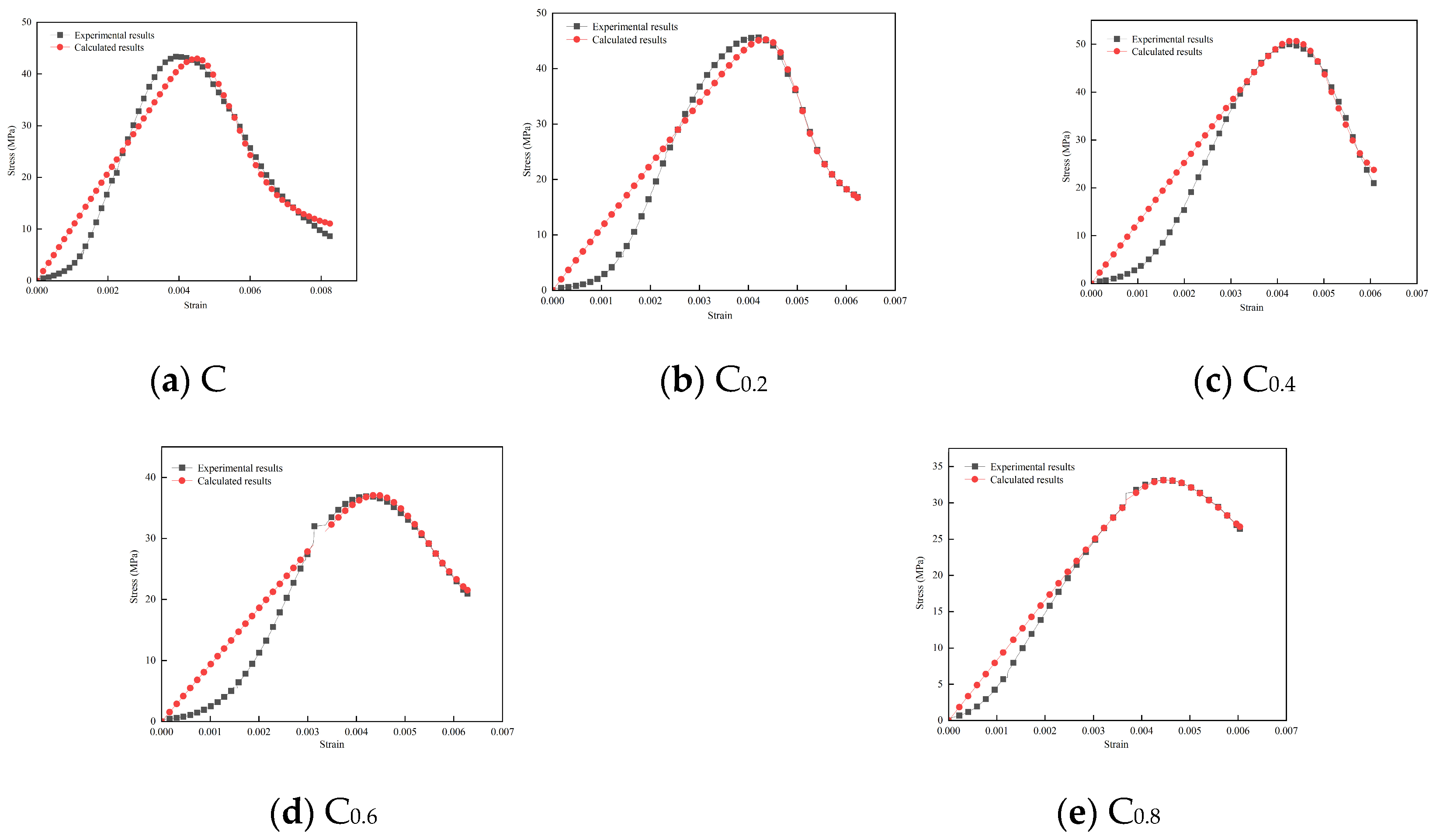

5.4. Model Confirmation

5.5. Damage Development

6. Conclusions

- (1)

- When the mixing amount of carbon fiber is 0.4%, the overall performance of the carbon fiber concrete is optimal. The compressive strength of the specimen is 15.02% higher than that of the reference concrete, the splitting tensile strength is increased by 51.12%, and the total strain energy and elastic strain energy reach their peak. With the gradual increase in the carbon fiber dosage, each energy of the carbon fiber concrete specimens at the peak stress showed a trend of increasing and then decreasing, and the peak strain gradually increased. At different strain rates, the compressive strength of the optimal content group is 10.01%, 15.02%, and 18.27% higher than that of the plain concrete.

- (2)

- The energy dissipation of the plain concrete at low strain rates is important in the compaction-density phase of the deformation damage process in CFRC; in the elastic deformation phase, the input energy is mainly converted into elastic strain energy storage, and the elastic strain energy ratio increases significantly with the increase in the strain rate. In the plastic deformation stage, the larger the strain rate. At the smaller proportion of dissipated energy and the same strain rate of the carbon fiber concrete, the dissipation energy increases significantly at the same strain rate as the plain concrete, effectively retarding the specimen deformation.

- (3)

- As the strain rate increases, the peak value increases, followed by a decrease in the minimum value of b, indicating that the strain rate has a large influence on the energy distribution. As the strain rate increases, the elastic strain energy percentage of the base concrete increases more than that of carbon fiber concrete, but the elastic strain energy percentage of carbon fibers is still higher than that of plain concrete, indicating that the carbon fibers have the ability to accumulate elastic strain energy and slow down the energy distribution of the concrete.

- (4)

- The CFRC material model is based on the damage mechanics theory and the probabilistic statistical method, and the calculated curve of the model fits well with the CFRC stress–strain test curve, which reflects the effect of carbon fiber doping on the CFRC material damage.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pontinha, A.D.R.; Mäntyneva, J.; Santos, P.; Durães, L. Thermomechanical Performance Assessment of Sustainable Buildings’ Insulating Materials under Accelerated Ageing Conditions. Gels 2023, 9, 241. [Google Scholar] [CrossRef]

- Mo, L.; Deng, M.; Tang, M.; Al-Tabbaa, A. MgO expansive cement and concrete in China: Past, present and future. Cem. Concr. Res. 2014, 57, 1–12. [Google Scholar] [CrossRef]

- Lawler, J.S.; Wilhelm, T.; Zampini, D.; Shah, S.P. Fracture processes of hybrid fiber-reinforced mortar. Mater. Struct. 2003, 36, 197–208. [Google Scholar] [CrossRef]

- Beeldens, A.; Van Gemert, D.; Schorn, H.; Ohama, Y.; Czarnecki, L. From microstructure to macrostructure: An integrated model of structure formation in polymer-modified concrete. Mater. Struct. 2005, 38, 601–607. [Google Scholar] [CrossRef]

- Aydin, A.C. Self compactability of high volume hybrid fiber reinforced concrete. Constr. Build. Mater. 2007, 21, 1149–1154. [Google Scholar] [CrossRef]

- Guo, H.; Tao, J.; Chen, Y.; Li, D.; Jia, B.; Zhai, Y. Effect of steel and polypropylene fibers on the quasi-static and dynamic splitting tensile properties of high-strength concrete. Constr. Build. Mater. 2019, 224, 504–514. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, Y.; Zhuo, J.; Zhang, Y.; Wan, C. A review of the mechanical properties and durability of basalt fiber-reinforced concrete. Constr. Build. Mater. 2022, 359, 129360. [Google Scholar] [CrossRef]

- Song, P.S.; Hwang, S. Mechanical properties of high-strength steel fiber-reinforced concrete. Constr. Build. Mater. 2004, 18, 669–673. [Google Scholar] [CrossRef]

- Muthukumarana, T.V.; Arachchi MA VH, M.; Somarathna HM, C.C.; Raman, S.N. A review on the variation of mechanical properties of carbon fiber-reinforced concrete. Constr. Build. Mater. 2023, 366, 130173. [Google Scholar] [CrossRef]

- Chen, T.; Wang, Z.H.; Wang, A.; Bai, E.; Zhu, X. Comparative study on the static and dynamic mechanical properties and micro-mechanism of carbon fiber and carbon nanofiber reinforced concrete. Case Stud. Constr. Mater. 2023, 18, e01827. [Google Scholar] [CrossRef]

- Patchen, A.; Young, S.; Penumadu, D. An Investigation of Mechanical Properties of Recycled Carbon Fiber Reinforced Ultra-High-Performance Concrete. Materials 2022, 16, 314. [Google Scholar] [CrossRef]

- Wu, L.; Lu, Z.; Zhuang, C.; Chen, Y.; Hu, R. Mechanical properties of nano SiO2 and carbon fiber reinforced concrete after exposure to high temperatures. Materials 2019, 12, 3773. [Google Scholar] [CrossRef]

- Boris, R.; Antonovich, V.; Spudulis, É.; Volochko, A.; Stonis, R. Effect of carbon fiber on medium-cement heat-resistant concrete properties. Refract. Ind. Ceram. 2014, 55, 352–355. [Google Scholar] [CrossRef]

- Kizilkanat, A.B. Experimental evaluation of mechanical properties and fracture behavior of carbon fiber reinforced high strength concrete. Period. Polytech. Civ. Eng. 2016, 60, 289–296. [Google Scholar] [CrossRef]

- Kan, W.; Yang, Z.; Yu, L. Study on Frost Resistance of the Carbon-Fiber-Reinforced Concrete. Appl. Sci. 2022, 12, 3823. [Google Scholar] [CrossRef]

- Deng, Z.H.; Zhou, Y.W.; Jiang, J.S.; Huang, X.; Liu, B. Mechanical properties and uniaxial constitutive model of fiber-reinforced coral aggregate concrete. Struct. Concr. 2023, 24, 4259–4275. [Google Scholar] [CrossRef]

- Wang, H.; Dang, F.; Ren, J.; Li, Y.; Zhu, L. Experimental Research on the Energy Evolution of Concrete under Impact Loading. Materials 2023, 16, 5140. [Google Scholar] [CrossRef]

- Geng, K.; Chai, J.; Qin, Y.; Li, X.; Duan, M.; Liang, D. Exploring the brittleness and fractal characteristics of basalt fiber reinforced concrete under impact load based on the principle of energy dissipation. Mater. Struct. 2022, 55, 78. [Google Scholar] [CrossRef]

- Ren, J.; Dang, F.; Wang, H.; Xue, Y.; Fang, J. Enhancement mechanism of the dynamic strength of concrete based on the energy principle. Materials 2018, 11, 1274. [Google Scholar] [CrossRef]

- Li, Y.; Zhai, Y.; Liu, X.; Liang, W. Research on fractal characteristics and energy dissipation of concrete suffered freeze-thaw cycle action and impact loading. Materials 2019, 12, 2585. [Google Scholar] [CrossRef]

- GB/T50081-2002; Standard for Test Method of Mechanical Properties on Ordinary Concrete. China Architecture and Building Press: Beijing, China, 2003. (In Chinese)

- Zhao, Z.; Ma, W.; Fu, X.; Yuan, J. Energy theory and application of rocks. Arab. J. Geosci. 2019, 12, 1–26. [Google Scholar] [CrossRef]

- Wang, C.; He, B.; Hou, X.; Li, J.; Liu, L. Stress–energy mechanism for rock failure evolution based on damage mechanics in hard rock. Rock Mech. Rock Eng. 2020, 53, 1021–1037. [Google Scholar] [CrossRef]

- Meng, Q.; Zhang, M.; Han, L.; Pu, H.; Nie, T. Effects of acoustic emission and energy evolution of rock specimens under the uniaxial cyclic loading and unloading compression. Rock Mech. Rock Eng. 2016, 49, 3873–3886. [Google Scholar] [CrossRef]

- Jin, X.C.; Hou, C.; Fan, X.L.; Lu, C.; Yang, H.; Shu, X.; Wang, Z. Quasi-static and dynamic experimental studies on the tensile strength and failure pattern of concrete and mortar discs. Sci. Rep. 2017, 7, 15305. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Ge, L.; Zhou, J.; Wu, S. Dynamic Brazilian test of concrete using split Hopkinson pressure bar. Mater. Struct. 2017, 50, 1–15. [Google Scholar] [CrossRef]

- Xiao, Y.J.; Chen, Z.S.; Zhou, J.T.; Leng, Y.; Xia, R. Concrete plastic-damage factor for finite element analysis: Concept, simulation, and experiment. Adv. Mech. Eng. 2017, 9, 1687814017719642. [Google Scholar] [CrossRef]

- Lemaitre, J. A Continuous Damage Mechanics Model for Ductile Fracture. J. Eng. Mater. Technol. 1985, 107, 83–89. [Google Scholar] [CrossRef]

- Wang, C.; Fu, P.; Liu, Z.; Xu, Z.; Wen, T.; Zhu, Y.; Long, Y.; Jiang, J. Study of the Durability Damage of Ultrahigh Toughness Fiber Concrete Based on Grayscale Prediction and the Weibull Model. Buildings 2022, 12, 746. [Google Scholar] [CrossRef]

| Density /(kg·m−3) | Tensile Strength/MPa | Length /mm | Carbon Content/% | Diameter /μm | Tensile Modulus/GPa |

|---|---|---|---|---|---|

| 1800 | 3450 | 3 | 95 | 7 | 230 |

| Specimens | Cement | Fine Aggregate | Coarse Aggregate | Water | Carbon Fiber |

|---|---|---|---|---|---|

| C0 | 361 | 650 | 1360 | 145 | 0 |

| C0.2 | 361 | 650 | 1360 | 145 | 3.6 |

| C0.4 | 361 | 650 | 1360 | 145 | 7.2 |

| C0.6 | 361 | 650 | 1360 | 145 | 10.8 |

| C0.8 | 361 | 650 | 1360 | 145 | 14.4 |

| Subject | Parameter |

|---|---|

| Maximum axial test force | 3000 kN |

| Test force accuracy | ±1% |

| Displacement range | 100 mm |

| Displacement accuracy | ±2% |

| Displacement equal velocity control | 0.5~50 mm/min |

| Power supply | 4 kW/AC380V/50 Hz |

| Specimens | C0 | C0.2 | C0.4 | C0.6 | C0.8 |

|---|---|---|---|---|---|

| Compressive strength/MPa | 43.456 | 45.6 | 49.982 | 36.928 | 33.14 |

| Tensile strength/MPa | 4.349 | 6.146 | 6.572 | 6.361 | 5.454 |

| Carbon Fiber Content/% | α | β | R2 |

|---|---|---|---|

| 0 | 0.1356 | 2.36205 | 0.94 |

| 0.2 | 0.12427 | 2.48615 | 0.92 |

| 0.4 | 0.14445 | 2.62611 | 0.91 |

| 0.6 | 0.11683 | 1.77243 | 0.90 |

| 0.8 | 0.13127 | 1.19205 | 0.97 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, R.; Pang, J.; Sun, J.; Su, Y.; Xu, G. Damage Model of Carbon-Fiber-Reinforced Concrete Based on Energy Conversion Principle. J. Compos. Sci. 2024, 8, 71. https://doi.org/10.3390/jcs8020071

Zheng R, Pang J, Sun J, Su Y, Xu G. Damage Model of Carbon-Fiber-Reinforced Concrete Based on Energy Conversion Principle. Journal of Composites Science. 2024; 8(2):71. https://doi.org/10.3390/jcs8020071

Chicago/Turabian StyleZheng, Ruiqi, Jianyong Pang, Jian Sun, Yongqiang Su, and Guoping Xu. 2024. "Damage Model of Carbon-Fiber-Reinforced Concrete Based on Energy Conversion Principle" Journal of Composites Science 8, no. 2: 71. https://doi.org/10.3390/jcs8020071

APA StyleZheng, R., Pang, J., Sun, J., Su, Y., & Xu, G. (2024). Damage Model of Carbon-Fiber-Reinforced Concrete Based on Energy Conversion Principle. Journal of Composites Science, 8(2), 71. https://doi.org/10.3390/jcs8020071