Effect of the Energy Director Material on the Structure and Properties of Ultrasonic Welded Lap Joints of PEI Plates with CF Fabric/PEI Prepreg

Abstract

1. Introduction

- -

- When joining layered composites (laminates), USW procedures are based on the insertion of an energy director (ED) between them, which is melted due to frictional (viscoelastic) heating and wets the contacting surfaces of parts to be welded (adherends) [2,3,4]; in doing so, it partially squeezes out of the fusion zone [5,6,7]. The efforts of researchers in this (predominantly technological) direction are focused on several problems: (i) justification of USW parameters, which makes it possible to evaluate the formation of a reliable joint, excluding damage to the adherends [8]; (ii) selection of ED materials, based on compatibility with adherends both chemically [9] and over their melting temperatures; (iii) use of EDs with controlled porosity, their surface microtexturing (perforation); shape and thickness variations, etc. [10,11]; (iv) assessment of the possibility of joining dissimilar materials, including laminates based on thermoplastic as well as epoxy binders [12,13,14]. Typically, progress in the development of USW procedures is assessed over the interlayer shear strength (ILSS) of lap joints, determined in tensile tests. Information on fiber-reinforced PEI lap joints might be found elsewhere in [15,16,17].

- -

- Preliminary consolidation of carbon fiber (CF) tapes with (thermoplastic) polymer films upon the formation of semi-prepregs or automated fiber placement (AFP) [18,19]. In such cases, achievement of the maximum adhesive strength is not the ultimate goal, since the components possess significantly different stiffness values and should maintain structural integrity during mutual displacement on friction (primarily, CF filaments). Thus, the criterion for the process effectiveness is maintenance of the structural integrity and improvement of the functional characteristics of the fabricated products [20,21,22].

- -

- Layer-by-layer consolidation of laminates from prepregs [23,24]. In this way, one of the challenges is the fabrication of the laminates, which is solved by various methods [25,26,27]. A key requirement there is ensuring fusion only between the interfaces and the prepregs, with minimal damage to the bulk component. The issue is complicated by the nonlinearity of frictional heating [11] and the presence of reinforcing CFs (inside thin prepregs), with the latter possessing significantly higher thermal conductivity than that of thermoplastic binders [28]. However, despite all these difficulties, this direction is under intense development, while increasing the durability of the adhesive joints remains a key challenge in design of carbon fiber-reinforced polymer composites (CFRP) [29,30,31].

2. Materials and Methods

2.1. Sample Preparation

2.2. Sample Testing and Characterization

3. Mechanical Properties and Structural Characteristics of the TecaPEI Lap Joints

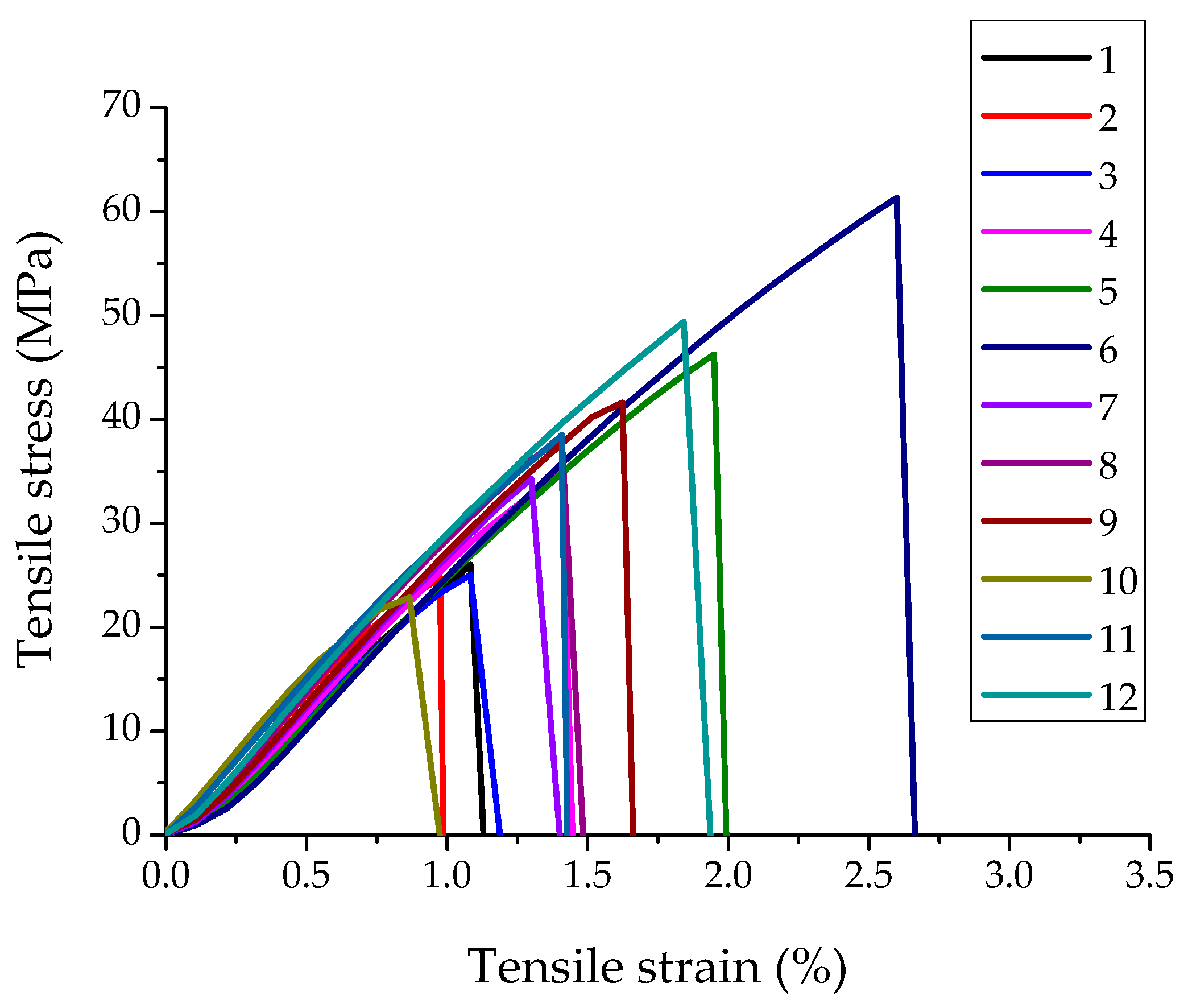

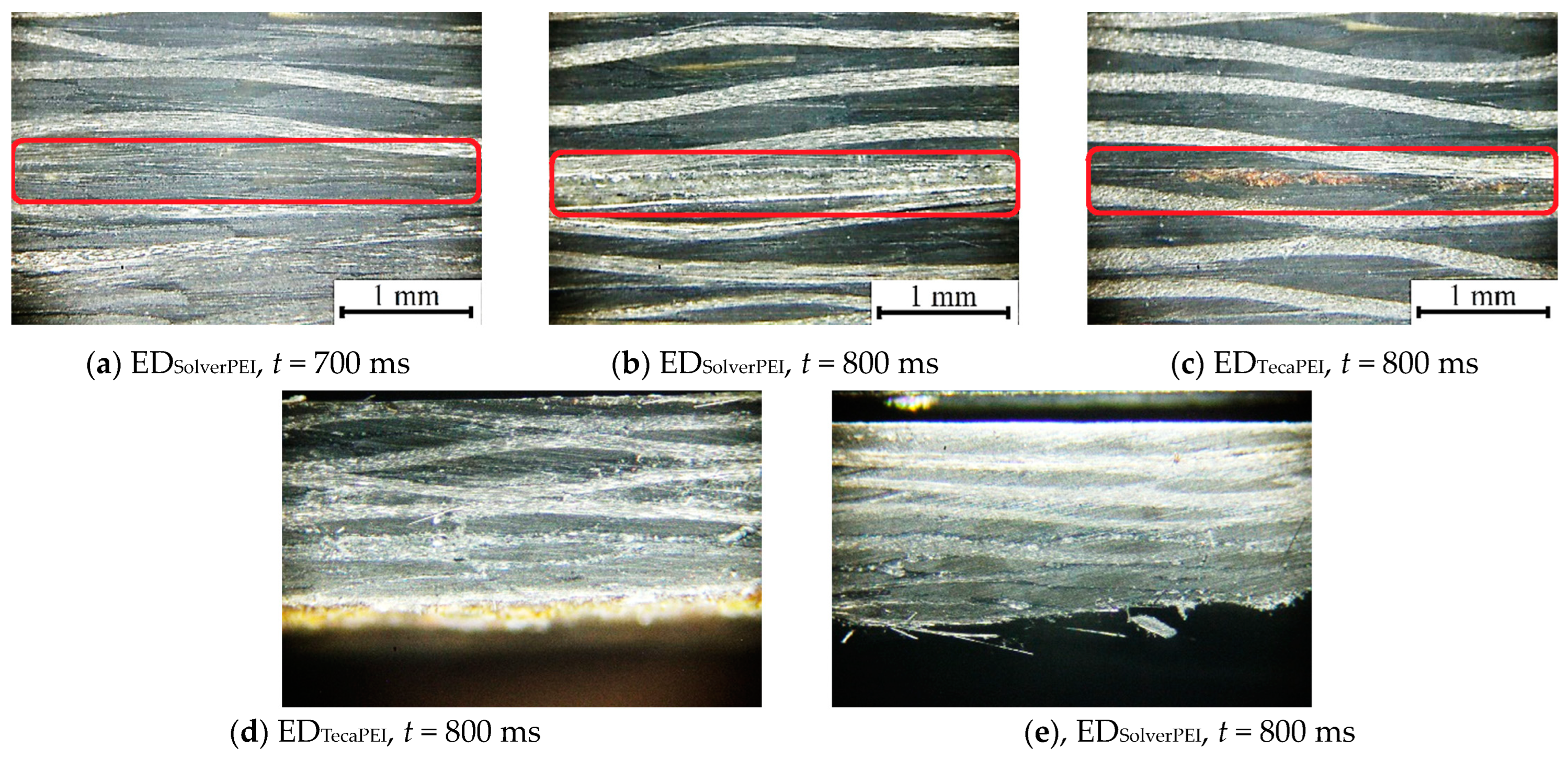

3.1. Tensile Tests

3.2. Cross-Section Structure

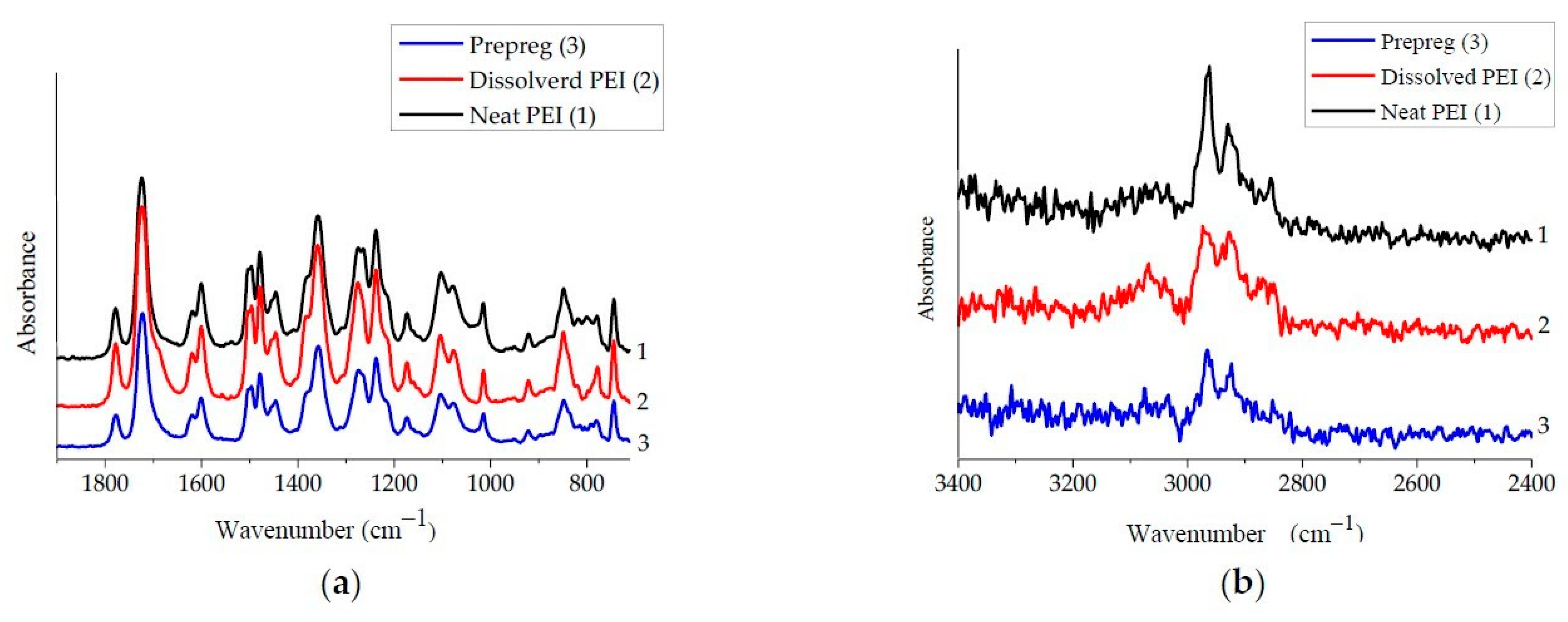

3.3. Chemical Structure

4. Application of Both Low-Melting TecaPEI and PEI Films for USW Consolidation of the CF Fabric–PEI Laminates

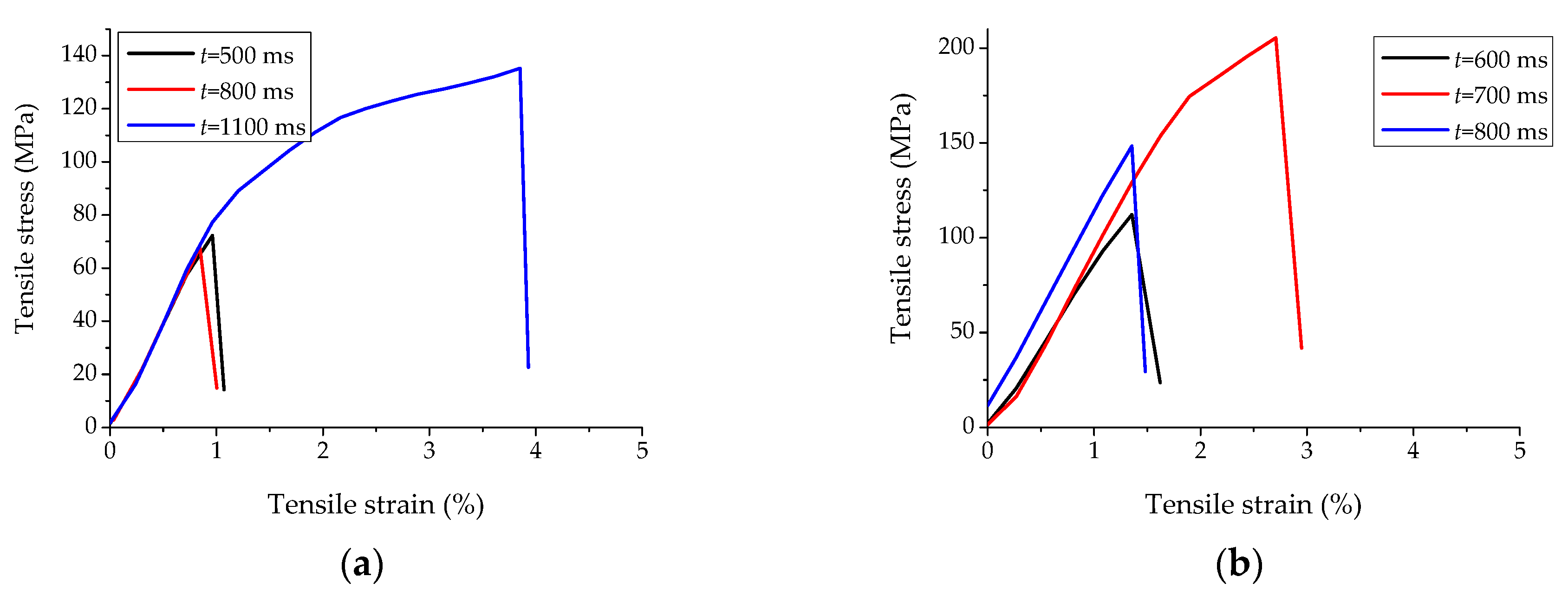

4.1. Tensile Tests

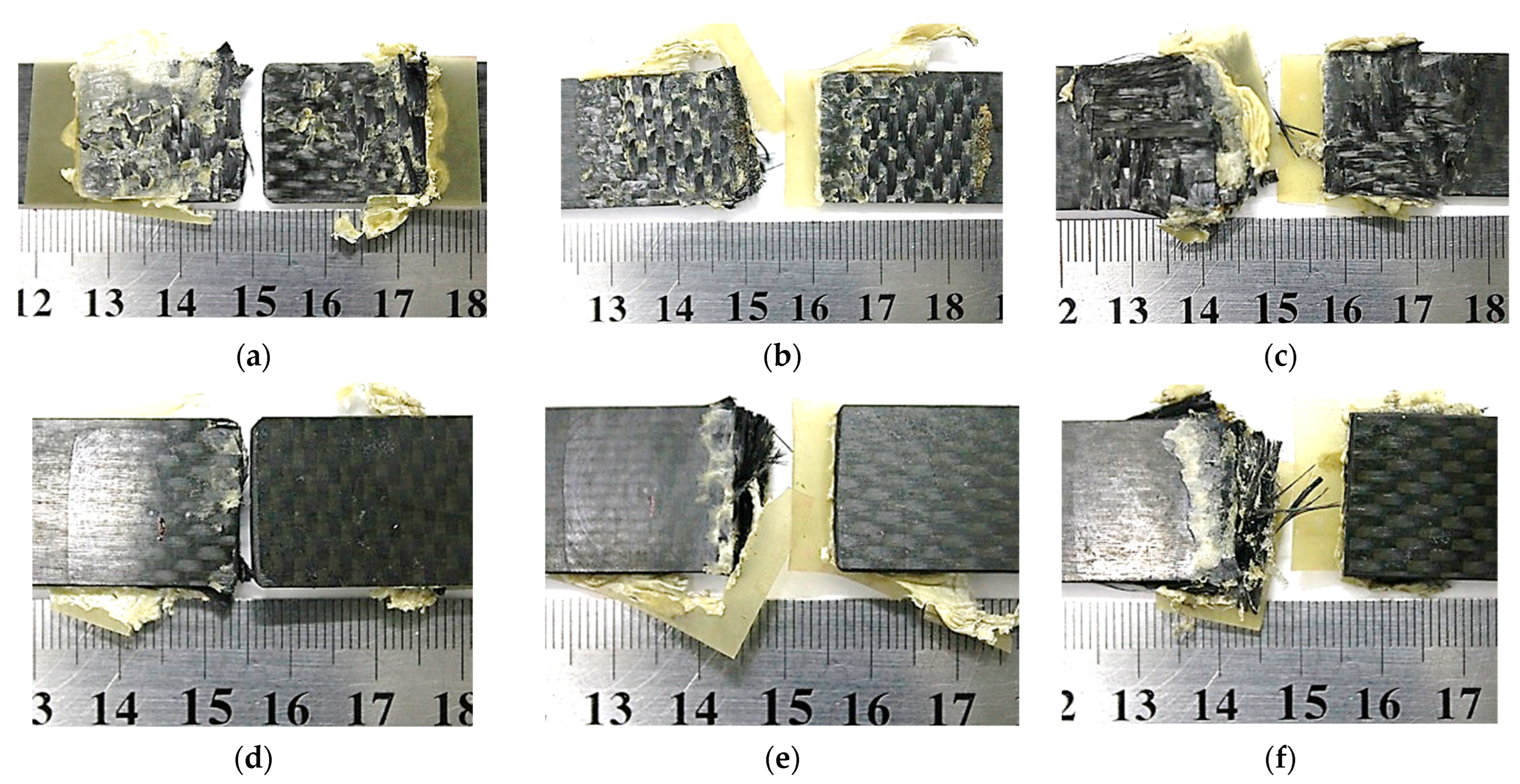

4.2. Cross-Section Structure

5. Discussion

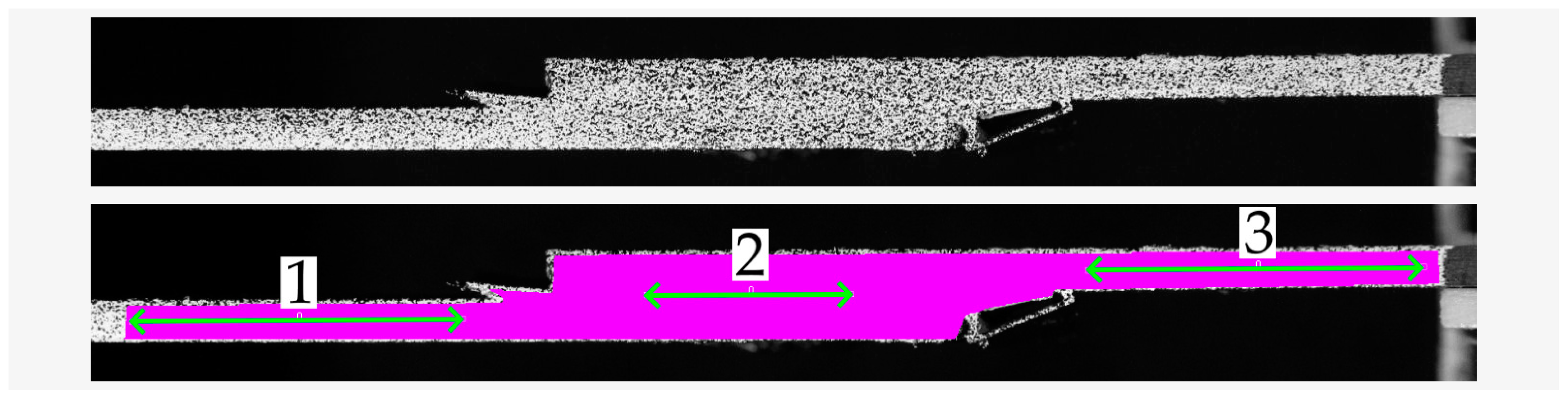

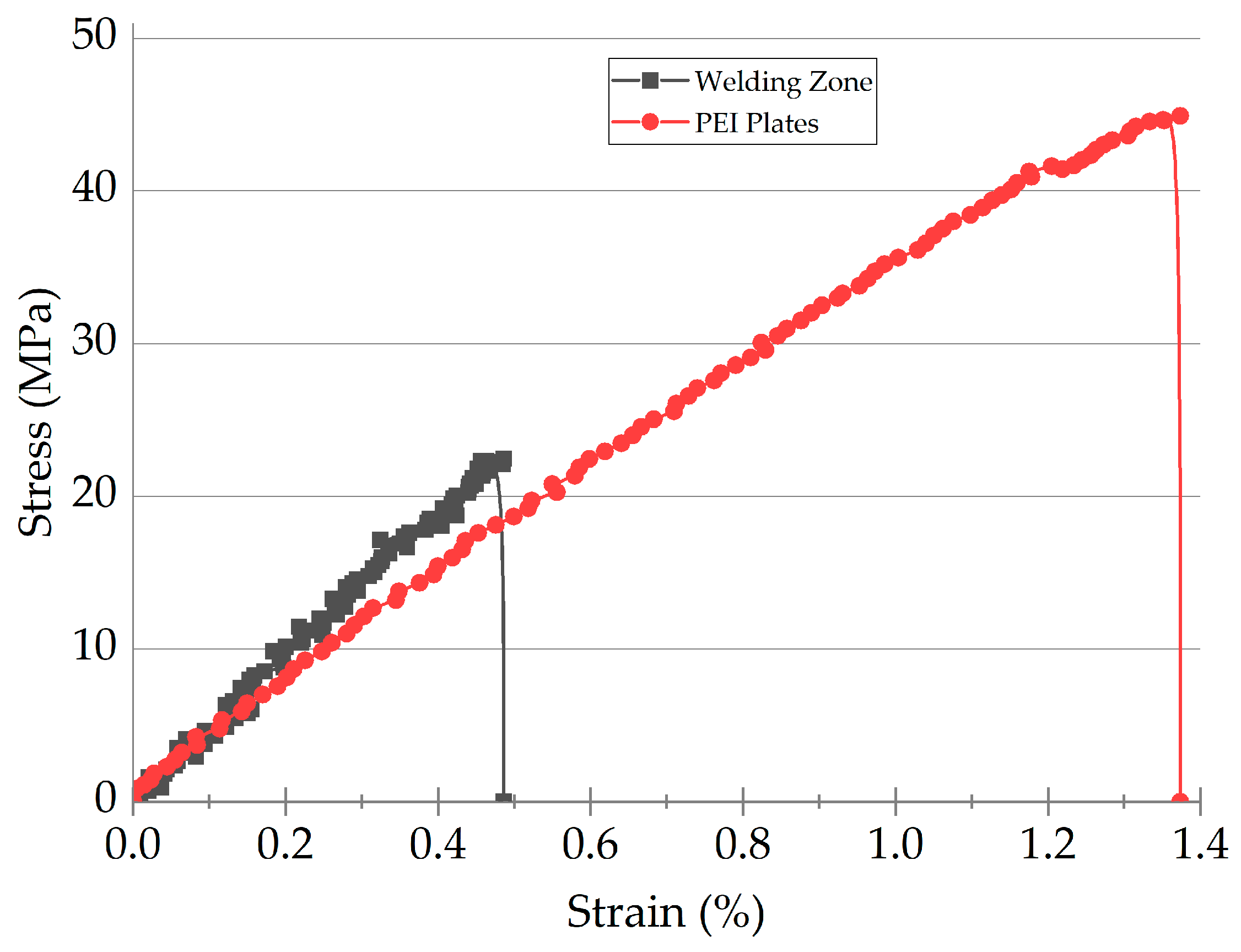

5.1. Deformation Behavior Characterization by the DIC Method

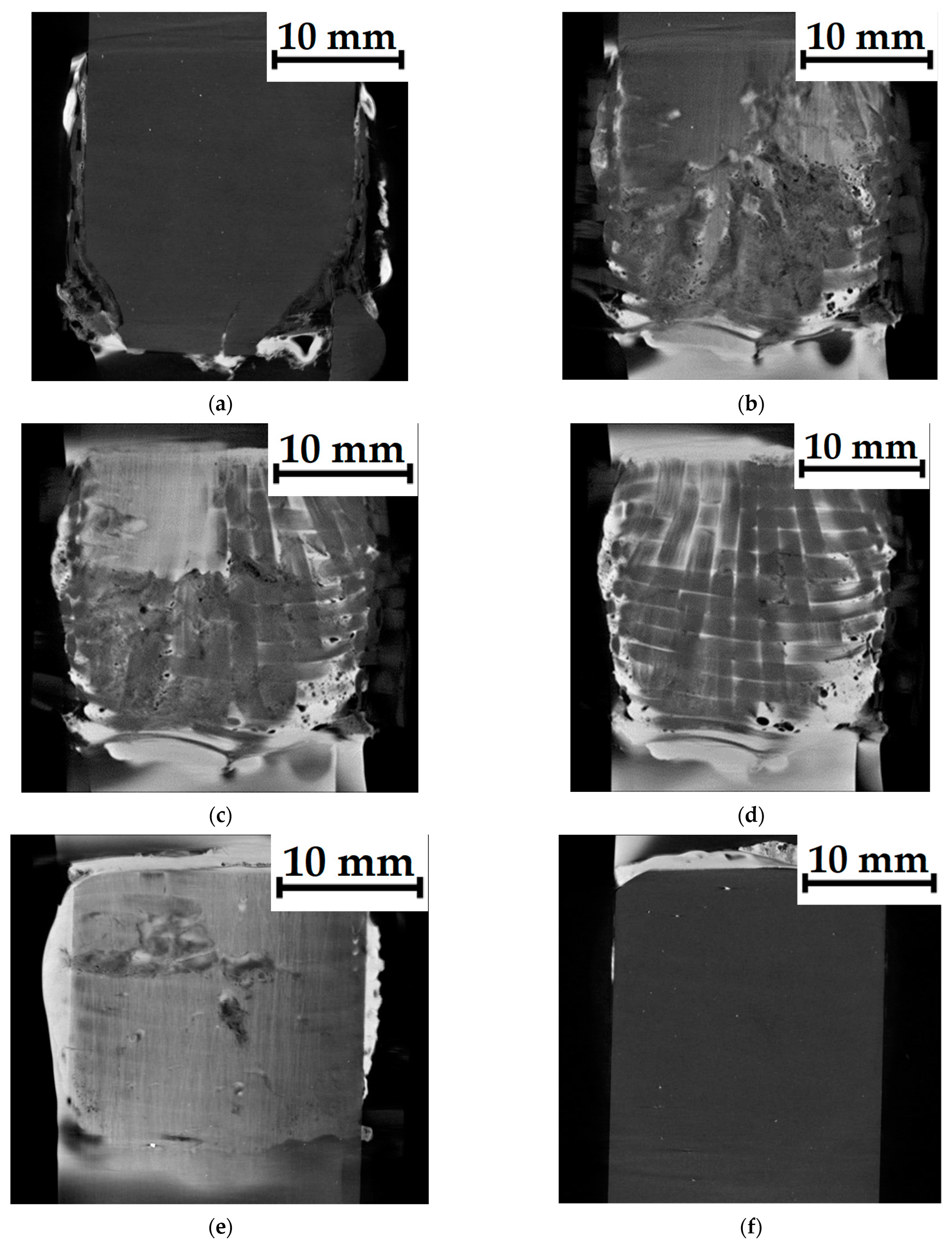

5.2. Computed Tomography

5.3. Process Analysis

5.4. USW Consolidation of a PEEK-Based Prepreg

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gallego-Juárez, J.A.; Graff, K.F. Power Ultrasonics: Applications of High-Intensity Ultrasound; Elsevier: Amsterdam, The Netherlands, 2015; pp. 295–312. [Google Scholar]

- Li, W.; Palardy, G. Investigation of welding repair methods for thermoplastic composite joints. Compos. Part B Eng. 2023, 264, 110924. [Google Scholar] [CrossRef]

- Ullah, M.A.; Li, W.; Palardy, G. Effect of ultrasonic welding process parameters on the crystallinity of GF/MWCNT/PP composites. In Proceedings of the American Society for Composites, Greater Boston, MA, USA, 17–20 September 2023. [Google Scholar]

- Li, W.; Frederick, H.; Palardy, G. Multifunctional films for thermoplastic composite joints: Ultrasonic welding and damage detection under tension loading. Compos. Part A Appl. Sci. Manuf. 2020, 141, 106221. [Google Scholar] [CrossRef]

- Bonmatin, M.; Chabert, F.; Bernhart, G.; Cutard, T.; Djilali, T. Ultrasonic welding of CF/PEEK composites: Influence of welding parameters on interfacial temperature profiles and mechanical properties. Compos. Part A Appl. Sci. Manuf. 2022, 162, 107074. [Google Scholar] [CrossRef]

- Jongbloed, B.; Teuwen, J.; Villegas, I.F. On the use of a rounded sonotrode for the welding of thermoplastic composites. J. Adv. Join. Process. 2023, 7, 100144. [Google Scholar] [CrossRef]

- Tsiangou, E.; de Freitas, S.T.; Villegas, I.F.; Benedictus, R. Investigation on energy director-less ultrasonic welding of poly-etherimide (PEI)-to epoxy-based composites. Compos. B Eng. 2019, 173, 107014. [Google Scholar] [CrossRef]

- Reis, J.P.; de Moura, M.; Samborski, S. Thermoplastic composites and their promising applications in joining and repair composites structures: A review. Materials 2020, 13, 5832. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Singh, R.; Ahuja, I.; Penna, R.; Feo, L. Weldability of thermoplastic materials for friction stir welding- A state of art review and future applications. Compos. Part B Eng. 2018, 137, 1–15. [Google Scholar] [CrossRef]

- Yan, J.C.; Wang, X.L.; Li, R.Q.; Xu, H.B.; Yang, S.Q. The Effects of Energy Director Shape on Temperature Field during Ultrasonic Welding of Thermoplastic Composites. Key Eng. Mater. 2007, 353–358, 2007–2010. [Google Scholar] [CrossRef]

- Palardy, G.; Villegas, I.F. On the effect of flat energy directors thickness on heat generation during ultrasonic welding of thermoplastic composites. Compos. Interfaces 2017, 24, 203–214. [Google Scholar] [CrossRef]

- Khatri, B.; Roth, M.F.; Balle, F. Ultrasonic Welding of Additively Manufactured PEEK and Carbon-Fiber-Reinforced PEEK with Integrated Energy Directors. J. Manuf. Mater. Process. 2023, 7, 2. [Google Scholar] [CrossRef]

- Tsiangou, E.; de Freitas, S.T.; Villegas, I.F.; Benedictus, R. Ultrasonic welding of epoxy- to polyetheretherketone- based composites: Investigation on the material of the energy director and the thickness of the coupling layer. J. Compos. Mater. 2020, 54, 3081–3098. [Google Scholar] [CrossRef]

- Villegas, I.F.; van Moorleghem, R. Ultrasonic welding of carbon/epoxy and carbon/PEEK composites through a PEI thermoplastic coupling layer. Compos. Part A Appl. Sci. Manuf. 2018, 109, 75–83. [Google Scholar] [CrossRef]

- Zhao, P.; Zhang, Z.; Li, Y.; Tian, L.; Wang, C.; Xiong, X. Resistance welding of thermoplastic composites via a novel carbon nanofilm implant. Mater. Lett. 2022, 328, 133216. [Google Scholar] [CrossRef]

- Marques, L.F.B.; Reis, J.F.; Abrahão, A.B.R.M.; Hein, L.R.D.O.; Botelho, E.C.; Costa, M.L. Interfacial, mechanical, and thermal behavior of PEI/glass fiber welded joints influenced by hygrothermal conditioning. J. Compos. Mater. 2021, 56, 239–249. [Google Scholar] [CrossRef]

- Gao, J.; Dong, J.; Zhang, S.; Yu, L.; Jin, H.; Zhang, J.; Shen, Y. Study of friction stir spot welding for thermotolerant engineering thermoplastic polyimide joints. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 235, 1810–1817. [Google Scholar] [CrossRef]

- Chu, Q.; Li, Y.; Xiao, J.; Huan, D.; Zhang, X.; Chen, X. Processing and characterization of the thermoplastic composites man-ufactured by ultrasonic vibration–assisted automated fiber placement. J. Thermoplast. Compos. Mater. 2018, 31, 339–358. [Google Scholar] [CrossRef]

- Kirby, M.; Naderi, A.; Palardy, G. Predictive Thermal Modeling and Characterization of Ultrasonic Consolidation Process for Thermoplastic Composites. J. Manuf. Sci. Eng. 2023, 145, 031009. [Google Scholar] [CrossRef]

- Slange, T.K.; Grouve, W.J.; Warnet, L.L.; Wijskamp, S.; Akkerman, R. Towards the combination of automated lay-up and stamp forming for consolidation of tailored composite components. Compos. Part A Appl. Sci. Manuf. 2019, 119, 165–175. [Google Scholar] [CrossRef]

- Forcellese, A.; Greco, L.; Pieralisi, M.; Simoncini, M.; Trevisan, G. Mechanical properties of carbon fiber reinforced plastic obtained by the automatic deposition of an innovative towpreg. Procedia CIRP 2020, 88, 451–456. [Google Scholar] [CrossRef]

- Struzziero, G.; Barbezat, M.; Skordos, A.A. Consolidation of continuous fibre reinforced composites in additive processes: A review. Addit. Manuf. 2021, 48, 102458. [Google Scholar] [CrossRef]

- Gomer, A.; Zou, W.; Grigat, N.; Sackmann, J.; Schomburg, W.K. Fabrication of Fiber Reinforced Plastics by Ultrasonic Welding. J. Compos. Sci. 2018, 2, 56. [Google Scholar] [CrossRef]

- Lionetto, F.; Dell’Anna, R.; Montagna, F.; Maffezzoli, A. Modeling of continuous ultrasonic impregnation and consolidation of thermoplastic matrix composites. Compos. Part A Appl. Sci. Manuf. 2015, 82, 119–129. [Google Scholar] [CrossRef]

- Esfandiari, P.; Silva, J.F.; Novo, P.J.; Nunes, J.P.; Marques, A.T. Production and processing of pre-impregnated thermoplastic tapes by pultrusion and compression moulding. J. Compos. Mater. 2022, 56, 1667–1676. [Google Scholar] [CrossRef]

- Yao, S.-S.; Jin, F.-L.; Rhee, K.Y.; Hui, D.; Park, S.-J. Recent advances in carbon-fiber-reinforced thermoplastic composites: A review. Compos. Part B Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Minchenkov, K.; Vedernikov, A.; Safonov, A.; Akhatov, I. Thermoplastic Pultrusion: A Review. Polymers 2021, 13, 180. [Google Scholar] [CrossRef] [PubMed]

- Tao, W.; Su, X.; Wang, H.; Zhang, Z.; Li, H.; Chen, J. Influence mechanism of welding time and energy director to the ther-moplastic composite joints by ultrasonic welding. J. Manuf. Process. 2019, 37, 196–202. [Google Scholar] [CrossRef]

- Kupski, J.; Teixeira de Freitas, S. Design of adhesively bonded lap joints with laminated CFRP adherends: Review, challenges and new opportunities for aerospace structures. Compos. Struct. 2021, 268, 113923. [Google Scholar] [CrossRef]

- SCase, W.; Das, A.; Bortner, M.J.; Dillard, D.A.; White, C.C. Durability and accelerated characterization of adhesive bonds. In Advances in Structural Adhesive Bonding; Dillard, D.A., Ed.; Woodhead Publishing: Sawston, UK, 2023; pp. 675–710. ISBN 9780323912143. [Google Scholar]

- Panda, H.S.; Samant, R.; Mittal, K.L.; Panigrahi, S. Durability Aspects of Structural Adhesive Joints. In Structural Adhesive Joints: Design, Analysis and Testing; Mittal, K.L., Panigrahi, S.K., Eds.; Wiley: Hoboken, NJ, USA, 2020. [Google Scholar] [CrossRef]

- Alexenko, V.O.; Panin, S.V.; Stepanov, D.Y.; Byakov, A.V.; Bogdanov, A.A.; Buslovich, D.G.; Panin, K.S.; Tian, D. Ultrasonic Welding of PEEK Plates with CF Fabric Reinforcement—The Optimization of the Process by Neural Network Simulation. Materials 2023, 16, 2115. [Google Scholar] [CrossRef]

- Ding, G.; Feng, P.; Wang, Y.; Ai, P. Novel pre-clamp lap joint for CFRP plates: Design and experimental study. Compos. Struct. 2022, 302, 116240. [Google Scholar] [CrossRef]

- Taguchi, G.; Phadke, M.S. Quality Engineering through Design Optimization. In Quality Control, Robust Design, and the Taguchi Method; Springer: Boston, MA, USA, 1984. [Google Scholar]

- Kacker, R.N.; Lagergren, E.S.; Filliben, J.J. Taguchis’s Orthogonal Arrays are Classical Design of Experiments. J. Res. Natl. Inst. Stand. Technol. 1991, 96, 577. [Google Scholar] [CrossRef]

- Taguchi, G. System of Experimental Design: Engineering Methods to Optimize Quality and Minimize Costs; Quality Resources: New York, NY, USA, 1987. [Google Scholar]

- Panin, S.V.; Bochkareva, S.A.; Panov, I.L.; Alexenko, V.O.; Byakov, A.V.; Lyukshin, B.A. Experimental and Numerical Studies on the Tensile Strength of Lap Joints of PEEK Plates and CF Fabric Prepregs Formed by Ultrasonic Welding. In Progress in Continuum Mechanics. Advanced Structured Materials; Altenbach, H., Irschik, H., Porubov, A.V., Eds.; Springer: Berlin/Heidelberg, Germany, 2023; Volume 196, pp. 321–354. [Google Scholar]

- Wang, J.; Lu, C.; Xiao, C.; Cheng, J.; Ren, R.; Xiong, X. Heat distribution simulation and effects of ultrasonic welding amplitude on carbon fiber/polyetherimide composite joint properties. Mater. Lett. 2023, 340, 134148. [Google Scholar] [CrossRef]

- Sutton, M.A.; Orteu, J.J.; Schreier, H.W. Image Correlation for Shape, Motion and Deformation Measurements: Basic Concepts, Theory and Applications; Springer: New York, NY, USA, 2009; 316p. [Google Scholar]

- Bogdanov, A.A.; Panin, S.V.; Lyubutin, P.S.; Eremin, A.V.; Buslovich, D.G.; Byakov, A.V. An Automated Optical Strain Measurement System for Estimating Polymer Degradation under Fatigue Testing. Sensors 2022, 22, 6034. [Google Scholar] [CrossRef] [PubMed]

- D5868-01 2014; Standard Test Method for Lap Shear Adhesion for Fiber Reinforced Plastic (FRP) Bonding. ASTM International: West Conshohocken, PA, USA, 2023.

- Antony, J. Design of Experiments for Engineers and Scientists, 2nd ed.; Elsevier: Waltham, MA, USA, 2014; p. 208. [Google Scholar]

- Xiong, H.; Hamila, N.; Boisse, P. Consolidation Modeling during Thermoforming of Thermoplastic Composite Prepregs. Materials 2019, 12, 2853. [Google Scholar] [CrossRef] [PubMed]

| No. | Level/Factor | ||

|---|---|---|---|

| USW Duration (t), ms | Clamping Force (P), atm | Holding Time (τ), ms | |

| (1) | 400 | 1.5 | 3000 |

| (2) | 400 | 1.7 | 5000 |

| (3) | 400 | 1.9 | 7000 |

| (4) | 500 | 1.5 | 5000 |

| (5) | 500 | 1.7 | 7000 |

| (6) | 500 | 1.9 | 3000 |

| (7) | 600 | 1.5 | 7000 |

| (8) | 600 | 1.7 | 3000 |

| (9) | 600 | 1.9 | 5000 |

| Additional USW modes | |||

| (10) | 400 | 2.1 | 3000 |

| (11) | 500 | 2.1 | 3000 |

| (12) | 600 | 2.1 | 3000 |

| Spatial Tomogram Resolution, µm | Up to 5 |

|---|---|

| X-ray machine | XWT 160-TC (X-RAY WorX) |

| Anode voltage, kV | 20–255 |

| Anode current, µA | 0.05–1.00 |

| Focal spot, µm | 0.9 |

| Detector panel | PaxScan-2520V (Varian) |

| Size of detector elements, µm | 127 |

| Detector operating area, mm | 193 × 242 |

| Matrix size, pixel | 1900 × 1516 |

| No. | Ultimate Tensile Strength (σP), MPa | Elongation at Break (ε), mm | USW Joint Thinning (Δd), μm | ED Photo (δED top), μm | ED Photo (δED bottom), μm | Distance between PEI Plates (δED+CF), μm | CF Layer Thickness (δCF), μm | PEI Plate Integrity (+/−) |

|---|---|---|---|---|---|---|---|---|

| 1 | 26.0 ± 1.6 | 1.13 ± 0.05 | 110 ± 60 | 210 ± 50 | 220 ± 40 | 620 ± 20 | 230 ± 30 | + |

| 2 | 24.7 ± 1.7 | 0.98 ± 0.06 | 160 ± 30 | 160 ± 60 | 200 ± 40 | 600 ± 20 | 230 ± 70 | + |

| 3 | 25.0 ± 1.5 | 1.19 ± 0.07 | 230 ± 20 | 170 ± 30 | 180 ± 40 | 550 ± 30 | 210 ± 50 | + |

| 4 | 35.2 ± 1.4 | 1.44 ± 0.07 | 160 ± 20 | 150 ± 70 | 160 ± 40 | 540 ± 40 | 210 ± 50 | + |

| 5 | 46.2 ± 3.2 | 1.99 ± 0.10 | 120 ± 20 | 120 ± 60 | 160 ± 20 | 550 ± 50 | 250 ± 110 | + |

| 6 | 61.3 ± 3.1 | 2.66 ± 0.11 | 400 ± 40 | 160 ± 40 | 140 ± 40 | 500 ± 40 | 190 ± 70 | + |

| 7 | 34.3 ± 2.1 | 1.40 ± 0.07 | 360 ± 20 | 100 ± 60 | 170 ± 70 | 430 ± 70 | 200 ± 60 | − |

| 8 | 38.2 ± 2.3 | 1.49 ± 0.07 | 290 ± 20 | 120 ± 40 | 170 ± 50 | 480 ± 60 | 180 ± 40 | − |

| 9 | 41.6 ± 1.7 | 1.66 ± 0.08 | 420 ± 20 | 120 ± 60 | 170 ± 70 | 440 ± 40 | 150 ± 70 | − |

| 10 | 22.9 ± 1.1 | 0.97 ± 0.06 | 190 ± 10 | 200 ± 100 | 200 ± 100 | 670 ± 50 | 240 ± 40 | + |

| 11 | 38.5 ± 2.3 | 1.43 ± 0.08 | 240 ± 10 | 70 ± 50 | 180 ± 20 | 460 ± 40 | 220 ± 40 | − |

| 12 | 49.4 ± 3.0 | 1.94 ± 0.11 | 500 ± 40 | 40 ± 20 | 160 ± 80 | 360 ± 60 | 180 ± 40 | − |

| ED Type | USW Duration (t), ms | USW Lap Joint Thinning (Δd), μm | Ultimate Tensile Strength (σP), MPa | Elongation at Break (εP), % | LSS, MPa |

|---|---|---|---|---|---|

| ED TecaPEI | |||||

| TecaPEI | 500 | 190 ± 30 | 72.2 ± 4.1 | 1.1 ± 0.2 | 7.6 ± 0.4 |

| TecaPEI | 800 | 210 ± 40 | 67.9 ± 3.4 | 1.0 ± 0.2 | 7.1 ± 0.4 |

| TecaPEI | 1100 | 390 ± 90 | 135.0 ± 8.0 | 3.9 ± 0.3 | 14.2 ± 0.6 |

| ED Solver PEI | |||||

| Solver PEI | 600 | 200 ± 30 | 112.2 ± 9.0 | 1.6 ± 0.2 | 11.8 ± 0.6 |

| Solver PEI | 700 | 220 ± 30 | 205.4 ± 10.0 | 2.9 ± 0.2 | 21.6 ± 1.3 |

| Solver PEI | 800 | 400 ± 90 | 148.3 ± 9.0 | 1.5 ± 0.2 | 15.6 ± 0.8 |

| Material | Ultimate Tensile Strength (σP), MPa | Elastic Modulus (E), GPa | Elongation at Break (ε), % |

|---|---|---|---|

| Fusion zone | 22.5 ± 0.7 | 4.5 ± 0.2 | 0.49 ± 0.02 |

| PEI plates | 44.9 ± 1.8 | 3.1 ± 0.1 | 1.37 ± 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, D.; Alexenko, V.O.; Panin, S.V.; Bogdanov, A.A.; Buslovich, D.G. Effect of the Energy Director Material on the Structure and Properties of Ultrasonic Welded Lap Joints of PEI Plates with CF Fabric/PEI Prepreg. J. Compos. Sci. 2024, 8, 150. https://doi.org/10.3390/jcs8040150

Tian D, Alexenko VO, Panin SV, Bogdanov AA, Buslovich DG. Effect of the Energy Director Material on the Structure and Properties of Ultrasonic Welded Lap Joints of PEI Plates with CF Fabric/PEI Prepreg. Journal of Composites Science. 2024; 8(4):150. https://doi.org/10.3390/jcs8040150

Chicago/Turabian StyleTian, Defang, Vladislav O. Alexenko, Sergey V. Panin, Alexey A. Bogdanov, and Dmitry G. Buslovich. 2024. "Effect of the Energy Director Material on the Structure and Properties of Ultrasonic Welded Lap Joints of PEI Plates with CF Fabric/PEI Prepreg" Journal of Composites Science 8, no. 4: 150. https://doi.org/10.3390/jcs8040150

APA StyleTian, D., Alexenko, V. O., Panin, S. V., Bogdanov, A. A., & Buslovich, D. G. (2024). Effect of the Energy Director Material on the Structure and Properties of Ultrasonic Welded Lap Joints of PEI Plates with CF Fabric/PEI Prepreg. Journal of Composites Science, 8(4), 150. https://doi.org/10.3390/jcs8040150