A Review on Abrasive Wear of Aluminum Composites: Mechanisms and Influencing Factors

Abstract

1. Introduction to Abrasive Wear of Aluminum Composites

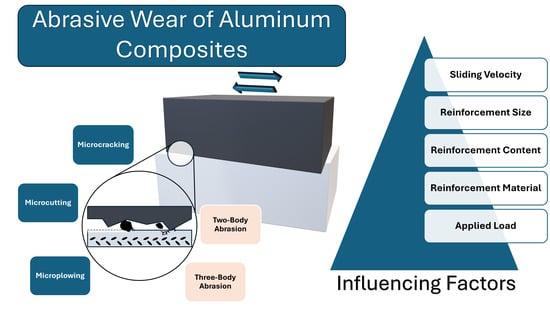

2. Wear Mechanisms

2.1. Microplowing

2.2. Microcutting

2.3. Microcracking

| Alloy | Reinforcement | Counter Part | Reported Wear Mechanisms | Ref. |

|---|---|---|---|---|

| AA7075 | 0–8 Wt.% ZrO2 | - | Adhesion and oxidation in alloy Abrasion and microcutting in composite | [18] |

| AA8011 | 0–8 Wt.% TiC | EN31 Steel | Abrasion and delamination in alloy Oxidation in composite | [19] |

| Pure Al | 0–15 Wt.% B4C | Al2O3 | Abrasion in alloy and composite Finer grooves in composites | [21] |

| AA7050 | 0–2 Wt.% BN | - | Delamination, abrasion, and adhesion in alloy and composite BN acts as a solid lubricant | [22] |

| Pure Al | 2 Wt.% CNT 0–5 Wt.% Graphene | - | Adhesion and delamination in alloy matrix Abrasion in composite | [30] |

| Pure Al | 0–0.75 Wt.% CNT 0–16 Wt.% Fly Ash | EN31 Steel | More microplowing reported in composite with high CNT and more microcutting in composite with high fly ash | [31] |

| AA6061 | SiC Graphite GNP CNT | Steel | Abrasion in Al-SiC-Graphite and Al-SiC-GNP Adhesion and delamination in Al-SiC-CNT | [33] |

| AA6061 | 10 Vol.% Al2O3 | Steel | Abrasion, adhesion, and oxidation in both composite and alloy Three-body abrasion and higher oxidation in the composite | [37] |

| AA2024 | 0–10 Vol.% Al2O3 | 5Cr15 Steel | Adhesion and delamination as the dominant wear mechanisms in all specimens Shallower microplowing by increasing the reinforcement content | [38] |

| A380 | 0–15 Wt.% NbC | Silica abrasive | Three-body abrasion and microcutting mechanisms reported for the sample with the highest reinforcement content Shallower microplowing by increasing the reinforcement content | [41] |

| A356 | 10–20 Vol.% SiC | AISI 52100 Steel | Microcracking under high applied load Severe wear only happens in unreinforced sample SiC suppresses the transition to severe wear | [47] |

| AA7075 | 0–6 Wt.% SiC | EN31 Steel | Abrasion and adhesion in all samples Three-body abrasion under high loads for composites Shallower microplowing by increasing the reinforcement content | [48] |

| AA2024 | 0–9 Wt.% SiC | EN31 Steel | Microplowing increases with an increase in applied load Delamination occurs more under high applied load | [49] |

| AA2024 | 0–30 Wt.% Al2O3 | SiC paper | Shallower microplowing by increasing the reinforcement content Microcutting and microplowing significantly reduced in composites with large size and higher content of reinforcements | [50] |

| AA6351 | 0–3 Wt.% Si3N4 | Steel | Adhesion and delamination in alloy matrix Abrasion in composite Shallower microplowing by increasing the reinforcement content | [51] |

| AA7075 | 0–8 Wt.% Si3N4 | EN31 Steel | Delamination in alloy matrix Abrasion in composite | [52] |

| AA6351 | 0–20 Wt.% AlN | Steel | Adhesion in alloy matrix Abrasion in composite Shallower microplowing by increasing the reinforcement content | [53] |

| AA7075 | 0–9 Wt.% TiB2 | AISI 52100 Steel | Shallower microplowing by increasing the reinforcement content Presence of reinforcement reduced microcutting and plastic deformation in the matrix alloy | [54] |

| AA7075 | 0–20 Vol.% B4C | OHNS Steel | Similar wear mechanisms in alloy matrix and composites Less plastic deformation, microplowing, and microcutting in the composites | [55] |

| Pure Al | 0–4 Wt.% Ti3AlC2 | 45 Steel | Adhesion in matrix alloy Abrasion in the composite Excessive Ti3AlC2 content led to microcracking and severe fatigue delamination wear Shallower microplowing by increasing the reinforcement content Self-lubrication in the composites | [56] |

| Pure | Ti3AlC2 | Steel | At low sliding speeds, the dominant wear mechanism was abrasion, and at higher sliding speeds, adhesion and delamination take over | [57] |

| AA7075 | Ti3AlC2 | AISI D3 steel | Adhesion in the matrix alloy Adhesion/abrasion in the composite | [58] |

| AA6061 | 10 Vol.% SiC 0–5 Vol.% Graphite | Steel | Adhesion in the matrix alloy In Al/SiC composites, by increasing the reinforcement size, the wear mechanism changed from adhesion and microcutting to abrasion and delamination Abrasion was dominant in the hybrid composites | [59] |

| AA5252 | 0–7 Wt.% SiC | AISI 52100 Steel | Abrasion and adhesion under low applied load Adhesion under high applied load | [60] |

| AA7075 | 5 Wt.% Al2O3 | AISI 52100 Steel | Abrasion in low load and sliding velocity Delamination under the high applied load and severe delamination under high load and high sliding velocity Microcracking increased with applied load | [61] |

| A319 A336 A390 | 15 Wt.% SiC | Cast iron | Transition from mild wear to severe wear by an increase in applied load and sliding velocity | [62] |

| AA2024 | 0–5 Wt.% ZrC | AISI 52100 Steel | Under low applied load and sliding velocity, abrasion is the dominant mechanism, and tribochemical and adhesion are the secondary mechanism Under high applied load and sliding velocity, tribochemical is the dominant mechanism, and abrasion and adhesion are the secondary mechanisms | [63] |

3. Effect of Reinforcement Material and Content

3.1. Ceramic Reinforcements

3.2. MAX Phases as Reinforcement

4. Effect of Reinforcement Size

5. Effect of Applied Load and Sliding Velocity

6. Research Gaps for Future Studies

7. Conclusions

- Reinforcement content significantly impacts the wear rate and tribological performance of AMCs. Generally, increasing reinforcement content enhances composite hardness and wear resistance. However, excessive reinforcement may lead to brittleness and inadequate bonding with the aluminum matrix. Achieving a homogeneous distribution of reinforcing particles is essential for optimal wear behavior.

- Smaller reinforcements tend to be more effective in improving mechanical response and hardness, while larger reinforcements excel in load-bearing during wear conditions, offering better matrix protection.

- Larger reinforcements are susceptible to being pulled out or broken under applied loads during wear.

- At critical loads and sliding velocities, a transition from mild wear to severe wear can occur, leading to seizure. The presence of reinforcements can elevate the critical load and sliding velocity.

- Elevated loads and sliding velocities increase surface temperature, promoting oxidation and potentially resulting in higher wear loss through the formation of defective mechanically mixed layers.

Author Contributions

Funding

Conflicts of Interest

References

- Ho, T.L.; Peterson, M.B. Wear formulation for aircraft brake material sliding against steel. Wear 1977, 43, 199–210. [Google Scholar] [CrossRef]

- Prasad, S.V.; Rohatgi, P.K. Tribological Properties of Al Alloy Particle Composites. JOM 1987, 39, 22–26. [Google Scholar] [CrossRef]

- Satish Kumar, T.; Nampoothiri, J.; Shalini, S.; Thankachan, T. Microstructure and Wear Characteristics of Nano Y2O3 Particles Reinforced A356 Alloy Composites Synthesized through Novel Ultrasonic Assisted Stir Casting Technique. Trans. Indian Inst. Met. 2022, 75, 417–426. [Google Scholar] [CrossRef]

- Pethuraj, M.; Uthayakumar, M.; Rajesh, S.; Abdul Majid, M.S.; Rajakarunakaran, S.; Niemczewska-Wójcik, M. Dry Sliding Wear Studies on Sillimanite and B4C Reinforced Aluminium Hybrid Composites Fabricated by Vacuum Assisted Stir Casting Process. Materials 2023, 16, 259. [Google Scholar] [CrossRef] [PubMed]

- Kumar, D.; Singh, S.; Angra, S. Dry sliding wear and microstructural behavior of stir-cast Al6061-based composite reinforced with cerium oxide and graphene nanoplatelets. Wear 2023, 516–517, 204615. [Google Scholar] [CrossRef]

- Surya, M.S.; Prasanthi, G. Effect of SiC Weight Percentage on Tribological Characteristics of Al7075/SiC Composites. Silicon 2022, 14, 1083–1092. [Google Scholar] [CrossRef]

- Bai, Y.; Wei, J.; Lei, N.; Li, J.; Guo, Y.; Liu, M. Effect of VN and TiB2-TiCx Reinforcement on Wear Behavior of Al 7075-Based Composites. Materials 2021, 14, 3389. [Google Scholar] [CrossRef]

- Sam, M.; Radhika, N. Influence of carbide ceramic reinforcements in improving tribological properties of A333 graded hybrid composites. Def. Technol. 2022, 18, 1107–1123. [Google Scholar] [CrossRef]

- Kumar, K.; Dabade, B.M.; Wankhade, L.N.; Agrawal, E.; Chavhan, G. Experimental investigation on tribological performance and development of wear prediction equation of aluminium composite at elevated temperatures. Int. J. Interact. Des. Manuf. 2022. [Google Scholar] [CrossRef]

- Gupta, R.K.; Vashishtha, N.; Sapate, S.G.; Udhayabanu, V.; Peshwe, D.R. Influence of ultrasonic agitation on the abrasive wear characteristics of Al-Cu/2 vol% Grp composite. Surf. Topogr. Metrol. Prop. 2022, 10, 15001. [Google Scholar] [CrossRef]

- Park, C.-S.; Kim, M.-H.; Lawley, A. Microstructure and wear response of spray cast Al-Si/SiCp composites. Int. J. Powder Metall. 1999, 35, 41–50. [Google Scholar]

- Park, C.-S.; Kim, C.-H.; Kim, M.-H.; Lee, C. The effect of particle size and volume fraction of the reinforced phases on the linear thermal expansion in the Al-Si-SiCp system. Mater. Chem. Phys. 2004, 88, 46–52. [Google Scholar] [CrossRef]

- Arunkumar, S.; Kumar, A.S. Studies on Egg Shell and SiC Reinforced Hybrid Metal Matrix Composite for Tribological Applications. Silicon 2022, 14, 1959–1967. [Google Scholar] [CrossRef]

- Hutchings, I.; Shipway, P. 6—Wear by hard particles. In Tribology, 2nd ed.; Hutchings, I., Shipway, P., Eds.; Butterworth-Heinemann: Oxford, UK, 2017; pp. 165–236. [Google Scholar] [CrossRef]

- Alpas, A.T.; Bhattacharya, S.; Hutchings, I.M. 4.5 Wear of Particulate Metal Matrix Composites. In Comprehensive Composite Materials II; Beaumont, P.W.R., Zweben, C.H., Eds.; Elsevier: Oxford, UK, 2018; pp. 137–172. [Google Scholar] [CrossRef]

- Basu, B.; Kalin, M. Wear Mechanisms. In Tribology of Ceramics and Composites; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2011; pp. 70–100. [Google Scholar] [CrossRef]

- Singh, J.; Chauhan, A. Overview of wear performance of aluminium matrix composites reinforced with ceramic materials under the influence of controllable variables. Ceram. Int. 2016, 42, 56–81. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, L.; Ma, H. Effect of ZrO2 additions on the microstructure, mechanical and wear properties of ZrO2/7075 aluminium alloy composite. Mater. Today Commun. 2023, 37, 107437. [Google Scholar] [CrossRef]

- Golla, C.B.; Babar Pasha, M.; Rao, R.N.; Ismail, S.; Gupta, M. Influence of TiC Particles on Mechanical and Tribological Characteristics of Advanced Aluminium Matrix Composites Fabricated through Ultrasonic-Assisted Stir Casting. Crystals 2023, 13, 1360. [Google Scholar] [CrossRef]

- Zhang, F.; He, Z.; Lu, K.; Zhan, Z.; Li, Z.; Wang, X. Interfacial microstructure and mechanical properties of 2124 aluminum alloy reinforced by AlCoCrFeNi high entropy alloy. J. Mater. Res. Technol. 2023, 26, 8846–8856. [Google Scholar] [CrossRef]

- Bayrak, Y.; Kisasoz, A.; Sezer, R. Production and Characterization of B4C Content-Dependent Aluminum Matrix Composites Fabricated via Hot Pressing. J. Mater. Eng. Perform. 2023. [Google Scholar] [CrossRef]

- Thomas, S.; Menachery, N.; Thomas, L.P.; Santhosh, N.; Pradeep Kumar, G.S.; Hebbar, G.S. Influence of nano hexagonal boron nitride on the wear properties of aluminium alloy. Adv. Mater. Process. Technol. 2023, 1–17. [Google Scholar] [CrossRef]

- Alshalal, I.; Al-Zuhairi, H.M.I.; Abtan, A.A.; Rasheed, M.; Asmail, M.K. Characterization of wear and fatigue behavior of aluminum piston alloy using alumina nanoparticles. J. Mech. Behav. Mater. 2023, 32, 20220280. [Google Scholar] [CrossRef]

- Hasan, S.A.; Zaki, M.U.; Hasan, F. Properties & characterization of reinforced aluminium metal matrix composites. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Bhansali, K.J.; Mehrabian, R. Abrasive Wear of Aluminum-Matrix Composites. JOM 1982, 34, 30–34. [Google Scholar] [CrossRef]

- Bin Yusoff, Z.; Jamaludin, S.B.; Amin, D.M. Tribology and Wear Theory of Aluminium Composites: Review and Discussion. In Proceedings of the International Postgraduate Conference on Engineering (IPCE 2010), Perlis, Malaysia, 16–17 October 2010. [Google Scholar]

- Deuis, R.L.; Subramanian, C.; Yellup, J.M. Dry sliding wear of aluminium composites—A review. Compos. Sci. Technol. 1997, 57, 415–435. [Google Scholar] [CrossRef]

- Hosking, F.M.; Portillo, F.F.; Wunderlin, R.; Mehrabian, R. Composites of aluminium alloys: Fabrication and wear behaviour. J. Mater. Sci. 1982, 17, 477–498. [Google Scholar] [CrossRef]

- Chak, V.; Chattopadhyay, H. Fabrication and heat treatment of graphene nanoplatelets reinforced aluminium nanocomposites. Mater. Sci. Eng. A 2020, 791, 139657. [Google Scholar] [CrossRef]

- HR, M.N.; LH, M.; Malik, V.; GC, M.P.; Saxena, K.K.; Lakshmikanthan, A. Effect of microstructure, mechanical and wear on Al-CNTs/graphene hybrid MMC’S. Adv. Mater. Process. Technol. 2022, 8, 366–379. [Google Scholar] [CrossRef]

- Devadiga, U.; Fernandes, P.; Buradi, A.; Emma, A.F. Significance of addition of carbon nanotubes and fly ash on the wear and frictional performance of aluminum metal matrix composites. Eng. Rep. 2024, e12865. [Google Scholar] [CrossRef]

- Baradeswaran, A.; Perumal, A.E. Wear and mechanical characteristics of Al 7075/graphite composites. Compos. Part B Eng. 2014, 56, 472–476. [Google Scholar] [CrossRef]

- Sharma, A.; Narsimhachary, D.; Sharma, V.M.; Sahoo, B.; Paul, J. Surface modification of Al6061-SiC surface composite through impregnation of graphene, graphite & carbon nanotubes via FSP: A tribological study. Surf. Coat. Technol. 2019, 368, 175–191. [Google Scholar] [CrossRef]

- Rengifo, S.; Zhang, C.; Harimkar, S.; Boesl, B.; Agarwal, A. Tribological Behavior of Spark Plasma Sintered Aluminum-Graphene Composites at Room and Elevated Temperatures. Technologies 2017, 5, 4. [Google Scholar] [CrossRef]

- Coronado, J.J.; Sinatora, A. Effect of abrasive size on wear of metallic materials and its relationship with microchips morphology and wear micromechanisms: Part 1. Wear 2011, 271, 1794–1803. [Google Scholar] [CrossRef]

- Hokkirigawa, K.; Kato, K. An experimental and theoretical investigation of ploughing, cutting and wedge formation during abrasive wear. Tribol. Int. 1988, 21, 51–57. [Google Scholar] [CrossRef]

- Pramanik, A. Effects of reinforcement on wear resistance of aluminum matrix composites. Trans. Nonferrous Met. Soc. China 2016, 26, 348–358. [Google Scholar] [CrossRef]

- Jiang, J.; Xiao, G.; Che, C.; Wang, Y. Microstructure, Mechanical Properties and Wear Behavior of the Rheoformed 2024 Aluminum Matrix Composite Component Reinforced by Al2O3 Nanoparticles. Metals 2018, 8, 460. [Google Scholar] [CrossRef]

- Coronado, J.J. Effect of Abrasive Size on Wear. In Abrasion Resistance of Materials; Adamiak, M., Ed.; IntechOpen: Rijeka, Croatia, 2012. [Google Scholar] [CrossRef]

- Wilson, S.; Ball, A. Wear resistance of an aluminium matrix composite. Eng. Dev. Appl. Compos. Mater. 1990. [Google Scholar]

- Arendarchuck, B.E.; Mayer, A.R.; Lourençato, L.A.; Lima, C.R.C.; Fals, H.D.C. Assessment of the Microstructure and Abrasive Wear Properties of an A380/NbC Aluminum Composite Produced by Stir Casting. Int. J. Met. 2023. [Google Scholar] [CrossRef]

- ASTM G65-15; Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel Apparatus. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- Nieto, A.; Yang, H.; Jiang, L.; Schoenung, J.M. Reinforcement size effects on the abrasive wear of boron carbide reinforced aluminum composites. Wear 2017, 390–391, 228–235. [Google Scholar] [CrossRef]

- Lee, G.Y.; Dharan, C.K.H.; Ritchie, R.O. A physically-based abrasive wear model for composite materials. Wear 2002, 252, 322–331. [Google Scholar] [CrossRef]

- Bai, B.N.P.; Ramasesh, B.S.; Surappa, M.K. Dry sliding wear of A356-Al-SiCp composites. Wear 1992, 157, 295–304. [Google Scholar] [CrossRef]

- Yan, C.; Zhang, L. Single-point scratching of 6061 Al alloy reinforced by different ceramic particles. Appl. Compos. Mater. 1994, 1, 431–447. [Google Scholar] [CrossRef]

- Alpas, A.T.; Zhang, J. Effect of SiC particulate reinforcement on the dry sliding wear of aluminium-silicon alloys (A356). Wear 1992, 155, 83–104. [Google Scholar] [CrossRef]

- Kumar, G.B.V.; Rao, C.S.P.; Selvaraj, N. Mechanical and dry sliding wear behavior of Al7075 alloy-reinforced with SiC particles. J. Compos. Mater. 2012, 46, 1201–1209. [Google Scholar] [CrossRef]

- Dey, D.; Bhowmik, A.; Biswas, A. Effect of SiC Content on Mechanical and Tribological Properties of Al2024-SiC Composites. Silicon 2022, 14, 1–11. [Google Scholar] [CrossRef]

- Kök, M.; Özdin, K. Wear resistance of aluminium alloy and its composites reinforced by Al2O3 particles. J. Mater. Process. Technol. 2007, 183, 301–309. [Google Scholar] [CrossRef]

- Mohanavel, V.; Ashraff Ali, K.S.; Prasath, S.; Sathish, T.; Ravichandran, M. Microstructural and tribological characteristics of AA6351/Si3N4 composites manufactured by stir casting. J. Mater. Res. Technol. 2020, 9, 14662–14672. [Google Scholar] [CrossRef]

- Ul Haq, M.I.; Anand, A. Dry Sliding Friction and Wear Behavior of AA7075-Si3N4 Composite. Silicon 2018, 10, 1819–1829. [Google Scholar] [CrossRef]

- Mohanavel, V.; Ravichandran, M. Influence of AlN particles on microstructure, mechanical and tribological behaviour in AA6351 aluminum alloy. Mater. Res. Express 2019, 6, 106557. [Google Scholar] [CrossRef]

- Michael Rajan, H.B.; Ramabalan, S.; Dinaharan, I.; Vijay, S.J. Effect of TiB2 content and temperature on sliding wear behavior of AA7075/TiB2 in situ aluminum cast composites. Arch. Civ. Mech. Eng. 2014, 14, 72–79. [Google Scholar] [CrossRef]

- Baradeswaran, A.; Perumal, A.E. Influence of B4C on the tribological and mechanical properties of Al 7075–B4C composites. Compos. Part B Eng. 2013, 54, 146–152. [Google Scholar] [CrossRef]

- Zhai, W.; Pu, B.; Sun, L.; Xu, L.; Wang, Y.; He, L.; Dong, H.; Gao, Y.; Han, M.; Xue, Y. Influence of Ti3AlC2 content and load on the tribological behaviors of Ti3AlC2p/Al composites. Ceram. Int. 2022, 48, 1745–1756. [Google Scholar] [CrossRef]

- Madhu, H.C.; Edachery, V.; Lijesh, K.P.; Perugu, C.S.; Kailas, S. V Fabrication of Wear-Resistant Ti3AlC2/Al3Ti Hybrid Aluminum Composites by Friction Stir Processing. Metall. Mater. Trans. A 2020, 51, 4086–4099. [Google Scholar] [CrossRef]

- Ahmadifard, S.; Momeni, A.; Bahmanzadeh, S.; Kazemi, S. Microstructure, tribological and mechanical properties of Al7075/Ti3AlC2 MAX-phase surface composite produced by friction stir processing. Vacuum 2018, 155, 134–141. [Google Scholar] [CrossRef]

- Mahdavi, S.; Akhlaghi, F. Effect of the SiC particle size on the dry sliding wear behavior of SiC and SiC–Gr-reinforced Al6061 composites. J. Mater. Sci. 2011, 46, 7883–7894. [Google Scholar] [CrossRef]

- Moazami-Goudarzi, M.; Akhlaghi, F. Wear behavior of Al 5252 alloy reinforced with micrometric and nanometric SiC particles. Tribol. Int. 2016, 102, 28–37. [Google Scholar] [CrossRef]

- Aydin, F. The investigation of the effect of particle size on wear performance of AA7075/Al2O3 composites using statistical analysis and different machine learning methods. Adv. Powder Technol. 2021, 32, 445–463. [Google Scholar] [CrossRef]

- Rajeev, V.R.; Dwivedi, D.K.; Jain, S.C. Effect of load and reciprocating velocity on the transition from mild to severe wear behavior of Al–Si–SiCp composites in reciprocating conditions. Mater. Des. 2010, 31, 4951–4959. [Google Scholar] [CrossRef]

- Zhou, X.; Gao, Y.; Wang, Y.; Xiao, P.; Huang, X. Effects of ZrC particles, load and sliding speed on the wear behavior of the ZrC/2024Al composites. Wear 2022, 506–507, 204465. [Google Scholar] [CrossRef]

- Sheasby, J.S.; Cohen, A.; Jia, C.D.; Sang, H.; Kenny, D. Wear of aluminium and Al-Si alloys in single-pass sliding against glass. Wear 1989, 133, 343–354. [Google Scholar] [CrossRef]

- Kanth, V.K.; Pramila Bai, B.N.; Biswas, S.K. Wear mechanisms in a hypereutectic aluminium silicon alloy sliding against steel. Scr. Metall. Mater. 1990, 24, 267–271. [Google Scholar] [CrossRef]

- Rahman, M.H.; Rashed, H.M.M. Al Characterization of Silicon Carbide Reinforced Aluminum Matrix Composites. Procedia Eng. 2014, 90, 103–109. [Google Scholar] [CrossRef]

- Lakshmipathy, J.; Kulendran, B. Reciprocating Wear Behaviour of 7075Al/SiC and 6061Al/Al2O3 Composites: A study of Effect of Reinforcement, Stroke and Load. Tribol. Ind. 2014, 36, 117–126. [Google Scholar]

- Singh, R.; Singla, R. Tribological characterization of aluminium-silicon carbide composite prepared by mechanical alloying. Int. J. Appl. Eng. Res. 2012, 7, 1420–1423. [Google Scholar]

- Alpas, A.T.; Embury, J.D. Sliding and abrasive wear behaviour of an aluminum (2014)-SiC particle reinforced composite. Scr. Metall. Mater. 1990, 24, 931–935. [Google Scholar] [CrossRef]

- Selvakumar, V.; Muruganandam, S.; Senthilkumar, N. Evaluation of Mechanical and Tribological Behavior of Al–4%Cu–x%SiC Composites Prepared through Powder Metallurgy Technique. Trans. Indian Inst. Met. 2017, 70, 1305–1315. [Google Scholar] [CrossRef]

- Alharbi, K.A.M.; Gamaoun, F.; Patra, I.; Kumar, T.C.A.; Gahar, A.K.; Sivaraman, R.; Galal, A.M. Mechanical properties and wear resistance of nano Al/SiC composites fabricated via APB. Hum. Ecol. Risk Assess. Int. J. 2023, 29, 463–470. [Google Scholar] [CrossRef]

- Nourouzi, S.; Damavandi, E.; Rabiee, S.M. Microstructural and mechanical properties of Al-Al2O3 composites focus on experimental techniques. Int. J. Microstruct. Mater. Prop. 2016, 11, 383–398. [Google Scholar] [CrossRef]

- Daoud, A.; El-Khair, M.; Abdel-Azim, A. Effect of Al2O3 Particles on the Microstructure and Sliding Wear of 7075 Al Alloy Manufactured by Squeeze Casting Method. J. Mater. Eng. Perform. 2004, 13, 135–143. [Google Scholar] [CrossRef]

- Perumal Ezhilan, M.; Emmanual, L.; Alagarsamy, S.; Meignanamoorthy, M. Investigations on microstructure, hardness and tribological behaviour of AA7075-Al2O3 composites synthesized via stir casting route. Rev. Metal. 2023, 59, e253. [Google Scholar] [CrossRef]

- Dougherty, T.; Xu, Y. Properties and characterization of an aluminium–silicon nitride fibre powder metal composite. SN Appl. Sci. 2018, 1, 135. [Google Scholar] [CrossRef]

- Suganuma, K. Strength and microstructure of silicon nitride/aluminum interface fabricated by squeeze cast brazing. J. Eur. Ceram. Soc. 1993, 11, 43–49. [Google Scholar] [CrossRef]

- Maddaiah, K.C.; Kumar, G.B.V. Mechanical Characterization of AA357 Metal Matrix Composite with Reinforcement of Si3N4. J. Test. Eval. 2023, 51, 3255–3272. [Google Scholar] [CrossRef]

- Manjunatha, C.J.; Narayana, V.; Raja, D.B.P. Investigating the Effect of Si3N4 Reinforcement on the Morphological and Mechanical Behavior of AA2219 Alloy. Silicon 2022, 14, 2655–2667. [Google Scholar] [CrossRef]

- ASTM G99-17; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2023. [CrossRef]

- Manjunatha, C.J.; Prasad, C.D.; Hanumanthappa, H.; Kannan, A.R.; Mohan, D.G.; Shanmugam, B.K.; Venkategowda, C. Influence of Microstructural Characteristics on Wear and Corrosion Behaviour of Si3N4-Reinforced Al2219 Composites. Adv. Mater. Sci. Eng. 2023, 2023, 1120569. [Google Scholar] [CrossRef]

- He, X.; Ye, F.; Zhang, H.; Zhou, Z. Study on microstructure and thermal conductivity of Spark Plasma Sintering AlN ceramics. Mater. Des. 2010, 31, 4110–4115. [Google Scholar] [CrossRef]

- Abe, H.; Sato, K.; Naito, M.; Nogi, K.; Hotta, T.; Tatami, J.; Komeya, K. Effects of granule compaction procedures on defect structure, fracture strength and thermal conductivity of AlN ceramics. Powder Technol. 2005, 159, 155–160. [Google Scholar] [CrossRef]

- Liu, Z.; Wu, B.; Gu, M. Effect of hydrolysis of AlN particulates on corrosion behavior of Al/AlNp composite in neutral chloride solution. Compos. Part A Appl. Sci. Manuf. 2007, 38, 94–99. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, G.; Wu, G.; Xiu, Z.; Luan, B. Property characteristics of a AlNp/Al composite fabricated by squeeze casting technology. Mater. Lett. 2003, 57, 1453–1458. [Google Scholar] [CrossRef]

- Wang, J.; Yi, D.; Su, X.; Yin, F.; Li, H. Properties of submicron AlN particulate reinforced aluminum matrix composite. Mater. Des. 2009, 30, 78–81. [Google Scholar] [CrossRef]

- Fale, S.; Likhite, A.; Bhatt, J. Compressive, tensile and wear behavior of ex situ Al/AlN metal matrix nanocomposites. J. Compos. Mater. 2015, 49, 1917–1928. [Google Scholar] [CrossRef]

- Mohanavel, V.; Ravichandran, M.; Anandakrishnan, V.; Pramanik, A.; Meignanamoorthy, M.; Karthick, A.; Muhibbullah, M. Mechanical Properties of Titanium Diboride Particles Reinforced Aluminum Alloy Matrix Composites: A Comprehensive Review. Adv. Mater. Sci. Eng. 2021, 2021, 7602160. [Google Scholar] [CrossRef]

- Singh, G.; Chan, S.L.-I.; Sharma, N. Parametric study on the dry sliding wear behaviour of AA6082–T6/TiB2 in situ composites using response surface methodology. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 310. [Google Scholar] [CrossRef]

- Idusuyi, N.; Olayinka, J.I. Dry sliding wear characteristics of aluminium metal matrix composites: A brief overview. J. Mater. Res. Technol. 2019, 8, 3338–3346. [Google Scholar] [CrossRef]

- Mistry, J.M.; Gohil, P.P. Experimental investigations on wear and friction behaviour of Si3N4p reinforced heat-treated aluminium matrix composites produced using electromagnetic stir casting process. Compos. Part B Eng. 2019, 161, 190–204. [Google Scholar] [CrossRef]

- Nieto, M.D.; Abad, F.J.; Hernández-Camacho, A.; Garrido, L.E.; Barrada, J.R.; Aguado, D.; Olea, J. Calibrating a new item pool to adaptively assess the Big Five; [Nuevo banco de ítems para evaluar adaptativamente los cinco grandes]. Psicothema 2017, 29, 390–395. [Google Scholar] [CrossRef]

- Kumar, G.B.V.; Gouda, P.S.S.; Chowdary, U.S.K.; Subash, T.; Vamsi, M.S.; Naresh, K. Development and experimental evaluation of titanium diboride particulate reinforcements on the Al6061 alloy composites properties. Adv. Mater. Process. Technol. 2022, 8, 1209–1225. [Google Scholar] [CrossRef]

- Miracle, D.B. Metal matrix composites—From science to technological significance. Compos. Sci. Technol. 2005, 65, 2526–2540. [Google Scholar] [CrossRef]

- Chen, Z.-C.; Takeda, T.; Ikeda, K. Microstructural evolution of reactive-sintered aluminum matrix composites. Compos. Sci. Technol. 2008, 68, 2245–2253. [Google Scholar] [CrossRef]

- El-Gallab, M.; Sklad, M. Machining of Al/SiC particulate metal-matrix composites: Part I: Tool performance. J. Mater. Process. Technol. 1998, 83, 151–158. [Google Scholar] [CrossRef]

- Ding, X.; Liew, W.Y.H.; Liu, X.D. Evaluation of machining performance of MMC with PCBN and PCD tools. Wear 2005, 259, 1225–1234. [Google Scholar] [CrossRef]

- Zhang, Z.; Duan, X.; Jia, D.; Zhou, Y.; van der Zwaag, S. On the formation mechanisms and properties of MAX phases: A review. J. Eur. Ceram. Soc. 2021, 41, 3851–3878. [Google Scholar] [CrossRef]

- Chirica, I.M.; Mirea, A.G.; Neaţu, Ş.; Florea, M.; Barsoum, M.W.; Neaţu, F. Applications of MAX phases and MXenes as catalysts. J. Mater. Chem. A 2021, 9, 19589–19612. [Google Scholar] [CrossRef]

- Lei, X.; Lin, N. Structure and synthesis of MAX phase materials: A brief review. Crit. Rev. Solid State Mater. Sci. 2022, 47, 736–771. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, Z.; Zhou, Y. Cu/Ti3SiC2 composite: A new electrofriction material. Mater. Res. Innov. 1999, 3, 80–84. [Google Scholar] [CrossRef]

- Gupta, S.; Barsoum, M.W. On the tribology of the MAX phases and their composites during dry sliding: A review. Wear 2011, 271, 1878–1894. [Google Scholar] [CrossRef]

- Gupta, S.; Filimonov, D.; Palanisamy, T.; El-Raghy, T.; Barsoum, M.W. Ta2AlC and Cr2AlC Ag-based composites—New solid lubricant materials for use over a wide temperature range against Ni-based superalloys and alumina. Wear 2007, 262, 1479–1489. [Google Scholar] [CrossRef]

- Anasori, B.; Caspi, E.N.; Barsoum, M.W. Fabrication and mechanical properties of pressureless melt infiltrated magnesium alloy composites reinforced with TiC and Ti2AlC particles. Mater. Sci. Eng. A 2014, 618, 511–522. [Google Scholar] [CrossRef]

- Wang, W.J.; Gauthier-Brunet, V.; Bei, G.P.; Laplanche, G.; Bonneville, J.; Joulain, A.; Dubois, S. Powder metallurgy processing and compressive properties of Ti3AlC2/Al composites. Mater. Sci. Eng. A 2011, 530, 168–173. [Google Scholar] [CrossRef]

- Hu, L.; Kothalkar, A.; O’Neil, M.; Karaman, I.; Radovic, M. Current-Activated, Pressure-Assisted Infiltration: A Novel, Versatile Route for Producing Interpenetrating Ceramic–Metal Composites. Mater. Res. Lett. 2014, 2, 124–130. [Google Scholar] [CrossRef][Green Version]

- Kothalkar, A.D.; Benitez, R.; Hu, L.; Radovic, M.; Karaman, I. Thermo-mechanical Response and Damping Behavior of Shape Memory Alloy–MAX Phase Composites. Metall. Mater. Trans. A 2014, 45, 2646–2658. [Google Scholar] [CrossRef]

- Samal, P.; Vundavilli, P.R.; Meher, A.; Mahapatra, M.M. Influence of TiC on dry sliding wear and mechanical properties of in situ synthesized AA5052 metal matrix composites. J. Compos. Mater. 2019, 53, 4323–4336. [Google Scholar] [CrossRef]

- Cai, Y.; Liu, Z.; Gong, K.; Zhang, Y. The effect of reinforcement particle size on the mechanical and fracture properties of glass matrix composites. Heliyon 2023, 9, e21895. [Google Scholar] [CrossRef] [PubMed]

- Skolianos, S.; Kattamis, T.Z. Tribological properties of SiCp-reinforced Al-4.5% Cu-1.5% Mg alloy composites. Mater. Sci. Eng. A 1993, 163, 107–113. [Google Scholar] [CrossRef]

- Liang, Y.N.; Ma, Z.Y.; Li, S.Z.; Li, S.; Bi, J. Effect of particle size on wear behaviour of SiC particulate-reinforced aluminum alloy composites. J. Mater. Sci. Lett. 1995, 14, 114–116. [Google Scholar] [CrossRef]

- Rahman, M.A.; Sirajudeen, N. Influence of aging, varying particle size & volume fraction of Al2O3 particles on the hardness and wear behavior of Al 7150 alloy composite produced by hot uniaxial compaction method. Mater. Res. Express 2018, 6, 35006. [Google Scholar] [CrossRef]

- Alpas, A.T.; Zhang, J. Effect of microstructure (particulate size and volume fraction) and counterface material on the sliding wear resistance of particulate-reinforced aluminum matrix composites. Metall. Mater. Trans. A 1994, 25, 969–983. [Google Scholar] [CrossRef]

- Arora, R.; Kumar, S.; Singh, G.; Pandey, O.P. Influence of particle size and temperature on the wear properties of rutile-reinforced aluminium metal matrix composite. J. Compos. Mater. 2015, 49, 843–852. [Google Scholar] [CrossRef]

- Srivallirani, K.; Rao, M.V. Assessing the role of reinforcement size and weight percentage on the mechanical and wear characteristics of Al7050-TiO2-hBN hybrid composites. Eng. Res. Express 2023, 5, 15049. [Google Scholar] [CrossRef]

- Lakshmipathy, J.; Kulendran, B. Effect of the amount of SiC, number of strokes, and applied load on the reciprocating wear behavior of Al-SiC composites. Sci. Eng. Compos. Mater. 2015, 22, 573–582. [Google Scholar] [CrossRef]

- Pasaribu, H.R.; Sloetjes, J.W.; Schipper, D.J. The transition of mild to severe wear of ceramics. Wear 2004, 256, 585–591. [Google Scholar] [CrossRef]

- Sharma, S.C.; Krishna, M.; Vizhian, P.S.; Shashishankar, A. Thermal effects on mild wear transition in dry sliding of aluminium 7075-short glass fibre composites. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2002, 216, 975–982. [Google Scholar] [CrossRef]

| Alloy | Reinforcement Material and Content | Reinforcement Size | Sliding Velocity | Applied Load | Observation/Remarks | Ref. |

|---|---|---|---|---|---|---|

| A356 | 0–25 Wt.% SiC | 43 µm ave. | 0.5 m/s | 2–26 MPa | Wear resistance increases with increasing reinforcement content Significant plastic deformation and material flow in the sample without reinforcement, which increases with pressure | [45] |

| A356 | 10–20 Vol.% SiC | 9–17 µm ave. | 0.16–0.8 m/s | 0.9–150 N | Wear rate increases with applied load and sliding velocity High levels of applied load lead to particle fracture and microcracking Presence of reinforcement suppresses the transition to severe wear, while severe wear occurs in unreinforced samples under high loads | [47] |

| Pure Al | 0–20 Wt.% SiC | 53–74 µm | 300 rpm | 10 N | Wear resistance increases with increasing reinforcement content | [66] |

| AA7075 | 0–6 Wt.% SiC | 150 µm ave. | 2.62 m/s | 10–60 N | Wear resistance increases with increasing reinforcement content Wear rate increases with applied load and sliding velocity | [48] |

| AA1100 | 0–10 Wt.% SiC | 40 nm ave. | 1 m/s | 20 N | Wear resistance increases with increasing reinforcement content | [71] |

| AA2024 | 0–9 Wt.% SiC | 20 µm ave. | 300 rpm | 10–30 N | Wear resistance increases with increasing reinforcement content Wear rate increases with applied load | [49] |

| AI-4.5% Cu-1.5% Mg | 0–0.29 Vol.% SiC | 29 μm ave. | 50–950 rpm | 3.150 N | Wear resistance increases with increasing reinforcement content | [109] |

| Pure Al | 15 Vol.% SiC | 3.5 µm, 10 µm, and 20 µm ave. | 0.01 m/s | 2.2 MPa | Composites containing large reinforcements exhibit superior wear resistance Under wear conditions characterized by some impact component in the load, composites containing small particles are preferred | [110] |

| AA5252 | 0–7 Wt.% SiC | SiC nano: 60 nm ave. SiC micro: 63 µm ave. | 0.5 m/s | 0.3–0.9 MPa | Micro-composite showed the best wear resistance under 0.3 and 0.6 MPa applied load Nano-composite samples exhibited superior wear resistance under 0.9 MPa Abrasion and adhesion under 0.3 and 0.6 MPa applied load Adhesion under 0.9 MPa applied load | [60] |

| AA7075 | 0–20 Wt.% SiC | 36 µm ave. | - | 25–75 | Wear resistance increases with increasing reinforcement content Wear rate increases with applied load | [115] |

| A319 A336 A390 | 15 Wt.% SiC | 32 µm ave. | 0.4–1 m/s | 30–150 N | The effect of applied load and sliding velocity on wear rate are dependent on each other Increase in load at low sliding velocity increases the wear rate gradually, while at high velocity with an increase in load, an abrupt increase in wear rate occurs Increase in sliding velocity imder a low load leads to a decreased wear rate, while at high loads, the wear rate first decreases with an increase in sliding velocity, and above a certain velocity, an abrupt increase in wear rate occurs | [62] |

| AA6061 | SiC Graphite GNP CNT | Graphite 44 µm ave. GNP 5–10 nm CNT 25 nm ave. dia. SiC 30 µm ave. | 20 rpm | 20 N | Al-SiC-GNP hybrid composite was reported to have the highest wear resistance due to self-lubrication and high thermal conductivity Al-Sic-CNT showed the highest wear rate | [33] |

| AA6061 | 10 Vol.% SiC 0–5 Vol.% Graphite | SiC: 19 µm, 93 µm, and 146 µm ave. Graphite: 75 µm ave. | 0.5 m/s | 20 N | Wear resistance increases with increasing reinforcement size Hybrid composites consistently showed higher wear resistance compared to Al/SiC composites. | [59] |

| AA7075 AA6061 | 0–20 Wt.% SiC 0–20 Wt.% Al2O3 | 36 µm ave. | - | 25–75 N | Wear resistance increases with increasing reinforcement content in all composites Wear rate increases with applied load | [67] |

| AA6061 | 10 Vol.% Al2O3 | 6−18 μm | 230–1480 rpm | 0.14–1.1 MPa | Wear resistance is higher in composite Presence of reinforcements delayed the transition to sever wear Wear rate increases with applied load and sliding velocity for both samples, but in a more predictable way for the composite Increase in size of debris with increase in load and sliding velocity | [37] |

| AA2024 | 0–10 Vol.% Al2O3 | 60 nm ave. | 0.8 m/s | 30 N | Wear resistance is maximum in composite with 7 Vol.% reinforcement | [38] |

| AA7075 | 0–20 Vol.% Al2O3 | 60–80 µm | 1 m/s | 10–50 N | Wear resistance is maximum in composite with 10 Vol.% reinforcement Wear rate increases with applied load | [73] |

| AA2024 | 0–30 Wt.% Al2O3 | 16 µm and 32 µm | 2 m/s | 2 N and 5 N | Wear resistance increases with increasing reinforcement content and size The effect of reinforcement content was less than that of reinforcement size Wear rate increases with applied load | [50] |

| AA7150 | 5–25 Vol.% Al2O3 | 21 nm ave. | 1 m/s | 1–3 kg | Wear resistance increases with increasing reinforcement content Wear rate increases with applied load | [111] |

| AA7075 | 5 Wt.% Al2O3 | 0.3 µm, 2 µm, and 15 µm ave. | 80–140 m/s | 5–30 N | Wear resistance increases with increasing reinforcement size Wear rate increases with applied load Increase in applied load and sliding velocity changed the wear mechanism from abrasion to severe delamination and microcracking Wear resistance of the composites was mostly dependent on load, followed by particle size and sliding velocity | [61] |

| AA6061 AA2124 AA2014 | 0–20 Vol.% Al2O3 0–20 Vol.% Al2O3 | Al2O3: 14.1 µm and 19.1 µm ave. SiC: 15.8 µm and 2.4 µm ave. | 0.2 m/s | 0.9–350 N | Wear resistance increases with increasing reinforcement content and size Wear rate increases with applied load Above a certain applied load, reinforcement fracture causes three-body abrasion, and the wear rate of composite and alloy matrix become almost equal | [112] |

| AA2219 | 0–9 Wt.% Si3N4 | 40 μm ave. | 1.57–4.71 m/s | 9.81–29.43 N | Wear resistance is maximum in composite with 6 Wt.% reinforcement Wear rate depends more on applied load and sliding velocity compared to reinforcement content Wear rate increases with applied load and sliding velocity | [78] |

| AA6351 | 0–3 Wt.% Si3N4 | 30 nm ave. | 1.5 m/s | 35 N | Wear resistance increases with increasing reinforcement content | [51] |

| AA7075 | 0–8 Wt.% Si3N4 | 40 μm ave. | 1 m/s | 10–50 N | Wear resistance increases with increasing reinforcement content Wear rate increases with applied load | [52] |

| AA7075 | 0–12 Wt.% Si3N4 | 10–40 μm | 3–5 m/s | 1–3 kg | Wear resistance increases with increasing reinforcement content Wear rate was found to decrease with an increase in sliding velocity, whereas it increased with increasing sliding distance and load Sliding distance was the most dominating factor | [90] |

| Pure Al | 0–5 Wt.% AlN | 40–50 nm | 2 m/s | 10–30 N | Wear resistance increases with increasing reinforcement content Wear rate increases with applied load Wear resistance is more influenced by the applied load than by sliding distance | [86] |

| AA6351 | 0–20 Wt.% AlN | Less than 44 μm | 1 m/s | 10–30 N | Wear resistance increases with increasing reinforcement content | [53] |

| AA7075 | 0–9 Wt.% TiB2 | Less than 2 μm | 1.2 m/s | 20 N | Wear resistance increases with increasing reinforcement content | [54] |

| AA6082 | 0–12 Wt.% TiB2 | - | 0.6–3.0 m/s | 29.42–73.55 N | Sliding distance was the most dominating variable to influence the wear resistance followed by sliding speed, load, and reinforcement content | [88] |

| AA6061 | 0–6 Wt.% TiB2 | 50 μm ave. | - | 10–60 N | Wear resistance increases with increasing reinforcement content Wear rate increases with applied load | [92] |

| AA7075 | 0–20 Vol.% B4C | 16–20 μm | 0.6 m/s | 10–40 N | Wear resistance of composite was significantly higher than matrix alloy The wear rate slightly decreased with increasing reinforcement content Wear rate increases with applied load | [55] |

| Pure Al | 0–15 Wt.% B4C | 14.17 µm ave. | 0.07 m/s | 5–10 N | Wear resistance increases with increasing reinforcement content Wear rate increases with applied load | [21] |

| AA5083 | 5 Vol.% B4C | µB4C:1–7 µm ave. sµB4C: 0.5 µm ave. nB4C: 40 nm ave. | - | 133 N | Maximum wear resistance is observed in the composite with nano reinforcement due to higher particle–matrix coherent interface Reinforcement pull-out and three-body abrasion become more significant factors in composites with larger reinforcements | [43] |

| AA8011 | 0–8 Wt.% TiC | 10 µm ave. | 1–5 m/s | 10–30 N | Wear resistance is maximum in composite with 5 Wt.% reinforcement Wear rate increases with applied load | [19] |

| AA7075 | 0–8 Wt.% ZrO2 | 200 nm ave. | 300 rpm | 5 N | Wear resistance is maximum in composite with 4 Wt.% reinforcement | [18] |

| A380 | 0–15 Wt.% NbC | 1.2 μm ave. | 200 rpm | 45 N | Wear resistance increases with increasing reinforcement content | [41] |

| LM13 | 20 Vol.% TiO2 | 50–75 µm 106–125 µm | 1.6 m/s | 49 N | Wear resistance increases with increasing reinforcement size | [113] |

| AA7075 | 0.1–0.5 Wt.% GNPs | 5–30 nm | - | - | Wear resistance increases with increasing reinforcement content Wear resistance is improved in composites due to the self-lubricating effect | [29] |

| Pure Al | 2 Wt.% CNT 1–5 Wt.% Graphene | CNT 10–20 nm dia. Graphene 5–10 nm | - | 10–30 N | Wear resistance increases with increasing reinforcement content Sel-lubricating effect only reported in composite with high amount of reinforcement | [30] |

| Pure Al | 0.25–0.75 Wt.% CNT 4–16 Wt.% Fly Ash | CNT 10–15 nm ave. dia. Fly Ash 9.29 µm ave. | 100–300 rpm | 10–30 N | Wear resistance is maximum in hybrid composite with 0.25 Wt.% CNT and 8 Wt.% fly ash compared to other mono-reinforced and hybrid-reinforced composites Excess amount of CNT results in particle agglomeration and excessive amount of fly ash causes formation of voids in the composite Wear rate increases with applied load and sliding velocity | [31] |

| AA7075 | 0–20 Wt.% Graphite | - | 0.6–1 m/s | 10–30 N | Wear resistance is maximum in composite with 5 Wt.% reinforcement Self-lubrication properties reported in composites Wear rate increases with increasing applied load and decreases with increasing sliding speed | [32] |

| Pure Al | 2 Vol.% GNP | GNP 6–8 nm ave. | 100 rpm | 1 N | Wear resistance reduces in composite due to agglomeration Composite had lower COF value compared to matrix alloy | [34] |

| Pure Al | 0–4 Wt.% Ti3AlC2 | - | 100 rpm | 10–40 N | Wear resistance is maximum in composite with 2 Wt.% reinforcement Excessive Ti3AlC2 content led to severe fatigue delamination wear Delamination was intensified and abrasive grooves were greatly reduced with the load increased | [56] |

| Pure | Ti3AlC2 | - | 0.01–1 m/s | 1.5 MPa | Wear resistance of the composite was higher than matrix alloy Wear resistance was initially reduced by increasing the sliding velocity up to 0.5 m/s and then increased afterward | [57] |

| AA7075 | Ti3AlC2 | 5 μm ave. | 0.4 mm/min | 10 N | Wear resistance of the composite was higher than matrix alloy. Presence of reinforcement increases the thermal stability and lowers the tendency for plastic flow | [58] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valizade, N.; Farhat, Z. A Review on Abrasive Wear of Aluminum Composites: Mechanisms and Influencing Factors. J. Compos. Sci. 2024, 8, 149. https://doi.org/10.3390/jcs8040149

Valizade N, Farhat Z. A Review on Abrasive Wear of Aluminum Composites: Mechanisms and Influencing Factors. Journal of Composites Science. 2024; 8(4):149. https://doi.org/10.3390/jcs8040149

Chicago/Turabian StyleValizade, Nima, and Zoheir Farhat. 2024. "A Review on Abrasive Wear of Aluminum Composites: Mechanisms and Influencing Factors" Journal of Composites Science 8, no. 4: 149. https://doi.org/10.3390/jcs8040149

APA StyleValizade, N., & Farhat, Z. (2024). A Review on Abrasive Wear of Aluminum Composites: Mechanisms and Influencing Factors. Journal of Composites Science, 8(4), 149. https://doi.org/10.3390/jcs8040149