Competitive Adsorption of Aqueous Cd(II) and Pb(II) Solutions onto Silicas Synthesized with Saponin as Template Agent

Abstract

1. Introduction

2. Materials and Methods

2.1. Reagents and Equipment

2.2. Synthesis of SiO2@Saponin and Meso-SiO2

2.3. Adsorption Studies

3. Results

3.1. Synthesis of SiO2@Saponin and Meso-SiO2

3.2. Adsorbents Characterization

3.2.1. FTIR Spectra

3.2.2. Thermal Analysis (TG-DSC)

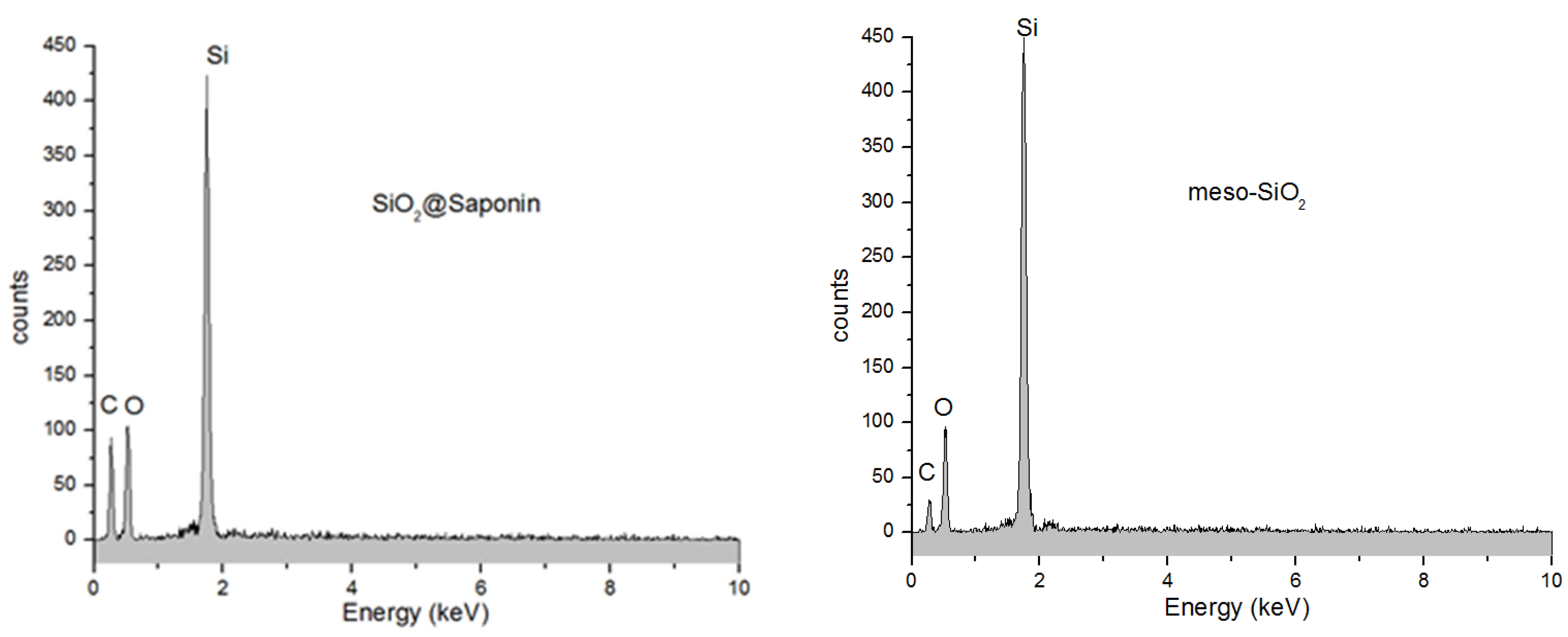

3.2.3. SEM/EDX Analysis

3.2.4. High-Resolution Transmission Electron Microscopy (HRTEM)

3.2.5. Nitrogen Adsorption–Desorption Isotherms

3.3. Adsorption Studies

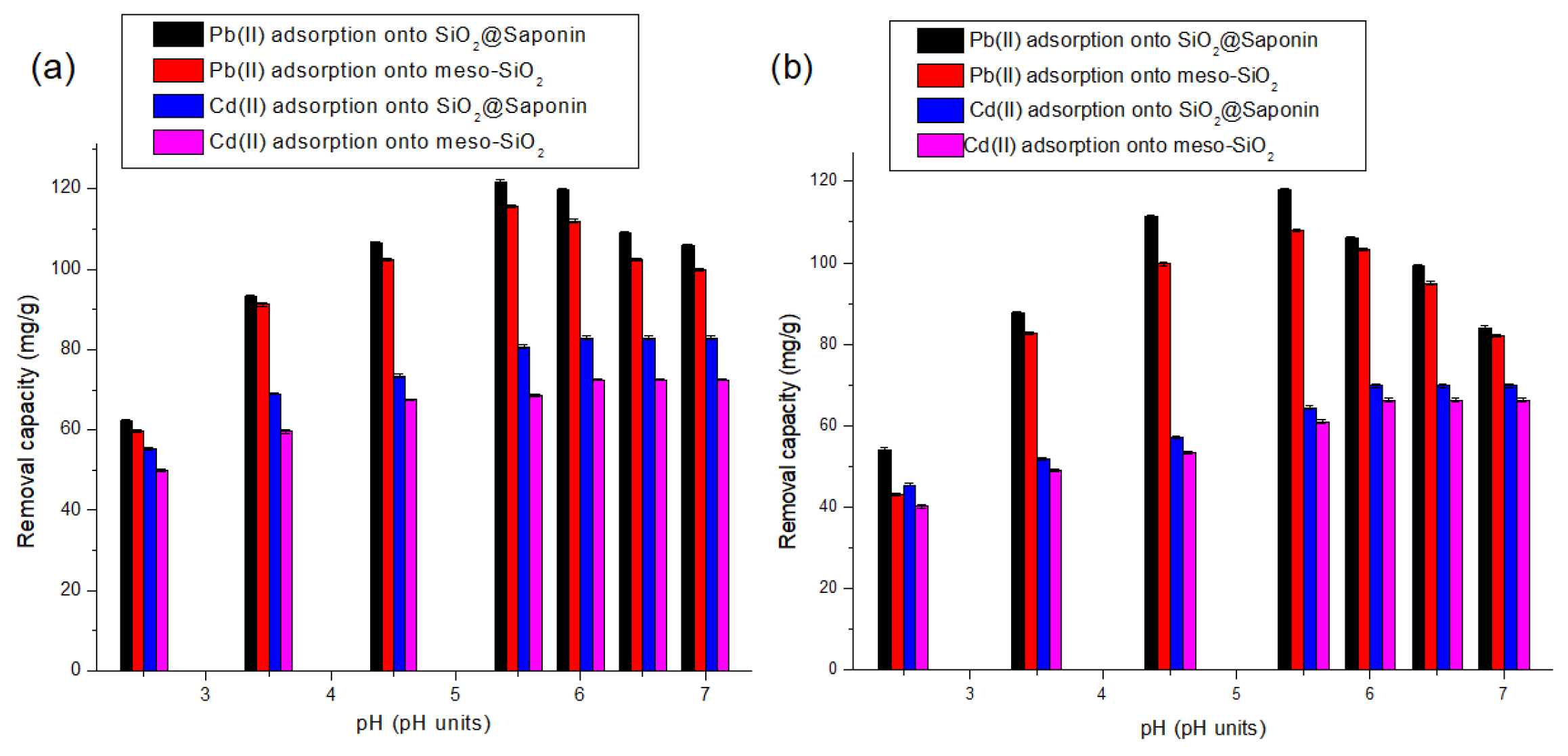

3.3.1. pH Effect

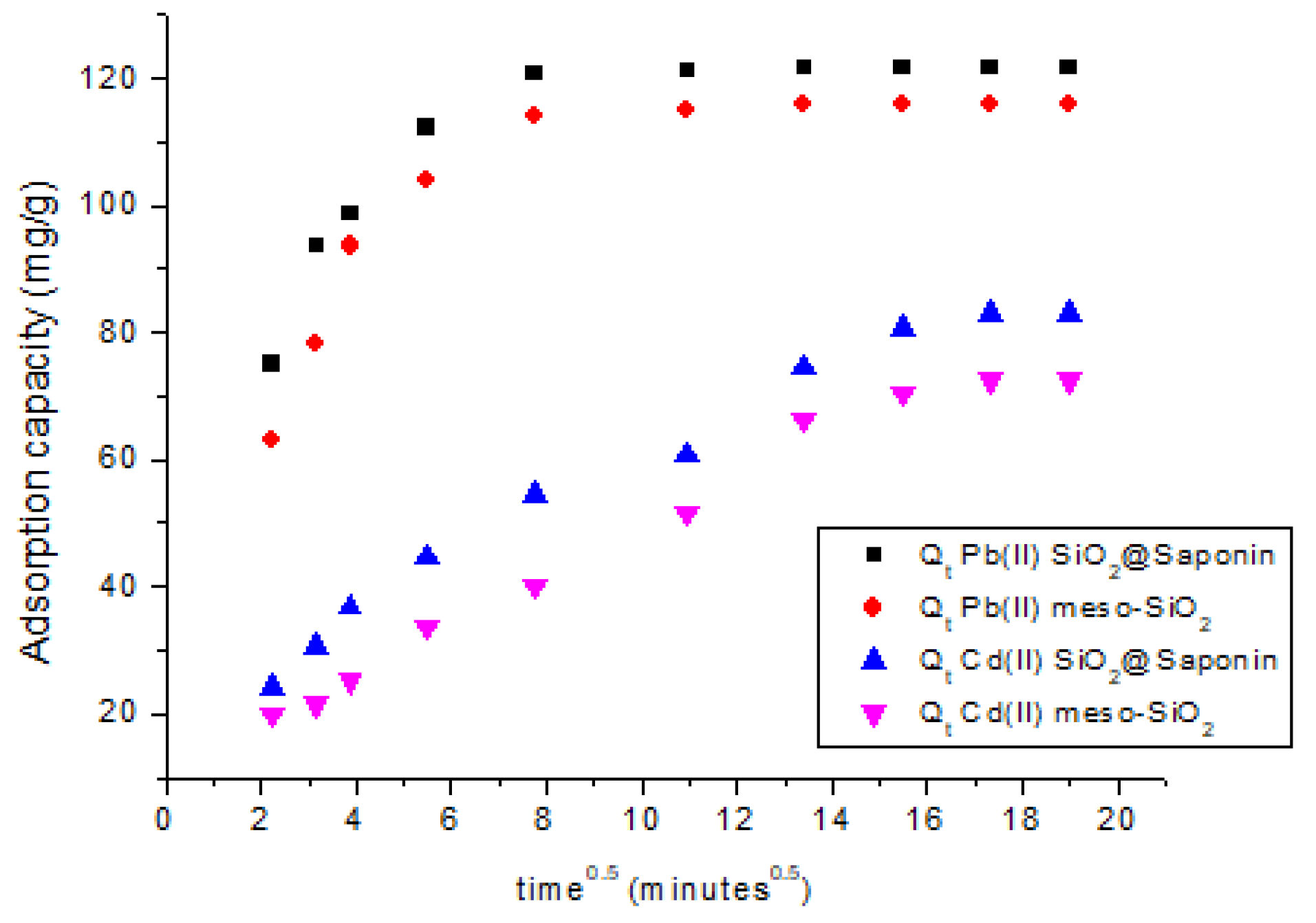

3.3.2. The Contact Time Effect

3.3.3. Adsorption Isotherm

- Ce,M1, Ce,M2, Qe,M1, and Qe,M2 represent the equilibrium concentrations and equilibrium retention capacity of metal ions (M1) (Pb(II)) and (M2) (Cd(II)) in binary solutions;

- KL,M1 and KL,M2 represent the characteristic equilibrium constants for the adsorption of the respective metal ions from single solutions;

- Qmax,M1 and Qmax,M2 represent the maximum adsorption capacities for the experiments with metal ions from the binary solutions.

- synergistic effects when the value of the ratio is above unity, and the effect of the mixture is stronger than the effect of individual metal ions;

- antagonistic effects if the ratio is below 1, the two metal ions have an antagonistic effect, and the mixture has a weaker effect compared to the effect of the individual metal ions;

- the mixture has no effect on the adsorption process of metal ions from binary solutions if the ratio is equal to 1 [68].

- both for the SiO2@Saponin and for the meso-SiO2, the values of the ratio are lower than 1, which reveals that the adsorption of Pb(II) ions is hindered by the adsorption of Cd(II) and vice versa (both metal ions show a competition effect);

- both for the Pb(II) ion and the Cd(II) ion, there is a decrease in the maximum retention capacity determined from the linearized Langmuir isotherm in the retention process from binary solutions compared to the retention from single solutions;

- the higher values of the retention capacity of Pb(II) ions are explained based on the properties of the previously retained Pb(II) ions;

- it was also observed that in the case of meso-SiO2, Pb(II) has a more intense effect on the Cd(II) removal from binary solutions, and in the case of SiO2@Saponinthe stronger effect has been manifested by the Cd(II) ions.

3.3.4. Kinetic Study

3.3.5. Comparison of the Adsorption Capacity of SiO2@Saponin and Meso-SiO2 with Other SiO2 Based Materials

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huy, D.H.; Seelen, E.; Liem-Nguyen, V. Removal mechanisms of cadmium and lead ions in contaminated water by stainless steel slag obtained from scrap metal recycling. J. Water Process. Eng. 2020, 36, 101369. [Google Scholar] [CrossRef]

- WHO. Guidelines for Drinking-Water Quality—Fourth Edition Incorporating the First and Second Addenda; WHO: Geneva, Switzerland, 2022. [Google Scholar]

- Jaishankar, M.; Tseten, T.; Anbalagan, N.; Mathew, B.B.; Beeregowda, K.N. Toxicity, mechanism and health effects of some heavy metals. Interdiscip. Toxicol. 2014, 7, 60–72. [Google Scholar] [CrossRef] [PubMed]

- Benoff, S.; Jacob, A.; Hurley, I.R. Male infertility and environmental exposure to lead and cadmium. Hum. Reprod. Update 2000, 6, 107–121. [Google Scholar] [CrossRef] [PubMed]

- Simonescu, C.M.; Mason, T.J.; Călinescu, I.; Lavric, V.; Vînătoru, M.; Melinescu, A.; Culiţă, D.C. Ultrasound assisted preparation of calcium alginate beads to improve absorption of Pb+2 from water. Ultrason. Sonochem. 2020, 68, 105191. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Wang, T.; Zhang, H.; Liu, Y.; Xing, B. Adsorption of Pb(II) and Cd(II) by magnetic activated carbon and its mechanism. Sci. Total Environ. 2021, 757, 143910. [Google Scholar] [CrossRef] [PubMed]

- Huang, R.; Lin, Q.; Zhong, Q.; Zhang, X.; Wen, X.; Luo, H. Removal of Cd(II) and Pb(II) from aqueous solution by modified attapulgite clay. Arab. J. Chem. 2020, 13, 4994–5008. [Google Scholar] [CrossRef]

- Joseph, I.V.; Tosheva, L.; Doyle, A.M. Simultaneous removal of Cd(II), Co(II), Cu(II), Pb(II), and Zn(II) ions from aqueous solutions via adsorption on FAU-type zeolites prepared from coal fly ash. J. Environ. Chem. Eng. 2020, 8, 103895. [Google Scholar] [CrossRef]

- Zhang, S.; Lv, T.; Mu, Y.; Zheng, J.; Meng, C. High adsorption of Cd(II) by modification of synthetic zeolites Y, A and mordenite with thiourea. Chin. J. Chem. Eng. 2020, 28, 3117–3125. [Google Scholar] [CrossRef]

- Simonescu, C.M.; Culita, D.C.; Marinescu, V.; Tardei, C.; Talpeanu, D. Hydroxyapatite nanoparticles for acidic mine waters remediation. Rev. Chim. 2019, 70, 3167–3175. [Google Scholar] [CrossRef]

- Amrulloh, H.; Kurniawan, Y.S.; Ichsan, C.; Jelita, J.; Simanjuntak, W.; Situmeang, R.T.M.; Krisbiantoro, P.A. Highly efficient removal of Pb(II) and Cd(II) ions using magnesium hydroxide nanostructure prepared from seawater bittern by electrochemical method. Colloids Surf. A Physicochem. Eng. Asp. 2021, 631, 127687. [Google Scholar] [CrossRef]

- Solic, M.; Maletic, S.; Isakovski, M.K.; Nikic, J.; Watson, M.; Konya, Z.; Roncevic, S.D.S. Removing low levels of Cd(II) and Pb(II) by adsorption on two types of oxidized multiwalled carbon nanotubes. J. Environ. Chem. Eng. 2021, 9, 105402. [Google Scholar] [CrossRef]

- Xiong, C.; Wang, W.; Tan, F.; Luo, F.; Chen, J.; Qiao, X. Investigation on the efficiency and mechanism of Cd(II) and Pb(II) removal from aqueous solutions using MgO nanoparticles. J. Hazard. Mater. 2015, 299, 664–674. [Google Scholar] [CrossRef] [PubMed]

- Xue, Y.; Teng, W.; Chen, Y.; Ma, Q.; Chen, X.; Sun, Y.; Fan, J.; Qiu, Y.; Fu, R. Amorphous Mn-La oxides immobilized on carbon sphere for efficient removal of As(V), Cd(II), and Pb(II): Co-adsorption and roles of Mn species. Chem. Eng. J. 2022, 429, 132262. [Google Scholar] [CrossRef]

- Valenzuela, F.; Quintana, G.; Briso, A.; Ide, V.; Basualto, C.; Gaete, J.; Montes, G. Cu(II), Cd(II), Pb(II) and As(V) adsorption from aqueous solutions using magnetic iron-modified calcium silicate hydrate: Adsorption kinetic analysis. J. Water Process. Eng. 2021, 40, 101951. [Google Scholar] [CrossRef]

- Enache, D.; Vasile, E.; Simonescu, C.M.; Culiță, D.C.; Vasile, E.; Oprea, O.C.; Pandele, A.M.; Răzvan, A.; Dumitru, F.; Nechifor, G. Schiff base-functionalized mesoporous silicas (MCM-41, HMS) as Pb(II) adsorbents. RSC Adv. 2018, 8, 176–189. [Google Scholar] [CrossRef]

- Culita, D.C.; Simonescu, C.M.; Patescu, R.E.; Stanica, N. Chitosan-based magnetic composites-efficient adsorbents for removal of Pb(II) and Cu(II) from aqueous mono and bicomponent solutions. Rev. Chim. 2018, 69, 2323–2330. [Google Scholar] [CrossRef]

- Culita, D.C.; Simonescu, C.M.; Patescu, R.-E.; Dragne, M.; Stanica, N.; Oprea, O. o-Vanillin functionalized mesoporous silica—Coated magnetite nanoparticles for efficient removal of Pb(II) from water. J. Solid State Chem. 2016, 238, 311–320. [Google Scholar] [CrossRef]

- Enache, D.F.; Vasile, E.; Simonescu, C.M.; Răzvan, A.; Nicolescu, A.; Nechifor, A.-C.; Oprea, O.; Pătescu, R.-E.; Onose, C.; Dumitru, F. Cysteine-functionalized silica-coated magnetite nanoparticles as potential nanoadsorbents. J. Solid State Chem. 2017, 253, 318–328. [Google Scholar] [CrossRef]

- Santos, T.J.; Paggiaro, J.; Cabral Silva Pimentel, H.D.; Karla dos Santos Pereira, A.; Cavallini, G.S.; Pereira, D.H. Computational study of the interaction of heavy metal ions, Cd(II), Hg(II), and Pb(II) on lignin matrices. J. Mol. Graph. Model. 2022, 111, 108080. [Google Scholar] [CrossRef]

- Chen, M.; Yu, M.; Kang, R.; Sun, H.; Zhang, W.; Wang, S.; Wang, N.; Wang, J. Removal of Pb(II) and V(V) from aqueous solution by glutaraldehyde crosslinked chitosan and nanocomposites. Chemosphere 2022, 297, 134084. [Google Scholar] [CrossRef]

- Lan, T.; Guo, S.; Li, X.; Guo, J.; Bai, T.; Zhao, Q.; Yang, W.; Li, P. Mixed precursor geopolymer synthesis for removal of Pb(II) and Cd(II). Mater. Lett. 2020, 274, 127977. [Google Scholar] [CrossRef]

- Huang, Z.; Xiong, C.; Ying, L.; Wang, W.; Wang, S.; Ding, J.; Lu, J. A post-functional Ti-based MOFs composite for selective removal of Pb(II) from water. J. Hazard. Mater. 2022, 432, 128700. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, Y.; Yang, Z.; Han, W.; Yuan, L.; Zhang, L.; Huang, X. Efficient removal of Pb(II) and Cd(II) from aqueous solutions by mango seed biosorbent. Chem. Eng. J. Adv. 2022, 11, 100295. [Google Scholar] [CrossRef]

- Chen, M.; Wang, X.; Zhang, H. Comparative research on selective adsorption of Pb(II) by biosorbents prepared by two kinds of modifying waste biomass: Highly-efficient performance, application and mechanism. J. Environ. Manag. 2021, 288, 112388. [Google Scholar] [CrossRef] [PubMed]

- Soria-Aguilar, M.D.J.; Martínez-Luévanos, A.; Sánchez-Castillo, M.A.; Carrillo-Pedroza, F.R.; Toro, N.; Narváez-García, V.M. Removal of Pb(II) from aqueous solutions by using steelmaking industry wastes: Effect of blast furnace dust’s chemical composition. Arab. J. Chem. 2021, 14, 103061. [Google Scholar] [CrossRef]

- Dudarko, O.; Kobylinska, N.; Mishra, B.; Kessler, V.G.; Tripathi, B.P.; Seisenbaeva, G.A. Facile strategies for synthesis of functionalized mesoporous silicas for the removal of rare-earth elements and heavy metals from aqueous systems. Microporous Mesoporous Mater. 2021, 315, 110919. [Google Scholar] [CrossRef]

- Noreen, S.; Maqbool, A.; Maqbool, I.; Shafique, A.; Khan, M.M.; Junejo, Y.; Ahmed, B.; Anwar, M.; Majeed, A.; Abbas, M.; et al. Multifunctional mesoporous silica-based nanocomposites: Synthesis and biomedical applications. Mater. Chem. Phys. 2022, 285, 126132. [Google Scholar] [CrossRef]

- Xie, Y.; Kocaefe, D.; Chen, C.; Kocaefe, Y. Review of Research on Template Methods for Nanomaterials. J. Nanomater. 2016, 2016, 2302595. [Google Scholar] [CrossRef]

- Grozdov, D.; Zinicovscaia, I. Mesoporous Materials for Metal-Laden Wastewater Treatment. Materials 2023, 16, 5864. [Google Scholar] [CrossRef]

- Khalifa, M.E.; Abdelrahman, E.A.; Hassanien, M.M.; Ibrahim, W.A. Application of Mesoporous Silica Nanoparticles Modified with Dibenzoylmethane as a Novel Composite for Efficient Removal of Cd(II), Hg(II), and Cu(II) Ions from Aqueous Media. J. Inorg. Organomet. Polym. Mater. 2020, 30, 2182–2196. [Google Scholar] [CrossRef]

- Li, S.; Li, S.; Wen, N.; Wei, D.; Dong, W.; Zhang, Y. Highly effective removal of lead and cadmium ions from wastewater by bifunctional magnetic mesoporous silica. Sep. Purif. Technol. 2021, 265, 118341. [Google Scholar] [CrossRef]

- Kregiel, D.; Berlowska, J.; Witonska, I.; Antolak, H.; Proestos, C.; Babic, M.; Babic, L.; Zhang, B. Saponin-Based, Biological-Active Surfactants from Plants. In Application and Characterization of Surfactants; Najjar, R., Ed.; InTech: London, UK, 2017. [Google Scholar] [CrossRef]

- McClements, D.J.; Gumus, C.E. Natural emulsifiers—Biosurfactants, phospholipids, biopolymers, and colloidal particles: Molecular and physicochemical basis of functional performance. Adv. Colloid Interface Sci. 2016, 234, 3–26. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W.; Yang, J.; Lou, L.; Zhu, L. Solubilization properties of polycyclic aromatic hydrocarbons by saponin, a plant-derived biosurfactant. Environ. Pollut. 2011, 159, 1198–1204. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Li, Z.; Zhong, H.; Zeng, G.; Liang, Y.; Chen, M.; Wu, Z.; Zhou, Y.; Yu, M.; Shao, B. Recent advances in the environmental applications of biosurfactant saponins: A review. J. Environ. Chem. Eng. 2017, 5, 6030–6038. [Google Scholar] [CrossRef]

- Samal, K.; Das, C.; Mohanty, K. Application of saponin biosurfactant and its recovery in the MEUF process for removal of methyl violet from wastewater. J. Environ. Manag. 2017, 203, 8–16. [Google Scholar] [CrossRef] [PubMed]

- Song, S.; Zhu, L.; Zhou, W. Simultaneous removal of phenanthrene and cadmium from contaminated soils by saponin, a plant-derived biosurfactant. Environ. Pollut. 2008, 156, 1368–1370. [Google Scholar] [CrossRef] [PubMed]

- Pei, G.; Zhu, Y.; Cai, X.; Shi, W.; Li, H. Surfactant flushing remediation of o-dichlorobenzene and p-dichlorobenzene contaminated soil. Chemosphere 2017, 185, 1112–1121. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Zhong, H.; Cao, Y. Effective extraction and recovery of rare earth elements (REEs) in contaminated soils using a reusable biosurfactant. Chemosphere 2020, 256, 127070. [Google Scholar] [CrossRef]

- Samal, K.; Das, C.; Mohanty, K. Eco-friendly biosurfactant saponin for the solubilization of cationic and anionic dyes in aqueous system. Dye Pigment 2017, 140, 100–108. [Google Scholar] [CrossRef]

- Tang, J.; He, J.; Liu, T.; Xin, X. Removal of heavy metals with sequential sludge washing techniques using saponin: Optimization conditions, kinetics, removal effectiveness, binding intensity, mobility and mechanism. RSC Adv. 2017, 7, 33385–33401. [Google Scholar] [CrossRef]

- Rai, S.; Acharya-Siwakoti, E.; Kafle, A.; Devkota, H.P.; Bhattarai, A. Plant-Derived Saponins: A Review of Their Surfactant Properties and Applications. Science 2021, 3, 44. [Google Scholar] [CrossRef]

- Croizet-Berger, B.K.K.; Delemeule, M.; Estager, J.; Mannu, N. Silices Mesoporeuses et leur Procede de Synthese. WO/2017/182245, 26 October 2017. [Google Scholar]

- Korchowiec, B.; Gorczyca, M.; Wojszko, K.; Janikowska, M.; Henry, M.; Rogalska, E. Impact of two different saponins on the organization of model lipid membranes. Biochim. Biophys. Acta-Biomembr. 2015, 1848, 1963–1973. [Google Scholar] [CrossRef] [PubMed]

- Lorent, J.H.; Quetin-Leclercq, J.; Mingeot-Leclercq, M.P. The amphiphilic nature of saponins and their effects on artificial and biological membranes and potential consequences for red blood and cancer cells. Org. Biomol. Chem. 2014, 12, 8803–8822. [Google Scholar] [CrossRef] [PubMed]

- Oleszek, W.; Hamed, A. Saponin-Based Surfactants. In Surfactants from Renewable Resources; Kjellin, M., Johansson, I., Eds.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2010; Chapter 12; pp. 239–249. [Google Scholar] [CrossRef]

- Böttcher, S. Interfacial Properties of Saponins from Quillajasaponaria Molina and Their Functionality in Dispersed Systems. Ph.D. Thesis, Technische Universität, Berlin, Germany, 2017. Available online: https://depositonce.tu-berlin.de//handle/11303/6734%0Ahttp://files/134/Böttcher (accessed on 1 February 2024).

- Mitra, S.; Dungan, S.R. Micellar Properties of Quillaja Saponin. 1. Effects of Temperature, Salt, and pH on Solution Properties. J. Agric. Food Chem. 1997, 45, 1587–1595. [Google Scholar] [CrossRef]

- Raffa, P. Design and Synthesis of Low Molecular Weight and Polymeric Surfactants for Enhanced Oil Recovery. In Surfactants in Upstream E&P. Petroleum Engineering; Solling, T., Shahzad Kamal, M., Shakil Hussain, S.M., Eds.; Springer: Cham, Switzerland, 2021; pp. 3–40. [Google Scholar] [CrossRef]

- Schmitt, C.; Grassl, B.; Lespes, G.; Desbrières, J.; Pellerin, V.; Reynaud, S.; Gigault, J.; Hackley, V.A. Saponins: A renewable and biodegradable surfactant from its microwave-assisted extraction to the synthesis of monodisperse lattices. Biomacromolecules 2014, 15, 856–862. [Google Scholar] [CrossRef] [PubMed]

- Amarowicz, R.; Pegg, R.B.; Okubo, K. Fourier Transform InfraRed (FTIR) spectra of soybean saponin Ab and Bb. Mol. Nutr. Food Res. 1996, 40, 342–343. [Google Scholar] [CrossRef]

- Gunde, M.K. Vibrational modes in amorphous silicon dioxide. Phys. B Condens. Matter. 2000, 292, 286–295. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of Gases with Special Reference to the Evaluation of Surface Area and Pore Size Distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Schlumberger, C.; Thommes, M. Characterization of Hierarchically Ordered Porous Materials by Physisorption and Mercury Porosimetry—A Tutorial Review. Adv. Mater. Inter. 2021, 8, 2002181. [Google Scholar] [CrossRef]

- Sumanjeet, K.; Neeta, S.; Manpreet, K. Single and Competitive Removal of Pb(II) in the Presence of Ni(II) using Polyacrylamide Grafted Rice Husk. J. Appl. Sci. Environ. Manag. 2023, 27, 63–70. [Google Scholar] [CrossRef]

- Verma, A.; Agarwal, M.; Sharma, S.; Singh, N. Competitive removal of cadmium and lead ions from synthetic wastewater using Kappaphycus striatum. Environ. Nanotechnol. Monit. Manag. 2021, 15, 100449. [Google Scholar] [CrossRef]

- Ifijen, I.H.; Itua, A.B.; Maliki, M.; Ize-Iyamu, C.O.; Omorogbe, S.O.; Aigbodion, A.I.; Ikhuoria, E.U. The removal of nickel and lead ions from aqueous solutions using green synthesized silica microparticles. Heliyon 2020, 6, e04907. [Google Scholar] [CrossRef] [PubMed]

- Sajid, M.; Kabeer, M.; Younas, M.; Ihsanullah, I.; Baig, N. Conocarpuslancifolius Leaves as Low-Cost, Green and Sustainable Sorbent Material for Simultaneous Removal of Cadmium, Chromium, and Lead Ions from Aqueous Samples. Arab. J. Sci. Eng. 2024, 49, 613–621. [Google Scholar] [CrossRef]

- Lian, W.; Yang, L.; Joseph, S.; Shi, W.; Bian, R.; Zheng, J.; Li, L.; Shan, S.; Pan, G. Utilization of biochar produced from invasive plant species to efficiently adsorb Cd (II) and Pb (II). Bioresour. Technol. 2020, 317, 124011. [Google Scholar] [CrossRef] [PubMed]

- Yadav, A.; Bagotia, N.; Sharma, A.K.; Kumar, S. Simultaneous adsorptive removal of conventional and emerging contaminants in multi-component systems for wastewater remediation: A critical review. Sci. Total Environ. 2021, 799, 149500. [Google Scholar] [CrossRef] [PubMed]

- Sangeetha, K.; Vidhya, G.; Vasugi, G.; Girija, G.V.E.K. Lead and cadmium removal from single and binary metal ion solution by novel hydroxyapatite/alginate/gelatin nanocomposites. J. Environ. Chem. Eng. 2018, 6, 1118–1126. [Google Scholar] [CrossRef]

- Foo, K.Y.; Hameed, B.H. Insights into the modeling of adsorption isotherm systems. Chem. Eng. J. 2010, 156, 2–10. [Google Scholar] [CrossRef]

- Langmuir, I. The constitution and fundamental properties of solids and liquids. Part II.—Liquids. J. Frankl. Inst. 1917, 184, 721. [Google Scholar] [CrossRef]

- Weber, W.J., Jr.; Digiano, F.A. Process dynamics in Environmental Systems, 1st ed.; John Wily and Sons: Hoboken, NJ, USA, 1996. [Google Scholar]

- Ramsenthil, R.; Meyyappan, R.M. Single and multi-component biosorption of copper and zinc ions using micro algal resin. Int. J. Environ. Sci. Dev. 2010, 1, 298–301. [Google Scholar] [CrossRef]

- Nharingo, T.; Ngwenya, J.T. Single and Binary sorption of lead(II) and zinc(II) ions onto Eichhornia Crassipes (water hyacinth) ash. Int. J. Eng. Sci. Innov. Technol. (IJESIT) 2013, 2, 419–426. [Google Scholar]

- Mahamadi, C.; Nharingo, T. Competitive adsorption of Pb2+, Cd2+ and Zn2+ ions onto Eichhornia crassipes in binary and ternary systems. Bioresour. Technol. 2010, 101, 859–864. [Google Scholar] [CrossRef]

- Chen, D.; Zeng, Z.; Zeng, Y.; Zhang, F.; Wang, M. Removal of methylene blue and mechanism on magnetic γ-Fe2O3/SiO2 nanocomposite from aqueous solution. Water Resour. Ind. 2016, 15, 1–13. [Google Scholar] [CrossRef]

- Kypritidou, Z.; El-Bassi, L.; Jellali, S.; Kinigopoulou, V.; Tziritis, E.; Akrout, H.; Jeguirim, M.; Doulgeris, C. Lead removal from aqueous solutions by olive mill wastes derived biochar: Batch experiments and geochemical modelling. J. Environ. Manag. 2022, 318, 115562. [Google Scholar] [CrossRef] [PubMed]

- El-Feky, H.H.; Behiry, M.S.; Amin, A.S.; Nassar, M.Y. Facile Fabrication of Nano-sized SiO2 by an Improved Sol–Gel Route: As an Adsorbent for Enhanced Removal of Cd(II) and Pb(II) Ions. J. Inorg. Organomet. Polym. Mater. 2022, 32, 1129–1141. [Google Scholar] [CrossRef]

- Ciesielczyk, F.; Bartczak, P.; Jesionowski, T. Removal of cadmium(II) and lead(II) ions from model aqueous solutions using sol–gel-derived inorganic oxide adsorbent. Adsorption 2016, 22, 445–458. [Google Scholar] [CrossRef]

- Liu, Y.; Fu, R.; Sun, Y.; Zhou, X.; Baig, S.A.; Xu, X. Multifunctional nanocomposites Fe3O4@SiO2-EDTA for Pb(II) and Cu(II) removal from aqueous solutions. Appl. Surf. Sci. 2016, 369, 267–276. [Google Scholar] [CrossRef]

- Liu, Y.; Lou, Z.; Sun, Y.; Zhou, X.; Baig, S.A.; Xu, X. Influence of complexing agent on the removal of Pb(II) from aqueous solutions by modified mesoporous SiO2. Microporous Mesoporous Mater. 2017, 246, 1–13. [Google Scholar] [CrossRef]

- Wang, J.; Zheng, S.; Shao, Y.; Liu, J.; Xu, Z.; Zhu, D. Amino-functionalized Fe3O4@SiO2 core-shell magnetic nanomaterial as a novel adsorbent for aqueous heavy metals removal. J. Colloid Interface Sci. 2010, 349, 293–299. [Google Scholar] [CrossRef]

- Harinath, Y.; Reddy, D.H.K.; Sharma, L.S.; Seshaiah, K. Development of hyperbranched polymer encapsulated magnetic adsorbent (Fe3O4@SiO2-NH2-PAA) and its application for decontamination of heavy metal ions. J. Environ. Chem. Eng. 2017, 5, 4994–5001. [Google Scholar] [CrossRef]

- Ren, Y.; Abbood, H.A.; He, F.; Peng, H.; Huang, K. Magnetic EDTA-modified chitosan/SiO2/Fe3O4 adsorbent: Preparation, characterization, and application in heavy metal adsorption. Chem. Eng. J. 2013, 226, 300–311. [Google Scholar] [CrossRef]

- Ghobadifar, V.; Marandi, G.B.; Kurdtabar, M.; Bardajee, G.R. Removal of Pb(II) and Cd(II) by MnFe2O4@SiO2@VTMS Nanocomposite Hydrogel from Aqueous Solutions. J. Polym. Environ. 2023, 31, 2686–2704. [Google Scholar] [CrossRef]

- Zarei, A.; Saedi, S.; Seidi, F. Synthesis and Application of Fe3O4@SiO2@Carboxyl-Terminated PAMAM Dendrimer Nanocomposite for Heavy Metal Removal. J. Inorg. Organomet. Polym. Mater. 2018, 28, 2835–2843. [Google Scholar] [CrossRef]

- Heidari, A.; Younesi, H.; Mehraban, Z. Removal of Ni(II), Cd(II), and Pb(II) from a ternary aqueous solution by amino functionalized mesoporous and nano mesoporous silica. Chem. Eng. J. 2009, 153, 70–79. [Google Scholar] [CrossRef]

- Anbia, M.; Kargosha, K.; Khoshbooei, S. Heavy metal ions removal from aqueous media by modified magnetic mesoporous silica MCM-48. Chem. Eng. Res. Des. 2015, 93, 779–788. [Google Scholar] [CrossRef]

- Li, G.; Zhao, Z.; Liu, J.; Jiang, G. Effective heavy metal removal from aqueous systems by thiol functionalized magnetic mesoporous silica. J. Hazard. Mater. 2011, 192, 277–283. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.Y.; Wang, X.P.; Luo, Z.Y.; Xue, Y.W.; Shi, Z.G. Hierarchically macro/mesoporous hybrid silica spheres for fast capture of heavy metal ions. Mater. Lett. 2014, 128, 140–143. [Google Scholar] [CrossRef]

- Tang, Y.; Liang, S.; Wang, J.; Yu, S.; Wang, Y. Amino-functionalized core-shell magnetic mesoporous composite microspheres for Pb(II) and Cd(II) removal. J. Environ. Sci. 2013, 25, 830–837. [Google Scholar] [CrossRef]

| Parameter | Experimental Conditions |

|---|---|

| Contact time 0–360 min | 25 mL Pb(II)/Cd(II) 100 mg/L; 0.01 g adsorbent, room temperature |

| pH 2.5–7 pH units | 25 mL Pb(II)/Cd(II) 100 mg/L; 0.01 g adsorbent; room temperature, 5 h contact time |

| Heavy metal ion concentration 5–100 mg/L | 25 mL heavy metal ions solution; 0.01 g adsorbent; room temperature, 3/5 h contact time depending on the type of heavy metal ion |

| Compound | T1 (°C) | Δm1 (%wt) | T2 (°C) | T3 (°C) | Δm2 (%wt) | T4 (°C) | Δm3 (%wt) | Residual Mass (%wt) | Δm (%wt) |

|---|---|---|---|---|---|---|---|---|---|

| Saponin | 80.8 | 7.23 | 330.9 | 483.8 | 55.27 | 586.5 | 34.18 | 1.9 | 98.1 |

| SiO2@Saponin | 84.5 | 8.45 | 349.4 | – | 8.29 | – | – | 82.01 | 17.99 |

| meso-SiO2 | 79.2 | 5.51 | 318.4 | – | 2.22 | – | – | 91.43 | 8.57 |

| Sample | SBET (m2/g) | Pore Volume (cm3/g) | d * (nm) |

|---|---|---|---|

| SiO2@Saponin | 587.5 | 0.466 | 3.28 |

| meso-SiO2 | 347.2 | 0.286 | 3.32 |

| Isotherm | Mathematical Expression | Plot |

|---|---|---|

| Nonlinear Freundlich | Qe vs. Ce | |

| Nonlinear Langmuir | Qe vs. Ce | |

| Linear modified Langmuir for heavy metal 1 | vs. | |

| Linear modified Langmuir for heavy metal 2 | vs. |

| Adsorbent | SiO2@Saponin | Meso-SiO2 | Adsorbent | SiO2@Saponin | Meso-SiO2 |

|---|---|---|---|---|---|

| Heavy metal ion | Pb(II) | Heavy metal ion | Cd(II) | ||

| Langmuir parameters | |||||

| Qmax (mg/g) | 159.6 | 152.9 | Qmax (mg/g) | 124.5 | 114.1 |

| KL (L/mg) | 0.0654 | 0.0547 | KL (L/mg) | 0.0262 | 0.0226 |

| R2 | 0.9965 | 0.9915 | R2 | 0.9939 | 0.9965 |

| RL | 0.1326 | 0.1259 | RL | 0.2762 | 0.3067 |

| AIC | 27.74 | 32.19 | AIC | 26.52 | 21.66 |

| Freundlich parameters | |||||

| KF ((mg/g)(L/mg)1/n) | 18.99 | 14.91 | KF ((mg/g)(L/mg)1/n) | 7.123 | 5.524 |

| 1/n | 0.4899 | 0.5277 | 1/n | 0.5773 | 0.6016 |

| R2 | 0.9748 | 0.9742 | R2 | 0.9922 | 0.9897 |

| AIC | 38.67 | 38.81 | AIC | 28.02 | 28.08 |

| Adsorbent | Heavy Metal Ion | Qmax (Single Solution) (mg/g) | Qmax (Binary Solution) (mg/g) | |

|---|---|---|---|---|

| SiO2@Saponin | Pb(II) | 159.6 | 94.51 | 0.5919 |

| Cd(II) | 124.5 | 75.22 | 0.6040 | |

| meso-SiO2 | Pb(II) | 152.9 | 85.47 | 0.5587 |

| Cd(II) | 114.1 | 62.89 | 0.5484 |

| Kinetic Model | Mathematical Expression | Plot |

|---|---|---|

| Pseudo-first-order | Qt vs. time | |

| Pseudo-second-order | Qt vs. time | |

| Intraparticle diffusion (IPD) | Qt vs. time1/2 |

| Adsorbent | SiO2@Saponin | Meso-SiO2 |

|---|---|---|

| Pb(II) | ||

| Qexp (mg/g) | 121.7 | 115.8 |

| Pseudo-first-order kinetic model | ||

| Qcalc (mg/g) | 119.3 ± 1.982 | 113.9 ± 1.738 |

| k1 (min−1) | 0.1622 ± 0.0151 | 0.1282 ± 0.0099 |

| R2 adjusted | 0.9796 | 0.9842 |

| Pseudo-second-order kinetic model | ||

| Qcalc (mg/g) | 123.9 ± 0.6681 | 118.8 ± 0.8907 |

| k2·10−4 (g/mg·min) | 24.3 ± 1.1382 | 18.6 ± 1.0691 |

| R2 adjusted | 0.9983 | 0.9970 |

| Cd(II) | ||

| Qexp (mg/g) | 82.97 | 72.50 |

| Pseudo-first-order kinetic model | ||

| Qcalc (mg/g) | 75.30 ± 4.063 | 68.64 ± 4.043 |

| k1 (min−1) | 0.0355 ± 0.0079 | 0.0202 ± 0.0046 |

| R2 adjusted | 0.8920 | 0.9051 |

| Pseudo-second-order kinetic model | ||

| Qcalc (mg/g) | 83.66 ± 3.750 | 78.04 ± 4.621 |

| k2·10−4 (g/mg·min) | 5.512 ± 1.299 | 3.433 ± 0.9730 |

| R2 adjusted | 0.9528 | 0.9471 |

| Adsorbent | Pb(II) Adsorption Capacity (mg/g) | Cd(II) Adsorption Capacity (mg/g) | Refs |

|---|---|---|---|

| SiO2 nanoparticles | 34.2 | 42.2 | [71] |

| MgO-SiO2 | 102.02 | 94.05 | [72] |

| Fe3O4@SiO2-EDTA | [73] | ||

| SiO2: EDTA= 1:1 | 74.07 | ||

| SiO2: EDTA = 1.5:1 | 79.37 | ||

| SiO2: EDTA = 2:1 | 86.21 | ||

| SiO2: EDTA = 2.5:1 | 114.94 | 50.25 | |

| SiO2: EDTA = 3:1 | 101.01 | ||

| SiO2-EDTA | 147.52 | [74] | |

| Fe3O4@SiO2–NH2 | 0.37 mmol/g at 25 °C 0.45 mmol/g at 35 °C 0.54 mmol/g at 45 °C | 0.20 mmol/g at 25 °C 0.27 mmol/g at 35 °C 0.33 mmol/g at 45 °C | [75] |

| Fe3O4@SiO2–NH2-PAA | 108.82 | 100.81 | [76] |

| chitosan/SiO2/Fe3O4 EDTA-modified chitosan/SiO2/Fe3O4 | 0.045 mmol/g 0.596 mmol/g | 0.040 mmol/g 0.563 mmol/g | [77] |

| MnFe2O4@SiO2@Vinyltrimethylsilane (VTMS) nanocomposite hydrogel | 131 | 126 | [78] |

| Fe3O4@SiO2@Carboxyl-Terminated PAMAM Dendrimer Nanocomposite | 117 | 115.82 | [79] |

| NH2-MCM-41 | 57.74 (ternary Ni(II) + Pb(II) + Cd(II) solns) | 18.25 (ternary Ni(II) + Pb(II) + Cd(II) solns) | [80] |

| Magnetic melamine-MCM-48 | 127.24 | 114.08 | [81] |

| SH-mSi@Fe3O4 | 91.5 | [82] | |

| Hierarchically macro/mesoporous hybrid silica spheres | 81.9 | 33.4 | [83] |

| Amino-functionalized Fe3O4@mesoporous SiO2 core-shell composite microspheres NH2-MS | 128.21 | 51.81 | [84] |

| SiO2@Saponin | 159.6 (Pb(II) solution) 94.52 (Pb(II) + Cd(II) solns) | 124.5 (Cd(II) solution) 75.22 (Pb(II) + Cd(II) solns) | This study |

| meso-SiO2 | 152.9 (Pb(II) solution) 85.47 (Pb(II) + Cd(II) solns) | 114.1 (Cd(II) solution) 62.93 (Pb(II) + Cd(II) solns) | This study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Simonescu, C.-M.; Dumitru, F.; Zărnescu, B.; Culiţă, D.C.; Răzvan, A.; Oprea, O.; Truşcă, R.; Vasile, E. Competitive Adsorption of Aqueous Cd(II) and Pb(II) Solutions onto Silicas Synthesized with Saponin as Template Agent. J. Compos. Sci. 2024, 8, 227. https://doi.org/10.3390/jcs8060227

Simonescu C-M, Dumitru F, Zărnescu B, Culiţă DC, Răzvan A, Oprea O, Truşcă R, Vasile E. Competitive Adsorption of Aqueous Cd(II) and Pb(II) Solutions onto Silicas Synthesized with Saponin as Template Agent. Journal of Composites Science. 2024; 8(6):227. https://doi.org/10.3390/jcs8060227

Chicago/Turabian StyleSimonescu, Claudia-Maria, Florina Dumitru, Bianca Zărnescu, Daniela Cristina Culiţă, Anca Răzvan, Ovidiu Oprea, Roxana Truşcă, and Eugeniu Vasile. 2024. "Competitive Adsorption of Aqueous Cd(II) and Pb(II) Solutions onto Silicas Synthesized with Saponin as Template Agent" Journal of Composites Science 8, no. 6: 227. https://doi.org/10.3390/jcs8060227

APA StyleSimonescu, C.-M., Dumitru, F., Zărnescu, B., Culiţă, D. C., Răzvan, A., Oprea, O., Truşcă, R., & Vasile, E. (2024). Competitive Adsorption of Aqueous Cd(II) and Pb(II) Solutions onto Silicas Synthesized with Saponin as Template Agent. Journal of Composites Science, 8(6), 227. https://doi.org/10.3390/jcs8060227